New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2024-09-04 06:12:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re #100

Thanks for confirming you do not yet have either the new database or the privileges.

I'll send a reminder request shortly.

My guess is that Mars Society business is higher priority.

(th)

Offline

Like button can go here

#102 2024-09-04 18:19:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re New database!

Yay!

Best wishes for success loading it with data.

I sure hope everything goes smoothly at this point.

(th)

Offline

Like button can go here

#103 2024-09-07 16:22:38

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re new post in FAA topic....

Thanks for that detailed history of the true flying car, with pictures.

I wonder if that type certification still stands, or is there an annual renewal process that would have caused it to expire?

***

I just received an upgrade kit from Spectrum. The sales person said 500 Mb DL is standard. I'll try to have it installed by tomorrow night.

(th)

Offline

Like button can go here

#104 2024-09-07 20:30:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

After a Type Certificate has been issued by the FAA, it only expires after all models of that type are withdrawn from service or destroyed and no more of that type are built. A first model year Cessna 172 from the 1950s, kept in service through maintenance, is still considered to be type certificated by the FAA, forever. It's Type Certificate doesn't magically expire because it's "getting old". There have been type-conforming Wright Flyers built during the past 10 years which are still considered to be Wright Flyers by the FAA. Even if you build a plane to your own unique specifications, you still receive a Special Airworthiness Type Certificate. Any plane built either is or is not an aircraft of a given type.

EAA Museum Aircraft Collection - 1903 Wright Flyer Exact Replica

The full-size replica of the Wright brothers’ historic 1903 Flyer — the first true airplane — is a centerpiece in the EAA AirVenture Museum’s collection. It is one of the first aircraft a visitor sees upon entering the main gallery. It stands as a tribute to the birth of aviation and to the accomplishments of Wilbur and Orville Wright and their mechanic, Charlie Taylor.

This replica was built jointly by EAA and Blackhawk Technical Institute of Janesville, Wisconsin, over a period of 10 years. Various components were built at Blackhawk, in the EAA shops, and by EAA volunteers around the United States. Final assembly and much of the detail work were carried out at Blackhawk by students in the aviation mechanics program. The replica was completed in 1978 — the 75th anniversary of the Wrights’ first flight — and was placed on permanent exhibit in EAA’s museum.

How Accurate Is the EAA’s Replica Flyer?

The simple answer is, “as accurate as it could be at the time.” The Wrights never drew complete plans of their 1903 Flyer and kept many of its details secret to protect their patents. The original Flyer was wrecked on the ground by a gust of wind on December 17, 1903, soon after four successful flights. The wreckage was packed up and taken back to the Wright Bicycle Shop in Dayton, Ohio. There, it remained in storage until 1928, when Orville rebuilt it for display in the Science Museum of London, England. The aircraft was returned to the United States in 1948 and put on display in the Smithsonian Institution. Today it is in the Smithsonian’s National Air & Space Museum in Washington, D.C.

It is not clear how accurately Orville restored the Flyer in 1928. Parts of the 1903 Flyer, including the engine, were used on other Wright aircraft. And there are features of the Smithsonian’s Flyer that historians and aeronautical engineers have doubts about. Were they original or were they repairs made in 1928 to an aircraft that was not intended to fly again?

EAA’s replica was built from plans drawn from the Smithsonian’s Flyer. The true degree of accuracy of those plans may never be known. Several teams attempted to “reverse-engineer” the 1903 Flyer for the 100th anniversary of powered flight in 2003. They encountered similar gaps in our knowledge about the original Flyer. The EAA museum’s replica, the Wright Experience reproduction and the other 100th-anniversary replicas are accurate in all of their most important features. Above all, they highlight the scientific and technological challenges and achievements that led to the first true airplane.

The First Homebuilt Aircraft

Wilbur and Orville Wright were bicycle manufacturers and mechanics by trade. Their quest to be the first to fly began in 1899, when Orville wrote to the Smithsonian, asking for information about aviation. Just four and a half years later, they found success on the wind-swept dunes of Kitty Hawk, North Carolina. They achieved their goal without corporate or government subsidies. They were the first homebuilders and their 1903 Flyer was the first truly successful heavier-than-air experimental aircraft, and their spirit lives on in EAA to this day.

Length: 21 feet

Wingspan: 40 feet, 4 inches (note that the right wing is four inches longer than the left wing, to compensate for the weight of the engine, which was mounted off center to the left of the pilot.)

Height: 9 feet, 3 inches

Empty Weight: 605 pounds

Gross Weight: 750 pounds

Crew: 1

Powerplant: 4-cylinder, water-cooled, horizontally in-line

Horsepower: 12 hp

NASA - Replica of Wright 1905 Aircraft

The man who built that replica flew his aircraft a dozen times when NASA's article went to press. Believe it or not, the FAA both allows and encourages the owner of an Experimental Amateur Built aircraft to build and maintain their own aircraft for the purposes of education and personal enjoyment. To keep a Type Certificated aircraft flying, even one built in a factory, the aircraft's owner is allowed to fabricate their own repair parts. So long as the part was made from the same material(s), has the same dimensions, and is equivalently made, it's an allowable repair part. Generally speaking, when original parts are still available you would pay for repair parts from the factory. This is not always possible, so the FAA makes allowances for the fact that original parts may cease to be available when the factory stops making parts or the company goes bankrupt.

Museum of Flight - Albatros D.Va Reproduction

Note it's registration or "tail number" in the "specs" section of the web page linked above, of "NX36DV". That means it's a Type Certificated aircraft, even if it's the only one of its type. The originals were built in 1917. This one was built in 1984, more than half a century after the company which built the original Albatros ceased to exist.

The fuselage of the WWI era Albatros was fabricated from two sheets of aircraft plywood, which are all but guaranteed to be nowhere near the quality of aircraft plywood available in 1984. The wing spars are likely to be some variety of Spruce or Douglas Fir. The wing is covered with doped and painted cotton or linen fabric.

There are a few practices which have fallen out of favor with the FAA over our many decades of learning, so the dope used in its construction is likely to NOT be of the highly flammable nitrate variety. The use of nitrate-doped fabric, rather than Hydrogen gas, is the more likely culprit which destroyed the Hindenburg airship. If a modern example was made using modern synthetic fabrics such as Ceconite, there likely would never have been an issue with the use of Hydrogen as a lifting gas. It's absurdly easy for Nitrate-doped fabric to catch fire from any stray spark or static electricity discharge, so we quite doing that quite some time ago and started using Butyrate dope or synthetic fabrics such as Ceconite.

Some advice given to builders of radio control model aircraft:

Nitrate and Butyrate Dope do not mix. Each has its own unique characteristics and uses. Nitrate, which comes only in clear, gives excellent penetration in bare wood. Because Nitrate is not fuel proof, builders often use it for free flight airplanes that are rubber band powered. Butyrate Dope comes in colors as well as clear, and it is fuel proof. To get the excellent penetration into bare wood that you are looking for, thin Butyrate Clear Dope to 70 percent. It will sink in and seal the wood, giving you a drum-tight finish. Remember, Butyrate Dope can go over Nitrate, but Nitrate cannot go over Butyrate Dope.

While both Nitrate and Butyrate dopants are available for finishing of wood and fabrics, there's probably no FAA DAR (Designated Airworthiness Representative) who will approve the use of a Nitrate dopant. Current practice is to use Butyrate dope for everything, or to simply use Ceconite fabric and heating iron to "melt" or "shrink" the synthetic fabric onto the wing, without the use of messy dopants. Paint is optional, but most people paint their aircraft.

Offline

Like button can go here

#105 2024-09-09 06:31:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re #104

Thank you for your detailed reply about type certification, and for the examples from history, and current practice.

Today's Internet feed included an item that caught my eye, and which looks to be right in your ballpark. Lead is a poison that should not be present in the air we breathe. It has a long history as an additive to petroleum fuel because of it's beneficial effects in the operation of internal combustion engines.

California has set out to remove lead from avgas by 2031. This decision may have an effect on older types, or it may not depending upon how the law is written. In any case I am hoping you will see this as an opportunity to analyze the use of lead in aviation fuel, and what consequences may ensue from it's removal.

We were talking just last night, about electric aircraft, and a policy decision to stop pouring lead into the atmosphere to avoid poisoning humans and other living creatures might accelerate adoption of alternatives to traditional internal combustion engines.

https://www.msn.com/en-us/news/us/calif … 3629e&ei=4

(th)

Offline

Like button can go here

#106 2024-09-09 07:39:44

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,148

- Website

Re: kbd512 Postings

The reason leaded avgas has persisted as long as it has is twofold: (1) it is the only way known to create 100 motor octane gasoline, and (1) the threat from piston aviation was minimal.

Piston aviation is a tiny source compared to motor transportation on the roads. The lead in avgas can only be just barely detected near the very busiest airports, and only almost on the airport site itself. The "newer" 100LL (for "low lead") avgas has at 2cc per gallon half the tetraethyl lead content of the older 100/130 grade it replaced (long ago).

Folks have been trying to create a lead-free 100 motor octane gasoline for at least 3 decades now. There might now be one "in the wings", but it's not out there yet. Not every airplane needs 100 MON, but most of the modern ones do. A stiff gasohol blend might serve, something around E-20 or E-25, but the aviation manufacturers never transitioned to ethanol-tolerant materials. Methanol is even worse for material incompatibilities. They'll have to do it without either of those alcohols.

Just to "calibrate" this, the unleaded regular in your car has about 82 motor octane and about 92 research octane. The average of those is the "pump octane number" or PON they can legally advertise on the pumps and signs. For unleaded regular, that's 87 PON. Mid grade is about 89 PON, and premium is about 91 or 92 PON. It's pretty easy to create lead-free gasolines down in that octane range. These days, it's done with ethanol additions up to about 10% (for an E-10). A few years ago when I was experimenting actively with these materials, unleaded regular as I tested it with the water separation test was usually an E-8 material.

Piston aviation just isn't much of a threat for poisoning the air with lead. Road transportation very definitely was. Size of an industry really does matter. But I'll also say this: the reason to get the lead out of motor gasoline was more about oxygen sensors for fuel injection than it was about protecting the public health. Lead poisons those sensors. They had to remove the lead to use the technology. Money talks.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#107 2024-09-09 12:06:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

GW,

The turbocharged engines you're referencing, the now-common 300hp Continental TIO-550s and Lycoming TIO-540s, do not require 100 Octane AVGAS for most use cases. If they're flying at, say, 20,000ft with full boost / full rated power, then yes, they need increased knock protection margin provided by a higher Octane fuel. Minor tweaks to engine operation, such as running richer mixtures, can address that concern. GAMI has all but unequivocally proven that they can run the various alternative fuels and have the test data to back up their claims. I would wager all of these engines now have hardened exhaust valve seats and Sodium-filled exhaust valves installed, which are capable of dissipating the excess heat without micro-welding or valve seat recession. 20 years ago? Not so much. I would be shocked if there are any cylinders / jugs left installed without those improvements. If the pistons they use were the Speed-of-Air design, then the other tweaks to the fuel and engine operation would not be required. If they were equipped with electronic ignition, then once again all other tweaks become irrelevant. The control system will advance or retard ignition timing to prevent knock. Both Continental and Lycoming already have Electronic Ignition control systems available, specifically for the IO-550s and IO-540s, but not widely deployed.

With Speed-of-Air pistons and FADEC, you get full rated power at a much lower boost level, while using significantly lower Octane fuel, without the use of potentially damaging Alcohols that all modern land motor vehicle engines now consume without any real issues. Liquid cooling is another potentially viable option, and there are liquid cooled jugs available for the Continental and Lycoming engines which would enable greater than rated power output, using lower Octane fuels. A third option is the all-Aluminum Chevy V8 big blocks, which can deliver the power of a TIO-550 / TIO-540, for a modest increase in weight. If equipped with a gearbox and turbocharger, then they can deliver a lot more power than an equivalent displacement air-cooled engine, up to 750hp or so.

IIRC, the geared and turbocharged Continental (GTSIO-520) and Lycoming (TIGO-541) variants can deliver up to 425hp, but 375hp is more common. The geared Big Block Chevy engines could deliver up to 600hp in a physically smaller package, or up to 750hp with turbocharging. A liquid-cooled, turbocharged, FADEC (EFI and EI), and gearbox equipped Big Block Chevy (572) / Ford (572) / Chrysler (572 Hemi) would be the best of all possible improvements to engine power using pump gas. For the cost of these archaic engines, you could have an all-billet Aluminum Big Block with all-forged internals, providing every conceivable performance advantage, while running on ordinary pump gas. Apart from not requiring TEL in the fuel, the "cherry on top" is a fuel burn rate dramatically below that of a gas turbine equipped aircraft, as well as below that of the old Continental and Lycoming piston engines. They would provide additional performance margin under "hot and high" atmospheric conditions.

I still don't understand why Continental and Lycoming haven't decided to abandon air-cooling in favor of vastly more plentiful Big Block engines. We will eventually be forced to divest the old airframes and engines, merely to use 1980s engine tech. Continental and Lycoming are slowly but surely dying because they cannot sell enough engines per year. Their total production across all engine models are only a few thousand engines per year, largely because few people can afford them. They've taken 1930s to 1940s air-cooled engine tech about as far as it's ever going to go. They've spent hundreds of millions on various diesel engine projects that went nowhere, rather than using something GM / Ford / Chrysler already spent billions of dollars on over the decades, because automotive manufacturers which make tens of millions of engines per year can afford to do that. Every bit of the big block and small block V8 engine tech is now far beyond what can be done with the air cooled boxer engines.

Air cooled engines are not any lighter than modern liquid-cooled automotive equivalents for equivalent power output. The turbocharged 195hp liquid cooled 1.5L Honda engines that Viking Aircraft Engines sells are the exact same dry weight (with a gearbox, exhaust system, and all accessories) as the 180hp air-cooled 5.9L Lycoming O-360s (without its exhaust system or alternator or other accessories). If we compare weights at equal power output levels, then appropriately sized automotive engines come out ahead without using TEL in their fuel. Fuel burn rate is nearly identical for equal power output. The real difference is the cost of the engine. The O-360 is more than twice as expensive than the Honda, even when you get a sweetheart deal by purchasing a Lycoming engine from a company like Vans Aircraft with your build kit. The boys and girls over at Viking have their install process down to a science. When you can complete an install for a customer in less than a day, and then successfully run-up the engine, you're doing something right.

As far as ultimate durability is concerned, GM runs their LS series of small blocks at WOT for more than a month. If you did that to any of these air-cooled engines, even with adequate air flow, they would be in pieces inside of a day or two. If all of our "go fast" birds and older agricultural aircraft were redesigned and re-powered with Small Blocks and Big Blocks, then they will burn less fuel at the same power level, they won't have as many durability issues, the engine oil won't have the consistency of tar after only 25 hours of run time, and they won't need TEL in the fuel. If you must run TEL (because that's all the airport has available) in one of these modern automotive engines, there's now an additive that prevents it from fouling the plugs and exhaust valves or messing up the electronic sensors.

There are a dwindling handful of old warbirds that actually require higher Octane fuel because they use high boost levels, but most of their engines can also be run at lower manifold pressure since they're not carrying any significant weight with their armaments removed. Their use in air racing requires even higher Octane levels, so very small special batches of fuel are produced each year with a TEL content appropriate for 115/145 Octane rating.

Out of pure economic necessity, the future of modern General Aviation will be powered by robust liquid-cooled automotive engines that have far fewer ongoing maintenance issues associated with air-cooling, TEL in the fuel, and failure-prone magnetos. That tech was a great enabler for early aircraft and automotive engines, but there are a variety of reasons they fell out of favor with the automotive manufacturers. Continental and Lycoming have already gone bankrupt more than once, so if they wish to stay in business they should at least consider partnering with automotive engine manufacturers. The FAA should start seriously evaluating the tech in modern automotive engines to determine what's actually required for them to type certify airframes powered by those engines.

Offline

Like button can go here

#108 2024-09-09 18:05:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

for kbd512 re quaoar...

Quaoar is a science fiction writer as well as a practicing physician (retired)

He's been telling us about his science fiction for as long as I've been here.

You might have missed that.

I suspect that Quaoar is describing a scenario he is constructing for a swash buckling set of novels set in this unusual planet.

That said, his imagination may have created an alloy that is possible on Earth (though I doubt it).

(th)

Offline

Like button can go here

#109 2024-09-10 07:40:51

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

Apologies. I must have missed that. I thought perhaps there was an entire Bronze Age empire I never learned about.

In modern times we do have specialty Aluminum-Bronze alloys with 95ksi tensile strengths:

Wieland C95410HT Aluminum-Bronze Alloy

Aluminum bronze is the highest strength standard copper based alloy. Wieland Concast produces C95400, C95500 and C95900 in standard sizes of rounds, tubes, and rectangles. Aluminum in conjunction with iron and nickel acts as a strengthener in these alloys. All of the aluminum bronzes can be heat treated, further increasing tensile strengths.

Tensile Strength: 95ksi <- about two thirds that of 1095

Yield Strength: 45ksi <- about half that of the 1095 commonly used for knife and short sword blades

Hardness: 177hb <- more than 3X softer than the hardest 1095

Hardness appears to be very low, though, so it wouldn't perform as well as steel. 1095 steel can be made more than three times as hard as that Aluminum-Bronze alloy, which isn't too surprising considering most of the alloy is Copper and Copper is pretty soft. I don't know what mechanical properties a micro-alloyed Aluminum-Bronze might have, but I suspect 1095 and the steels available from about the Middle Ages onwards will still be much stronger, harder, and less likely to dull with hard use.

Offline

Like button can go here

#110 2024-09-10 17:25:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kdb512 re #109

I have to admit I did a double take when Quaoar shifted from talking about the hypothetical conditions on his hypothetical planet, to full blown cultures interacting with each other. Your initial response to that imaginary alloy is understandable.

My guess is that the citizens of such a planet would discover the benefits of bellows (and from there blast furnaces) and thus be able to make refined metals, but from Quaoar's descriptions, I get the impression those folks would have a lot more to worry about.

***

I logged in just now to thank you for your post in RobertDyck's topic, about the (possible/likely) lack of standards in the aircraft industry.

The ** really ** big standards are the English units system, and the Metric one. I expect that ** all ** manufacturers around the world use those standards.

***

Regarding your point about NASA and supervision .... It seems to me that the facts argue NASA did NOT supervise much of anything in the Starliner fiasco.

***

Regarding NASA .... this evening's news included a segment on the future of NASA...

This was added to the report on the successful launch of the Polaris Dawn mission by SpaceX.

The analysts pointed to NASA support for commercial enterprise (including SpaceX) and offered the opinion that NASA is drained of talent, and cannot complete the ambitious missions it set for itself, let along take on new ones.

The analyst is someone who I've been following for a while, and generally I find his predictions reliable.

The analyst observed that NASA is subject to the whims of Congress, and Congress itself has been unreliable in recent years.

I've just decided to create a Polaris Dawn topic, if we don't already have one.

(th)

Offline

Like button can go here

#111 2024-09-11 01:09:05

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

If we did have true standards in the aircraft industry, then fiascos such as the Boeing 737 Max 8's MCAS software should not be possible. A completely new and untested computer software control system was introduced in an attempt to avoid pilot retraining to contend with the fact that the much larger and heavier new engines on that new model of the 737 caused a significant CG shift in the airframe which altered its takeoff and landing characteristics in a significant way. The FAA should have interpreted that simple fact of flight physics to mean that the new type required pilot re-training and re-certification in type, because it was indeed a new type with substantially different flying characteristics, prior to flying the new 737 Max 8. That change was projected to increase the overall cost of purchasing and operating the new 737 model, which Boeing sought to avoid to secure orders that may otherwise have gone to a different model of Airbus competitor product.

I'm not a FAA Designated Engineering Representative (DER) or Designated Airworthiness Representative (DAR), but even I could tell you that the 737 Max 8's low speed flying characteristics, which always affect takeoff and landing maneuvering limits, was a major departure from the otherwise docile flying characteristics of the previous 737 models. This is why we need people who exhibit personal integrity to put the brakes on whenever someone makes a spurious claim that runs directly contrary to well known flight physics.

The effect of moving outside of acceptable CG limits is very well known to every newly minted Private Pilot, because it's taught during your first week of flight school, that exceeding the CG limits of any airframe is a life-threatening mistake which is typically non-recoverable. For any specific airframe design and load its carrying, there exists a "CG box" you have to work within. If you start operating outside of that box, only bad things will happen, because physics guarantees they will happen. Even if you have a properly functioning software stabilization augmentation system, there's only so much the control software can do to keep your unstable bird in the air.

There are multiple video tapes of cargo freighter airliners wherein the load shifted during flight because it was improperly secured, the nose goes up during takeoff, the unsecured load further shifts all the way to the back of the plane, elevator authority is woefully insufficient to counteract the extreme load shift and departure from CG limits, and so that airliner and all aboard her are doomed. Worse still, those on the ground who are not active participants in that aviation endeavor may also be doomed, as a function of the speed with which these accidents happen and their unrecoverable nature.

Deliberately designing-in a marginal CG box for the pilots to work within, if the plane is not carefully loaded and maneuvered, is inexcusable from an engineering standpoint. It's engineering malpractice that illustrates the very worst aspects of how corporatism and government regulation have conspired to have the exact opposite effect of what was intended. FAA DERs and DARs were supposed to evaluate the airworthiness of the new 737 Max 8 design without favoritism or prejudice. Both government regulation and a desire to avoid malpractice lawsuits on the part of Boeing were studiously ignored in favor of "profits now, to make this quarter look good".

That kind of thinking is corrosive to public trust and faith in both competent government regulation and in corporations to at least make decisions that don't directly lead to the deaths of their paying customers. It's really hard to run an airlines industry when the manufacturer knows they've released a defective product that's killing people by the plane load and the regulators who were supposed to prevent that sort of malpractice from ever being allowed to enter airline service, took the word of Boeing corporate executives or engineers over their own good sense as pilots, aeronautical engineers, and prudent regulators.

Deliberately designing a fighter jet to be unstable in flight might be an acceptable design practice or tradeoff made for military purposes, such as enhanced maneuverability in combat. Deliberately making a passenger airliner only marginally stable without computer flight control sensors and software is something that should never be permitted, regardless of who is doing the regulating or what kind of latitude the regulators give to our airliner manufacturers. An airliner is supposed to fly and handle exactly like a Mack truck driving across Kansas- smooth, stable, predictable, dependable, utterly reliable, and effectively unstoppable, because it's working with the physics of flight instead of against it.

You made a comment about the design tradeoff of putting the tail planes (the elevator and rudder) in front of or behind the wing. That design tradeoff has its own ramifications. Dick Rutan, of Scaled Composites fame, designed multiple high performance aircraft (experimental amateur built, type certificated commercial, and military designs) with "canards" (elevators), meaning placing the elevator forward of the wing, typically near the nose, instead of well aft the wing. There are good and bad aspects of canards, as Dick Rutan designed them.

His entire stated reason for using canards was to reduce the incidence of aerodynamic stalls causing aircraft to fall out of the air during critical phases of low speed flight, namely takeoff and landing. The general idea was that the canard would stall before the wing, so it would tend to drag the nose back down to horizontal so that the main wing would not stall, and thus the plane would keep flying. The problem with this design approach is that if the main wing ever does stall, it's almost always a fatal / non-recoverable event. After that wing stalls, unlike a more conventional aircraft where the nose drops and the plane resumes flying, the aerodynamics involved with canards typically prevent that from happening. If you were at 5,000ft or so and you stalled a canard-equipped plane, then you might pick up enough speed during the stall and subsequent fall back to Earth to resume flying before you hit the ground. This doesn't help you during takeoff and landing, though. You're going to hit the ground at significant speed. With a conventional tailplane layout, unless it's a very deep stall, the stall will typically not result in significant loss of altitude before recovery is possible.

For that reason, amongst many others, my own trainer design has a conventional tailplane layout and the distribution of the load is such that you cannot move the CG outside of acceptable limits, with the usual caveat that this refers to the pilot and fuel. Whether the pilot is a 90 pound woman or a 250 pound man, and regardless of fuel load, that very heavy Iron block LS V8 engine prevents the CG from wandering outside the box. The original Taylor Mini-IMP design was capable of being loaded outside of CG limits, because it was so light. My design won't be as performant as those designs with lighter engines. However, I'm not trying to "best" those designs. I'm trying to design a very low cost and docile training aircraft with STOL capabilities. My plane is NOT a speed machine. There are plenty of truly excellent cross-country travelers for those with fat wallets and lots of free time.

Engine cost and durability is a major selling point of my design. I think it's better to sacrifice some performance if it means the cost of the engine plummets from $50,000 to $5,000. If you want equivalent power output AND weight as a Lycoming IO-360, then Viking Aircraft Engines (Honda car engines) or AeroMomentum (Suzuki power sports engines) has you covered. On top of that, the engines are physically much smaller. Viking's turbocharged 1.5L Honda engine conversion has identical weight to the very lightest versions of the IO-360 and it produces a dyno-proven 195hp. Yes, that engine does indeed "makes more power in the car", but an aircraft engine has to "run and survive" at high constant power output levels, so aircraft engine conversions limit their maximum operating rpm to ensure long term survival. That's almost as much power output as the heavier and slightly more powerful but less reliable IO-390 engine (200hp to 215hp), but that Honda engine conversion will set you back about $19,000. In return, Viking provides a complete "firewall forward" package ready to run. The "360" in the IO-360 engine moniker for the Lycoming refers to the engine's cubic inches of displacement. All stock Lycoming IO-360s displace 361 cubic inches (5.125in bore x 4.375in stroke x 4 cylinders), hence "IO-360". The "I" stands for "fuel-injected", as opposed to carbureted. The "O" stands for opposed-cylinder, aka a "boxer" engine configuration, like the Porsche and VW Beetle engines. The "GTSIO" in the Continental GTSIO-520 engine stands for "Geared (reduced rpm to the propeller using a gearbox integrated into the crankcase), Turbo-Supercharged, fuel-Injected, Opposed-cylinder, 520 cubic inches of displacement".

Continental's most numerous models include the following:

O-200 (4 cylinder); 100hp

O-300 (6 cylinder); 145-175hp (GO-300 model)

O-470 (6 cylinder); 165-250hp

O-520 (6 cylinder); 285hp to 435hp (GTSIO-520 models)

IO-550 (6 cylinder); 300-360hp (TSIO-550 models)

Lycoming's most numerous models include the following

IO-320 (4 cylinder); 150-160hp

IO-360 (4 cylinder); 180hp

IO-390 (4 cylinder); 210-215hp

IO-540 (6 cylinder); 230-380hp (IGSO-540); almost all of them are 260-300hp

IO-720 (8 cylinder); 400hp (all models)

There are also a literal handful of "round engines" (radials) still in use. Most are Jacobs R-755s (225-300hp) or Pratt and Whitney R-985s (300-525hp; most are 450hp) or R-1340s (425-600hp; most are 600hp). Examples of much larger radials still exist, mostly Pratt and Whitney R-2800s (2,000-,2500hp), R-4360s (2,650-4,300hp), or Wright R-3350s (2,200-3,800hp), but none of these are used by General Aviation, because they were military engines adapted to airline transport uses following WWII, most notably the R-4360s and R-3350s. We should have developed modernized versions of these engines, because late 1950s examples achieved TBOs beyond what early turboprop engines were capable of, at much lower cost. A modern R-3350 would cost about $1,000,000, go as long as modern PT-6As between overhauls, and burn cheaper fuel. They achieved 0.4lbs/hp-hr back in the 1950s. If we took the TEL out of the fuel and updated the components, these could be incredibly reliable engines achieving 450mph cruising speeds.

If a R-3350 equipped airliner flies for 2 hours, then the engine weight differential, in terms of fuel burn, between a gas turbine like the AE2100 (a very modern turboprop derivative of the T406 that powers the V-22 Osprey), has already been made up. The R-3350 airliners and modern turboprop equipped airliners already fly at the same speeds (modern Lockheed C-130J Super Hercules vs an old Douglas DC-7 series airliner). Your available engine power goes down really fast with the gas turbines as density altitude increases, while fuel efficiency goes down. Overall, the reason those old radial engines stayed in service for so long was the incredible engine purchase cost differential and fuel burn rates, back when fuel was cheap.

In the modern world, 550hp is approaching the "cross-over point" where we dispense with the more efficient piston engines and start using PT-6A or TPE-331 gas turbine / turboprop engines. This is for General Aviation, rather than Commercial Aviation, where virtually everything is gas turbine powered. However, a 750hp full-on custom billet-everything Big Block V8 engine might cost $100,000. A stronger-still Iron block engine will bring that price right back down to something reasonable, meaning $10,000 to $20,000 for a complete engine. If you need to make up the 150 pound weight differential, then on aircraft so-powered that's readily achievable using fabric rather than Aluminum. The old but reliable and common PT-6A engines start around $500,000 for a well-used example and the cost goes up from there. A new example would cost about $1,000,000. An overhaul is at least $250,000. This is why we still need piston engine tech. They burn less fuel and they cost a lot less, even for the most tricked-out examples.

Between the Honda, Suzuki, Yamaha, Chrysler, Ford, and GM engines, we can easily cover the 50hp to 750hp range using modern automotive aircraft engine conversions. Between 150hp to 750hp, reliable domestic designs are available, but up to about 200hp, the Japanese engines are very hard to beat. With proper engine selection, the liquid-cooled automotive engine conversions are lighter than equivalent air-cooled engines, more reliable because they don't reach oven baking temperatures, don't require Leaded fuels for knock suppression since they do run cooler, and don't burn excessive amounts of engine oil, nor do they require excessively frequent oil changes. We might retain radials for nostalgic reasons, but the boxer configuration Continental and Lycoming aircraft engines are "carryovers" from the 1950s. All the advanced aircraft engine tech started in WWII (EFI, EI, VVT, etc), but only modern solid state electronic control systems became reliable enough for practical en-masse implementations.

My engine displaces 359 cubic inches (3.78in bore x 4in stroke x 8 cylinders). It's based upon the much cheaper and more plentiful 5.3L LS Iron "truck" engine block that's powered so many millions of GM vehicles, such as the Silverado, Tahoe, Suburban, H3 Hummer, passenger vans, medium duty trucks, etc. It will use the less common Iron cylinder heads, although Aluminum heads can be had just as cheaply. The crankshaft and rods are aftermarket Scat branded 4340 steel forgings. The crank has all 8 counterweights to reduce flex / torsion / improve internal balance. I trust the word of Jack Kane of EPI Engineering on this point. He's an aerospace engineer, almost as old as my father, and he's participated in numerous automotive aircraft engine conversion projects involving various GM and in-house designed V-12 engines. I'm not using the 2618 forged pistons he recommended, but I am using 4032 forged pistons. Thermal expansion factors into piston longevity. 4032 simply does a better job than 2618 on that metric, so there's less piston slap inside the bore while the engine heats up. 2618 expands considerably as it heats up, in comparison to 4032. He's worked on a lot of air racing / high performance V8 engines using boost from turbochargers and superchargers, whereas I want long-term durability, less purchase cost, and less maintenance cost. Using 2618 forged pistons almost dictates more frequent replacement of expensive 2618 pistons. I'm not using boost, nor am I combining high compression with high rpm engine operation, so I fail to see the point in using something expensive that will beat itself to death. Heavy duty trucks and fishing boats use 4032 pistons. Offshore powerboats or drag racers and drifters running insane boost levels use 2618, because 2618 can survive the odd detonation under boost. Factory Continental and Lycoming pistons are all castings, so they don't even use forgings. They use 2618 in their air racing engines because those engines heat up and expand significantly because they're air-cooled. Piston slap is not even detectable at the power levels they're running, because they vibrate like mad. The vibrations are so bad that they have their counterweights loosely pinned to their crankshafts to absorb / prevent torsional vibration from shearing them.

At 2,700rpm, a Lycoming IO-360 is beating itself to death. There's a reason operation at that rpm is time-limited. An Iron block LS V8 running at 2,700rpm is loafing along, and under no significant stress. Before overdrive transmissions were commonplace, Chrysler / Ford / GM small blocks were running at 3,500rpm on the highway, all day long, everyday. If you ran an IO-360 at 3,500rpm, I can all but guarantee that it won't make its stated TBO of 2,000hrs. There were military ground auxiliary power units based upon these engines which ran at 3,500rpm. Those didn't last 2,000hrs before a teardown and rebuild was required. Point is, at 2,700rpm the Continental and Lycoming engines are under significant stress and their linear piston speeds are approaching practical limits for the castings they use. Their crankcase seals rely upon a single strand of silk thread to prevent oil leaks. I have MLS gaskets with Silicone coatings. Silk thread obviously does work when the mating surfaces are near-perfect, but MLS and Silicone are better for preventing oil leaks. These air-cooled engines have the equivalent of a road draft tube which can and quite frequently does barf dirty engine oil all over the belly of the plane. I have crankcase and valve cover ventilation hoses to feed oil vapor back through the air intake to combust it. That makes less of a dirty nasty mess to clean up after the flight, and is far more environmentally friendly. IMO, our government got that particular environmental regulation correct. It's quite reasonable to configure an engine so as not to puke engine oil all over the road or into the air. The aerobatic air-cooled engines prevent this by connecting breather hoses to a catch can that re-routes the oil back into the oil pan.

My design only has a single pilot aboard because that represents over 90% of General Aviation flying, to include flight training. It does not store any significant baggage because it's intended for flight training. I may explore the use of baggage pods hung from the wings at a later date to cater to lone adventurers using STOL aircraft for hunting and camping, since my design is also a STOL design. The stations where the heaviest components in the airframe (engine and fuel) have been located preclude any significant CG shift. On the ground, it won't have as much of a tendency to tilt back onto its tail, which was a problem with the Mini-IMP and Dick Rutan's canard series of experimental amateur built designs. This is a design tradeoff, though. My engine weighs twice as much as the Lycoming IO-360s that power typical Rutan canard designs and STOL tail draggers.

After seeing multiple examples of severe material degradation of Rutan moldless composite designs which make use of a special type of styrofoam core (this is not the same material as the styrofoam in a coffee cup) with layers / plies of plastic-reinforced glass fiber laid up and cured over the top of the core, I've lost confidence in even relatively short-term durability of that construction method. It's a great way to build otherwise expensive one-off composite components on the cheap, but not-so-great for ultimate durability. Rutan has explicitly stated that the foam core is integral to the strength / airworthiness of the structure, despite some false claims made online that it's "merely a mold over which the GFRP is laid up". It's an integral structure, period. If the plane is stored outside in a place with significant heat and moisture or salt in the air, such as any coastline, then that can happen inside of two years. The surface bond with the styrofoam underneath the composite can quite literally "turn to powder", even when properly constructed and cured. This core material durability issue was apparently far more common than I initially knew, and very commonly seen in GFRP sailing boats stored outside. After the outer composite layer separates from the foam core material, both stiffness and strength are lost, so the composite becomes non-repairable junk at that point.

Anyway, just some more thoughts on the future of General Aviation, which might be all we have left if our major aerospace manufacturers keep messing up airliner design to save a few dollars here and there.

Offline

Like button can go here

#112 2024-09-14 21:39:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re carbon 14 nuclear battery reference in a post to RobertDyck in Spacesuit topic ...

The Wikipedia entry for this interesting topic has not been updated (apparently) since 2020.

If you can find an update, please add it to the SpaceSuit topic....

As of 2020, commercialization was still in discussion but it ** was ** at least in discussion ...

Proposed applications

Due to its very low power density, conversion efficiency and high cost, a 14C betavoltaic device is very similar to other existing betavoltaic devices which are suited to niche applications needing very little power (microwatts) for several years in situations where conventional batteries cannot be replaced or recharged using conventional energy harvesting techniques.[13][14][15] Due to its longer half-life, 14C betavoltaics may have an advantage in service life when compared to other betavoltaics using tritium or nickel. However, this will likely come at the cost of further reduced power density.Commercialization

In September 2020, Morgan Boardman, an Industrial Fellow and Strategic Advisory Consultant with the Aspire Diamond Group at the South West Nuclear Hub of the University of Bristol, was appointed CEO of a new company called Arkenlight, which was created explicitly to commercialize their diamond battery technology and possibly other nuclear radiation devices under research or development at Bristol University.[16]

Arkenlight does not appear to have it's own web site.... it has numerous links in media sites of various kinds.

(th)

Offline

Like button can go here

#113 2024-09-15 06:12:19

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re CAES ...

Nice post about the Hummer for Mars using LCO2!

I still think dry ice is a far more practical way to pack the "fuel" for the trip. If you ** must ** have the liquid for the turbine (and I'm assuming you're specifying that for good reasons) then there would need to be a heat process to convert the dry ice to the liquid form.

Trying to hold large quantities of LCO2 in tanks seems like an unnecessary additional mass and equipment complexity.

If I can interest you in looking at the dry ice to LCO2 conversion process, it would potentially save your customers a lot of mass for hardware that can be better invested in "fuel" for the vehicle.

(th)

Offline

Like button can go here

#114 2024-09-15 12:16:20

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

The tanks have to be capable of containing the pressure, but the pressure is relatively modest, at around 50 bars (735psi) to 75 bars (1,103psi). That is well below the pressure at which SCUBA tanks are pressurized to, which operate at 165 bars (2,426psi) to 241 bars (3,543psi). The tanks can be much lighter as a result. Low cost and weldable Mangalloy steel sheet / plate (now used for cryogen storage aboard LNG tankers) can be used to provide the tensile strength (50 to 150ksi). Mangalloy can be forged and bent while hot quite easily, but cutting or grinding it when cold is quite difficult. We'll need to use water jet cutting and annealing when it's cold, but rapid quenching in a cryogen will make it "soft" again, rather than "hard", which is what would happen if you dunked ordinary steel in LN2. I know that sounds very strange, because knife blades are rapidly quenched to make them very hard, but Mangalloy is very different. The same process makes them very soft / ductile again for cold-working- the exact opposite of what one who has worked with steel would expect.

The most important reason for choosing Mangalloy is the combination of its much higher tensile strength relative to any kind of non-brittle but harder / stronger stainless steel and its ability to withstand cryogenic temperatures without loosing ductility, the way plain Carbon steel does. The stronger / harder martensitic stainless steel variants undergo a crystalline phase change at cryogenic temperatures, just like ordinary carbon steels, that they become so hard / strong as to be very brittle, much like a ceramic. That makes Mangalloy suitable for hot-pressed / stamped parts used to fabricate a vehicle frame or body the way we typically make off-road vehicles such as the Hummer.

We don't typically think of Mangalloy as a steel suitable for making vehicles because we have even lower cost and easier to form high strength low alloy carbon steels that are easier to work with, but don't have to withstand hard use in mildly cryogenic environments. However, it is relatively cheap, it is used for a variety of industrial purposes, and it is remarkably tough, strong, hard, and abrasion resistant.

It might be more practical to store dry ice, but something has to apply heat to generate pressure to extract CO2 gas from dry ice or LCO2, which implies a build-up of pressure in the tank itself if dry ice is used. If the pressure is already high enough to keep the CO2 liquid, then it flows out of the tank under gravity without undue effort, so a heating element can then provide the input heat required to rapidly expand the LCO2 into a much greater volume of gas, outside the tank.

Offline

Like button can go here

#115 2024-09-15 14:43:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,304

Re: kbd512 Postings

Martian night time temperatures get down to about -90°C even at the equator. This is far beneath the triple point of CO2. Provided that we have an energy source that works at night, like an RTG, very little compressor work will be needed to force the CO2 into liquid. But the compressor itself will need to be large, because the density of the Martian atmosphere is pathetically low at 0.013kg/m3. Assuming an input windspeed of 5m/s, 1m2 inlet area compressor, will take 4.7 hours to gather 1m3 of liquid CO2. The same RTG can provide the heat needed to drive the regassification of CO2 during the day, which can power the vehicle.

Last edited by Calliban (2024-09-15 14:51:28)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#116 2024-09-16 12:00:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re post in CAES topic ...

I've been creating the "index" posts when folks create new topics, so the topics don't sit unanswered. However, the index post could be helpful to a future reader if I can find time to update it.

I decided your post in CAES today is worth including in the index. While your post covers more than one subtopic, it ** does ** include at least one reference to compressed gas.

Please consider adding a bit of detail to your idea of filling the pipe with something other than air. I'm just launching the idea of using old oil wells in this way, and your response is interesting. I'm at a disadvantage because I don't understand how it would work, but that's probably easy to remedy. The simple concept of compressing gas has the distinct advantage that the gas is ready to do useful work immediately when you turn the spigot, but perhaps more energy can be stored using other materials.

One detail from your post that caught my eye is the 16 hour time frame for stored energy to be delivered to the grid when the solar panels are in darkness. The system would need electronics to manage the flow of energy. I don't think a simple mechanical system is up to the job, especially if the system is to be interfaced to the larger regional grid

(th)

Offline

Like button can go here

#117 2024-09-16 14:14:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

I'm saying that you load the well with an incompressible fluid, such as hot water or molten salt, and you stick your radiator (a metal pipe) in that fluid, and you transfer heat in and out of the fluid using a gas (CO2). Heat is pumped into the well using CO2. Heat is extracted from the well using CO2. Topside, you have a heat exchanger that uses water or air. The gas flows through the radiator in the well, where it picks up heat and expands, so it comes rocketing back out of the well and you run the hot expanding gas through a power turbine. In addition to the power turbine which extracts mechanical work from the hot expanding gas, you also have a heat exchanger to cool the gas before it's re-injected into the well. This is your complete thermal power transfer loop.

The first loop pumps heat into the well using heat collected from solar thermal. We don't have to worry about "loosing" heat, because we're always pumping more in, and the insulation provided by the wellbore liner is pretty good.

The second loop routes hot CO2 into the radiator piping (a literal steel pipe that transfers heat into the gas using conduction) in the well where it gets heat from the water or salt sitting in the wellbore. The exit pipe leaving the well is fed into a sCO2 gas turbine. Immediately after the sCO2 turbine, you have a radiator to cool the gas before it then passes back into the thermal storage well.

Only the small diameter metal piping has to contain and deal with pressure changes. The well itself is only containing a hot fluid (salt or water), that doesn't mess with the static pressure at any given point in the well, so the ambient conditions in the well do not involve extreme expansions and contractions from huge pressure changes, as would be the case if we pressurized and depressurized the well. Hydrostatic pressure changes as depth increases. Maybe you could do 350bar at the bottom of the well bore, Earth is pressing inwards on the wellbore with 350bar of pressure at the deepest point in the well, but 350bar at the top of the wellbore may fracture the concrete casing / wellbore liner and then you start loosing gas into the rock formation. This concept is very important to prevent a catastrophic collapse or a surge of pressure forcing the contents of the wellbore out of the well. Adjusting hydrostatic pressure was a constant concern while drilling. The well has to be filled with something at all times, or the Earth fills it for you.

Offline

Like button can go here

#118 2024-09-16 17:13:23

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re new concept for energy storage in abandoned oil wells....

I had in mind starting a new topic just for your idea, but the posts went into the existing topic instead.

It should be possible to compute the total thermal energy that might be stored using the method you have suggested, and the original proposal to compress air.

The compressed air proposal should be comparatively easy to compute.

Your proposal will be a bit more complex to analyze but I am hoping it can still provide believable numbers.

Your proposal (as I understand it) would circulate CO2 (or some other suitable fluid) down an abandoned oil well and back up, so that heat can be stored in the material you choose for the oil well pipe, and then retrieved when needed.

If an abandoned oil well is 12,000 feet deep, then the fluid circulation loop would be 24,000 feet long.

The material chosen for the circulation loop will have the ability to hold together despite dramatic temperature differences over it's length.

There may be details you'll be adding to your vision as we go along.

(th)

Offline

Like button can go here

#119 2024-09-17 10:00:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re pipe bursting pressure....

I wrote to FriendOfQuark1 to ask for his take on the CAES idea for unproductive oil wells. He replied at great length, and I've asked for permission to post the reply.

In the meantime, I picked up a couple of items:

1) Lines built for fracking can handle truly astonishing pressures.

Obviously lines built prior to fracking would have to be tested to see how much pressure they can handle.

2) Many less productive wells are being held in reserve in case market conditions warrant restarting them.

3) Wells that are considered of no value for oil or gas are plugged with concrete, but how deep that concrete goes is a question.

I would expect that producers would use only enough concrete to satisfy the regulators and not an ounce more.

To bring such a well back into service for CAES, it might be necessary to dig down to the bottom of the concrete.

On the ** other ** hand, if the regulators insist that concrete fill the entire pipe, then the cost to the producer would be considerable, and recovery of the asset would not be possible/practical.

I asked FriendOfQuark1 if a company holding onto a low yield well might be willing to consider CAES as an alternative revenue stream, if the changes to allow that use can be made reversible.

(th)

Offline

Like button can go here

#120 2024-09-20 17:33:38

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512...

https://newmars.com/forums/viewtopic.ph … 02#p226702

News from SpaceNut

(th)

Offline

Like button can go here

#121 2024-10-05 18:56:19

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 ... thanks for picking up on RobertDyck's interesting idea ...

I'm hoping he will stay with it a bit further.

If I understand the concept the idea is to use sound as a way to overcome atomic force repulsion.

I don't have any resources to analyze the potential of sound for this exercise, but I do have several text books that explain atomic force in some detail.

An analysis would require knowledge of both sets of forces, in order to compare one to the other.

(th)

Offline

Like button can go here

#122 2024-10-14 06:18:57

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512,

Thanks for your substantial contributions to the two topics, Starship and Cycler!

The Boeing drawings show the ambition that fueled those early visionaries!

The review of alternative cycler designs is ** really ** interesting and valuable!

Based upon the frequency-of-opportunity criteria, of 7 in 15 years, I think the Aldrin Cycler is going to receive a ** lot ** of attention in coming years! Two cyclers would (presumably) offer 14 opportunities in the same time period.

Update 2024/10/15 -- The idea that two cyclers would offer 14 flight opportunities needs clarification. The Aldrin Cycler flight plan is based upon the same planetary movement relationship as is used by the Hohmann Transfer orbit. Two cyclers would have to fly the same path, so the frequency of flight opportunities remains 7 in 15 years. However, having two cyclers traveling in a convoy is a good idea in any case. It would increase the resilience of the flight package, while doubling the carrying capacity. The construction plans for the second cycler could be re-used so the expense of developing those plans would be eliminated.

And the 174 day transit time is going to look ** really ** attractive to a lot of humans wealthy enough to make the trip, not to mention the comfort of spin gravitation, the protection of ** real ** radiation protection, and whatever other amenities the transport company adds to the mix.

If there is anything to the maxim that "time is money" the savings of three months or more using the Aldrin Cycler is going to justify the expense of the fast taxi service to connect with the cycler or with the destination.

Plus, it seems likely to me that the business case for the high speed taxi service is going to drive innovation in use of atomic power.

The target dV change is 11 km/s.

Question for enterprising NewMars members: What value might be found in the long outer phase of the Aldrin Cycler orbit?

Does that orbit go anywhere interesting? Are there resources that might be collected along the way?

(th)

Offline

Like button can go here

#123 2024-10-19 04:50:37

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,075

Re: kbd512 Postings

For kbd512 re another outstanding post...

This time it is another in your series in Louis's Solar power topic...

http://newmars.com/forums/viewtopic.php … 66#p227366

Your estimate of 75 years life for solar reflector systems, compared to 25 for silicon panels, sure looks good.

I'm wondering if the fluid handling component of such systems would also have a 75 year life. It might. I wonder if there are any examples in existence that might provide a guide for estimates.

It seems to me no one has achieved the holy grail of manufacture of silicon panels using all solar power input.

I don't even know if such a thing is possible, but it might be. If that loop can be closed, then it seems to me all the arguments about energy efficiency go out the window, because the Sun provides more power than we humans are currently using.

****

It seems to me that while the number of contributors to the forum is one the low side these days, the quality of contributions is high.

At some point we may be able to create an environment that someone else would like to join.

(th)

Offline

Like button can go here

#124 2024-10-20 00:05:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Re: kbd512 Postings

tahanson43206,

So long as you maintain the steel, it doesn't magically "just quit working" as a mirror. NREL's own prototype solar thermal plant has operated for more than 50 years. It dates back to the early 1970s. So far as I know, it's still running. In the same way that NASA has run those turbo-electric generators for over 10 years (going on 15 now, I think), just to see how long they can actually run for, NREL has some experiments they simply run until they break. There's little reason to think their plant will suddenly stop working after 75 years. If a sheet or tube of steel is sufficiently corrosion protected, and its polished surface is not scratched by atmospheric dust in the case of the mirrors, then those parts could conceivably continue to operate for centuries. We have intact steel artifacts dating back to before the time of Christ. That said, I'm quite sure that minor periodic repairs will be required. Since it's a simplistic thermo-mechanical system, that periodic repair is a realistic possibility.

The lifespan of the thermal fluid handling systems depends greatly upon operating temperature, any chemical interactions between the working fluid(s) flowing through the steel piping, manufacturing quality control (base metal and weld quality), as well as any service life enhancements imparted to a specific steel alloy through the use of corrosion inhibiting aerospace coatings. If you dunk an unprotected sheet of steel into a salt water tank, then it will be a rusted mess after a matter of months. If that same piece of steel had a Silicon-based aerospace coating applied to it, then it may not look much worse for wear than it did when brand new. Silicon carbide aerospace coatings are why electric range top heating elements don't look like a nasty corroded mess inside of a year. They can heat up and cool down many thousands of times. If they got hot and stayed hot, then they would last even longer. Thermal cycling does more real damaged to all kinds of metals and ceramics, especially the kinds used in electronics, than "getting hot and staying hot", within the temperature limits of the materials in question.

If you warm up a circuit board (while not overheating it) and keep it warm within minimal thermal cycling, then it's going to last a lot longer than if you power up the machine every day, turn it off, and then do the same thing the next day, over and over again. The repeated expansion and contraction (thermal cycling) of metal breaks both welds and electrical connections. That statement of fact is not the least bit controversial within the realm of mechanical engineering and known materials science. GW, Calliban, or pretty much any other engineer will tell you exactly what I've stated here.

So far as I'm aware, there's no such thing as a functional solid state electronic device which has survived 50 years of more or less continuous operation. Variable state electronics (vacuum tubes) won't last nearly that long. If you don't care at all about energy or money, then you can optionally replace an electronics-based system in its entirety, typically with a newer superior model, but that is your only realistic option. You are going to replace it at least once, if not several times, over 75 years. In practice, photovoltaics degrade to the point of providing about 80% of what they output when new, over a time span of 25 years or so. Some won't last 2 years and some might last quite a bit longer, but all are guaranteed to degrade significantly over time. The universe is unkind to electronics. If you need a 1MW power plant, but your device is only generating 0.8MW 25 years later, then you can expand that power plant's physical footprint or replace the degraded photovoltaics and power electronics with new and hopefully better models. Up to this point, everyone has opted for that total replacement option. Land and electrical conductor wiring are finite resources. Expanding the plant footprint with longer wiring runs increases electrical resistance and losses within the plant itself. Thus, total replacement makes good value sense, but not much economic sense if there are alternatives that don't require such frequent replacement and don't degrade over time at nearly the same rate.

Perhaps this will help you understand why that is so, and shall remain so, until absolute manufacturing perfection is achievable:

Even if we could manufacture physically flawless photovoltaics for a reasonable cost, what about all the power electronics, battery charge controllers, and wiring runs? If flawless manufacture is not practical, or perhaps functionally impossible at high manufacturing volumes, and complexity only increases linearly with each component added to a photovoltaic power plant (this is frequently not descriptive of reality), then how much can we realistically scale-up before a casualty-inducing manufacturing flaw is guaranteed? Here on Earth, equipment not working is an annoyance most of the time. On Mars, people are staking their lives on their equipment working at all times.

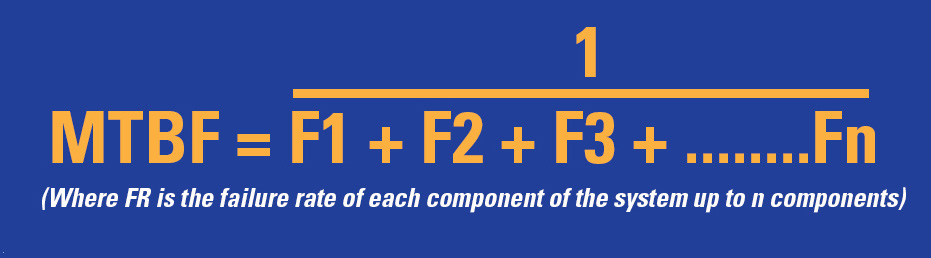

A microelectronic device contains millions or even billions of electronic circuits. Producing them with a suitable level of manufacturing quality is exceptionally difficult. When the total number of devices incorporated into an integrated circuit reaches into the billions, or enormous numbers of simpler devices with only a few thousand or million circuits are used, tell me how it is that anyone believes that an electronic device could ever be as durable and reliable as a piece of corrosion protected steel? Doesn't the Mean Time Between Failure formula shown above pretty much dictate that as you increase total component count, your odds of a manufacturing defect adversely affecting operational reliability only become a certainty?

During my time at Unisys when I was still in college, I worked with a guy who previously worked in QC for a chip fab in Austin. He worked for AMD and a couple other companies. I think he went back to that job after they re-opened the fab following a shut down. I don't recall the reason for the shut down. Bringing a new process online, maybe? This was over 20 years ago. He told me that the closer to perfection the circuitry must come, the higher your rejection rate and the greater your cost, as more chips are discarded after failing to pass QC. They got better over time and threw away fewer chips, but their rejection rate was never zero, merely tolerable. No chip is totally flawless, but some come closer to "perfectly made" than others. I asked him how it was that any chip with a few flaws can still pass QC. He told me that the internal circuitry is designed in such a way that the loss of one electronic pathway through all the logic gates of a CPU chip (they use massively parallel compute architecture) doesn't totally disable its utility as a CPU. At least some chips can (apparently) "degrade gracefully". I learned a bit about electronics reliability from him, because we'd talk for hours while we worked at our cubicles. I was more interested in software than hardware, but learning about how the hardware side of things affected the software I wrote was pure gold.

The same applies to a photovolatic cell, which is merely another application of semiconductor tech with a higher tolerance for manufacturing defects than CPUs. NASA's tolerance for manufacturing defects for their Mars-rated triple-junction photovoltaics is still exceptionally low, which is why they're also exceptionally expensive ($1M/kW), beyond the simple fact that they're triple-junction vs single-junction cells and have some additional protective features built into them that their Earth-bound analogs lack. A photovoltaic power plant contain a vastly greater total number of components on the panels themselves, even if they're non-moving electronic components, than an entire solar thermal power plant has total discreet components. The fact that you cannot even see some of these components without a microscope doesn't change what it is or how it works. Each photovoltaic cell is the electronic equivalent of a diode and pair of resistors. Each panel has about 72 of those. The discreet components of a solar thermal power plant are also drastically physically larger than a photovoltaic or microcircuit wafer, so their tolerance for manufacturing defects and environmental damage is far greater. If a mirror is 0.1mm out-of-spec, it's still a functional mirror. If a photovoltaic cell contained a far smaller manufacturing defect, it would short circuit. Do that enough times over enough cells, and you start to suffer from operationally significant failures.

Photovoltaic cell circuitry equivalent:

I now understand why it is that the on-panel inverters use both under-voltage and over-voltage protection:

The explanation for this setup (and why it didn't function on cloudy but bright days) is shown below:

Look at the relationship between current and voltage, along with voltage vs solar irradiance. You get about 4.4 milliAmps of current from any light striking the panel, up to 2.5V or so. How do you regulate power output when current is nearly fixed, up to that "sweet spot" of 3V to 3.5V?

The answer is that you don't, because doing so would cost extra money for better (heavier and more costly) electrical conductors, both on-panel and all the rest of the wiring into the point of distribution / consumption. That chart aptly explains the preference for Silver over Copper on the panel itself. If you have Silver, then you can "cut-in" at a lower voltage. To deal with high current / low voltage, you turn off the output because both your current and voltage have regulation limits. At low voltage, you're mostly electrically heating all the circuitry, due to resistance from high amperage relative to voltage, without providing much usable power output, shortening the lives of the components for marginal net benefit, because most of the time your current drops off as voltage rises in full Sun. That might still be okay in the morning if the equipment is "cold", but maybe not in the evening when it's "hot". You either need very low internal electrical resistance, or you need to sacrifice the additional power output in favor of longevity of the power regulation equipment and the photovoltaic cell circuitry.

Offline

Like button can go here

#125 2024-10-20 00:07:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,500

Offline

Like button can go here