New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2026-01-15 07:35:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,912

Ring Habitat on Mars Doughnut Torus

This topic is inspired by a suggestion from kbd512.

In discussion of domes that might be built on Mars, kbd512 suggested building a half-torus shaped structure.

Calliban had suggested a dome the size of the famous Superbowl at New Orleans.

Calliban's design would employ all native materials for the structure, and it would employ no imported materials at all for the primary structure.

kbd512's concept would employ a blend of local and imported materials.

This topic is offered for NewMars members who might wish to help kbd512 develop his idea.

It would be helpful to know the dimensions of the structure kbd512 has in mind.

The torus will have a diameter, and the ring of the torus will have a diameter.

In this early stage of definition of the concept, we do not know if kbd512 has a shape in mind for the cross section of the half ring.

Calliban has suggested a catenary shape so that forces are distributed evenly throughout the material of the wall of the ring.

This topic has significant growth potential.

The Stanford Torus is a model to study, since it dealt with many of the issues that will confront the designer of a half ring set on Mars.

I asked Google for help with the terminology:

AI Overview

Torus Shape – Definition, Examples, and Diagrams

A torus has two main diameters: the Major Diameter, which defines the overall size (center-to-center of the tube), and the Minor Diameter, which determines the thickness of the tube itself, often called the tube diameter or core diameter. These correspond to the Major Radius (distance from center of hole to center of tube) and Minor Radius (radius of the tube's cross-section) respectively.

Key Terms:

In the context of Calliban's dome, diameter is 200 meters at the ground, and the height is 120 meters.

The major and minor diameters remain to be defined for kbd512's ring habitat.

(th)

Last edited by tahanson43206 (2026-01-15 07:41:23)

Offline

Like button can go here

#2 2026-01-15 07:36:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,912

Re: Ring Habitat on Mars Doughnut Torus

This post is reserved for an index to posts that may be contributed by NewMars members.

Index:

On January 18, 2026, kbd512 made a critical decision that allows this project to proceed.

https://newmars.com/forums/viewtopic.ph … 75#p237375

In the post at the link above, kbd512 is reported to have decided to plan for a population of 1000 individual humans.

(th)

Last edited by tahanson43206 (Yesterday 20:48:23)

Offline

Like button can go here

#3 2026-01-15 15:03:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

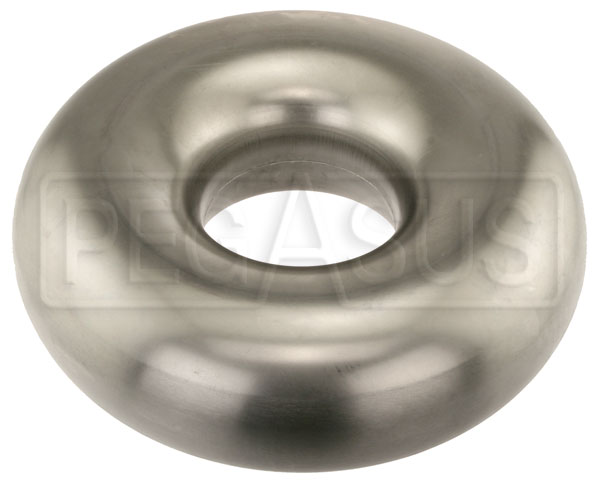

Here is what was in the re-purposed starship stainless shell.

If we provide 125m^3 of pressurized volume for each family of 4, then we need approximately 10 Super Domes worth of pressurized volume to house a million people. Domes tend to have a lot of unusable space, though. What about a ring?

This sounds just like what a caretaker doughnut design from empty starships would be.

Leave the crewed ship in the center of what is constructed from the ships hull materials.

The proposed project of creating a 9-meter stainless steel doughnut cross-section with a crewed starship in the center, utilizing materials from unused cargo ships, is not technically feasible using current industrial and engineering methods.

Here are the key reasons why this concept is impractical:

Material Limitations:

Steel Type: The steel used in standard cargo ships is not typically high-grade stainless steel suitable for precision aerospace or habitat construction. It is standard structural steel, which has different properties regarding corrosion resistance, strength-to-weight ratio, and material consistency.

Repurposing Difficulty: While steel can be recycled, melting down and reshaping massive cargo ship hulls into a precise, large-scale, high-quality "doughnut" cross-section requires specialized industrial remelting processes (like electroslag remelting for high-grade applications) that are complex and costly, making on-site or large-scale transformation unfeasible.

Material Integrity: The structural integrity of repurposing cut and welded sections of existing cargo ships for such a specific, high-stress application (especially if intended for space or extreme environments) would be difficult to guarantee without extensive and costly engineering.

Engineering and Design Challenges:

Structural Requirements: Designing a 9-meter "doughnut" structure to house a starship would have highly specific operational and stiffness requirements that repurposed, potentially compromised, cargo ship materials cannot easily meet.

Scale and Precision: The precision needed for a 9-meter cross-section that interacts seamlessly with a crewed starship is immense. Achieving this precision by modifying large, existing, non-uniform cargo ship sections is impractical.

Feasibility vs. New Construction: It would be significantly more efficient, reliable, and cost-effective to produce the necessary components using new, purpose-built stainless steel designed for the specific application rather than attempting to salvage and heavily modify existing ship parts.

In summary, the foundational materials and engineering processes required to create such a specific, high-specification structure from generic, used cargo ships make the project technologically unviable.What challenges are

You will need 4 sections of the 60 m tube to achieve a total length of 240 m. The final circle will have an approximate diameter of \(76.4\) m.

Step 1: Calculate material needs First, determine the total length of tubing required. The user's desired circumference is 240 meters. The calculation confirms that exactly 4 of the 60-meter tubes are needed to reach this length. The 9 m diameter of the individual tubes is the cross-sectional diameter, not the circle's final diameter.

Step 2: Join the tubes Join the four 60-meter stainless steel tubes end-to-end to create one continuous 240-meter length. This is typically done by welding the joints, which requires specific techniques for stainless steel.

Step 3: Form the circle The 240-meter length of tube must be mechanically bent or rolled into a circular shape. Given the large scale, specialized industrial equipment for bending large diameter, thick-walled (implied by 9m diameter) steel is necessary.

Step 4: Cut and finish A final, precise cut will be needed to join the two ends of the 240-meter length after it is formed into the circle. For cutting stainless steel tubes, common methods include using a portable band saw or an angle grinder with a cut-off wheel, applying slow speed and cutting oil to manage the material's hardness and heat.

Answer: You will need to use 4 of the 60 m tubes to achieve a total length of 240 m. The final circle made from this length will have a diameter of approximately \(76.4\) m (\(240/\pi \)). The tubes must be joined end-to-end and then formed into the circular shape, requiring precise cuts and welding to secure the final joint

That means the inside diameter is 76.4 - 18 = 54 m diameter

The volume of the doughnut shape is approximately 15268.14 cubic meters.

Make 3 floors similar to a submarine flight decks. Assume that the three are 2.5 meters ceiling to floor for each.

Offline

Like button can go here

#4 2026-01-15 15:05:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

For kbd512 re post in SpaceNut's Superdome topic ...

https://newmars.com/forums/viewtopic.ph … 62#p237162

Nice vision !!!

I hope that it comes to pass.

It certainly ** could ** come to pass.

As a reminder, Calliban's dome has varied in population but the starting number is 1000.

The logistics of providing sewer service, heating, water, power, communications and interior structures (ie, living and retails space) seem to lead toward solving the 1000 person population problem before advancing to something greater.

Thus your vision of a population of 1,000,000 people could be realized with 1000 domes. Mars has ** plenty ** of room for that many domes, since they are only 200 meters in diameter. That said, it appears that siting the domes in craters has advantages.

Calliban's vision was to create the domes out of locally sourced material, which led to his initial idea of bricks, followed by the suggestion of "voudrois" shaped blocks. Calliban's concept includes the Ziggurat ramps to facilitate construction while simultaneously providing force to resist the internal pressure of .5 bar for the standard Mars habitat atmosphere.

In any case, it is good to see SpaceNut's topic developing, and your post adds to the flow.

(th)

For kbd512 ... There is a new topic available if you would care to develop your ideas for a ring shaped habitat on Mars...

https://newmars.com/forums/viewtopic.php?id=11287

Please begin by setting the dimensions so that others can begin to help to build up a vision of the idea.

The Stanford Torus may be larger than you have in mind, but is a well developed model that might provide inspiration for your concept.

Unlike Calliban's dome, your concept appears to have potential for construction outside a Crater.

It will definitely be interesting to see what members do with the concept, but it needs dimensions so that folks have something to work with.

(th)

Since the details were missed for number of meters for the number. which was above my information in the quote.

If we provide 125m^3 of pressurized volume for each family of 4,

Math: 1000 / 4 = 250 family units but that does nothing else other than house people....

250x 125 m^3 = 31,250 cubic meters of volume

Offline

Like button can go here

#5 2026-01-15 15:12:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

You also missed the secondary choice to bring all materials

SpaceNut,

I was thinking of using a combination of 304L from the expended Starships and indigenous materials in a "space frame" design wherein the Starship steel provides external structural support so that locally-sourced cast basalt tiles interlock into the space frame and are pressed outwards and into the space frame by internal pressurization, with sealing accomplished using either a thin internal layer of stainless sheet steel welded into the space frame, over the top of the inner tile faces, or a Silicone-based adhesive sealant could also be used. We can bring enough 304L and Silicone sealant from Earth to build this kind of structure by scrapping / recycling the Starships. I don't think it's feasible to bring enough concrete or basalt tiles, hence why that material must be locally sourced.

Do you remember the structure of the "Biosphere 2" built in Arizona?

So, imagine that we create a giant ring-shaped habitat, rather than a Super Dome, so as to keep tensile stresses sane, so as to economize on recycled steel, so as to allow us to safely use cast basalt tiles without the thickness of said tiles needing to greatly resemble the stones used to build the pyramids. This maximizes internal volume, minimizes material consumption. We can still build a Super Dome from locally sourced meteorite Nickel-steel, but for sake of argument presume that we can only handle local production of indigenous liquid water, atmospheric gases, and one construction material that we only have to melt and cast into a limited number of molds. More could always be done using more equipment and labor, but we have to bring those things with us.

That changes everything for what is going to be required as well.

Offline

Like button can go here

#6 2026-01-15 22:00:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,438

Re: Ring Habitat on Mars Doughnut Torus

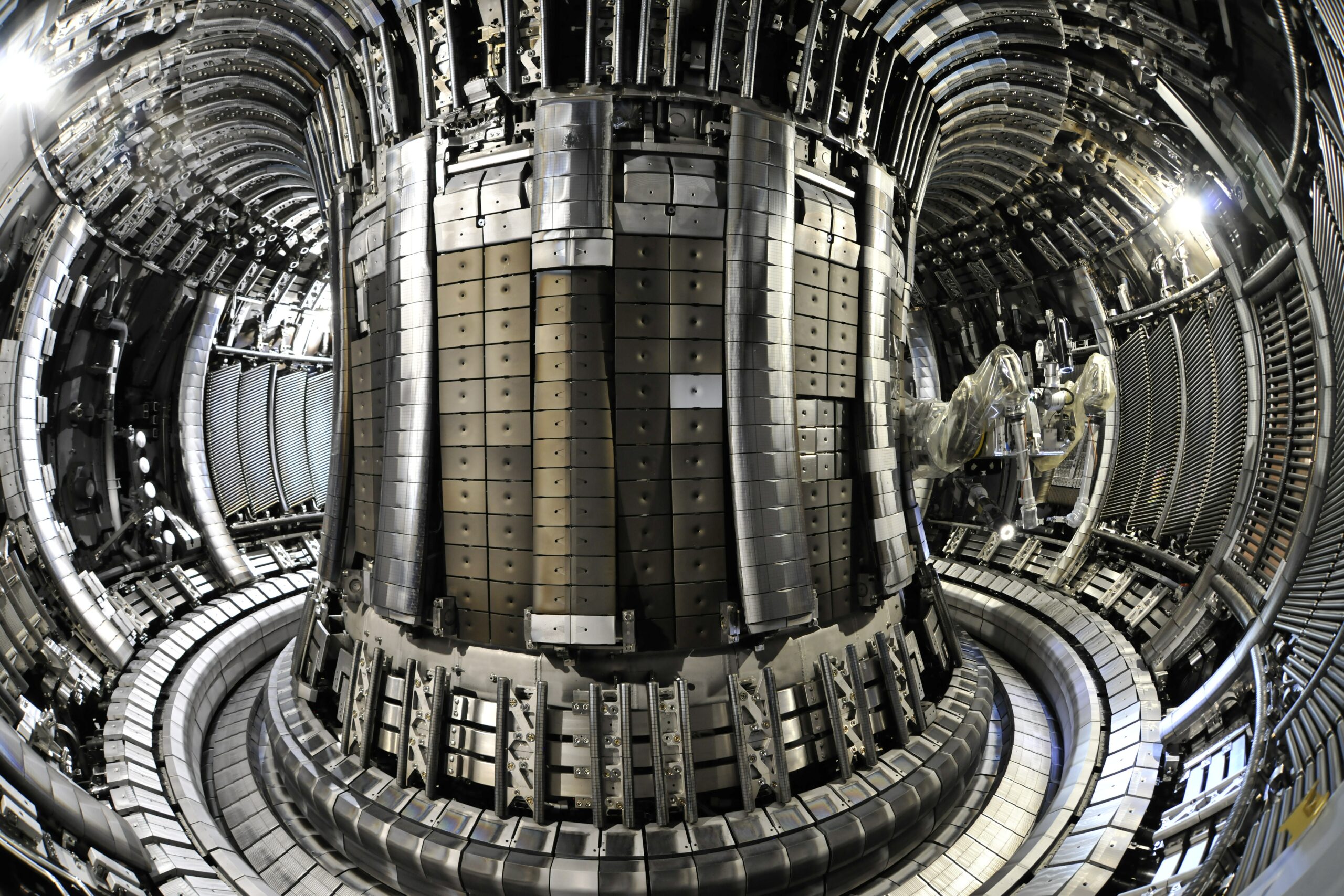

This Stanford Torus structure artistic rendering from Nichlas Benjamin is more in line with what I had in mind for the exterior support rest of the habitation ring:

Except that I wanted a shape that maximizes usable floor space, which implies more of a D-shaped toroidal structure, like a tokamak.

The interior of this D-shaped tokamak is broadly similar to what I had in mind:

The structure would only be one or perhaps two stories high, with the bottom of the torus housing water piping and the top housing electrical power cables, data cables, and light pipes.

Try to visualize all those interior metal electromagnet "tiles" being replaced with cast basalt tiles:

The interior would be lined with cast basalt tiles like these:

Basalt can be cast into relatively complex shapes and has a strikingly beautiful natural appearance:

So, basic concept is as follows:

1. D-shaped torus to provide more usable floor space without an excessive number of floors requiring elevators, with reduced structural materials strength and therefore mass requirements, relative to a Super Dome.

2. Starship's 304L stainless steel is converted into a tubular exoskeleton / space frame. The external frame is intended to allow for thermal expansion and contraction in the Martian temperature extremes between day and night.

3. Cast basalt tiles / blocks are inserted into the frame and sealed using Silicone caulk.

4. Liquid CO2 will be pumped through the space frame in an attempt to improve upon the room temperature strength of 304L, and to regulate its temperature to avoid excessive expansion and contraction. We want to keep that stainless cold, definitely below zero, because it's weaker than A36 at room temperature, but not mildly cryogenic because we start to lose ductility and we definitely want to keep that. We're after about 517MPa to 621MPa. We don't go any colder than is required to achieve that yield strength.

5. The structure size / progression is ultimately limited by the number of arriving Starships. We have around 70t of the right kind of material to work with per Starship. The engines are higher grades of stainless that would be repurposed for making fasteners, tooling, and molds.

304L Temperature vs Yield Stress for Conventional 304L (green) and Laser Powder Bed Fusion (red):

As the graph above shows, laser sintering of 304 powder delivers high yield strength, partially due to formation of martensite, but we don't want martensite formation in a steel exposed to cryogenic temperatures, so we're sticking with a conventional cold-rolled seamless tubing material produced in a miniature electric arc furnace that accepts bits of recycled Starship hull scrap steel. The yield strength mechanical property is reduced, but that other important metallurgical property, namely an austenitic grain structure which confers ductility at very low temperatures, is more important for our application than pure tensile strength, which we are "thermally improving" by keeping the steel cold using cold LCO2.

Offline

Like button can go here

#7 2026-01-16 17:35:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

For kbd512 ... There is a new topic available if you would care to develop your ideas for a ring shaped habitat on Mars...

https://newmars.com/forums/viewtopic.php?id=11287

Please begin by setting the dimensions so that others can begin to help to build up a vision of the idea.

The Stanford Torus may be larger than you have in mind, but is a well developed model that might provide inspiration for your concept.

Unlike Calliban's dome, your concept appears to have potential for construction outside a Crater.

It will definitely be interesting to see what members do with the concept, but it needs dimensions so that folks have something to work with.

(th)

It could be the same size or different due to other factors yet not determined...

For kbd512 re D shaped habitat ring ...

https://newmars.com/forums/viewtopic.ph … 29#p237229In some habitat designs, regolith is piled on top to provide radiation shielding. Is the structure you've considering strong enough to handle that load? The cast basalt panels might be strong enough to handle the compression load.

A regolith outer layer would provide thermal buffering, although some heat will be lost as the planet sucks energy out of any structure. Heat from a fission reactor might provide a constant supply of fresh thermal energy for an extended period.

Your D shaped structure has the distinct advantage of solving the foundation problem that other designs must handle.

(th)

Again shape still may change as its never been built as if we are on mars.

It is unknown how fast the mining of ore, processing to be able to cast panels, but to make and weld the frame is also a question. Time and crew size plus equipment causes the build to be pushed across multiple cycles.

reminds me of

Offline

Like button can go here

#8 2026-01-16 17:46:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

Funny we have been there for Cast Basalt

With Basalt melting at temperatures of 1175 - 1350°C, depending on composition.

Similar equipment for other mining operations.

Basalt mining and processing require extremely wear‑resistant, high‑capacity equipment because basalt is one of the hardest and most abrasive natural stones. The core machinery includes drilling/blasting tools, heavy-duty loaders, jaw and cone crushers, VSI sand makers, vibrating screens, and dust‑controlled conveyor systems.

Below is a clear, structured breakdown of the full equipment lineup and process flow, grounded in the latest industry data.

? What Equipment Is Used for Basalt Mining & Processing?

1. Mining / Quarrying Equipment

Basalt is typically extracted from open‑pit quarries.Extraction Tools

Drilling rigs – for blast‑hole drilling in hard rock.Explosives & blasting systems – controlled fragmentation of basalt benches.

Hydraulic excavators (30–70 ton) – for loading blasted rock.

Wheel loaders & haul trucks – transport raw basalt to the processing plant.

? 2. Primary Processing Equipment (Crushing)

Basalt’s hardness (Mohs 5–6.5) demands high‑strength crushing machines.Primary Crusher

Jaw CrusherHandles large basalt blocks up to 700–1200 mm.

High-strength manganese plates.

Example: C6X Jaw Crusher.

Secondary Crusher

Hydraulic Cone CrusherIdeal for medium-hard basalt.

Produces uniform, cubical aggregates.

Multi‑cylinder design reduces wear costs.

Tertiary Crusher (Optional)

VSI Sand MakerUsed when producing manufactured sand or highly cubic aggregates.

Common in asphalt and concrete aggregate plants.

? 3. Screening & Sorting Equipment

Vibrating screens (2–4 decks)Separate crushed basalt into size fractions (e.g., 0–5 mm, 5–12 mm, 12–22 mm).

High-strength screen meshes

Required due to basalt’s abrasiveness.

? 4. Material Handling Systems

Belt conveyors (650–1000 mm width)Abrasion‑resistant belts and dust‑proof covers.

Hoppers & feeders

Heavy-duty vibrating feeders with wear liners.

? 5. Optional Processing Equipment

Depending on the final product:For Manufactured Sand

VSI or HVI sand-making machinesAir separators for fine control

For High‑Quality Aggregates

Hydraulic cone crushers (HPT, HP series)Washing systems (log washers, spiral washers)

For Basalt Fiber Production

Basalt melting furnaceFiber drawing equipment

Winding machines

? 6. Typical Basalt Crushing Plant Configuration

Based on industry-standard setups:Stage Equipment Purpose

Feeding Hopper + Vibrating Feeder Regulated feeding of raw basalt

Primary Jaw Crusher First-stage size reduction

Secondary Cone Crusher Produces uniform aggregates

Tertiary VSI Crusher Sand making / shaping

Screening Multi‑deck Vibrating Screen Size classification

Conveying Belt Conveyors Material transport

Example capacity: 250–450 TPH basalt plant with jaw + cone + VSI + screens.? Tips for Choosing Basalt Processing Equipment

Prioritize wear resistance (manganese steel, ceramic liners).Use compression crushers (jaw + cone) to reduce wear costs.

Ensure dust suppression for environmental compliance.

Choose variable-speed feeders to stabilize plant output.

For sand production, include VSI or HVI machines.

? Sources

MINEVATE Basalt Crushing & Screening PlantLiming Heavy Industry Basalt Crusher Overview

Zoneding Basalt Crushing Plant Guide

CCE Online News – Basalt Quarry Equipment Selection

Fote Machinery – Basalt Crushing Process & Machines

Designing interlocking cast‑basalt thick tile panels for use on Mars is a fascinating challenge because it blends planetary engineering, materials science, and in‑situ resource utilization (ISRU). You’re essentially asking: How could we manufacture basalt‑based structural panels on Mars that lock together like giant LEGO blocks and survive Martian conditions?

Let’s build a complete, realistic process from extraction to finished interlocking tiles.

? 1. Basalt as a Martian Manufacturing Feedstock

Basalt is abundant on Mars. It’s chemically similar to terrestrial basalt and ideal for:Casting into tiles or panels

Melting into basalt fiber

Forming abrasion‑resistant surfaces

Thermal and radiation shielding

Its melting point (~1200–1250°C) is high but manageable with electric or solar‑thermal furnaces.

? 2. Full Process for Creating Interlocking Cast Basalt Panels on Mars

Step 1 — Basalt Collection & Pre‑Processing

Robotic excavators or small autonomous rovers gather basalt rubble.Material is crushed into uniform feedstock (5–20 mm).

Magnetic separation removes iron-rich particles if needed for furnace efficiency.

Mars advantage: Low gravity reduces wear on crushers and conveyors.

Step 2 — Melting the Basalt

Basalt must be melted into a homogenous liquid.Possible furnace types for Mars

Solar‑thermal concentrator furnaceUses mirrors to reach >1300°C

No oxygen required

Ideal for daytime production

Electric resistance furnace

Powered by nuclear or solar arrays

More stable temperature control

Induction furnace

Efficient if basalt is pre‑enriched with iron

The melt is held at ~1250–1350°C.

Step 3 — Casting Into Interlocking Tile Molds

This is the heart of your idea.Tile geometry

Interlocking basalt tiles could use:Tongue‑and‑groove edges

Dovetail joints

Hexagonal puzzle‑fit geometry

Male/female castellated edges

These shapes prevent lateral shifting and allow construction without adhesives.

Casting process

Pre‑heated molds (steel, ceramic, or regolith‑ceramic composite) are prepared.Molten basalt is poured into molds under low atmospheric pressure.

Controlled cooling prevents cracking.

Annealing phase relieves internal stresses.

Thickness:

20–80 mm for structural panels

100–150 mm for radiation shielding or load‑bearing walls

Step 4 — Controlled Cooling & Annealing

Mars’ environment is extremely cold, so cooling must be regulated, not passive.Tiles are cooled in insulated chambers to avoid thermal shock.

Annealing at 500–600°C for several hours improves toughness.

Step 5 — Surface Finishing

Depending on use:Polished for interior habitats

Textured for traction on exterior walkways

Grooved for mechanical interlock with regolith backfill

Coated with thin basalt‑fiber mesh for crack resistance

Step 6 — Quality Testing

Tiles must survive:Thermal cycling from −120°C to +20°C

Dust abrasion

Low‑pressure fracture tests

Radiation exposure simulations

Impact resistance (meteoroid micro‑debris)

? 3. Assembly of Interlocking Panels on Mars

Dry‑fit construction

Because water is scarce, tiles should assemble without mortar.Possible assembly methods

Robotic arms place tiles into interlocking patterns.Regolith backfill locks panels in place.

Basalt‑fiber tie rods or pins reinforce joints.

Vacuum‑tight interior walls may use a thin polymer seal between tiles.

? 4. Why Cast Basalt Panels Are Ideal for Mars

Radiation shielding (dense, high‑silica material)Thermal stability

Abrasion resistance against dust storms

ISRU‑friendly (basalt is everywhere)

Non‑toxic, non‑flammable

Long lifespan

Interlocking geometry reduces the need for adhesives, which are expensive to transport from Earth.

? 5. Optional Enhancements

Basalt‑fiber reinforcement

Mixing chopped basalt fiber into the melt increases toughness.Hollow‑core tiles

Reduce mass and improve insulation.Embedded channels

For wiring, heating loops, or gas lines.Self‑locking hexagonal tiles

Inspired by honeycomb structures for pressure‑resistant habitats.If you want, I can also design:

A specific interlocking geometryA full production line layout for a Martian basalt tile factory

A tile panel standard (dimensions, tolerances, strength specs)

A robotic assembly system for building habitats with these tiles

The most promising sites cluster around volcanic provinces, ancient lakebeds, and polar regions, according to recent analyses.

Below is a clean, practical breakdown of where humans would actually mine on Mars based on current science.

? 1. Best Locations for Basalt Mining (for cast basalt tiles, ISRU construction)

Basalt is everywhere on Mars, but the richest, freshest, and easiest‑to‑access deposits are:Tharsis Volcanic Province

Includes Olympus Mons, Ascraeus Mons, Pavonis Mons, Arsia MonsGiant basaltic shield volcanoes

High‑purity basalt ideal for casting, fiber production, and structural materials

Highlighted as resource‑rich volcanic zones

Elysium Planitia

Young basaltic lava plainsSmooth terrain → easy rover access

Good for large‑scale basalt tile production

Gale Crater Region

Curiosity rover confirmed basaltic provenance in sedimentsAbundant basalt fragments transported by ancient rivers

Jezerο Crater

Perseverance rover found basaltic igneous rocks in crater floorEasy to collect and crush for ISRU

❄️ 2. Best Locations for Water Ice Mining

Water ice is the most valuable early resource.Mid‑Latitude Ice Deposits

Arcadia PlanitiaUtopia Planitia

Vast subsurface ice sheets

Easy to access with shallow drilling

Polar Regions

North Polar Layered DepositsThick, clean water ice

Highest volume but harder to reach for early missions

? 3. Metal & Mineral Mining Locations

Based on rover samples and meteorite analysis:Volcanic Slopes of Tharsis & Elysium

Likely sources of:Nickel

Chromium

Titanium

Identified as high‑value targets for future mining robots

Hematite‑Rich Regions

Meridiani Planum (Opportunity rover site)Contains iron oxides (hematite “blueberries”)

Sulfur, Chlorine, Potassium, Phosphorus

Widely distributed in Martian regolithUseful for agriculture, batteries, and chemical processing

? 4. Best Locations for Construction Materials (Regolith, Basalt, Silicates)

Valles Marineris walls – layered basalt and sedimentLava tubes in Tharsis & Elysium – natural shelters + basaltic rock

Isidis Basin – basaltic plains with fine regolith

?️ 5. Summary Table: What to Mine and Where

Resource Best Locations Why

Basalt Tharsis, Elysium, Gale, Jezero Casting, tiles, fibers

Water Ice Arcadia, Utopia, Poles Life support, fuel

Metals (Ni, Ti, Cr) Tharsis volcanoes Concentrated in volcanic flows

Iron Oxides Meridiani Planum Hematite nodules

Silicates Everywhere Glass, ceramics

Salts & Volatiles Regolith globally Agriculture, chemistry

? If your goal is specifically basalt tile production for Mars:

The top two mining zones are:⭐ Elysium Planitia

Flat, accessible, young basaltIdeal for large automated factories

⭐ Tharsis Montes (volcano slopes)

Highest‑quality basaltRich in metals for tools and furnace components

If you want, I can also map out:

A full mining + processing base layout

A site selection comparison (Elysium vs Tharsis vs Jezero)

A logistics plan for transporting basalt to a casting facility

Offline

Like button can go here

#9 2026-01-17 19:58:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

The industrial production of cast basalt blocks is a multi-stage process involving melting raw basalt at very high temperatures and annealing it to create a durable, abrasion-resistant product. The total, comprehensive production cycle is often shortened in modern methods to roughly 5 to 6 days (approx. 130 hours), according to manufacturing patents.

Here is the breakdown of the time required for each phase:

Mining/Quarrying (Raw Material Gathering): Variable, depending on the scale of the operation, but typically, this is done in bulk.

Melting (Smelting): Basalt is melted at temperatures between 1280°C and 1500°C. Some studies indicate that the melting process itself, in a batch furnace, lasts about 4.5 hours.

Molding (Casting): The molten basalt is poured into molds or cast into cylinders. This is done shortly after melting.

Annealing (Heat Treatment/Crystallization): This is the most crucial, time-intensive step. The molded basalt is placed in a kiln for annealing to eliminate internal stresses and form a microcrystalline structure. This process usually takes 16 to 21 hours, though some specialized processes might take longer depending on the thickness of the material.

Cooling to Room Temperature: After annealing, the tiles are cooled, which can take an additional 9 to 14 hours.

Total Production Cycle Time:

Older, traditional methods could take significantly longer.

Modern, optimized manufacturing processes aim for a, total production cycle (from raw material to finished cast) in a significantly shorter timeframe, with some patents mentioning a, total cycle of 130+ hours (approx. 5.4 days).

Other Factors:

Preparation: Before melting, the basalt may need to be crushed into smaller particles.

Customization: Special molds and cooling processes for specific shapes or custom designs may increase the total turnaround time

Making things fast if we collect mars basalt sand.

Black Sand Dunes on Mars taken by NASA’s Curiosity Rover,

It appears that, Mars has abundant basalt sand, derived from volcanic activity, making up much of its dark dunes and regolith, with minerals like olivine, unlike Earth's quartz-dominant sands, creating unique features like "sandfall" streaks from sublimating dry ice.

Key Characteristics

Volcanic Origin: Mars's surface is dominated by basaltic rocks, the same dark volcanic rock common on Earth, so Martian sand is typically basaltic.

Dark Color: This basalt composition gives Martian sand its characteristic dark color, similar to dark volcanic sand beaches on Earth.

Primary Minerals: The sand contains igneous minerals like olivine and pyroxene, indicating formation through physical breakdown (wind, thermal stress) rather than extensive chemical weathering.

Dune Fields: Vast dune fields, such as the North Polar erg and the Bagnold Dunes, are composed of this basaltic sand.

Unique Martian Phenomena

Dark Sand Cascades: In the Martian spring, sunlight warms seasonal dry ice (frozen CO2) on dunes, causing it to sublimate (turn to gas) and trigger sand slides, leaving behind dark streaks that look like "trees" or "sandfalls".

Light Dust Cover: While the sand is dark, much of the Martian surface is covered by lighter-toned dust, which can obscure the dark sand unless it's actively moving or newly exposed.

Exploration

Curiosity Rover: The rover has extensively studied dark basaltic dunes in the Bagnold Dune Field, observing active sand movement and ripple formation.

BASALT Program: NASA's BASALT (Biologic Analog Science Associated with Lava Terrains) project studies Earth's volcanic areas to understand potential Martian environments for human exploration

Basalt sand is widespread on Mars, forming vast dark dunes, especially around the North Polar erg (Olympia Undae), where winds sculpt them into active patterns, and in regions like Meridiani Planum (seen by Opportunity) and near volcanoes like Syrtis Major, often appearing dark or blueish due to mineral composition, contrasting with the reddish dust and sometimes mixed with gypsum.

Key Locations & Features:

North Polar Region (Olympia Undae): A massive ring of basaltic (and some gypsum) sand dunes, some over 100 feet high, showing active movement and sublimation-driven "tree-like" streaks.

Meridiani Planum: Explored by the Opportunity rover, this area features basaltic sand grains, sometimes forming spherical aggregates, with distinct dark patches.

Syrtis Major: A large volcanic region where dark basaltic sand and rock are prominent, showcasing volcanic origins for the sand.

Impact Craters: Many craters expose underlying basalt layers, providing sources for sand that gets reworked by wind.

Characteristics:

Color: Dark, often appearing black or bluish in images due to volcanic minerals like olivine.

Formation: Created from volcanic eruptions and mechanical weathering, then shaped by wind (aeolian processes).

Activity: Dunes are very active, shifting significantly over time, influenced by seasonal frost and dry ice sublimation.

How it's Found:

Orbital imagery (like NASA's Mars Reconnaissance Orbiter (MRO) and its HiRISE camera) reveals large dune fields.

Rovers (Curiosity, Opportunity) analyze surface sands up close, confirming their basaltic composition

Offline

Like button can go here

#10 Yesterday 18:17:57

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

Basalt sand processing is a multi-stage industrial process, rather than a single-step action. Because basalt is an extremely hard, high-density rock (\(2.8-3.0\text{\ g/cm}^{3}\)), processing focuses on efficient, multi-stage crushing, typically lasting for a few minutes per batch, but operating continuously. Basalt Sand Processing Time Chart Note: This represents the mechanical processing time of rock-to-sand in a typical industrial crusher.

Production Stage OperationEstimated Time (Duration)

1. FeedingVibrating Feeder (removes debris)Continuous (immediate)

2. Primary CrushingJaw Crusher (\(>300\text{mm}\rightarrow <50\text{mm}\))Seconds to Minutes

3. Secondary/FineCone Crusher (\(50\text{mm}\rightarrow \text{smaller}\))Seconds to Minutes

4. Sand MakingVSI Crusher (shapes and grinds)Seconds to Minutes

5. ScreeningSeparating particle sizesContinuous (concurrent)

6. Washing/DewateringWashing & Drying (if wet process)10–30+ minutes

Total Cycle TimeRaw Rock \(\rightarrow \) Finished Sand\(<1\text{\ hour\ per\ batch}\)

Key Processing Steps & Considerations

Crushing Technology: Due to the hardness of basalt, laminated principle crushing equipment is recommended to minimize wear and tear.

Production Volume: Large-scale, high-capacity plants (e.g., 350-400 TPH) are common for basalt, focusing on creating construction aggregate, asphalt material, and manufactured sand.

Dry vs. Wet Process: Dry, vertical shaft impact (VSI) crushers are often used to create a uniform particle size, while wet processes are used to wash and remove fine dust.

Performance Metrics: The process aims for high efficiency, with a high crushing rate and low operational costs

[table]

[tr][td][b]Process Step[/b][/td][td][b]Description[/b][/td][td][b]Estimated Time[/b][/td][/tr]

[tr][td]1. Quarrying/Mining[/td][td]Extracting raw basalt rock[/td][td]1-3 Days[/td][/tr]

[tr][td]2. Primary Crushing[/td][td]Jaw crusher reduces rock size[/td][td]2-5 Hours[/td][/tr]

[tr][td]3. Secondary/Fine Crushing[/td][td]Cone crusher/Impact crusher[/td][td]3-6 Hours[/td][/tr]

[tr][td]4. Screening[/td][td]Separating by particle size[/td][td]1-2 Hours[/td][/tr]

[tr][td]5. Washing/Drying[/td][td]Removing fines/Moisture control[/td][td]4-12 Hours (varies by drying method)[/td][/tr]

[tr][td]6. Bagging/Shipping[/td][td]Packaging and dispatch[/td][td]1-2 Days[/td][/tr]

[/table] Typical Production Metrics

Production Capability: 154,000 T/month (system capacity).

Throughput: 30–700+ t/h (depending on line size).

Basalt Hardness: High (139-185 MPa) requires heavy duty equipment.

Offline

Like button can go here

#11 Yesterday 19:53:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

Isogrid technology, which involves creating rigid, lightweight triangular-stiffened structures, is a critical technique for designing space-hardened habitats and shells on Mars. While specific "plug-and-play" software labeled "Isogrid Maker for Mars" does not exist, aerospace and structural engineers use several advanced CAD and simulation tools to model these, often utilizing additive manufacturing (3D printing) for implementation.

Key Software and Modeling Techniques for Mars Domes:

Autodesk Fusion 360: Used for parametric modeling of isogrid structures. It allows engineers to create, test, and adapt the geometry of triangular ribs, which is critical for optimization.

Continuous Composites (CF3D): NASA-selected technology that uses advanced robotics to print continuous carbon fiber in isogrid rib patterns for space applications.

Finite Element Analysis (FEA) Software: Tools like ANSYS or NASTRAN are used to simulate the structural loads (internal pressure vs. external atmosphere) on isogrid domes to ensure they can withstand Martian conditions.

Roboze One+400: A 3D printer specifically used in research for producing high-performance, lightweight isogrid structures.

Geodesic Dome Calculators: For the basic geometry of polyhedral domes, tools that calculate chord factors and strut lengths are used.

Applications on Mars:

3D Printed Shells: Research suggests using 3D-printable inner spherical shells and outer parabolic domes to protect habitats from the Martian climate.

Regolith Manipulation: Techniques like sintering or microwave melting of Martian regolith are planned for creating geodesic domes.

Structural Efficiency: Isogrid designs are used to minimize mass while maximizing pressure resistance, necessary for transporting materials from Earth or using indigenous resources.

Commonly Used Tools:

CAD: Autodesk Fusion 360, SolidWorks, CATIA.

Analysis: ANSYS, Abaqus, Altair HyperWorks.

Manufacturing: Specialized 3D printing software (slicers for robotic arms).

These tools are part of a broader approach to designing and testing Martian habitat structures, which must be both lightweight for transit and rigid enough to handle the 101 kPa pressure differential on Mars

These are the quick google of software to use in a isogrid construction.

Offline

Like button can go here

#12 Yesterday 20:10:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

We launched the evening with discussions of kbd512's vision of a ring/dome habitat

SpaceNut joined in with numerous suggestions for materials and procedures.

We settled on a population to serve: 1000

That is a nice round number to work with. SpaceNut agreed to consult his AI friends to see if any of them can work out the requirements for all the equipment needed to sustain that population.

We are in need of fresh water and sewerage systems, and the equipment to recover fresh water from the sewerage.

SpaceNut is in an industry that deals with humans in closed life support environments.

Hopefully he will be able to help kbd512 size the complex.

Kbd512 gave us an expectation that some support systems would be inside the building and some outside.

To build for 1,000 a dome with isogrid structure of mars materials to use and do develop of stainless insitu materials is going to be a 40 year plus plan involving heavy mining and smelting, with a 1-meter deep, 8x8 km pit of regolith necessary for material to sustain a large population's infrastructure.

Leaving even more time for getting the cast basalt processing for insertion into the grid.

Offline

Like button can go here

#13 Yesterday 20:46:20

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,912

Re: Ring Habitat on Mars Doughnut Torus

The project is under way!

kbd512 has taken the important step of DECIDING the population to be served.

Everything else will flow from that critical decision. Every detail of the project plan will flow from that one critical decision.

That is the role of a leader.

The rest of us are able to perform our responsibilities because someone in authority has made a decision.

All we have to do now is to implement that decision.

SpaceNut has volunteered (with some arm twisting) to discover what equipment and related supplies are needed to sustain that population. With that information, kbd512 will be able to size the structure.

kbd512 has already predicted that he will place some equipment outside the building and other equipment inside.

SpaceNut will work with multiple AI assistants to find the answers to all the questions that will arise.

When SpaceNut runs into a situation that requires another decision, kbd512 will make that decision and we will proceed.

Ultimately if all goes well, we will have in hand a detailed project plan that specifies every nut and bolt, and more importantly, when that nut/bold pair are needed and exactly how much torque to apply to the nut to secure the piece in question.

This project is comparable in complexity to building a nuclear powered submarine.

Fortunately, SpaceNut has spent decades in an industry closely related to nuclear powered submarines.

This forum is looking for persons with appropriate knowledge who will be willing to allocate some of their precious personal time to advancing the project.

Mars Society is the sponsor who allocates funds to support this forum. Any success achieved by this forum will flow to the credit of the Mars Society.

Mars Society members are welcome to join this forum. However, we are moving away from the entertainment business model with which this forum began. We have an opportunity to transition to a knowledge store with a focus on the Mars Settlement problem.

(th)

Offline

Like button can go here

#14 Today 06:02:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Ring Habitat on Mars Doughnut Torus

KBD512 needs to star the wiki document for constructing structure for a 1,000 crewed on Mars station to place all items as decided with in.

Just a reminder Calliban's dome has varied in population but the starting number is 1000 could only support 350 crew with life support for the size of of the 200m diameter parabolic 120m tall with probably 50 meters deep to house greenhouse, waste recovery and other such thing.

Deciding on shape structure is as you can see still is in concept.

Internal support is still unknown but if we are using submarine and aircraft construction for internal spaces then this is not a home style for civilians.

If we go with stainless steel ISOGRID then where is the source other than the build up of empty unused starship cargo ship which is in the neighborhood of 70MT of the ships hull and more. Other items can be removed and set aside for building.

The facts of mars for plumbing are going to be below the structures floor but inside the pressurized area hull of 0.1 M with depth of the floor depends on materials and where there is more floors above. ceiling are 2 meters tall with lighting 0.05M, electrical 0.05M, HAVC 0.3m set aside to keep these out of the way of the people with in. This layout repeats for the next and so on.

That means the proposed 125m^3 of pressurized volume for each family of 4 is a rectangle of 2.5 m tall with 5 m wide x 10 m long.

1,000 crew / 4 means 250 such rooms but that is not all of the internal requirement as hall ways are need on both side of these so that is 2.5 M x 1 M wide x 2 x 250 x 10 M = 62,500 cubic meter for living space regardless of shape for sleeping quarters.

Greenhouse volume for 1,000 need per single person is 2m x 4m x5m = 40 cubic meter x 1,000 = 40,000 cubic m volume to add to the sleeping quarters.

running total is 62,500 x 40,000 = 102,500 cubic meters

Volume of space still not complete

other things to consider are rest rooms, showers and Private Hygiene: ? sq meters per crew. or this not in the family room but in a common area

Exercise/Equipment: ? sq meters per crew. is this the a consolidated gym are like a planet fitness

Health/Medical Area: 23-28 sq meters per crew patient bed for monitoring, leave space for all side of bed

surgery suite and triage room for emergency care ?

4 lights for each room but how many outlets for each as they may have a drop down desk area ?

current wiki for human waste management AI content plus we have the starship fuel tanks to make use of for this purpose.

A 4-person crew can generate up to 2,500 kg of waste in a one-year mission.

A 3-year, 8-person crew is projected to generate roughly 12,600 kg of inorganic waste alone.

locations for Basalt and for Iron to make steel or stainless with

Building a large-scale stainless steel isogrid dome on Mars to house 1,000 crew members requires an industrial-scale, multi-decade construction effort, focusing on in-situ resource utilization (ISRU) to minimize the immense cost of transporting materials from Earth.

Structural Design and Engineering Isogrid Structure: An isogrid—a triangular pattern of ribs—provides high stiffness-to-weight ratios, ideal for resisting the high tensile stresses of a pressurized dome against the near-vacuum of Mars.

Dome Sizing: To house 1,000 people, the structure would likely need to be a large, multi-hectare habitat, similar to "mega dome" concepts.

Dimensions: A 20-meter high, 24mm thick steel plate wall, bolstered by vertical stringers, can withstand internal pressure.

Anchoring: Large domes create immense upward pressure (approx. 10 tonnes per \(m^{2}\)). The dome must be anchored deeply into the ground, likely using the weight of Martian regolith.

Construction Process and Materials Stainless Steel Sourcing: Stainless steel components can be fabricated on-site. Using locally sourced materials requires 40-50 years of development, involving heavy mining and smelting, with a 1-meter deep, 8x8 km pit of regolith necessary for material to sustain a large population's infrastructure.

Fabrication: Panels would be manufactured on Mars and welded in place to create a pressure-tight, airtight structure.

Prefabrication Limits: Due to transport constraints, domes cannot be brought in one piece; they must be constructed using modular, assembled components.

Protection: The steel shell must be shielded from radiation and micrometeoroids, typically by covering it with 1–3 meters of compacted Martian regolith.

Challenges and Considerations Atmospheric Pressure: The 78,000 tonnes of force on a 100-meter dome requires massive, specialized structural engineering.

Surface Conditions: Extreme cold and dust storms will hinder construction, requiring durable, automated robotic equipment.

Alternative Approaches: While steel is possible, some experts suggest that 3D-printed regolith, ice, or carbon fiber might be more efficient in terms of weight and material, as bringing steel from Earth is too costly.

Redundancy: To prevent single-point failures, the habitat should consist of multiple interconnected domes rather than one single, massive structure

Stainless steel isogrid dome construction on Mars offers a robust method for creating large-volume, pressurized habitats, leveraging high-strength, lightweight, and durable materials that can be transported from Earth or potentially manufactured on-site. Isogrid structures (triangular, lattice-reinforced, or sandwich panels) are engineered for maximum stiffness, providing the necessary pressure vessel strength to withstand the high-pressure differential (approx. 14.6 PSI) between a breathable, pressurized interior and the near-vacuum, low-pressure (0.1 PSI) Martian environment.

Key Aspects of Stainless Steel Isogrid Dome Construction on Mars

Structural Integrity: Isogrid designs, often used in aerospace for their exceptional strength-to-weight ratio, are considered for large domes to manage the massive tension loads on the dome surface. These designs use stiffeners to prevent the panels from "ballooning".

Material Advantages: Stainless steel is deemed more cost-effective to produce and, for certain applications, more reliable than inflatable alternatives. SpaceX, for instance, has developed technologies to work with stainless steel for large pressure vessels.

Construction Process:

Modular Assembly: Domes would likely be constructed from smaller, manageable panels rather than being sent as one large unit, given cargo constraints (e.g., SpaceX's 12m diameter limit).

Welding and Joining: Electron beam welding or similar advanced, automated techniques would be used to join panels, taking advantage of the vacuum of space (or, by extension, the Martian atmosphere) for high-quality welds.

Foundations: The structure would likely be anchored firmly into the Martian regolith to withstand internal pressures and environmental stressors.

Environmental Protection: While the steel provides the pressure vessel, additional layers are needed for radiation shielding and to handle the extreme temperature differences (around -63°C average).

Regolith Shielding: Covering the dome with 3–5 meters of local soil (regolith) is proposed to protect against high radiation levels and micrometeoroid impacts.

Hybrid Designs: Using a "thermos" style, with an inner pressurized steel hull and an outer shell, is a potential design to manage thermal and structural loads simultaneously.

Potential Challenges:

Massive Pressure Load: A large, unburied dome would need to be extremely heavy to prevent it from bursting. This requires significant anchoring and material strength.

Transport Costs: Moving large amounts of steel from Earth is expensive, necessitating, in the long term, on-site, in-situ resource utilization (ISRU) to create construction materials.

Stainless steel isogrid domes are a viable, high-tech option, often discussed in parallel with other techniques like 3D-printed ice habitats or underground, excavated, or "buried," in-situ, "dome-on-a-crater" conceptsConstructing a stainless steel isogrid dome on Mars to maintain an internal atmosphere of 0.5 bar (approx. 7.25 psi, similar to Apollo-era spacecraft) is an engineered solution designed to balance high structural efficiency with the need to withstand intense internal tensile stress. At this pressure, the dome is primarily a pressure vessel, requiring superior anchorage to prevent it from lifting or buckling.

1. Structural Design & Advantages (Isogrid)

An isogrid structure—a triangular, lattice-like reinforcement on the interior of the skin—is ideal for a Mars dome because it offers high bending stiffness with minimal material weight.

Tensile Strength: Because the 0.5 bar internal pressure far exceeds the 0.006 bar external pressure, the dome is under constant, significant tension. Isogrid structures efficiently manage these hoop stresses.

Material Selection: Stainless steel is favored for its high strength-to-weight ratio, ease of welding/prefabrication on-site, and high cryogenic strength at low temperatures.

Shape Optimization: While geodomes are common, low-pressure Mars environments might favor "egg-like" or flatter shell geometries to better distribute the internal pressure loads.2. Construction Methodology on Mars

Constructing such a structure requires automated, robotic assistance to handle hazardous, low-pressure, and cold conditions.

Prefabrication and Welding: Stainless steel panels can be pre-manufactured on Earth and transported, then welded together on-site. Welding is considered feasible for stainless steel compared to other materials like carbon fiber.

Anchorage: The dome must be heavily anchored to the Martian surface to prevent it from lifting off, requiring foundation engineering or covering the dome with several meters of regolith (soil) for ballast and radiation shielding.

In-Situ Resource Utilization (ISRU): Long-term construction can leverage ISRU by producing steel on Mars using local iron oxide and carbon, although this is a long-term goal.3. Key Challenges at 0.5 Bar

Pressure Management: The dome must maintain its structural integrity under constant outward pressure, necessitating robust sealing against air loss.

Material Embrittlement: Although stainless steel has good low-temperature properties, it must be carefully selected to avoid becoming brittle in extreme cold.

Dust Accumulation: Abrasive Martian dust can settle on the dome, reducing solar gain and requiring maintenance.

Radiation Protection: While 0.5 bar of pressure provides some, it is insufficient to block harmful cosmic radiation; therefore, a covering of regolith is often necessary.4. Comparison with Alternatives

vs. Rigid Domes: Stainless steel isogrid provides superior strength over standard rigid domes but is heavier to transport.

vs. Inflatable Domes: While lighter, inflatable structures (like the NASA Ice Home concept) require thicker insulation layers to prevent freezing and, often, a protective outer shell.

vs. Cut-and-Cover: Using buried or "cut and cover" techniques is often preferred for long-term, high-pressure habitation to minimize tension, whereas isogrid domes are excellent for high-volume work/living spaces.

A 0.5 bar environment represents a balance between the high cost of maintaining a 1-bar Earth-like atmosphere and the metabolic needs of humans, making it a viable, high-efficiency compromise for Martian habitationYes, an isogrid structure made from flat stainless steel sheets is a viable concept for large Martian habitats, offering high strength-to-weight with triangular ribs from single sheets, ideal for withstanding Martian pressure/loads while being potentially manufacturable (even 3D printed) in-situ or from pre-fab, balancing lightweight needs with Mars's harsh environment, though material processing and thermal swings remain key challenges.

Why Isogrids Work for Mars:

Strength & Lightness: Isogrids, essentially thin skins with stiffening ribs (often triangular), provide high structural stiffness and strength while minimizing mass, crucial for space structures.

Single-Sheet Fabrication: They can be machined or printed from single sheets, reducing complex assembly and potential leak points compared to honeycomb structures.

Isotropic Properties: The triangular pattern makes them behave like an isotropic material (same properties in all directions), offering uniform performance.

Material Adaptability: While traditionally metal, new additive manufacturing allows printing composite isogrids, and stainless steel offers durability.

Stainless Steel & Mars:

Durability: Stainless steel offers excellent resistance to corrosion and extreme temperatures, making it suitable for the harsh Martian environment.

Manufacturability: While requiring significant energy, it's a known material, and techniques like additive manufacturing (3D printing) are being explored for creating these structures on Mars using local resources or brought materials.

Challenges & Solutions:

Thermal Swings: Extreme temperature variations on Mars (e.g., 20°C to -73°C) can affect material adhesion and performance, requiring software/design solutions.

In-Situ Resource Utilization (ISRU): Processing Martian regolith or imported steel into printable/formable sheets for these structures is a major engineering hurdle.

Habitat Design: Integrating isogrid panels with other systems (like regolith shielding for radiation) and ensuring airtightness for large volumes remains complex.

In essence, an isogrid made from flat stainless steel sheets is a strong structural choice, but its practical application on Mars hinges on advanced manufacturing and material science to overcome thermal and processing challenges

Last edited by SpaceNut (Today 06:35:10)

Offline

Like button can go here