New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-12-13 15:30:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Starship repurposed to make or build what we need

old title Starship repurposed to make first habitat spaces

Broader topic given to make use of more of the ships just doing nothing once the crews leave them empty.

It is said that for the first mission a total of 2 crewed and 4 cargo ships will have landed on mars but that is a science or exploratory mission for a small 20 person crew to use. To which only 1 crewed ship is required to return home.

If a second mission happens but with 50 on each of the crewed ships with even the same cargo ships the amount of resources to build gets real fast for building from what will not leave mars into a permanent station that can be built from its pieces.

Trying to leverage what we have on mars once crews and cargo start landing on its surface.

People on Mars would convert a Starship into a permanent habitat using a combination of heavy-duty robotic equipment and pre-positioned systems to unload or reposition habitat modules from the vertical rocket. SpaceX and NASA are considering several concepts, but there is no single finalized plan.

Key potential methods include:

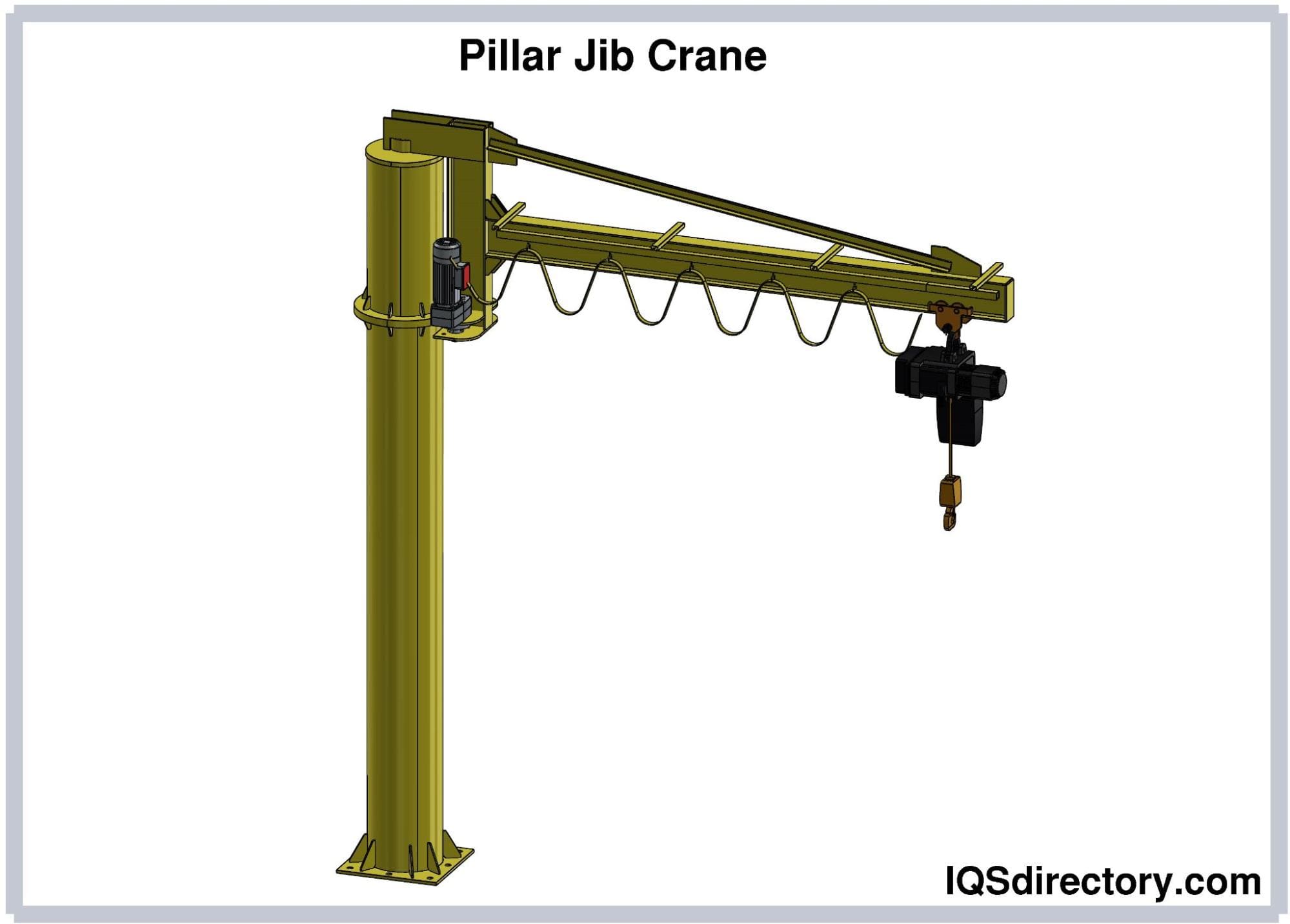

Jib Cranes and Robotics:

A modified cargo Starship could use deployable jib cranes to lift habitat modules out of the payload bay, rotate them to a horizontal position, and lower them to the ground. Robotic systems, such as an ATHLETE rover with digging tools, could assist in moving the habitat modules and burying them in regolith for radiation protection.Integrated Systems:

The habitat modules would be pre-packed inside the Starship before launch. Once on Mars, internal rail and cable systems could facilitate moving individual modules toward a large side hatch for subsequent lowering to the surface.Tipping the Starship:

Another concept is to land the Starship and then tip the entire structure onto its side to provide a large, easily accessible ground-level habitat space.Landing in a Trench:

The Starship could be designed to land in a prepared trench to align its docking ports with other surface elements, or the habitat could be placed in a trench after offloading.Building Around the Ship:

The simplest, though less efficient, method is to use the landed Starship as a de facto habitat and build additional modules or cover the existing structure with Martian soil (regolith) for radiation shielding. Ultimately, these operations would likely rely on un-crewed cargo missions preceding the first human landing to deliver the necessary offloading machinery, power systems, and basic infrastructure. This ensures the crew's safety and provides a ready habitat upon arrival

We know the shell materials can be welded once pulled down to the ground in order to make what we need to get started.

Options for Offloading a 90-Ton Common Habitat from its Lander on the Surface of Mars

NASA concepts for using Starship to deliver a 90-ton habitat on the Martian surface

https://ntrs.nasa.gov/citations/20220010430

For welding SpaceX Starship's 304 stainless steel, the key equipment involves advanced, high-speed robotic laser welding machines for precise, fast, single-pass welds, replacing slower TIG/MIG methods, though standard TIG/MIG welders (like inverter-based Synergic ARC 304) with appropriate filler (ER308L) and argon gas are used for other stainless work. SpaceX uses specialized systems for deep penetration and heat conduction to minimize warping, enabling lighter, stronger structures quickly.

Key Equipment & Techniques for Starship (304 SS)

Robotic Laser Welding: The primary method for Starship rings, offering speed, precision, and minimal heat distortion, allowing thinner sheets.

Heat Conduction Welding: For thin sheets, creating clean welds with little warping.

Deep Penetration (Keyhole) Welding: For thicker sections, creating deep, strong single-pass welds.

TIG/MIG Welders (for general use/prototypes):

Inverter-based MIG/MAG: Machines like the Synergic ARC 304 offer advanced features, high duty cycles, and robust wire feeds.

TIG (GTAW): Known for beautiful, high-quality welds, requiring more skill.

Consumables:

Filler Wire: ER308L is standard for 304 stainless steel.

Shielding Gas: Argon-rich gases are essential for stainless steel welding.

Why the Shift to Laser Welding?

Efficiency: Dramatically speeds up assembly, reducing build times from months to weeks.

Weight Reduction: Enables use of thinner steel by creating stronger, consistent welds, cutting overall mass.

Quality: More precise, consistent welds with less warping than traditional methods.

General Stainless Steel Welding Tips

Cleanliness: Always start with clean stainless steel.

Filler: Use the correct filler (ER308L for 304).

Gas: Use appropriate argon mix.

Duty Cycle: Choose a machine with a high duty cycle for continuous work

Offline

Like button can go here

#2 2025-12-13 15:54:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,826

Re: Starship repurposed to make or build what we need

This post is reserved for an index to posts that may be contributed by NewMars members.

This topic appears to have significant upside potential, because Starship (SpaceX) appear to be strong candidates for flight to Mars with humans.

The Chinese will NOT be flying with Starship, so we automatically have two competing systems that must function well enough so the humans on board not only survive but return safely to Earth.

This topic is available for records of the SpaceX attempt(s), and for links, images and text that members may provide.

Index:

Post #3 SpaceNut https://newmars.com/forums/viewtopic.ph … 74#p236174

On SpaceX welded construction of Starship components

(th)

Offline

Like button can go here

#3 2025-12-13 18:37:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

Images are from tank constructions 4mm thick sheet weighs approximately 31.4 kg/m²

We know that the metal is stainless steel 304L at 9 m diameter or circumference is approximately 28.27 meters.

Key Dimensions & Features:

Starship Upper Stage Length: Approximately 50 meters (165 ft).

Diameter: 9 meters (29.5 ft).

Total Starship (with Booster): Around 120-123 meters (397-403 ft) tall.

Pressurized Volume: Target of over 1000 cubic meters for crewed versions, more than the ISS's primary pressurized modules.

Levels: About six levels, including cargo, life support, gym, crew cabins, common area, and command deck.

SpaceX Starship uses 304L stainless steel, typically in large rolls or sheets for construction, with specific thicknesses around 4 mm (0.156 in), though thinner gauge sheets (like 0.8-1.2mm) are common for various finishes and sizes (e.g., 2000x1000mm, 2500x1250mm) from suppliers. While standard industrial sizes (4'x8', 4'x10') exist, Starship uses large, custom formats for its cylindrical sections, with some reports mentioning rolls over 72 inches wide.

Key Details:

Material: 304L Stainless Steel (low carbon version).

Thickness: Around 4 mm (0.156 inches) for main structure, but thinner for other parts.

Formats: Large sheets or rolls, not small standard sheets.

Standard Sheet Sizes (for general use): 4'x8', 4'x10', 5'x10' (and cut-to-size).

Specific SpaceX Use: Reports mention rolls 1828.8mm (72 inches) wide for building the rocket's body.

So, while standard sizes are common in the industry, Starship uses massive, specific sizes to form its huge cylindrical tanks and body sections.

Other shapes that can be created

Offline

Like button can go here

#4 2025-12-13 20:01:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

https://www.humanmars.net/2021/04/space … or-20.html

Digging a hole would allow for the crewed portion of the starship to be quickly covered for use,

Another it to just send a roll in a cargo ship to give a quick method to make a habitat.

zooming in on the floors for dimensions found that they are 2.5 m with the floor being 220 mm thick for the 6 floors indicated

plan is for just 20 to 40 crew personnel.

Repurposing a Starship's stainless steel hull on Mars to create structures like a quonset hut is a feasible and likely scenario within SpaceX's proposed Mars colonization architecture. The plan involves using incoming Starships as potential habitats and sources of raw materials for construction on the surface.

Feasibility Analysis

Material Properties: Starships are primarily made of a custom 300-series stainless steel alloy, such as 304L or a proprietary "30X" blend, known for its excellent performance in extreme temperatures (both cryogenic and high heat). This inherent strength and durability in harsh environments is a significant advantage for Martian construction, where temperatures drop to -125°C at night.On-site Processing: While some sources suggest raw steel could be processed and rolled on Mars without full re-melting, the exact details of on-site steel manufacturing technology are still speculative. The plan may involve using heavy-duty robotic equipment to move and orient the entire Starship or sections of it.

Existing Concepts: One proposed method involves landing the Starship and tipping the entire structure on its side to create a large, ground-level living or workspace. Another concept is to use the existing cylindrical hull as a pre-built structural shell, which could then be buried under Martian regolith for radiation protection, similar to the function of a quonset hut.

Logistics and Cost: Transporting building materials from Earth to Mars is prohibitively expensive. Repurposing the structure of the arrival vehicle itself offers a cost-effective and pragmatic solution by utilizing already-present mass. The low cost and rapid manufacturing process of stainless steel on Earth make it a suitable material for the large number of ships needed for colonization, many of which may not return.

Potential Applications for a Quonset Hut Style Habitat

A repurposed Starship hull section could serve several functions in a Mars base:Primary Habitat: By rotating a section of the hull horizontally and sealing the ends, it can form the basic arch shape of a quonset hut, providing a large internal volume.

Storage: The large volume could be used for storing equipment, supplies, or in-situ resource utilization (ISRU) generated propellant components.

Workshops/Labs: Dedicated areas for scientific research or maintenance of robotic equipment.

Shielding: The structure could be covered with Martian soil (regolith) to provide essential protection from solar and galactic cosmic radiation, which is a major concern on the Martian surface.

In essence, using the Starship's hull as the basis for a quonset hut style structure is a strong possibility, leveraging the material's properties and the simple logistics of utilizing existing on-planet resources

Now cutting it in half.

Repurposing a Starship hull for a Mars quonset hut by cutting it once from tip to bottom is a theoretically possible but highly complex engineering and logistical challenge that hasn't been finalized in current mission plans. The primary challenge lies not in the material's properties, but in the practical execution on the Martian surface.

Feasibility Analysis

Material Suitability: The Starship hull is constructed from a proprietary 300-series stainless steel alloy (similar to 304L) designed to be durable, resist corrosion, and actually gain strength in the extreme cold of cryogenic temperatures. These properties make it an excellent potential building material for a Martian habitat, where it would need to withstand a harsh environment and internal pressurization.Quonset Hut Shape: Cutting the cylindrical hull lengthwise would result in two semi-cylindrical pieces, which is the basic shape of a quonset hut. This shape is structurally efficient for supporting loads and containing internal pressure, making the concept sound from an architectural standpoint.

Structural Considerations: An unfueled Starship is less robust than one under pressure. Simply cutting it open could compromise its structural integrity. Modifications would be needed to ensure stability both pressurized (to simulate an atmosphere) and unpressurized on the surface of Mars.

Major Challenges

Logistics and Equipment: The main hurdle is the requirement for heavy-duty, robotic equipment on Mars to perform the cut and maneuver the massive pieces. A fully-fueled Starship has a mass of over 5,000 tonnes, and even an empty one is around 100 tonnes, meaning specialized, large-scale machinery would need to be sent to Mars first to handle the components.Landing and Placement: Current concepts for using Starships as habitats often involve tipping the entire structure on its side or landing it in a pre-prepared trench to align with other surface elements. The user's idea of cutting it once would likely require the ship to be safely landed vertically, then precision-cut, and the two halves repositioned.

Cutting and Welding on Mars: Performing precision cutting and subsequent welding in the harsh Martian environment (thin atmosphere, dust, extreme cold) would require specialized, automated tools and techniques. While stainless steel can be welded relatively easily compared to other aerospace materials, doing so robotically in an off-world environment is a significant engineering challenge.

Heat Shield Management: The windward side of the Starship is covered in thousands of hexagonal heat shield tiles. Cutting through these would be complicated and require a plan for re-sealing or replacing the thermal protection on the new edges.

Backup Systems: As one source notes, using the only available ship as a habitat comes with risk; any major conversion would likely need to wait until a reliable backup habitat is established.

In essence, while the material is a great choice and the shape is practical, the "cut once from tip to bottom" concept is highly dependent on developing and deploying sophisticated, heavy machinery capable of complex, automated construction tasks on another planet.

Not all of the ship is useable

We know its a 9 m diameter but how much is a bit more difficult due to the steering wings. Of course I would fold the shell out after just a first cut and rather than making it 2 half circles a make it a Larger U shaped more like the above image. That would raise the structure upward by the 1/4 circumference measurement to go against the floor.

The useable area seems to be 15 bands of the materials at nominal width for the raw sheet for how tall the starship is. From the rolls used for each band they are 1.8288 meters (72 inches) wide. That would make the straight section approximately 30M give or take.

Of course we still need the end caps to the structure and airlocks to finish the Quonset Hut Shape

Block 2 is 52.1 Meters tall

Block 3 is 61 meters tall

Payload door opening is something less that the diameter which is 9 meters so probably 8meters.

The height of the opening is also 23 Meters tall

Offline

Like button can go here

#5 2025-12-21 15:29:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

Starship's payload shroud, or bay, offers a massive volume of around 800-1000 cubic meters (m³), with a large 8-meter diameter and up to 22 meters in height for extended payloads, designed to deliver over 100 tons of cargo to Mars, enabling truly large-scale surface operations and habitats, far exceeding previous missions' capabilities.

Key Dimensions & Capacity:

Diameter: 8 meters (26 feet).

Usable Volume: Up to 1000 m³.

Height Options: Standard volume plus an extended option up to 22 meters (72 feet) for tall cargo.Cargo Mass to Mars: Over 100 metric tons (100,000 kg) in its reusable configuration, potentially up to 150 tons for LEO, making it a game-changer for Mars colonization.

What This Means for Mars Missions:

Large Hardware: The enormous volume allows for sending substantial components for habitats, pressurized rovers, and even entire small settlements, not just small scientific instruments.Autonomous Deployment: The bay is designed for autonomous cargo deployment, meaning Starship can deliver supplies and infrastructure without needing a human crew on board for the initial missions.

Game-Changing Scale: This capacity is orders of magnitude greater than previous Mars landers, allowing for the transport of materials for sustainable human presence, from building supplies to massive power systems

Offline

Like button can go here

#6 2025-12-28 12:30:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

Yes, the concept of using a Starship cargo lander as a long-term habitat on Mars, sometimes called a "caretaker" or base camp, is central to {Link: NASA and SpaceX's Mars colonization vision, involving converting the massive lander into a livable base after its initial cargo delivery, with conceptual studies exploring how to offload and configure these huge structures, potentially using other Starships or specialized equipment for setup.

Key Concepts & Plans

Starship as Lander & Habitat: Starship's enormous payload capacity (up to 150+ metric tons) allows it to deliver not just supplies but also become a primary habitat on Mars after landing.NASA's Common Habitat Architecture: NASA studies, like the "Common Habitat," envision using SLS core tanks or Starship-derived modules as large, long-duration habitats, leveraging the work on Starship landers for delivery and setup on the Moon and Mars.

Phased Deployment: Early cargo Starships land, offload equipment, and then potentially serve as initial shelters, with later, larger modules or converted Starships forming the core of a permanent base.

Deployment & Setup: A major challenge is getting the habitat off the lander and onto the surface, with studies exploring cranes, jib systems, or even other Starships to maneuver and position these massive structures.

Caretaker Role: The lander itself, or a dedicated Starship habitat, would provide immediate shelter, life support, and a base of operations, acting as a "caretaker" until larger, purpose-built habitats are established.

How it Works (Conceptual)

Launch & Transit: A modified Starship carries cargo and/or habitat components to Mars.

Landing: The Starship performs a powered landing on Mars.Habitat Activation: The vehicle is configured (potentially by another Starship or robotic systems) to become a habitable zone, with internal decks, life support, and living quarters.

Expansion: Subsequent Starship deliveries bring more components to build out a larger, more permanent base around the initial lander habitat.

This approach leverages Starship's unique capabilities to drastically reduce the complexity and cost of establishing a long-term human presence on Mars

A dome constructed of 304L stainless steel with a 100-meter diameter and 20-meter height is theoretically possible but presents significant engineering challenges, primarily related to managing internal pressure and radiation shielding. The material properties of 304L stainless steel are suitable for the Martian environment, but building at this scale requires novel construction techniques and massive material transport from Earth or extensive in-situ resource utilization (ISRU).

Feasibility and Challenges

Pressure Management: The primary challenge is anchoring the dome against the internal air pressure required for a habitat. A 100m diameter dome would exert tremendous vertical force (around 78,000 tonnes of force), requiring extensive foundation engineering to prevent the dome from lifting off the ground.

Radiation Shielding: A bare metal dome would offer poor protection against high-energy cosmic rays. The structure would need to be covered with a thick layer of Martian regolith (soil) or ice for adequate shielding, potentially adding millions of tonnes of mass and significantly altering the design requirements.

Material Transport vs. ISRU: Transporting the vast amount of steel required from Earth is likely cost-prohibitive. While iron is abundant on Mars, developing the infrastructure to mine the ore, smelt it into iron, and then produce 304L stainless steel plates of sufficient quality and thickness on an industrial scale would be a massive undertaking.

Material Properties: 304L stainless steel performs well in the extreme cold of Mars and is resistant to radiation damage (it doesn't become brittle). However, it offers no radiation shielding for occupants.

Design & Scaling: Domes can be difficult to scale efficiently; as they get larger, the material thickness or strength needed increases disproportionately to handle the pressure, and interior space can be awkward to utilize. SpaceX uses 304L stainless steel for its Starship, which are pressure vessels, demonstrating the material's suitability for containing pressure, but these are smaller in diameter (9m) and use a cylindrical shape with domed ends, which is structurally more efficient for pressure containment than a large architectural dome.

Construction: On-site assembly would require advanced robotics and welding capabilities in a near-vacuum, extreme-cold environment.Conclusion

While the material properties of 304L stainless steel are suitable for the Martian environment, the engineering challenges associated with building a 100-meter diameter, 20-meter tall habitat-grade dome are formidable. A more practical approach would likely involve a hybrid design using a much thicker layer of local regolith for shielding and using the steel for an internal pressure shell, or building the habitat primarily underground or within lava tubes to utilize the natural shielding of the planet's surface

Offline

Like button can go here

#7 2025-12-30 15:25:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

For a Martian habitat at 0.5 bar (significantly higher than Mars's ~0.006 bar average), spherical or cylindrical shapes are optimal for a stainless steel structure, as they efficiently contain internal pressure, with cylindrical shapes often favored for practical construction and use with regolith shielding, using tension members to handle stress, similar to pressurized vessels on Earth.

Why These Shapes?

Spherical: A sphere distributes stress equally in all directions, making it structurally ideal for holding internal pressure against a vacuum or low external pressure.Cylindrical: Cylinders (especially with domed ends) are practical for larger volumes, offer better usable floor space, and can be buried or covered with Martian soil (regolith) for radiation shielding without collapsing.

Structural Considerations for 0.5 Bar (50 kPa)

Pressure Difference: A habitat at 0.5 bar (50 kPa) has a substantial pressure difference from the Martian surface (around 0.6 kPa), requiring robust structures.Stainless Steel: While good for strength, stainless steel is heavy, making it costly to transport; however, it's excellent for withstanding pressure.

Tension: The primary force is outward tension. Structural members (like steel bands) wrapped around cylindrical habitats help contain this.

Design ConceptsBuried Cylinders: Building cylindrical habitats within trenches and covering them with regolith provides shielding from radiation and micrometeoroids, using the soil's weight to help counteract the internal pressure, notes Marspedia and NIH.

Domes: Dome-shaped structures (hemispherical) are also efficient for pressure containment, as studied by NASA.

In essence, think of large, pressurized tanks – spheres and cylinders are the best shapes for holding pressure, and adding regolith makes them even more effective Martian habitats

Parts of the cargo payload door and crew airlocks will be critical parts to use in making a larger insitu building.

Starship Nosecone with payload bay door cutout

Then there is the pez dispensor door.

The stainless steel used in the construction of the Starship and Super Heavy booster, including the Block 3 version, has a uniform diameter of 9 meters (30 feet). The steel is typically sourced in rolls that are cut into rings to form the vehicle's tanks and structure.

Key Dimensions and Material

Diameter: The standard diameter for all current Starship and Super Heavy booster versions, including Block 3, is 9 meters (approximately 30 feet).Steel Thickness: The stainless steel used is generally 3.6 mm thick (about 0.14 inches) for many parts of the structure.

Material Type: SpaceX primarily uses a custom variant of 304L stainless steel, which performs well in the extreme cryogenic temperatures of rocket propellants.

Band/Roll Width: The raw steel is often delivered in rolls that are 1.8288 meters (72 inches) wide and then welded together to form the large rings of the rocket's structure.

Block 3 Changes

While the diameter remains the same, the Block 3 iteration introduces changes to the overall height and internal capacity:Super Heavy (Booster): The Block 3 booster is expected to be 72.3 meters (237 feet) tall, a slight increase from the Block 2's 71 meters. It also has increased propellant capacity and uses Raptor 3 engines.

Starship (Second Stage): The Block 3 ship is expected to be part of a taller, 124.4 m (408 ft) stacked vehicle, and is designed to carry significantly more fuel than previous versions.

The consistency in the 9-meter diameter across versions allows SpaceX to use the same manufacturing tooling and launch infrastructure, such as the high bay and launch tower arms

Offline

Like button can go here

#8 2026-01-11 18:53:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

A 100-meter diameter, 20-meter or taller 304L stainless steel dome with a 3-meter regolith radiation shield is a highly challenging, but theoretically plausible, conceptual design for a Martian habitat, primarily utilizing in-situ resources for the shielding.

Feasibility and Challenges

The feasibility hinges on several critical engineering and logistical considerations:Radiation Protection: The 3 meters of regolith (Martian soil) is an effective and essential radiation shield against both galactic cosmic rays (GCRs) and solar energetic particles (SEPs). Studies indicate this thickness can significantly reduce radiation exposure to safe levels for long-term habitation.

Structural Integrity: The primary structural challenge on Mars is not external loads like wind (which are minor) but the immense outward pressure from maintaining an Earth-like internal atmosphere. This places the dome under significant tensile stress. While 304L stainless steel is a suitable material with known tensile strength properties at low temperatures, a structure of this size would require substantial engineering to manage these forces.

Construction Logistics: Transporting the vast amount of steel required from Earth to Mars would be prohibitively expensive and logistically impossible with current technology. The construction would necessitate advanced robotic systems and require developing in-situ resource utilization (ISRU) capabilities to extract and refine steel from available Martian resources (e.g., meteoritic iron, or processed ore). NASA's MMPACT (Moon-to-Mars Planetary Autonomous Construction Technology) project is actively researching such methods.

Regolith Management: Moving the estimated millions of tonnes of regolith needed for the shield is a massive undertaking, requiring specialized heavy-duty robotic equipment and significant power infrastructure.

Sealing and Atmosphere Retention: The dome must be hermetically sealed to prevent catastrophic air loss, a major engineering hurdle. The pressure differential is several orders of magnitude greater than that of inflatable domes on Earth.

Thermal Stress: Mars experiences extreme temperature variations, which would induce significant thermo-elastic loads on metallic structural members, a factor that requires careful design consideration.

In summary, while the design addresses a critical need for radiation shielding, its realization depends entirely on developing robust, autonomous, and large-scale manufacturing and construction capabilities on Mars, a goal of ongoing research and development efforts

Offline

Like button can go here

#9 Yesterday 16:39:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,177

Re: Starship repurposed to make or build what we need

I found images of the building of the super dome

Scalable structure that could be made from the cannibalized starships, cut and bend to shape.

Offline

Like button can go here