New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2022-07-30 11:05:35

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Propane - Energy Carrier

For SpaceNut ... we had no topic containing the word "propane"

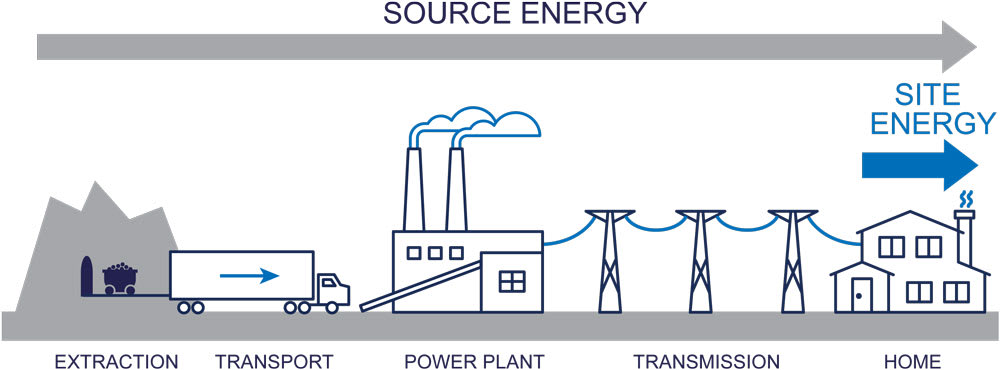

Propane is an energy carrier like gasoline, kerosene or methane.

Propane has advantages and disadvantages, like all energy carriers.

This new topic was inspired by a news item that reported a grant to design a more efficient propane internal combustion engine.

If anyone can find the article and post a link, and perhaps part of the article, it would be a helpful addition to the topic.

However, since this ** is ** the Mars forum, I'd be interested in factual comparison of the advantages and disadvantages of propane for use there.

Opinions are welcome in the Chat topics. Please include numbers or links to numbers in your posts.

This topic is intended to be a repository/reference for those who might wish to quickly refresh on the details of use of propane as an energy carrier on Earth or Mars.

(th)

Offline

Like button can go here

#2 2022-07-30 16:36:09

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Propane - Energy Carrier

tahanson43206,

A more efficient internal combustion engine is only possible by virtue of more complete combustion and the higher Octane-rating of Propane fuel, relative to gasoline, which enables engines to run higher static compression ratios. There's no more magic to it than that. Propane is cleaner than gasoline or diesel because it's a shorter hydrocarbon chain. The engine should last longer in normal operation because there are fewer Carbon deposits created by the shorter hydrocarbon chains, so less deposition of Carbon onto the combustion chamber and into the lubricating oil, via blow-by.

As a fuel, Propane works quite well in all existing combustion engines, from boilers to reciprocating pistons to gas turbines, after the fuel delivery hardware (injectors / fuel lines / fuel tank) is optimized to deliver Propane (in gaseous or liquid form) instead of gasoline or diesel. The reasons we mostly use gasoline or alcohol and diesel here in America are the fact that Propane is only produced as a byproduct of oil refining, and those longer-chain hydrocarbon fuels exhibit improved storability over CNG / LNG / LPG, with decreased explosion hazards due to combustible vapors from leaks that light hydrocarbons like Methane or Propane would create.

If fuel systems are regularly inspected and serviced, then the leaks and subsequent explosion hazards are minimized, but you can't skimp on the quality of the componets used or the routine maintenance. In practice LPG is no more dangerous than gasoline. LPG has much greater volumetric energy density than CNG, but it's no better than LNG. However, LNG is also a non-storable cryogenic liquid, whereas LPG remains liquid at normal atmsopheric temperatures with about as much pressure or compression as that found in heavy duty truck tires or heavy aircraft tires, meaning 120psi to 160psi or so.

There are plenty of farmers and oil companies that operate piston or small gas turbine engines off of Methane or Propane instead of gasoline or diesel. Fork lifts are commonly operated off of CNG or LPG as well. Many of the riding mowers, especially the ones in commercial use, use LPG instead of gasoline or diesel.

Here in Houston the various city service trucks (like the school buses or public transport buses and garbage trucks) run on CNG, because it's readily available at low cost, the infrastructure to deliver the fuel is already present, the driving ranges are fairly short, and conversion over to battery electric would cost as much as 3 brand new trucks powered by CNG or LPG fuel. All of these trucks are powered by diesel engines. Those trucks are regularly serviced at a depot-like facility where they are stored between uses. I've seen a few of these facilities scattered around the city. It's a giant gravel parking lot with 100+ garbage trucks or school buses and other sorts of vehicles used in construction by City of Houston, sheet metal service garage buildings, and loading docks for spare parts or engines. You see some of the diesel engines in the yard with the trucks, they have forklifts and cranes to work on the trucks, and a refilling pump.

Towards the end of the Soviet era, the Russians operated commercial airliners using LNG instead of kerosene. Methane and Propane burn much cleaner than kerosene or diesel. Virtually all commercial electric power gas turbine generator sets of any appreciable size use CNG, because that's the cheapest fuel available. I suppose LPG could also be used, but wouldn't be on cost and availability grounds. Aircraft gas turbines could run on LPG, though, since LNG is impractical. The Soviets successfully used LNG on a series of test flights, but that didn't mean it was practical. I can't see every airport having its own cryogenic fuel storage infrastructure, even though the military airfields make and store LOX. Existing jet airliners would have to be completely redesigned to use LNG. Running them off of LPG instead of kerosene is a much lower technological hurdle to clear.

Straight Talk about CNG - Is CNG worth the investment?

The pros and cons of using LPG butane or propane in your car or truck

In depth engine tuning with LPG liquid injection dual fuel | fullBOOST <- Watch this video to understand the intricacies of using both LPG and gasoline in a high-performance (393 cubic inch, 650hp) Ford V8 street car engine in a daily driver that will see 30,000km per year, from the perspective of an Australian engine tuner with 20+ years of experience installing LPG conversion kits into various engines used in street cars. This guy actually writes custom software for engine tuning, as opposed to someone who only knows how to adjust fuel tables.

You know how you get polymerization and coking in high-pressure direct-injectors?

Using pure CNG or LPG, that wouldn't be near as much of a problem.

Offline

Like button can go here

#3 2022-07-30 17:21:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For kbd512 re #2

Thank you for your detailed review of advantages (and some disadvantages) of use of propane as a fuel for internal combustion engines.

SearchTerm:propane ... See post #2 for detailed overview

The article I saw today implied that funds have been allocated to an attempt to improve efficiency of propane consuming engines.

It would be helpful (for this topic) if numbers are available for existing internal combustion engine designs, so we (readers and forum members alike) can evaluate performance of any improvements that might be attempted.

(th)

Offline

Like button can go here

#4 2022-07-30 19:28:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

The fuel is a favored for inside building use due to the lower exhaust co2 output from its use.

All of the hydrogen carrying gasses are fuels https://en.wikipedia.org/wiki/Fuel_gas

Offline

Like button can go here

#5 2022-07-30 19:54:01

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Propane - Energy Carrier

tahanson43206,

If you're asking for an economics case for switching everything over to use some other type of fuel, then there isn't one. If all of our existing infrastructure was designed around synthesis / refining / transport of LPG to power the various gasoline or diesel or kerosene burning engines produced over the years, then it wouldn't make any sense to switch over to gasoline or diesel or kerosene, either. No amount of make-believe about better this / that / the other will change that. The reason we use gasoline and diesel and kerosene is that they combine the most desirable qualities for a fuel to have in their respective applications. That's why they're so widely used.

The primary advantages to running LPG, if it were synthesized in the required quantities of hundreds of million gallons per day, would be lower cost to manufacture the fuel, as compared to gasoline or diesel or kerosene, and approximately half the CO2 emissions when burned. It's little different in practice than combusting CNG / LNG / Methane. We've already applied CNG where appropriate and feasible, namely short haul trucking and electric power generation. We can't readily apply it to anything else in a practical manner, which is why we haven't. The same applies to LPG and batteries. Shoe-horning a combustion engine inside a cell phone or laptop is every bit as inappropriate as powering cars and trucks with existing batteries. Gas turbines are the only appropriate engine choice for commercial and military aircraft. There's a running engineering theme here. We've already applied various energy technologies where they work well or work best. Now we're trying to hammer square pegs into round holes. Predictably, that isn't going very well.

LPG could only feasibly be used in passenger vehicles and aircraft if we started synthesizing mass quantities of the stuff. Otherwise, fuel demand would immediately outstrip all existing production capacity. That is why most vehicles are powered by gasoline or diesel or kerosene. Engineers know that LPG is a cleaner fuel, but that doesn't mean anything when there's not enough available, like Lithium for Lithium-ion batteries. There is plenty of gasoline / diesel / kerosene when investment dollars into production continue to flow. I'm a proponent of fuel synthesis because it means there's no practical limitation on how much fuel we can make and use. We are not beholden to OPEC or oil companies.

In the same way that roads and bridges and railways and military bases are designated as "national infrastructure", the chemical products that makes such infrastructure usable should also have the same label applied to them. If batteries are required for cell phones and computers and networks, which are arguably every bit as critical to our modern way of life, then the same applies to batteries. I think government should control the infrastructure so that there is no corporate or nation-state threat to sovereignty, but day-to-day operations must be run by specialist corporations under contract, for-profit, same as the Lake City Arsenal ammunition plant. For mass production of commodity products of relatively simple construction, such as fuel or ammunition, that business model has served both the tax payer and government better than any other. If you do a good job, then profits, though modest, are an absolute guarantee. The business realm can't deliver profits for economic growth of the country when the demand and supply are continually subjected to radical swings over time. Government can absorb the shocks, because the input base is the entire economy.

Offline

Like button can go here

#6 2022-07-30 20:32:20

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For kbd512 re #5 with additional perspective on use of propane

I found what ** may ** have been the citation that seemed to indicate funding to improve efficiency...

It turns out this was an incentive program for farmers to convert from diesel ... The date on the web site I just found was 2020, so i don't know if the incentive program is still in effect.

In any case, the points you've made about the relative abundance of various fuels would have to be a factor in the decision making process for a given farmer ...

With the USDA Rural Energy for America Program Renewable Energy Systems & Energy Efficiency Improvement Guaranteed Loans & Grants, there’s never been a better time to update your outdated and inefficient diesel irrigation engines with cleaner, more cost-effective propane alternatives. Applying is simple.

BENEFITS THAT DIESEL CAN’T MATCH

28% HIGHER PERFORMANCE

compared to previously owned diesel engines50% REDUCED ENERGY COST

per hour compared to previously owned diesel enginesWHO CAN APPLY?

Any ag producer who makes over 50% of gross income from agriculture is eligible. The program was designed for farmers looking to make energy efficiency upgrades to their operation.HOW MUCH CAN YOU GET?

This grant is good for up to 25% of your total upgrade cost, with a $1,500 minimum and $250,000 maximum.WHAT DOES IT COVER?

This was from: https://propane.com/for-my-business/agr … formation/

I note that in 2020, there were still farmers thinking about using stationary engines to move water.

Those days may be gone.

(th)

Offline

Like button can go here

#7 2022-07-30 21:44:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Propane - Energy Carrier

tahanson43206,

They can't convert from diesel because there's not enough Propane to go around. US agriculture direct energy consumption per year would require a 5X to 6X increase in LPG production to replace diesel fuel, or all the other users of LPG would have to replace that LPG with some other fuel source. Remember when I stated that all energy sources have only ever been additive?

US EIA - Petroleum & Other Liquids

How much cleaner could we possibly make the emissions from diesel engines?

It will always be a non-zero value, so when is it good enough?

Offline

Like button can go here

#8 2022-07-31 07:11:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For kbd512 re #7 and earlier posts in the Propane topic.

I'm picking up here on your mention of shorter chains in propane, compared to other hydrocarbon energy carriers.

Can you (would you) compare the energy required to produce a given amount of stored energy, such as one kilowatt-hour (3600000 joules)

Because multiple steps are required at each stage of processing for kerosene, gasoline and the various gases, I'm unsure which is the most efficient for the purpose of your proposal to make stored hydrocarbon from air and water using solar energy.

I ask primarily in hopes that propane might be an optimum product for this purpose.

If you felt like it (and have the time and energy) ... could you (would you) describe the manufacturing steps for each hydrocarbon fuel you might wish to make?

If you are willing to take that on, please put the sequence for Propane in this topic, and we can create other topics for the others you might wish to describe.

This forum can become a repository of useful knowledge as well as a record of the writings of the members over (by now) two decades.

In the case of propane, I am going to guess that 1 kilowatt hour of stored energy can be created by spending 10 kilowatt hours of solar energy.

The actual efficiency might be worse, or it might be better, but if the source is sunlight, then the cost remains zero (setting aside hardware costs).

(th)

Offline

Like button can go here

#9 2022-07-31 07:18:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

This topic is about Propane, and I have asked kbd512 to contribute a post (or more) about how to make propane using solar energy, air and water.

To set the stage, here is data about propane supplied by Google:

The most commonly used propane tank, the 20 lb tank is the standard size tank for barbecue grills, mosquito magnet, turkey fryer, small space heaters. However, the 20 lb tank can be used on several other propane applications. A 20 lb propane tank holds 4.5 gallons of propane and weighs 37 pounds full.

Tank Sizes and Specifications - Tanks 2 You Propane

www.emptygrilltank.com › tank-sizes-and-specifications

About Featured Snippets

Asking Google "how much energy in a pound of propane"

Knowing the Numbers Propane vs. Electricity - Blossman Gas

www.blossmangas.com › knowing-the-numbers-propane-vs-electricity

1 Gallon of Propane = 27 kWh (Kilowatt Hours) of electricity, which means that one gallon of propane contains the same amount of usable energy as 27 kilowatt ...

Ok, no answer by pound, but instead, by gallon ... a gallon is reported to contain 27 Kilowatt Hours of stored energy.

A 20 pound tank is reported to contain 4.5 gallons of propane. By calculator then, a 20 pound tank contains: 121.5 kilowatt hours of stored energy.

I am guessing it would take 1215 kilowatt hours of solar energy to make that 20 pound tank, but hopefully kbd512 can do better than that.

(th)

Offline

Like button can go here

#10 2022-07-31 09:07:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

A properly filled 20lb tank with 20lbs of propane will only be 80% full.

Propane is a three-carbon alkane with the molecular formula C3H8 = 44.09562 g/mol and Liquified propane (at 60 degrees) contains a little more than 92,000 Btu per gallon. With 1 BTU/hr = 0.29307107 W.

https://en.wikipedia.org/wiki/Propane

https://propane.com/for-my-business/res … h-propane/

https://afdc.energy.gov/fuels/propane_production.html

https://www.quora.com/Consider-the-comp … -air-weigh

https://www.parkergas.com/2020/04/13/ho … pane-made/

https://preparinginthecity.com/how-long … f-propane/

The conversion of hydrogen gas to liquid methanol as a form of energy storage whose energy re-use efficiency is estimated at around 45%. So, unless we change the characteristics of the conversion it's going to be about the same. We know that depending on the supply of each into a chamber and the catalyst used as well as the temperature change not only the fuel output but its efficiency to make it from the input energy

https://www.nature.com/articles/s41467-020-20214-z

Offline

Like button can go here

#11 2022-07-31 10:39:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For SpaceNut re #10

Thank you for your substantial boost to this new topic.

I asked Google for help with British Thermal Units.... Your post delivers information converted to watts.

1 british thermal unit =

0.000293 kilowatt hour

I see the correspondence in the value "293"

As a reminder, this forum has an entire topic devoted to Methanol: http://newmars.com/forums/viewtopic.php?id=9989

What I'm hoping will come out of this discussion will be posts that can be used for reference.

The question I am asking is for comparison of the amount of energy needed to make one kilowatt hour (3600000 joules) of stored energy.

We have many hydrocarbons to choose from, and even ammonia if someone wants to go in that direction.

All energy storage media have advantages and disadvantages.

What I'm looking for in ** this ** topic is the exact (or as close as possible) amount of energy needed to make propane holding 1 kilowatt hour.

In this case, referring again to Google:

Propane Usage Information - Small Cabin Forum

www.small-cabin.com › forum

Propane tanks are typically filled to 80% capacity to leave room for expansion. 1 Gallon of Propane = 27 kWh (Kilowatt Hours) of electricity. 1 ...

The quantity of propane to be manufactured is 1/27th of a gallon.

Asking Google again:

1 gallon of propane weighs 4.11 lb. It's important to understand that the 4.11 lb/gallon density of LPG only applies at room temperature (77°F). As you know, gases (even liquified gasses such as liquid propane) expand with higher temperatures and shrink with lower temperatures.

so 1/27th of 4.11 pounds is (calculator:) 0.152 pounds, 2.435 ounces, or 1.844 Kg.

It should be possible for a home fuel manufacturing system to make propane (or any of the alternative hydrocarbon energy storage media), if the quantity is on the order of a pound or two a day.

What would it take to accomplish that?

Here is a link to an article that is reported to consider that question using a biological conversion engine.

https://www.theguardian.com/environment … coli-genes

(th)

Offline

Like button can go here

#12 2022-07-31 14:37:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

https://learnmetrics.com/propane-tank-sizes/

1 lb is 16 ounces

1 kg is 2.2 lbs

The typical camp stoves use a 16 oz bottle

https://outdoorcommand.com/16-4-oz-prop … s-it-last/

A much smaller tank than the 20 lb is the 5 lb tanks hold about 1 gallon (sometimes 1.2 gallons) of propane.

Offline

Like button can go here

#13 2022-07-31 16:46:42

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Propane - Energy Carrier

The following list assumes that all fuels are completely combusted with Oxygen / O2 gas, except for Dynamite:

Hydrogen / H2: 142MJ/kg; 0.01188MJ/L at STP (15C / 1ATM) or 10.044MJ/L in cryogenic liquid phase

Methane / CH4: 55.5MJ/kg; 0.0378MJ/L at STP; Note #1

Natural Gas: 38.3MJ/m^3; 0.0364MJ/L at STP or 22.2MJ/L in cryogenic liquid phase; Note #2

Propane / C3H8: 50.3MJ/kg; ~25.3MJ/L at STP and density is ~0.473kg/L at 37C / 98F, thus 23.8MJ/L; Note #3

Kerosene: 46.3MJ/kg; Note #4

Motor Gasoline (87 Octane): 45.8MJ/kg; 34.2MJ/L, but only 31.2MJ/L with 10% Ethanol; Note #5

Aviation Gasoline (100LL): 43.5MJ/kg; 31.2MJ/L; Note #6

Diesel: 45.3MJ/kg; 38.6MJ/L; Note #7

Jet-A: 43.3MJ/kg; 35MJ/L; Note #8

Anthracite Coal / "Hard Coal": 32.6MJ/kg; 34MJ/L to 43MJ/L; Note #9

Kiln Dried Wood: ~20MJ/kg; volumetric energy density varies greatly by species of tree

Notes:

#1: Methane is first in gravimetric energy density, as compared to all other hydrocarbon fuels, and #2 behind pure H2 / Hydrogen

#2: Natural gas is mostly Methane, but almost always mixed with other gaseous hydrocarbons (Ethane, Propane, Butane, etc)

#3: Propane is second in gravimetric energy density, as compared to all hydrocarbon fuels

#4: Not the sort of fuel that gas turbine powered aircraft actually burn; it lacks the additives package

#5: Higher octane gasoline contains less energy by unit weight

#6: See Note #5; the Tetraethyl-Lead and other additives blended into 100 Low-Lead (100LL) AVGAS lowers gravimetric energy density

#7: Just as gasoline energy density varies by Octane-rating, diesel varies by Cetane-rating

#8: The energy density of the kerosene fuel, plus additives package, that power virtually all airliners

#9: All lesser grades of coal, like Bituminous or Lignite coals, contain substantially less gravimetric energy density

Overall, we can see that as fuels go, Methane and Propane pack quite a wallop per unit mass or weight. However, Methane and Propane have far les "oomph" per unit volume than gasoline or diesel. In rough numbers, Propane is about 20% less energy dense than gasoline per unit volume. As SpaceNut pointed out, a properly filled Propane tank is also about 20% empty space to allow the vapors to expand into the void space, in order to control tank pressure as temperature rises.

Let's say I want to design a car using the new Nissan series hybrid engine, but fueled by Propane, that goes 250 miles / 402km between fill-ups. I need 3.9L of gasoline to go 100km. Standard 10% Ethanol motor gasoline is 32.1MJ/L, so 125.19MJ to go 100km. I divide that by about 24 to obtain realistic gas tank volume for a vehicle operated in Texas heat. Therefore, I need a minimum of 5.2L of tank volume to contain the Propane, per 100km of range. I multiply by 4.02 to arrive at 20.97L of tank volume. I multiply that figure by 1.2 to account for the 20% increase in tank volume void space that propane requires. My tank volume is now 25.16L or about 6.65 US gallons. If I was using gasoline instead of Propane, then my tank volume is 15.68L or 4.14 US gallons. That's a significant volume increase, as well as weight increase since the tank must be much stronger than a typical gasoline tank, but hardly catastrophic for a passenger vehicle.

The Propane itself would weigh 27.3lbs. Equivalent gasoline would weigh 24.8lbs. A 30 pound steel Propane tank weighs about 25lbs, so 52.3lbs total. A 31 pound fiberglass Propane tank weighs 16lbs, or 43.3lbs total. A 5 gallon steel gasoline tank weighs about 8.85lbs, or 33.69lbs total for the gasoline. All tanks listed are real US DoT-certified mass-produced commercial products that anyone with cash can purchase.

However, the 31 pound fiberglass Propane tank from Viking costs $190 USD, whereas the 30 pound steel Propane tank from Flame King only costs $100 USD. I would expect a CFRP Propane tank to cost approximately $500 USD and weigh 12lbs, but to my knowledge we stick with steel / Aluminum / fiberglass for Propane tanks. However, steel-lined CFRP dive cylinders or fluoropolymer-lined Hydrogen gas cylinders are made using CFRP. A 30lbs Aluminum Propane tank used in forklifts costs about $320 USD and weighs 18lbs.

As such, I can save 7lbs with Aluminum for an additional $220 USD. I can save 9lbs with fiberglass composite for an additional $90 USD. I can save 13lbs with CFRP, for an additional $400 USD. The entire notion of even bothering with weight savings is rather silly, though. It's a meaningless difference, given how much every other part of the car weighs. If I had a plastic body / chassis compact car that weighs 1,200lbs, then the steel gas tank represents a whopping 2% of the total vehicle weight. If the tank is expensive CFRP, then it's 1%. Zippity-doo-dah! Who cares? Focus on something that actually matters, like the weight of the chassis / body, engine, and interior, in that order. I would never contemplate charging my customers an extra $400 for a CFRP gas tank, because it's an absurdity.

I would only ever consider using high-strength steel Propane fuel tanks in any US NHTSA-approved passenger vehicle. The gas tank mass differential of 16lbs over a conventional 5 gallon steel gasoline can, which also costs $50 to $100 USD, isn't worth a second thought. Nothing else will ever be as durable, cost-effective, and trouble-free as steel. I could justify using fiberglass / GFRP in a light aircraft fuel tank. I could only ever justify carbon fiber / CFRP for a commercial airliner. No other application warrants the cost.

Propane as spark-ignited engine fuel, as compared to gasoline, means about 12% less CO2, 20% less NOx, and 30% less CO. You have to burn a bit more of it, but produce less emissions overall. As compared to diesel fuel, you have a rough 80% reduction in emissions. This is why they want to replace diesel with Propane, but again, the only way to do that is to synthesize it.

To answer tahanson43206's question, this is the synthesis path for producing Propane from Methane:

Alkcon Process - Methane-to-Propane

Their scientific research papers backing their commercial products are listed on the page linked to above. They sell products that transform Methane (natural gas) into Propane for residential (AC power plus a natural gas feed line, for up to 53 gallons / 217.83lbs per week), as well as commercial / fleet type operations (220VAC and up to 262 gallons per week). If we were using the Nissan series hybrid engines in lightweight cars and drove 500km per week (up to 31 miles one-way to work for 5 days per week, longer than my daily commute from Northwest Houston to work in Sugarland or downtown Houston), then we're still well below what the system can produce on a per-household basis. I know a handful of IT people with longer one-way commutes, but 25 miles is pretty close to what most people seem to be willing to tolerate with Houston traffic, and in practice this means 2 or more hours of driving per day. Since we won't need 188hp to power plastic cars that weigh half as much as the steel cars we're presently riding around in, 100hp is gross overkill. 50hp per American ton is perfectly adequate in a hybrid setup, whether electric or hydraulic. Nissan's engine is so efficient (3.9L/100km) because it's optimized to run at WOT at all times, recharging a battery or a hydraulic cylinder to provide greater acceleration torque. I think the very modest battery pack is fine, and possibly the better proposition using Sodium-ion batteries that can achieve 50,000 charge / discharge cycles before capacity is reduced to 80%, albeit at 160Wh/kg vs 250Wh/kg for Lithium-ion.

The first step in the Alkcon Process is to synthesize Methane or natural gas. We already know how to do that, because it's the simplest / easiest hydrocarbon to synthesize. As we also know, Methane is not storable except at extreme pressures or extremely low temperatures. You can't set a tank of liquid Methane on the ground outside. It will either burst from pressure build-up or evaporate through a pressure-release valve. You either go to crazy-high pressures using CNG / compressed natural gas, or expend energy for liquefaction and cryogenic cooling until it's consumed. That type of limitation is "no bueno" for most types of long-range land-based passenger vehicles, here on Earth or on Mars, which means you need a storable energy-dense liquid at modest pressures. Propane fits the bill better than any other alternatives, and again, you produce fewer emissions overall. The total weight differential is of little to no practical consequence- it's real but not a show-stopper. We know this because lots of people already use Propane-powered daily drivers (cars and light duty trucks), forklifts, riding lawn mowers.

There are some long-haul heavy duty trucks that have been converted to use CNG if it's available on the transport route, because it's so inexpensive relative to diesel, reduced emissions, maintenance no more costly than the engine tear-downs that diesel mandates. If the US was set up to supply vehicles with Propane, then we could as easily use Propane as gasoline or diesel with modern / current technology. The engines would have to feature direct-injection and increased compression ratios to combust Propane as efficiently as gasoline (equivalent horsepower for equivalent fuel burn, as compared to gasoline). There's a trade-space here where Propane combustion in spark or compression ignition piston engines and gas turbines could generate as much usable power per gallon of fuel burned, further reducing emissions.

In practice, Propane is no more dangerous to use than gasoline or diesel or kerosene. The fuel rapidly evaporates and dissipates at atmospheric pressures / temperatures, much like Methane. The flammable mixture limits range between 2.1% and 10.1% Propane-to-Air. Any more or less results in incomplete combustion and production of excess Carbon Monoxide, which is undesirable. This range is similar enough to gasoline, which has a 1.4% LFL to 7.6% UFL range. Methane is 4.4% to 16.4%. Pure Hydrogen is 4% to 75%.

Offline

Like button can go here

#14 2022-07-31 17:14:24

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For kbd512 re #13

Thank you for another fact filled post to enhance this topic ...

There are numerous search terms that could apply here, but I'll select the manufacture of propane section for focus

SearchTerm:Propane manufacture of (from scratch) (not distilled from crude or otherwise of fossil origine)

For all ... please add other search terms as you are inspired by the kbd512 post!

(th)

Offline

Like button can go here

#15 2022-07-31 18:43:43

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

One issue for all gaseous tank supplied fuels is they do not end up with an empty tank as its still got fuel in it, but pressure has dropped to the point that it does not get pushed out to be burned. Most propane tanks weigh around 18 1/2 pounds when they are empty. Place your tank on a household scale and subtract 18 1/2 from that number. From there, you can determine how much you have left. Of course, that is if you weighed it initially and have the same scale for later to prove you are out.

https://www.todayimhome.com/post/how-mu … tank-weigh

https://www.propanetankstore.com/blog/p … -or-empty/

https://www.charbroil.com/how-tos/how-t … ne-is-left

https://www.doityourself.com/stry/propa … -explained

Not all propane tanks come with a fuel gauge, but there is one handy tip to finding out how much pressure is left in the tank. Before turning the gas on, pour hot water on the tank (not the hose end). As the hot water touches the side, the cold gas will absorb the heat and by feeling the side of the tank with your hand, you'll be able to tell where the gas level is wherever the side of the tank gets cold.

Neat trick...

Pressure in a propane tank can range between 100 and 200 PSI and even higher if the tank is in the sun. The pressure is then reduced and regulated to 6 ounces for residential use at the home, camper, motor home, or outdoor appliances by a low-pressure regulator either on the tank or nearby. Some gas appliances such as a high heat cast iron burner, however, will require a high-pressure regulator to deliver between 1 PSI and up to 60 PSI pressure to the appliance.

So usage depends on application.

The real issue is when we burn fuels containing carbon is that we need to capture it before it can be released into the atmosphere where by some ends up in the oceans.

Offline

Like button can go here

#16 2022-08-01 12:08:32

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Propane - Energy Carrier

SpaceNut,

Most "empty" but sealed gasoline tanks still contain gasoline vapor plus a small amount of liquid gasoline in the bottom. This is not unique to Propane tanks. You have more Propane vapor because it's under more pressure, but gasoline also vaporizes at normal atmospheric temperatures and pressures.

Offline

Like button can go here

#17 2022-08-01 15:18:57

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For SpaceNut re #15

Your suggestion of capturing exhaust in order to recycle it is a good one.

The ideal application is to feed the (cooled) exhaust into one of kbd512's hydrocarbon manufacturing plants, which itself would (if realized) be powered by solar energy.

If that highly desirable situation ever comes to pass, the existing massive investment in gas powered electric plants can be retained indefinitely.

Please try to encourage kbd512 to move ahead on his project. Coming out of last night's Zoom meeting, I have the impression that kbd512 has a strong interest in pursuing this while the dollars are gushing like an oil well.

(th)

Offline

Like button can go here

#18 2022-08-01 18:37:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

Its the solar thermal concentration that is what will be required to make the fuel in a chamber that is design to split the water and the co2 into co +h2 to make into fuel.

Yes the tank has vapor but its under pressure still since the regular needs to be higher than 1 atm or 14.7 psi plus the outlet value to push the fuel out of the tank through the regulator.

Shell CANSOLV is a leader in gas treating and carbon dioxide (CO2) recovery technologies.

Offline

Like button can go here

#19 2022-08-01 18:53:37

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For SpaceNut re Post #18

Thank you for both of those encouraging links!

The Shell solution looks (to me at least) like a large scale operation, the MIT offering appears to be suitable for small scale situations, such as the cabin of a space craft. I'd like to encourage you to consider posting those links in at least the Large Ship topic, and if you have the time and energy, in other topics where capturing CO2 is important.

(th)

Offline

Like button can go here

#20 2022-08-02 04:20:45

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: Propane - Energy Carrier

Dimethyl ether has similar vapour pressure to propane, but it's mass energy density is only about two-thirds that of propane. But still, 50% higher than methanol.

https://en.m.wikipedia.org/wiki/Dimethyl_ether

One thing that might make it preferable is that it is much easier to synthesise from H2 and CO2. First you make methanol and then react two methanol molecules together to make DME. DME has been trialed as a diesel substitute, and is more suitable for compression ignition engines.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#21 2022-08-02 06:13:16

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For Calliban re #20

Thank you for your contribution to this topic, in the spirit of creating a useful reference for a future reader who might wish to refresh or perhaps take a first look at the subject of propane, and related options.

In particular, thanks for your concise description of DME, which is covered in "Beyond Oil and Gas" but there is SO much covered in that book, I had missed this connection.

If you are willing (and have the time, which I understand is precious) can you (would you) provide a word of advice for kbd512?

kbd512 is (somewhat bravely) looking at the potential opportunity to snag a few of the billions of dollars gushing from (or about to gush from) the US Congress, to help the nation move from fossil fuels.

kbd512 is planning (overview by me which may be subject to correction) to make hydrocarbon fuel from air and water using solar power.

This has already been done (see announcement of Spanish achievement recently) so there is no new technology needed. The question is how to present a case for funding.

I would imagine that methanol might be more efficiently produced in large quantities than other precursor materials, and as you pointed out it can be used to make DME and other daughter molecules.

If you could provide advice to kbd512 (and others seeking to make their fortunes in the hydrocarbon manufacturing field), what might it be?

The goal (as I see it) would be to manufacture stored energy carriers at prices competitive with existing fossil fuel supply, and to do so in quantities competitive with coal suppliers, or ground sourced oil suppliers.

(th)

Offline

Like button can go here

#22 2022-08-02 20:04:43

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,920

Re: Propane - Energy Carrier

I think that now we have the basis for making the fuel and even for the various types that might be profitable on a startup to larger scale for those that get good solar isolation hours and location that optimize it use.

Next would be cost of containers to compress for storage the fuel and the compressing equipment that is made safe by design for this purpose.

Given above were the pressure to liquify and temperatures of storage. Other things are the conversion rate so that the pumping and storage are adequate to the task. Things like flow or check valves, shut offs and quick disconnects come to mind being part of a complete system. In addition to a gas cooling system from the reaction chamber output.

There will also be a need for out gassing monitoring equipment and waste product management.

Offline

Like button can go here

#23 2022-08-03 06:38:32

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

For SpaceNut re #22 ... thank you for thinking about the infrastructure needed to support an industry set up to make propane from air and water, using solar or nuclear power.

The use of propane is a mature industry, so there are a variety of vendors already in place from which to choose for storage and delivery of product. Propane is sold in many grocery stores for backyard barbeque, so a distribution network seems to be in place at that level. In addition, larger propane tanks are in use for rural customers, and distribution by tank truck is a well established industry.

Today, in asking Google about propane, I found this site:

https://afdc.energy.gov/vehicles/propane.html

Propane Basics

Benefits & Considerations

Stations

Vehicles

Availability

Conversions

Emissions

Laws & Incentives

Propane VehiclesPropane, also known as liquefied petroleum gas (LPG), or propane autogas, is considered an alternative fuel under the Energy Policy Act of 1992. According to the Propane Education & Research Council, there are nearly 60,000 on-road propane vehicles with certified fuel systems in the United States. Many are used in fleet applications, such as school buses, shuttles, and police vehicles.

Propane vehicles are available from original equipment manufacturers (OEMs) or via a conversion. Propane engines and fueling systems are also available for heavy-duty vehicles, such as step vans and school buses, including some prep-ready engines from OEMs.

Types of Propane Vehicles

Propane vehicles have been widely used and refined for decades, and a propane vehicle's power, acceleration, and cruising speed are similar to those of conventionally fueled vehicles.There are two types of propane vehicles: dedicated and bi-fuel. Dedicated propane vehicles are designed to run only on propane. Bi-fuel vehicles have two separate fueling systems, enabling the vehicle to run on either propane or gasoline. This provides the flexibility of using either fuel, which typically provides bi-fuel vehicles a greater range than dedicated propane or gasoline vehicles. Extra storage tanks can increase range, but the tank size and additional weight affect payload capacity.

Because a gallon of propane has 27% less energy than a gallon of gasoline, the fuel economy of propane vehicles is slightly lower. However, propane has a higher octane rating than gasoline (104–112 compared to 87–92 for gasoline), and some OEMs offer dedicated engines optimized to take advantage of this higher rating. This can result in improved performance and fuel economy over non-optimized engines.

The potential for lower maintenance costs is one reason behind propane's popularity for use in light- and medium-duty vehicles, such as trucks and taxis, and for heavy-duty vehicles, such as school buses. Propane's low carbon and low oil contamination characteristics may result in longer engine life. Propane performs well in cold weather climates because the fuel's mixture (propane and air) is completely gaseous when it enters the injection system and engine. This factor allows propane-powered vehicles to avoid many cold-start issues associated with using diesel.

Related Information

It would seem (to me at least) that investment in a solar powered propane manufacturing site, using air and water as inputs, would have a large and well established market to serve. The investment in hardware for the site is significant, but the cost of energy and supplies is zero, so if the equipment is sell designed and well maintained, the cost of the investment should be retired by selling product at competitive rates with suppliers of propane sourced from fossil fuel.

This topic is available for someone to post a concise list of equipment/plant needed, and a clear explanation of processing steps to be carried out.

(th)

Offline

Like button can go here

#24 2022-08-03 06:43:03

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,468

Re: Propane - Energy Carrier

I finally found the article that inspired this topic ....

The tag line was: Colorado State University was awarded a federal grant to develop high-efficiency propane engines to take the place of dirty diesel ones.

https://engr.source.colostate.edu/propa … rgy-grant/

Propane could be the new diesel with $3.5 million U.S. Department of Energy grant

22

Jul, 2020

By Emily WilmsenA student works next to a big red Cummins engine at the CSU Powerhouse campus.

A student works on a Cummins engine that will be used to test research on energy efficient propane engines.

Propane could be competitive with diesel as a cost-saving, energy-efficient fuel for large trucks and school buses, say Colorado State University mechanical engineers awarded a $3.5 million U.S. Department of Energy grant to develop a new, high-efficiency propane engine.

The research team, led by Professor Daniel Olsen, will spend the next three years working with large engine manufacturer Cummins Inc. and Argonne National Laboratory developing advanced combustion strategies for direct-injection large propane engines.

DOE announced CSU’s award on July 16 with 54 other projects by universities, governments and industry totaling $139 million.

Daniel Olsen

Daniel Olsen, mechanical engineering professor

“This project has all of the signature elements of a Powerhouse project,” noted Bryan Willson, director of the CSU Energy Institute and the Powerhouse Energy Campus. “It includes a large team with diverse talents and a commercial partner so there is a direct path from discovery to impact.”

Willson also pointed out that CSU has a 30-year history of developing better engines for use with alternative fuels such as propane, natural gas, hydrogen, and biofuels.

Olsen and his team, including Professor Anthony Marchese and Assistant Professor Bret Windom, are already working on making natural gas engines as efficient as diesel through a current DOE grant and partnership with Cummins and Fort Collins-based Woodward, Inc.

Propane, or liquified petroleum gas, is 40 percent cheaper than gasoline and diesel and cleaner burning, but current propane engines are not as energy efficient as diesel engines so it can lead to higher operating costs and less miles per gallon.

“What’s really exciting is 75 percent of what we’re proposing to do we’ve done with natural gas,” Olsen said. “If we drive up the efficiency, that would be helpful for the environment and the economy and people might be more inclined to purchase more of these types of engines.”

“You use propane in your gas grill, but there’s a lot of potential to use more propane in the transportation sector,” said Marchese, associate dean for Academic and Student Affairs in the Walter Scott, Jr. College of Engineering and co-director with Olsen of the Engines and Energy Conversation Laboratory.

Bret Windom

Bret Windom, mechanical engineering assistant professor

In the first phase of the three-year project, Marchese will test the chemistry and combustion of propane fuels. Windom will examine LPG fuel injection strategies that lead to optimal fuel-air mixtures and required for efficient combustion. He’ll use laser diagnostics to characterize the fuel “spray” and how it evaporates and mixes, which will be critical to share with Argonne researchers who will build new spray models for the project, he said.

The technology they develop takes advantage of a new technique that they call “controlled end-gas autoignition”, which enables “engine knock” to occur in a controlled setting. Normally, engine knock is a problem for spark-ignited engines, but the researchers say they can do it in a way that drives up efficiency.

“Our controls are good enough to operate right at the ragged edge where you wouldn’t hear knock and it wouldn’t do any damage,” Olsen said. “Woodward pioneered this approach – they have a real-time control system and have developed algorithms to sense combustion properties and quickly react.”

Anthony Marchese

Anthony Marchese, mechanical engineering professor and associate dean

Assisting the CSU team from Argonne are Sibendu Som and Lorenzo Nocivelli. Olsen will work with Hui Xu at Cummins to test the technology on a Cummins X15 single cylinder engine currently housed at CSU.

The project will include CSU graduate and undergraduate students and include a training internship for a graduate student at Argonne, Olsen said. Students working on the project will be learning from some of the best researchers in the field.

“Receiving this award shows that the CSU engine research program is on the map,” Marchese said. “DOE – and the engine research community – knows who we are, and they recognize that we have the expertise and the resources. We can do this.”

TAGS ASSIGNED TO THIS STORY

CSU ENERGY INSTITUTEDEPARTMENT OF MECHANICAL ENGINEERINGRESEARCHWALTER SCOTT JR. COLLEGE OF ENGINEERING

Emily Wilmsen

More posts by Emily Wilmse

(th)

Offline

Like button can go here

#25 2022-08-03 07:33:01

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,269

Re: Propane - Energy Carrier

Peak Oil and Peak Gold are here!

https://srsroccoreport.com/public/peak- … es-coming/

As globalisation breaks down, synthetic fuels (including propane) may be the only way for some populations to have access to liquid fuels.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here