New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-11-14 15:20:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

WIKI Project construction design meaning for insitu materials

This is not a discussion Topic

Old title information that was in the Bricks for Mars as indicated as a distraction to Caliban's use there in for building an non lines dome..

This title is meaningless or unwanted

Project design in a proposal is the strategic blueprint detailing what you'll do, why, how, when, and for how much, showing how your solution addresses a need with clear goals, activities, resources, budget, and outcomes, often using visuals like Gantt charts to gain stakeholder buy-in and set expectations before detailed planning begins. It bridges the initial idea and the detailed project plan, ensuring feasibility and alignment.

Key Components in a Project Proposal Design Section

• Problem Statement/Need: Clearly state the issue or opportunity the project addresses, directly linking to the design's purpose.

• Goals & Objectives: Define what success looks like (vision) and the specific, measurable outcomes (SMART goals).

• Methodology/Strategy: Explain the logical steps, activities, and reasoning behind your approach, showing how you'll achieve goals.

• Deliverables: List the tangible products or features to be completed (e.g., workshops, software, reports).

• Timeline & Schedule: Provide a high-level overview of key milestones and phases, often with visual aids.

• Resources: Identify necessary personnel, materials, and tools.

• Budget: An estimated financial breakdown of costs.

• Monitoring & Evaluation (M&E): How you'll track progress and measure impact (e.g., using logical frameworks).

• Risks & Contingencies: Identify potential challenges and your backup plans

Purpose in the Proposal

• Secures Buy-In: Persuades stakeholders (clients, funders) that the solution is viable and well-thought-out.

• Sets Expectations: Creates a shared understanding of scope, deliverables, and timelines.

• Provides Blueprint: Acts as a foundational document from which the detailed project plan is built

How It Works in Practice

1. Identify Need: Start with a clear problem.

2. Develop Solution: Brainstorm and select interventions (design phase).

3. Structure the Proposal: Organize these into the components above, using visuals (Gantt charts, flowcharts) for clarity.

4. Refine: Get early stakeholder feedback to avoid late roadblocks.

Project design requirements are the specific goals, features, functions, constraints, and criteria that define what a project must achieve, ensuring clarity for stakeholders and guiding development from start to finish, encompassing business needs (the "what") and technical solutions (the "how"), and covering scope, deliverables, budget, timeline, resources, and success metrics.

Key Categories of Requirements

• Business Requirements: What the organization needs to achieve (e.g., increase sales by 10%, improve customer satisfaction).

• Stakeholder Requirements: Needs of specific user groups or individuals involved.

• Functional Requirements: Specific features and actions the system or product must perform (e.g., "user must be able to log in").

• Non-Functional Requirements (Quality Attributes): How well the system performs (e.g., speed, security, usability, reliability).

• Technical/System Requirements: How the solution will be built (e.g., operating system, hardware, software dependencies).

• Constraints: Limitations like budget, time, or technology.

Essential Elements of a Project Design

1. Goals & Objectives: What success looks like (SMART: Specific, Measurable, Achievable, Relevant, Time-bound).

2. Scope: Boundaries of the project, defining what's in and out.

3. Deliverables: Tangible outputs or features.

4. Stakeholders: Who is involved and their roles.

5. Timeline & Milestones: Key dates and progress points.

6. Resources & Budget: Personnel, tools, and financial allocation.

7. Risks: Potential problems and mitigation plans.

8. Metrics: How progress and success will be measured.

Process for Defining Requirements

1. Identify Needs: Meet with stakeholders to understand problems and desired outcomes.

2. Define Goals & Objectives: Establish clear, high-level aims.

3. Detail Outcomes & Features: Break down goals into specific, functional requirements.

4. Analyze Constraints: Understand limitations (budget, time, tech).

5. Document Everything: Create a formal Project Requirements Document (PRD) or Design Document.

6. Validate: Get sign-off from stakeholders to ensure alignment

Fishbone theory, or the Fishbone Diagram (also known as an Ishikawa Diagram or Cause-and-Effect Diagram), is a visual tool for root cause analysis that maps out potential causes of a problem in a fish-skeleton-like structure, helping teams brainstorm, categorize, and identify underlying issues, not just symptoms, for better problem-solving in quality control and management. The problem is the "head," and major causes branch off the "backbone" as "ribs," with sub-causes extending further, revealing hidden linkages and process bottlenecks for future improvements.

You do not do discussion of problems with in the main topic as you link them into there own.

Mars you will need to understand not only materials but shapes for how any structure will be made and used.

Insitu does not mean you bring nothing.

Just think MOXIE as it was brought to use the atmospheric co2 to make oxygen for humans to breath.

What AI thinks

In-situ (Latin for "on-site" or "in its original place") in the context of Mars construction refers to the practice of using local Martian resources, rather than transporting all materials and equipment from Earth. This is officially called In-Situ Resource Utilization (ISRU).

The core concept is "living off the land" to drastically reduce the enormous cost and logistical challenge of sending supplies across vast distances from Earth.

The idea that you would have no equipment at all is generally not feasible; some minimal, specialized equipment and robotic systems would be sent from Earth to act as the initial "factories" and "builders". How ISRU Addresses the "No Equipment" Constraint (Relatively) The goal is to minimize the mass and volume of material that must be launched from Earth, not to eliminate equipment entirely. Specialized, compact, and often autonomous, equipment would be sent first to leverage local materials.

The strategy involves: Sending minimal, critical machinery: Instead of sending heavy raw materials like concrete or steel beams, lightweight robotic equipment, 3D printers, and processing hardware are sent.

Utilizing local materials: The robots would use abundant Martian resources, primarily the soil (regolith) and atmosphere, to produce usable products.

Automated construction: The construction process would likely be managed by autonomous or semi-autonomous robots before humans arrive, allowing for the creation of habitats and infrastructure in advance.

Examples of In-Situ Resources for Construction With specialized equipment,

Mars offers several resources: Regolith (Martian soil): This can be used as a primary building material. Processes like sintering (fusing with heat) or mixing with binding agents (like an epoxy or sulfur) can create bricks, ceramics, and concrete-like structures for radiation shielding and general construction..Water ice: Found below the surface, water is a critical resource. Once extracted, it can be used for life support (drinking water, growing food), split into hydrogen and oxygen (for breathing air and rocket propellant), or used in industrial processes.Atmospheric \(\text{CO}_{2}\): The Martian atmosphere is mostly carbon dioxide. Equipment like the MOXIE experiment on the Perseverance rover can extract oxygen from the atmosphere for life support and as an oxidizer for rocket fuel.

Basalt: Basaltic rocks are abundant and can be processed into glass or glass fibers, which have good insulating properties and can be used for construction. Essentially, "in-situ construction" is the practice of building with what you have on Mars, which is crucial for long-term sustainability and survival when resupply from Earth is nearly impossible

Mars in-situ regolith mining equipment involves robotic excavators (like RASSOR/Razer), drilling/microwave probes for volatiles, and processing units for extracting water, metals (iron/steel), and oxygen, using systems like Solid Oxide Electrolysis Cells (SOEC) (MOXIE heritage) and 3D printing for construction materials, with key technologies focusing on automation, heat recycling, and handling abrasive Martian dust for ISRU (In-Situ Resource Utilization).

Key Equipment & Technologies

Excavation & Collection:

Robotic Excavators/Rovers: Systems like RASSOR 2.0 and Razer use counter-rotating drums or buckets for digging in low gravity, designed for high volume and autonomous operation.

Microwave Probes: Non-excavation method to heat subsurface ice, turning it into vapor for collection, reducing mass/cost of heavy machinery.Processing & Extraction (ISRU):

Water/Volatiles: Extraction from regolith via microwave sublimation or drilling, followed by purification (membranes, distillation) and electrolysis to produce hydrogen (fuel) and oxygen (life support).

Metals & Oxygen: Systems (like MMOST) use electrolysis and reduction processes (e.g., using H₂/CO) to extract iron, steel, and oxygen from iron oxides in regolith.

Sifting/Refining: Machinery to achieve optimal particle size for construction aggregates, often involving heating and mixing with binders like sulfur.Manufacturing & Construction:

3D Printers: Use processed regolith (sintered, mixed with binders) to build structures, reducing reliance on Earth-imported materials.

Sulfur Concrete Units: Heated mixers (pugmills) to combine regolith aggregate with molten sulfur (around 120°C) for bricks.

Key Processing Units:

Solid Oxide Electrolysis Cells (SOEC): Efficiently split water and CO₂ into constituent gases (H₂, O₂, CO) for chemical processing.

Heated Mixers/Kilns: For creating construction materials like sulfur concrete or sintering regolith.

Challenges & Considerations

Automation: Mining must be fully robotic and autonomous due to distance and communication delays.

Abrasion: Martian dust is highly abrasive, requiring robust seals and durable components.

Power & Logistics: Requires reliable, renewable power and efficient transport/storage systems.

High-Fidelity Simulants: Accurate testing relies on materials like MGS-1C (clay-rich) and MGS-1S (sulfate-rich) to mimic real Martian conditions.Example System (Conceptual)

An integrated system might include a Razer excavator, feeding a processing unit that uses SOECs and heat recycling to produce oxygen, water, and metal powders, with a 3D printer using these materials to build habitats.

Online

Like button can go here

#2 2025-11-14 17:56:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

As you can see you must plan resources to utilize as well.

For a Martian habitat at 0.5 bar (significantly higher than Mars's ~0.006 bar average), spherical or cylindrical shapes are optimal for a stainless steel structure, as they efficiently contain internal pressure, with cylindrical shapes often favored for practical construction and use with regolith shielding, using tension members to handle stress, similar to pressurized vessels on Earth.

Why These Shapes?

Spherical: A sphere distributes stress equally in all directions, making it structurally ideal for holding internal pressure against a vacuum or low external pressure.Cylindrical: Cylinders (especially with domed ends) are practical for larger volumes, offer better usable floor space, and can be buried or covered with Martian soil (regolith) for radiation shielding without collapsing.

Structural Considerations for 0.5 Bar (50 kPa)

Pressure Difference: A habitat at 0.5 bar (50 kPa) has a substantial pressure difference from the Martian surface (around 0.6 kPa), requiring robust structures.Stainless Steel: While good for strength, stainless steel is heavy, making it costly to transport; however, it's excellent for withstanding pressure.

Tension: The primary force is outward tension. Structural members (like steel bands) wrapped around cylindrical habitats help contain this.

Design ConceptsBuried Cylinders: Building cylindrical habitats within trenches and covering them with regolith provides shielding from radiation and micrometeoroids, using the soil's weight to help counteract the internal pressure, notes Marspedia and NIH.

Domes: Dome-shaped structures (hemispherical) are also efficient for pressure containment, as studied by NASA.

In essence, think of large, pressurized tanks – spheres and cylinders are the best shapes for holding pressure, and adding regolith makes them even more effective Martian habitats

sure we can build using a system of bricks or blocks and even the hull of stainless steel from all not be repurposed starships left after each missions end.

For building arch shapes, you can use either tapered/wedge-shaped bricks or standard rectangular bricks. Tapered bricks are specially designed for arches to create uniform mortar joints, while rectangular bricks can be used for a flatter arch, sometimes called a soldier arch. Special shapes like double-tapered arch bricks or bricks with a specific angle (like a 70° skew-back angle for flat arches) are also available for curved elements.

Types of bricks for arches

Tapered or wedge-shaped bricks:

These are the most common for rounded arches. They are tapered to ensure that the mortar joints are of a consistent thickness throughout the depth of the arch.Double-tapered arch bricks: These are double-tapered in either width or length to form curved features, like an archway or a circular window.

Rectangular bricks (cut or full-size):

Soldier arches:

These are created by placing standard rectangular bricks on their ends, with their long sides set vertically. This type is more of a flat arch and requires support like a lintel or frame.Flat arches:

Flat arches are often constructed with standard rectangular bricks that are the same size and have parallel sides, sometimes with a specific skew-back angle.Specialty and pre-fabricated arches: Modern technology allows for pre-fabricated brick arches built to specific dimensions and designs, which can be a cost-effective solution.

Key considerations for size and shapeUniformity:

The key for most arches is achieving uniform mortar joints for structural integrity. Tapered bricks achieve this, while flat arches often use standard rectangular pieces with a consistent, small mortar joint.Angle:

For flat arches, a 70° skew-back angle is common for the voussoirs (the wedge-shaped stones used to build the arch).

Customization:If your design requires specific angles, curves, or a certain rise, you may need to specify custom dimensions or use pre-fabricated arches

A none clear dome could be done with brick of course.

Building a 200-meter diameter brick dome is a massive engineering challenge, a project that would surpass the scale of the world's current largest masonry dome, the Florence Cathedral dome, which has a diameter of approximately 42 meters.

Such a structure would require advanced engineering, modern materials science, and innovative construction techniques to ensure stability and durability.Key Considerations for a 200m Diameter Brick Dome

Structural Feasibility:

A 200m dome is possible in theory, but traditional unreinforced masonry techniques (like those used in historical domes) might not be sufficient at this scale due to the immense weight and stress. Modern construction would likely involve reinforced masonry, steel, or concrete elements.Foundation:

A robust and secure foundation is essential to handle the massive load of a 200m dome and transfer it evenly to the ground without settling.Construction Techniques:

Formwork:

Unlike smaller domes that can sometimes be built with minimal or no formwork using specific "tricks" like sticky mortar and specialized tools, a dome of this size would likely require extensive temporary support structures (centering or formwork) or innovative construction methods.Geometric Design:

The geometry is critical. Engineers would need to select an appropriate profile (e.g., a hemisphere, which might not be practical for the internal space usage, or a different curve).Material Science:

The bricks would need to be strong, and the mortar would play a critical role in bonding the massive structure.Engineering Expertise:

Collaboration between structural engineers and architects is vital to ensure all aspects of the design and construction are feasible and safe.Modern Alternatives:

For a dome of this size, modern construction methods like those used for Monolithic Domes (using an inflatable membrane, foam, rebar, and shotcrete) are more common and potentially more practical and cost-effective.

Seismic Considerations:

If built in an earthquake-prone region, specific reinforcement and design considerations would be critical to ensure the structure's integrity.

SummaryA 200m diameter brick dome would be a monumental architectural and engineering feat, far exceeding existing examples of masonry domes. Its construction would require substantial engineering innovation, modern reinforced techniques, and extensive structural analysis to overcome the challenges posed by its unprecedented scale.

While some of the content is earth many things for mars are still relevant.

Online

Like button can go here

#3 2025-11-15 14:03:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Asking AI for Mars is not what we need first as we need to understand the difficulties of building first on earth where man does this manually. Mars will not allow this which means mars needs new machines and processes. Lack of materials for bricks is an issue, there is no commodity shop for other materials to bind or to make them adhere to the made bricks. That is why you develope within a chamber with the conditions that you would use on mars once you have methods to try.

The largest brick dome that can be made on Mars is likely limited to around 150 feet in diameter, (45.72 meters) though even this would require extensive foundation engineering. This is because a pressurized dome on Mars is under tension and would attempt to tear itself from the ground, a problem that increases with size, as lifting force scales with area while anchoring force scales with circumference.

Limitations of domes on Mars

Structural tension:

Unlike on Earth, where the atmosphere presses a dome down, on Mars a pressurized dome's own weight creates outward tension, making it want to pull itself out of the ground.

Anchoring challenges:

A dome's anchoring force scales with its circumference, while its lifting force (the force trying to pull it up) scales with its area. This means a wider dome requires a proportionally larger foundation to resist the greater forces.

Practicality:

While domes are a common concept for Martian habitats, traditional brick domes may not be the most practical due to the extreme anchoring requirements. Alternatives like multi-layered vaults, foam-filled arcs, or 3D-printed habitats using local regolith are being explored as more viable options.Potential solutions for Martian domes

Reinforced structures:

A multi-layered vault settlement made from bricks with a steel-reinforced outer layer is a concept that could offer more structural integrity.

Inflatable structures:

A combination of inflatable arcs and a hard foam filling could allow for the creation of very large buildings without the need for heavy machinery.

3D-printed habitats:

NASA has supported 3D printing competitions where proposals use Martian regolith as a primary building material to create structures for astronauts

Online

Like button can go here

#4 2025-11-15 18:59:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

No single "epoxy" product exists for Mars temperatures,

but

researchers are developing specialized polymer composites using epoxy resins mixed with simulated Martian soil (regolith) and other local materials. These composites are designed for high physical properties and thermal stability in extreme Martian conditions, with some examples including modifications with tetraethoxysilane (TEOS) or the use of thermoplastic polymers for enhanced durability and UV resistance.

Epoxy and polymer composites for Mars

Polymer composites:

Researchers are creating polymer composites that use local regolith as a filler in epoxy resins.

High physical properties: These composites are being developed to achieve high physical properties, including mechanical strength and thermal stability, for use as building materials.

Modified fillers:

Chemical modification of the Martian regolith filler, such as with TEOS, can significantly enhance the properties of the final composite, notes this study from Cambridge University Press & Assessment.

Other considerations

Thermoplastics:

In addition to traditional epoxy, advanced thermoplastics are also being explored for their UV resistance and recyclability, which are crucial for space environments, according to this article from SpringerLink.

Sulfur concrete:

Another research avenue is the development of sulfur-based concrete, which uses sulfur as a bonding agent and is recyclable, notes this article from ScienceDirect.

Waterless concrete:

Given the lack of liquid water on Mars, many of these new building materials, including the epoxy-based composites, are being designed to be waterless.

Geopolymer cement:

Other research is focused on creating geopolymer bricks by mixing Martian soil with a high-pH solution to create a strong, cement-like material, according to University of Delaware.

Online

Like button can go here

#5 2025-11-16 17:35:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

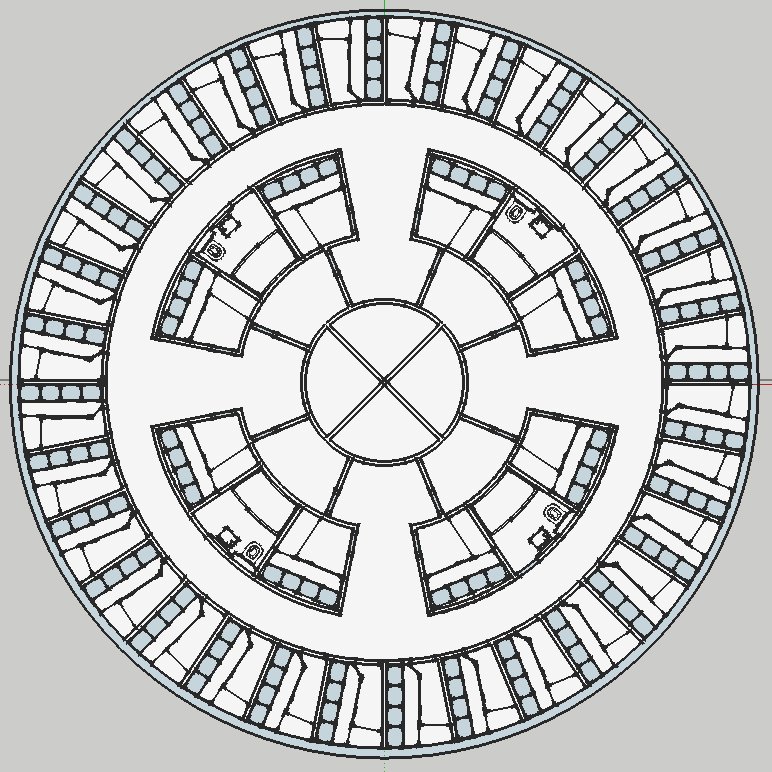

The 2 drawings give me the impression that the buildings are also tied into the actual dome for support and strength with each wall contact of vertical rise.

Online

Like button can go here

#6 2025-11-17 15:44:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

For walls that are on earth the bricks are limited to just about 15 m height without rebar in them with concrete as the binder to hold a wall upright.

This will not only need lots of trial and error just to get a process for any design.

Online

Like button can go here

#7 2025-11-18 15:29:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

I was not adocating for the use of Rebar but we may need to think about a substitute.

here is the brick types that are currently employed in building.

Class A construction bricks are a type of engineering brick known for their high compressive strength and low water absorption. These durable bricks, often called Staffordshire Blues, are used in demanding civil and commercial projects requiring extreme resistance to water and frost, such as retaining walls, sewers, and tunnels.

They have a compressive strength of over \(125N/mm^{2}\) and a water absorption rate of less than 4.5%.

Characteristics and specifications Compressive Strength:

Greater than \(125N/mm^{2}\) (approximately over \(18,000\) psi).Water Absorption: Less than 4.5%.

Composition:

Typically made from clay that is fired at very high temperatures to create a dense, strong, and non-porous material.

Appearance:

Often a dark blue color due to the high-temperature firing process, though other colors may be available. Aesthetics are less important than their physical properties.Common applications

Below-ground structures exposed to high moisture and frost.

Retaining walls.

Sewer systems.

Manholes.

Tunnels.

Damp proof courses.

Severe exposure applications and contrasting detailing in brickworkClassification/Grade: Class A construction bricks

Key Properties:

[] Compressive Strength: High (typically around 125 N/mm²)

[] Water Absorption: Low (typically less than 4.5%)

Typical Applications:

[] Structural applications

[] Foundations

[] Tunnels

[] Below-ground work

There is no established "Class A" construction brick for Mars, but scientists are developing several promising alternatives to build habitats using in-situ resources. These methods include using Martian soil (regolith) compacted under pressure, with iron oxide acting as a natural binder, or creating binding agents from organic materials like potato starch, or through synthetic biology with biominerals and fungal mycelium.

Methods for creating Mars bricks

Compacted Martian soil:

Researchers have found that Martian soil simulant, when compacted under pressure alone, can form durable, strong bricks.

The iron oxide in the soil acts as a natural binding agent, and the bricks are reportedly stronger than steel-reinforced concrete.

This method is compatible with additive manufacturing, where layers of soil are compacted to build structures.

Starcrete (starch-based binder):

A material called Starcrete uses potato starch, salt, and Martian soil as a binding agent.

This method allows for the on-site production of building materials, avoiding the need to transport them from Earth.

It is stronger than regular concrete.

Biomineralization:

This method uses self-growing blocks created by agents like cyanobacteria and fungi to produce biominerals (e.g., calcium carbonate) and biopolymers.

These agents bind the regolith particles together to form building materials.

This is a "living bricks" concept where the materials are self-creating and require no human input for production, as discussed in SciTechDaily.

Other binding agents:

Scientists have also explored using protein from blood as a binder for Martian soil, similar to a concrete, as described in Stanford University's news.

Research has been conducted on using human blood, urine, and feces to create construction materials.

Sulfur cement and other types of cement substitutes are also being considered for use on Mars.

Key takeaway

While no official "Class A" designation exists, the primary goal is to use in-situ resources to create a sustainable building material for Mars habitats, with many different methods being explored and developed by researchers worldwide

Online

Like button can go here

#8 2025-11-18 17:14:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Found the oth4r topic which is related Buried geodesic domes

Online

Like button can go here

#9 2025-11-19 15:18:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

For SpaceNut re link to topic about buried domes...

Just FYI ... I have tried to bring up bedrock, but so far I haven't seen any mention of the importance of setting the base of a massive building on bedrock. At present, we humans have very limited ability to know where bedrock is on Mars. There may be some data collected by satellites that could be helpful, but I'll bet no one has sifted that data looking for bedrock.

(th)

The depth of Martian bedrock varies, with the crust reaching up to \(23\) miles (\(37\) kilometers) in some areas and potentially being multi-layered, while the shallow subsurface is about \(200\) meters (\(656\) feet) deep in certain plains. The deepest bedrock layers can be up to \(37\) kilometers thick and contain water in some regions, with a shallow sedimentary layer sandwiched between solidified lava flows just below the surface.

Crustal and shallow subsurface depth Crust:

The overall thickness of Mars' crust is estimated to be between \(12\) miles (\(20\) kilometers) and \(23\) miles (\(37\) kilometers), depending on the number of sub-layers it has.Shallow subsurface: Studies of plains like Elysium Planitia have revealed a shallow subsurface about \(200\) meters (\(656\) feet) deep, which includes a layer of basaltic rock (cooled lava flows) and an intermediate layer of low seismic velocity.Layered subsurface:

The shallow subsurface is not a single layer of bedrock but appears to be multi-layered, with a sedimentary layer between lava flows in some locations. Deeper bedrock and water Deepest crust: The deepest parts of the crust are estimated to be as deep as \(23\) miles (\(37\) kilometers).Water in the crust:

Some models suggest that the mid-crust, around \(10\)-\(20\) kilometers (\(6\)-\(12\) miles) deep, may be porous and cracked, with enough water to form a global ocean \(1\)-\(2\) kilometers deep if collected.Other depths Surface layers:

The very top layer of the crust (first \(5\) meters) is thought to be a porous granular material, while the next layer down, from \(5\)-\(180\) meters, could be porous volcanic/sedimentary rock or consolidated volcanic rock.Polar deposits:

In the polar regions, layered deposits of CO2 and water ice extend to a depth of \(1\) kilometer (\(0.6\) miles).Bedrock on Mars generally refers to the underlying solid rock of the planet's crust, which varies significantly in depth depending on location and local geology.

The Bedrock Depth on Mars

Varies by location: The depth to bedrock can be very shallow in some areas, potentially just a few meters or less from the surface, especially in specific crater rims or outcrops.

Deep in other areas: In other regions, particularly where significant layers of regolith (soil and loose rock) have accumulated, the bedrock may be much deeper.

Crustal Thickness: The overall Martian crust (which is all bedrock) ranges in thickness from about 6 to 30 miles (10 to 50 kilometers). Data from the NASA InSight mission at its landing site suggested the crust was approximately 20 kilometers or 39 kilometers thick in two potential layers.

Scientists study the depth and composition of the bedrock using data from orbiters, landers, and rovers, which employ tools like ground-penetrating radar, cameras, and drills to analyze the surface and subsurface

Online

Like button can go here

#10 2025-11-22 15:49:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Martian sand grain sizes vary, with most active sand being very fine, around 50–150 micrometers, but coarser grains up to 500 micrometers or more are found in specific bedforms like coarse-grained ripples. The soil also contains dust particles smaller than this, and some inactive areas have a surface layer of much larger, dust-covered grains.

Fine sand

Dominant size:

The most common size for active sand is very fine, typically between 50–150 micrometers.Location:

This size is abundant in the troughs and on the surface of active ripples and other wind-blown features.Color:

The fine sand is often reddish due to the presence of iron oxides.

Coarser grainsSize:

Coarser grains can reach up to 500 micrometers and sometimes even larger, occasionally up to 1.4 mm or more.Location:

These larger grains are found on the crests of coarse-grained ripples and can be found on inactive bedforms.

Appearance: They may be reddish or whitish and have irregular shapes, suggesting they are formed from the erosion of local bedrock.Other particle sizes

Dust:

A significant amount of dust, much smaller than sand grains, is also present. It can mix with the sand or form a thin layer on top of other features.Gravel:

In certain areas, such as crater rims, gravel-sized particles (diameters above 2 mm) have been observed

Online

Like button can go here

#11 2025-11-22 19:10:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

A counter pressure is generally not how an internal atmosphere in a Martian dome would be contained. The force from an internal, human-habitable atmosphere on Mars is immense (around 10 tonnes per square meter), meaning the structure needs sufficient mass and design to resist this tension and prevent it from being lifted off its foundations. The most practical engineering approach for a dome made of Martian regolith bricks involves using the weight of the material itself (or an external regolith covering) to counteract the internal pressure differential.

Internal Pressure Requirements

Mars's Atmospheric Pressure:

The external atmospheric pressure on the surface of Mars is extremely low, averaging only about 0.6 kilopascals (kPa), which is less than 1% of Earth's sea-level pressure. It is effectively a near-vacuum from an engineering perspective.Human Habitable Pressure:

A human habitat requires a total internal pressure of at least 25 kPa with sufficient oxygen partial pressure to be functional without a pressure suit, or full Earth-equivalent pressure of 101.3 kPa (1 atm) for a standard environment.Pressure Differential:

The critical engineering challenge is the 100+ kPa pressure differential between the inside of the dome and the outside Martian atmosphere. This creates a massive outward and upward force on the structure.Structural Considerations for Regolith Domes

Tension vs. Compression:

Domes on Earth are compression structures, meaning their shape naturally handles the force of their own weight pushing down. On Mars, the low gravity and high internal pressure put the dome under tension, trying to tear it apart and lift it from its foundations.Material Limitations:

Regolith bricks, even advanced "StarCrete" or sintered versions with high compressive strength (up to 72 MPa), have lower tensile strength. Standard bricks and concrete perform poorly in tension.Design Solution: Weight and Reinforcement:

The primary method to manage the internal pressure is to use a thick layer of regolith as shielding/ballast.

Proposals often suggest using an internal inflatable bladder or a strong internal shell (perhaps with steel or carbon fiber reinforcement) to contain the air.This internal structure is then buried under several meters of Martian soil/bricks. The sheer weight of this external material provides the necessary "counter pressure" by pushing down and counteracting the upward lift from the internal atmosphere.

In short, the counter pressure is not an engineered force applied externally but rather the passive mass of significant regolith shielding used to anchor the structure to the ground.

The value of 10 tonnes per square meter is commonly used in discussions about Mars colonization, but it refers to two different concepts:

Earth's Atmospheric Pressure:

The pressure of Earth's atmosphere at sea level is approximately 10 tonnes of force per square meter (or about 100 kPa). This immense force is a key engineering challenge for designing habitats on Mars. Structures would need high tensile strength to contain a standard Earth-like atmosphere while resisting this outward pressure.Radiation Shielding Mass:

Around 10 tonnes of material (such as Martian soil or regolith) per square meter of surface area is considered sufficient for complete shielding from cosmic rays and solar radiation for a Mars habitat. This would require burying a habitat under several meters of soil (e.g., about 6.67 meters if the soil density is 1.5 tonnes per cubic meter).The actual atmospheric pressure on the surface of Mars is much lower, varying with elevation and season but averaging around 600 Pascals (Pa), which is less than 0.1 tonnes of force per square meter (about 0.6% of Earth's sea-level pressure). This pressure is far too low for humans to survive without a pressure suit.

Online

Like button can go here

#12 2025-11-22 19:34:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Building a dome on Mars using local soil to create bricks is a feasible concept being actively researched by scientists and engineers. Bricks made from compressed Martian soil simulant have been found to be stronger than steel-reinforced concrete, potentially exceeding the specified Grade A brick 125 N/mm² strength requirement.

Martian Brick Strength

Material: Martian soil (regolith) contains iron oxide nanoparticles which act as a natural binding agent under high pressure.Method:

A simple high-pressure compression method (like a blow from a hammer) can create sturdy bricks without needing an oven or additional binding agents from Earth. Other research explores using bacteria and urea or molten sulfur as binders.Strength:

Compressed Martian soil bricks have a compressive strength comparable to or even greater than steel-reinforced concrete (average adobe bricks have a much lower strength of 250-300 psi or 1.7-2.0 N/mm²). The specified 125 N/mm² (equivalent to approximately 18,129 psi) is an extremely high "Grade A" strength, which may be achievable or exceeded with these advanced composite materials/methods.Dome Construction and Soil Usage

Dome Feasibility:

Domes are a potential structure for human habitats on Mars, but they must be able to withstand the low external atmospheric pressure, internal positive pressure, and harsh environment (radiation, micrometeoroids).Construction Method:

The compression method is compatible with additive manufacturing (3D printing), where layers of soil are compacted to build a structure.Radiation Shielding:

10 tonnes of soil can provide significant radiation shielding. Habitats are likely to be built underground or covered with a thick layer of regolith to protect inhabitants from intense radiation. A depth of around 3-4 meters (or more to be safe) of rock/soil is needed to completely react out the pressure load and provide necessary shielding for a pressurized habitat.

In essence, using Martian soil to create extremely strong bricks for a protective dome is considered a promising strategy for future Martian settlements, as it drastically reduces the amount of material that would need to be transported from Earth

Online

Like button can go here

#13 2025-11-23 07:51:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

The spiral Ziggurat is a structure that would pile the berm msterial around the dome.

That mean counter compression is not the same externally for the shape of the domes upward pressure rise for the internal shape.

A ramp that increases means more mass above the dome shape which is not the same inside forcing that mass to cause calapse. It is physics as the dome is not gettting thicker as the ramp load changes.

Online

Like button can go here

#14 2025-11-23 15:36:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

A pressurized dome on Mars creates an "air pressure lift" that pushes outwards and upwards, a force that must be counteracted by the dome's structure and foundation to prevent it from tearing away from the Martian surface. The pressure is a result of the difference between the internal, breathable atmosphere and the extremely thin external Martian atmosphere. This upward force increases with the size of the dome, so while the internal pressure can support the dome's weight, the primary engineering challenge is managing the tension and anchoring the structure against the outward and upward forces.

How the air pressure lift works Pressure differential:

The core principle is the pressure difference. A dome designed for human life would have an internal pressure (e.g., \(15\) PSI, similar to Earth's sea level) that is hundreds of times greater than Mars's external atmospheric pressure (about \(0.006\) times Earth's).Outward and upward force:

This pressure difference exerts a force on every part of the dome's interior surface, pushing outwards in all directions and upwards against the ground.Force equation:

The total upward force on the dome is equal to the pressure difference multiplied by the dome's internal area. For a large dome, this can be an enormous force, measured in millions of tonnes.

For example, a \(100\)-meter diameter dome with a pressure of \(1\) atmosphere would exert a lifting force of about \(78,000\) tonnes.Structural tension:

This outward force places the dome's structure under tension, meaning it is constantly being stretched and pulled apart.How to counter the lift Anchoring and foundations:

The most critical engineering challenge is anchoring the dome to the Martian surface to resist this force.Force scaling:

The force trying to lift the dome increases with the square of its diameter (\(Force\propto Diameter^{2}\)), while the anchoring force is limited by the dome's circumference (\(Anchoring\ force\propto Circumference\propto Diameter\)). This means that the force-to-strength ratio becomes increasingly unfavorable as the dome gets larger.Structural design:

Because of this, early Mars dome designs are limited in size, and engineering focuses on creating a strong foundation and using tension-resistant materials. Some concepts also use internal structures, like multiple layers of pressure cells, to contain the pressure

Online

Like button can go here

#15 2025-11-23 18:10:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

So why different answers....

The area of a 200 m diameter dome, assuming it is a perfect hemisphere, is approximately 62,831.85m^2.

Step 1: Determine the radius and formula The dome is assumed to be a perfect hemisphere (half of a sphere). The diameter (\(D\)) is given as \(200\text{\ m}\). The radius (\(r\)) is half the diameter, \(r=D/2=100\text{\ m}\). The formula for the curved surface area of a hemisphere is \(A=2\pi r^{2}\).

Step 2: Calculate the area Substitute the radius into the area formula and calculate the result: \(A=2\pi (100\text{\ m})^{2}\)\(A=2\pi (10000\text{\ m}^{2})\)\(A=20000\pi \text{\ m}^{2}\)Numerically approximated, this value is: \(A\approx 62831.85\text{\ m}^{2}\)

Answer: The area of the dome is approximately \(62,831.85\text{\ m}^{2}\) (or exactly \(20000\pi \text{\ m}^{2}\)).

That makes the weight not correct only being half what is needed.

Number of bricks to make a wall 1 meter thick?

The number of bricks needed for a 1-meter wall depends on the wall's height and thickness.

For a 1-meter-high, single-layer "half-brick" wall, you will need approximately 60 bricks.

For a 1-meter-high, two-layer "one-brick" wall, you will need approximately 120 bricks.

You can calculate the total for any wall by multiplying the wall's square meterage by the appropriate number of bricks per square meter (60 or 120) and adding about 10% for wastage.Calculation for a 1-meter-high wall

Step 1: Determine the wall's length and thickness.

Let's assume the wall is 1 meter long and 1 meter high.Step 2: Determine the thickness of the wall.

Single-layer (half-brick) wall: You'll need about 60 bricks per square meter.

Two-layer (one-brick) wall: You'll need about 120 bricks per square meter.Step 3: Calculate the total number of bricks.

Single-layer: 1 meter (length) x 1 meter (height) x 60 bricks/sq meter = 60 bricks.

Two-layer: 1 meter (length) x 1 meter (height) x 120 bricks/sq meter = 120 bricks.Step 4: Add extra for wastage.

Add an extra 5-10% for cuts and mistakes.

For a 60-brick wall, add 3 to 6 extra bricks. For a 120-brick wall, add 6 to 12 extra bricks

Online

Like button can go here

#16 2025-11-24 15:28:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Domes are usually a topper for a structure that is under them.

Types of Domes in Architecture: A Comprehensive Guide

What is a Dome?

Types of Domes

Dome Types Based on Support System

Dome on Pendentives

Dome on Squinches

Types of Domes Based on Shape/ Form

Hemispherical Dome

Bulbous Dome/ Onion Dome

Beehive Dome

Geodesic Dome

Ellipsoidal/ Oval Dome

Sail Dome

Cloistered Dome

Cross-Arched Dome

Compound Dome

Types of Domes Based on Material

Masonry Domes

Concrete Domes

Tensile Fabric Domes

Metal and Glass Domes

Getting a Dome Structure Builtome structures can be classified on the basis of three major factors, as follows:

Types of Domes Based on Support System: Two types of structures have been used to support masonry domes for many centuries, and historically allowed builders to transition from square-shaped rooms to circular roof forms efficiently. These are:

Domes on pendentives

Domes on squinches

Types of Domes Based on Shape/ Form: Although typically hemispherical, dome shapes can be modified to form other related forms. Some of the commonly observed dome shapes are:

Hemispherical dome

Bulbous/ onion dome

Beehive dome

Geodesic dome

Ellipsoidal/ oval dome

Sail dome

Cloistered dome

Cross-arched dome

Compound dome

Types of Domes Based on Material Used: Domes can be constructed using a wide range of materials, including the following types:

Masonry domes

Concrete domes

Tensile fabric domes

Metal and glass domes

Dome Types Based on Support System

Online

Like button can go here

#17 2025-11-25 15:23:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Here is the nanoparticle compressed brick topic No bake Mars bricks/cdn.vox-cdn.com/uploads/chorus_image/image/54479463/mars_brick_1.0.jpg)

Edit to add Nasa document

Regolith Adaptive Modification Systems (RAMS)

If this is a grade A class brick then I will pass as it is cracked.

Online

Like button can go here

#18 2025-11-26 14:05:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

You can get a rough internal volume but once the structures are placed inside and you start to divi it up that volume will be less.

approximate 2,261,946 cubic meters.

Early structures should account for crew number count and equipment to do the initial toe and foot hold of settlement.

Online

Like button can go here

#19 2025-11-27 09:50:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

10 m wide spiral that has end retaining wall hieght of 1 meter around that parabolic dome.

Structure Description

[]Dome: A [size=15]parabolic dome[/size] that is 200 m in diameter and 120 m tall.

[]Road: A 10 m wide road wraps around the dome.Spiral: A 1 m high spiral encircles the road/dome structure.

Assuming the user wants to calculate the total length of the 10-meter wide spiral road around the parabolic dome, here is the solution. The "1 meter high spiral" is assumed to be the pitch of the spiral (vertical distance per full revolution), and the road is assumed to follow the surface of the parabolic dome.

Step 1: Define the Parabolic Dome Equation The parabolic dome has a diameter of \(200\) m (radius \(R=100\) m) and a height \(H=120\) m. The equation for the height \(h\) as a function of the radius \(r\) is:\(h=H-ar^{2}\)Using the base dimensions (\(h=0\) when \(r=R=100\) m):\(0=120-a(100^{2})\implies a=\frac{120}{10000}=0.012\)The equation of the dome is \(h=120-0.012r^{2}\). The radius can be expressed in terms of height:\(r=\sqrt{\frac{120-h}{0.012}}\)

Step 2: Formulate the Arc Length Integral The road is a spiral with a pitch \(P=1\) m. The total length \(L\) of a spiral can be found using the arc length formula for a 3D curve in cylindrical coordinates:\(L=\int _{0}^{H}\sqrt{\left(\frac{dr}{dh}\right)^{2}+r^{2}\left(\frac{d\theta }{dh}\right)^{2}+1}\,dh\)The angular change \(\frac{d\theta }{dh}\) is constant, where \(2\pi \) radians corresponds to the pitch \(P\):\(\frac{d\theta }{dh}=\frac{2\pi }{P}=\frac{2\pi }{1}=2\pi \text{\ rad/m}\)Differentiating \(r(h)\) with respect to \(h\):\(\frac{dr}{dh}=\frac{1}{2\sqrt{\frac{120-h}{0.012}}}\cdot \left(\frac{-1}{0.012}\right)=-\frac{1}{2\sqrt{0.012(120-h)}}\)The integral becomes:\(L=\int _{0}^{120}\sqrt{\left(-\frac{1}{2\sqrt{0.012(120-h)}}\right)^{2}+\left(\sqrt{\frac{120-h}{0.012}}\right)^{2}(2\pi )^{2}+1}\,dh\)\(L=\int _{0}^{120}\sqrt{\frac{1}{4(0.012)(120-h)}+\frac{120-h}{0.012}\cdot 4\pi ^{2}+1}\,dh\)

Step 3: Calculate the Integral This integral is complex. After evaluation, the approximate length of the spiral is:\(L\approx 4768.8\text{\ m}\)The road width of 10 m is used for context but does not affect the centerline length calculation.

Answer: The calculated total length of the spiral road with a 1 meter pitch around the parabolic dome is approximately 4768.8 meters (or about 4.77 km).

The dome will need a lead up ramp that can grow as we approach the overlap area after going around to achieve each loop height change of 1 M. The dome also has not ground level entrances that would most likely be arched and 10 M wide as an air lock for equipment to go in and out of the city in at least 2 or more locations.

Digging the material downward while it would allow for building on bedrock still means a huge amount of work to bring it out depending on how deep it gets. It would be simular to the open pit mines earth has.

To move 10 cubic meters of Mars regolith, you would need a tandem axle dump truck or a medium-to-large single-axle dump truck. A standard commercial tandem axle dump truck typically holds between 7.6 to 10.7 cubic meters (10 to 14 cubic yards) of material, making it a suitable option for exactly 10 cubic meters.

Dump Truck Options for 10 Cubic Meters

Medium Dump Truck (Single Axle):

These can hold a load volume of 3 to 6 cubic meters, so you would likely need two trips, or a very large single-axle model near its upper limit.Tandem Axle Dump Truck:

This is the most efficient option, as its typical capacity of 7.6 to 10.7 cubic meters can handle the entire volume in a single load. Some models can even handle up to 13 to 20 cubic meters.

Large Dump Truck (Tri-Axle/Super Dump): These trucks have capacities ranging from 13 to over 25 cubic meters, which would easily manage the load, though the truck might not be operating at full volumetric capacity.

Important ConsiderationsWeight vs. Volume:

The weight of the regolith (Martian soil) is a critical factor, even more so than volume. The density of material matters in determining the actual safe load capacity to avoid overloading the truck's weight limits.Martian Gravity:

The user's prompt specifies "Mars regolith," which implies an off-world scenario. The lower gravity on Mars (roughly 38% of Earth's gravity) would significantly alter the weight constraints and potentially allow a standard Earth-rated dump truck to carry a larger mass of material than it could on Earth, assuming the engineering for the martian environment is addressed.Equipment Specialization:

For actual off-world operations, the equipment would be specifically designed for the Martian environment, likely featuring wider cutting heads or different axle configurations to handle the unique terrain and gravity conditions.

How Many Cubic Yards Are in a Dump Truck?

Larger dump trucks can carry approximately 10 to 16 cubic yards of material. However, the total volume is not usually the limiting factor. In most cases, the vehicle’s weight limit will determine how much material you are ultimately able to safely transport.

So a dump truck that we could use is

A tri-axle dump truck typically weighs between 25,000 and 35,000 pounds when empty, but can weigh up to 80,000 pounds when fully loaded, depending on the load and local regulations. The specific weight varies based on the materials used to construct the truck (e.g., aluminum bodies are lighter than steel), the size and type of the dump body, and the weight of the fuel and driver

Digging a cylinder or depth depends on how deep it will go.

To calculate the volume of a cylinder in cubic meters with only the diameter provided, we must assume a value for the height (h) of the cylinder, as it is a required parameter. Assuming the height is equal to the diameter (200 m), the volume can be calculated.

BBCode Output

Assumed Parameters:

Diameter (d) = 200 m

Radius (r) = d / 2 = 100 m

Assumed Height (h) = 200 m

Formula:

The volume (V) of a cylinder is calculated using the formula V = πr²h.

Calculation:

V = π × (100 m)² × 200 m

V = π × 10,000 m² × 200 m

V = 2,000,000π m³

V ≈ 6,283,185.3 cubic meters (using π ≈ 3.14159265)

Result:

The volume of a cylinder with a 200 m diameter and an assumed 200 m height is approximately 6,283,185.3 m³ (cubic meters).

Of course we can practice the spiral ramp in reverse for digging the material...

Online

Like button can go here

#20 2025-11-28 16:09:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Why would we cheap material thickness as from what I have seen of the bricks seem to be brittle coming out ot the compression form. I know that is the number Caliban put in the description but so far we have not made real bricks on mars at temp or from raw regolith.

Metric brick dimensions vary by region, but common sizes include the Metric Modular (\(190\times 90\times 90\) mm or \(194\times 92\times 57\) mm) and the UK standard brick (\(215\times 102.5\times 65\) mm).

For a nominal size, the Metric Modular is often specified as \(200\times 100\times 100\) mm to include a \(10\) mm mortar joint.

Common metric brick sizes Metric Modular (actual size):

\(190\times 90\times 90\) mm or \(194\times 92\times 57\) mm.

Often specified as nominal size: \(200\times 100\times 100\) mm to account for a \(10\) mm mortar joint.UK Standard Brick: \(215\times 102.5\times 65\) mm.

Metric Norman: \(290\times 90\times 57\) mm.

South African Standard: \(222\times 106\times 73\) mm.

Swedish Standard: \(250\times 120\times 62\) mm.

How to choose the right size Identify the region:

The specific dimensions depend on the country or region where you are building.Consider the nominal vs. actual size:

Some standards, like the Metric Modular, have both an "actual" size and a "nominal" size that includes the typical mortar joint for planning purposes.Match existing bricks:

If you need to match existing brickwork, a small deviation is usually acceptable, as the mortar joint can absorb a few millimeters of difference. It is best to choose a brick that matches the height of the existing course as closely as possibleHere are common metric brick dimensions output in BBCode format, specifying both the brick's actual manufactured size and its nominal size (which includes an allowance for a standard mortar joint, typically 10mm).

Dimensions are listed as Length x Width x Height.

Common Metric Brick Dimensions

[li]Standard UK Metric Size (widely adopted since 1970):[/li]

[] Actual Size: 215 mm x 102.5 mm x 65 mm

[] Nominal Size (with 10mm joint): 225 mm x 112.5 mm x 75 mm[li]International Modular Size (common in countries like India):[/li]

[] Actual Size: 190 mm x 90 mm x 90 mm

[] Nominal Size (with 10mm joint): 200 mm x 100 mm x 100 mm[li]US Modular Size (metric conversion):[/li]

Actual Size: 194 mm x 92 mm x 57 mm

[li]European "Normal Format" (NF):[/li]

Actual Size: 240 mm x 115 mm x 71 mm

Note: Actual dimensions can vary slightly by manufacturer and region due to tolerances. The nominal dimensions are generally used for design and estimating purposes to fit within modular building systems.

Grade A engineering bricks in the UK typically have the following dimensions in metric units:

Length: 215 mm

Width (Depth): 102.5 mm

Height: 65 mm (other heights like 73mm and 80mm are also available)

These are the actual dimensions of the brick unit.When planning construction, a standard 10 mm mortar joint is usually included, making the "working size" for calculation purposes 225 mm x 112.5 mm x 75 mm.

Grade A engineering bricks are defined by their physical properties rather than their size, specifically having a high compressive strength of greater than 125 N/mm² and low water absorption of less than 4.5%

Online

Like button can go here

#21 2025-11-30 18:45:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

I am coming into earths season of winter where the sill foundation heave with the frost, and cold cycles. Mars have them for not only brime water but for co2 as well. Which I see in my concrete block cement that are used in my cellar. Some cracks on the inside while other are only on the outside but I have a few that go straight through.

Mars has two types of seasonal frost and ice: carbon dioxide (CO2) "dry ice" that forms in winter and retreats in summer, and water ice frost that forms at lower latitudes in specific conditions. The CO2 frost forms the planet's polar ice caps, which can reach a maximum depth of 1.5 to 2 meters in winter, while water ice frost is found in smaller quantities, primarily on pole-facing slopes at lower latitudes.

Carbon dioxide (CO2) frost and freeze depthFormation:

In the fall and winter, atmospheric CO2 freezes and forms a seasonal polar cap on the surface.Depth:

At its maximum depth in mid-winter, the CO2 frost can reach 1.5 to 2 meters at the poles.Retreat:

As the seasons change and the sun returns, the CO2 sublimates (turns directly into gas), and the ice cap recedes.

Atmospheric Transport: The sublimation process releases large amounts of dust and water vapor, which can create Earth-like frost and clouds.Water ice frost and freeze depth

Formation:

Water ice frost is found on Mars primarily in the form of small patches at lower latitudes, especially on pole-facing slopes where temperatures are lower. It can also be found subsurface in the northern hemisphere and in the southern polar regions.Freeze Depth:

The freeze depth of water ice is more complex to measure, but some studies suggest the depth can range from less than 1 cm to over 19 cm in certain areas.Sublimation:

Like CO2 frost, water ice also sublimates during the summer, with some being trapped under the CO2 ice and re-freezing as water ice fans.Seasonal variations

Winter:

CO2 ice accumulates at the poles, and the seasonal polar caps grow. Water ice also forms subsurface deposits in the northern hemisphere.Spring:

As temperatures rise, the CO2 ice begins to sublimate, and the seasonal polar caps start to recede.Summer:

The CO2 ice sublimates completely, and the polar caps disappear, while the water ice deposits also begin to sublimate and retreat.Autumn:

The polar caps begin to re-form as temperatures drop again

Insight showed this with the hammer drill that did not reach depth.

Online

Like button can go here

#22 2025-12-04 16:41:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

One more thing to think of

A map of thorium on Mars, created by NASA's Mars Odyssey spacecraft, shows that thorium is not evenly distributed across the planet. High concentrations are found in the northern part of Acidalia Planitia, while areas to the north of Olympus Mons and the Tharsis and Elysium Mons volcanoes show lower abundance. The map, generated using gamma-ray spectroscopy, reveals these surface concentrations of thorium, a naturally radioactive element.

Key features of the Mars thorium map

Data source: The data comes from the gamma-ray spectrometer on NASA's 2001 Mars Odyssey mission, which detects elements by measuring gamma rays they emit after being activated by cosmic rays.

High thorium areas: The highest concentration of thorium is located in the northern part of Acidalia Planitia.

Low thorium areas: Areas with low thorium content are widespread, including locations north of Olympus Mons, east of the Tharsis volcanoes, and south and east of Elysium Mons.

Geological insights: The map helps scientists understand Mars's volcanic history and the composition of its surface, including variations in magmatic water over time

Online

Like button can go here

#23 2025-12-06 19:13:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Some think that sulfur as a binder but it means processing the ingredients to make a regolith brick with such maters which are being done with 3D printing while still hot.

I Overview

Scientists develop Martian concrete for building in space

Building concrete floors on Mars involves using local materials like Martian soil (regolith) and sulfur (abundant on Mars) or even protein-based binders, eliminating water needs, often using 3D printing robots for efficient construction of habitats that resist extreme cold, radiation, and dust, making structures strong yet light enough for space transport. Key methods focus on sulfur concrete (heating sulfur to bind soil) or biocomposites, creating strong, recyclable materials for floors and walls.Key Materials & Methods

Sulfur Concrete:

Process:

Mix sulfur (heated to ~240°C to liquefy) with Martian soil (regolith) as aggregate, then let it cool.

Benefits:

Water-free, strong as traditional concrete, recyclable, resistant to cold, salt, and acid.

Application:

Can be 3D printed directly, ideal for robotic construction.

Biocomposites (Using Human/Biological Materials):

Process: Mix Martian simulant with human serum albumin (a blood protein) or chitin (from insects/crustaceans) as binders.

Benefits:

Creates strong materials (ERBs) that can be 3D printed; chitin could come from farmed insects.

Magnesium-Silicon Binders:

Process:

Mix magnesium and silicon (found in Martian basalt) to create a cement-like binder.

Benefits:

Strong, behaves like Earth cement but potentially stronger.

Construction for Floors & Habitats

3D Printing:

Robotic arms with extruders print structures layer-by-layer using molten sulfur or other mixes.

In-Situ Resource Utilization (ISRU):

Using local resources drastically cuts down on expensive imports from Earth.

Design:

Structures are often designed for compressive strength (like domes or vertical layouts) to suit concrete, with floors as integral parts.

Why it Works on Mars

Water Scarcity:

Traditional concrete needs water, but these methods use sulfur or other binders, perfect for Mars' dry environment.

Abundant Sulfur:

Mars has vast sulfur deposits, making it an ideal binding agent.

Harsh Environment:

Martian concrete needs to withstand extreme temperatures, low pressure, and radiation, properties these new materials offer

AI Overview

Scientists are actively researching ways to create building materials, including bricks, on Mars using in-situ resource utilization (ISRU). One method under investigation involves using epoxy resins or other polymers as binders for Martian soil simulants.Methods for In-Situ Martian Bricks

The goal of ISRU is to minimize the need to transport heavy building materials from Earth, making long-term settlement more feasible.Several binding agents and methods are being explored:

Epoxy Resin/Polymer Binders:

Researchers have successfully synthesized stable bricks in lab experiments by mixing Martian regolith simulant with an epoxy-resin or other polymers. This approach involves creating a composite material that can be poured into molds or used in 3D printing systems, the latter of which allows for complex shapes.Pressure Compaction ("No-Bake" Bricks):

Engineers at UC San Diego accidentally discovered that by applying high pressure alone, without any polymers or heat, Martian soil simulant can form strong, durable bricks. The iron oxide in the soil acts as the binding agent when compacted.Biological Processes:

In collaboration with the Indian Space Research Organisation (ISRO), researchers at the Indian Institute of Science (IISc) developed "space bricks" using a slurry of Martian soil simulant, guar gum, bacteria (Sporosarcina pasteurii), urea, and nickel chloride. The bacteria induce the precipitation of calcium carbonate crystals, binding the soil particles together.

Sulfur-based Materials:

Another promising waterless method involves using molten sulfur as a binder for Martian regolith. This creates a type of extra-terrestrial concrete ("Marscrete") with high compressive strength suitable for construction.

Sintering/Heating:

Other methods explore using high temperatures (sintering) to fuse the soil particles into a solid mass, potentially powered by nuclear or solar energy on Mars.Applications and Future Steps

These in-situ bricks would be used to construct essential infrastructure, such as protective shelters and research stations, that can withstand the harsh Martian environment (low pressure, extreme temperatures, high radiation). Future research involves scaling up production, testing materials in simulated Martian atmospheres, and developing automated robotic construction methods

Online

Like button can go here

#24 2025-12-08 19:13:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

This is one of the starships floor plans posts that make sense for crews first homes.

The terrraced over layed hill would have greater numbers for each floor

Online

Like button can go here

#25 2025-12-09 18:05:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: WIKI Project construction design meaning for insitu materials

Away to fit in the rooms in the dome

looking up at the top from the inside of a We finally know why Roman concrete has survived for nearly 2,000 years

Online

Like button can go here