New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Yesterday 07:35:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,854

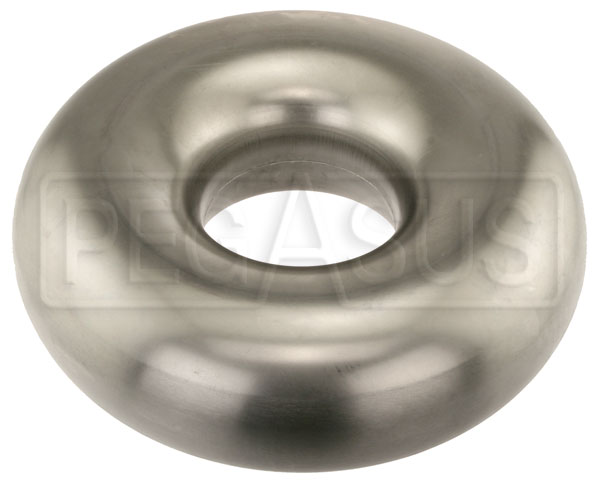

Ring Habitat on Mars Doughnut Torus

This topic is inspired by a suggestion from kbd512.

In discussion of domes that might be built on Mars, kbd512 suggested building a half-torus shaped structure.

Calliban had suggested a dome the size of the famous Superbowl at New Orleans.

Calliban's design would employ all native materials for the structure, and it would employ no imported materials at all for the primary structure.

kbd512's concept would employ a blend of local and imported materials.

This topic is offered for NewMars members who might wish to help kbd512 develop his idea.

It would be helpful to know the dimensions of the structure kbd512 has in mind.

The torus will have a diameter, and the ring of the torus will have a diameter.

In this early stage of definition of the concept, we do not know if kbd512 has a shape in mind for the cross section of the half ring.

Calliban has suggested a catenary shape so that forces are distributed evenly throughout the material of the wall of the ring.

This topic has significant growth potential.

The Stanford Torus is a model to study, since it dealt with many of the issues that will confront the designer of a half ring set on Mars.

I asked Google for help with the terminology:

AI Overview

Torus Shape – Definition, Examples, and Diagrams

A torus has two main diameters: the Major Diameter, which defines the overall size (center-to-center of the tube), and the Minor Diameter, which determines the thickness of the tube itself, often called the tube diameter or core diameter. These correspond to the Major Radius (distance from center of hole to center of tube) and Minor Radius (radius of the tube's cross-section) respectively.

Key Terms:

In the context of Calliban's dome, diameter is 200 meters at the ground, and the height is 120 meters.

The major and minor diameters remain to be defined for kbd512's ring habitat.

(th)

Last edited by tahanson43206 (Yesterday 07:41:23)

Offline

Like button can go here

#2 Yesterday 07:36:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,854

Re: Ring Habitat on Mars Doughnut Torus

This post is reserved for an index to posts that may be contributed by NewMars members.

Index:

(th)

Offline

Like button can go here

#3 Yesterday 15:03:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,201

Re: Ring Habitat on Mars Doughnut Torus

Here is what was in the re-purposed starship stainless shell.

If we provide 125m^3 of pressurized volume for each family of 4, then we need approximately 10 Super Domes worth of pressurized volume to house a million people. Domes tend to have a lot of unusable space, though. What about a ring?

This sounds just like what a caretaker doughnut design from empty starships would be.

Leave the crewed ship in the center of what is constructed from the ships hull materials.

The proposed project of creating a 9-meter stainless steel doughnut cross-section with a crewed starship in the center, utilizing materials from unused cargo ships, is not technically feasible using current industrial and engineering methods.

Here are the key reasons why this concept is impractical:

Material Limitations:

Steel Type: The steel used in standard cargo ships is not typically high-grade stainless steel suitable for precision aerospace or habitat construction. It is standard structural steel, which has different properties regarding corrosion resistance, strength-to-weight ratio, and material consistency.

Repurposing Difficulty: While steel can be recycled, melting down and reshaping massive cargo ship hulls into a precise, large-scale, high-quality "doughnut" cross-section requires specialized industrial remelting processes (like electroslag remelting for high-grade applications) that are complex and costly, making on-site or large-scale transformation unfeasible.

Material Integrity: The structural integrity of repurposing cut and welded sections of existing cargo ships for such a specific, high-stress application (especially if intended for space or extreme environments) would be difficult to guarantee without extensive and costly engineering.

Engineering and Design Challenges:

Structural Requirements: Designing a 9-meter "doughnut" structure to house a starship would have highly specific operational and stiffness requirements that repurposed, potentially compromised, cargo ship materials cannot easily meet.

Scale and Precision: The precision needed for a 9-meter cross-section that interacts seamlessly with a crewed starship is immense. Achieving this precision by modifying large, existing, non-uniform cargo ship sections is impractical.

Feasibility vs. New Construction: It would be significantly more efficient, reliable, and cost-effective to produce the necessary components using new, purpose-built stainless steel designed for the specific application rather than attempting to salvage and heavily modify existing ship parts.

In summary, the foundational materials and engineering processes required to create such a specific, high-specification structure from generic, used cargo ships make the project technologically unviable.What challenges are

You will need 4 sections of the 60 m tube to achieve a total length of 240 m. The final circle will have an approximate diameter of \(76.4\) m.

Step 1: Calculate material needs First, determine the total length of tubing required. The user's desired circumference is 240 meters. The calculation confirms that exactly 4 of the 60-meter tubes are needed to reach this length. The 9 m diameter of the individual tubes is the cross-sectional diameter, not the circle's final diameter.

Step 2: Join the tubes Join the four 60-meter stainless steel tubes end-to-end to create one continuous 240-meter length. This is typically done by welding the joints, which requires specific techniques for stainless steel.

Step 3: Form the circle The 240-meter length of tube must be mechanically bent or rolled into a circular shape. Given the large scale, specialized industrial equipment for bending large diameter, thick-walled (implied by 9m diameter) steel is necessary.

Step 4: Cut and finish A final, precise cut will be needed to join the two ends of the 240-meter length after it is formed into the circle. For cutting stainless steel tubes, common methods include using a portable band saw or an angle grinder with a cut-off wheel, applying slow speed and cutting oil to manage the material's hardness and heat.

Answer: You will need to use 4 of the 60 m tubes to achieve a total length of 240 m. The final circle made from this length will have a diameter of approximately \(76.4\) m (\(240/\pi \)). The tubes must be joined end-to-end and then formed into the circular shape, requiring precise cuts and welding to secure the final joint

That means the inside diameter is 76.4 - 18 = 54 m diameter

The volume of the doughnut shape is approximately 15268.14 cubic meters.

Make 3 floors similar to a submarine flight decks. Assume that the three are 2.5 meters ceiling to floor for each.

Offline

Like button can go here

#4 Yesterday 15:05:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,201

Re: Ring Habitat on Mars Doughnut Torus

For kbd512 re post in SpaceNut's Superdome topic ...

https://newmars.com/forums/viewtopic.ph … 62#p237162

Nice vision !!!

I hope that it comes to pass.

It certainly ** could ** come to pass.

As a reminder, Calliban's dome has varied in population but the starting number is 1000.

The logistics of providing sewer service, heating, water, power, communications and interior structures (ie, living and retails space) seem to lead toward solving the 1000 person population problem before advancing to something greater.

Thus your vision of a population of 1,000,000 people could be realized with 1000 domes. Mars has ** plenty ** of room for that many domes, since they are only 200 meters in diameter. That said, it appears that siting the domes in craters has advantages.

Calliban's vision was to create the domes out of locally sourced material, which led to his initial idea of bricks, followed by the suggestion of "voudrois" shaped blocks. Calliban's concept includes the Ziggurat ramps to facilitate construction while simultaneously providing force to resist the internal pressure of .5 bar for the standard Mars habitat atmosphere.

In any case, it is good to see SpaceNut's topic developing, and your post adds to the flow.

(th)

For kbd512 ... There is a new topic available if you would care to develop your ideas for a ring shaped habitat on Mars...

https://newmars.com/forums/viewtopic.php?id=11287

Please begin by setting the dimensions so that others can begin to help to build up a vision of the idea.

The Stanford Torus may be larger than you have in mind, but is a well developed model that might provide inspiration for your concept.

Unlike Calliban's dome, your concept appears to have potential for construction outside a Crater.

It will definitely be interesting to see what members do with the concept, but it needs dimensions so that folks have something to work with.

(th)

Since the details were missed for number of meters for the number. which was above my information in the quote.

If we provide 125m^3 of pressurized volume for each family of 4,

Math: 1000 / 4 = 250 family units but that does nothing else other than house people....

250x 125 m^3 = 31,250 cubic meters of volume

Offline

Like button can go here

#5 Yesterday 15:12:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,201

Re: Ring Habitat on Mars Doughnut Torus

You also missed the secondary choice to bring all materials

SpaceNut,

I was thinking of using a combination of 304L from the expended Starships and indigenous materials in a "space frame" design wherein the Starship steel provides external structural support so that locally-sourced cast basalt tiles interlock into the space frame and are pressed outwards and into the space frame by internal pressurization, with sealing accomplished using either a thin internal layer of stainless sheet steel welded into the space frame, over the top of the inner tile faces, or a Silicone-based adhesive sealant could also be used. We can bring enough 304L and Silicone sealant from Earth to build this kind of structure by scrapping / recycling the Starships. I don't think it's feasible to bring enough concrete or basalt tiles, hence why that material must be locally sourced.

Do you remember the structure of the "Biosphere 2" built in Arizona?

So, imagine that we create a giant ring-shaped habitat, rather than a Super Dome, so as to keep tensile stresses sane, so as to economize on recycled steel, so as to allow us to safely use cast basalt tiles without the thickness of said tiles needing to greatly resemble the stones used to build the pyramids. This maximizes internal volume, minimizes material consumption. We can still build a Super Dome from locally sourced meteorite Nickel-steel, but for sake of argument presume that we can only handle local production of indigenous liquid water, atmospheric gases, and one construction material that we only have to melt and cast into a limited number of molds. More could always be done using more equipment and labor, but we have to bring those things with us.

That changes everything for what is going to be required as well.

Offline

Like button can go here

#6 Yesterday 22:00:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,427

Re: Ring Habitat on Mars Doughnut Torus

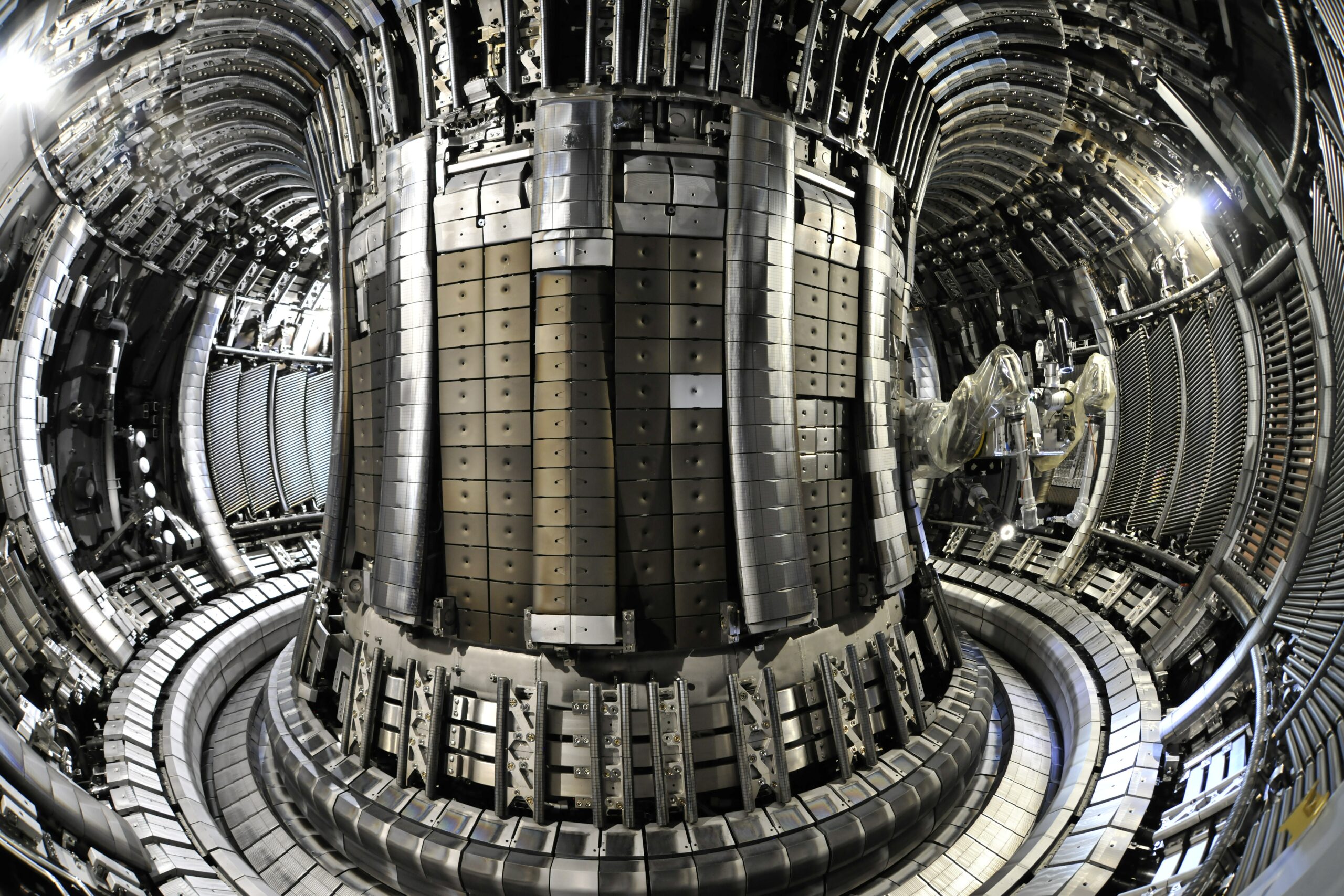

This Stanford Torus structure artistic rendering from Nichlas Benjamin is more in line with what I had in mind for the exterior support rest of the habitation ring:

Except that I wanted a shape that maximizes usable floor space, which implies more of a D-shaped toroidal structure, like a tokamak.

The interior of this D-shaped tokamak is broadly similar to what I had in mind:

The structure would only be one or perhaps two stories high, with the bottom of the torus housing water piping and the top housing electrical power cables, data cables, and light pipes.

Try to visualize all those interior metal electromagnet "tiles" being replaced with cast basalt tiles:

The interior would be lined with cast basalt tiles like these:

Basalt can be cast into relatively complex shapes and has a strikingly beautiful natural appearance:

So, basic concept is as follows:

1. D-shaped torus to provide more usable floor space without an excessive number of floors requiring elevators, with reduced structural materials strength and therefore mass requirements, relative to a Super Dome.

2. Starship's 304L stainless steel is converted into a tubular exoskeleton / space frame. The external frame is intended to allow for thermal expansion and contraction in the Martian temperature extremes between day and night.

3. Cast basalt tiles / blocks are inserted into the frame and sealed using Silicone caulk.

4. Liquid CO2 will be pumped through the space frame in an attempt to improve upon the room temperature strength of 304L, and to regulate its temperature to avoid excessive expansion and contraction. We want to keep that stainless cold, definitely below zero, because it's weaker than A36 at room temperature, but not mildly cryogenic because we start to lose ductility and we definitely want to keep that. We're after about 517MPa to 621MPa. We don't go any colder than is required to achieve that yield strength.

5. The structure size / progression is ultimately limited by the number of arriving Starships. We have around 70t of the right kind of material to work with per Starship. The engines are higher grades of stainless that would be repurposed for making fasteners, tooling, and molds.

304L Temperature vs Yield Stress for Conventional 304L (green) and Laser Powder Bed Fusion (red):

As the graph above shows, laser sintering of 304 powder delivers high yield strength, partially due to formation of martensite, but we don't want martensite formation in a steel exposed to cryogenic temperatures, so we're sticking with a conventional cold-rolled seamless tubing material produced in a miniature electric arc furnace that accepts bits of recycled Starship hull scrap steel. The yield strength mechanical property is reduced, but that other important metallurgical property, namely an austenitic grain structure which confers ductility at very low temperatures, is more important for our application than pure tensile strength, which we are "thermally improving" by keeping the steel cold using cold LCO2.

Offline

Like button can go here