New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-12-13 15:30:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Starship repurposed to make first habitat spaces

Trying to leverage what we have on mars once crews and cargo start landing on its surface.

People on Mars would convert a Starship into a permanent habitat using a combination of heavy-duty robotic equipment and pre-positioned systems to unload or reposition habitat modules from the vertical rocket. SpaceX and NASA are considering several concepts, but there is no single finalized plan.

Key potential methods include:

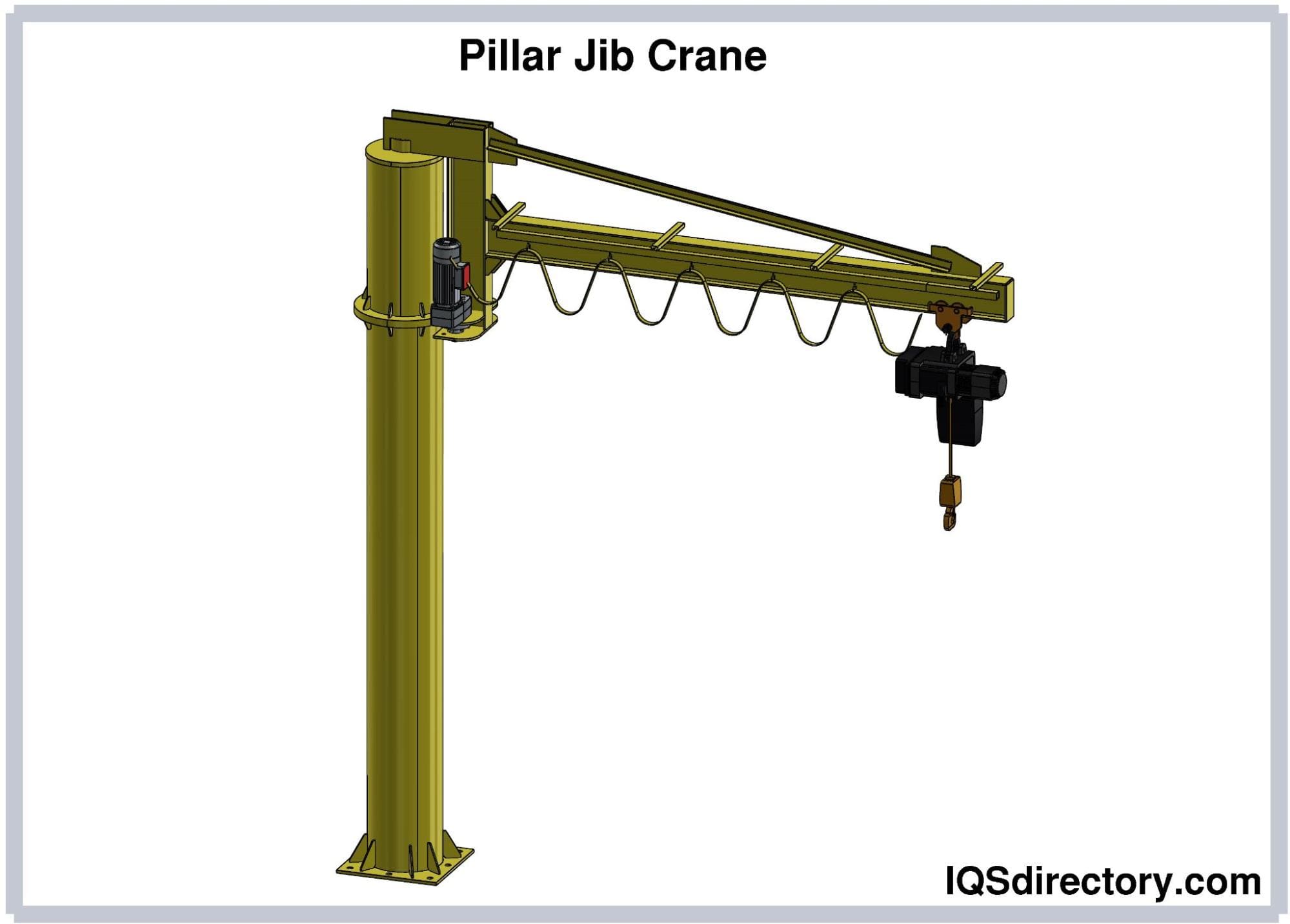

Jib Cranes and Robotics:

A modified cargo Starship could use deployable jib cranes to lift habitat modules out of the payload bay, rotate them to a horizontal position, and lower them to the ground. Robotic systems, such as an ATHLETE rover with digging tools, could assist in moving the habitat modules and burying them in regolith for radiation protection.Integrated Systems:

The habitat modules would be pre-packed inside the Starship before launch. Once on Mars, internal rail and cable systems could facilitate moving individual modules toward a large side hatch for subsequent lowering to the surface.Tipping the Starship:

Another concept is to land the Starship and then tip the entire structure onto its side to provide a large, easily accessible ground-level habitat space.Landing in a Trench:

The Starship could be designed to land in a prepared trench to align its docking ports with other surface elements, or the habitat could be placed in a trench after offloading.Building Around the Ship:

The simplest, though less efficient, method is to use the landed Starship as a de facto habitat and build additional modules or cover the existing structure with Martian soil (regolith) for radiation shielding. Ultimately, these operations would likely rely on un-crewed cargo missions preceding the first human landing to deliver the necessary offloading machinery, power systems, and basic infrastructure. This ensures the crew's safety and provides a ready habitat upon arrival

We know the shell materials can be welded once pulled down to the ground in order to make what we need to get started.

Options for Offloading a 90-Ton Common Habitat from its Lander on the Surface of Mars

NASA concepts for using Starship to deliver a 90-ton habitat on the Martian surface

https://ntrs.nasa.gov/citations/20220010430

For welding SpaceX Starship's 304 stainless steel, the key equipment involves advanced, high-speed robotic laser welding machines for precise, fast, single-pass welds, replacing slower TIG/MIG methods, though standard TIG/MIG welders (like inverter-based Synergic ARC 304) with appropriate filler (ER308L) and argon gas are used for other stainless work. SpaceX uses specialized systems for deep penetration and heat conduction to minimize warping, enabling lighter, stronger structures quickly.

Key Equipment & Techniques for Starship (304 SS)

Robotic Laser Welding: The primary method for Starship rings, offering speed, precision, and minimal heat distortion, allowing thinner sheets.

Heat Conduction Welding: For thin sheets, creating clean welds with little warping.

Deep Penetration (Keyhole) Welding: For thicker sections, creating deep, strong single-pass welds.

TIG/MIG Welders (for general use/prototypes):

Inverter-based MIG/MAG: Machines like the Synergic ARC 304 offer advanced features, high duty cycles, and robust wire feeds.

TIG (GTAW): Known for beautiful, high-quality welds, requiring more skill.

Consumables:

Filler Wire: ER308L is standard for 304 stainless steel.

Shielding Gas: Argon-rich gases are essential for stainless steel welding.

Why the Shift to Laser Welding?

Efficiency: Dramatically speeds up assembly, reducing build times from months to weeks.

Weight Reduction: Enables use of thinner steel by creating stronger, consistent welds, cutting overall mass.

Quality: More precise, consistent welds with less warping than traditional methods.

General Stainless Steel Welding Tips

Cleanliness: Always start with clean stainless steel.

Filler: Use the correct filler (ER308L for 304).

Gas: Use appropriate argon mix.

Duty Cycle: Choose a machine with a high duty cycle for continuous work

Offline

Like button can go here

#2 2025-12-13 15:54:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,455

Re: Starship repurposed to make first habitat spaces

This post is reserved for an index to posts that may be contributed by NewMars members.

This topic appears to have significant upside potential, because Starship (SpaceX) appear to be strong candidates for flight to Mars with humans.

The Chinese will NOT be flying with Starship, so we automatically have two competing systems that must function well enough so the humans on board not only survive but return safely to Earth.

This topic is available for records of the SpaceX attempt(s), and for links, images and text that members may provide.

Index:

Post #3 SpaceNut https://newmars.com/forums/viewtopic.ph … 74#p236174

On SpaceX welded construction of Starship components

(th)

Offline

Like button can go here

#3 2025-12-13 18:37:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Starship repurposed to make first habitat spaces

Images are from tank constructions 4mm thick sheet weighs approximately 31.4 kg/m²

We know that the metal is stainless steel 304L at 9 m diameter or circumference is approximately 28.27 meters.

Key Dimensions & Features:

Starship Upper Stage Length: Approximately 50 meters (165 ft).

Diameter: 9 meters (29.5 ft).

Total Starship (with Booster): Around 120-123 meters (397-403 ft) tall.

Pressurized Volume: Target of over 1000 cubic meters for crewed versions, more than the ISS's primary pressurized modules.

Levels: About six levels, including cargo, life support, gym, crew cabins, common area, and command deck.

SpaceX Starship uses 304L stainless steel, typically in large rolls or sheets for construction, with specific thicknesses around 4 mm (0.156 in), though thinner gauge sheets (like 0.8-1.2mm) are common for various finishes and sizes (e.g., 2000x1000mm, 2500x1250mm) from suppliers. While standard industrial sizes (4'x8', 4'x10') exist, Starship uses large, custom formats for its cylindrical sections, with some reports mentioning rolls over 72 inches wide.

Key Details:

Material: 304L Stainless Steel (low carbon version).

Thickness: Around 4 mm (0.156 inches) for main structure, but thinner for other parts.

Formats: Large sheets or rolls, not small standard sheets.

Standard Sheet Sizes (for general use): 4'x8', 4'x10', 5'x10' (and cut-to-size).

Specific SpaceX Use: Reports mention rolls 1828.8mm (72 inches) wide for building the rocket's body.

So, while standard sizes are common in the industry, Starship uses massive, specific sizes to form its huge cylindrical tanks and body sections.

Offline

Like button can go here

#4 2025-12-13 20:01:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,917

Re: Starship repurposed to make first habitat spaces

https://www.humanmars.net/2021/04/space … or-20.html

Digging a hole would allow for the crewed portion of the starship to be quickly covered for use,

Another it to just send a roll in a cargo ship to give a quick method to make a habitat.

zooming in on the floors for dimensions found that they are 2.5 m with the floor being 220 mm thick for the 6 floors indicated

plan is for just 20 to 40 crew personnel.

Offline

Like button can go here