New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#276 2025-06-06 08:00:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For SpaceNut re lubrication of bearings ....

A possible solution to the very real problem you have identified is to allow for the rotating habitat batons to turn with only magnets keeping the walls of the rotating components away from each other. This could be done during flight when there are no forces acting to move the fuselage. When it becomes necessary to apply force for navigation, the rotating components could be brought back together so they can accept acceleration loads.

I've never heard of such a system, and there may be practical reasons why it would not work.

I'm pretty sure magnetic bearings do exist, but the machines involved might be small.

(th)

Offline

Like button can go here

#277 2025-06-06 12:30:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

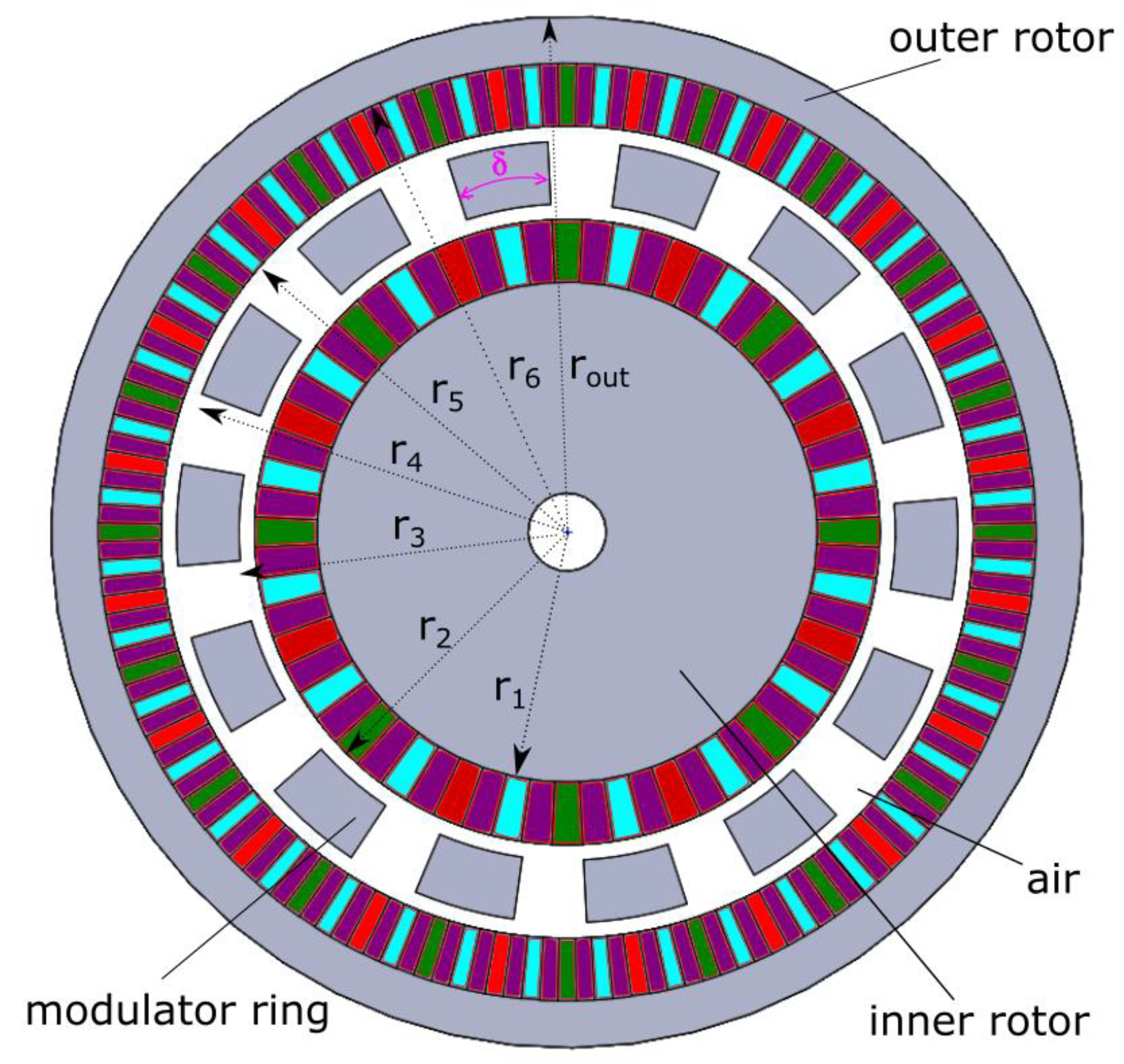

Using rings of permanent magnets in a Halbach array could lock all rotating and "stationary" parts of the vehicle in place without physical contact. Permanent magnets are typically heavier than electromagnets for the field strength they provide, but they do not require any input electrical power. For the strength of the field required for this application, stronger fields are likely irrelevant. Beyond that, we really don't want the magnets to be "turned off" in this application. The vehicle will function best if the magnets are "on" at all times, and the various parts "float" perhaps a centimeter away from each other.

The label "air" would be replaced with "vacuum" in space:

A planar permanent magnet array:

Axial flux electric motor:.jpg)

Halbach arrays can also be incorporated into a "curved" inner and outer lip type of geometry, so that the magnetically suspended habitation modules cannot readily "fly apart", even if the magnets themselves fail.

Offline

Like button can go here

#278 2025-06-06 13:20:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

A much cheaper option would be using full ceramic bearings with minimal Silicone-based lubricant. At 6rpm, the duty cycle is 3,153,600 cycles per year.

A drastically cheaper option would be using standard Babbitt metal bearings with lubricants. Much hay is made over this, but the battery operated tools used by the astronauts to repair the Hubble Space Telescope, such as the bit driver they used to unscrew and re-torque bolts, did in fact use bearing lubricants. The photovoltaic arrays on the ISS do in fact use sealed metal bearings with a vacuum-compatible grease.

That means there are 3 ways to solve this centering and bearing problem:

1. Contactless permanent magnets or electromagnets.

2. Dry or minimally lubricated ceramic bearings.

3. Lubricated metal bearings.

Option 1 is scientifically interesting because it will theoretically never fail from direct contact friction.

Option 2 can work, but is also expensive at the scale required and will still require periodic replacement.

Option 3 will work for many years before replacement and is exhaustively well proven on Earth and in orbit aboard ISS.

Offline

Like button can go here

#279 2025-06-13 08:51:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kdb512 re #278...

There is an additional option that might be worth adding to your list.

A hybrid system would use physical bearings when the habitats are undergoing acceleration by the fuselage, and magnetic bearings during free flight.

This post is to note your contributions to the RDE topic, and to ask what I hope will be a useful question for a future post.

My understanding (so far) of RDE is that it is more efficient in mixing gases for propulsion, and I've picked up the impression that RDE delivers better performance than alternatives.

My impression from reading your posts and other sources, is that a significant benefit of RDE is reduced mass, possibly due to elimination of turbo pumps but I'm not clear on that point.

Aside from those issues, I'm wondering if RDE provides better ISP for a given propellant mixture?

If if does, what is the mechanism that provides that improvement?

(th)

Offline

Like button can go here

#280 2025-06-13 09:02:47

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: kbd512 Postings

The shock wave moves circumferentially around and around. Flow ahead of it is supersonic, but flow behind it is subsonic, because it is a normal shock. It has to be. So this technology is inapplicable for anything claimed to be "supersonic combustion". The confusion factor with terminology here is with "supersonic" ahead of the wave. That is NOT due to the flow speed coming into this thing from the inlet, it is due to the speed of the circulating wave itself, which must be inherently supersonic in its circumferential speed.

Shock wave-induced combustion is a pressure-gain kind of combustion that we call "detonation", as opposed to merely explosively-fast "deflagration" that occurs with a slight pressure loss. Those are the only two kinds, and achieving stable and controlled detonation combustion has been a very difficult thing to do. For the same pressure gain from the air inlet hardware, the detonation-wave combustion will result in a higher-pressure subsonic chamber condition behind the circulating wave, than could possibly be produced by deflagration in a more conventional combustor scheme. That higher pressure results in a different nozzle throat size, too.

Higher chamber pressure is simply higher thrust potential, which for the same fueling rate is higher specific impulse (if a rocket). That definition of thrust and specific impulse gets a lot more complicated if you do this as an airbreather. But the nozzle thrust term in airbreather thrust really is bigger.

GW

Last edited by GW Johnson (2025-06-13 09:06:06)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#281 2025-06-14 15:35:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

With respect to your question about RDE Isp, I think GW already explained how detonation vs deflagration delivers more thrust for the same propellant mass flow rate.

Expander cycle conventional deflagration-based chemical rocket engines use waste heat from the engine nozzle and combustion chamber to drive the pumps, up to output levels of about 300kN or so, which implies 600kN output levels for a RDE. For RDEs with thrust levels much beyond 600kN, my assumption is that you still require turbopumps, but those pumps will only need to deliver half of the work output which would otherwise be required to feed propellant into conventional deflagration engines.

For a "main engine" using rotating detonation, my assumption is that the engine must still be pump-fed, but the shaft power consumed by the oxidizer and fuel pumps is approximately half that of a thrust-equivalent deflagration-based engine. Let us assert that a particular deflagration-based rocket engine requires 10MW of shaft power. The equivalent RDE should require about 5MW. One would therefore expect that the pump mass for the RDE is about half that of the deflagration engine. This assumption may not be 100%-true-to-reality accurate, but it will be a reasonably close approximation.

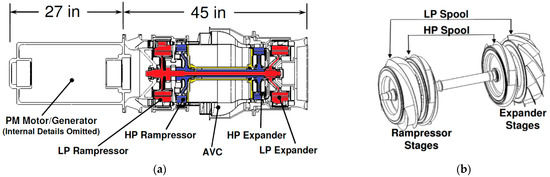

As far as air-breathing RDEs are concerned, I think Dresser-Rand's "rampressor" (supersonic ram-air compressor), which was originally designed to compress CO2 exhaust gas from coal-fired power plants for storage, can deliver compressed air to the engine with a supersonic inlet velocity. Unlike a conventional gas turbine engine, there's no need to slow the incoming airstream to subsonic velocities before feeding it into the compressor stages of the gas turbine. The rampressor uses a special inlet ramp geometry to permit shockwave-assisted gas compression, rather than massive wave drag, which is what you get when the tips of prototypical "fan blades" used by conventional gas turbine engine compressor stages approach or exceed the speed of sound. Conventional blade-based compressor stages could deliver 2:1 CO2 compression ratio per stage. The rampressor designed by Dresser-Rand delivered 10:1 compression per stage, with the ability to recuperate some of the waste heat to reduce the power required to drive the compressor.

The thrust that a rampressor based turbojet engine can deliver is roughly double that of a conventional turbojet. Another way of saying that is a gas turbine engine using rampressor technology to feed air into the engine has double the thrust-to-weight ratio of a conventional blade-based subsonic air compression gas turbine engine, because it needs fewer compressor stages and is far more compact than a conventional turbojet engine as a result.

A "RamGen" Engine with Dual Supersonic Inlet and Dual Supersonic Expander Stages:

The air going into the engine inlet is supersonic, combustion happens at supersonic velocities, and gas expansion happens at supersonic velocities. This would destroy or severely damage a conventional turbojet engine. However, the "rampressors" are deliberately designed to compress and expand supersonic air. The supercomputer-designed inlet ramp geometry uses the "trapped" shockwave to actually assist with compressing the incoming air stream, which is how the test models achieved 10:1 to 12:1 compression per stage, vs the 2:1 compression achievable with "normal" fan blades. A conventional turbojet or turbofan engine would use complex inlet geometry to trap the shockwaves from the supersonic flow and also slow the incoming flow to subsonic speeds, loosing kinetic energy and generating heating in the process.

The most advanced models of GE's GEn-9X turbofan (an advanced GE-90 derivative engine design) that power jets like the Boeing 787 use, IIRC, 14 stages of compression, and achieve an overall pressure ratio (OPR) of about 58:1 during certain phases of flight, with 42:1 at takeoff. OPR is a figure of merit that describes the overall efficiency of a jet engine. A 2 stage Rampressor achieves a 100:1 OPR.

In gas turbine engines, the overall pressure ratio (OPR) is a crucial parameter that significantly impacts engine performance, efficiency, and thrust output. It represents the ratio of the total pressure at the exit of the compressor to the total pressure at the inlet. A higher OPR generally leads to increased thermal efficiency, more thrust, and improved fuel consumption.

A Review of Shock Wave Compression Rotary Engine Projects, Investigations and Prospects

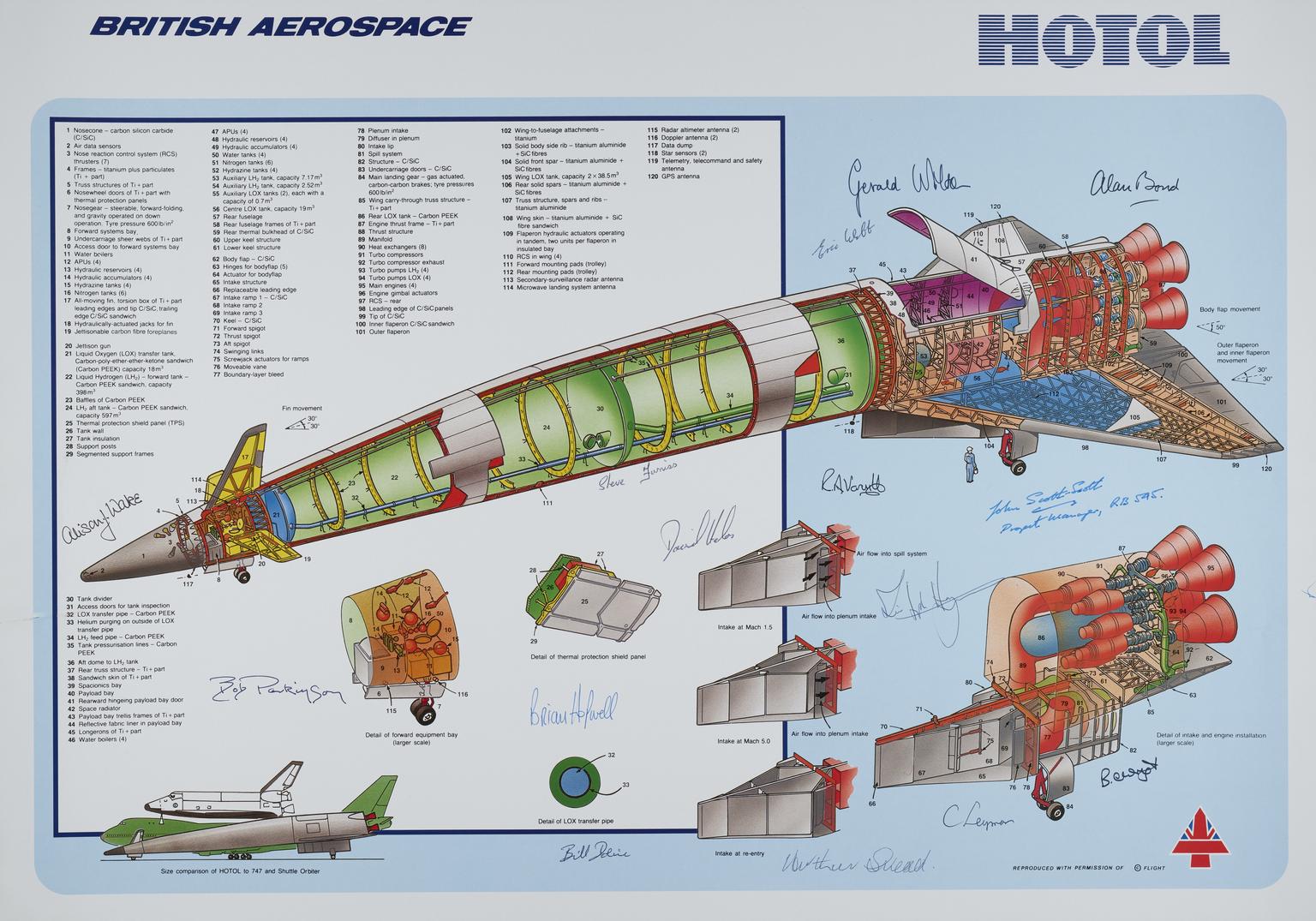

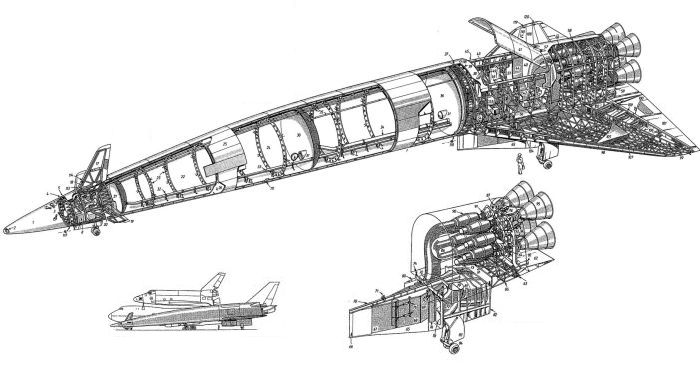

British Aerospace HOTOL:

North American-Rockwell's STS orbiter delivered 12,500kg to a 400km (ISS-like) circular orbit.

BAE's HOTOL was intended to deliver 7,000kg to 8,000kg to a 300km circular orbit.

HOTOL would carry about 205,000kg of LOX/LH2 propellant, with the fuselage containing 48,000kg (677.488m^3) of LH2 and 157,000kg (137.599m^3) of LOX. Isp was said to be about 700s overall, and around 2,000s at sea level when consuming atmospheric Oxygen to power the engines. Total burn time to achieve orbit was to be about 730s. HOTOL would transition to using pure rocket propulsion between Mach 5 and Mach 6, which correlates well with prototypical booster burnout velocity for a TSTO.

I envision a SSTO somewhat similar to BAE's HOTOL concept, meaning a HTHL vehicle that takes off and lands on a conventional runway, but powered by rampressors to do away with those large and heavy variable geometry inlets, ultimately force-feeding atmospheric Oxygen into RDEs. Rather than including all the machinery to convert atmospheric air into a liquid, we instead use hot high pressure gas from the rampressors, and use some of the waste heat to convert RP1 into a vapor to feed into the RDEs. RP1 was selected over LH2 to both reduce the volume of the vehicle for a given payload mass, and to avoid the complexities of handling LH2 on the ground. The vehicle will be heavier as a result, but we can get more payload to orbit using higher thrust from RP1 and greatly reduced turbopump size / mass / volume.

This vehicle would use advanced materials for structure and thermal protection that simply did not exist when the HOTOL concept was being developed in the 1980s, along with and an advanced combined cycle propulsion system that uses RamGen and RDE engine tech that also did not exist.

The purpose of this vehicle, once again, is purely passenger transport to orbit to either a space station or awaiting interplanetary transport vehicle. We already have Starship, New Glenn, and perhaps Vulcan to do the heavy lifting. If we apply pure RDE power, meaning no air-breathing, and the same materials tech to a VTVL TSTO, it's still likely to deliver more payload for less money. Even our miraculously powerful new engines and advanced materials cannot compensate for discarding 2/3rds of a vehicle's dry mass on its way to orbit.

Something similar to HOTOL will deliver 1t of payload per 31.25t of vehicle and propellant mass. I'm sure we can improve on that using modern materials, but only to a point. HOTOL would've used bleeding edge engine and materials tech when it was developed. The only real night-and-day performance improvement is related to the engines.

Starship 3 will deliver 1t per 25t of vehicle and propellant mass with full reusability, or 1t per 12.5t to 16.7t fully expended. No SSTO is ever going to compete with an expendable TSTO on payload performance, and it's pointless to try. We are never going to beat basic flight physics, even if we manage to devise a SSTO that is only marginally worse than TSTO.

The only real "game changer" that might be possible in another 30 years or so is using fusion to superheat a monopropellant like LH2 or LCH4. That kind of SSTO may make using TSTOs for heavy cargo delivery a thing of the past, but only because fusion rather than chemical energy supplies the heat input, and it will probably need to be aneutronic fusion to minimize shielding requirements, which implies He3, which implies lunar mining. That makes fusion-powered SSTOs a far future technology that requires greenfield development work, and lots of it.

Until then, we really need to have mass-competitive air-breathing SSTOs for minimal risk passenger delivery to orbit, to allow airline transport services to take shape. We'll continue to use advanced TSTOs for heavy cargo until something like aneutronic fusion heat engines (~7,000s of Isp with H2) makes chemically powered SSTOs and TSTOs superfluous. On top of that, we really must have a propellantless launcher, either a rotary slingshot type machine or electromagnetic gun, for cost-effective delivery of bulk delivery of metals and liquids.

Offline

Like button can go here

#282 2025-06-15 02:50:05

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

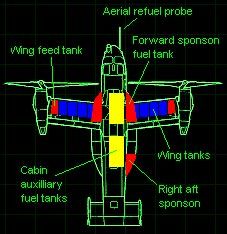

For clarity, in the first illustration above you will see a different variant of the HOTOL vehicle with 995m^3 of tank volume allocated to LH2 (70,496kg at most), plus 114m^3 (130,074kg) of LOX tank capacity, and possibly up to 140m^3 of LOX, although the actual capacity of the aft LOX tank near the engine cluster is not provided. LH2 fuel mass for HOTOL is listed as 48t, but there were multiple variants of the vehicle and I don't have definitive data to know which propellant capacities applied to which specific variant. What ought to be readily apparent is how much internal vehicle volume LH2 fuel requires.

Engine Type Specific Impulse with Hydrogen vs Hydrocarbon Fuels:

University of Texas at Arlington - Aerodynamics Research Center - Pulsed Detonation Engines

PDE = Pulsed Detonation Engine (RDE is a type of PDE)

Presumably, what the chart actually means is that a RDE being fed atmospheric Oxygen can achieve that kind of Isp, because pure rocket propulsion Isp is shown at the bottom of the chart, and ranges between about 360s (RP1) and 470s (H2). Detonation engines don't achieve substantially greater Isp (thrust generating efficiency) than conventional deflagration-based chemical rocket engines when all of the oxidizer and fuel must be carried onboard the vehicle. I think the term applicable here is "Effective Isp". When the atmosphere can be used as reaction mass and to provide the oxidizer consumed to generate thrust, the Effective Isp for turbojets, turbofans, and pulsed engines greatly exceeds that of pure rocket engines, to include PDEs / RDEs.

Anyway...

In my proposed SSTO vehicle design using vertical launch and pure rocket propulsion, propellant mass was 2,185,289kg to deliver about 100t to orbit.

SSTO Engine Technology Post #29

1,875.496m^3 of LOX/RP1 propellant was required.

SSTO Propellant Masses and Volumes for a STS Orbiter Equivalent Payload to Orbit:

LOX: 1,597,846kg (1,192.422m^3)

RP1: 587,443kg (683.074m^3)

Total: 2,185,289kg (1,875.496m^3)

Saturn V S-IC Stage Propellant Masses and Volumes:

LOX: 1,444,506kg (1,266m^3)

RP1: 647,800kg (790m^3)

Total: 2,092,306kg (2,056m^3)

This was intended to deliver the same total dry mass to orbit as the historical Space Shuttle, inclusive of its nominal max payload. Effective Isp over the entire flight regime (sea level to orbit) was 90% of the RD-180's Vacuum Isp. Engine mass was derived from Raptor 3's 200:1 engine TWR and from the requirement for a 1.5:1 vehicle TWR at ignition, in accordance with GW's admonishment to ensure that liftoff thrust is sufficient to get the vehicle "smartly moving downrange". This was presumed to be feasible on the basis of Raptor 3's 200:1 TWR while burning LCH4 fuel, which is only about half as dense as RP1, and consequently requires larger and heavier turbopumps than a RP1 burning Raptor 3 thrust-equivalent. Essentially, if a 200:1 engine TWR is achievable with LCH4, then it's also achievable with RP1. If anything, the engine should get lighter and provide a higher TWR because the fuel pump requires less mass / volume / input shaft power to deliver the same flow volume to the combustion chamber. There's nothing too outlandish about these assumptions.

When we talk about a pure rocket powered SSTO designed to deliver 500 passengers to orbit, we're discussing a vehicle with roughly double the Space Shuttle orbiter's total internal volume, on-par with the S-IC stage of the Saturn V, but using much lighter and stronger structural materials, modern thermal protection materials, and thrust equivalent to the 5X F-1 engines attached to the S-IC stage, albeit using much lighter / more powerful engines. If we're able to substitute the onboard oxidizer mass and volume by using air-breathing engines up to normal booster burnout velocity, then our vehicle's total internal volume becomes more similar to that of the Space Shuttle orbiter or HOTOL design, and we can say with a fair degree of confidence that such a vehicle will be able to attain orbit and return to a runway on Earth, just as the Space Shuttle did.

Now back to the "big idea" behind using RDEs:

Thrust-equivalent RDE should require half as much input shaft power, thus much smaller / lighter pumps, and consequently, a bump in engine TWR from 200:1 to 400:1 ought to be possible using the same materials (high grade stainless steels and Nickel-Copper alloys. RCC is only 2g/cm^3 vs 8g/cm^3 for stainless and Nickel-Copper alloys, so a 800:1 to 1,600:1 engine TWR becomes feasible. Since NASA has already tested scale RDEs and RCC engine components (the combustion chamber and nozzle), I think the material and engine tech are "ready to apply", even though more development is still required. RCC turbopump components were fabricated and tested for Project Timberwind, many moons ago. It's not outlandish to think that all the major components can be fabricated from RCC and that regenerative cooling is largely optional. We may still choose to extract heat from the combustion chamber and nozzle to reduce pumping power, not because the engine would melt if we did not. At 800:1 TWR or higher, even when Saturn V thrust levels are demanded, engine mass becomes a minor fraction of total vehicle mass, so propellant tank mass and TPS mass will become the focus of development work.

All together now, we're using supersonic air compressors to extract atmospheric Oxygen and atmospheric Nitrogen to use as reaction mass, possibly driven by sCO2 gas turbines that transfer heat from the compressed air into the fuel, to force feed gobs of air and vaporized fuel into rotating detonation wave engines, so that our sea level to orbit propulsion system can generate the thrust required for a mass that a SSTO vehicle can tolerate.

Offline

Like button can go here

#283 2025-06-15 23:14:30

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

Buran, Space Shuttle, HOTOL Size Comparison:

Gross Liftoff Mass; Orbiter Vehicle Mass; Max Payload Capability

Buran: 2,524,000kg; 75,000kg; 30,000kg (presumably 251km circular orbit)

Space Shuttle: 2,029,633kg; 78,000kg; 24,400kg (204km circular orbit) or 12,500kg (407km circular orbit)

HOTOL: 250,000kg; 50,000kg; 8,000kg (300km circular orbit)

HOTOL LH2 vs RP1 Mass and Volume Comparison for Equal Stored Energy

1. HOTOL had sufficient internal volume to store 995m^3 (70,495.75kg; 10,080,892.25MJ) of LH2 fuel, at most, ignoring the fact that some void space must be present to vent boil-off.

2. 10,080,892.25MJ / 43MJ/kg = 234,439.35kg (285.902m^3) of RP1

3. HOTOL also had up to 140m^3 (159,740kg) of LOX onboard, at most, which implies that 26,623.33kg (3,807,136.67MJ) of LH2 was consumed using pure rocket propulsion (presuming the typical 6:1 O/F ratio). 88,538.06kg of RP1 provides equivalent energy, which implies that 230,198.96kg (201.752m^3) of LOX (presuming the typical 2.6:1 O/F ratio for RP1 fueled engines) must be carried aboard an RP1 powered HOTOL variant for pure rocket propulsion.

4. That means total onboard propellant volume for a RP1 powered HOTOL equivalent is 487.654m^3, so 230,198.96kg LOX + 234,439.35kg RP1 = 464,638.31kg of total propellant mass.

5. The LOX/RP1 propellant mass is slightly more than double that of HOTOL's stated LOX/LH2 propellant load, but the total propellant volume in the vehicle is less than half of the LH2 volume alone. The TWR of RP1 fueled engines is more than double that of LH2, so engine mass would be significantly reduced, which directly translates into greater payload mass since HOTOL is a SSTO.

The most obvious "better option" associated with choosing RP1 power is the ability to carry significantly more useful payload mass to orbit in a vehicle with the same internal volume as an equivalently-sized LH2 powered vehicle.

Offline

Like button can go here

#284 2025-06-16 08:38:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

I watched a YouTube video last night on how the RB545 engine actually works:

HOTOL - Anatomy of a spaceplane engine

Apparently, HOTOL's RB545 engine would dump 1/2 to 2/3 of its entire LH2 load directly overboard (never combusted in any engine) after using it as a heat sink to help "almost liquefy" the incoming airstream to reduce the compression work required to supply atmospheric air to the engine for the first phase of the flight from takeoff to Mach 5 or so. That aptly explains how a vehicle with an average Isp of over 700s needed so much LH2 onboard.

Using a rampressor, sCO2 gas turbine, and a heat sink, we can dramatically improve upon that without dumping any fuel overboard.

Offline

Like button can go here

#285 2025-06-16 20:47:41

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 ... first, thanks for the link in #284... I'll check it out after posting this...

Update ... that looks like a well done video! Interesting that the presenter pulled a patent to use for the study!

The Internet feed thought I'd be interested in the US Army cancelling the Booker. It was right. I remembered your analysis of the Booker, and your conclusion that it was a poor choice.

https://www.msn.com/en-us/news/us/we-go … a4b6&ei=21

The article explains that the brass decided the vehicle had become too heavy to fly and that it would even break temporary bridges.

(th)

Offline

Like button can go here

#286 2025-06-18 07:25:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

The M10 Booker was always a bad idea, one previously killed by the Army decades ago when it appeared in the form of the M8 Buford, which was arguably a better light tank that met more program targets, since the M8 was at least C-130 transportable, mounted the same 105mm main gun used by the earlier versions of our Abrams at that time, had excellent cross-country mobility on account of its light weight / low ground pressure, and could cross most bridges in Europe without damaging them. The M10 is neither a weight-optimized light tank like the M551 Sheridan, which is what our airborne forces requested, nor does it mount a modern 120mm caliber gun more suitable for taking out the latest generation of main battle tanks. The Sheridan's 152mm main gun was optimized for supporting infantry assaults by busting field fortifications and keeping heads down with highly effective HE shells, with a secondary capability to fire gun-launched ATGMs at enemy tanks. In contrast, the M10 was never optimized for any specific target set that our airborne infantry wants to take out. It's more expensive than the Abrams main battle tank, lacks both the 120mm-class main gun armament and heavy composite armor of an Abrams, and its HE shells are much smaller than they could be if it was optimized to fire 155mm caliber shells over short distances from a compact and light direct-fire howitzer type gun.

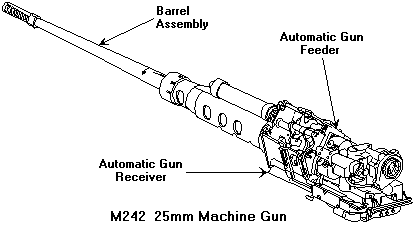

After seeing what our new 50mm Bushmaster chain gun can do to armored vehicles and drones, and watching Ukrainian Bradley IFVs smoke Russian T-72s using their far less powerful 25mm chain guns in Ukraine, merely by flanking the Russians to take shots at their weaker side and rear turret armor, my argument would be for a light semi-autonomous uncrewed mobile gun system, similar in concept to Russia's SPRUT 125mm anti-tank field gun. SPRUT is nominally a towed variant of the T-72's main gun, but with its own onboard engine to move itself about the battlefield without a separate prime mover vehicle, except for long distance travel. Our take on their idea would be even more mobile, so able to go most places infantry can go on account of its small size and low weight. Our miniaturized version of Russia's self-mobile direct-fire anti-tank field gun concept would minimize its mass and physical size by not attaching a giant attention-getting vehicle to the gun. We'd use the same tricycle wheel arrangement of the SPRUT with a small onboard engine providing running pace motive power. If the gun can move itself at 10mph over rough terrain, basically as fast as a man can sprint, that's all we really need it to do. The gun moves with the infantry, not ahead of them. Short of a mountain top or house, such a small gun can go pretty much anywhere else that our soldiers can go, so they always have a medium caliber cannon nearby that can fire programmable airburst HE shells at field fortifications or helicopters and APFSDS at armored targets.

Russian SPRUT 125mm Self-Mobile Anti-Tank Gun

It's not a perfect solution, but a C-130 could easily carry multiple air-droppable guns onboard, something not remotely feasible with a light tank, which is far too heavy to parachute deploy. The UH-60 can easily sling-load such a light gun as well. Each self-mobile gun system would weigh 550-600kg. That's about 50-100kg lighter than the old but still useful 1927 vintage 653kg 75mm M116 pack howitzers that were man-handled through mountains during WWII, and remain in service to this day. The entire weapon would be 4.5-5m in length, with a width of about 1.5m across the outside of the main wheels. A small tire would be locking collar-mated to the muzzle for transport. Onboard ammo supply would be limited, no more than 20 rounds or so, but that's sufficient. The gun would be operated in single shot mode, rather than fully automatic, to minimize stabilization weight. Every soldier in an airborne unit would carry 3 to 5 additional rounds of ammo in their pack to feed their unit's cannon. In the same way that WWII Wehrmacht units were organized around their machine gunner or light wheeled autocannon or pack howitzer, American units would be centered around their autocannon.

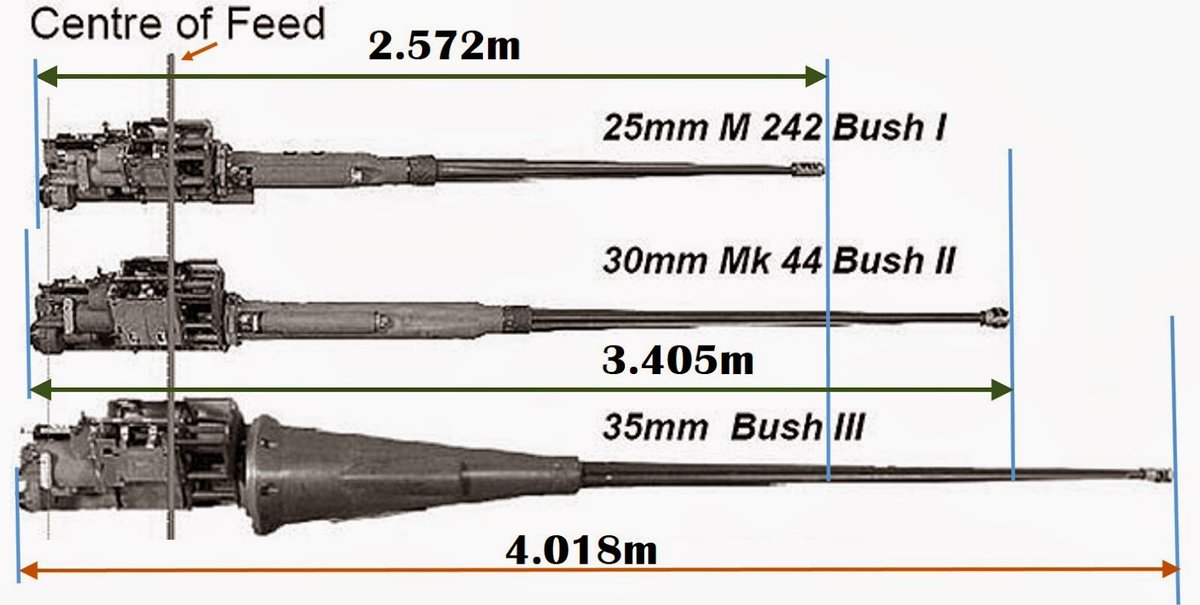

In our coming fight with the Chinese over Taiwan, we would "mix-and-match" units equipped with 30mm (a belt-fed version of the Apache's autocannon), 25mm (Bradley), 50mm (Bradley replacement), heavy machine guns or grenade launchers (normally used to equip jeep-like vehicles), and Javelin (anti-tank) or Stinger (anti-drone / helicopter) launchers. Heck, we can probably make a version that mounts a few Peregrine missiles to pop any enemy fighters that venture too close.

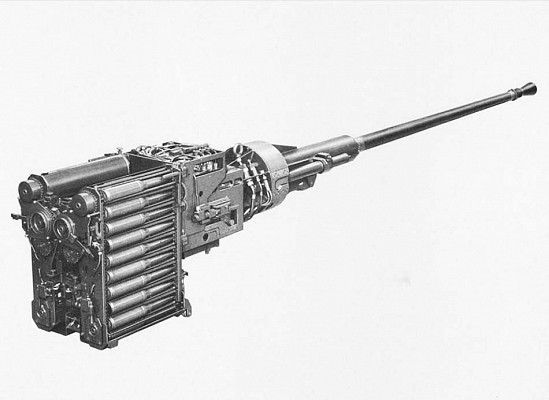

M242 25mm Chain Gun

XM913 50mm Chain Gun

Cannon Size Comparison

Note:

The 35mm and 50mm chain guns are almost identical in size. IIRC, the 35mm and 50mm caliber units only need to be " barrel swapped" to change calibers. The 35mm cartridge's base diameter and overall length is the same size as the 50mm cartridge, merely "necked down" to 35mm. The Germans use 35mm caliber for short range air defense, but we don't. We prefer IR-guided missiles.

34 Round On-Gun Linkless Dual Feeder Example 35mm Oerlikon KDE Cannon

By trading absurdly conspicuous / expensive / fuel-thirsty vehicles, we'll save money on destroyed vehicles and fuel and destroyed ships that must supply the fuel and munitions. Some weapons will inevitably be lost to enemy action, but we're about to fight another island-to-island campaign in closed terrain. We don't need any more ponderous land vehicle units for the enemy to attrit. We need more firepower that moves with and protects our infantry in close quarters. Protection takes many forms. One of the most underrated forms of protection is a reduced target signature and physical size, which is what this proposal would provide. Any land that is not directly "taken" from the enemy by a man with a rifle in his hands is not something we actually control, and many of these places are simply too small to drag a critical mass of heavy mechanized units ashore to dominate the battlefield. I've already been to some of these islands. They're the size of postage stamps. You can walk across them in an hour or two, and I have. Even roaming around in a tank is akin to waving around a giant "Shoot Here!" sign. The armored "thunder runs" to places like Baghdad were only possible due to the vast open spaces of Middle Eastern deserts. We won't be fighting that kind of war. WWII island hopping campaigns were all about bringing men and supplies ashore, using radios and offshore naval gunfire for heavy fire support, and traveling light and fast for shock effect.

Offline

Like button can go here

#287 2025-06-19 13:27:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512

First, thanks for picking up on the Booker cancellation ... it took too long, as near as I can tell, but perhaps some useful research was done along the way.

Second, thanks for your initial response to the black nanotubes material... I tend to overlook the kinds of things you noticed and reported upon.

For example, I noticed the possibility that carbon nano tubes might be better at capturing photons (and not reradiating them) than other materials.

It seems to me this might something that would be of interest for space craft design, but at this point I'm not sure how the material could be used most effectively. One application might be stealth, if the material can be engineered to absorb microwave as well as visible light photons.

I am hoping the new topic will attract some contributions that show how the material can be used.

The first application cited appears to be "stealth" in the visible light spectrum to reduce light pollution. But perhaps other applications are possible.

***

If this post reaches you, I'm hoping you will be able to attend next Sunday's Google meeting, and I hope SpaceNut can show up as well.

SpaceNut says he thinks there is a file storage option in the Admin menu that I cannot see (of course). I would like to modify that (if it exists) so a moderator can use it. It appears I am out of space on imgur.com, so I need another site for GW's images, which is producing at his usual rapid pace.

(th)

Offline

Like button can go here

#288 2025-06-19 18:36:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

I was thinking truly superlative spacecraft radiator panels are the most obvious first application for the "blackest of black pigments". Near-perfect black bodies are superb at both absorbing incoming radiation and re-radiation, though not necessarily at the same wavelength as the incoming photons. I guess that's a roundabout way of saying that while black pigments readily absorb visible spectrum photons, they also tend to be really good at both absorbing and re-radiating infrared photons. If said panel was held in shadow, then it would very efficiently radiate heat into space. If the panel was exposed to sunlight, then that same black pigmentation property would work against you, unless you actually wanted it to absorb heat from the Sun. Ordinarily, rejecting excess heat is the primary environmental control problem for a spacecraft, even in deep space far from a star or other warm planetary body.

I don't know how "ultimate black" pigments will help or hurt stealthiness because almost nothing in nature is black. I would think that it would make visual observation exceptionally difficult at night, but that same optical property draws the eye during daylight hours. Modern stealth aircraft significantly reduce their IR signatures by rejecting heat through fuel-air heat exchangers that use their fuel as a heat sink to absorb and concentrate heat from aerodynamic heating, onboard electronics, and the portion of the airframe surrounding the engine(s). A very black pigment could make said heat exchangers more efficient at thermal power transfer into the fuel or incoming airstream. Automotive radiators are painted black for this reason. If we had "super black" radiators, then they'd be more efficient.

Offline

Like button can go here

#289 2025-06-19 19:14:12

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re #288

Thank you for considering this technology further...

Something I'm not clear on but which would potential be of interest, is:

Do these nanotubes radiate anything at all?

Ordinary black paint would radiate in the black body spectrum. If the nanotubes MIT found are truly working as photon capture devices, they would NOT allow photons to leave the tubes.

However, I would assume the photon energy would transfer into the material and that it would ultimately show up as thermal activity.

***

FYI ... I'm about to drop off a Python program that shows how a point launch system (like SpinLaunch or Hunter's Gas Gun) would work. The program generates points that can be loaded into Excel or Calc or whatever Apple uses, and you can see (a) the Earth as a circle (b) the stub of the launch ellipse assuming circularization at 300 km, and (c) the ellipse if the circularization does not occur.

For educational purposes the failure ellipse is show as though the Earth were transparent.

(th)

Offline

Like button can go here

#290 2025-06-19 20:20:31

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

Your point about nanotubes absorbing or re-radiating photons is something of a misunderstanding that most people have. For example, ordinary Carbon Fiber, which is also typically "very black", can be truly excellent at absorbing and re-radiating heat into space, in the plane that the fibers run along. In directions perpendicular to that plane, their radiative abilities are typically very pedestrian to quite poor.

This image is small, but notice how the Vertically-Aligned CNT fiber on the left affects radiative properties for the substrate vs the substrate on the right, which has fibers that are both vertically aligned as well as other fibers running parallel to the surface of the substrate:

The CNT surface coating on the left is going to be a very good thermal conductor and emitter. The one on the right, much less so. That said, it's more about what specific thing you want to do with CNTs than it is about whether or not the material is capable. CNT can either be an effective conductor or insulator, dependent upon how it's used.

Offline

Like button can go here

#291 2025-06-19 21:42:48

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re 290

Thanks for the image of the vertical nanorods...

This is the original text that led to this discussion. The image you found seems to support the claim in the text.

The hull-darkening material is a version of Vantablack, a substrate covered with vertical carbon nanotubes that absorb almost all the light waves that hit it from nearly every angle. It is often described as the blackest material on Earth, although this has been disputed by competitors in recent years.

What is a bit misleading about the text is that it does not hint at what happens after the photons are absorbed. My vision of this was that the photons fall into the spaces between the rods, and cannot bounce around and escape.

That mental model may be incorrect.

It would definitely be interesting to learn why the vertical rods might be better at holding onto photons than the disordered array you showed.

(th)

Offline

Like button can go here

#292 2025-06-20 12:17:38

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re Starship...

https://newmars.com/forums/viewtopic.ph … 30#p232330

Thanks for your reporting on the recent Starship explosion!

I would like to point out that if data transmitted in real time reported explosion of a tank, it should not take weeks to identify the cause of the explosion.

This is an advantage of modern wireless communication networks and the related sensor technology.

You are not someone who has expressed the view that it should weeks to find the cause of the explosion. However, this forum is read by members and non-members alike, so I trust (and hope) you will recognize this observation was not directed at you.

Thanks again for your timely reporting!

(th)

Offline

Like button can go here

#293 2025-06-20 13:09:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

Essentially, this "very very black" hull coating will cause thermal heating of the satellite or vehicle it's applied to. At the same time, there will also be enhanced re-radiation of photons in the thermal vs visible spectrum. If the energy imparted by a photon impact isn't reflected off into space, then it's absorbed. All that energy has to go somewhere, meaning it won't simply "disappear". This implies that said photonic energy is absorbed by whatever matter it strikes, which further implies thermal heating of said matter (hull of the spacecraft in this case). It will then be re-radiated by the spacecraft hull, back into space. The reason thermal runaway does not occur from the absorbed photons is that there is also re-radiation of the energy from the absorbed photons, in the form of outgoing photons, until a thermal equilibrium is achieved. In that regard, it's less of a "photon trap" than it is a method by which to "convert" photons from one energy level to another, after that energy is absorbed and re-radiated by atoms to maintain a given energy level / state. UV spectrum photons, in turn, are more energetic than visible spectrum photons. X-ray spectrum photons are more energetic than UV rays, and Gamma rays are more energetic than X-rays.

Q (posed to Google AI): Are visible spectrum photons more energetic than thermal spectrum photons?

A: Yes, visible spectrum photons are generally more energetic than thermal spectrum photons. Photons in the visible light range (which includes the colors we see) have higher frequencies and therefore higher energies compared to photons in the infrared (IR) range, which is part of the thermal spectrum, according to physics resources.

Q (me asking and answering your question): What is this "Vantablack" coating actually doing?

A: It's "down-converting" the energy of the photons.

A real life application of photon down-conversion to generate energy:

In solar cell technology, downconversion or downshifting refers to using materials that convert high-energy UV or visible light into lower-energy infrared light that can be used by solar panels. This process aims to increase solar cell efficiency by using a wider portion of the solar spectrum.

Is what that Vantablack coating actually doing any clearer to you now, or did I still do a bad job of explaining this?

Offline

Like button can go here

#294 2025-06-20 13:50:24

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

tahanson43206,

I will generally agree with your premise that it shouldn't take weeks to discover the cause of an explosion within a rocket sitting on the test stand with no engines running, provided that Starship 36 had sufficient instrumentation attached to it for testing purposes. Something capable of instantly releasing tremendous energy, which at least did not superficially appear to involve combustion, occurred while the rocket was loading propellants. The force generated was sufficient to split the entire upper hull open like a busted pinata. Since this same failure mode has happened before to other launch vehicles, a COPV rupture is the most probable explanation.

Space Shuttles, Falcon 9s, and now Starships have all suffered casualties as a result of COPV ruptures. Once the COPV ruptures and throws high velocity tank fragments through paper thin propellant tanks, it's only a matter of moments before those highly volatile cryogenic fuels like LCH4 or LH2 find an ignition source and rapidly combust.

If it seems like we experience these failures more frequently than other space programs do, that might be because we fly more often than anyone else does, except for the Russians, who don't typically use COPVs in their launch vehicles. I've no idea how many other launch vehicles use COPVs, but this same sort of failure happened to Falcon 9s when frozen LOX became trapped between the CFRP overwrap and the tank liner, causing the COPV to explode and destroy those vehicles.

Offline

Like button can go here

#295 2025-06-22 18:06:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re HarmonyOS

Thanks for the perspective on that OS...

I had not heard of it before...

Here is a bit more about it:

HarmonyOS

Wikipedia

https://en.wikipedia.org › wiki › HarmonyOS

HarmonyOS (HMOS) is a distributed operating system developed by Huawei for smartphones, tablets, smart TVs, smart watches, personal computers and other smart ...

HarmonyOS NEXT

HarmonyOS version history

OpenHarmony

LiteOS

People also ask

Is HarmonyOS on Android?

HarmonyOS NEXT was announced on August 4, 2023, and officially launched on October 22, 2024. It replaced the OpenHarmony multi-kernel system with its own HarmonyOS microkernel at its core and removed all Android code.

(th)

Offline

Like button can go here

#296 2025-06-23 06:21:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re GW Johnson's recent study on Tangent Launch.

It was a number of years ago (between 2018 and now) that you wrote a series of posts about horizontal launch.

In our Google Meeting your reviewed recent impressive work on hypersonic aircraft. Such aircraft could provide a means of achieving a Tangent Launch as shown in the drawings GW created over the past week.

The flight path is a straight line that proceeds from takeoff to orbit, with air supplied oxidizer while air is available and rocket thereafter.

If you can find that earlier work please add a post to make whatever topic it was visible.

Technology has advanced since you wrote that original series.

Perhaps it is more practical now.

(th)

Offline

Like button can go here

#297 2025-07-02 17:14:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re Post in Electric flight....

https://newmars.com/forums/viewtopic.ph … 62#p232562

Please continue developing your ideas in the Electric Flight topic, but instead of branching off to consider maritime applications, I think our readers might be interested in your extrapolation of the mass of fuel cells that would be needed to power just one 10 MW motor for an hour of flight. That would be a small plane, but perhaps not TOO small, if your prediction holds. I (for one) have difficulty visualizing the size of the fuel cell compartment that would be needed. It would also be necessary to consider the kind of fuel you are considering. I think of hydrogen but I'm pretty sure there are other fuels to consider. In short, if you had a DARPA grant to build an airplane using this technology, what would you propose to them?

Question: Is DARPA funding improved fuel cells? They might be, but I don't know if DARPA grants are publicized. They may be ** published ** in some obscure journal or web site.

Update ... I was curious to know what power is generated by a diesel electric locomotive... the figure was less than I was expecting. For long trains or rising grades multiple locomotives can be added to a string. Here is a Google response:

AI Overview

A typical modern diesel-electric locomotive pulling a heavy load can consume power in the range of 3 to 4.5 megawatts (MW).

Some sources suggest modern locomotives generate about 3.1 MW (4200 horsepower).

Others use figures like 3.3 MW when describing locomotives in use, such as those operating in California. Units in Australia's Pilbara region are noted as producing around 4000-4400 hp (approximately 3-3.3 MW).

Powerful locomotives listed on Wikipedia have outputs such as 3,281 kW (approx 3.3 MW) for the EMD SD70ACe-T4, and 4,698 kW (approx 4.7 MW) for the EMD SD90MAC.

It's important to note that this is often the rated power output of the locomotive's engine and generator when under a heavy load. The actual power consumption can vary depending on factors such as:

The weight and type of the load being pulled.

The speed of the train.

The gradient of the track (e.g., climbing a hill versus level track).

The number of locomotives in the consist (a train with multiple locomotives will draw more power in total).

Whether the locomotive is using regenerative braking (generating power) or accelerating.

While a locomotive might have a peak power output, it doesn't constantly operate at that level; full throttle is often used mainly for acceleration, and consumption is lower during cruising or idling.

A locomotive might be able to carry fuel cells in the quantity your calculations may reveal are needed.

(th)

Offline

Like button can go here

#298 2025-07-03 02:05:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: kbd512 Postings

Using electric motors for marine propulsion has "battle heritage" with the US Navy:

NavWeaps - History and Technology - Turboelectric Drive in American Capital Ships, by Joseph Czarnecki

From the article:

...

Turboelectric drive offers several advantages:1. There is no mechanical connection between the turbogenerator shaft and the propeller shaft, allowing both to turn at their disparate efficient speeds. This reduces propeller rotation speeds and increases fuel efficiency.

2. The motor rooms can be placed nearer the stern than can reduction-geared turbines, eliminating the need to lead the propeller shafts farther forward in the ship.

3. The machinery components are more easily segregated into multiple compartments, and require fewer steam line penetrations of watertight bulkheads.

4. The turbo-electric drive consumes less beam, allowing more hull breadth to be devoted to the torpedo defense system.

5. The propeller shafts can be immediately reversed by simply switching the direction of the electric motors without the need to reroute steam to a separate reversing turbine.

6. Equal power (but not speed) is available for ahead or astern steaming. Astern steaming can also be maintained indefinitely.

7. The machinery is more easily cross-connected in the event of battle damage through the switching of electrical loads between different turbogenerators and motors, and the elimination of propulsive steam lines.

8. More steam is available at all power levels for the ship's service turbogenerators (SSTGs), making more power available for ancillary systems (including main battery elevation and training) and electronics.

9. Most major electrical components are reparable by the ship's company at sea.The turboelectric drive also has several inherent negatives:

1. It is heavier and more expensive than a direct drive or reduction geared turbine installation.

2. It is susceptible to turbogenerator room damage.

3. It is susceptible to damage to the main control compartment containing the bus bar system.

4. It is susceptible to shorting out from shock damage to the bus bar system.Turboelectric drive ships realized fuel economies of as much as 20% compared to comparable turbine ships, according to Freedman's report of the difference in fuel consumption between USS New Mexico (BB-40) and her two direct drive turbine sister ships USS Mississippi (BB-41) and USS Idaho (BB-42).

In compartmentation, the turboelectric drive was typically twice as segregated as a direct drive plant and four times as segregated as later reduction geared turbine plants in US service. The machinery in the direct drive turbine USS Idaho (BB-42) was divided into eight main spaces, while the machinery in the turboelectric USS Tennessee (BB-43) was divided into fifteen main spaces. This increase in compartmentalization meant that there would be less flooding in the ship in case of battle damage such as from a torpedo. The later reduction geared USS North Carolina (BB-55) had only four main spaces and required each propeller shaft to be led progressively farther forward in the hull.

Turboelectric machinery also permitted more rapid development of accelerating and decelerating power on the shafts. It made the last ditch maneuver of "twisting" a ship out of a torpedo's path by backing down one side's shafts while running the opposite side full ahead and applying full rudder toward the backing side more effective. It also permitted extended periods of backing. After suffering a torpedo hit in the extreme bow while at anchor off Saipan in 1944, USS Maryland (BB-46) backed to Pearl Harbor at 10 knots so as not to strain the collision bulkhead forward.

The same ship also escaped two collisions in a matter of minutes during a close order fleet maneuvering exercise between the wars. When USS Oklahoma (BB-37) sheered out of column to avoid running down an errant destroyer, she intruded on the next column of ships, crossing the Maryland's bow. The Maryland performed an immediate "crash back" to avoid the Oklahoma, decelerating and letting the other battleship pass ahead, only to be confronted with the direct drive turbine USS Arizona (BB-39) vainly trying to back down behind her. Maryland's electric motors were immediately thrown back to flank speed ahead and the turboelectric ship accelerated ahead of the less responsive Arizona.

The Maryland also escaped an aerial torpedo at Leyte Gulf by "twisting" the ship out of the torpedo's path. When the order was given to put the helm over to evade the torpedo, the steering gear shorted out, leaving the rudder amidships. The captain then directed maneuvering by the motors while a damage control team attempted to restore the helm. The ability to maneuver effectively prior to the restoration of helm control saved the ship from being hit. Helm control was restored prior to the weapon crossing Maryland's track and placing the helm hard over near the end of the maneuver may have assisted in moving the ship's stern out of the path of the weapon which passed close aboard. Had the ship not commenced its maneuver under motor control prior to recovering helm control the ship would have been hit.

...

Wartime experience fighting the Imperial Japanese Navy showed that their survivability was well above that of purely steam powered warships, and their implementation by the US Navy dates back to just before WWI. The only reason they were not more widely implemented during the interwar years was the Treaty Era ship size / mass constraints imposed by all the signatories to the treaties.

If we had modern 40kW/kg electric motors and 8kW/kg kerosene or diesel burning Solid Oxide Fuel Cells, then we would definitely want said motors and fuel cells powering all of our warships, because they would maximize range and mitigate battle damage if ship and fleet tonnage restrictions were still in place. In modern times, economy dictates fleet size and tonnage, but the restriction still exists, regardless of treaties.

I think our readers might be interested in your extrapolation of the mass of fuel cells that would be needed to power just one 10 MW motor for an hour of flight.

Let's use the Kuznetsov NK-12 turboprops from the 1950s Tupolev Tu-95 "Bear" bomber as our "airliner-like" example:

Each NK-12 weighs 2,900kg, the Tu-95 has 4 of them for 11,600kg of power plant mass, each one generates 11,000kW of output, so 44,000kW of takeoff power. Overall power-to-weight ratio is 3.79:1- not great by modern standards but acceptable for an airliner.

State-of-the-art PEMFCs created for Toyota Hydrogen-fueled hybrids can achieve up to 5kW/kg, so a 44MW fuel cell would weigh 8,800kg. If each 11,000kW PMSM weighed in at 440kg (at 25kW/kg for takeoff power), then we can achieve 10,560kg for the installed power plant weight. To this weight, we must either add compressed Hydrogen tanks or cryogenic liquid Hydrogen fuel tanks. That will rapidly increase our installed mass to achieve the same payload-to-distance because Hydrogen has such absurdly low density, despite the fact that its very low mass makes Hydrogen an ideal fuel from a power-to-weight perspective. Regardless, we can "just beat out" 1950s Soviet gas turbines that were installed in numerous military and civil aircraft, by about 1,000kg, for a vehicle with a MTOW of 188,000kg. If we're reverting back to 1950s aircraft performance, then this may be an acceptable trade. I would argue that nobody would willingly "time travel" back to the 1950s, as it relates to aircraft power plant performance, unless the "competitive advantage" was greatly reduced per-flight-hour operating cost. For a variety of reasons, Hydrogen fuel cells and superconducting electric motors make that a highly unlikely outcome.

Modern high-output gas turbines such as the Rolls-Royce T406 turboshaft engine installed in numerous V-22 Ospreys will serve as an example of how far we've come since the early gas turbines of the 1950s. T406's takeoff power is 4,586kW and it weighs 440kg (at 10.4kW/kg), so 880kg and 9,172kW (close enough to the 10MW airliner example you asked about) of takeoff power for both engines. An equivalent pair of electric motors only weighs 367kg at 25kW/kg- a spectacular mass reduction over the T406. However, our 5kW/kg PEMFC is a hefty 1,834.4kg, so 2,201kg is our final power plant mass. At 40kW/kg, our electric motors now weigh 229kg, which reduces our total power plant mass to 2,064kg. This is still a major fundamental technology problem. We cannot double the power plant mass of a V-22 without severely cutting into its payload-to-distance capability. Internal fuel capacity between the variants ranges between 1,450 gallons and 2,025 gallons, and 1,184kg equates to 384 gallons of jet fuel. T406 thermal efficiency at cruise is only around 32%, however, so an 8kW/kg SOFC, with thermal-to-electrical efficiency of up to 85%, might make that trade worthwhile, with the understanding that as vehicle dry mass increases, so does cost. Each V-22 costs about as much as the F-35 stealth fighter, which is why production ended.

Hydrogen is much lighter than Jet-A, but we're also carrying far less of it unless we dramatically increase the internal volume of the V-22, which is not practical to do. Even moving the engines inboard and using pairs of generators and flight motors to eliminate the mass of the cross-connect shafting and gearboxes doesn't really solve our total installed power plant mass problem, because the weight of a gas-turbine-to-generator-to-motor setup still doubles total power plant mass with 40kW/kg electric motors. This is why featherweight electric motors don't really solve any existing modern aircraft design problems. The electric motor mass is not the primary design problem and hasn't been for at least a decade now, since the widespread adoption of axial flux PMSMs. The issue is solely related to the mass of whatever generates the electricity, which is either a gas turbine with an attached generator, a fuel cell, or electro-chemical batteries. None of those setups have total lower installed mass than gas turbines alone, but this is what matters for practical electrically-powered flight applications. The only correct answer is to dramatically reduce the mass of the fuel cell or batteries.

To illustrate how acute the electric power generation vs power delivery problem is:

880kg - 229kg (pair of 40kW/kg motors) = 651kg

9,172,000 / 651 = 14,089W/kg

14kW/kg would be the required power density of whatever provides the electricity, when combined with 40kW/kg electric motors, for equal mass when compared with hydrocarbon fueled gas turbine power delivery solutions. All the claims about "the future" and all the tantrums thrown by our "green energy" advocates over our use of gas turbines as the preferred power delivery solutions for commercial and military aircraft will never make electric aircraft a practical solution to any aviation problem beyond infrequently used very short range personal aircraft. Personal aircraft are owner-operator aircraft taken out every weekend or two for what amounts to minimal currency training. No kind of "working aircraft", which generates 90%+ of all aviation-related CO2 emissions, will ever be powered by something that roughly doubles the total installed power plant mass over present day gas turbine engines.

Anyone who thinks they can arbitrarily "hang" an extra 500kg worth of fuel cell off each engine nacelle, simply because we can burn less fuel when consumed by a more efficient fuel cell, doesn't know a thing about aircraft design. The wing doesn't magically become any stronger than it already is. CG changes won't improve stability in flight. The pivoting nacelles could be replaced with pivoting rotor heads and electric motors only, as in the new Bell V-280. However, that design uses similarly light yet powerful (10kW/kg) gas turbine engines. The V-22's fuel is stored in its wings and in sponson tanks located on either side of the fuselage. The "wing" of the V-22 had to be specially designed to make it much stronger than either a conventional aircraft wing or "stub wings" that large attack and transport helicopters use to both carry heavy ordnance and "unload" their main rotor during high speed forward flight, specifically to deal with the weight of the T406 engines, which rotate between horizontal and vertical positions, cross-connect shafting and gearboxes, in addition to the massive torques generated by its helicopter-length rotor blades. Doubling the mass hanging off the tip of each wing is a non-starter. Maybe we can make the wing stronger for the same weight maybe we can make the massive engine pivot bearings even stronger without increasing airframe weight too much, but I doubt it. Every moving part of a V-22 operates perilously close to clearly defined materials limits- engines, shafting, gearboxes, rotors, and major airframe structures like the wing box. If you exceed the specified operating hours between maintenance cycles on a V-22, something you can usually get away with on a conventional transport helicopter like a Blackhawk or Chinook, a V-22 stands a better than average chance of literally "falling out of the sky" when one or more of its highly stressed power plant and/or airframe parts fails catastrophically. If the maintenance manual says, "replace this shaft after 2,000 flight hours", that's exactly what it means, no exceptions, no waivers, no additional service life margin remaining. The Marines learned that the hard way, more than once.

If not directly behind the electric motors in the nacelles that previously housed the gas turbines, someone tell me where exactly we can fit roughly 1.223m^3 (at ~8kW/L) worth of SOFCs inside this thing:

A locomotive might be able to carry fuel cells in the quantity your calculations may reveal are needed.

A locomotive could readily be adapted to carry a fuel cell that burns low-Sulfur diesel fuel. The fuel cell would be much lighter and more compact than a locomotive's diesel engine for equivalent electrical power output and requires no electric generator, so this application would benefit from a fuel cell installation. Virtually all trains already burn diesel fuel and use electric traction motors. Using superconducting motors would add quite a bit of pointless cost and complexity for a minor improvement in energy efficiency, but a diesel-burning SOFC is already significantly more efficient than the most diesel engine and electric generator combination, so why bother?

There are plenty of ways to reduce conductor mass and volume in an electric motor:

Radical electric motor runs without metal coils

Electric Motor Engineering - From nanomaterials to the new generation of electric motors

Carbon Nanotubes as an Alternative to Copper Wires in Electrical Machines: A Review

Enhanced Copper-Carbon Nanotube Hybrid Conductors with Titanium Adhesion Layer

Offline

Like button can go here

#299 2025-07-03 20:10:07

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re post in Louis' Electric Flight...

https://newmars.com/forums/viewtopic.ph … 94#p232594

I went to see if Post #1 was available for an index but it was not.

That long and detailed and nicely illustrated post about the S4 and the traditional comparable helicopters is a great read.

It might be read by someone who picks the topic and reads it through to the second page.

(th)

Offline

Like button can go here

#300 2025-07-04 18:14:25

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: kbd512 Postings

For kbd512 re GW Johnson study showing SSTO is possible...

With Sunday's meeting coming up, I'm hoping you might be interested in helping to match physical structures to GW's estimated inert mass for his plan to deliver 100 metric tons to LEO with an SSTO. In that scenario, the vehicle itself would be valuable as raw material for on-orbit construction. What I'm not clear on is whether GW's plan could actually be built.

As a reminder if you haven't read his paper recently, GW found that LH2 and LOX could perform the SST feat, whereas LOX and CH4 could not.

Instead of spending time disputing his conclusions, please get that out of the way ahead of time so we can spend our limited time productively.

(th)

Offline

Like button can go here