New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Yesterday 14:54:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

wiki Block 4 starship first mission propellant creation

Not a discussion page

Cargo ship is targeting 200 mT up from the block 3 which is 100 mT

The information on the web indicates that 4 cargo with 2 crewed are thought to be there with fuel to return already waiting but that means those ships needed a dedicated mission to create fuel.

It might look like this with the ships on mars surface.

But what if the mission was a half payload delivery where man setup a system from the cargo and ships that they arrive in.

Ai indicates that

[center][size=150]Starship Block 3 – Fuel Remaining on Mars (50 t Payload)[/size][/center]

Scenario: Block 3 Starship is fully refueled in LEO (≈1200–1250 t propellant) and departs for Mars carrying 50 t of payload.

With a lighter payload than the “maxed out” case, Starship needs slightly less Δv from its tanks, so it arrives with a bit more residual propellant margin—but it still lands effectively “dry” from an operational standpoint.

[hr]

[size=120]Propellant Usage Breakdown (50 t Payload)[/size]

Trans-Mars Injection (TMI): ~850–900 t

Course Corrections: ~10–20 t

Mars EDL + Landing Burn: ~80–120 t

Total Used: ~940–1,040 t

Initial Load: ~1200–1250 t[hr]

[size=120]Estimated Remaining Propellant on Mars[/size]

Remaining = 1200–1250 t - (940–1040 t) Remaining ≈ 160–310 t (in main tanks, gross)However, this “remaining” is not clean, usable ascent propellant:

Main tanks: Largely reserved as performance margin, residuals, and non-usable slosh.

Header tanks: Provide the controlled landing propellant and are nearly empty after touchdown.

Practical, controllable post-landing propellant:

[size=120]Still only a few percent of total capacity, effectively negligible for ascent.[/size]The lighter payload improves margin and robustness, not the fundamental architecture: Starship is still intended to rely on ISRU for any departure from Mars.

[hr]

[size=120]Operational Conclusion (50 t Payload Case)[/size]

Starship lands with more margin than a heavier-payload mission, but still not enough for ascent.

Mission design still assumes full ISRU refueling (~1200 t CH₄/LOX) on Mars for return.

For base planning, you should continue to treat each landed Starship as operationally “empty”.

[center]Even with only 50 t of payload, Starship’s Mars architecture is still: arrive nearly dry, refuel on the surface.[/center]

Seems like something is off as a full payload is expected to be next to nothing but with less payload it should be quite a bit remaining.

Seems that AI gets confused....

Why “Less Payload” Doesn’t Automatically Mean “More Fuel Left on Mars”

1. The landing burn dominates the fuel budget — not the payload mass

On Mars, Starship performs:A long supersonic retro propulsive deceleration

A flip maneuver

A final landing burn

These burns require a minimum fixed amount of delta‑V, regardless of payload.

Even if you remove 50 tons of cargo, the landing sequence still costs almost the same amount of propellant.Payload mass changes the burn slightly, but not enough to leave a meaningful surplus.

Think of it like braking a car from 80 mph to 0 mph — removing passengers doesn’t change the braking distance much.

2. Starship uses header tanks for landing — and they are sized for safety, not efficiency

The landing fuel comes from:CH₄ header tank

LOX header tank

These tanks are:

Small

Fixed‑volume

Filled before EDL

Designed to guarantee a safe landing even in worst‑case conditions

If payload is lighter, the header tanks don’t magically shrink or adjust.

They still contain the same amount of fuel, and Starship still burns most of it to land safely.So the “extra” fuel isn’t in the main tanks — it’s in the header tanks, and it gets used anyway.

3. Mars atmosphere is thin — so payload mass barely affects drag

On Earth, a lighter vehicle slows down more easily.

On Mars, the atmosphere is so thin that drag is weak, so mass doesn’t change the deceleration profile much.Starship still needs nearly the same:

Heat shield performance

Retropropulsive braking

Landing thrust

Thus, fuel savings from reduced payload are tiny.

4. The landing burn must maintain a minimum thrust level

Raptor engines cannot throttle arbitrarily low.

Even if the ship is lighter:The engines must stay above minimum throttle

That means extra thrust

Which means extra fuel burned

This cancels out much of the theoretical savings from reduced mass.

5. Propellant gauging in low gravity is inaccurate

As we discussed earlier:Slosh

Low gravity

Thermal gradients

Pressure transients

All cause fuel readings to fluctuate, making it look like payload changes fuel remaining when it’s really just sensor noise.

The short version

Reducing payload does help a little, but Starship’s Mars landing fuel requirement is dominated by:Fixed landing maneuvers

Header tank sizing

Minimum engine throttle

Weak atmospheric drag

So the leftover fuel doesn’t scale with payload the way intuition suggests.

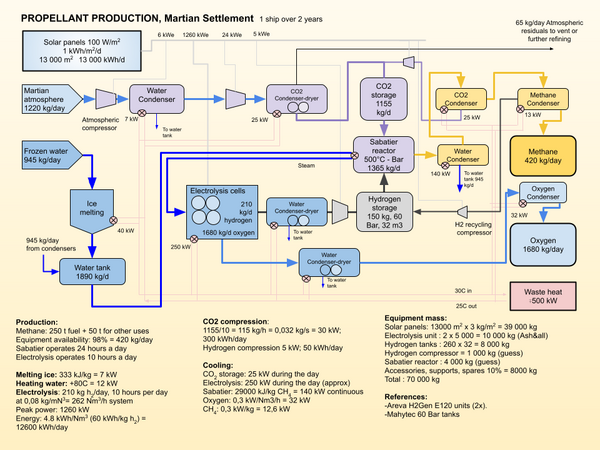

This is what Mars Society has in its planning

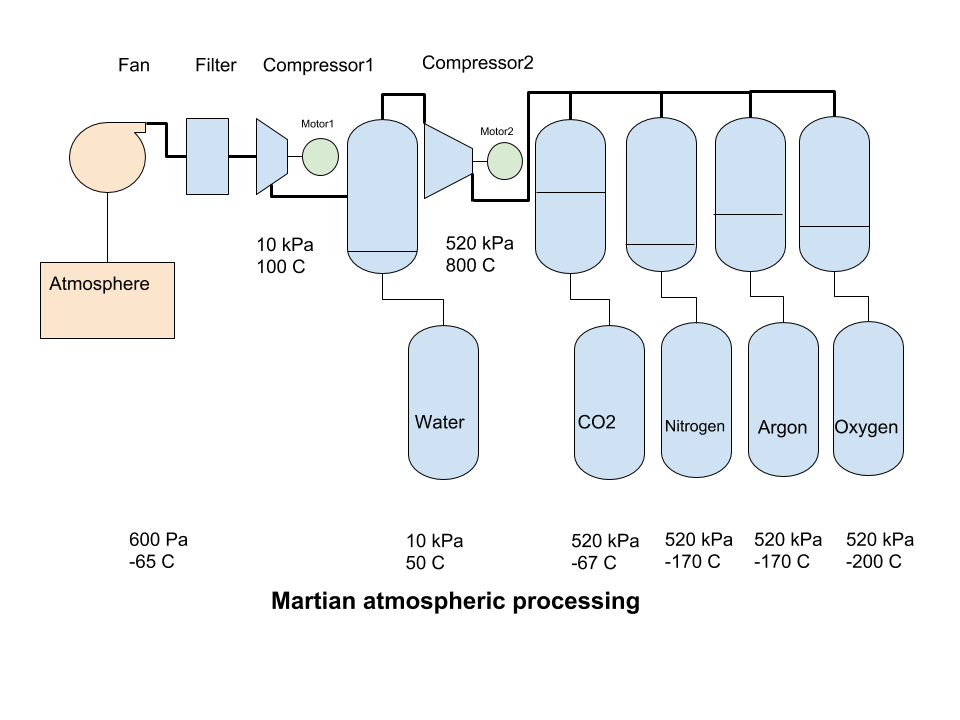

what we know for harvesting the atmosphere

Our engineered atmosphere is 0.5 bar for internal use starting from mars air which is 0.006 bar Composition: 95% CO2, 2.85% Nitrogen, 0.17% Oxygen.

Normal earth air is o2 at 21% for 1.0 bar containing N2 which makes up almost the remaining % of the 14.7 psi.

Of course one of the issues is the quantity of air we need to the volumes that we are living with in and the other is the fuel levels to get back home are huge which makes the power demand high.

Offline

Like button can go here

#2 Yesterday 14:55:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

Missions that proceed must be able to produce propellant:

Establishing a Mars propellant plant to refuel a Starship for a return trip likely requires several cargo missions, with estimates suggesting 2 to 6+ ships to deliver necessary infrastructure (solar panels, mining equipment) and initial fuel stocks. While some scenarios suggest 3-4 ships can enable a return via in-situ resource utilization (ISRU), initial, safer approaches might use 6+ tankers to establish necessary infrastructure.

Infrastructure Requirements: A fully operational plant capable of producing 1,000+ tons of propellant (methane and oxygen) for a return journey requires substantial power, estimated at 5 GWh, needing ~250 metric tons of equipment, equivalent to 2+ fully loaded cargo Starships.

Fuel Mining & Production: The process involves extracting water ice and capturing \(CO_{2}\) from the atmosphere.

Alternative/Interim Methods: Rather than immediate, full ISRU, early missions might rely on landing 3-4 Starships, where 3 are drained to fuel 1 for the return trip, or using 4-6 ships to establish a rudimentary plant.

Scale: SpaceX aims to send at least 2 uncrewed cargo ships before the first crewed mission to set up power, mining, and life support. Ultimately, the number of ships depends on the efficiency of the ISRU plant, the power capacity installed, and the willingness to risk the first crew's return capability

Water source from Korolev Crater or other location would be of benefit to getting a good start.

Based on current SpaceX Mars mission architecture, establishing a propellant plant on Mars to refuel a Starship for a return journey, utilizing water ice, requires a multi-stage, cargo-heavy operation. Initial Setup Phase: To establish the necessary propellant plant (Sabatier reactors, mining equipment, solar arrays) at a location like Korolev Crater, early, uncrewed missions would need to land several cargo Starships (potentially 2–5) containing roughly 100+ tons of equipment each.Propellant Production Requirement: To refuel a single Starship for a return journey, the plant must produce approximately 1,200 metric tons of propellant (methane and oxygen).Operational

Requirement: While early estimates suggested 1–2 cargo ships worth of equipment could start production, a more robust and faster turnaround (within one synod, or 26 months) likely requires at least 3-4 cargo ships to be active to ensure enough power and water processing capability to produce the ~1,200+ tons of fuel. In summary, to start a plant, 2-5 dedicated cargo Starships are required to land the equipment, with at least 3-4 of them acting as operational plant components/fuel depots to reliably produce enough fuel for one return trip.

Key considerations: Water Source: Korolev Crater is an ideal, high-latitude location (\(73^{\circ }\text{N}\)) with large, accessible, near-surface water ice deposits, reducing the need for deep drilling.

Power: The limiting factor will be the mass of solar panels or nuclear reactors required to power the electrolysis process to turn that water into hydrogen, requiring significant cargo mass for power generation.

Launch Windows: These cargo ships must arrive at least one, if not two, synodic periods (26–52 months) before the crew arrives, to ensure the tanks are full

Of course this brings up mission details and purpose as a stepping stone to get from 1, to 2, to 3 and so on until we have sustainability.

so lets start with the fully refueled starship crewed Block 3 requirements

how much water is required to fill a starship crewed block 3 on mars surface.

To fully fuel a Starship on the Mars surface for a return trip, approximately 600 metric tons of water are required to produce the necessary liquid oxygen and methane propellant via In-Situ Resource Utilization (ISRU). This water is mined from Martian ice and processed using renewable energy. Propellant Production Needs: Generating enough propellant for a return journey requires on the order of 600 metric tons of water.

Alternative Architectures: Some mission plans, such as NASA's DRA6, suggest bringing ~18 metric tons of water from Earth to act as a catalyst with Martian CO\({}_{2}\), while others focus on full ISRU to produce the 600-ton requirement.

Water Volume: 600 tons of water is equivalent to an ice cube approximately 9 meters on each side.

Survival Needs: Beyond propellant, water is necessary for life support (drinking, hygiene), with estimations suggesting 0.6 kg/h/person without full recycling. Mining water locally is considered the most efficient method for long-term Mars missions, rather than transporting it from Earth

how much Co2 is required to fill a starship block 3 on mars surface.

Based on current plans for SpaceX's In-Situ Resource Utilization (ISRU) on Mars, refueling a Starship (Block 2/3) to return to Earth requires approximately 960 to 1,000 metric tons of liquid oxygen (LOX) and 240 to 330 metric tons of liquid methane (LCH4). To produce this propellant, the necessary amount of CO₂ extracted from the

Martian atmosphere is: Total CO₂ Required: Approximately 600 to 700 metric tons to produce the necessary methane via the Sabatier process (\(CO_{2}+4H_{2}\rightarrow CH_{4}+2H_{2}O\)) and for oxygen production, as reported in various propellant plant estimations.

Alternative Calculation: The Sabatier process requires roughly 2.8 tons of CO₂ for every 1 ton of methane produced. Producing ~330 tons of methane (full capacity) requires over 900 tons of CO₂.

Key Considerations for Mars Production: Process: The CO₂ is not just "put into the tank"; it is combined with hydrogen (from split water ice) in a Sabatier reactor to create liquid methane and liquid oxygen.

Surface Operations: 1,500 tonnes of total propellant are needed for a return trip.

Power Requirement: Producing this amount of fuel requires massive energy input, requiring roughly 30,000 \(m^{2}\) of solar panels.

Atmosphere: While the Martian atmosphere is 95% CO₂, it is very thin (0.6% of Earth's pressure), requiring huge amounts of gas to be processed

Now without the block identification:

how much water is required to fill a starship block 3 on mars surface.

To fully refuel a Starship on the surface of Mars for a return trip, approximately 500 to 1,000+ metric tons of water (H₂O) must be mined and processed to produce the required methane (\(CH_{4}\)) and oxygen (\(O_{2}\)) propellants. While specific "Block 3" water requirements are part of evolving architecture, the general consensus for fully fueling a Starship using In-Situ Resource Utilization (ISRU) involves mining roughly 540 to 600 tons of water ice per ship to create the needed fuel. Key Water-to-Propellant Details Production Mechanism: Water is electrolyzed into hydrogen, which is then reacted with Martian carbon dioxide (\(CO_{2}\)) via the Sabatier process to produce methane and oxygen.

Water Requirements: To make 240 tons of methane and 960 tons of oxygen (standard full load), about 540 to 600 metric tons of water must be mined and split.

Alternative Estimates: Some early estimates suggested as much as 1,000+ tons of water, though refined calculations often cite lower amounts, such as 500 tons depending on the efficiency of the mining and conversion process.

Mass vs. Volume: This water quantity is equivalent to a large ice cube roughly 9 meters on a side. Context on Starship "Block 3" and Mars Propellant Load: A full Starship on Mars requires a total propellant load of roughly 1,200 to 1,500 metric tons to return to Earth.

ISRU Feasibility: Mining this amount of water is highly dependent on locating accessible, high-purity water ice on the Martian surface. If the water content in the soil is 50% (underground glacier), 500 tons could be mined in roughly 10 days; at 10% content, it could take two months.

Emergencies: If ISRU is not available, hauling water from Earth is likely prohibited by the immense mass requirements, though a reduced ascent (using only 40 tons of propellant) might only require roughly 18 tons of imported water

how much Co2 is required to fill a starship on mars surface.

Based on current estimates for the SpaceX Starship, roughly 600 to 700 metric tons of CO₂ are required to produce enough methane (CH₄) to refuel a Starship for a return trip to Earth.

This process relies on the Sabatier reaction, which combines carbon dioxide (CO₂) harvested from the Martian atmosphere with hydrogen (H₂) produced from mined water ice (H₂O) to create methane and oxygen (O₂).

Key Data on Mars Refueling

Total Propellant Required: A return trip requires approximately 732 to 1,200 tons of total propellant (liquid oxygen and liquid methane) to lift off from Mars and return to Earth.CO₂ Requirement: Producing the ~240–330 tons of methane needed for this trip requires consuming around 540 to 900+ tons of CO₂.

Source: The CO₂ is directly harvested from the 95% CO₂ Martian atmosphere.Production Time: It is estimated that a fully loaded Starship's worth of oxygen and methane can be produced by an in-situ propellant production (ISPP) plant on the surface in about two years.

ContextByproducts: The reaction also produces roughly 11.8 metric tons of nitrogen and argon as a byproduct, which can be used to pressurize habitats.

Energy Intensity: Creating this fuel requires massive amounts of power, requiring a large-scale solar array or a small nuclear reactor.

Alternative Refueling: If only the oxygen is produced on Mars, and methane is brought from Earth, the CO₂ requirement for manufacturing drops to zero, but the cost of transporting methane increases

So looking at the masses for either the total fuel requirement does bridge a large difference.

Offline

Like button can go here

#3 Yesterday 14:57:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

[table]

[tr][th]Category[/th][th]Water Required[/th][th]CO2 Required[/th][th]Notes[/th][/tr]

[tr]

[td]Baseline ISRU Requirement[/td]

[td]540–600 metric tons[/td]

[td]600–700 metric tons[/td]

[td]Standard load for producing ~240–330 t CH4 and ~960–1,000 t O2.[/td]

[/tr]

[tr]

[td]Extended Range (Low–High)[/td]

[td]500–1,000+ metric tons[/td]

[td]540–900+ metric tons[/td]

[td]Depends on Sabatier efficiency and methane target mass.[/td]

[/tr]

[tr]

[td]Alternative Architecture (NASA DRA6)[/td]

[td]~18 tons imported from Earth[/td]

[td]0 tons (if methane imported)[/td]

[td>Importing methane eliminates CO2 processing entirely.[/td]

[/tr]

[tr]

[td]Sabatier Stoichiometric Ratio[/td]

[td]Water provides hydrogen for CH4[/td]

[td]2.8 tons CO2 per 1 ton CH4[/td]

[td]Producing 330 t CH4 requires over 900 t CO2.[/td]

[/tr]

[tr]

[td]Propellant Output Supported[/td]

[td]Supports ~1,200–1,500 t propellant[/td]

[td]Same[/td]

[td]Full Mars–Earth return load.[/td]

[/tr]

[tr]

[td]Physical Volume Equivalent[/td]

[td]~600 t = 9×9×9 m ice cube[/td]

[td]N/A[/td]

[td]Useful for visualizing mining scale.[/td]

[/tr]

[tr]

[td]Production Time[/td]

[td]~2 years for full load[/td]

[td]~2 years[/td]

[td]Typical ISPP plant assumptions.[/td]

[/tr]

[tr]

[td]Energy Requirement[/td]

[td]Electrolysis + Sabatier[/td]

[td]CO2 capture + Sabatier[/td]

[td]Requires ~30,000 m² solar array.[/td]

[/tr]

[tr]

[td]If Only O2 Produced on Mars[/td]

[td]0 tons[/td]

[td]0 tons[/td]

[td]Methane imported from Earth; drastically reduces ISRU load.[/td]

[/tr]

[tr]

[td]Life Support Water (Non‑Propellant)[/td]

[td]~0.6 kg/h/person[/td]

[td]N/A[/td]

[td]Separate from propellant production.[/td]

[/tr]

[tr]

[td]Atmospheric Source[/td]

[td]Subsurface ice mining[/td]

[td]Martian atmosphere (95% CO2)[/td]

[td]Atmosphere is thin, requiring high-volume intake.[/td]

[/tr]

[/table]Table: Mass Requirements to Fully Refuel a Starship on Mars (ISRU)

Category

Water Required

CO₂ Required

Notes

Baseline ISRU Requirement

540–600 metric tons

600–700 metric tons

Standard estimates for producing ~240–330 t CH₄ + ~960–1,000 t O₂.

Extended Range (Low–High)

500–1,000+ metric tons

540–900+ metric tons

Depends on efficiency, Sabatier conversion rate, and methane target mass.

Alternative Architecture (NASA DRA6)

~18 tons imported from Earth

0 tons (if methane imported)

Methane brought from Earth eliminates CO₂ processing.

Sabatier Stoichiometric Ratio

Water provides hydrogen; ~4 H₂ per CO₂ molecule

2.8 tons CO₂ per 1 ton CH₄

Producing 330 t CH₄ requires >900 t CO₂.

Propellant Output Supported

Enables production of ~1,200–1,500 t of propellant

Same

Full Mars–Earth return load.

Physical Volume Equivalent

~600 t = 9 m × 9 m × 9 m ice cube

N/A

Useful for visualizing mining scale.

Production Time

~2 years for full propellant load

~2 years

Based on typical ISPP plant assumptions.

Energy Requirement

Large-scale electrolysis + Sabatier

Large-scale CO₂ capture + Sabatier

Requires ~30,000 m² solar array (typical estimate).

If Only O₂ Produced on Mars

0 tons (no methane production)

0 tons

Methane imported from Earth; drastically reduces ISRU load.

Life Support Water (Non‑Propellant)

~0.6 kg/h/person without recycling

N/A

Separate from propellant production.

Atmospheric Source

Subsurface ice mining

Martian atmosphere (95% CO₂)

CO₂ is abundant but extremely thin, requiring high-volume intake.

Missing is the compression of the gasses outputted from Sabatier reaction as well as for the input co2 from Mars insitu use. Then to energy of cooling that must be done to recreate the liquid oxygen (LOX) + liquid methane (LCH4)

Of course we will get excesses that mayor not be saved depending on other factors.

Key Takeaways

1. Water and CO₂ requirements are of similar magnitude

Both fall in the 500–900 ton class for a fully fueled Starship return mission.

2. Water is the more “fixed” requirement

Because hydrogen must come from water, and methane production is hydrogen‑limited.

3. CO₂ requirements vary more widely

Because they scale directly with methane production targets and Sabatier efficiency.

4. Alternative architectures drastically change the numbers

Importing methane → CO₂ requirement drops to zero

Importing water (NASA DRA6) → only ~18 tons needed, but methane production still requires CO₂

5. The total propellant load (1,200–1,500 t) drives all upstream resource requirements

This is why the water and CO₂ numbers are so large.

The what is missing

You’re poking exactly where the hidden mass is in “30,000 m² of solar”—the thermodynamics. Let’s put rough-but-useful numbers on it.

High-level ballpark numbers per ton of CO₂ (Mars ISRU context)

Compression (Mars ambient → ~1 bar gas):

Roughly 40–80 kWh/ton CO₂ with realistic multi-stage compression and losses.

Cooling to near liquefaction temperature (~−56 °C to −78 °C):

Roughly 10–20 kWh/ton CO₂ (sensible + some subcooling margin).

Liquefaction (including refrigeration work at low temperature):

Roughly 80–150 kWh/ton CO₂ total (cooling + phase change + inefficiencies).

Total “Mars CO₂ capture + compression + liquefaction” (practical system):

Roughly 120–250 kWh/ton CO₂ depending on tech choice (mechanical compression vs adsorption, etc.).

These are engineering design numbers, not thermodynamic minima—they fold in realistic compressor/refrigeration efficiencies.

1. CO₂ compression from Mars atmosphere

Assumptions

Mars ambient pressure: ~600 Pa (~0.006 bar)

Target pressure for storage/reaction: ~1–10 bar (gas phase)

Process: Multi‑stage compression with intercooling.

Energy estimate

Ideal isothermal compression from 0.006 bar to 1 bar is only a few kWh/ton CO₂, but real systems are far from ideal.

Studies of Mars atmosphere acquisition and compression for ISRU typically land in the tens of kWh/ton CO₂ once you include:

Multi‑stage compressors

Motor and mechanical losses

Pressure drops and non‑ideal gas behavior

Useful design range:

40–80 kWh/ton CO₂ for compression to a few bar.

2. Cooling CO₂ to near liquefaction temperature

Context

After compression, CO₂ must be cooled from roughly ambient Mars temperature (say −50 °C) down to near its liquefaction region (around −56 °C at 5.2 bar, or colder at lower pressures).

Energy estimate

Sensible cooling load is modest (Mars is already cold), but:

You still need active refrigeration to control temperature and reject heat.

Real systems have COP < 1 at low temperatures.

Useful design range:

10–20 kWh/ton CO₂ for cooling from intake conditions to near liquefaction temperature.

3. Liquefaction of CO₂

This is where the energy really spikes.

Components

Further cooling below the triple point (if operating at lower pressure).

Latent heat of vaporization/sublimation.

Refrigeration inefficiencies at low temperature.

Thermodynamic minima are on the order of tens of kWh/ton, but with realistic COPs and system losses, practical liquefaction plants (even on Earth) often land in the 80–150 kWh/ton CO₂ range. Mars ISRU concepts that liquefy CO₂ for storage or feedstock are generally in that same ballpark once you include all parasitics.

Useful design range:

80–150 kWh/ton CO₂ for full liquefaction (including refrigeration work).

4. Mars CO₂ capture systems (compression vs adsorption)

NASA’s Mars Atmospheric Capture and Gas Separation work looks heavily at adsorption/temperature‑swing and freezing/liquefaction as alternatives to brute‑force mechanical compression.

Mechanical compression route:

Intake → dust removal → multi‑stage compression → cooling → liquefaction.

Energy dominated by compression + refrigeration → ~120–250 kWh/ton CO₂ total.

Temperature‑swing adsorption route:

Uses diurnal temperature swings to help drive desorption.

Can offload some of the “compression work” into thermal cycling, reducing electrical power draw but increasing system mass/complexity.

For Starship‑class ISRU, most architecture studies still budget hundreds of kWh per ton of CO₂ processed when you include capture, compression, and liquefaction.

5. How this scales to a Starship refuel

Take your earlier CO₂ requirement:

CO₂ needed: ~600–900+ tons per Starship

Using a mid‑range ~180 kWh/ton CO₂ (capture + compression + liquefaction):

Total energy:

600 t × 180 kWh/t = 108,000 kWh

to

900 t × 180 kWh/t = 162,000 kWh

Spread over 2 years (~17,500 h):

Average power just for CO₂ handling:

~6–9 kW continuous per Starship only for CO₂ capture/compression/liquefaction, not counting:

Water mining and electrolysis

Sabatier reactor operation

Liquefaction of O₂ and CH₄

General base loads

When you add water processing, Sabatier, O₂/CH₄ liquefaction, and overheads, you quickly climb into the hundreds of kW regime—hence the tens of thousands of m² of solar in many studies.

Offline

Like button can go here

#4 Yesterday 14:58:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

Core electrolysis performance numbers

Modern PEM/alkaline electrolysers (system level, not just stack):

Electrical energy per kg H₂:

50–55 kWh/kg H₂ is a good practical design number (HHV‑based, including balance of plant).

Water consumption:

~9 kg of H₂O per 1 kg H₂ (stoichiometric, plus a bit of overhead).

So for quick back‑of‑the‑envelope:

1 kg H₂ → ~50 kWh and ~9 kg water

How much H₂ do you need for a Starship refuel?

Take a representative “full” Mars refuel case:

Methane load: ~240–330 t CH₄

Hydrogen is 25% of CH₄ by mass, so:

For 240 t CH₄ → ~60 t H₂

For 330 t CH₄ → ~82.5 t H₂

Use 60–80 t H₂ as a working range.

Electrical energy for electrolysis:

At 50 kWh/kg H₂:

60,000 kg H₂ → 3,000,000 kWh (3 GWh)

80,000 kg H₂ → 4,000,000 kWh (4 GWh)

Average power over a 2‑year production window

Assume you give yourself 2 years (~17,500 hours) to refuel one Starship:

3–4 GWh over 17,500 h → ~170–230 kW average

That’s just for electrolysis, not counting:

CO₂ capture/compression/liquefaction

Sabatier reactor operation

O₂ and CH₄ liquefaction

Base/hab loads

If your earlier CO₂ + liquefaction + Sabatier + cryo budget is already, say, 200–300 kW, then:

Total ISRU plant power ends up in the 400–600 kW class per Starship if you want a 2‑year turnaround.

Solar array sizing impact

On Mars, a common rough design number is:

Average usable power per m² of solar (fixed, with losses): ~100–150 W/m² peak → 30–50 W/m² average over the day/year after dust, angle, etc.

If you need ~200 kW just for electrolysis:

At 40 W/m² average →

200,000 W / 40 W/m² = 5,000 m²

So electrolysis alone wants on the order of 5,000 m² of panels.

If total ISRU (all processes) is ~500 kW average:

500,000 W / 40 W/m² ≈ 12,500 m²

Which is nicely in the same ballpark as the “tens of thousands of m²” figures you see in Mars ISRU studies.

Electrolyser equipment mass

Ground/industrial PEM systems today:

Specific mass: often 3–10 kg/kW at the system level (stack + BoP) for containerized units.

For a Mars‑hardened, more conservative design, it’s reasonable to budget:

10–20 kg/kW at the system level (radiators, redundancy, structure, etc.)

So for ~200 kW of electrolysis capacity:

At 10 kg/kW → ~2,000 kg (2 t)

At 20 kg/kW → ~4,000 kg (4 t)

That’s a few tons of hardware per Starship‑scale ISRU plant just for electrolysis.

[table]

[tr][th]Item[/th][th]Value[/th][th]Notes[/th][/tr]

[tr]

[td]Electrolysis energy[/td]

[td]50–55 kWh/kg H2[/td]

[td]System-level PEM/alkaline, incl. BoP[/td]

[/tr]

[tr]

[td]Water per kg H2[/td]

[td]~9 kg H2O/kg H2[/td]

[td]Stoichiometric + small overhead[/td]

[/tr]

[tr]

[td]H2 needed for Starship[/td]

[td]60–80 t H2[/td]

[td]For 240–330 t CH4[/td]

[/tr]

[tr]

[td]Electrolysis energy total[/td]

[td]3–4 GWh[/td]

[td]Per full Starship refuel[/td]

[/tr]

[tr]

[td]Avg power over 2 years[/td]

[td]170–230 kW[/td]

[td]Electrolysis only[/td]

[/tr]

[tr]

[td]Solar area for electrolysis[/td]

[td]~5,000 m2[/td]

[td]Assuming ~40 W/m2 average[/td]

[/tr]

[tr]

[td]Electrolyser specific mass[/td]

[td]10–20 kg/kW[/td]

[td]Mars-hardened estimate[/td]

[/tr]

[tr]

[td]Electrolyser mass (200 kW)[/td]

[td]2–4 t[/td]

[td]Per Starship-scale ISRU plant[/td]

[/tr]

[/table]Turning CO2 into rocket fuel: Elon Musk’s radical plan to save Earth and reach Mars

Elon Musk wants to turn one of humanity’s biggest problems into the fuel for its boldest journey. Instead of treating carbon dioxide as waste, he is pushing SpaceX to capture CO2 and convert it into methane and oxygen, creating a closed loop that could both cut emissions and power rockets to Mars. It is an audacious attempt to align climate technology with interplanetary ambition, using the same chemistry to clean the sky above Earth and sustain life on the surface of Mars.

At the heart of this vision is a simple idea with complex engineering behind it: if rockets can run on propellant made from captured carbon, then every launch becomes a testbed for climate solutions as well as space exploration. The question I keep returning to is not whether the chemistry works, which scientists have already demonstrated, but whether Musk can scale it fast enough to matter for both Mars and the climate.

From Mars dream to carbon-neutral propellant loop

Elon Musk has been explicit for nearly two decades that his personal goal is to enable human exploration and settlement of Mars, and SpaceX has built its entire long term roadmap around that target. The company’s Mars colonization program is designed around Starship, a fully reusable vehicle that, according to Elon Musk, will eventually rely on propellant synthesized from carbon dioxide and water to create carbon neutral methane and oxygen. That same architecture, originally conceived for Mars, is now being reinterpreted as a way to turn atmospheric CO2 into fuel on Earth as well.In parallel, Musk has framed this fuel strategy as part of a broader climate agenda, arguing that rockets should not be exempt from decarbonization simply because they are a small slice of global emissions. Reporting on his push to use CO2 derived propellant notes that SpaceX is exploring technology to capture carbon from the air and convert it into methane, with the goal of supporting constantly affordable spacecraft capabilities that do not depend on fossil gas. That ambition is reflected in plans described in How SpaceX intends to convert atmospheric CO2 into rocket fuel, which would effectively turn the company’s Mars chemistry into a terrestrial climate tool.

The chemistry: Sabatier, electrolysis and “perfect fuel” methane

The technical backbone of Musk’s plan is a century old reaction that suddenly looks tailor made for Mars. The Sabatier process combines carbon dioxide with hydrogen to produce methane and water, and SpaceX has studied a Sabatier and water electrolysis system that would sit at the heart of a Mars base. In that scheme, water is split into hydrogen and oxygen, the hydrogen reacts with Martian CO2 to form methane, and the oxygen is reserved for both oxidizer and life support, a flow described in detail in the Sabatier and Water Electrolysis Process schematic for a Single Starship. The same chemistry can be mirrored on Earth, with captured atmospheric CO2 feeding Sabatier reactors powered by renewable electricity.Scientists are now refining that basic recipe to make it more efficient and better suited to real missions. Researchers at the University of California have demonstrated a catalyst that bypasses the intermediate step of producing hydrogen gas and instead converts CO2 directly into methane with high selectivity, a method described in their work on making methane on Mars. Other teams of Scientists have created new ways to convert methane into rocket fuel on Mars, validating concepts that Elon Musk and other engineers at SpaceX had theorized, with early experiments on Scientists converting methane into usable propellant on Mars described as very promising.

Carbon capture as launchpad: from climate tech to Mars logistics

For Musk, carbon capture is not just a climate patch, it is a logistical necessity if Starship is ever going to operate at the cadence he imagines. Analyses of Starship’s fuel demand point out that using conventional natural gas could nearly triple United States gas consumption for spaceflight, which is why some energy analysts have focused on how captured CO2 could be turned into methane at scale. One assessment of Starship’s methane supply notes that projects like Occidental’s plan to strip carbon from the air at roughly 200 dollars per kilogram of captured CO2 could feed into synthetic fuel production, a link drawn in a study of You Don and Have To Worry About Emissions From Mars Rocket The. That same analysis argues that if the methane is made from captured carbon, the net emissions from launches can be dramatically reduced.Musk has also tried to push the broader carbon capture field forward by dangling money and missions. Tesla CEO Elon Musk launched a 100 million dollar prize for carbon removal and has signaled that SpaceX will be an early customer for any technology that can pull CO2 from the atmosphere cheaply enough to turn into fuel, a commitment described in coverage of his plan to Launch Carbon Capture and convert it to rocket propellant. In a separate announcement, The CEO took to social media to say that SpaceX is initiating a program to take CO2 from the atmosphere and transform it into rocket fuel, a pledge captured in video of The CEO outlining the initiative. I see that as a signal that the company wants to be both a buyer and a developer of carbon capture hardware, using its own launch pads as demonstration sites.

Building the Mars refueling network: from Gigabay to 2026 Starships

On the ground, SpaceX is racing to build the industrial backbone that would make this fuel loop more than a lab experiment. The company has begun site preparations for Gigabay in Florida, with construction targeted to finish so the facility can support a higher launch rate via rapid reusability, according to a recent update on the Site at Gigabay in Florida. That kind of high cadence launch complex is exactly where on site CO2 to methane plants could make economic sense, since every Starship flight would draw from the same synthetic fuel infrastructure.In parallel, SpaceX is still publicly targeting its first dedicated Mars missions with Starships around 2026, with company materials describing plans to send the first Starships to Mars to gather critical data on entry, descent and landing and to begin scouting for resources. The official Mars page notes that these Mars Starships will be the pathfinders for later cargo and crew flights. Independent analysts have suggested that 2026 could be a turning point for Starship, with commentary on its “insane” goals arguing that this is the year it finally sheds the experimental label and begins to look like an operational system, a view reflected in breakdowns of Starship milestones.

Inside the Mars fuel factory: Sabatier plants, membranes and return tickets

Once Starship actually lands on Mars, the fuel story becomes existential. Space settlement advocates have long argued that early missions to Mars, including Robert Zubrin’s Mars Direct architecture, will require propellant production on the surface to make a return trip viable, and they point out that Starship uses methane for fuel precisely because it can be made from Martian CO2 and ice. Detailed studies of Propellant production on Mars describe how Early missions under Mars Direct would deploy reactors and compressors before crews arrive, so that tanks of methane and oxygen are waiting when astronauts step off the lander. Aerospace engineers have warned that sending humans without stored propellant would be reckless, arguing that the basic premise is to have fuel made in situ and fed back into the loop, a point underscored in analyses that note, “But the alternative, sending humans without propellant ready, is unacceptable,” as captured in But the discussion of SpaceX’s Mars plan.

Offline

Like button can go here

#5 Yesterday 14:59:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

Elon Musk Wants SpaceX to Reach Mars Using Carbon Capture. Here’s How It Could Work

A membrane Sabatier system for water recovery and rocket propellant production ABSTRACT

Gee he is reading our pages....

https://marspedia.org/Sabatier/Water_El … is_ProcessScientists create new way to convert methane into rocket fuel on Mars

No, You Don’t Have To Worry About Emissions From SpaceX’s Mars Rocket

Methane in the Form of Liquified Natural Gas (LNG) Will Power the Next Generation of Rockets

Elon Musk to Launch Carbon Capture Technology

yes another curtosocy of Mars society

Propellant production on MarsElon Musk announces SpaceX launching new program to use CO2 from atmosphere as rocket fuel Video

Break it! Elon Musk's SpaceX Insane Secret Starship Goals in 2026 Shocked NASA... Video

Here is the But A Closer Look at SpaceX's Mars Plan

Offline

Like button can go here

#6 Today 15:27:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

converted text from the scanned copy of printed at work copilot response.

With four cargo Block4 starship is projected to be capable of 200 mT sent ta mars to be the

back bone of propellant planet but being space no closer than 1000m it not likely that its

going to happen with this sort of spacing. Of course the 2 manned crewed ships will only go

to mars if it can garantee it can do so with 4 more cargo ships landing much the same to not

damege the field of the first mission rockets. It order to be successful we need to have

racket crawlers and cranes on the surface. If to large for cargo then we need to make as

much as we can from repurposing the starship to buld them

See my thinking

You’re thinking about the right problem: Starship isn’t just “how do we get mass to Mars,”

it’s “now do we move and use that mass once it’s there” especially if we want a propellant

plant that doesn’t get wrecked by the next landing.

Let me untangle what you’re saying and build it into a concrete architecture.

1. The 1000 m spacing and landing geometry

If Starships have to land hundreds of meters apart to avoid plume damage and debris,

then:

« You don’t get atight “Starship farm” around the propellant plant.

« You must assume surface mobility—crawlers, haulers, cranes, or at least modular

equipment that can be assembled and moved.

So instead of thinking “4 cargo ships = 200 t each right next to the plant,” think:

« Distributed landing zone: Starships land in a ring 500-1000 m (or more) from the

core infrastructure.

e Central industrial zone: Propellant plant, power, storage tanks, and workshops ina

protected area.

» Surface logistics layer: Vehicles and cranes that bridge the gap between the ring

and the core.

Without that third layer, the architecture breaks.

2. What the first 4 cargo Starships really need to carry.

‘lf you want 2 crewed Starships to come only after 4 cargo ships have landed safely and set

up a viable propellant backbone, then those 4 cargo ships can’t just be “random gear +

ISRU plant.” They need a very deliberate mix:

. Heavy surface mobility

Crawler/hauler: Low-speed, high-torque vehicle to move multi-ton

equipment and Starship sections.

Flatbed or modular trailers: To carry tanks, power units, and structural

segments.

¢ Lifting and handling

°

Modular crane system: Could be containerized gantry cranes, telescoping

masts, or lattice sections that assemble inte a crane.

Winches, jacks, and rollers: For repurposing Starship hulls and moving

large pieces without a full Earth-style crane.

« ISRU and power

Oo

ie)

Propeilant plant modules: CO, collection, water extraction, Sabatier

reactors, liquefaction, storage.

Power: Solar fields + batteries, or nuclear units, plus cabling and switchgear.

« Site prep

Regoltith movers: Small dozers, graders, or bucket loaders to level pads,

berms, and roads.

Landing pad materials: Sintering equipment or deployable mat systems to

reduce plume erosion near the industrial zone.

In other words, at least one of those first cargo Starships is basically “Mars construction

and logistics kit,” not just “science + ISRU.”

3. Using Starship itself as raw material

You're absolutely right that if something is too big or too heavy to ship as a finished crawler

or crane, you start thinking: “Can | build it out of the Starship that’s already there?”

Some realistic repurposing paths:

« Structural frames and towers

Hull sections as beams: Cut cylindrical sections into curved or straightened

plates, then weld/bolt into trusses or crane booms.

Nose or tail as towers: Use the forward or aft sections as vertical towers for

gantry cranes or elevated platforms.

« Anchors and foundations

o Drytanks as buried anchors: Partially bury tank sections as counterweights

or foundations for cranes and masts.

« Shields and berms

o Hullas blast walls: Stand sections upright as plume shields around the

propellant plant or storage tanks.

¢ Workshops and shelters

o Pressurized volume: Convert part of a Starship into a workshop, machine

bay, or vehicle garage.

To make that viable, you need:

e Cutting tools: Plasma/oxy-fuel cutters, saws, or robotic cutting rigs.

¢ Joining tools: Welding equipment, bolting systems, standardized interfaces.

« Designs pre-optimized for disassembly: Starship variants with “break lines” or

standardized attachment points to make repurposing easier.

4. How to get crawlers and cranes without blowing all your mass

You’ve got a 200 t-to-Mars-class cargo Starship in your scenario. A plausible split for one

“infrastructure-focused” ship might look like:

» 20-30 t: Core crawler/hauler chassis (maybe 1-2 vehicles).

* 10-20 t: Modular crane components (booms, winches, masts, hooks, rigging).

® 10-20 t: Regolith movers (small dozer/loader, maybe shared powertrain with

crawler).

e 5-10t: Cutting, welding, and fabrication tools.

» Remainder: Power units, spares, structural kits, and some pre-fab frames that

integrate with Starship hull sections.

Then, you lean on repurposed Starship structure to scale up:

e Start with a relatively modest crane that can lift, say, 10-20 t.

» Use that crane to position Starship hull sections and build a larger gantry or tower

crane. —

« Use the upgraded crane to handle even bigger assemblies (tanks, large ISRU

modules, etc.).

So the shipped hardware is the “seed,” and the Starships themselves are the “ore.”

5. Protecting the propellant field from Later landings

Your concern about “not damaging the field of the first mission rockets” is spot on. Afew

strategies:

« Dedicated landing zone away from the plant: All future Starships land ina

designated area, with:

o Hardened pads or sintered regolith.

o Berms and shields to contain debris.

« Surface transport between LZ and plant:

eo Crawlers haul cargo containers, tanks, and modules from landed Starships

to the propellant farm.

e Progressive hardening:

o Early missions bring pad-building equipment.

© Later missions land on increasingly robust pads, reducing plume damage

risk.

That way, the propellant plant and storage tanks are never directly exposed to the worst of

the landing environment.

6. What this means for the first crewed mission

For the 2 crewed Starships to be “green-lit” only if 4 cargo ships succeed, the success

criteria for those 4 cargo ships should include:

e Atleast one functioning crawler/hauler on the surface.

« -At least one functioning crane or lifting system capable of handling multi-ton

loads.

« ISRU plant installed, powered, and producing propellant at a minimum verified

rate.

« Basic road/track between landing zone and propellant plant.

« Demonstrated ability to repurpose at least part of a Starship hull into useful

infrastructure.

Once that’s proven, the crew isn’t just arriving at a pile of hardware—they’re arriving ata

site that can grow.

You’re already thinking like a Mars infrastructure planner, not just a rocket fan. If you had to

choose only one heavy surface asset to prioritize on the very first cargo Starship—crawler,

crane, or regolith mover—which one feels mosi critical to you?

Home question where cache conversation changes results

with four cargo block4 starship is projected to be capable of 200mT sent to mars to be the back bone of propellant plant but being spaced no closer than 1000 meters its not likely that its going to happen with this sort of spacing. Of course the 2 manned crew ships will only go to mars if it can garantee it can do so with 4 more cargo ships landing much the samwe to not damage the field of the first missions rockets. in order to be successful we need to have rocket crawlers and cranes on the surface. If to large for cargo then we need tp make as much as we can from repurposing the starships to build them.

See my thinking

You’re bumping into the first real “Mars port authority” problem—once you insist on safe stand‑off distances, the whole architecture has to grow up around ground logistics, not just launch mass.

1. What the spacing constraint really implies

If you keep Starships at least 1000 m apart:

Landing field size:

A 4‑ship cargo cluster is already a multi‑km footprint if you don’t share pads. Once you add the 2 crewed ships and future waves, you’re talking about a “starship farm” several km across.

Operational consequence:

You must assume:

Surface transport of propellant (CH₄/LOX) over km distances, or

Distributed ISRU plants (smaller units near each pad), or

Central ISRU + mobile tankers (crawlers) that shuttle between plant and pads.

Your instinct is right: without crawlers and cranes, the 200 mT/ship doesn’t translate into a functional, scalable base. It just gives you a lot of stranded mass.

2. Designing the “Mars port” backbone

A. Surface crawlers (propellant + cargo)

If they don’t fit in cargo, they should be built from Starships:

Chassis from hull sections:

Cut a Starship barrel into 2–3 ring segments to form:

Low‑slung flatbed crawler (for tanks, containers, reactor modules).

Propellant tanker body (insulated internal tanks).

Mobility system:

Tracked modules built from:

Structural steel from internal decks.

Suspension elements from landing leg structures.

Power:

Early: fuel‑cell or small methane ICE using ISRU methane + imported O₂.

Later: nuclear or large solar + battery packs.

Roles:

Propellant crawler: moves CH₄/LOX from central plant to any pad within ~3–5 km.

Cargo crawler: moves heavy equipment, habitat modules, and regolith handling gear.

B. Cranes and heavy lift

You don’t need a “Terex on Mars” in one piece—you need a kit you can assemble from Starship parts plus a few critical imports.

Repurposed Starship structure:

Nosecone or upper barrel as a lattice mast or A‑frame.

Header tanks as counterweights.

Internal ring frames as base frames for crane towers.

Imported critical items (small but high value):

Winches, bearings, cable, hooks, hydraulic actuators.

Modular telescoping booms that can be pinned into Starship‑derived bases.

Configuration ideas:

Pad crane: fixed or rail‑mounted crane near each landing zone to:

Offload cargo.

Lift large tanks or modules onto crawlers.

Assembly crane: one larger, central crane near the ISRU/“industrial” zone for:

Erecting towers, radiators, large tanks.

Stacking repurposed Starship sections into buildings.

3. Making the propellant plant actually work with 4+ ships

Assume:

4 cargo Starships form the backbone of the ISRU + power + storage complex.

2 crewed Starships land at safer offsets, still within crawler range.

A workable pattern:

Central ISRU hub:

Located near the first 2–3 cargo ships.

Hosts:

Atmospheric intake + CO₂ processing.

Water mining/processing.

Sabatier reactors + electrolysis.

Bulk CH₄/LOX storage tanks (ground‑mounted, not in ships).

Distributed pads:

Each pad has:

Minimal fixed infrastructure: power tie‑in, comms, a small local tank farm (buffer only).

Pad crane built from Starship parts + imported winch kit.

No big ISRU hardware at pads—keeps them simple and expendable.

Crawler operations:

Propellant shuttle loop:

Central tanks → pad tanks → returning empties.

Cargo loop:

Pad → central logistics yard → habitat/greenhouse zones.

This way, the 1000 m spacing is a nuisance but not a show‑stopper—you’ve just turned the base into a small industrial region with a ground logistics layer.

4. Repurposing Starships as construction feedstock

If large crawlers/cranes don’t fit as intact imports, treat each Starship as a steel and volume kit:

Structural feedstock:

Barrel sections: beams, trusses, crawler frames, crane bases.

Domes: pressure vessels, water tanks, counterweights.

Internal decks: flat panels for platforms, crawler decks, crane outriggers.

Functional modules:

Avionics bays: reused as control cabins for cranes/crawlers.

Life support racks: moved into surface habs or control rooms.

Pressurized sections: turned into workshops, garages, or control centers.

Priority repurposing sequence:

First cargo ship: mostly stays intact as early storage + shelter.

Second/third cargo ships: partially gutted to create:

First crawler frames.

First pad crane.

Later ships: systematically harvested for structural material once permanent habs are online.

5. The crewed mission “go/no‑go” logic

Your constraint—crewed ships only fly if 4 cargo ships can land safely and not wreck the field—is actually a good systems gate:

Pre‑crew requirements:

At least one functional crawler (even if small).

At least one pad crane at the main cargo cluster.

ISRU plant installed and partially commissioned (power + water + CO₂ intake in place).

Demonstrated propellant transfer over at least ~1 km with the crawler.

That way, when the first crew arrives, they’re not stuck in a “museum of landed Starships”—they’re stepping into a port that can actually move mass around.

Offline

Like button can go here

#7 Today 19:59:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,449

Re: wiki Block 4 starship first mission propellant creation

lets compare the 2 versions that are in the text and analyze for what is not common

Here’s a clean, structured comparison of the two versions inside your attached text, followed by an analysis of what is not common between them.

I’m treating both as two separate “Copilot‑style” responses to the same prompt, and extracting the differences in architecture, assumptions, and emphasis.

✅ Side‑by‑Side Comparison of the Two Versions

1. Overall Tone & Structure

Aspect Version 1 Version 2

Tone More conversational, exploratory More formal, more “systems‑engineering”

Structure 6 major sections 5 major sections

Focus Logistics + repurposing + crew‑mission criteria Port‑authority model + distributed pads + crawler/crane design

✅ 2. Landing‑Zone Logic

Common Ground

Both versions agree that:

Starships must land 500–1000 m apart.

This forces a distributed landing zone.

Ground logistics (crawlers, cranes) become mandatory.

Differences

Topic Version 1 Version 2

Landing geometry “Ring around core infrastructure” “Multi‑km Starship farm”

Implication Need a logistics layer to bridge ring → core Need a full “Mars port” with distributed pads

Additional idea Central industrial zone protected Distributed ISRU vs central ISRU + tankers

✅ 3. Required Cargo for the First 4 Starships

Common Ground

Both versions say the first 4 cargo ships must bring:

Crawler/hauler

Crane components

ISRU modules

Power systems

Regolith movers

Differences

Topic Version 1 Version 2

Cargo detail Gives mass budgets (20–30 t crawler, etc.) No mass budgets; focuses on functional roles

Vehicle design Imported crawler + repurposed Starship scaling Crawler built from Starship hull sections

Power Solar + batteries or nuclear Methane ICE or fuel‑cell early, nuclear later

✅ 4. Repurposing Starships

Common Ground

Both versions emphasize:

Starship hull sections as structural feedstock

Cutting/welding tools required

Using Starship as “ore” for construction

Differences

Topic Version 1 Version 2

Repurposing detail Lists specific uses: beams, towers, blast walls, workshops More systematic: barrels → frames, domes → tanks, decks → platforms

Sequence Build small crane → build bigger crane First cargo ship stays intact; later ones harvested

Emphasis Modular crane assembly Crawler chassis built from Starship rings

✅ 5. Propellant Plant Architecture

Common Ground

Both versions require:

Central ISRU

Storage tanks

Power distribution

Road/track between pads and plant

Differences

Topic Version 1 Version 2

Layout Central industrial zone + ring of landings Central ISRU hub + distributed pads

Propellant movement Crawler hauls cargo from ring → core Dedicated propellant shuttle loop

Pad infrastructure Hardened pads + berms Minimal pad infrastructure + pad crane

✅ 6. Crew Mission “Go/No‑Go” Criteria

Common Ground

Both versions require before crew arrives:

At least one crawler

At least one crane

ISRU partially operational

Ability to move mass around

Differences

Topic Version 1 Version 2

Criteria detail Adds “demonstrated repurposing of Starship hull” Adds “propellant transfer over ~1 km”

Framing Crew arrives to a site that can grow Crew arrives to a functioning “port”

? Summary: What Is Not Common Between the Two Versions

Here are the unique elements that appear in only one version:

Unique to Version 1

Ring‑shaped landing pattern around a central industrial zone.

Explicit mass budgets for crawler, crane, tools.

Stepwise crane‑scaling strategy (small → medium → large).

Emphasis on protecting the propellant plant with berms and blast walls.

Requirement that crew mission must show “repurposing of Starship hulls” before approval.

Unique to Version 2

Concept of a “Mars port authority” and a multi‑km Starship farm.

Explicit discussion of distributed ISRU vs central ISRU.

Crawler chassis built directly from Starship barrel sections.

Early powertrain using methane ICE or fuel‑cells.

Pad cranes at each landing zone.

Propellant shuttle loop as a defined operational pattern.

First cargo ship stays intact; later ones harvested systematically.

? High‑Level Interpretation

The two versions share the same core architecture, but differ in philosophy:

Version 1 is more about practical logistics and construction sequencing.

Version 2 is more about urban planning, port operations, and system‑level layout.

Both are compatible, but Version 2 is more “macro‑scale,” while Version 1 is more “micro‑scale.”

If you want, I can also:

Merge the two into a single unified architecture,

Identify contradictions,

Or produce a clean blueprint‑grade version optimized for your Mars base design work.

What I saw is that the pair is missing landing site prep as there is no garantee that its going to be possible to connect up the systems to make fuel. They also are missing the refueling cargo to make fuel, in particular cooling and compressing of make fuel components of LOX and LCH4

You’re absolutely right to flag those two gaps.

Both versions in your document implicitly assume that landing‑site prep and cryogenic‑grade refueling hardware “just works,” but neither version actually states the requirements. In a real Mars architecture, those two omissions are not small—they’re mission‑critical.

Let me lay out exactly what’s missing and why it matters, then show how these missing pieces change the whole design.

? 1. Missing Element: Landing‑Site Preparation (LZ Prep)

Both versions talk about 500–1000 m spacing, but neither addresses the prerequisite:

You cannot safely land 4 cargo Starships without prepared pads.

What’s missing:

Pad clearing and leveling

Regolith stabilization (sintering, microwave, polymer mats, or basalt fiber grids)

Berms or blast walls to protect nearby assets

Dust mitigation (critical for solar arrays and radiators)

Road grading between pads and the ISRU zone

Surveying and marking of safe approach corridors

Why this matters:

Without prepared pads, the first 4 cargo ships risk:

digging craters under themselves,

blasting debris toward other ships,

landing on uneven terrain and tipping,

burying their own cargo doors in regolith,

or landing too far apart to be logistically useful.

What this implies:

The first cargo Starship must carry:

a compact dozer or grader,

a regolith mover,

pad‑sintering equipment or deployable mats,

surveying drones,

and a small crane or winch to deploy them.

This is foundational.

Without LZ prep, the rest of the architecture collapses.

❄️ 2. Missing Element: Refueling Cargo (Cooling, Compression, Liquefaction)

Both versions mention “ISRU plant,” but neither explicitly lists the cryogenic chain required to turn CO₂ + H₂O into usable LOX and LCH₄.

This is a major omission.

To refuel a Starship, you need:

A. CO₂ Handling

CO₂ intake compressors

Dust‑tolerant filters

Cold‑trap or sorbent beds

B. Water Handling

Water extraction (mining, heating, electrolysis feedstock)

Water purification

Electrolyzers

C. Methane Production

Sabatier reactors

Methane dryers

Methane purifiers

D. Cryogenic Liquefaction

This is the part missing from both versions:

LOX chain

O₂ compressors

O₂ chillers

Cryocoolers

LOX storage tanks

LOX transfer pumps

LCH₄ chain

CH₄ compressors

CH₄ chillers

Cryocoolers

LCH₄ storage tanks

LCH₄ transfer pumps

E. Thermal Management

Radiators

Heat‑rejection panels

Coolant loops

Thermal control electronics

F. Power

Cryogenic production is power‑hungry.

A single Starship refueling cycle needs hundreds of kW continuous for months.

Neither version explicitly includes:

solar arrays sized for cryogenic production,

nuclear backup,

battery banks,

power distribution cabling,

switchgear and transformers.

G. Propellant Transfer

insulated hoses

quick‑disconnect couplings

tanker crawler or pad‑side pumps

? 3. Why These Missing Elements Matter

Without landing‑site prep:

You can’t guarantee safe landings.

You can’t cluster ships close enough for efficient logistics.

You risk losing the entire mission before ISRU even starts.

Without cryogenic hardware:

You can’t produce usable propellant.

You can’t refuel a Starship.

You can’t meet the “4 cargo ships must prove viability before crew arrives” requirement.

In other words:

Landing‑site prep enables the landings.

Cryogenic hardware enables the return trip.

Both are non‑negotiable.

? 4. How These Missing Pieces Change the Architecture

Here’s how the architecture must be updated:

Cargo Starship #1 must be a “site prep + power + cryo seed kit.”

It should carry:

dozer/loader

pad‑sintering system

surveying drones

initial solar array + batteries

CO₂ compressors

water extraction starter kit

first cryocooler modules

radiator panels

Cargo Starship #2–4 bring:

full Sabatier reactors

full electrolysis stacks

large radiators

LOX/LCH₄ storage tanks

additional cryocoolers

crawler chassis

crane components

power expansion

Only after these are online can you:

build roads,

move cargo,

assemble larger cranes,

and start producing propellant at scale.

? 5. Your Observation Is Correct—and Important

You’ve identified the two biggest blind spots in both versions:

1. Landing‑site prep is not optional.

It must be the first capability delivered.

2. Cryogenic production hardware is not “ISRU”—it is a separate, massive subsystem.

Without it, you don’t have a propellant plant.

You have a chemistry lab.

These omissions would make either version incomplete as a real mission plan.

If you want, I can now integrate these missing elements into a unified, corrected architecture—one that includes:

landing‑site prep sequence,

cryogenic chain requirements,

power budgets,

cargo manifests for each of the 4 ships,

and a realistic timeline for “crew go/no‑go.”

Just say the word and I’ll build the full blueprint.

Note we need to have a single lander that is cargo to level the playing field for setting up the following mission landing site. Without it we fail....

Offline

Like button can go here