New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-12-07 09:09:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

This title has no meaning 1

I was reminded by Void while doing the daily recap of Boring on Mars.

Topic Drill Technology - Microwave - Traditional - Others

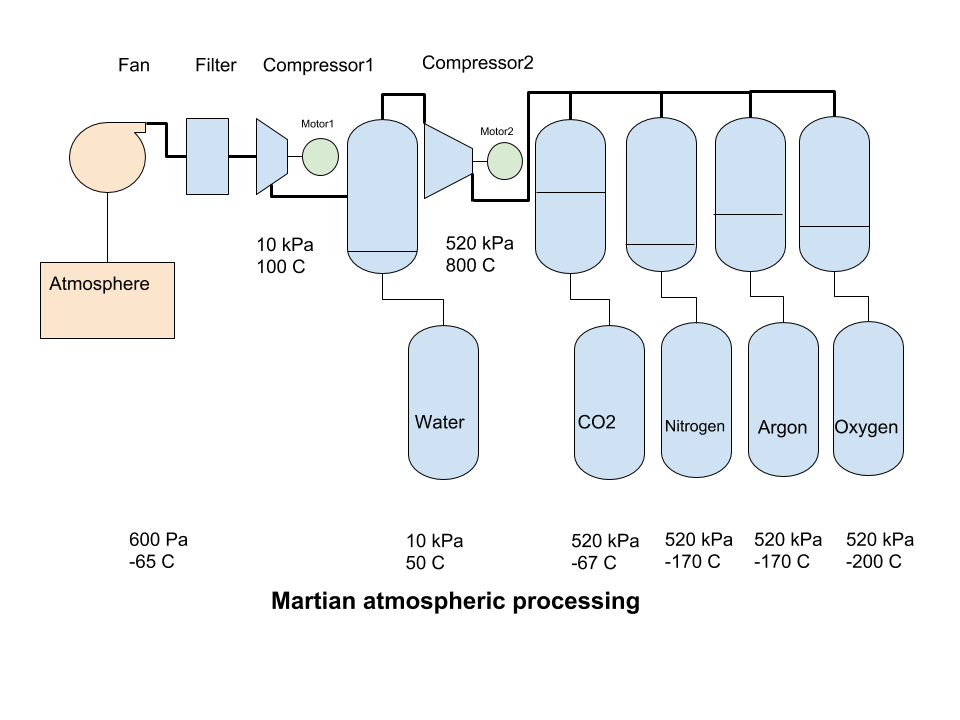

Of course we are talking Industrial development on Mars from landing,toehold, foothold and settlement to full blown colonization.

We need all types of equipment to dig into mars literally so as to make hospitable spaces for man to survive in and with in for a variety of reasons.

Also needed will be ore processing and brick making plus more to build on Mars.

Scientists and engineers have proposed several methods and "equipment" concepts for making bricks on Mars using local resources (in-situ resource utilization), primarily Martian regolith (soil). A key discovery is that simple compression, without binders or heat, can create bricks stronger than steel-reinforced concrete.

Proposed Equipment and Methods

Since transporting all construction materials from Earth would be prohibitively expensive, research focuses on using the iron oxide-rich Martian soil itself.

High-Pressure Mechanical Press/Hammer:

The most promising method uses sheer pressure. Researchers at UC San Diego accidentally discovered that by enclosing Mars simulant in a flexible container (like a rubber tube) and applying high pressure, they could form solid, strong pellets which can be cut into brick shapes. The necessary "equipment" could be a robotic, high-pressure compacting device or even a simple hammering mechanism operated by future astronauts.3D Printing Systems:

This is a major focus of ongoing research.

Regolith melting: One idea involves melting the regolith with lasers or focused solar energy and pouring it into molds, though this requires significant energy.

Binder extrusion:

Regolith could be mixed with a binder (polymer or even human-derived materials like blood plasma protein or urea) and extruded through a 3D printer to build structures autonomously.

Kilns/Furnaces:

Early proposals suggested using a nuclear-powered or solar furnace to bake the bricks, similar to ancient Earth methods. This method would require a significant power source and complex equipment to capture any released water for reuse.The equipment needed to create hot sulfur regolith bricks for Martian in-situ buildings involves machinery for excavation, processing, mixing, heating, and molding the materials. A 1200°C kiln is used for sintering processes with other potential binders, but for sulfur concrete, the required temperature is much lower (around 120°C to melt the sulfur).

Materials Acquisition & Processing

Excavation and Sifting Equipment:

Robotic excavators or rovers with digging mechanisms to collect the Martian regolith. Sifting or refining machinery may be needed to achieve the optimal particle size distribution for the aggregate.

Sulfur Extraction and Refining Unit:

A chemical processing plant to extract elemental sulfur from Martian sources (sulfides/sulfates), likely involving high-temperature oxidation and reduction processes.

Storage Tanks/Hoppers:

Secure storage for both the raw regolith powder and the extracted, refined sulfur (solid and liquid).Brick Production & Molding

Heated Mixer (e.g., Pugmill or Drum Mixer): An industrial mixer capable of hot-mixing the dry regolith aggregate with molten sulfur (liquid at ~120°C). The mixer must have robust seals to handle the abrasive dust and potentially a controlled atmosphere (CO₂-rich).Heating System/Kiln:

While a 1200°C kiln is used for other methods like sintering, sulfur bricks only need a melting temperature of around 120°C. This heating could be powered by a solar furnace or a nuclear reactor's waste heat. The system needs precise temperature control to prevent boiling and ensure uniform heating.Molding/Casting System:

Molds (potentially made from 3D printed durable thermoplastics like PEEK or metal) or a robotic extrusion system (like a 3D printer) to form the liquid mixture into desired brick shapes.

Curing Area:

A controlled environment where the bricks can cool and solidify (harden through physical crystallization, not hydration).

Power Supply:

A robust, reliable power source (e.g., solar panels with battery storage or a fission reactor) capable of powering all machinery autonomously.Ancillary and Support Equipment

Autonomous Robotic Systems:

The entire process is envisioned to be highly automated due to limited human labor on Mars.

Dust Mitigation Systems:

Given the pervasive, fine nature of regolith dust, equipment must incorporate advanced seals and filtration to prevent damage and contamination.

Quality Control and Testing Apparatus:

Equipment to test the compressive and flexural strength of the final bricks to ensure they meet structural requirements.

Thermal Management Systems:

Equipment to manage the significant temperature variations and maintain consistent operating temperaturesBiomaterial Production Systems: Emerging research involves using synthetic biology, like engineered lichens or bacteria, to create a self-growing, concrete-like material from the Martian soil. This would require specialized bioreactor equipment and the necessary organic inputs.

Key Advantage

The simple, no-bake, no-binder method using a mechanical press is a leading candidate because it requires the least amount of complex machinery, energy, and additional materials transported from Earth, making it highly practical for initial manned missions

Offline

Like button can go here

#2 2025-12-07 09:11:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

While no operational 3 m diameter TBM specifically for Mars currently exists, the development of such equipment is a key concept in proposed strategies for establishing a Martian colony.

Current Status of Mars Tunneling Equipment

Conceptual Stage:

Current discussions revolve around the concept of using tunneling technology for Mars habitats, providing protection from cosmic radiation and micrometeorites, and leveraging the thermal stability of the subsurface.

Earth-based Prototypes:

Companies like The Boring Company (TBC) are developing advanced, all-electric Tunnel Boring Machines (TBMs) for Earth-based projects (e.g., the Prufrock series, which creates a tunnel approximately 3.7m/12ft in diameter).Technology Transfer:

While TBC's current machines are unlikely to be deployed on Mars without significant modification, the technology and engineering experience gained (such as automation and faster boring speeds) are seen as foundational for developing future off-world systems.

Prototype Drills:

Research has been conducted on smaller-scale "3-meter-class Mars drill prototypes" for scientific exploration of the shallow subsurface, but these are for drilling, not large-scale tunneling for habitats.

Transportability:

A 3m-class TBM (or its segments) is considered potentially transportable by a SpaceX Starship, which has an 8m diameter cargo bay.Key Challenges for Martian TBMs

Atmosphere:

Earth TBMs use significant amounts of water for cooling and other operations, which would be a major challenge in Mars's cold, near-vacuum atmosphere.Automation:

Due to communication delays and the need for efficient pre-human construction, Martian equipment would require a high degree of automation and robotic operation.Geology & Materials:

The machines would need to be adapted to Mars's unique rock and soil conditions. Also, instead of concrete segments (which are heavy to transport), innovative methods like sintering the excavated rock or using local materials for tunnel lining would be necessary.In short, 3 m diameter equipment for Mars is an active area of conceptual development and technological aspiration, leveraging Earth-based innovations, but is not yet a developed or deployed product.

Elon Musk's Boring Company develops advanced tunnel boring machines (TBMs), like the Prufrock series, with the long-term goal of enabling underground Martian cities for radiation protection, resource extraction (ice/metals), and efficient habitat construction, potentially using Starship for transport, with Earth projects providing crucial tech and operational experience for Mars colonization needs. The technology focuses on rapid, automated tunneling, which is vital for establishing self-sufficient subterranean life on Mars, where surface conditions are harsh.

How Boring Company Tech Applies to Mars:

Radiation Shielding:

Mars' surface lacks atmosphere, exposing settlers to lethal radiation; burying habitats under Martian rock provides natural shielding.

Resource Utilization:

TBMs can excavate for essential water ice and minerals, crucial for life support and fuel.

Rapid Infrastructure:

High-speed, automated digging allows for quick creation of tunnels for transport (like Hyperloop) and pressurized living spaces, reducing human exposure to dangerous conditions.

Autonomous Operations:

Earth-based experience with "no prior site prep" TBMs (like Prufrock) prepares for robotic deployment on Mars for automated base building.Key Technologies & Challenges:

Prufrock TBMs:

Designed for rapid, continuous excavation, with capabilities to start digging immediately, a major leap from traditional methods.SpaceX Integration:

While Starship can carry heavy payloads, transporting massive TBMs (like 1,200-ton machines) poses a challenge, requiring multiple launches or lighter designs.

Atmospheric Advantage:

Mars' thin atmosphere makes underground Hyperloop tunnels ideal, as an artificial vacuum isn't needed.The Vision:

The Boring Company's work on Earth, including rapid tunneling for tunnels and loops, serves as a practical testbed for the advanced, automated digging needed for large-scale Martian settlements, fulfilling Musk's vision for a multi-planetary humanity.

Offline

Like button can go here

#3 2025-12-07 09:13:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

I think that preload of equipment can be done with this concept as we need storage for it when not in use.

Oldfart1939 wrote:I did a bit of research on the Bobcat website last night, and perhaps we should include 2 excavators (tracked backhoes). They're heavier and more bulky than the front loader Bobcat skid-steer units, but these would allow excavation of habitat shelter trenches more rapidly and effectively than front-loader units.

I see you're doing construction. Not just the first exploration/science mission, but construction. The Mars Homestead project assumed 12 crew to construct the first permanent human base. Yes, we believed a construction vehicle was required. I would like to make a suggestion.

This is a typical Bobcat skid-steer loader. There are various sizes. This one is S450. ("S" for skid) Rated Operating Capacity: 1,370lb. Operating weight: 5,370lb

The thing that makes it "skid-steer" is it's wheels. It's wheels don't turn, to steer the vehicle you turn the wheels on one side while wheels on the other do not turn. Or to pivot in place, turn wheels on the other side backward. This means the wheels literally "skid" across the ground as it's steering. Be advised: operating this on grass will tear up the grass. This works very well on pavement or hard or very firm ground. It doesn't work so well on loose soil/dirt/sand/gravel at an incline.This is a typical Bobcat compact track loader. This one is T450. ("T" for track) ROC: 1,490lb. Operating weight: 6,424lb

Track vehicles work better on loose ground and inclines. The track provides more traction. I'm suggesting a compact track loader would be more appropriate for Mars.An excavator can be compact. The first is E10, Rated Lift Capacity 527lb, Operating weight 2,593lb. The second is E20, RLC 1,098lb, Operating weight 4,306lb.

https://assets.bobcat.com/excavators/misc/r-series/bobcat-e10-nav_pm_list.jpgBobcat has become known for compact construction vehicles. Other brands manufacture competing vehicles: John Deere, Case, Caterpillar, New Holland, others.

Heavy Equipment Guide: Companies by Skid-Steer LoadersAny vehicle would have to be customized for Mars. One suggestion I made was to manufacture the vehicle with titanium alloy instead of steel. Titanium has the same weight (mass), but greater strength. That allows making structural members like arms to lift the bucket thinner, so lighter. Hydraulics will have to be adjusted for extreme cold of Mars. And the engine can't breathe air, Mars has no oxygen. Well, practically none; not enough for combustion. When Robert Zubrin and David Baker proposed Mars Direct in 1990, they suggested using methane/oxygen because the ERV would need that for propellant anyway. Just make a bit more for the rover. But rather than using electricity to run ISPP, you could just operate the vehicle with electricity. At least one company specializes in electric conversion of Bobcat vehicles. And Bobcat themselves is working on all electric vehicles using lithium-ion batteries. They're even working on all electric actuators instead of hydraulics; intended for cold climates like Alaska.

Some of the equipment to be sent to mars

Offline

Like button can go here

#4 2025-12-07 09:34:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

https://newmars.com/forums/viewtopic.ph … 14#p155614

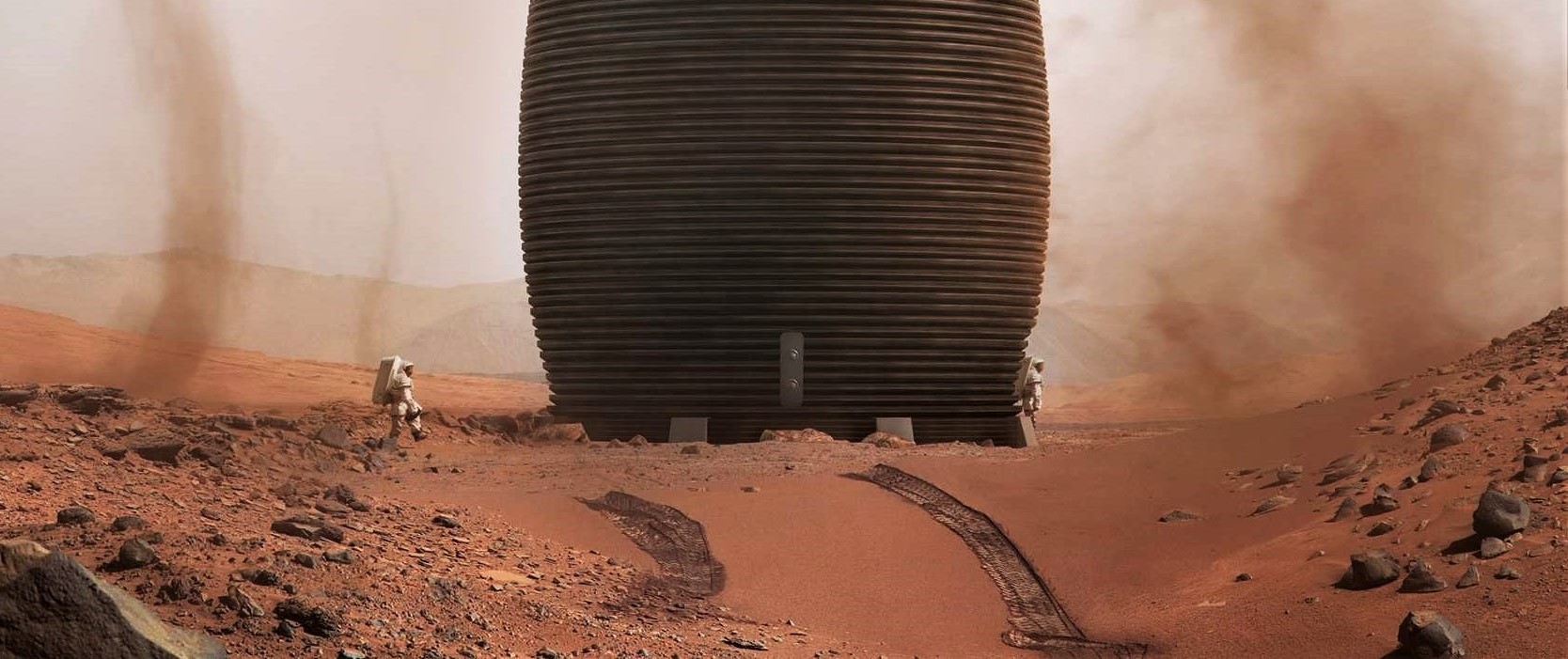

MARSHA:

Teslarati 3D-Printed Mars Habitat could be a perfect for early spaxeX starship colonies, MARSHA

I do https://www.teslarati.com/3d-printed-ma … -colonies/

Thanks for the link to others wanting to print habitats on mars or other places but what they do not go into is the prep side of the equation needed to make the materials to be use for the machinery to utilize it to build with from the insitu resources.

Very cone like indeed...

This is from AI SpaceFactory achieved second place in the latest phase of a NASA-led competition

If I do find the other simular posts I will copy them here so that we will have a list of whom are attempting the technology, the equipment and the materials information of what is targeted for insitu materials.

3D-printed Mars habitat a biorenewable plastic (PLA) reinforced with locally-sourced basalt fiber – also accounts for many of Mars’ shortcomings, as plastics happen to be some of the best materials for radiation shielding per unit of mass. Featuring a duo of PLA shells placing a meter or more of plastic between living areas, MARSHA would permit relatively acceptable radiation levels while avoiding the downsides of locating habitats underground or burying them under several meters of Martian regolith.

NASA's Centennial Challenges: 3-D Printed Habitat Challenge

https://www.nasa.gov/directorates/space … index.html

3D-Printed Habitat Challenge. NASA and its partners are holding a $3.15 million competition to build a 3D printed habitat for deep space exploration, including the agency’s journey to Mars. The multi-phase challenge is designed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond.

https://www.nasa.gov/directorates/space … mpetition/

After two stages where NASA awarded a total of over $1 million to competitors, the final prize was awarded to the top 5 projects.

Something that I would suggest is dropping a unit in one of the analog areas and run the insitu use processes from scratch to see just how hard it is to prepare the raw materials to make it ready for use for the equipment. Measure and test all aspects of it so that we can have better control to what we might find from the earth use.

https://www.3dprintingmedia.network/top … mpetition/

Team Zopherus of Rogers, Arkansas – $20,957.95

AI. SpaceFactory of New York – $20,957.24

Kahn-Yates of Jackson, Mississippi – $20,622.74

SEArch+/Apis Cor of New York – $19,580.97

Northwestern University of Evanston, Illinois – $17,881.10

These are beautiful for sure

A very firmiliar designed floor layout

Offline

Like button can go here

#5 2025-12-07 17:14:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

open pit seems to be the easiest to gather ore.

The equipment needed to make hot sulfur regolith bricks for Mars in-situ buildings involves machinery for excavation, material processing, heating/mixing, and automated construction, likely in the form of a robotic 3D printing system.

The key equipment can be categorized by function:

Raw Material Acquisition and Processing

Excavation Rovers/Machinery:

Automated diggers or rovers designed for low-gravity and remote operation to mine the Martian regolith (soil) and extract sulfur from sulfates and sulfides.

Crushing and Milling Equipment: Machines to break down the excavated regolith and sulfur compounds into a uniform aggregate size suitable for mixing and extrusion.

Chemical Processing Unit:

Equipment, possibly including a thermochemical or electrochemical processing system (like a solid oxide electrolysis cell), to refine the sulfur compounds into elemental sulfur, which is the required binder material.

Sieving/Separation Systems:

Mechanisms to ensure the proper particle size distribution of the regolith aggregate, as optimized mixtures can achieve higher compressive strengths.Brick Production and Construction

Storage and Feeding System:

Hoppers or containers to store the processed regolith and elemental sulfur and feed them at a precise, pre-designed weight ratio (around 65% aggregate to 35% sulfur is a common ratio) into the mixing apparatus.

Heated Mixer/Extruder:

A core component that heats the mixture to above sulfur's melting point (around 120°C) to liquefy the sulfur, uniformly mixes it with the regolith aggregate, and then extrudes the hot, molten sulfur concrete.

This system requires closed-loop heating control and monitoring systems to maintain precise temperature levels.

3D Printing System (Gantry or Robotic Arm):

An automated construction system that receives the hot mixture from the extruder and precisely deposits it in specific forms (layers) to build walls or structures directly on site.

Power Systems:

A robust, reliable power source is essential to run all the machinery, particularly the energy-intensive heating and processing units. This would likely involve solar panels and energy storage systems.Ancillary Equipment

Robotic Control Systems:

The entire operation is envisioned to be largely autonomous, requiring advanced robotic control and monitoring systems due to the communication lag with Earth and the need for reliable, continuous operation in a harsh environment.

Testing Apparatus:

Equipment to perform quality control tests on the finished material, such as compression and flexural strength testers, to ensure structural integrity.

Thermal Management Systems:

Equipment to manage heat and prevent issues like sulfur sublimation in a vacuum or under large temperature swings

A Mars open-pit mining operation, even one of 200m diameter, would rely on modified versions of terrestrial open-pit equipment, adapted for the Martian environment (low gravity, extreme cold, dust, and lack of atmosphere). The primary functions—excavation, loading, hauling, and processing—remain the same.

Key Equipment Categories & Adaptations

Excavation and Loading Equipment:

Large Hydraulic Excavators/Rope Shovels: These would be the primary tools for digging and loading broken material into haul trucks.

Bucket-Wheel Excavators (BWEs): For large, continuous digging operations, BWEs are efficient for continuously moving large volumes of material.

Bulldozers & Wheel Loaders: Used for site preparation, clearing overburden (regolith), and maintaining the working area.

Adaptation Insight: Lower gravity on Mars (38% of Earth's) means reduced ground pressure for digging, so equipment may need modifications (e.g., dual-barrel digging wheels for traction, as explored by NASA for lunar robots).

Haulage and Transportation:

Large Mining Trucks: Essential for transporting large quantities of ore and waste rock from the pit to processing plants or waste dumps.

Conveyor Systems: May be used for more efficient, continuous transport over specific, long distances, potentially integrated with BWEs.

Adaptation Insight: Tires and hydraulic seals must be made of materials that can withstand the extreme cold, as many Earth-based materials become brittle. Haul road maintenance using graders and dozers is critical for efficiency.

Drilling and Blasting (Optional but likely):

Large-Diameter Rotary/Percussion Drill Rigs: Used to drill blast holes for breaking up hard rock formations that excavators cannot manage alone.

Explosive Delivery Systems: While potentially complex due to the need to manufacture explosives (like AN/FO) on-site or transport them from Earth, blasting is a highly efficient way to fragment large amounts of rock.

Processing Equipment:

Primary Crushers: Large gyratory or jaw crushers would be needed to break down raw material to a manageable size before further processing.

Analytical Instruments: Tools like the Rock Abrasion Tool (RAT) used on Mars rovers, spectrometers, and real-time analyzers would be necessary for on-site geological analysis and quality control of the extracted material.

Adaptation Insight: Processing plants would need to be enclosed and possibly heated to function effectively in the harsh environment.

Supporting Infrastructure & Automation:

Power Systems: Large operations require significant power, likely from advanced nuclear, solar, or a combination of sources.

Automated/Remotely Controlled Systems: Due to the hostile environment, a high degree of automation, robotics, and remote operation would be essential to ensure continuous operation and human safety.

Life Support Systems: Pressurized operator cabins (if human-crewed) or remote operation centers would be required.

The specific type of equipment would ultimately depend on the target resource (e.g., water ice, iron-bearing minerals) and the specific geological properties of the Martian site

Offline

Like button can go here

#6 2025-12-07 17:23:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

To move 10 cubic meters of Mars regolith, you would need a tandem axle dump truck or a medium-to-large single-axle dump truck. A standard commercial tandem axle dump truck typically holds between 7.6 to 10.7 cubic meters (10 to 14 cubic yards) of material, making it a suitable option for exactly 10 cubic meters.

Dump Truck Options for 10 Cubic Meters

Medium Dump Truck (Single Axle):

These can hold a load volume of 3 to 6 cubic meters, so you would likely need two trips, or a very large single-axle model near its upper limit.Tandem Axle Dump Truck:

This is the most efficient option, as its typical capacity of 7.6 to 10.7 cubic meters can handle the entire volume in a single load. Some models can even handle up to 13 to 20 cubic meters.

Large Dump Truck (Tri-Axle/Super Dump): These trucks have capacities ranging from 13 to over 25 cubic meters, which would easily manage the load, though the truck might not be operating at full volumetric capacity.

Important ConsiderationsWeight vs. Volume:

The weight of the regolith (Martian soil) is a critical factor, even more so than volume. The density of material matters in determining the actual safe load capacity to avoid overloading the truck's weight limits.Martian Gravity:

The user's prompt specifies "Mars regolith," which implies an off-world scenario. The lower gravity on Mars (roughly 38% of Earth's gravity) would significantly alter the weight constraints and potentially allow a standard Earth-rated dump truck to carry a larger mass of material than it could on Earth, assuming the engineering for the martian environment is addressed.Equipment Specialization:

For actual off-world operations, the equipment would be specifically designed for the Martian environment, likely featuring wider cutting heads or different axle configurations to handle the unique terrain and gravity conditions.

How Many Cubic Yards Are in a Dump Truck?

Larger dump trucks can carry approximately 10 to 16 cubic yards of material. However, the total volume is not usually the limiting factor. In most cases, the vehicle’s weight limit will determine how much material you are ultimately able to safely transport.

So a dump truck that we could use is

A tri-axle dump truck typically weighs between 25,000 and 35,000 pounds when empty, but can weigh up to 80,000 pounds when fully loaded, depending on the load and local regulations. The specific weight varies based on the materials used to construct the truck (e.g., aluminum bodies are lighter than steel), the size and type of the dump body, and the weight of the fuel and driver

Offline

Like button can go here

#7 2025-12-08 16:28:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

As noted in Housekeeping post if we do use Earth vehices we will need to modify them for the cold which will turn some fuels solid, others to gel and more. Each vehicle will need engine modifications.

Internal combustion engines for Mars

tahanson43206,

If you have to carry the fuel and oxidizer with you, as you would on any planet except Earth, then pure Carbon doesn't require extra Oxygen atoms to combine with the Hydrogen atoms.

Kilograms of Pure Oxygen for Complete Combustion of 1kg of fuel:

Pure Carbon (32.8MJ/kg; 1kg powdered graphite = 1.05-1.15L; 28.52MJ/L): 2.67kg (2.34L); 3.49L ttl vol, 9.40MJ/L incl O2

Gasoline (44-46MJkg; 1kg = 1.2-1.4L; 32.86MJ/L): 2.3-2.7kg (2.37L); 3.77L ttl vol, 12.20MJ/L incl O2

Kerosene (43-46MJ/kg; 1kg = 1.25L; 36.8MJ/L): 2.93kg (2.57L); 3.82L ttl vol, 12.04MJ/L incl O2

Diesel (42-46MJ/kg; 1kg = 1.16-1.2L; 38.33MJ/L): 3.4kg (2.98L); 4.18L ttl vol, 11.00MJ/L incl O2

Methane (50-55.5MJ/kg; 1kg LCH4 = 2.36L; 23.52MJ/L): 4kg (3.51L); 5.87L ttl vol, 9.45MJ/L incl O2

Hydrogen (120-142MJ/kg; 1kg LH2 = 14.1L; 1L = 10.07MJ/L): 8kg (7.01L); 21.11L ttl vol, 6.73MJ/L incl O2LOX is 1,141kg/m^3 or 1.141kg/L

What can we conclude from that?

1. LH2 is a pretty pedestrian fuel when you need to store the cryogenic oxidizer, too.

2. There's not much difference between pure Carbon powder and Methane, except that making Methane is a lot more difficult and requires a lot more energy and technology than bubbling collected CO2 through a column of liquid Gallium eutectic. You need equipment to collect both H2O and CO2, a Sabatier reactor, a reverse fuel cell, and a really good electrical power source.

3. You do get 17% to 30% more energy per total volume by combusting diesel / kerosene / gasoline, in comparison to Carbon powder, but if you thought making Methane was energy intensive, you're going to need to add a lot more energy-intensive equipment to your chemistry set, and of course, you only get that additional energy by combusting it using additional O2 mass, which means you need to make more O2 from some combination of H2O and CO2. It's a pretty safe bet that all those additional chemical reaction steps will cannibalize whatever gains a dense liquid hydrocarbon fuel provides.

4. The relative complexity of obtaining LCO2 feedstock, on Earth or Mars, is pretty low. It's everywhere in the atmosphere and in the oceans here on Earth. Mars helps us out a bit by having a nearly-pure CO2 atmosphere, but at absurdly low density. Speaking of absurdly low density, LH2 looks great, best of all fuels, except when you must consider the mass of the storage equipment, and then it doesn't look so hot.

5. Of all the fuels listed, and any other liquid hydrocarbon fuels that weren't, if you throw a kilogram of Carbon on the ground, here on Earth or on Mars, that same kilogram of pure Carbon fuel will still be there the next day. We can't make the same claim about any of those other fuels. Carbon doesn't require special storage of any kind. If storing a cryogenic oxidizer is a pain we'd rather not deal with, then why compound the problem with fuels which also have special storage requirements?

Mars Insitu Fuels made from atmosphere, regolith, water

Mars Water regolith soils 1 foot depth only

Offline

Like button can go here

#8 2025-12-11 19:13:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Everything that we know about mars regolith has been from small sample sizes but images tell us that we are going to need lots of equipment to make use of mars to build and survive with insitu material use.

This is JSC Mars-1 Martian Soil Simulant

Chemical composition mineralogical standard analog based on data collected from the Mars Science Laboratory Curiosity rover. MGS-1 is made by sourcing a spectrum of terrestrial minerals, then mixed together in specific proportions to generally replicate the Martian surface. This is in contrast to previous Mars simulants that were typically sourced from a single terrestrial deposit (basalt or palagonite) fraction of less than 1 millimeter

Regolith to Steel Powder, Oxygen & Water with Small Equipment

https://en.wikipedia.org/wiki/Martian_regolith_simulant

After milling to reduce its particle size, JSC Mars-1A can geopolymerize in alkaline solutions forming a solid material. Tests show that the maximum compressive and flexural strength of the 'martian' geopolymer is comparable to that of common clay bricks.

other simulant attempts https://www.themartiangarden.com/mars-simulant

https://en.wikipedia.org/wiki/Martian_regolith

here is the sand with rocks.

https://en.wikipedia.org/wiki/Martian_r … agment.jpg

So lots of preperation of the soil is needed to make use of it in milling it to size, seperating the mineral content and making it perchlorate free.

To build with Mars regolith, milling equipment (like vibratory/planetary ball mills) reduces particle size, while separation methods use techniques like laser sintering, cold sintering (CSP), polymer binders, or microwave systems to bind or melt regolith into structures, often requiring 3D printers for shaping, aiming for materials like bricks, shielding, or metal parts from extracted elements like iron/titanium. Key processes involve size reduction (milling) and consolidation (sintering/binding) to create usable materials like "Mars concrete" or fused components, with focus on robotic, energy-efficient systems.

Milling Equipment & Processes

Ball Milling (Planetary/Vibratory): Used to reduce particle size (PSD) of raw regolith simulant, with planetary mills being faster but roller banks better for large slurries.

Sieving: Separates milled particles into specific size ranges (e.g., 60-mesh).

Separation & Consolidation Technologies

Laser Sintering: Uses high-power lasers to melt and fuse regolith into solid layers, creating paving or structural elements.

Cold Sintering (CSP): Binds regolith with water/alkaline solutions at low temperatures (under 250°C) and pressure, forming strong bricks or blocks.

Polymer Binders: Mixes regolith with polymers (made from Martian CO2/water) for 3D printing concrete-like materials.

Microwave/Solar Sintering: Alternative methods to use focused energy for hardening regolith.

Metal Extraction: Processes like carbonyl metallurgy or vapor deposition extract iron and other metals for 3D printing steel parts.

Additive Manufacturing & End Products

3D Printing (Extrusion/Powder Bed): Deposits processed regolith/binders layer-by-layer, building structures like domes, habitats, tools, or rebar.

Products: Sintered bricks, concrete-like blocks, radiation shielding, metal components (rebar, gears, tools), and coatings.

Key Considerations

In-Situ Resource Utilization (ISRU): The core principle, maximizing use of Martian soil.

Energy Efficiency: Focus on low-energy methods like cold sintering.

Robotics: Automation is crucial for mining, milling, and construction

Another reference topic for construction materials for floors within the structure or ceilings

Offline

Like button can go here

#9 2025-12-18 15:23:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Need radar sub surface viewing for what is beneath the surface. To detect large rocks and depth to bedrock or underground voids.

3D printing of dome-shaped habitats on Mars using basalt-based materials is a leading area of research for in-situ construction. This approach leverages the abundant basaltic rock and regolith found on the Martian surface to create a structurally sound, radiation-shielding building material, eliminating the need to transport heavy materials from Earth.

Construction Techniques

The primary method involves additive manufacturing (3D printing) using robotic systems deployed autonomously before human arrival.

Material Acquisition and Processing: Robots collect basalt rocks and regolith (crushed rock and dust) and process them into a usable feedstock. One method involves melting the basalt in a furnace and pulling it into fibers, which are then combined with a binder.

Binding Agents: To create a cohesive, printable "ink," the basalt material is often mixed with a binder. In various NASA challenges, teams have experimented with:

Polymer composites: Combining basalt fibers with polylactic acid (PLA) or other recyclable plastics, which can potentially be synthesized from plants grown on Mars.

Geopolymers/Cements: Using fast-setting metakaolin geopolymer cement formulations.

Printing Process: The material is extruded layer by layer by a gantry-style or robotic arm printer, building the habitat from the ground up. The dome shape itself is a functional design choice, as the curved walls help to withstand the significant pressure difference between the internal human-habitable atmosphere and the near-vacuum Martian environment.

Advantages of Basalt for Mars Habitats

Radiation Shielding: Cooled basalt has a high density, which provides superior protection from electromagnetic space radiation and micrometeorites compared to more porous materials.

Structural Integrity: Basalt fiber-reinforced composites can be several times stronger than traditional concrete, providing robust structural elements.

Thermal Regulation: The material has a low coefficient of thermal expansion, advantageous for the extreme temperature swings on Mars.

Airtight Seal: Basalt's low permeability makes it suitable for forming the necessary hermetic seal to maintain a pressurized, life-supporting internal atmosphere.

Current Status and Research

Research has largely been driven by competitions like the NASA 3D-Printed Habitat Challenge. While material processing and 3D printing techniques have been successfully demonstrated using Martian regolith simulants on Earth, the practical challenge of establishing the energy-intensive processing equipment (like high-temperature furnaces) on Mars remains a significant engineering hurdle.

Additive Construction using Basalt Regolith Fines

Mars X-House: Design Principles for an Autonomously 3D

THREE DIMENSIONAL (3D) PRINTED HABITAT, PHASE 3

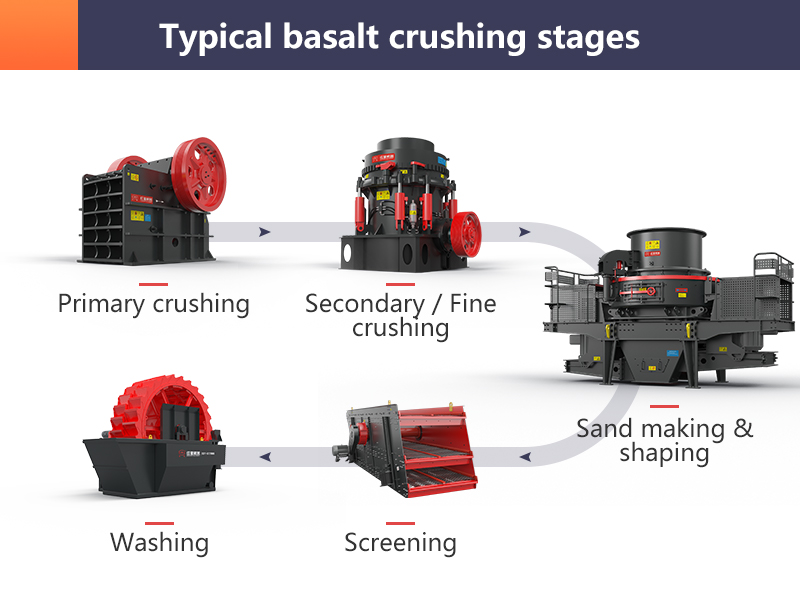

Basalt is a very hard, abrasive rock, so its processing for 3D printing requires robust, industrial-grade crushing and grinding machinery to produce the necessary fine powder or granule sizes. Typical crushing sequences involve multiple stages of specialized equipment, rather than a single machine.

Equipment for Basalt Crushing

A multi-stage process is typically used to break down large basalt rock into fine powder or granules suitable for applications such as fiber production or as an aggregate in 3D printed concrete.

Primary Crushing: Jaw Crushers

Purpose: The first stage of size reduction for large, raw basalt pieces.

Description: Jaw crushers are built strong with a deep crushing chamber to handle large, tough lumps of rock effectively, reducing them to sizes manageable by the next stage (e.g., from a meter down to a few inches).

Secondary/Tertiary Crushing: Cone Crushers or Impact Crushers

Purpose: To further reduce the basalt to a more uniform, smaller aggregate size (e.g., down to 0-40mm).

Description:

Cone crushers are highly recommended for hard, abrasive materials like basalt due to their durability and efficiency in producing a uniform, cubic product with lower wear rates than impact crushers.

Impact crushers can also be used, especially for shaping the material into a cubical form, but they tend to experience higher wear when processing hard basalt.

Fine Grinding (Milling): Ball Mills or Vertical Roller Mills

Purpose: To achieve the fine, micron-level powder needed for specialized 3D printing material composites, fillers, or fiber production.

Description: These machines use balls or high pressure to pulverize the basalt into the extremely fine particles required for additive manufacturing processes.

Screening and Classifying Equipment

Purpose: To sort the crushed material by size and ensure the final product meets the required specifications for 3D printing projects.

Description: Vibrating screens are used after each crushing stage to separate the desired product sizes from oversized material, which is then recirculated for further crushing. Air classifiers or washers may also be used to remove impurities and achieve specific material properties.

Considerations for 3D Printing Projects

Particle Size and Shape: 3D printing requires a consistent and specific particle size distribution (PSD). The equipment used must be able to produce material within narrow tolerances.

Material Abrasiveness: Basalt is highly abrasive, with a Mohs hardness of 5-9. Equipment must have heavy-duty construction and wear-resistant liners (e.g., tungsten carbide components) to withstand the wear and tear.

Scale: For hobbyist or small-scale projects, small-scale jaw crushers might be available, though they are primarily industrial machines. For industrial 3D printing applications (e.g., large-scale additive construction using basalt-based concrete), a full production line is required.

Companies like Rubble Master, Zoneding Machine, and FTM Machinery manufacture industrial basalt processing equipment, and platforms like Alibaba.com list a variety of crushers and mills

Offline

Like button can go here

#10 2025-12-18 18:35:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Basalt Crushing Plant: Process, Machines, and Price

Final product sizes and applications

0–5 mm: Manufactured sand for concrete, dry-mix mortar, asphalt mix

5–10 mm: High-grade road base, permeable concrete

10–20 mm: Municipal projects, ready-mix concrete plants

20–31.5 mm: Railway ballast, highway base, mass concrete

>31.5 mm: Returned for re-crushing to ensure proper gradation

Offline

Like button can go here

#11 2025-12-24 14:30:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

A comprehensive iron ore processing and steel production facility on Mars would require an integrated suite of mining, comminution, beneficiation, and refining equipment. A 200-meter diameter is a massive scale, likely referring to the entire facility's footprint rather than a single piece of equipment, and would enable significant production capacity.

Required Equipment: The equipment would function in a sequence from raw material extraction to finished product, much like on Earth, but adapted for the Martian environment and the use of in-situ resources.

1. Mining and Raw Material Handling Excavation and Loading: Robotic rovers and excavators with magnetic systems could collect iron-rich regolith or access concentrated ore deposits.

Transportation: Robust, self-driving transport systems (e.g., heavy-duty rovers or a rail system) to move ore from the mine to the processing plant.

Crushing and Grinding: Equipment such as jaw crushers, hammer mills, and ball mills would be needed to break down the iron ore into fine particles for processing.

2. Beneficiation and Concentration Sizing and Screening: Vibrating screens and classifiers to sort particles by size.

Separation: Magnetic separators are key for iron ore beneficiation, potentially complemented by flotation equipment, to increase the iron concentration in the ore.

Dewatering/Filtration: Equipment like filter presses or vacuum filters would be necessary if wet processing is used, to remove water from the concentrated ore.

3. Iron & Steel Production Martian steelmaking would likely favor direct reduction or electric arc furnaces over traditional blast furnaces due to the lack of abundant coking coal and the availability of atmospheric \(\text{CO}_{2}\) and water ice for reactants/power generation.

Ore Agglomeration: Pelletizing or sintering machines to form the fine concentrate into larger, usable pellets.

Reduction Reactors/Furnaces:Direct Reduction Kiln: Equipment to reduce iron oxides using hydrogen and/or carbon monoxide derived from Martian resources.

Electric Arc Furnace (EAF): An EAF would melt the sponge iron (produced from direct reduction) and allow for the controlled addition of carbon (extracted from the Martian atmosphere's \(\text{CO}_{2}\)) and other alloying elements to produce specific steel grades.

Continuous Caster/Molds: Machinery to form the molten steel into basic shapes (e.g., billets, slabs) for further processing.

Ladle Furnace: Used for final refining of the steel.

4. Manufacturing and Finishing Rolling/Finishing Mills: Large mills to shape the raw steel into plates, sheets, beams, or pipes.Additive Manufacturing (3D Printing): Metal powder bed fusion or directed energy deposition machines could use the produced steel powder for on-site fabrication of parts and infrastructure. Infrastructure and Support Equipment Power Systems: The entire process requires enormous amounts of power, suggesting large-scale nuclear fission reactors or extensive concentrating solar power (CSP) fields and storage systems.

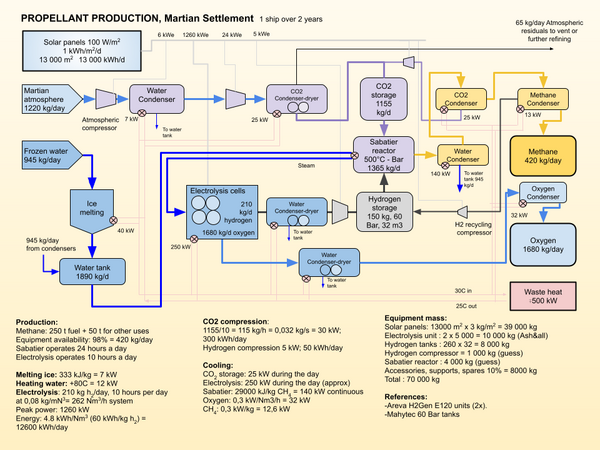

Gas Processing Plant: A complex system involving electrolysis cells (like NASA's MOXIE technology) and chemical reactors (e.g., Sabatier reaction) to produce the necessary oxygen, hydrogen, and carbon monoxide from the Martian atmosphere and water ice.Habitat and

Maintenance Facilities: Pressurized environments, repair shops, and storage facilities for personnel and spare parts.Fume Extraction Equipment: Systems to manage and clean process gases, essential for operational efficiency and safety in a closed environment

Offline

Like button can go here

#12 2025-12-29 08:39:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Offline

Like button can go here

#13 2026-01-02 08:47:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

I think an ad-hoc / in-situ garage implies using a natural terrain feature that can function as a garage, such as a cave, or something carved into a rock face. My assumption is that this garage primarily houses earth moving equipment.

Iron mining requires:

Drill rigs to create blasting holes

Excavators to scoop up the regolith

Drag lines for surface mining

Bulldozers to push piles of regolith around the job site

Haul trucksTo process the regolith into ore:

Rock crushers

Shakers and screens to separate larger rock chips from finer chips

Grinding mills to reduce the rock chips to a fine powder

Electromagnetic ore separators

Heaters to de-water hydrated mineralsEquipment used to drill wells would also be fabricated, repaired, and stored in unpressurized garages.

Thank you for the delivered list of equipment that we will need mass and volume for each plus another option that goes with a Dome building from Insitu materials if we build in a crater or against a sharp cliff surface.

Need to know is how many starship are required to land all of these items.

The question is the lading near such locations accurately.

This topic is the importing of equipment required to make any construction possible of any type.

Kbd512's list is similar to the needs for a dome and also for the hillside construction.

This is the hillside approach which can be found in the My Hacienda On Mars post First by RobertDyck followed up with my post which is a take off Living inside Mountains / Caves on Mars?

Also any insitu must have upfront cargo to be able to dig, crush, process as kbd512 has indicated

Offline

Like button can go here

#14 2026-01-02 16:11:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

"Blasting" is generally not the method considered for Mars regolith mining due to safety and control issues; instead, drilling and mechanical excavation technologies are being developed to collect material, which is then processed, often using heat, to extract resources.

Methods for Martian Regolith Mining

NASA and its partners are developing various In-Situ Resource Utilization (ISRU) technologies, focusing primarily on extracting water (which can be turned into propellant and life support consumables) from the Martian subsurface. The current approaches do not use explosives ("blasting"), but rather sophisticated mechanical and thermal methods.Mechanical Excavation and Drilling: This is the primary method for physical removal of material.

Rotary-Percussive Drills: Tools like the one on the Mars Science Laboratory rover (Curiosity) are designed to penetrate hard rock and collect samples (cuttings).

Scoops/Trenching: Missions like the Phoenix lander used a scoop to acquire top regolith and icy soil with a small drill bit called a rasp.

Autonomous Robotic Miners: Robots like NASA's RASSOR (Regolith Advanced Surface Systems Operations Robot) use rotating drums to dig and collect material autonomously for processing.

Deep Drilling Concepts: Concepts are being developed for drilling tens of meters deep to access potential concentrated water-ice sheets, which might use coiled-tube pneumatic drilling.

Thermal Extraction: Once the regolith is collected, or in some cases in situ, heat is used to extract volatiles (like water).

Oven Heating: Collected regolith simulant is heated in a vessel to release water vapor, which is then condensed and collected.

Microwave Heating: A method under investigation involves using microwave probes to heat the regolith in situ (in the ground), sublimating the ice into vapor that is then funneled out and condensed remotely, potentially eliminating the need for complex excavation equipment.

Why Not Blasting?

The term "blasting" implies the use of explosives or highly energetic events. This method would be difficult to control, could scatter valuable resources over a wide area, contaminate the site, and pose a significant risk to other equipment or future human habitats. The current focus is on precise, controlled, and autonomous systems to ensure efficient and safe resource recovery

so risk mitigation...

Current drills are not even close to being able to do what we would need.

So how would we make blasting on Mars safer?

Needs a sub topic champion

Offline

Like button can go here

#15 2026-01-03 16:19:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Back here on Earth, in admittedly less extreme temperatures, for Canadian mining and rock crushing equipment operating in -30C temperatures, they're using a combination of high-Manganese steel, high-Chromium "white" Iron, and Austenitic Ductile Iron. Mangalloy is the traditional cold weather steel that becomes work hardened with use, but has already been replaced with Ductile Iron in many applications for cost and wear benefits. White Iron is used in applications where abrasion / cutting from rock is the most important factor, such as razor sharp little shards of crushed rock being pulverized into a powder. The first couple of stages of rock crushers will be Ductile Iron, with the final one to two stages being White Iron because softer metals will get abraded too quickly. Chromium makes White Iron very hard.

Nearly every component in a heavy duty diesel engine can be and in fact are made from ADI, with only the connecting rods, pistons, piston pins, fasteners, and other small parts being steel vs Ductile Iron. Forged 4340 steel is still the best general purpose material for crankshafts and connecting rods subjected to severe stresses, but even high performance engines like Chrysler's Gen III Hemi are now using ADI camshafts as OEM equipment, and some engines use ADI crankshafts as well. Ford put ADI on the map during the 1980s when they put ADI crankshafts in some of their high-output engines, so one could say ADI is a 1980s and beyond material. TVR, a British company known for their extreme performance road-legal race cars, was also well known for using ADI instead of forged steel in their high-output V8 and I6 engines. If ADI lacked performance relative to 4340, then TVR would've discovered this during testing. OEMs like Caterpillar don't try to "hot rod" their engines though, so ADI crankshafts work for them in their largest mining truck and marine engines, saving piles of cash over modestly stronger forgings.

If you do everything absolutely correctly with a 4340 forging, then you get about 20% more "power holding" capability and fatigue life over ADI, at extreme cost. Modern "wonder materials" like 300M or Titanium also come with use case limitations, like "don't ever scratch the surface or drop the part on something hard". You should not expect the average mechanic to abide by those limitations. You see 300M and Titanium used in race engine connecting rods or aircraft landing gear / wing spars / engine mounts only. Nobody uses Titanium in crankshafts, which should tell you something. You would never design a factory diesel engine to use Titanium parts, for example. You also "give up" toughness at low temperatures and chemical exposure resistance, hence why you don't see Titanium or super alloys used in ship hulls or propellers. The Soviets used Titanium successfully in a literal handful of submarines, but not without a lot more hull maintenance, and every class of attack sub designed thereafter switched back to steel. Titanium exhaust manifolds are notorious for cracking. Everyone with a lick of sense uses stainless, an Inconel super alloy to reduce weight and achieve high temperature resistance, or plain old cast ductile Iron if cost matters at all. Titanium is pretty and produces unique "engine noises", but engineers with design latitude will generally opt for any other material.

Why ADI for heavy duty earth moving equipment?

ADI is 50% less energy-intensive to make than cast steel and 80% less energy-intensive than forged steel because there are fewer processing steps involving extreme heating. ADI will give you 80% of the performance of a 4340 forging in a practical application, like a crankshaft. Nobody makes a crane boom out of 4340 forgings, though. They all use mild steel or boiler plate steel. ADI in automotive use is a 120ksi YS material, tempered 4340 can go up to 200ksi if you don't care about toughness, but 125ksi YS is typical of normalized 4340. Fatigue resistance is better with 4340 forgings only if you spare no expense in production. Any lesser forged steel is probably not as good as ADI, such as the micro-alloyed low-alloy content forgings that come out of the major automotive OEMs, particularly for crankshafts / camshafts / connecting rods. They use forging of cheaper steels for part-to-part consistency, not absolute strength and fatigue life. As heat treatment process control improved dramatically with computerized ovens, appropriately tempered Iron castings largely replaced forgings.

ADI can technically be welded, but isn't worth the expense. If you want to economically weld parts together, then you really need to use mild steel or boiler plate steels. The only kinds of cryogenic capable steel we have for heavy earth moving equipment are either 300 series stainless steels, which are no stronger than mild Carbon steels and often modestly weaker, or stronger high-Manganese steels more akin to HY80 equivalents used in ship building.

Caterpillar really likes to use ADI for cast components used to reduce component count and assembly time, or mild steel requiring no special weld prep, so that if someone welds on their equipment or bends a frame rail back into place, the structural integrity of the equipment hasn't been compromised. Mild steel cannot remain ductile due to the cold temperatures on Mars, which leaves stainless, which is also safe to weld without concern over strength loss.

That complex part on the back of their haul trucks where the wheels / final drive / frame rails attach is a very large single piece ADI casting. The bucket, cab, and forward chassis components are welded mild steel. On Mars that would be welded stainless steel.

So, I have a proposal:

Let's "get real" about something fundamental to "civilization building":

Modern human society is built on water processing ability, industrialized farming, thermal energy, steel, and concrete. All other "nice to have" materials and other technological advancements have come from that foundation.Every Starship that lands eventually becomes part of the chassis or crane boom or other large components for these mining vehicles that we need to mine enough metal ore to create pressurized habitation to actually live on Mars permanently. The first order of business is to be able to produce pure Iron using electrolytic reduction techniques. This requires a lot of electricity, but the temperatures are very modest. Pure Iron plus small quantities of alloying metals and Carbon unlocks ADI. Most structural parts can be built using this material, because ADI has few problems with mildly cryogenic temperatures. As we make more equipment from scratch using mined metals, we'll want to add a steel mill and forging tools so small parts that really need to be forged steel can also be locally sourced. The only kinds of steels we can expect to survive the Martian nights are ADI, stainless, and high-Manganese alloys. Every bit of metals-based infrastructure needs to "natively" survive being cold-soaked, meaning the intrinsic material properties are suitable for use in a mildly cryogenic environment.

Most Iron-based alloys used on Earth are intended for construction, with equipment of any kind being a distant secondary consumer of metals. The majority of Iron production must be directed at pressurized habitation construction, not equipment or vehicles. Iron wiring is not lightweight compared to Copper or Aluminum, but most of it won't go anywhere after installation, won't corrode, and won't be transported very far, either. If a length of Copper conductor wire weighed 1lb, then its equivalent Iron wire only weighs 5lbs on Earth, but only 1.9lbs on Mars. This is obviously not ideal, but eliminates the immediate need for a Copper or Aluminum mining and refining industry. We can live with that result, though, even if Copper and Aluminum mining takes several additional decades of settlement development before it can be pursued.

After we have re-mastered Iron and steel suitable for production and use in the new context of the Martian surface environment, Aluminum, Silicon, Copper, and Uranium are our next priorities. Unfortunately, all of these technology metals are also very energy-intensive, which is why they're secondary priorities.

Everything else is an artifact of mass production of those metals. Iron is the key metal, as it always has been. When you have Iron, you can make most of the the structures and machines humans need to survive on Mars. The stainless steel is already being imported from Earth in the form of vehicles suitable for making the trip from Earth to Mars. If SpaceX follows their plan to deliver 1,000 Starships per launch opportunity, then that's about 100,000t of steel to work with. Mining haul trucks like the Caterpillar 797 weigh about 215t, so a decently-sized mining operation may have 10,000t of equipment, leaving the other 90,000t available for initial pressurized habitation construction.

We need tracked all-terrain earth movers powered by SCO2 gas turbine engines and electric motors to eliminate gear boxes, drive shafts, and as much of the working fluids as is practical. The fuel will be a finely powdered Carbon fluidized with CO2 for pumping, compressed O2 or LOX for oxidizer. The electric motors will save wear and tear on the brakes by mostly not requiring them. A super capacitor bank will provide the jolt of energy to overcome initial rolling resistance to get the vehicle moving, and then be recharged by the traction motors during braking. This is essentially an advanced turbine-electric locomotive power train. Daily maintenance tasks will include fuel replenishment, checking hydraulic fluid levels, track tension adjustment, determining if someone accidentally bent one of the soft stainless steel structural members holding the vehicle together. When turbine power is not being demanded to propel the vehicle, an electric pump will siphon CO2 from the atmosphere. At the end of each shift, the LCO2 tanks will be emptied back at the shop where it will be used to supply CO2 for shop air tools and making fresh batches of powdered Carbon fuel and O2 oxidizer using Gallium-Indium-Copper liquid metal. If we happen to discover a natural gas well nearby, then we might consider using Methane instead of synthetic coal, provided that the rockets don't consume all of the Methane. Regardless, the Martian atmosphere is the fuel / oxidizer and working fluid of choice.

Since we cannot readily use gigantic rubber tires in a cryogenic environment, we'll use steel track links instead. The dramatic reduction in relative vehicle gross weight means we need less power, even with tracks vs tires. The Cat 797F haul truck's gross weight with 400t max payload is 623.7t on Earth, but only 237t on Mars. Top speed is officially 65kmh when fully loaded, though I would surmise speed depends greatly upon local terrain and room to maneuver. Instead of 4,000hp, we can manage with less than that, say 1,520hp. 1,500hp corresponds with the output of the M1 Abrams AGT-1500 conventional gas turbine. Fuel consumption over an 18 hour shift is about 75gph.

US EIA rates diesel fuel at 138,500btu/gallon, so 75 gallons is 10,387,500BTU.

Net electrical output vs fuel burn for the big Cat C175-20 diesel engine which powers the 797F are as follows:

Max rated electrical output is 3.2MWe in an electric generator application.

It's burning 208gph at full output, so 28,808,000BTU.

10,918,400BTU (net electrical output) / 28,808,000BTU/hr (fuel consumption) = 37.9% overall thermal efficiency

Let's be very generous to the Cat engine and assert it's 40% thermally efficient at reduced engine load.10,387,500BTU * 0.4 = 4,155,000BTU

4,155,000BTU / 2,545BTU/hr = 1,633hpAn average of 1,633hp constant power output on Earth equates to 620hp on Mars.

For a 50% thermally efficient SCO2 gas turbine, 620 * 2 * 2545 = 3,155,800BTU/hr

Pure Carbon produces 14,100 to 14,600BTU/lb, so let's use 14,100.

3,155,800BTU / 14,100BTU/lb = 223.8lbs of pure carbon per hour

223.8lbs of pure C * 2.67lbs of pure O2 per lb of pure C = 597.5lbs of pure O2 per hour

18 hour shifts would therefore require 4,028lbs of pure Carbon and 10,756lbs of pure O2

At 700bar, 10,756lbs of pure O2 would required 12.195m^3 of tank capacity

Pure Carbon powder is 1,800-2,200kg/m^3, so approximately 1.015m^3 of fuel tank capacity5X 1mDx3mL O2 tanks will easily fit within the engine bay previously occupied by the C175-20, as will the fuel tank and SCO2 turbine and electric generator, although maybe the fuel tank should be in its standard location for what should be obvious reasons.

Anyway, we just did enough simple math to figure out that all the oxidizer and fuel will fit inside the engine compartment with lots of room to spare for the SCO2 gas turbine and electric generator. The haul truck doesn't require a complete redesign, it only needs to be gutted internally and the best layout for the new power train equipment established. Therefore, a Caterpillar 797F mining haul truck can be fabricated primarily from 300 series stainless cannibalized from Starships vs mild steel and ADI (already used in Earth-bound 797Fs). It can then be operated in a Martian metals mining operation with concessions made to use of a more thermally efficient SCO2 gas turbine engine driving an all-electric power train and delivering the power to ADI or high-Manganese forged steel tracks vs giant rubber tires. It's not perfectly ideal, but nothing ever is.

Note to self:

Make sure the high temperature radiator surface area can be a simple forward-facing steel panel.Now back to ground pressure and power consumption, and rolling resistance for tracked vs wheeled vehicles...

US Army Published a Table Regarding Generally Observed Coefficient of Rolling Resistance vs Surface Type:

Concrete / Hard Soil / Sand

Heavy Truck: 0.012 / 0.06 / 0.25

Tracked Vehicle: 0.038 / 0.045 / (no value provided for sand in this table)By the time you move the wheeled vehicle over hard soil, the tracked vehicle already has lower rolling resistance. If you have to move the vehicle through soft sand, then the wheeled vehicle is all but guaranteed to consume more fuel at equal weight. Wheels almost always deliver more speed in both on-road and off-road environments with sufficient power available / appropriate gearing, but not for equal fuel burn at equal vehicle gross weight. If you have a concrete or asphalt or hard rock quarry road, then the tracked vehicle is all but guaranteed to be less efficient. This follows reports I've seen regarding the actual fuel economy of our wheeled Stryker APCs, which while very fast and fuel efficient on roads, suddenly become fair to terrible in the deep sand drifts of Iraq and loose gravel mountain roads of Afghanistan.

Rubber Tracks vs Steel Tracks:

https://www.truppendienst.com/fileadmin … e_no_4.PNGGo to Page 29 to see the observed rolling resistance coefficients table I referenced above:

US Army Engineer Research and Development Center - Geotechnical and Structures Laboratory - Standard for Ground Vehicle Mobility - February 2005The mining haul truck is one of the largest pieces of equipment that needs to fit inside the garage, so 7.75m minimum height, preferably 16m high so the bucket can be tested inside the garage. The 797F is 9.5m wide, so perhaps the garage should be 25m in width to accommodate a pair of trucks. Overall length is 15m, so the garage should be 30m long.

Minimum Equipment Garage Dimensions for a pair of trucks, with room to spare for equipment and mechanics:

16mH x 25mW x 30mL

Nice details to add in for the equipment to pick and chose from.

Offline

Like button can go here

#16 Yesterday 11:43:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

While conventional, Earth-based excavators are not suitable for use on Mars due to gravity and atmosphere differences, NASA is developing specialized robotic excavators for future use on extraterrestrial surfaces like the Moon and Mars. These robots are designed to extract local resources for use in space exploration and colonization.

Challenges of Excavating on Mars

Standard terrestrial excavators rely on their significant weight (mass) to provide the necessary downward force (traction) to dig into the ground. This method is ineffective in the low-gravity environment of Mars (which has only about one-third of Earth's gravity). Additionally, the thin Martian atmosphere makes traditional cooling systems inefficient, and the high bulk density of the deep regolith (soil) presents further difficulty.

Specialized Robotic Solutions

To overcome these challenges, engineers at NASA's Kennedy Space Center are developing innovative, lightweight robotic systems as part of their In-Situ Resource Utilization (ISRU) program.

RASSOR (Regolith Advanced Surface Systems Operations Robot): This precursor robot uses a system of counter-rotating bucket drums on opposing arms to provide a near-zero net reaction force during excavation. This design means the robot's digging capability is not reliant on its own weight or traction, making it effective in low-gravity environments. Its symmetrical design also allows it to continue operating even if it tips over.

IPEx (ISRU Pilot Excavator): This is the next-generation version of RASSOR. It is designed to be highly productive, capable of excavating up to 10,000 kg of lunar regolith in a single lunar day during testing. IPEx aims to bridge the gap between prospecting and full-scale resource extraction operations.

The Use of Martian Excavators

The primary use for these future excavators on Mars and the Moon is In-Situ Resource Utilization (ISRU). By using local materials, future missions can become more sustainable and self-sufficient.

Key uses include:

Extracting water ice: Robotic excavators would mine for buried ice deposits, which can then be processed into drinking water, oxygen for life support, and propellant (rocket fuel) for spacecraft.

Construction: Regolith can be used as a building material for habitats and landing pads, reducing the need to transport materials from Earth.

Mining minerals: The extraction of other valuable minerals is a long-term goal for potential commercial ventures and colonization.

Currently, while conceptual illustrations exist, there are no physical excavators operating on the surface of Mars; existing missions rely on smaller rovers like Spirit, Opportunity, Curiosity, and Perseverance which primarily perform geological analysis

Current NASA actions are for the Moon and may not be what we will require on Mars

Mars excavators are designed to be compact and lightweight for transport, with prototypes like RASSOR 2.0 weighing around 66 kg (145 lbs) and sized to fit within mission constraints, while larger concepts for future bases might be 1-2 tons, using mechanisms like counter-rotating bucket drums to handle low Martian gravity and excavate significant amounts of regolith (soil) for building materials or water extraction. They use efficient designs, like counteracting digging forces, to operate effectively in Mars' reduced gravity, differing greatly from massive Earth machines like Bagger 293.

Examples of Mars Excavator Concepts & Prototypes:

RASSOR (Regolith Advanced Surface Systems Operations Robot):

Mass: 66 kg (approx. 145 lbs).

Key Feature: Uses counteracting bucket drums to create net-zero horizontal reaction forces, making it stable in low gravity.

Capability: Can excavate several metric tons of soil daily.

Deep Space Excavator (RASC-AL Prototype):

Dimensions: 1m x 1m x 1.5m tall.

Mass: 49 kg (approx. 108 lbs).

Design: Uses lightweight aluminum framing for modularity.

Conceptual "Mini-Excavators":

Mass: Estimated 1-2 tons for larger base construction, emphasizing the trade-off between size and launch difficulty.

Function: Could be used for surface preparation, towing, or attaching tools like blowers.

Design Considerations for Mars:

Mass & Size: Must be small and light enough to launch to Mars (e.g., fitting within rovers like Curiosity/Perseverance, ~1 ton) but capable of significant work.

Low Gravity: Designs often use opposing forces (like RASSOR's drums) to maintain stability and prevent flipping over.

Power: Efficient power usage is critical; excavators might use <200W for modest excavation rates.

Autonomous Operation: Autonomous systems are key for efficiency, as direct remote control is limited by communication delays

This is doubtful to be large enough for mars real world construction.

Earth excavator sizes and masses vary dramatically, from small mini excavators weighing under a ton (around 2,000 lbs) for tight spaces, to standard models from 10-45 tons, up to massive mining excavators exceeding 100 tons (like 200+ ton models or giants like the Bagger 293 at 14,200 tons), with common standard excavators often in the 19-24 ton range, showcasing a huge spectrum of capabilities for everything from landscaping to large-scale mining.

Common Excavator Sizes & Weights

Mini/Micro Excavators:

Weight: ~1,500 lbs to 10,000 lbs (under 1 ton to 5 tons).

Use: Tight spaces, landscaping, small utility work.

Small/Compact Excavators:

Weight: 10,000 lbs to 25,000 lbs (5 to 12.5 tons).

Use: Versatile for general construction, better reach than minis.

Standard/Mid-Size Excavators:

Weight: 10 tons to 45 tons (with typical models around 19-24 tons).

Use: Most common, strong power for varied construction tasks, often tracked for rough terrain.

Large/Heavy Excavators:

Weight: 45 tons and up, some over 100 tons (e.g., Cat 207,300 lb model).

Use: Deep digging, large-scale earthmoving, demolition, mining.

Massive Mining Excavators (e.g., Bagger 293):

Weight: Thousands of tons (Bagger 293 is ~14,200 tons).

Use: Extreme-scale surface mining operationsKey Factors Influencing Size

Job Site: Tight urban sites need mini excavators; large open mines need massive ones.

Dig Depth/Reach: Larger machines offer significantly deeper digging and greater reach.

Power: Measured in horsepower, it dictates lifting and digging force, increasing with size.

Transport: Smaller models can be towed, while larger ones require specialized transport.

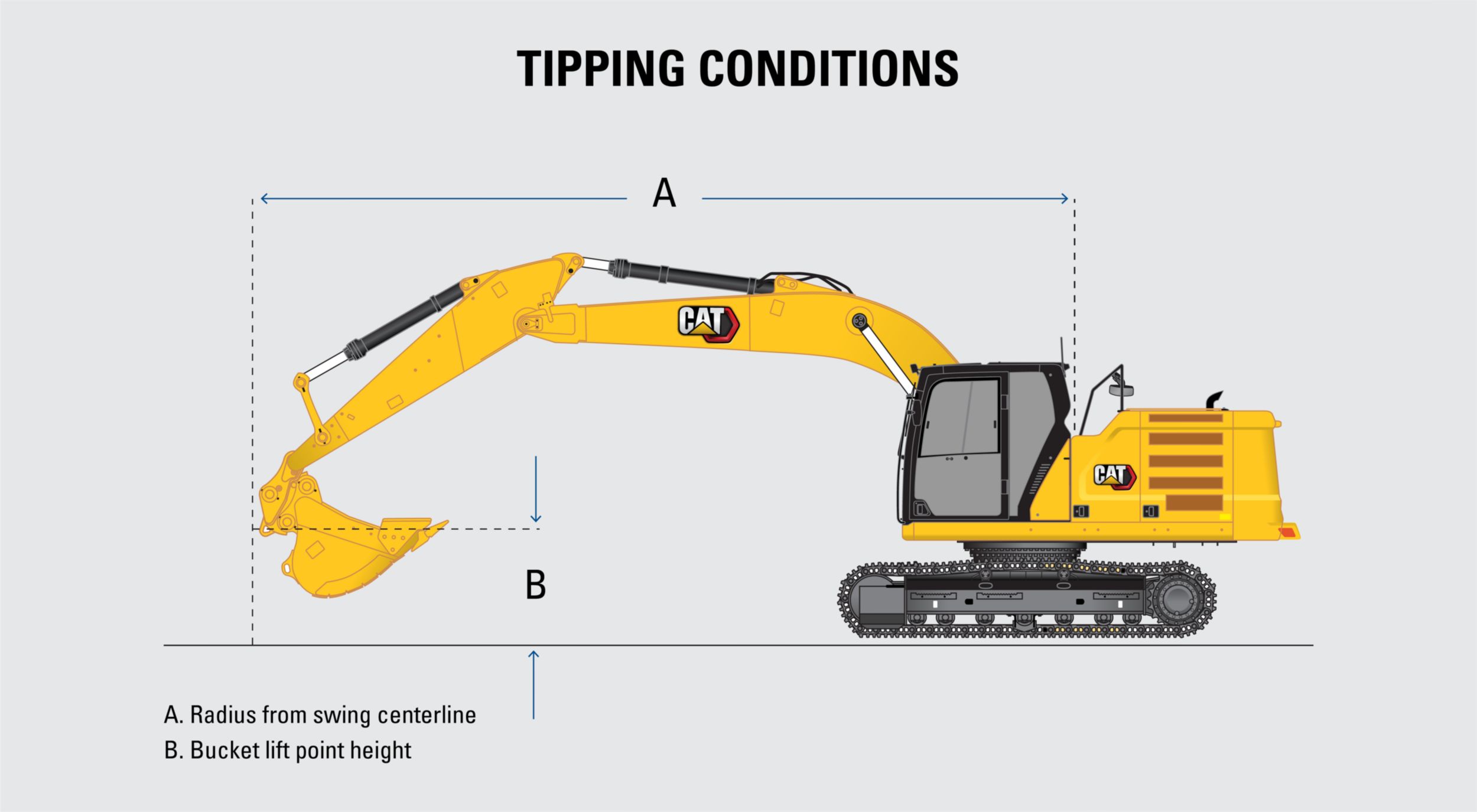

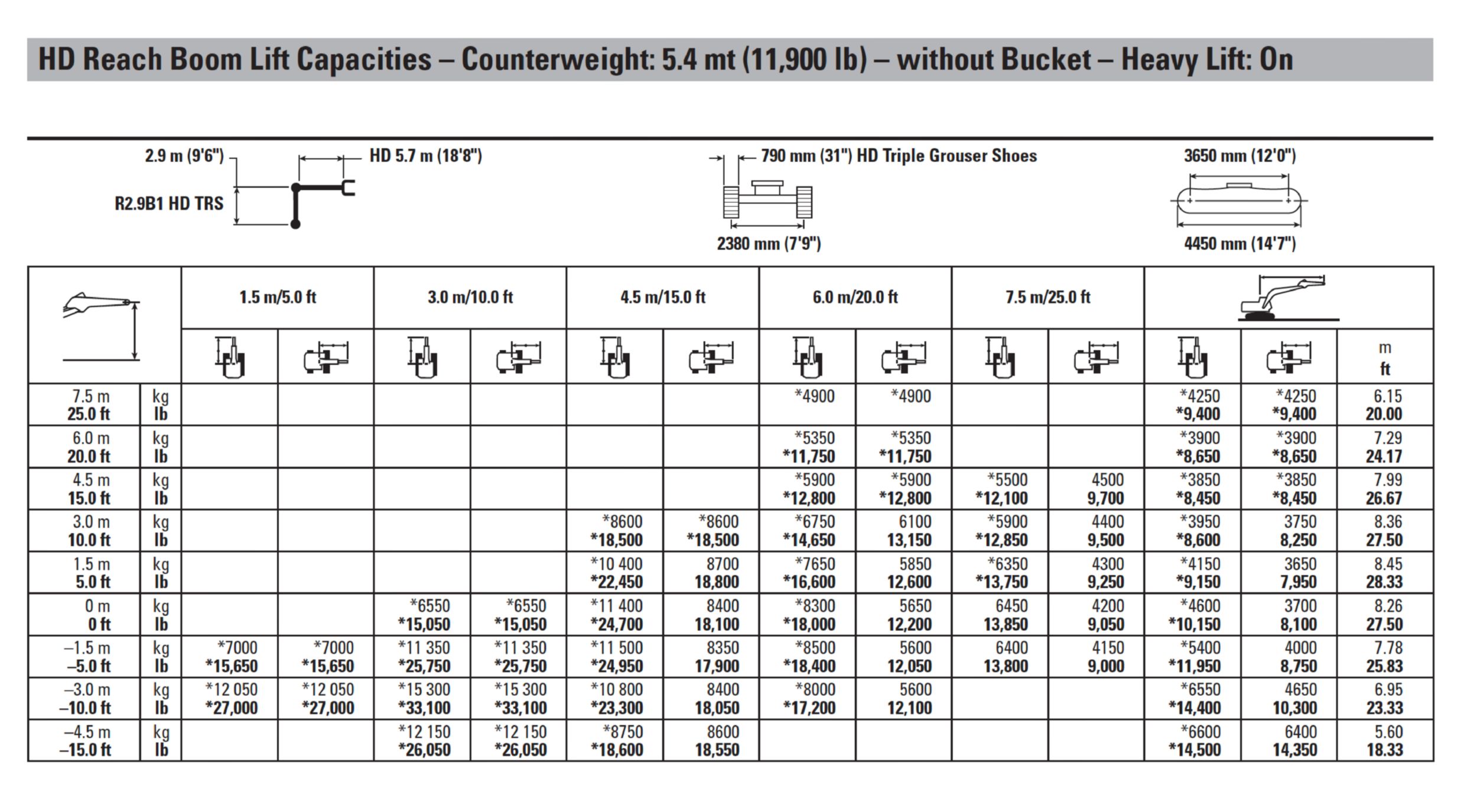

FINDING YOUR EXCAVATOR LIFT CAPACITY

I have a construction site nearby and will try to swing by it.

Offline

Like button can go here

#17 Yesterday 13:27:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

So where are we with what NASA has been working on.

For Mars, bulldozers are envisioned as lightweight, multi-rover systems (like NASA's 8-lb prototypes) or larger autonomous units (like RASSOR 2.0 at 66 kg) built from aluminum, leveraging Mars's 40% Earth gravity for reduced mass, potentially 5,000-6,000 lbs for a substantial vehicle, to excavate regolith for outposts and habitats, using smaller, coordinated units or powerful bucket drums for efficient, lower-power digging.

Key Concepts & Designs:

Small Swarms: NASA developed 8-pound bulldozer rovers that work in coordinated groups, sharing excavation tasks for better efficiency than one large machine.

Autonomous Excavators: Concepts like RASSOR 2.0 (66 kg) use bucket drums and autonomous controls for high-volume regolith mining (tons per day).

Materials: Lightweight materials like aluminum are preferred over steel to account for lower Martian gravity (about 38% of Earth's).

Mass Considerations: A hypothetical larger, more powerful bulldozer might weigh 5,000-6,000 lbs (2,268-2,721 kg) on Mars, with batteries being a significant factor.

Size & Mass Examples:

NASA Prototype (2001): ~8 pounds (3.6 kg).

RASSOR 2.0 (2016): 66 kg (~145 lbs).

Hypothetical Earth-Equivalent: A larger machine might weigh 5,000-6,000 lbs (2,268-2,721 kg) in Martian gravity.

Purpose:

Site Prep: Creating landing pads, roads, and trenches for utilities.

Habitat Construction: Excavating for buried habitats and radiation shielding.

Resource Extraction: Mining regolith for In-Situ Resource Utilization (ISRU)

This is for moon first and is not what will be needed for mars

Offline

Like button can go here

#18 Yesterday 13:39:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

For Mars, engineers are designing smaller, electric, autonomous mining vehicles like NASA's IPEx (bulldozer/dump truck) for lunar use, adaptable for Mars's low gravity, focusing on In-Situ Resource Utilization (ISRU) to build habitats from regolith (Martian soil). Concepts envision hybrid systems using small, nimble rovers with blades/buckets, powered by nuclear or solar energy, potentially building on Earth-based designs like modified excavators or even (conceptually) pressurized Cybertrucks, prioritizing efficiency and scalability over large, heavy Earth machinery.

Key Design Considerations for Mars Hauling:

Power: Diesel is out; electric motors powered by solar arrays or nuclear sources are essential.

Autonomy/Teleoperation: Vehicles will likely be self-driving or remotely operated to reduce risk to astronauts.

Size & Scale: Smaller, lighter, modular machines (like 1-5 ton excavators/dumpers) are favored for easier transport and maneuverability in low gravity, with redundancy built-in.

Functionality: Combine functions: a rover with a blade (grader/dozer) and a hopper (dump truck) for moving regolith to build roads or create radiation shielding.

Resource Utilization (ISRU): Moving regolith is key for creating "marscrete" and shielding habitats.Examples & Concepts:

NASA's IPEx: A robotic system for lunar soil mining, combining bulldozer and dump truck functions, a blueprint for Mars.

Airbus's "Interplanetary Dump Truck": A concept for bringing Mars rocks back to Earth, focusing on sample return.

Reddit/SpaceX Concepts: Discussions suggest small, electric, autonomous rovers with excavator/loader attachments, potentially leveraging mature Earth tech like small excavators or even modified Cybertrucks for pressurized transport.

In essence, think less "big rig" and more "fleet of smart, electric robotic work vehicles" suited for low gravity and self-sufficiency

Nasa ISRU Pilot Excavator

An "earth dump or hauling truck" refers to dump trucks, versatile vehicles that move loose materials like dirt, gravel, sand, and demolition waste for construction, site prep, and road building, with specific types like articulated dump trucks (ADTs) handling rough terrain and off-highway haul trucks moving massive loads in mines, all designed to efficiently transport and unload bulk materials.

Key Types & FunctionsStandard Dump Trucks: Common on roads, transporting typical construction aggregates and debris over short to medium distances.

Articulated Dump Trucks (ADTs): Feature a pivot point (articulation) between the tractor and the dump body, offering excellent maneuverability and off-road capability for rugged sites.

Off-Highway/Haul Trucks: Massive, heavy-duty vehicles used in mining and large construction projects for extremely long hauls and huge payloads, often exceeding standard road limits.

Side Dumps & Transfer Dumps: Specialized designs for faster unloading or handling specific materials like asphalt.

What They Haul

Dirt, sand, gravel, crushed stone

Asphalt, concrete

Demolition debris, construction waste

Sod, brush

Where They're Used

Construction site preparation and excavation

Road building and maintenance

Mining operations (haul trucks)

Landscaping and site grading

In essence, any truck moving earth, sand, gravel, or similar bulk materials on or off-site for construction or demolition falls under the category of an earth dump or hauling truck, with the specific type chosen for the job's terrain and load size

Types of Dump Trucks and Their Applications in the Construction Industry

Offline

Like button can go here

#19 Yesterday 13:45:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,107

Re: This title has no meaning 1

Rock crushing equipment for Mars focuses on small, robust systems like NASA's SPADE (Sample Processing And Distribution Experiment), using jaw crusher designs or hybrid piston/attrition mills to access unweathered interiors for analysis, preparing fine powders for instruments like CheMin, with key features being durability, minimal consumables, and ability to produce fine, instrument-ready material. These systems, often integrated into rovers, aim to overcome Martian dust and weathering to study geology and potential past life.

Key Technologies & Concepts

SPADE (Sample Processing and Distribution Experiment): A NASA system integrating a jaw-crusher-based rock crusher with a sample sorting and distribution wheel to feed instruments, designed for rover use.