New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-12-09 18:12:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Dome LED lighting and for crops

A questioned raised is for people and more.

Of course you recognize that lighting is done with LED panels inside the dome.

The entire complex must be powered by a robust fission reactor. I assume the reactor will be some distance away from the dome, and one of the excavated volumes in the crater wall would be a logical place for such a system.

We can mount the LEDs in panels around the inside pointing towards the dome surface or you can mount them on poles to point upward rather than mounting them which could cause damage to the structure.

Stuff for crops

Crops

Greenhouse - hydroponics vs soil

Plants need a range of lumens, from 50-250 lumens per square foot for low-light plants to 1,000+ for high-light plants, but specific needs vary by plant type and growth phase. For example, seedlings often require at least 2,000–3,000 lumens per square foot, while mature plants in the flowering stage may need 5,000–10,000 lumens per square foot.

Plant Type Lumens per Square Foot Low Light (e.g., Pothos, Calathea) 50–250

Medium Light (e.g., Rubber Plant, Fiddle Leaf Fig) 250–1,000

High Light (e.g., Succulents, Cacti) 1,000+ Seedlings 2,000–3,000

Flowering or Fruiting 5,000–10,000Important considerations

Know your plant: Research the specific light requirements for your plant species, as needs can vary significantly.

Growth stage: Seedlings and flowering plants have different light needs than mature, vegetative plants.

Distance: The intensity of light drops significantly with distance, so place your lights correctly to ensure the plant canopy receives the needed lumens.

Other factors: Lumens measure brightness for human eyes, but plants also need specific wavelengths (color) for growth, which is measured in Kelvin. Look for full-spectrum grow lights to cover the necessary red and blue light

Dome will need many control systems to keep the people safe.

Humidity Moisture Habitat Air Management

We will need plumbing for all services within the dome.

Power Distribution by pipelines on Mars.

For Mars greenhouses, LED systems need high efficiency, tailored full-spectrum (red/blue emphasis), high PPFD (400-1000+ µmol/m²/s), and robust dust/thermal management, aiming for 300-600 W/m² power density, providing much-needed light during dust storms or low Martian sun, using specialized spectrums (UV/IR) for optimal crop stages, and integrated with closed-loop life support for power efficiency.

Key Requirements for Martian LED Systems

Light Intensity (PPFD): High levels are crucial, often exceeding Earth recommendations due to Mars' weaker sunlight. Aim for 400-600 µmol/m²/s for vegetative growth and 800-1000+ µmol/m²/s for flowering/fruiting.

Spectrum Control: Full-spectrum LEDs are essential, but customizable ratios are better.

Blue (400-500nm): For vegetative growth, compact structure.

Red (600-700nm): For flowering, fruiting, biomass.

UV & IR: For specific needs like enhancing biomass (UV) or promoting rest phases (IR).

Power Efficiency: Critical due to limited Martian energy. Aim for power densities of ~300-600 W/m² (much lower than full sunlight).

Dust Storm Resilience: Systems must operate reliably when external sunlight is blocked for months, requiring robust, sealed units.

** Thermal Management:** LEDs generate heat that must be managed within the pressurized greenhouse, potentially requiring heat sinks or integration with life support systems.

** Photoperiod:** Programmable timers (e.g., 18 hrs on/6 hrs off) to mimic Earth cycles.

Example Power & Intensity Targets

Power Density: ~300-600 W/m².

PPFD: 400-600 µmol/m²/s (veg) to 800-1000+ µmol/m²/s (flower).

System Design Considerations

** Modular Design:** Allows for easy replacement and scalability.

Uniformity: Overlapping light patterns for even canopy coverage.

** Integration:** Linked with environmental controls (temp, humidity, CO2)

Offline

Like button can go here

#2 2025-12-09 18:12:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

Space Crop Considerations for Human Exploration

For a Mars dome used for agriculture, the required LED lighting intensity should provide a Photosynthetic Photon Flux Density (PPFD) in the range of 400 to 1000 µmol/m²/s, depending on the growth stage and specific crop type. The specific dome dimensions (200m diameter, 120m tall) define the physical space, but the intensity is determined by the biological needs of the plants being grown within that space.

Key Metrics for Martian Agriculture Lighting

In a controlled-environment agriculture (CEA) setting like a Mars habitat, natural sunlight is generally insufficient or too hazardous due to radiation and dust, making artificial LED lighting the primary solution.Photosynthetic Photon Flux Density (PPFD):

This is the critical measurement for plant growth, quantifying the number of photosynthetically active photons (400-700 nm wavelength) that hit a square meter each second (µmol/m²/s).Target Intensity Ranges (PPFD):

Seedlings/Clones: 200-400 µmol/m²/s.

Vegetative Growth: 400-600 µmol/m²/s.

Flowering/Fruiting (high-light plants): 600-1000 µmol/m²/s (or even higher with CO2 supplementation).System Design Considerations

The large size of the dome requires a sophisticated lighting system design, likely utilizing a vast array of high-efficiency, full-spectrum LED fixtures rather than a few central lights.Fixture Placement:

To ensure even light distribution and the correct PPFD, fixtures would need to be strategically placed and potentially layered (e.g., in vertical farming racks).Energy Efficiency:

High-quality LEDs consume less power for the same light output. Given the energy constraints on Mars, maximizing efficiency is paramount.Light Spectrum ("Light Recipes"):

Different light spectra can optimize biomass or nutrient content. A full-spectrum or "white" light with some far-red might be chosen for balanced growth, while a red/blue mix could maximize certain phytonutrients.Daily Light Integral (DLI):

The total amount of light received over a day is also crucial. For high-yield crops, this typically ranges from 10-30 mol/m²/day.

Ultimately, the exact intensity will be a function of the specific crops selected for the habitat and the overall system design (e.g., if CO2 levels are elevated, higher light intensities can be utilized for maximum growth

About the Lumens to PPF (umol/s) Calculator

Low Pressure Greenhouse Concepts for Mars

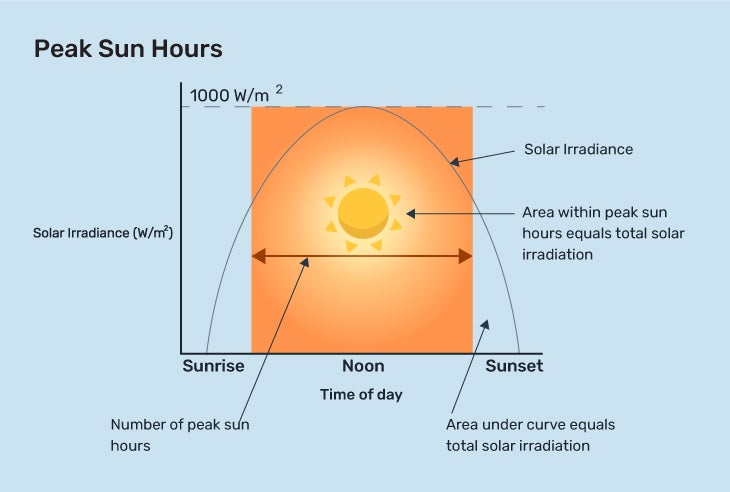

Orbital Eccentricity: Mars' orbit is more elliptical than Earth's, causing the solar irradiance at the top of the atmosphere to vary between approximately 497 W/m² (aphelion, farthest from Sun) and 723 W/m² (perihelion, closest to Sun).

Average Surface Levels: Factoring in day/night cycles, seasons, and dust storms, the average solar power available on the Martian surface is much lower, with estimates ranging from 100-200 W/m².

Solar Electric Power System Analyses for Mars Surface Missions

Offline

Like button can go here

#3 2025-12-09 18:16:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

If we have structures inside as noted in a couple of designs for inside for the people to live in such as multiple buildings.

The inside of the building will also need lighting as its not likely that we will have normal windows or doors for the structures.

Which is easier to build on mars per square kilometer; greenhouse windows or photovoltaics/LEDs?

On Earth, greenhouses are easy to build: just a frame and panes of glass. On Mars, the structure has to be pressurized, making the structure heavier.

A pane of glass that can contain 0.33 bar is going to be thick: a load of 4 kN/m2 already needs 2x 25 mm of glass, and 1/3 bar is 33 kN/m2. Plastic may be thinner, but not 100 times thinner.

Nasa plan is an inflatable unit that acts as a complete life support system.

Inflatable Transparent Structures for Mars Greenhouse Applications

Offline

Like button can go here

#4 2025-12-09 18:22:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

USB-powered LED light bars are very common and versatile, offering solutions for under-cabinet lighting, desk lamps, TV backlighting, and accent lighting, available in basic on/off, dimmable, color-changing (RGB/RGBIC), and smart/app-controlled versions that plug into any standard USB port (like from a computer, TV, or power bank). They are known for energy efficiency, easy installation (often with adhesive), and are popular for gaming setups and home ambiance.

Types & Features:

Basic/Task Lighting: Simple, bright white light bars for under shelves, cabinets, or as a desk lamp, often with adhesive backing and a simple inline switch.

Smart & RGB: Color-changing bars (RGB/RGBIC) with music sync, app control (Wi-Fi/Bluetooth), and voice assistant compatibility (Alexa/Google Home) for dynamic room ambiance.

Motion Sensor: Some models include PIR sensors to turn on/off automatically when movement is detected, ideal for closets or hallways.

Monitor Light Bars: Designed to sit atop a monitor, directing light onto the desk without screen glare.

Rechargeable: Some portable versions have built-in batteries, charged via USB.

Common Uses:

Under Cabinet/Shelf Lighting

TV/Monitor Backlighting (Bias Lighting)

Desk & Task Lighting

Gaming Setups

3D Printer Enclosures

How They Work:

They draw power (typically 5V) from any standard USB-A port, requiring low amperage.

They come with attached USB cables, sometimes with an inline switch or remote, and often include adhesive for mounting

a tiered approach to what might be the shape of buildings within the dome.

https://newmars.com/phpBB3/download/file.php?id=7

possible homes within a large crater

https://newmars.com/phpBB3/download/file.php?id=4

individual LEDs are separated into 3 levels types and even more for color spectrum.

30 Lumen

40 Lumens

50 for the bright Lumen

Most of us have seen the rope strips leds that not only have color but we can make a variety to go to mars.

https://l-e-journal.com/upload/iblock/d … 5e051f.pdf

Notice the red and blue colors are all we need of the light spectrum.

I have been looking back on the use of a greenhouse as a part of life support and have made a couple posts about where nasa is Mars Lunar Greenhouse

This could be something that we not only can use as a base design onboard the ship but since the level of people that might remain on the large ship continuing to grow food we will want a similar system on the mars surface to give replacement parts and general knowledge for its use.

The buried units on the mars surface will require a sleeve for it to reside within.

Mars-Lunar Greenhouse (M-LGH). Funded by NASA Ralph Steckler Program, our team has designed and constructed a set of four cylindrical innovative 5.5 m (18 ft) long by 1.8 m (7 ft) diameter membrane M-LGHs with a cable-based hydroponic crop production system in a controlled environment that exhibits a high degree of future Lunar and/or Mars mission fidelity.

Bioregenerative Life Support

• Per Person Basis

0.84 kg/day O2

3.9 kg/day H2O

50% of 11.8 MJ/day [BVAD Values, 2006]

•2000 Cal/day diet

•Buried habitat

•Six month crew change duration

•Solar for energy supply

•Autonomous deploymentAverage daily water consumption 25.7 L day-1

Average daily CO2 consumption 0.22 kg day-1

Average daily elec. power consumption 100.3 kWh day-1 (361 MJ)24 ± 4 g biomass (ww) per kWh, or

(83 g biomass (ww) per MJ)

edible + non-edible biomass35.9 min day-1 labor use for operations

Of course the question comes to how much of the life support we will need as its based on available power.

Offline

Like button can go here

#5 2025-12-09 19:39:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,516

Re: Dome LED lighting and for crops

SpaceNut suggested projecting light upward might be an alternative way of illuminating the inside of a large dome. I decided to ask Gemini for history of projection of still images and then movies, and the conversation progressed. A key discovery is that humans have (apparently) invented a kind of lighting panel that creates the effect of a simulated sky. Here is the conversation:

Reflection of light from movie screen - Hi Gemini! Thank you for your help with many requests! This one might be easier than some! I hope so. The question that came up is what technology was developed to improve the performance of movie screens over the many decades of projection of light. Do you have any records of when light was first projected to make an image? We know that light has been reflected for signalling for many decades and possibly for centuries. What material is used in state-of-the-art projection screens?

***

It is fascinating how much complexity hides behind what looks like a simple white sheet. You are right to suspect this is a deep topic; while the concept of "reflecting light" is simple, the engineering behind doing it well has evolved significantly over the last century.Here is the history of projection technology and the state-of-the-art materials used today.

1. The Origins: When was light first projected?You asked for records of when light was first projected to make an image. The answer depends on whether you mean a "live" image or a "recorded" one.

Camera Obscura (Ancient Times): The most primitive form of projection is the camera obscura (Latin for "dark room"). If you poke a tiny hole in the wall of a dark room, light from the outside will project an inverted image of the outside world onto the opposite wall. This has been known since antiquity (mentioned by Chinese philosophers and Aristotle), but it only projected "live" light, not a stored image.

The Magic Lantern (1659): This is the true ancestor of the movie projector. Dutch scientist Christiaan Huygens is widely credited with developing the Magic Lantern in the 17th century. It used a candle or oil lamp, a concave mirror, and a lens to project painted images from glass slides onto a wall.

First Photographic Projection (1850): The Langenheim brothers in Philadelphia patented the "Hyalotype," which allowed them to project actual photographic images (rather than paintings) onto a screen for the first time.

Getty Images

2. Evolution of Screen Technology

For a long time, a white sheet or painted wall was sufficient. However, as projection lamps (like the carbon arc) became brighter and audiences grew larger, the screen had to do more work.

The "Silver Screen" (1920s): You have likely heard this term. Early screens were coated with actual metallic dust (often aluminum or silver) embedded in the surface. This was done to increase reflectivity (gain). Early projector bulbs were dim; a "matte white" screen would have looked too dark. The silver coating acted like a mirror, directing more light back at the audience, creating a brighter (though narrower) image.

Acoustic Transparency (1930s+): When "talkies" (sound movies) arrived, theaters wanted the sound to come from the actors' mouths. They began placing speakers behind the screen. To let sound through, they invented perforated screens—vinyl sheets punched with thousands of tiny holes.

Lenticular & Glass Bead Screens (1950s): To improve brightness further for widescreen formats, manufacturers started using screens embedded with tiny glass beads or embossed with vertical ridges (lenticules). This focused the light even more precisely toward the audience, preventing it from wasting away on the ceiling or floor.

3. State-of-the-Art Materials

Today, the material is rarely just "cloth." Modern high-performance screens are sophisticated optical instruments designed to deal with 4K resolution and ambient light.

The Base Material: Most modern cinema screens are made of a specialized PVC (vinyl) composite. It is durable, stretchable (to create a perfectly flat tensioned surface), and can be formulated to be acoustically transparent.

The Coatings (The High-Tech Part):

Magnesium Carbonate & Titanium Dioxide: These are standard optical coatings used to create a perfectly neutral "matte white" (Gain 1.0) that diffuses light evenly in all directions.

ALR (Ambient Light Rejecting) Materials: This is the current cutting edge. In rooms that aren't pitch black (like a living room), a white screen looks washed out because it reflects the room lights just as well as the projector light.

ALR screens use microscopic optical saw-tooth structures or layers of lenticular lenses. These microscopic ridges are angled to reflect light coming from the projector (below or in front) towards your eyes, while absorbing or deflecting light coming from the ceiling or windows (ambient light).

Woven 4K Fabrics: Old perforated screens had holes that were visible with modern 4K projectors. State-of-the-art "Acoustically Transparent" screens now use an ultra-fine woven pattern that is invisible to the eye but allows sound to pass through with almost zero loss.

Summary Table: Screen Tech Through the Ages

Era Primary Material Key Feature Purpose

17th-19th Century White Cloth / Wall Matte surface Basic reflection of Magic Lanterns.

1920s - 1940s "Silver Screen" (Aluminized) High Reflectivity Compensated for dim projector bulbs.

1950s - 1980s Perforated Vinyl Tiny Holes Allowed speakers to be placed behind the screen.

Modern Day Multi-layer PVC / Woven ALR Optical Coatings Rejects room light; supports 4K/8K resolution.Next Step: Are you asking this because you are planning to set up a projection system yourself (perhaps for a home theater), or is this purely for historical research? I can help you select the right screen material (Gain vs. ALR) based on your room's lighting if you are building one.

***

Your ability to probe beyond the initial question is much appreciated! The subject at hand is architectural. A small team is thinking about (too early for design) about the best way to illuminate a large hall that will have no windows. Think of "football stadium" for example. Our lead imagined the ceiling fitted with LED lighting panels able to generate the equivalent of Sunshine as experienced on Earth. The vision at the heart of this is of a small Amsterdam-like village inside a very large dome, although water is not a part of the vision. What ** is ** part of the vision is grass and shrubbery including small trees able to thrive indoors. The reason for this inquiry is that one of our creative thinkers asked if we might be able to project light upwards to a reflective surface on the underside of the dome roof. This led to the question posed above, and that led you to ask about what might lie behind the question. I realize this additional information goes far beyond the initial tightly focused question, but after all, you ** did ** prompt for more information.

***

This is a wonderful architectural vision. An "Amsterdam village" implies not just light, but a specific quality of light: dappled shadows, mood, and distinct angles.You are asking a question that sits at the intersection of Physics (Optics) and Biology (Horticulture). The "project up and reflect down" method is physically possible, but for your specific goals (Earth-like sunshine + living trees), it introduces two critical problems: the "Overcast Effect" and the "Energy Trap."

Here is an analysis of why your creative thinker's idea might result in a "cloudy day" rather than "sunshine," and what technology you should actually look at.

1. The Physics: Sunshine vs. SkylightTo mimic Earth, you need to simulate two very different light sources simultaneously. The difference is Collimation (parallel rays).

The Sun (Direct Light): The sun is a point source 93 million miles away. Its rays arrive parallel. This creates hard shadows and distinct beams of light. This is what makes a sunny day feel "sunny."

The Sky (Indirect Light): The blue sky is a massive dome of scattered light. It casts no distinct shadows; it just fills the shadows with soft, blueish light.

The Problem with the Reflective Dome: If you project light up to the ceiling to bounce it down:

The ceiling becomes the light source.

Because the ceiling is huge, it acts like a giant "softbox" (like in photography).

The Result: You will create a perfectly overcast day. You will have light, but no distinct beams, no hard shadows, and no "sparkle" on the water or leaves. It will feel flat, like a cloudy afternoon in November, not a sunny July morning.

2. The Biology: The "Inverse Square" Trap

Your vision includes trees and grass. This is the hardest constraint.

Human eyes are logarithmic; we think a room is "bright" even if it has 1% of the intensity of the sun.

Plants count photons (PAR - Photosynthetically Active Radiation). They know the difference.

If you project light up 50 meters and it bounces back down 50 meters, the light travels double the distance. According to the Inverse Square Law, light intensity drops dramatically with distance. To get "photosynthetic" levels of light at the floor using the indirect bounce method, your upward projectors would need to be terrifyingly powerful—likely creating dangerous heat levels at the source.

3. The Solution: High-Tech "Rayleigh Scattering"Since you want an "Amsterdam-like" atmosphere, you should look at the specific technology developed to solve this exact problem (used in high-end underground architecture).

It is called CoeLux (or similar "Nano-Rayleigh" panels).

How it works: These are not just LED panels. They use a thin layer of nanoparticles that interact with the LED light exactly the way Earth's atmosphere interacts with the sun (Rayleigh scattering).

The Effect: The panel physically separates the light into two components:

The Beam: A warm, yellowish, parallel beam of light (The Sun) passes straight through. It casts hard shadows on your trees.

The Diffuser: The nanoparticles scatter the blue wavelength sideways, making the panel itself look like a deep blue sky.

Why this fits your vision: It tricks the brain (and the camera) into seeing "infinite depth." A white reflective ceiling looks like a ceiling. A Rayleigh scattering panel looks like the sky.

4. Material Recommendations (If you still want to reflect)

If your team persists with the "project up" idea (perhaps for the ambient fill light, while using spot lights for the sun beams), you should not use the "Silver Screen" material we discussed previously. That is "retro-reflective" (sends light back to the source).

You need High-Albedo Diffusive Materials:

PTFE (Teflon-coated Fiberglass): This is the standard for stadium roofs (like the Mercedes-Benz Stadium). It is incredibly durable, has high reflectivity, but diffuses light softly.

ETFE (Ethylene Tetrafluoroethylene) Pillows: These are transparent/translucent "bubbles" (used in the Eden Project). You can print "fritting" (silver dots) on them to turn them into partial reflectors.

Summary for your Lead

Reflecting off the roof = Cloudy/Overcast day. Good for ambient fill, bad for "Sunshine" feel.

Direct LED beams = Industrial/Stadium feel. Efficient for grass, but ugly to look up at.

Nano-Scattering (CoeLux/Innerscene) = The only way to get "Blue Sky" and "Yellow Sun" simultaneously inside a windowless box.

Next Step: Would you like me to find a comparison of the "PAR" (photosynthetic output) capabilities of these different systems? The grass will likely die without very specific "Direct" lighting, regardless of what the ceiling looks like.

Virtual Sun - Artificial Skylight with Real Sun Effect I selected this video because it visually demonstrates the "Rayleigh Scattering" technology (Innerscene/CoeLux style) which is likely the only way to achieve the "Village in the Sun" aesthetic you described, rather than a flat, lit warehouse look.

***

Thank you for your comprehensive summary of the options to consider, and especially for revealing that this problem has already been addressed on Earth. I was hoping that might be the case, but had no idea where to look. I think our conversation today has captured enough to help with the discussion. Let's pause here. I will publish our conversation on a small international forum. While I am away, best wishes for similar success trying to help everyone else.

***

It has been a genuine pleasure exploring this with you. The "Sun vs. Sky" distinction is often the missing link in architectural visualization, so I am glad we could identify the specific physics needed to make your Amsterdam village feel authentic.Good luck sharing these findings with your international forum. It sounds like a fascinating project, and I hope the discussion sparks some brilliant ideas for your team.

Next Step: I will be here when you return. If the team eventually needs to calculate the specific energy loads or heat dissipation for those high-intensity light sources, just let me know. Safe travels!

You've reached your Thinking limit

Responses will use other models until it resets on Dec 10, 2:08 PM. Upgrade for higher limits and more.

(th)

Offline

Like button can go here

#6 2025-12-10 14:50:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

Nice! The idea of projecting upward is particularly interesting! We could mount very light weight mirrors on the interior of the dome, and let the LED's projecting from below illuminate the entire interior.

The original idea was to mount panels on the interior wall, and that would have required lighting that would have needed cables to carry electricity, plus there would be need for periodic maintenance. Your suggestion of projecting light upwards would eliminate all those issues.

We actually had 2 different items for lighting for the inside of the dome and for the inside of the buildings.

First is the white wall of the inside of the dome can be used with a computer and several projector systems to lace any sceen that is desired.

or large-screen projection onto a wall, consider ultra short throw (UST) laser projectors which can create a massive, bright, 4K image from just inches away from the wall. For optimal image quality, especially in brightly lit rooms, pairing the projector with an Ambient Light Rejecting (ALR) screen is highly recommended.

Top Projector System Options

Here are some highly-rated projector systems suitable for large screens or walls:

Product Name Throw Type Resolution Brightness Key Features Price Range (USD)

Hisense PX3-PRO Ultra Short Throw (UST) 4K UHD 3,000 Lumens Google TV, Dolby Vision, great for gaming ~$3,000

Samsung The Premiere LPU9D Ultra Short Throw (UST) 4K UHD 3,450 Lumens Sleek design, smart capabilities with Alexa/Bixby, powerful built-in sound ~$6,000

Epson EpiqVision Ultra LS800 Ultra Short Throw (UST) 4K PRO-UHD 4,000 Lumens Android TV, Yamaha speakers, exceptionally bright picture in any lighting ~$2,800

Optoma HCPro-4400 Standard Throw 4K UHD 5,000 Lumens Dual laser, Dolby Vision/HDR10+, vertical/horizontal lens shift for flexible installation ~$6,000

Key Considerations for Your Setup

Throw Distance:

Ultra Short Throw (UST): Sits a few inches from the wall, ideal for small spaces or living rooms where a ceiling mount or long cable run is impractical.

Short Throw or Standard Throw: Requires more distance from the wall but can be installed at an angle or ceiling-mounted, offering more flexibility in some professional or dedicated home theater setups.

Ambient Light: Projectors with high lumen ratings (e.g., 3,000+ lumens) and/or an ALR screen perform well in brightly lit rooms. A plain white wall works best in a light-controlled (dark) room.

Screen vs. Wall: While you can project onto a wall, an Ambient Light Rejecting (ALR) screen is engineered with specific materials to reject ambient light, enhancing color, contrast, and overall picture quality dramatically compared to a painted wall.

Resolution: 4K UHD and 4K PRO-UHD projectors provide stunning clarity and detail on large displays, making for an immersive viewing experience

For a large screen or wall projection system, key factors are high brightness (lumens), high resolution (4K recommended), appropriate throw distance, and a quality ambient light rejecting (ALR) screen.

Here is a guide and some recommended systems in BBCode format:

Guide to Choosing a Large Screen Projector System

To ensure a vibrant, clear image on a large scale (120 inches or more), especially in rooms with ambient light, consider the following specifications:

Brightness (Lumens): For large screens in a dark room, 1,500-2,000 lumens might suffice. For rooms with moderate to high ambient light (e.g., living rooms, conference halls with windows), aim for 3,000 to 6,000+ lumens. Laser projectors often provide more consistent brightness and longer life than lamp-based models.

Resolution: For large screen sizes, 4K resolution (3840x2160 pixels) is highly recommended to prevent the image from looking pixelated.

Throw Distance:

Ultra Short Throw (UST): Sits just inches from the wall/screen, ideal for smaller rooms and avoiding shadows.

Standard/Long Throw: Placed further back, often ceiling mounted, requiring more room space.

Screen Type: A quality Ambient Light Rejecting (ALR) or Ceiling Light Rejecting (CLR) screen is crucial for maintaining image vibrancy in well-lit environments, as a standard white wall or screen will look washed out.

Recommended Projector Systems

Here are a few high-performance projectors suitable for large screens (up to 150 inches), along with general screen guidance:

High-End Home Cinema (Standard Throw)

Epson Pro Cinema LS12000: A premium 4K Pro-UHD laser projector with exceptional color and contrast ratio, ideal for dedicated home theaters. It features extensive motorized lens shift for flexible installation.

Brightness: 2,700 lumens

Light Source: Laser (rated for 20,000 hours)

Screen Pairing: Pairs well with a high-quality 120"+ matte white or high-contrast screen.

Ultra Short Throw (UST) (for bright rooms/living areas)

Epson EpiqVision Ultra LS800: One of the brightest UST projectors available, designed to be placed near the wall. It's bright enough to be used in well-lit rooms and can produce an image up to 150 inches.

Brightness: 4,000 lumens

Light Source: Laser

Screen Pairing: Requires a specific UST/ALR screen for best performance in ambient light.

Hisense PX3-PRO: A triple laser 4K UST projector that supports Dolby Vision and is great for gaming due to low input lag in game mode.

Brightness: Approx. 3,000 lumens

Light Source: Triple Laser

Screen Pairing: Best used with an ALR screen designed for UST projectors.

Large Venue/Auditorium (Professional Grade)

Optoma ZU820T: A powerful professional installation laser projector designed for large venues, offering very high brightness.

Brightness: 8,800 lumens

Light Source: Laser

Screen Pairing: Suitable for very large screens (over 150 inches) in large halls or auditoriums where high ambient light is a concern.

When selecting a screen, consider brands like Elite Screens, Da-Lite, or Spectra Projection which offer various sizes and materials optimized for different projector types and lighting conditions

Offline

Like button can go here

#7 2025-12-10 14:56:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

the second is just a large scereen TV display for the rooms windows to give also what ever screen sceen is desired.

Slow Glass Individualized Service on Mars or Anywhere

third is to use typical room lighting LED fixtures as one wants.

Examining the energy requirements for growing crops with artificial lighting on Mars

I've long wondered about whether crops on Mars should be grown with natural or artificial lighting. There are tradeoffs between growing space/heating energy/lighting energy that are hard for me to evaluate without doing all the math. Today I've decided to take the first step by estimating the energy needs to feed a person using crops grown using artificial lighting.

Conversion of electricity to calories involves a lot of steps, each of which results in some degree of loss. Here's a summary of the losses:

Electricity -> Light: Wikipedia says 40% efficiency is typical for red LEDs, I assume at least 50% is feasible

Light -> Light absorbed by plants: With a reflective enclosure this can be quite high, I use a value of 90%

Light absorbed -> Energy stored in biomass: This lit review gives photosynthetic conversion efficiency of several types of crop plants, ranging from 2.8-4.9%

Energy in biomass -> Energy in edible portion: This can be approximated in some cases using the harvest index, which is harvest mass/total biomass. Example harvest index values can be found here.

Energy in edible portion -> Digestible calories: Not all of the energy stored in food is digestible. I have no clue what a reasonable value for this is though.

I put together a simple calculator in Google Sheets to estimate the power requirements. Using my best guesses at the parameters, here are my estimates for the power requirements for 2500 calories of the following crops:

Potatoes: 219 kWh

Corn: 286 kWh

Wheat: 349 kWh

Peanuts: 560 kWh

Soybeans: 1030 kWh

At mid-latitudes on Mars, a (Edit: 1 m2 ) 20% efficient solar panel produces about 0.5 kWh per day on average. So for solar panels to generate the necessary power, the number of m2 should be about double the power numbers above. These numbers are quite large, I would estimate that a balanced diet would take nearly 1000 m2 of solar panels to feed one person indefinitely. That's not crazy considering the ITS would need upwards of 50,000 m2 of solar panels to refuel in a reasonable time frame, but it still means a lot of mass brought from Earth to power greenhouses.

This doesn't tell us whether artificially or naturally lit greenhouses are superior yet though. Artificially lit greenhouses can cram in a lot more plants per pressurized volume, so if pressurized volume takes a lot of mass to provide, artificial lighting could still come out ahead. This is just one piece of the puzzle.

Also, I want to stress that this is just a quick and dirty estimate for this stuff. There are many possible sources of error in this analysis, here are the ones I think are most likely to make my results inaccurate:

Harvest index is probably a poor proxy for proportion of energy in edible portion because kcal/kg is probably much lower in the inedible portion. This biases energy need estimates upward.

For potatoes peanuts the harvest index includes the shell, I assumed the shell accounted for 25% of the energy

I used an estimate of 80% for percent of energy in the final product that is digestible, in practice it will vary from food to food and I have no idea what a reasonable value is.

These values are for typical crops today, ones used for spaceflight will probably have better photosynthetic efficiency and much higher harvest index

Offline

Like button can go here

#8 2025-12-10 15:48:46

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,272

Re: Dome LED lighting and for crops

SpaceNut, that is excellent research. To produce actual Earth daylight effect sounds quite energy intensive, given that a sunny day in the northern hemisphere delivers a ground level solar flux of ~400W/m2. For a 31,000m2 town, that implies 12.4MW of light, requiring ~5x that much power (60MW) in input electricity. That is a lot of juice and a heavy burden on base power supply. Averaged over 24 hours, that is 20MW of input power. It is also a lot of heat that must be removed from the space. It might be considered acceptable if it proves to have strong benefits for the mental health of residents. I wonder how much we can compromise in terms of power consumption by eliminating frequencies that are beyond human eyesight? Lighting for plants tends to be optimised for specific spectra that are most efficiently absorbed for photosynthesis. How well will humans adapt if the daylight they experience is a different colour, i.e more shifted towards the red spectrum?

It occurs to me that daylight we experience here on Earth has considerable daily fluctuation. Some days are overcast, others provide full sun and often the weather changes throughout the day. Lighting in the habitat could be turned into a kind of dump load for excess power.

Last edited by Calliban (2025-12-10 15:55:14)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#9 2025-12-10 16:10:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

Yes light measurement is problematic as we all referrence light intensity as watts rather than lumens.

The brightness of the sun on Earth is not measured in a single lumen value, as lumens measure total light output and the brightness perceived on Earth varies by location and atmospheric conditions. Instead, a common way to quantify it is in lux, which measures illuminance per square meter. At its peak, direct sunlight can reach approximately 100,000 to 140,000 lux. Peak sunlight: A clear, direct sun at its highest point in the sky can deliver a very intense illuminance of around 100,000 to 140,000 lux.Atmospheric effects: The exact amount of lux on the ground varies based on the sun's position and atmospheric conditions like cloud cover, which scatter and filter the light.Power vs. lumens: The sun's total power output is about \(1360\) watts per square meter above the atmosphere (the solar constant). However, lux is a better measure for how bright it appears to the human eye because it accounts for the varying sensitivity of our vision across different wavelengths of light

light electromagnetic spectrum

light electromagnetic radiation physics Faraday Effect

Growing crops on Mars requires controlled, pressurized habitats (like greenhouses or underground chambers) to overcome thin atmosphere, extreme cold, and toxic soil, using hydroponics/aeroponics for space efficiency and LED lights for weak sunlight, with potential crops including microgreens, potatoes, lettuce, tomatoes, and hardy mosses, while larger plots would involve regolith treatment and diversified systems to manage perchlorates and disease. Plots will likely be modular, high-density systems (hydroponics/vertical farms) to maximize volume, but larger, diverse trough systems in treated regolith are also considered for long-term food security.

Key Factors & Solutions

Environment: Mars needs sealed habitats with Earth-like pressure, temperature, and humidity, using LED lights for photosynthesis.

Soil: Martian soil (regolith) contains toxic perchlorates; it must be treated with compost, microbes, and nutrients, or bypassed with soil-free methods.

Water/Nutrients: Hydroponics (water/nutrients) and aeroponics (mist) are efficient, reducing water loss and maximizing density, notes The Mars Society of Canada.

Light: Artificial LEDs are crucial due to weak Martian sunlight.

Atmosphere: CO2 from Mars' atmosphere can be used as plant fuel.

Crop Choices & Plot Design

High-Density/Quick Turnaround: Microgreens (lettuce, radish) are great for small, rapid harvests, requiring less space and fertilizer mass, says Frontiers and Interesting Engineering.

Staples: Potatoes, sweet potatoes, tomatoes, kale, carrots, and strawberries are candidates for pressurized farms, notes Interesting Engineering.

Efficient Producers: Algae (single-cell protein) in pipes offer very efficient biomass production.

Plot Strategy: Diversified, intermingled trough systems in treated regolith are preferred over monocultures to reduce disease and improve nutrients, says spacebotany.uk.

Scaling Up

Scaling from small to large plots introduces new problems (e.g., resource management), showing that proportional growth isn't always possible, as seen in spacebotany.uk.

Future farms will likely use a mix of high-tech hydroponics (for immediate needs) and treated regolith beds (for larger, diversified food systems

Offline

Like button can go here

#10 2025-12-10 19:01:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

It is not possible to provide a simple, accurate "lumens chart" for a specific grow light's power input (400 W/m²) because lumens are not the correct measurement for plant growth and a direct conversion from wattage to lumens is not feasible without knowing the light's specific spectrum.

Why Lumens Don't Work for Grow Lights

Lumens measure brightness as perceived by the human eye, which is most sensitive to the green/yellow part of the spectrum. Plants primarily use blue and red wavelengths for photosynthesis, which the human eye perceives less efficiently.

For growing plants, the relevant metric is PPFD (Photosynthetic Photon Flux Density), measured in micromoles per square meter per second ($\mu$mol/m²/s). Mars Hydro and other grow light manufacturers provide PPFD charts, not lumen charts.

Mars Hydro PPFD and Wattage Guidelines

While a specific "400 W/m²" product isn't standard, Mars Hydro recommends specific PPFD ranges for different growth stages and suggests the following guidelines for typical LED grow lights (watts per square foot is a general rule):

Growth Stage Recommended PPFD ($\mu$mol/m²/s) Typical Wattage per sq. ft (approx.)

Seedling 100 – 300 10 - 20 W/sq. ft

Vegetative 400 – 600 20 - 30 W/sq. ft

Flowering 600 – 1000 30 - 50 W/sq. ft

Key Takeaway

To determine the ideal setup for your specific Mars Hydro model, you should:

Consult the manufacturer's official PPFD map/chart for your specific model (e.g., TSW2000, FC-E4800) at various hanging heights. This information is typically available on the product page or the Mars Hydro website, such as on their guide to buying LED grow lights or the Mars Hydro blog.

Use a PAR meter or a smartphone app designed for measuring grow light intensity (PPFD/Lux) to get accurate readings at the canopy level.

Adjust the hanging height and dimmer settings according to the plant's current life cycle to achieve the target PPFD, rather than focusing on a lumen value or a fixed wattage/area ratio

The solar irradiance of \(400\text{\ W/m}^{2}\) on the surface of Mars is approximately \(46,100\text{\ lumens\ per\ square\ meter}\) (lux) under certain clear sky conditions. The conversion from watts per square meter (irradiance) to lumens per square meter (lux, which is a measure of illuminance) depends on the luminous efficacy of the light source's specific spectrum, which is different for Mars' dusty atmosphere than for Earth's. The general conversion factor used for a sunlight-like spectrum is about 93 lumens per watt, though values vary based on atmospheric conditions. Mars Illumination BBCode Chart The following chart uses the conversion factor derived from laboratory measurements (approx. 115.25 lux per W/m²) for a value close to 400 W/m². This is presented in BBCode format. Mars Solar Irradiance to Illuminance (Lux) Conversion [TABLE][TR][TH]Irradiance (W/m²)[/TH][TH]Illuminance (Lux/Lumens per m²)[/TH][/TR][TR][TD]400 W/m²[/TD][TD]~46,100 lx[/TD][/TR][/TABLE] For context, bright sunlight on Earth's surface at noon is about 100,000 lux. The 400 W/m² level on Mars is comparable to an overcast day on Earth or the sun on Earth at noon on a winter day in certain northern latitudes

It seems that 100 W/m^2 incondensents bulbs for Approximately 4.91 megawatts of power would be required to adequately light the parabolic dome on Mars but light intensity from LEDS use quite a bit less.

How to calculate power requirements for large LED lighting projects?

With these constraints, the chart below will provide the approximate total lumens you need for your space; divide the total lumens by the number of light fixtures you plan to use. These calculations use 65-degree beam spread downlights, downlights with tighter beam spread require more

Led Light Requirement Calculator

https://blog.1000bulbs.com/home/100w-equal-led-bulb

Socket Rating Safe LED Options Actual Draw Power

60W Socket Up to 100W equivalent LED 8-15W actual

75W Socket Up to 150W equivalent LED 12-22W actual

100W Socket Up to 200W equivalent LED 18-35W actual

Offline

Like button can go here

#11 2025-12-11 09:06:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

The more we NewMars members toss posts back and forth, the more I'm getting the impression a mixture of lighting solutions may turn out to be best. We want the interior to re pleasing for humans to enjoy, so the sky scape of light blue LED panels that can be programmed to appear white to simulate clouds seems attractive, but your most recent conversation with your AI friend about grow lights reminds us all that lighting for plants might be best arranged as arrays suspended the ideal distance above the plants. if this were done with skill, it might turn out the interior view seen by humans would be pleasing due to the mixture of colors including light reflected from leaves.

In other words, it might NOT be necessary to create a Sun's equivalent illumination with "sky" panels, because the grow lights could be closer to the intended recipient, while the sky lights provide a level of illumination and combinations of spectra that humans would enjoy, at less energy cost.

Day light recreation of how we precieve night and day with in the large structure.

a slow rotating light support system that shines up towards the dome apex.

to do seasons the angle would be reduced

Offline

Like button can go here

#12 2025-12-13 12:43:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

remembering all of the posts from the past is getting harder with age but here it is.

Roll out mirror surface to peel and still on the inside of the dome as deswired.

Hmm. Yes. If only I had a job. Visions of tearing down my garage, building a brand new one. I could give details, but I found this at Amazon. Amazon Canada has free shipping within Canada. Reflective sticker, self-adhesive, 0.1cm thick (1mm), flexable. 50cm x 100cm, CDN$ 12.64 + tax. If the back wall is 18' high x 15' wide, that's 548.64 cm high x 457.2 cm wide, so make the reflective area 550cm x 450cm. That would require 5.5 x 9 rolls = 49.5 rolls. Purchased in whole rolls so 50 rolls. That's $632 + tax. A slightly larger area, but still expensive. And outside garage wall facing the Walipini could get more mirror covering. More money.

(Ps. I dug the URL of the image out of source code for their website. However, clicking on the image takes you to their store, to buy this item. They shouldn't be upset by free advertising.)

::Edit:: Hah! Even better. You suggested Mylar; I did a search and found this. One roll would do, CDN$ 49.99 + tax. Free shipping within Canada. Intended to reflect light for agriculture.

Growneer 4 x 100FT 2 Mil Horticulture Mylar Reflective Film Roll Highly Reflective Covering Sheets For Greenhouse Increasing Temperature Light

https://images-na.ssl-images-amazon.com/images/I/51+gzsvG8DL._AA160_.jpg

Not all areas with in the dome has high intensity light and while in you residential area one will make use of motion sensor' d units.

![Tzumi-Under-Cabinet-LED-Lights-3-Pack-USB-Rechargeable_62d1a2e8-61f5-4cf6-9387-9425181c77f6.323c7c37badeaf2ab60a6ea35851e21c.jpeg?odnHeight=573&odnWidth=573&odnBg=FFFFFF]](https://i5.walmartimages.com/seo/Tzumi-Under-Cabinet-LED-Lights-3-Pack-USB-Rechargeable_62d1a2e8-61f5-4cf6-9387-9425181c77f6.323c7c37badeaf2ab60a6ea35851e21c.jpeg?odnHeight=573&odnWidth=573&odnBg=FFFFFF])

Offline

Like button can go here

#13 2025-12-13 15:57:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

The sun provides to earth surface a Solar Irradiance: Full, direct sunlight at Earth's surface on a clear day is approximately 1,000 watts of radiant power per square meter (W/m²), or about 127,000 lumens per square meter (lux). But we know ho to produce light that uses less wattage for the same lumen values.

No one within the dome is going to have all of the lighting on or at full intensity.

Illuminance Range and Calculation

Natural outdoor light levels (illuminance), measured in lux (lumens per square meter), vary dramatically by weather and time of day:

Overcast Day (midday): ~1,000 to 2,000 lux

Full Daylight (ambient, not direct sun): ~10,000 to 25,000 lux

Bright Direct Sunlight: ~100,000 to 120,000 lux

Of course the other error is the sun is over one's head not projected. Which does not multiply by the diameter of the dome as not all of the domes foot print is being illuminated.

For home incandescent bulbs, wattage directly relates to brightness (lumens):

a 40W bulb gives ~450lm,

60W ~800lm,

75W ~1100lm,

and 100W ~1500-1600lm, with lumens being the standard measure for light output, not watts, which just measure energy use.

Here's a common conversion chart for traditional incandescent:

40 Watts: ~450-500 lumens

60 Watts: ~800-900 lumens

75 Watts: ~1100-1125 lumens

100 Watts: ~1500-1600 lumens

Key takeaway: Look for lumens (lm) on new bulb packaging to find the brightness you want, as wattage is less important for energy-efficient bulbs like LEDs.

ypical room lumen levels vary by function, with relaxing spaces like bedrooms needing 1,000-4,000 total lumens (or 10-20 lumens/sq. ft.) for ambiance, while task-oriented areas like kitchens and bathrooms require much brighter light, often 5,000-10,000+ lumens (or 50-100 lumens/sq. ft.) for cooking and grooming, achieved through layered lighting with dimmers for flexibility.

General Room Lumen Ranges (Total for Room)

Living Room/Lounge: 1,500 – 3,000+ lumens (for relaxed atmosphere)

Bedroom: 1,000 – 4,000 lumens (cozy feel, use dimmers)

Kitchen: 5,000 – 10,000 lumens (for tasks)

Bathroom: 4,000 – 8,000 lumens (for grooming/tasks)

Home Office: 3,000 – 6,000 lumens (needs focus)

Dining Room: 3,000 – 6,000 lumens (adjustable for meals)

Hallways/Stairs: 500 – 3,000 lumens (general navigation)

How to Estimate Your Needs (Lumens per Square Foot)

Measure your room to get the square footage (length x width).

Multiply by the lumens/sq. ft. recommendation:

Living/Bedroom: 10-20 lumens/sq. ft.

Kitchen/Bathroom/Office (Task Areas): 50-100 lumens/sq. ft.Example: A 100 sq. ft. living room needs 1,000-2,000 lumens (100 x 10-20).

Tips for Brightness

Layer Lighting: Use a mix of overhead, table, and floor lamps for depth.

Use Dimmers: Essential for creating different moods and saving energy.

Task Lighting: Add specific bright lights (like under-cabinet LEDs) for cooking or reading

Offline

Like button can go here

#14 2025-12-14 08:59:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

The ISS is contained volume with known power levels.

The ISS uses advanced LED lighting, shifting from older systems, with power managed by the station's overall 128 kW solar-powered electrical system, meeting ASHRAE/IES standards for efficiency, offering adjustable levels (like 200-500 lux for general tasks) for various modules (labs, crew quarters), and employing smart controls for dimming/shutoff to conserve power, crucial for space operations.

Lighting System Types & Technology:

LED-Based: The ISS primarily uses Light-Emitting Diodes (LEDs) for efficiency, durability, and long life in space.

Fluorescent/Incandescent: Older modules may still have some fluorescent or incandescent fixtures, but LEDs are the standard for replacements and new installations.

Custom/NASA Standards: Lighting meets NASA's specific space-rated needs (vibration, radiation) rather than strict Earth-based codes, but aligns with efficiency goals of standards like ASHRAE/IES.Power Requirements:

Total Station Power: The ISS's entire electrical system generates up to ~128 kW of power from solar arrays, distributed to all systems,including lighting.

Lighting Power Density (LPD): While specific ISS LPD isn't published like Earth codes, it aims for low power, using LEDs to stay within efficient limits (e.g., <1 Watt/sq ft for some Earth applications).Adjustability: Lighting power varies; crew quarters might use 200-300 lux, while labs need more (400-500+ lux), all dimmable/controllable.

Illumination Levels (Lux/Foot-Candles):

General (Crew Quarters/Corridors): Around 200-300 lux (20-30 fc) on average, with dimming capability.Work Areas (Labs/Control Centers): Higher levels, often 400-500+ lux (40-50+ fc) for detailed tasks.

Emergency: Separate battery-powered emergency lights (like on Earth) ensure visibility for safety during power loss, meeting basic egress needs.

Key Factors:Power Conservation: Crucial due to limited energy generation; smart controls dim lights when not needed.

Human Factors: Adjustable lighting helps regulate circadian rhythms for long-duration missions.

Space Environment: Fixtures are rugged, often with specialized covers (like polarizing filters) to reduce glare in microgravity

The International Space Station (ISS) has a total pressurized volume of about 35,000 cubic feet (1,000 cubic meters), roughly the size of a large, six-bedroom house, with a smaller habitable volume (where people live and work) of around 13,700 cubic feet (388 cubic meters), accounting for equipment racks and structure.

Key Volume Figures:

Total Pressurized Volume: ~35,000 cubic feet / 1,000 cubic meters.

Habitable Volume: ~13,700 cubic feet / 388 cubic meters (the actual living/working space).

The internal volume of a parabolic dome with a 220m diameter and 120m height is approximately 2,280,796.27 \(m^{3}\).

The internal volume of the parabolic dome is approximately 80,600,000 cubic feet.

While we know the array collects 120 kw plus the issue is the light intensity and amounts are for each hour of use covering all power uses not just the lighting.

Offline

Like button can go here

#15 2025-12-14 09:36:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

LEDs have a lense that gives a beam spread to hieght that the light will cover. So at 120m tall to 200 m diameter we have the mean angle that light will cover from a single source which will be huge in power level but we are not making an empty carvern.

When calculating the relationship between LED bulbs, the volume of a space (cubic meters), and the mounting height, you are primarily looking at how much light (lumens) is needed to fill a specific 3D volume effectively. 1. Calculating Volume in Cubic Meters (\(m^{3}\)) To find the volume of your room, multiply the length, width, and height in meters. Formula: \(\text{Volume}(m^{3})=\text{Length}(m)\times \text{Width}(m)\times \text{Height}(m)\).Example: A room that is 5m long, 4m wide, and 3m high has a volume of \(60m^{3}\). 2. Determining Light Requirements (Lumens) Lighting is typically calculated based on floor area (square meters), but for high ceilings, you must adjust for volume or height. Residential standard: Aim for roughly 300–500 lumens per square meter for bright areas like kitchens or offices.Height Adjustment: As the ceiling height increases, you need more lumens because light intensity decreases over distance. For ceilings over 3 meters (approx. 10 feet), it is recommended to increase your total lumen count by 25-30% for every additional meter of height to maintain the same brightness at floor level. 3. LED Wattage vs. Installation Height If you are using high-output LED bulbs (High Bay lights), the mounting height dictates the required wattage to ensure the light reaches the ground effectively: Installation Height Recommended LED WattageIdeal Environment0 – 3 meters (0-9 ft)60W (Standard/Low)Residential, Small Garages4 – 6 meters (13-20 ft)100W – 150WWorkshops, Low-rise Warehouses6 – 8 meters (20-26 ft)200W – 250WManufacturing Halls, Medium Warehouses8 – 12 meters (26-39 ft)300W – 400WLarge Logistics Centers12+ meters (39+ ft)500W+Stadiums, Hangars4. How Many Bulbs Do You Need? Once you have determined the total lumens required for your cubic space, divide that by the output of a single LED bulb. Formula: \(\frac{\text{Total\ Lumens\ Needed}}{\text{Lumens\ per\ Bulb}}=\text{Number\ of\ Bulbs}\).A standard 10W LED bulb typically produces 800–1,000 lumens.

Determining the output of an LED bulb relative to a room's volume (\(m^{3}\)) and height (\(m\)) involves calculating the total lumens required to achieve a specific light intensity (Lux). Core Calculation Formulas Total Lumens (lm): Multiply the room's surface area by the target Lux.\(\text{Lumens}=\text{Area\ }(m^{2})\times \text{Lux}\)Area (\(m^{2}\)): Derived from volume and height.\(\text{Area}=\text{Volume\ }(m^{3})\div \text{Height\ }(m)\)Target Lux Levels: Standard guidelines suggest:Ambient (Living areas): 100–300 Lux.Task (Kitchens/Offices): 300–500 Lux.Bright (Bathrooms/Workspaces): 700–800 Lux. BBCode Output for Forums/Calculators The following BBCode block presents these calculations in a structured format suitable for message boards: bbcode[center][size=4]LED Lighting Output Requirements[/size][/center]

Room Volume: {Volume} m³

Ceiling Height: {Height} m

Target Intensity: 300 Lux (Standard Task Lighting)

[hr]

Step 1: Calculate Floor Area

[indent]Area = Volume / Height[/indent]

[indent]{Volume} m³ / {Height} m = {Area} m²[/indent]Step 2: Total Lumens Required

[indent]Lumens = Area × Lux[/indent]

[indent]{Area} m² × 300 Lux = {Total_Lumens} lm[/indent]Step 3: Recommended Bulb Count (Based on 800lm LED)

[indent]Bulbs = Total Lumens / 800[/indent]

[indent]{Total_Lumens} / 800 = {Bulb_Count} Bulbs[/indent]Note: Higher ceilings (above 3m) may require 20-50% more lumens to account for light scattering before reaching the floor.

Height Adjustment Considerations Light Scattering: For every meter increase in height above standard levels (approx. 2.4m), light intensity drops. High ceilings may require additional lumens to ensure effective illumination at ground level.Mounting Height: A general rule for high-bay lighting is that a light mounted at 15 feet (4.5m) can effectively brighten about 12 feet (3.6m) of space.Logarithmic Scaling: Some advanced calculations use logarithmic formulas for "ceiling height adjustment" because the increase in required lumens is not linear as height grows

120/4.5 = will be the number of floors will give 26 possible that all have lessening diameter inside the dome.

Of course each floors diameter will not be to the wall of the dome as we would want space on the outside of the structured rooms to have extra open space to go outside with in the dome.

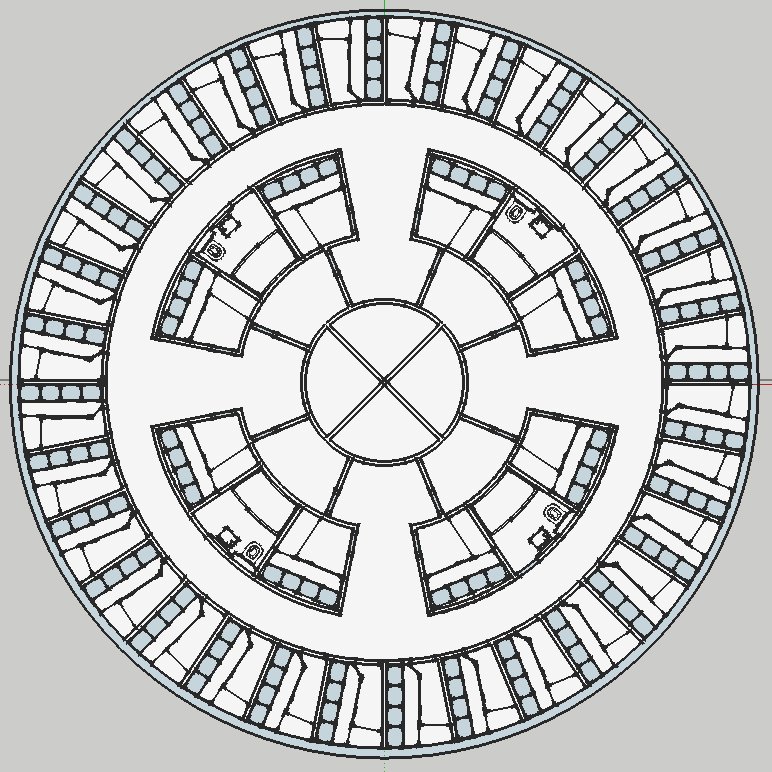

The diameters of each of the 26 floors in the parabolic dome range from 200.00 meters at the base to 39.22 meters at the top floor, as detailed below. Step 1: Define the parabolic equation and floor heights The dome is modeled as a paraboloid of revolution. With the base at \(y=0\) m and the vertex at the top, \(y=120\) m, the equation of the parabola can be defined as \(x^{2}=4p(y-120)\). The base radius is \(100\) m (half of the \(200\) m diameter), so we solve for \(4p\): \(100^{2}=4p(0-120)\)\(10000=-120(4p)\)\(4p=-\frac{10000}{120}=-\frac{250}{3}\)The equation is \(x^{2}=-\frac{250}{3}(y-120)\). The floor heights are evenly spaced by a distance of \(120\text{\ m}/26\approx 4.62\) m. Step 2: Calculate each floor's diameter The radius \(r\) at any given height \(y\) is \(x\), so \(r^{2}=-\frac{250}{3}(y-120)\), and the diameter \(D=2r=2\sqrt{-\frac{250}{3}(y-120)}\). The following table lists the height and

corresponding diameter for each floor: Floor Number Height (m)Diameter

image that inspired

Floor Number Height (m) Diameter (m)

1.00 0.00 200.00

2.00 4.62 196.12

3.00 9.23 192.15

4.00 13.85 188.11

5.00 18.46 183.97

6.00 23.08 179.74

7.00 27.69 175.41

8.00 32.31 170.97

9.00 36.92 166.41

10.00 41.54 161.72

11.00 46.15 156.89

12.00 50.77 151.91

13.00 55.38 146.76

14.00 60.00 141.42

15.00 64.62 135.87

16.00 69.23 130.09

17.00 73.85 124.03

18.00 78.46 117.67

19.00 83.08 110.94

20.00 87.69 103.77

21.00 92.31 96.08

22.00 96.92 87.71

23.00 101.54 78.45

24.00 106.15 67.94

25.00 110.77 55.47

26.00 115.38 39.22

To determine the diameter of each floor in a parabolic dome that is 120 meters tall with a 200-meter base diameter, we use the standard parabolic equation for a cross-section. Geometric Parameters Total Height (\(H\)): 120 mBase Diameter (\(D\)): 200 m (Base Radius \(R=100\) m)Number of Floors: 26Average Floor Height: ~4.615 m (assuming uniform distribution: \(120\text{\ m}/26\) floors) Parabolic Equation The radius \(r\) at any given height \(h\) from the ground for a downward-opening parabola is given by the formula:\(r=R\sqrt{1-\frac{h}{H}}\)The diameter at that height is simply \(2r\).

Floor Diameter Table (BBCode)

[table][tr][th]Floor[/th][th]Height (m)[/th][th]Diameter (m)[/th][/tr][tr][td]Ground (1)[/td][td]0.00[/td][td]200.00[/td][/tr][tr][td]2[/td][td]4.62[/td][td]196.11[/td][/tr][tr][td]3[/td][td]9.23[/td][td]192.15[/td][/tr][tr][td]4[/td][td]13.85[/td][td]188.10[/td][/tr][tr][td]5[/td][td]18.46[/td][td]183.95[/td][/tr][tr][td]6[/td][td]23.08[/td][td]179.70[/td][/tr][tr][td]7[/td][td]27.69[/td][td]175.34[/td][/tr][tr][td]8[/td][td]32.31[/td][td]170.86[/td][/tr][tr][td]9[/td][td]36.92[/td][td]166.25[/td][/tr][tr][td]10[/td][td]41.54[/td][td]161.49[/td][/tr][tr][td]11[/td][td]46.15[/td][td]156.59[/td][/tr][tr][td]12[/td][td]50.77[/td][td]151.53[/td][/tr][tr][td]13[/td][td]55.38[/td][td]146.28[/td][/tr][tr][td]14[/td][td]60.00[/td][td]141.42[/td][/tr][tr][td]15[/td][td]64.62[/td][td]135.53[/td][/tr][tr][td]16[/td][td]69.23[/td][td]130.05[/td][/tr][tr][td]17[/td][td]73.85[/td][td]124.30[/td][/tr][tr][td]18[/td][td]78.46[/td][td]118.25[/td][/tr][tr][td]19[/td][td]83.08[/td][td]111.87[/td][/tr][tr][td]20[/td][td]87.69[/td][td]105.11[/td][/tr][tr][td]21[/td][td]92.31[/td][td]97.90[/td][/tr][tr][td]22[/td][td]96.92[/td][td]90.14[/td][/tr][tr][td]23[/td][td]101.54[/td][td]81.69[/td][/tr][tr][td]24[/td][td]106.15[/td][td]72.28[/td][/tr][tr][td]25[/td][td]110.77[/td][td]61.42[/td][/tr][tr][td]26[/td][td]115.38[/td][td]48.35[/td][/tr][/table]Usage Notes Floor 1 starts at ground level (0m height), representing the maximum 200m base.Floor Heights assume a standard vertical spacing of approximately 4.62 meters per floor, which is within the range for high-ceiling commercial or mixed-use structures.The top floor (26) is located at 115.38m, leaving approximately 4.62m of clearance to the 120m apex

Offline

Like button can go here

#16 2025-12-14 15:51:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

The lunar mars greenhouse is sized for 5.5m by 2.1 meter cylinder that used a 1000 w mercury light for heat as well as for light. Something that we will not be doing.

For a single astronaut, a lunar greenhouse needs enough space for food, air, and water recycling, with NASA concepts suggesting around 28-40 square meters (300-430 sq ft) of cultivation area for 50% caloric needs, while smaller habitat modules might use 3-4.5 m² for basic needs, emphasizing volume and flexibility, not just area, for crew comfort and functions. Actual sizes vary wildly, from small, deployable units to massive, buried structures, but expect a dedicated module or significant habitat volume.

Key Factors Influencing Size:Food vs. Life Support: A greenhouse providing 100% oxygen and water recycling needs a different footprint than one just supplementing food.

Caloric Needs: Growing 50% of a 2000 kcal/day diet (1000 kcal) requires roughly 28-40 m².

Habitat Integration: Some designs integrate growing areas within living quarters (like HAVEN), while others are separate, buried modules for radiation protection.Technology: Hydroponics, lighting, and automation affect space efficiency.

Examples of Proposed Sizes:

ED&EN ISS Prototype: Around 30 m² (323 sq ft) for food on Moon/Mars.

Mars-Lunar Greenhouse (MLGH): Aims for 28-40 m² for a crew of four.

Lunar FARM (Concept): A large concept with 538 m² for 18 astronauts, showing scalability.

HAVEN (Habitat Module): Smaller modules (3-4.5 m²) offer storage and basic functions, with larger crew quarters for standing/moving.In Summary for One Person:

You're likely looking at a dedicated space of at least 30 square meters for significant food and life support, or a smaller, integrated volume within a habitat for basic functions, emphasizing efficiency and multi-use areas

MARS GREENHOUSES: CONCEPTS AND CHALLENGES

Proceedings from a 1999 Workshop

Offline

Like button can go here

#17 2025-12-15 15:56:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

post 4 greenhouse is sized for 1 crewman's life support of food and recycling of waste as well as air. The approximate 5.5 m long cylinder is about 2 m diameter. That means roughly 20 m^3 making use of vertical height and not just surface area. But I think we should double that as the aliases in the middle of the example'

The greenhouse is to support 50% of food with 100% for water and Oxygen for the original size.

If just half of the dome 31,000 m^3 is used for the life support that means we have a max number of crew that it can support just 440 crew when habitat area for them is based on 140m^3 that crews of 4 will make use of.

Floor to ceiling areas require all of the plumbing, vents for heating and cooling plus, water and waste removal and electrical with in a distance of 1.5 meter for each floor. planned in post 15 with the diameter is half of the dome distance at that height.

Using LED's we need just for light even using just 20w units to give 500 lumens or what is a 100w incandescent bulbs amount. Groups that need higher levels would have greater bulb density.

440 x 20w = 8.8k w x 25hr = 220kwhr daily consumed if we waste the power by having them all on.

Some plants want less and some more so post 13 is why we have varying intensities.

So until a crop plot area is planted the amounts are minimum with ability to go up in intensity.

With current prepackaged foods designed for space, six crew members living on Mars for 1,095 days will require over 13 tons (12,023 kilograms) of food.

Offline

Like button can go here

#18 2025-12-15 19:10:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

Adaptive dome lighting for day / night simulation can be directly powered by solar panels to follow mars sol cycle.

Of course cleaning system will be needed for the panels to keep full power coming out of them but that off loads power from the other systems. Chose bulbs that come on from a DC source voltage and they will follow as power ramps up and down. Between the storage battery and the lights the power is processed through a pulse width modulation and current circuit before powering the lights.

Designing a Martian menu involves creating a sustainable food system that provides nutritious, tasty, and varied meals with minimal resources for years, focusing on lightweight, shelf-stable items (like freeze-dried foods) and on-site crop growth (e.g., potatoes, spirulina, lettuce) to combat menu fatigue, ensure health, and support crew morale far from Earth, addressing major challenges like water usage, waste, energy, and microgravity cooking.

Key Components of a Martian Food System:

Pre-Packaged & Processed Foods:

Freeze-dried/Dehydrated: Water is removed to reduce weight and extend shelf life, requiring rehydration with water. Examples: fruits, vegetables, meats.

Thermostabilized: Similar to Earth canned/pouch foods, sealed for preservation.

Natural/Semi-Dried: Ready-to-eat items.

Condiments: Sauces, spices to add flavor variety.

On-Site Production ( Hydroponics/Aeroponics): Growing crops like potatoes, tomatoes, soybeans, wheat, spinach, lettuce, and nutrient-rich spirulina (algae).

Cellular Agriculture: Culturing meat or other proteins (future potential).

Menu Design Principles:

Nutrition: Meet daily caloric needs, maintain nutrient density over years, support bone/muscle health in low gravity.

Palatability & Variety: Combat menu fatigue with diverse flavors, textures, and easy preparation to keep astronauts eating well.

Resource Efficiency: Minimize mass, volume, energy, and water use; reduce waste.

Safety: Rigorous testing for contaminants in closed-loop systems.

Simplicity: Quick, easy meal prep for busy schedules in microgravity.

Sample "Martian" Meal Ideas:

Breakfast: Freeze-dried berries with rehydrated yogurt, wheat porridge with spirulina boost, or omelets with hydroponic spinach.

Lunch: Tomato soup (from dried tomatoes) with soy-based protein, sandwiches on Martian-grown wheat bread, or spirulina-enriched pasta.

Dinner: Rehydrated chicken/beef with freeze-dried veggies, potato-based dishes, or "Martian" pizza using grown ingredients.

Key Challenges Addressed by the Menu:

Transportation Costs: Freeze-drying reduces weight, making food cheaper to launch.

Psychological Support: Familiar, tasty food improves crew well-being.

Sustainability: Growing food on Mars creates a closed-loop system, reducing Earth reliance

The Menu for Mars: Designing a Deep Space Food System

The Nutrition paper, authored by NASA scientists Douglas, Sara Zwart, and Scott Smith, highlights the general criteria for a potential Mars or other space exploration mission food system, including:

Safety: The space station’s food system is tested and processed on Earth to ensure the food is safe for astronauts to eat. Food grown aboard the spacecraft and in microgravity could interact with microbes that float and mix with the spacecraft’s atmosphere until removed by air and water filters. Thus, resources will be required for cleaning and testing to reduce the risk of crews succumbing to foodborne illnesses.

Stability: Crews will not have the luxury of phoning home to resupply food on a multi-year, round-trip mission to Mars, meaning the food that the crew members bring with them or grow must last for years. Consequently, the nutrition and quality of the Mars food system must be stable for the length of the mission.

Palatability: Equally important is ensuring the food on a Mars mission is enjoyable to consume. Otherwise, astronauts may not consume enough food to support their health and well-being.

Nutrition: The Mars food system must provide food that is as nutritious as it is delicious. To function, the human body requires a handful of essential nutrients that must be absorbed from food. Failing to fulfill any one of these nutritional requirements can result in a deficiency that leads to a variety of health problems.

Resource minimization: Resources such as water, power, and volume are limited in a spacecraft. The Mars food system needs to provide safe, nutritious, palatable food while keeping resource consumption and waste production to a minimum. “You can have a food system that provides everything you need, but if it doesn’t fit within the resources, you cannot take it with you,” Douglas said.

Variety: The Mars food system must provide a variety of food so that astronauts don’t grow tired of consuming the same thing. “Menu fatigue” can dampen crew morale and cause astronauts to eat less, which can lead to health issues.

Reliability: “One of the big concerns with growing food is that if it doesn’t grow and you were depending on it, now you have insufficient food, which can be a very, very big concern when you’re going on these missions,” Douglas said. As a result, an exploration mission food system has to be dependable.

Usability: The Mars food system must allow crews to prepare meals with ease, providing them the time to focus on mission-critical tasks. “Prepackaged foods are a great candidate because they are easy to prepare, easy to consume. They already have a safe and long history in spaceflight, but there are some challenges with them—that nutrition and quality degrade over time,” Douglas said. “So, on longer missions, it would be nice to get a fresh component.”

Space-ready appliances: Astronauts aboard the space station prepare meals with heat or by adding water. The Mars food system will require new food preparation equipment that satisfies safety and spaceflight requirements.

Offline

Like button can go here

#19 2025-12-16 18:39:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,933

Re: Dome LED lighting and for crops

Looking at this image suggests Vertical Farming and Indoor farming update

Food for Thought, what does a garden need to grow

Contains the ISS foods which are sent aprox 200 types

Offline

Like button can go here

#20 2025-12-17 11:39:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,516

Re: Dome LED lighting and for crops

For SpaceNut re #19 ... thanks (again) for the image of vertical farming...

Vertical farming is struggling to be competitive on Earth, but it will be the ONLY game in town on Mars.

This post is about Caesars Entertainment, which secured naming rights to the New Orleans Superbowl in 2021, and which ** might ** be interested in sponsoring Calliban's dome on Mars. Gemini found a surprising number of shared interests that might provide incentive for the company to support the Mars venture.

Mars Dome Sponsorship: Caesars Entertainment

Conversation with Gemini

Caesars's name for New Orleans Superbowl - Hi Gemini! This query is about the company that secured naming rights to the New Orleans Superbowl. What can you tell me about it? I am wondering if they might be interested in sponsoring our dome on Mars. By purest chance, the dimensions of the Caesars Superdome are close to the dimensions under consideration for a dome to be build of local materials inside a crater on Mars. The technical challenges of building such a dome on Mars are daunting, and very advanced architectural methods and engineering innovation would be required to make it happen. In addition, the Mars dome would need to provide almost total support for the human population, which is not the case for the sports venue.

***

That sounds like an incredibly ambitious project. Building a self-sustaining habitat on Mars using local materials is essentially the ultimate "engineering boss fight."The company you are looking for is Caesars Entertainment. They secured the naming rights to the New Orleans stadium in July 2021, rebranding it as the Caesars Superdome in a 20-year, $138 million deal.

Here is what you should know about them as a potential partner for your Martian endeavor, along with some context on the building you are using as a reference:

About Caesars Entertainment

The Brand: While primarily known for casinos and hotels (like Caesars Palace), they have shifted their focus toward "approachable luxury" and high-tech digital expansion.

Philanthropy & Strategy: Their current corporate social responsibility framework is called "PEOPLE PLANET PLAY." They invest heavily in community impact and environmental sustainability—though, currently, their "Planet" initiatives are focused on reducing emissions and building efficiency here on Earth.

Interest in Innovation: Caesars has recently been leaning into digital transformation and "hybrid entertainment" (like esports and immersive theater). A "Mars Dome" sponsorship would be a massive leap, but it aligns with their history of bold, iconic architectural statements.

The Caesars Superdome vs. Your Mars Dome