New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Yesterday 09:09:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

I was reminded by Void while doing the daily recap of Boring on Mars.

Topic Drill Technology - Microwave - Traditional - Others

Of course we are talking Industrial development on Mars from landing,toehold, foothold and settlement to full blown colonization.

We need all types of equipment to dig into mars literally so as to make hospitable spaces for man to survive in and with in for a variety of reasons.

Also needed will be ore processing and brick making plus more to build on Mars.

Scientists and engineers have proposed several methods and "equipment" concepts for making bricks on Mars using local resources (in-situ resource utilization), primarily Martian regolith (soil). A key discovery is that simple compression, without binders or heat, can create bricks stronger than steel-reinforced concrete.

Proposed Equipment and Methods

Since transporting all construction materials from Earth would be prohibitively expensive, research focuses on using the iron oxide-rich Martian soil itself.

High-Pressure Mechanical Press/Hammer:

The most promising method uses sheer pressure. Researchers at UC San Diego accidentally discovered that by enclosing Mars simulant in a flexible container (like a rubber tube) and applying high pressure, they could form solid, strong pellets which can be cut into brick shapes. The necessary "equipment" could be a robotic, high-pressure compacting device or even a simple hammering mechanism operated by future astronauts.3D Printing Systems:

This is a major focus of ongoing research.

Regolith melting: One idea involves melting the regolith with lasers or focused solar energy and pouring it into molds, though this requires significant energy.

Binder extrusion:

Regolith could be mixed with a binder (polymer or even human-derived materials like blood plasma protein or urea) and extruded through a 3D printer to build structures autonomously.

Kilns/Furnaces:

Early proposals suggested using a nuclear-powered or solar furnace to bake the bricks, similar to ancient Earth methods. This method would require a significant power source and complex equipment to capture any released water for reuse.The equipment needed to create hot sulfur regolith bricks for Martian in-situ buildings involves machinery for excavation, processing, mixing, heating, and molding the materials. A 1200°C kiln is used for sintering processes with other potential binders, but for sulfur concrete, the required temperature is much lower (around 120°C to melt the sulfur).

Materials Acquisition & Processing

Excavation and Sifting Equipment:

Robotic excavators or rovers with digging mechanisms to collect the Martian regolith. Sifting or refining machinery may be needed to achieve the optimal particle size distribution for the aggregate.

Sulfur Extraction and Refining Unit:

A chemical processing plant to extract elemental sulfur from Martian sources (sulfides/sulfates), likely involving high-temperature oxidation and reduction processes.

Storage Tanks/Hoppers:

Secure storage for both the raw regolith powder and the extracted, refined sulfur (solid and liquid).Brick Production & Molding

Heated Mixer (e.g., Pugmill or Drum Mixer): An industrial mixer capable of hot-mixing the dry regolith aggregate with molten sulfur (liquid at ~120°C). The mixer must have robust seals to handle the abrasive dust and potentially a controlled atmosphere (CO₂-rich).Heating System/Kiln:

While a 1200°C kiln is used for other methods like sintering, sulfur bricks only need a melting temperature of around 120°C. This heating could be powered by a solar furnace or a nuclear reactor's waste heat. The system needs precise temperature control to prevent boiling and ensure uniform heating.Molding/Casting System:

Molds (potentially made from 3D printed durable thermoplastics like PEEK or metal) or a robotic extrusion system (like a 3D printer) to form the liquid mixture into desired brick shapes.

Curing Area:

A controlled environment where the bricks can cool and solidify (harden through physical crystallization, not hydration).

Power Supply:

A robust, reliable power source (e.g., solar panels with battery storage or a fission reactor) capable of powering all machinery autonomously.Ancillary and Support Equipment

Autonomous Robotic Systems:

The entire process is envisioned to be highly automated due to limited human labor on Mars.

Dust Mitigation Systems:

Given the pervasive, fine nature of regolith dust, equipment must incorporate advanced seals and filtration to prevent damage and contamination.

Quality Control and Testing Apparatus:

Equipment to test the compressive and flexural strength of the final bricks to ensure they meet structural requirements.

Thermal Management Systems:

Equipment to manage the significant temperature variations and maintain consistent operating temperaturesBiomaterial Production Systems: Emerging research involves using synthetic biology, like engineered lichens or bacteria, to create a self-growing, concrete-like material from the Martian soil. This would require specialized bioreactor equipment and the necessary organic inputs.

Key Advantage

The simple, no-bake, no-binder method using a mechanical press is a leading candidate because it requires the least amount of complex machinery, energy, and additional materials transported from Earth, making it highly practical for initial manned missions

Offline

Like button can go here

#2 Yesterday 09:11:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Re: Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

While no operational 3 m diameter TBM specifically for Mars currently exists, the development of such equipment is a key concept in proposed strategies for establishing a Martian colony.

Current Status of Mars Tunneling Equipment

Conceptual Stage:

Current discussions revolve around the concept of using tunneling technology for Mars habitats, providing protection from cosmic radiation and micrometeorites, and leveraging the thermal stability of the subsurface.

Earth-based Prototypes:

Companies like The Boring Company (TBC) are developing advanced, all-electric Tunnel Boring Machines (TBMs) for Earth-based projects (e.g., the Prufrock series, which creates a tunnel approximately 3.7m/12ft in diameter).Technology Transfer:

While TBC's current machines are unlikely to be deployed on Mars without significant modification, the technology and engineering experience gained (such as automation and faster boring speeds) are seen as foundational for developing future off-world systems.

Prototype Drills:

Research has been conducted on smaller-scale "3-meter-class Mars drill prototypes" for scientific exploration of the shallow subsurface, but these are for drilling, not large-scale tunneling for habitats.

Transportability:

A 3m-class TBM (or its segments) is considered potentially transportable by a SpaceX Starship, which has an 8m diameter cargo bay.Key Challenges for Martian TBMs

Atmosphere:

Earth TBMs use significant amounts of water for cooling and other operations, which would be a major challenge in Mars's cold, near-vacuum atmosphere.Automation:

Due to communication delays and the need for efficient pre-human construction, Martian equipment would require a high degree of automation and robotic operation.Geology & Materials:

The machines would need to be adapted to Mars's unique rock and soil conditions. Also, instead of concrete segments (which are heavy to transport), innovative methods like sintering the excavated rock or using local materials for tunnel lining would be necessary.In short, 3 m diameter equipment for Mars is an active area of conceptual development and technological aspiration, leveraging Earth-based innovations, but is not yet a developed or deployed product.

Elon Musk's Boring Company develops advanced tunnel boring machines (TBMs), like the Prufrock series, with the long-term goal of enabling underground Martian cities for radiation protection, resource extraction (ice/metals), and efficient habitat construction, potentially using Starship for transport, with Earth projects providing crucial tech and operational experience for Mars colonization needs. The technology focuses on rapid, automated tunneling, which is vital for establishing self-sufficient subterranean life on Mars, where surface conditions are harsh.

How Boring Company Tech Applies to Mars:

Radiation Shielding:

Mars' surface lacks atmosphere, exposing settlers to lethal radiation; burying habitats under Martian rock provides natural shielding.

Resource Utilization:

TBMs can excavate for essential water ice and minerals, crucial for life support and fuel.

Rapid Infrastructure:

High-speed, automated digging allows for quick creation of tunnels for transport (like Hyperloop) and pressurized living spaces, reducing human exposure to dangerous conditions.

Autonomous Operations:

Earth-based experience with "no prior site prep" TBMs (like Prufrock) prepares for robotic deployment on Mars for automated base building.Key Technologies & Challenges:

Prufrock TBMs:

Designed for rapid, continuous excavation, with capabilities to start digging immediately, a major leap from traditional methods.SpaceX Integration:

While Starship can carry heavy payloads, transporting massive TBMs (like 1,200-ton machines) poses a challenge, requiring multiple launches or lighter designs.

Atmospheric Advantage:

Mars' thin atmosphere makes underground Hyperloop tunnels ideal, as an artificial vacuum isn't needed.The Vision:

The Boring Company's work on Earth, including rapid tunneling for tunnels and loops, serves as a practical testbed for the advanced, automated digging needed for large-scale Martian settlements, fulfilling Musk's vision for a multi-planetary humanity.

Offline

Like button can go here

#3 Yesterday 09:13:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Re: Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

Oldfart1939 wrote:I did a bit of research on the Bobcat website last night, and perhaps we should include 2 excavators (tracked backhoes). They're heavier and more bulky than the front loader Bobcat skid-steer units, but these would allow excavation of habitat shelter trenches more rapidly and effectively than front-loader units.

I see you're doing construction. Not just the first exploration/science mission, but construction. The Mars Homestead project assumed 12 crew to construct the first permanent human base. Yes, we believed a construction vehicle was required. I would like to make a suggestion.

This is a typical Bobcat skid-steer loader. There are various sizes. This one is S450. ("S" for skid) Rated Operating Capacity: 1,370lb. Operating weight: 5,370lb

The thing that makes it "skid-steer" is it's wheels. It's wheels don't turn, to steer the vehicle you turn the wheels on one side while wheels on the other do not turn. Or to pivot in place, turn wheels on the other side backward. This means the wheels literally "skid" across the ground as it's steering. Be advised: operating this on grass will tear up the grass. This works very well on pavement or hard or very firm ground. It doesn't work so well on loose soil/dirt/sand/gravel at an incline.This is a typical Bobcat compact track loader. This one is T450. ("T" for track) ROC: 1,490lb. Operating weight: 6,424lb

Track vehicles work better on loose ground and inclines. The track provides more traction. I'm suggesting a compact track loader would be more appropriate for Mars.An excavator can be compact. The first is E10, Rated Lift Capacity 527lb, Operating weight 2,593lb. The second is E20, RLC 1,098lb, Operating weight 4,306lb.

https://assets.bobcat.com/excavators/misc/r-series/bobcat-e10-nav_pm_list.jpgBobcat has become known for compact construction vehicles. Other brands manufacture competing vehicles: John Deere, Case, Caterpillar, New Holland, others.

Heavy Equipment Guide: Companies by Skid-Steer LoadersAny vehicle would have to be customized for Mars. One suggestion I made was to manufacture the vehicle with titanium alloy instead of steel. Titanium has the same weight (mass), but greater strength. That allows making structural members like arms to lift the bucket thinner, so lighter. Hydraulics will have to be adjusted for extreme cold of Mars. And the engine can't breathe air, Mars has no oxygen. Well, practically none; not enough for combustion. When Robert Zubrin and David Baker proposed Mars Direct in 1990, they suggested using methane/oxygen because the ERV would need that for propellant anyway. Just make a bit more for the rover. But rather than using electricity to run ISPP, you could just operate the vehicle with electricity. At least one company specializes in electric conversion of Bobcat vehicles. And Bobcat themselves is working on all electric vehicles using lithium-ion batteries. They're even working on all electric actuators instead of hydraulics; intended for cold climates like Alaska.

Some of the equipment to be sent to mars

Offline

Like button can go here

#4 Yesterday 09:34:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Re: Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

https://newmars.com/forums/viewtopic.ph … 14#p155614

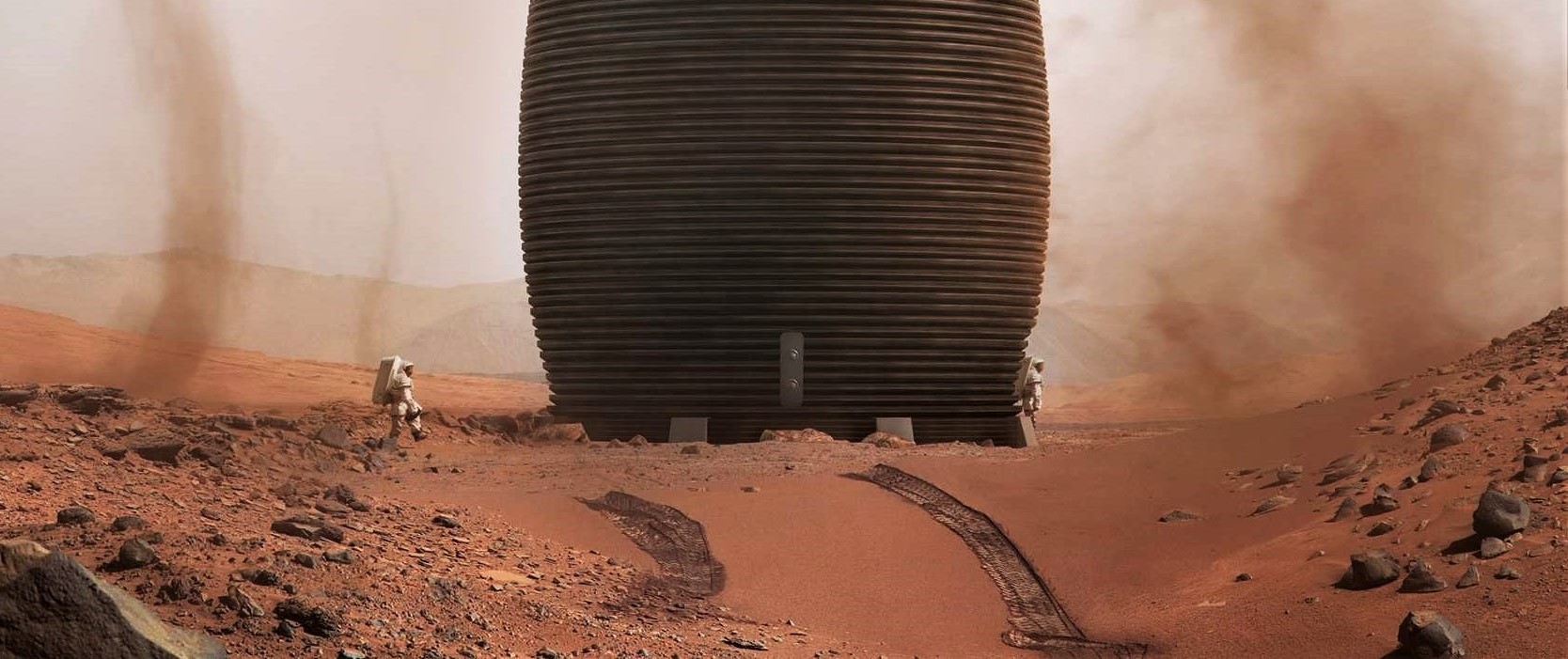

MARSHA:

Teslarati 3D-Printed Mars Habitat could be a perfect for early spaxeX starship colonies, MARSHA

I do https://www.teslarati.com/3d-printed-ma … -colonies/

Thanks for the link to others wanting to print habitats on mars or other places but what they do not go into is the prep side of the equation needed to make the materials to be use for the machinery to utilize it to build with from the insitu resources.

Very cone like indeed...

This is from AI SpaceFactory achieved second place in the latest phase of a NASA-led competition

If I do find the other simular posts I will copy them here so that we will have a list of whom are attempting the technology, the equipment and the materials information of what is targeted for insitu materials.

3D-printed Mars habitat a biorenewable plastic (PLA) reinforced with locally-sourced basalt fiber – also accounts for many of Mars’ shortcomings, as plastics happen to be some of the best materials for radiation shielding per unit of mass. Featuring a duo of PLA shells placing a meter or more of plastic between living areas, MARSHA would permit relatively acceptable radiation levels while avoiding the downsides of locating habitats underground or burying them under several meters of Martian regolith.

NASA's Centennial Challenges: 3-D Printed Habitat Challenge

https://www.nasa.gov/directorates/space … index.html

3D-Printed Habitat Challenge. NASA and its partners are holding a $3.15 million competition to build a 3D printed habitat for deep space exploration, including the agency’s journey to Mars. The multi-phase challenge is designed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond.

https://www.nasa.gov/directorates/space … mpetition/

After two stages where NASA awarded a total of over $1 million to competitors, the final prize was awarded to the top 5 projects.

Something that I would suggest is dropping a unit in one of the analog areas and run the insitu use processes from scratch to see just how hard it is to prepare the raw materials to make it ready for use for the equipment. Measure and test all aspects of it so that we can have better control to what we might find from the earth use.

https://www.3dprintingmedia.network/top … mpetition/

Team Zopherus of Rogers, Arkansas – $20,957.95

AI. SpaceFactory of New York – $20,957.24

Kahn-Yates of Jackson, Mississippi – $20,622.74

SEArch+/Apis Cor of New York – $19,580.97

Northwestern University of Evanston, Illinois – $17,881.10

These are beautiful for sure

A very firmiliar designed floor layout

Offline

Like button can go here

#5 Yesterday 17:14:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Re: Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

open pit seems to be the easiest to gather ore.

The equipment needed to make hot sulfur regolith bricks for Mars in-situ buildings involves machinery for excavation, material processing, heating/mixing, and automated construction, likely in the form of a robotic 3D printing system.

The key equipment can be categorized by function:

Raw Material Acquisition and Processing

Excavation Rovers/Machinery:

Automated diggers or rovers designed for low-gravity and remote operation to mine the Martian regolith (soil) and extract sulfur from sulfates and sulfides.

Crushing and Milling Equipment: Machines to break down the excavated regolith and sulfur compounds into a uniform aggregate size suitable for mixing and extrusion.

Chemical Processing Unit:

Equipment, possibly including a thermochemical or electrochemical processing system (like a solid oxide electrolysis cell), to refine the sulfur compounds into elemental sulfur, which is the required binder material.

Sieving/Separation Systems:

Mechanisms to ensure the proper particle size distribution of the regolith aggregate, as optimized mixtures can achieve higher compressive strengths.Brick Production and Construction

Storage and Feeding System:

Hoppers or containers to store the processed regolith and elemental sulfur and feed them at a precise, pre-designed weight ratio (around 65% aggregate to 35% sulfur is a common ratio) into the mixing apparatus.

Heated Mixer/Extruder:

A core component that heats the mixture to above sulfur's melting point (around 120°C) to liquefy the sulfur, uniformly mixes it with the regolith aggregate, and then extrudes the hot, molten sulfur concrete.

This system requires closed-loop heating control and monitoring systems to maintain precise temperature levels.

3D Printing System (Gantry or Robotic Arm):

An automated construction system that receives the hot mixture from the extruder and precisely deposits it in specific forms (layers) to build walls or structures directly on site.

Power Systems:

A robust, reliable power source is essential to run all the machinery, particularly the energy-intensive heating and processing units. This would likely involve solar panels and energy storage systems.Ancillary Equipment

Robotic Control Systems:

The entire operation is envisioned to be largely autonomous, requiring advanced robotic control and monitoring systems due to the communication lag with Earth and the need for reliable, continuous operation in a harsh environment.

Testing Apparatus:

Equipment to perform quality control tests on the finished material, such as compression and flexural strength testers, to ensure structural integrity.

Thermal Management Systems:

Equipment to manage heat and prevent issues like sulfur sublimation in a vacuum or under large temperature swings

Offline

Like button can go here

#6 Yesterday 17:23:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,861

Re: Boring plus Drilling tech, 3D printing insitu and Tunneling equipment

To move 10 cubic meters of Mars regolith, you would need a tandem axle dump truck or a medium-to-large single-axle dump truck. A standard commercial tandem axle dump truck typically holds between 7.6 to 10.7 cubic meters (10 to 14 cubic yards) of material, making it a suitable option for exactly 10 cubic meters.

Dump Truck Options for 10 Cubic Meters

Medium Dump Truck (Single Axle):

These can hold a load volume of 3 to 6 cubic meters, so you would likely need two trips, or a very large single-axle model near its upper limit.Tandem Axle Dump Truck:

This is the most efficient option, as its typical capacity of 7.6 to 10.7 cubic meters can handle the entire volume in a single load. Some models can even handle up to 13 to 20 cubic meters.

Large Dump Truck (Tri-Axle/Super Dump): These trucks have capacities ranging from 13 to over 25 cubic meters, which would easily manage the load, though the truck might not be operating at full volumetric capacity.

Important ConsiderationsWeight vs. Volume:

The weight of the regolith (Martian soil) is a critical factor, even more so than volume. The density of material matters in determining the actual safe load capacity to avoid overloading the truck's weight limits.Martian Gravity:

The user's prompt specifies "Mars regolith," which implies an off-world scenario. The lower gravity on Mars (roughly 38% of Earth's gravity) would significantly alter the weight constraints and potentially allow a standard Earth-rated dump truck to carry a larger mass of material than it could on Earth, assuming the engineering for the martian environment is addressed.Equipment Specialization:

For actual off-world operations, the equipment would be specifically designed for the Martian environment, likely featuring wider cutting heads or different axle configurations to handle the unique terrain and gravity conditions.

How Many Cubic Yards Are in a Dump Truck?

Larger dump trucks can carry approximately 10 to 16 cubic yards of material. However, the total volume is not usually the limiting factor. In most cases, the vehicle’s weight limit will determine how much material you are ultimately able to safely transport.

So a dump truck that we could use is

A tri-axle dump truck typically weighs between 25,000 and 35,000 pounds when empty, but can weigh up to 80,000 pounds when fully loaded, depending on the load and local regulations. The specific weight varies based on the materials used to construct the truck (e.g., aluminum bodies are lighter than steel), the size and type of the dump body, and the weight of the fuel and driver

Offline

Like button can go here