New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2020-12-17 20:56:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Internal combustion engines for Mars

Why not since we will have methane and Lox for fuel.

Of course in time we can add other light carbon fuels and bio desiel as well....

So engines and how they work would be a good skill to develop for a far off mars future.

This topic I will move my post to for the Subaru and escape problems in time....others can add there stuff here as well...

Lets start off in education...

Auto club draws students at west suburban high school

Learning is getting your hands on it not just books

1995 Mustang GT they're rebuilding with their own tool kits.

Offline

Like button can go here

#2 2020-12-18 06:15:24

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,546

Re: Internal combustion engines for Mars

Best wishes for success with this new topic

The designs pioneered for Mars should find application in many locations away from Earth.

Electric drives would seem to me to be the first choice to consider for an application, but circumstances may give the edge to internal combustion engines.

If simplicity is a major consideration, and IC engines are the better choice, then I would expect Oxygen to be carried as a gas.

In many other topics, CO has been offered as a fuel, so it would seem a strong candidate for the simplest possible fuel, and again, I expect it would be packaged as a gas.

Thus, vehicles will be designed (in this scenario) with large tanks.

I hope that other forum members will contribute some design details to this new topic.

For example, a bulldozer to excavate material from the Martian terrain would be useful.

What would such a machine look like if it were designed to exert a ton of force on it's load, and able to do so for eight hours?

An electric version of the same machine would be similar in bulk, because it would either carry large volumes of batteries, or it would carry large volumes of Oxygen and Hydrogen for fuel cells.

As Void has demonstrated, it is possible for contributors to put images of designs on imgur.com, and set the bbcode links here for readers.

Fusion 360 is a free design package that can be used to create simple designs for illustration, all the way to complex machines.

Fusion 360 does require a fairly modern computer. It runs well on Windows 7, although the program grumbles about not running on Windows 10.

If we can interest current or prospective members to contribute designs, this topic could develop into quite a showcase of creativity for the off-world environments we (humans) will be entering.

At present, the known way to become a member of this forum is to become a Mars Society member and contact SpaceNut using the Members forum.

(th)

Offline

Like button can go here

#3 2020-12-18 18:34:23

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,356

Re: Internal combustion engines for Mars

tahanson43206,

This response post comparing batteries and fuel cells has been moved to the battery powered construction equipment thread.

Last edited by kbd512 (2020-12-18 19:06:15)

Offline

Like button can go here

#4 2020-12-18 18:46:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

Battery power construction equipment would be where this comes in as its not burning in an engine.....

Offline

Like button can go here

#5 2020-12-18 21:14:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

Speaking of internal combustion

here is a post from the Housekeeping...

For GW Johnson

I would very much like to see serious students interacting with GW Johnson at a level above what I can reach. That would allow readers who are at my level to absorb part of the flow, even if we can't grasp it all.***

This post is created to note another item from a technical newsletter that arrived recently:A how-to checklist to troubleshoot thermal fluid system performance

Recognizing the key importance of pressure gauges and other system features

Fluid flow is essential to the performance of any system. Download this whitepaper to learn how to troubleshoot such problems, along with quick tips and a go-to checklist.

This reminder of the need for technical knowledge and attention to operation of vital equipment is close to me right now. A friend owns a Kohler generator, and it stopped performing weekly tests recently. Due to the embarrassment of limited funds, the generator has not received inspection/maintenance by the authorized vendor for five years. When we looked at the control menu, we discovered that the algorithm programmed by the Kohler engineers did not take Leap Year into account, so the master date was one short. I assume this would have been approved by management, because the intention and expectation is that the generators would be inspected and maintained each year.

In relation to Mars .... equipment like that generator is going to be running 24/7 to maintain habitats and productive volumes, and the well being of the population is going to require that at least one person have the necessary knowledge, skill and experience to keep close tabs on each and every piece of hardware, and to perform repairs or adjustments as needed.

(th)

My friend with the Kohler generator received a visit from the friendly local maintenance team today. The problem turned out to be a battery failure.

I admit I have not yet absorbed more than a tiny fraction of what is knowable about lead acid batteries. Such batteries are likely to find employment on Mars, but whatever battery technology is chosen for service on Mars, I'll bet the same facts of deterioration will become problems for the maintenance teams.

The specific learning point I confronted today was a misunderstanding about voltage level as an indication of battery readiness-for-service.

I was asked to serve as a gopher, and at the local automotive parts store, the clerk showed me a fancy instrument they have (apparently) received recently. It showed that the old battery was unable to crank, despite having a voltage well in excess of the rated 12 VDC.

The replacement battery started the generator instantly.

My friend got away without what might have been a major service charge, and I got a lesson about battery deterioration. Fair exchange !!!

The battery had been in service for five years, which is one year past when I change automobile batteries, whether they need it or not.

(th)

The ability to test batteries are going to be an important skill for whether we go with all batteries or just 1 to start the machines engine...

Offline

Like button can go here

#6 2020-12-18 21:16:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

There is a simple tool called a battery load tester, made for lead-acid automotive batteries, that has a voltmeter with a specially-marked scale and a big resistor. It works on any larger or smaller engine-starting battery that is lead-acid.

You put the leads on the battery terminals and read the voltage. Presuming the battery is not discharged, you then use the "load" switch to short the battery into the resistor for several seconds, watching the voltage change under load.

If the voltage drops too sharply, the battery is "dying" or "dead" and must be replaced. A "good" 12 volt battery won't drop more than a volt or two. The special scale has color zones for weak or not, and for 6 volt and 12 volt batteries.

But you can use it on an 8-volt tractor battery, even though there is usually no 8 volt scale: just watch for a volt or two drop, versus 3 or more.

A good battery can test "bad" if it is discharged when you load test it, so trying charging the battery first, then load test it. But if a 12 volt reads only 10 volts after charging, you already know it is bad. Same for a 6 volt that reads 4, or an 8 volt that reads 6. That 2 volt drop is a dead cell.

These things are available in auto parts stores and hardware stores. Not very expensive, really. I use mine all the time.

GW

For GW Johnson

Thanks for the helpful tip for maintaining a fleet of 12 Volt (or similar) batteries!

I'll start looking for a load test instrument as you've described it.

I keep a set of 12 volt batteries in a state of (intended) readiness, based only on voltage showing before and after charge.

The new instrument you've described would be well worth having in the collection here!

Thanks!

Edit#1: I took one of my "stock" (retired automobile) batteries to the job site this morning, and was dismayed to see that it did not have enough cranking power to start the generator. It did better than the dead battery in the machine, but not a lot better. The instrument you've described would have enabled me to skip the labor of carting that old battery around. It might still be good for emergency lighting, but it's no longer suitable for emergency equipment use.

(th)

The open loop value of the batteries voltage is not a good indicator and that is why you need to put a load on it. The charging voltage is also another indicator as that will be 13.8 but not more than 14.5 when connected to the unit. Most likely the cells oxides with sulfur or other contaminant such that when you charge them you are trying to wake the cell back up. The lead acid batteries like to be in continual working operation and not idle. Other battery material types require other needs so as to not break down....

For SpaceNut re #160 ... thanks for adding to GW Johnson's advice on care (and testing) of lead acid batteries.

As a follow up to the earlier report of maintenance on a generator ... it occurs to me that the generator itself is providing a pretty good load test. It cranked right up to the day it stopped cranking. It is quite possible the sound of the cranking operation changes. A recording of the cranking operation could be programmed to start just before the scheduled weekly test.

I'll look for the kind of test instrument GW Johnson suggested.

The instrument at the local automobile parts store looked (to me at least) like a professional multi-hundred dollar unit.

It was similar to one I've seen in use at Batteries+ stores.

(th)

Offline

Like button can go here

#7 2020-12-18 21:22:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

kbd512 gave a long post about the batteries in general which really is a better post for the other equipment that uses batteries... which was copied there

http://newmars.com/forums/viewtopic.php … 10#p170410

Tahanson43206:

I posted a battery testing and maintenance article on "exrocketman". It is titled "Taking Care of Car Batteries", and is dated 7-25-2020. It applies to car batteries, tractor batteries, and batteries on lawn and garden equipment. Anything that is lead acid, and used to start engines. I tried to keep it simple and to-the-point.

GW

of course a reply is here http://newmars.com/forums/viewtopic.php … 38#p170438

Of course you found this tool to have

This is a follow up on #158 (from 2020-07-20 14:33:22) by GW Johnson ...

I've been trying to add a battery tester to my tool collection, since GW Johnson recommended one. Yesterday I was driving by Harbor Freight, and since an acquaintance had suggested looking at their offerings, i stopped in. It is possible to invest more in an instrument, but I brought home a simple, hefty, sturdy unit that fires up what looks like a miniature hot dog grill to test the battery.

The instrument confirmed that the retired automobile battery I'd used to try to start a generator is "weak".

However, the battery held the load for an extended period while the hot dog grill baked off its paint, so I figure it can still serve for emergency lighting for a while longer.

(th)

Offline

Like button can go here

#8 2020-12-18 21:28:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

I myself started to have issues with my Ford 2005 escape.

I am now solving what is happening with my computerized vehicle but the starter seems shorted and in need of replacing as well as its not turning.

The multiple computer modules that are designed for functions like anti/theft sends a signal to the computer that controls the spark to make the engine not run if the key is wrong for the vehicle can even come on when running down the road which is a bad thing to have happen...Its also got a defective coolant temperature sensor and a thermostat that appears to be sticking. It seems to have a small leak of oil near where the oil pressure sensor is as well. Hopefully there are no other problems to fix....

2005 Ford escape but none of its hard just the ground that I have to do the work on....

Starter is on the back close to the firewall, with coolant sensor and thermostat are relatively easy but the oil sensor is behind the ac compressor and not sure if I can get that out with out pulling more of the vehicle appart....since splash guards need to be removed to gain access to it.

Of course GW gave some good sage wisdom here http://newmars.com/forums/viewtopic.php … 76#p171376

with a picking up the ball to lend a hand in reference information by

SpaceNut,

I don't have any experience with Fords, unfortunately.

You probably already have this taken care of, but:

2005 - 2007 Ford Escape XLS 2.3 Thermostat and Housing Replacement

Ford 2.0L 2.3L 2.5L Engines P0125 P0128 Insufficient Coolant Temp: Thermostat Housing Replacement

Ford Escape Oil pressure sensor replacement (easy! no AC removal)

Some follow up work to trouble shoot my issue with the vehicle Did trouble shooting of the starter so far and by touching the +B post power to the s connection on the starter was able to learn that its not bad. Went next to trouble shooting the computer to S connection and there are some circuit items but thanks to a horrible electrical diagram learned that the computer puts out a low signal that turns on the relay that brings power into the s connection point. There is a diode between the computer and the coil of the relay on one side while the other is switch ignition start power. The power side of the relay was good and then I placed a bypass to ground for the diode and the starter would turn when the key is turned.

The dash lights of the anti theft is indication by a rapid flashing that its in enabled mode... Which stops the ignition spark.

Now off to google bypassing that signal fault....

Looks like thats going to be an item to look out for in the future.

Offline

Like button can go here

#9 2020-12-18 21:31:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

of course the suggestions and follow up continued through out the page 5 of the house keeping topic.

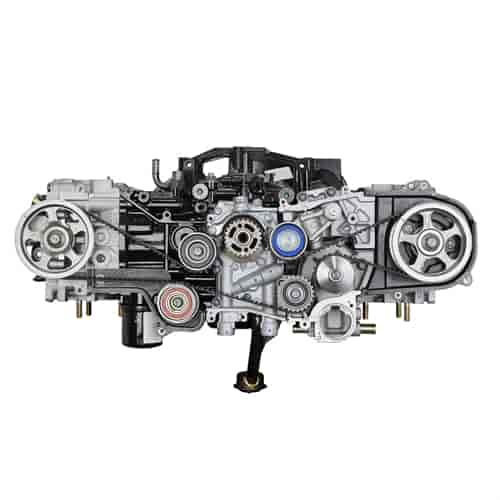

In time I did go out and got a 2008 Subaru Outback but as luck would have it only lasted until it began to over heat from head gasket issues....

Will post more from the housekeep on that vehicle and on the ford escapes out come for its running and the heads are being worked....

House call done on the 2005 computer, seems to be not resettable as the dealer tools to interface while it could read all the codes it had no effect when changing the stored value. That said I could have a bad chip key, a bad receiver unit amoung other possible.

Offline

Like button can go here

#10 2020-12-18 21:40:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

Researched head gaskets and found that several generations of them were utilized to solve how quickly they went bad...

Long day working on the cooling system replaced water pump, timing belts and radiator. Did the degas burp which happens for pockets of air trapped in engines cooling system. Its the super heated air that will cause in a normally pressurized system to block fluid flow by the pressure by the air bubble. Garage cost for this work roughly $700 but it cost me just the new radiator of $148...

But what you can not tell even with the normal head pressure test is leaking into the cooling system by this test as this is cylinder to exhaust or intake and not to the cooling to exhaust which is the gasket failures.

https://www.cargurus.com/Cars/Discussio … 5_ds711540

Looking at cost and dyi for head gasket.

this is what is needed for the head gasket issues.

The process of doing the work in the vehicle or out changes much on how the work can be done.

The video's of such dyi are helpful but it comes down organizing, planning and tools to do the work with lots of time.

video of the work engine still in car

https://www.subaruoutback.org/threads/c … sket.3963/

https://www.ericthecarguy.com/forums/to … ing-issue/ covers testing coolant leak and cost for mostly diy as machining of heads should be done as well as checking for warping.

edit

cost for head gasket around $60

his shows typical failing points

https://scanneranswers.com/the-truth-ab … -problems/

https://itstillruns.com/head-gasket-sym … 44309.html

usual tells that you have a problem.

GW reminded me that I might see both oil and coolant failures respond with different observable results.

Offline

Like button can go here

#11 2020-12-18 21:42:25

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,356

Re: Internal combustion engines for Mars

SpaceNut,

Apologies for veering off-topic in my response to tahanson43206.

I will now discuss a diesel engine technology that I think is sufficiently durable for use on Mars. This would be a modified GM DuraMax diesel that's had nearly every component replaced with much stronger analogs, sufficient to sustain a 550hp output level for at least a few thousand hours of operation. This is a $75,000 custom-built special purpose engine, not something you can buy from GM. It's also one of the most strengthened, relative to stock, diesel engines available. It's suitable for marine or generator applications here on Earth, but also capable of brief excursions well in excess of 1,000hp. The stock GM L5P DuraMax weighs in at a svelte 835 pounds without fluids, not much different than a Chrysler 426 Hemi of the 1970s. This modified engine will weigh between 1,100 to 1,200 pounds. Apart from the basic block / head / fuel delivery system design, it shares nothing else in common with a GM L5P DuraMax engine. The block and heads will have an ion-bonded surface finish for corrosion protection, rather than high temperature paint. The exhaust headers and turbine bodies will use a ceramic fiber overwrap insulation to inhibit heat transfer and improve thermodynamic efficiency, along with ceramic thermal barrier coatings to prevent oxidation at high temperatures.

Alternative Caterpillar C15 ACERT inline 6 cylinder diesel engines that produce equivalent horsepower would be more than three times as heavy, though only a third to half of the price. Since weight matters so greatly for anything sent to Mars, the cost of the engine is more than offset by the cost of transporting it to Mars. The L5P components are much lighter than the C15 components, so replacement parts are cheaper as well. The upgraded Caterpillar components are likewise very expensive and not as readily available as DuraMax components, on account of how many DuraMax engines have been produced, relative to C15 engines. There are several source suppliers for similar aftermarket DuraMax upgrade components. Wagler is featured prominently below because their components are well known for winning pulling competitions, they have an excellent warranty policy (free replacements if you manage to break it, while staying within specified horsepower limitations), and they have incredibly stringent quality control procedures. That said, for most of these components, at least 2 if not 4 or 5 different manufacturers can supply similar quality upgrade parts, so there are no single-source suppliers.

Block: LSM Systems Engineering billet ductile iron block

* replaces stock GM grey cast iron, the most expensive single component at around $20K or so

Crankshaft: Callies / Wagler (designed by Wagler, produced by Callies for Wagler) fully counter-weighted billet and WPC treated

* replaces GM forged steel crankshaft, internally balanced and significantly stronger

Main Caps: Wagler billet steel with WPC treatment

* replaces GM cast steel to provide greater stiffness

Main Cap Fasteners: ARP Custom Aged 625+ studs and nuts

* replaces GM bolts to provide more consistent clamping force to prevent main cap walking

Main Girdle: Wagler billet steel

* not present on stock GM L5P DuraMax engine, but used to prevent main cap walking by improving bottom end rigidity

Flywheel / Flex Plate: SunCoast billet steel

* replaces GM casting with pinned bezel ring for starter; prone to stripping starter and ring gear teeth

Torsional Vibration Damper / TVD: FluiDampr heavy duty shear thickening fluid / inertia ring TVD

* replaces GM VibraTech rubber TVD; far more effective crankshaft torsion dampening over the entire RPM range

Connecting Rods: Wagler billet with WPC treatment and ARP Custom Aged 625+ rod bolts

* replaces GM powdered steel con-rods and bolts, which are incapable of continuous high power output applications

Pistons: Mahle forged steel ceramic coated pistons

* replaces GM cast Aluminum pistons; steel is almost as light, within a few grams, but three times stronger than Aluminum

Heads: No Limit Manufacturing cast iron headers

* replaces GM cast Aluminum headers; the cast Aluminum is incapable of continuous high output without warping

Head Studs: ARP Custom Aged 625+ studs and nuts

* replaces GM bolts; nearly all high-output applications use ARP studs instead of stock bolts

Rocker Arms: Manton billet tool steel roller rocker arms with WPC treatment

*replaces GM steel castings; nearly a hard requirement for sustained high-output

Rocker Bridges: Wagler billet rocker bridges with WPC treatment

*replaces GM steel castings; nearly a hard requirement for sustained high-output

Rocker Shafts: XDP rocker shafts with WPC treatment

*replaces GM carbon steel with an upgraded alloy; nearly a hard requirement for sustained high-output

Pushrods: Manton 7/16" Heavy Duty with WPC treatment

* replaces stock 3/8" GM pushrods; not strictly necessary, but we're going all out here

Lifters: No Limit Manufacturing tool steel

* replaces GM low alloy steel lifters; not strictly necessary, but we're going all out here

Camshaft: No Limit Manufacturing billet tool steel alternate firing order with WPC treatment

* replaces GM cast steel; nearly a hard requirement for sustained high-output to reduce crankshaft stresses

Camshaft and Crankshaft Gears: No Limit Manufacturing billet tool steel with WPC treatment

* replaces GM low alloy steel; nearly a hard requirement for sustained high-output

Valve Covers: Wagler billet upper and lower valve covers

* replaces GM cast Aluminum; not strictly necessary, but adds thermal sink mass and is much stronger

Seal and Bearing Kit: Mahle (I think it's actually Cometic, but I could be wrong)

* replaces stock GM seals and bearings; not strictly necessary, but nearly all competitors use them

Exhaust Headers: Gale Banks Engineering flow-optimized cast iron headers

* replaces GM stock exhaust headers; Gale uses these to reduce pumping losses within the engine to produce more power with less fuel

Water Pump: Wagler Competition billet

* replaces cast GM cast Aluminum housing and cast iron pump impeller; the billet unit doesn't have the corrosion problems of the cast iron and is stronger, despite being Aluminum

Oil Pump: Barra (Australian) billet steel with a Wagler pinned gear

* replaces cast GM internals with billet steel; not strictly necessary, but highly recommended

Oil Filter: Hubb lifetime reusable billet Aluminum

* replaces disposable oil filters; we won't have an infinite supply of filters on Mars, so reusability is necessary

Turbo: PPE compound turbo

* replaces stock GM variable-geometry turbo; a single turbo can make just as much power and has a reasonably flat torque curve, but the compound setup produces a Kansas-flat torque curve over the entire RPM range and can deliver more than 1,000hp without over-speeding the turbo impeller and we want all of our high-stress components to be under-stressed, to the extent possible

Water-Air Intercooler: Gale Banks Engineering (this will be a custom unit)

* not present on stock GM L5P DuraMax engine; this is intended to produce more power with less fuel by improving what Gale Banks calls MAD, or Manifold Air Density (even though we're going to use LOX and LCH4 or LPG, we're also going to recirculate exhaust gases to recover as much O2 and unburnt fuel as possible)

Fuel Delivery System: Bosch CP3 pump and S&S over-bore injectors

* replaces stock Bosch CP4.2 and injectors; CP4.2 is a "weak link" for the new L5P, and the older high pressure fuel pump design didn't have the design problems of the new one

Offline

Like button can go here

#12 2020-12-18 21:43:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

In trouble shooting response to GW to what failed

There is zero coolant in the exhaust and same for the oil.

When the heat is coming on its hot but as you drive and the temperature rises it will blow cold.

Thats due to hot air displacing the coolant to the expansion tank dropping it from the high point in the system. This is with a pressure cap and thermostat which closes the loop building up the air bubble.

Will remove thermostat and try it again when cold.

The degassing or bubble bleed is done open with open espansion above radiator to remove air. This is a running car rev'd up to 2000 rpm to push cooant to all parts of engine. It never got overheated in this process even after running for an hour but put the pressure cap on and it overheats.

https://mdhmotors.com/subaru-headgasket … rocedures/

More knowledge and wisdom

Spacenut:

Your head gasket is leaking more coolant, under pressure on the coolant (radiator cap on), than when there is no pressure on the coolant (radiator cap off), whether or not you are seeing it in the exhaust. Running with no thermostat should help clarify a "muddy" situation.

You should be seeing bubbles of gas in the coolant while the engine is running that stop when you turn the engine off. They may be small, but they represent blowby gas getting past the head gasket via the same leak path. If you can see the top of the core through the open cap, you have a chance of seeing these bubbles. Otherwise, no.

You'll have to pull the head, have it milled flat (it is probably warped), and replace the head gasket. Be SURE to properly torque the head bolts. The newer designs are far more sensitive to this than any of the older designs. Many of the newer designs have been using torque-to-yield bolts. Do NOT EVER reuse such! Get new ones. You cannot tell the difference by looking at them, either.

One thing to check is your water pump. Is it, or is it not, pumping considerable volume of water? Some (not all) of these modern water pump designs can fail to transmit shaft motion to the actual pump blading. Depends upon how they were made. These things are no longer utterly reliable, the way they were decades ago with the dick-simple designs used then.

GW

Offline

Like button can go here

#13 2020-12-18 21:46:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

I needed to keep using the vehicle as best that I could for many reasons and here is some of what followed

Started to pull lower radiator hose to remove thermostat. Have made a second radiator cap to be lower pressure to allow bubbles to escape to keep internal pressure down into espansion tank.

At the top of each head is a combining tube that brings both coolant exits to the radiator of which I am looking to see if it can tell which side the problem is at if I can make something to bolt to them as well.

The new gaskets are designed with more layers and of a different material.

I have used high temp rtv to solve warped heads in the past as the problem could be on the block surface that are never planed.

The water pump, timing belt and radiator are all new...

confirmed Head bolt replacement Required due to Torque to yield head bolts used

https://allwheeldriveauto.com/subaru-he … explained/

https://allwheeldriveauto.com/subaru-he … d-part-ii/

Its either that or just plain no more cash to get anything else and not wanting any loans....

SOHC 2.5L 4-cylinder head gaskets came from the factory with a single layer steel HG with a coating that deteriorates over time. This causes external oil and coolant leaks. Every last SOHC 2.5 we have seen has this issue, even the brand new ones.

this gives a view of engine out of vehicle for where the timing belt and water pump showing

Offline

Like button can go here

#14 2020-12-18 21:49:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

Lack of money forces one to do the best to resolve an issue and even on mars we will be much in the same realm since we will not have parts to do a repair regardless of the equipment that we bring in time.

Todays experimentation was to reduce radiator cap pressure and to remove thermostat to do short refill and drive use to monitor temp rise to heating dropping out. Also was noted engine rpm as well as heating for conditions as to or if flow was stopping as fluid level in coolant system dropped.

When heat dropped during run was when it was below 1500 rpm but would comeback when it was above 2500 rpm with total distanced covered round trip being 10 miles with temperature still below thermostat opening temperature if it were installed.

Will be adding cooant leak product tomorrow while early in the day, placing normal radiator cap on once at operating temp just prior to turning vehicle off after circulating. This should while hot and under pressure force the sealant into the gap to fix the issue temporarily. Of course retest after cooling with the low pressure cap installed after cool down.

This plus putting in a ph conditioner are usually tried before doing the head gasket work. It is a known problem that its the cooling system ph that is damaging the original gaskets.

update

this is where i am as well with idle rpm under 1,000

https://www.subaruoutback.org/threads/t … h6.495737/

the heater will blow cold but raise the rpm to 1,200 and it gets warm which indicates lower fluid or flow rate or pump head pressure...

Update on vehicle as I have been able to monitor conditions of idle and heat control such as to be able to work. The coolant head gasket sealing product did not full seal the leaking seam but was pretty close. Possibly another filling of the product will finish the job to make that seal more permanent such as to not need an engine or head work in the short term future.

Still watchful eye as when its in stop and go traffic the temperature will rise rapidly as the low 600 rpm does not make the coolant circulate through the engine properly. The tell is the heat coming from the heater is absent but if you bring that rpm up to 1200 rpm minimum you will get heat. Monitoring the heat and temperature guage allows the vehicles use. I still need to wire in some sort of indicators to see if the cooling fans ever come on under normal use. They do work as pushing the AC switch allows for them to phase on and off even when the vehicle is first started but at a reduced rpm.

Offline

Like button can go here

#15 2020-12-18 22:00:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

During the period of grace with the heads not failing totally I was able to work and get the 2005 escape running once more and with a bit more work to restores it to a safe function vehicle for use as it was required months later when... you guessed it..the head gasket finally failed...

On another note the garage removed the engine from the Subaru outback on Tuesday morning and I gave aid to the mechanic to push the vehicle out of the lift bay so that he could use it for his normal business.

Tonight I started to break the engine down removing the intake manifold and most of the wiring from sensors on the engine that was connected to it on the top portion of the engine. Also removed was the alternator and air conditioning brackets adjusters.

Tomorrow I am hoping to finish breaking down each sides valve covers and remove the heads to expose the gaskets for the rebuild if there is no signs of damage. If there is I have a back up engine to make use of for heads if they are in need to be replaced.

Will buy the gaskets and sealing cover gaskets for the rebuild after doing an inspection of the parts.

Each evening after work more was done to break the engine down as follows

Tonight's engine work entailed removing the harmonic balancer pulley, belt guards, torsion pulley and timing belt after marking gear alignments for top dead center. Removed the compressor for the AC such as to free up the dipstick holder tube. I was able to get all bolts out of the passenger valve cover but the drivers side has one rusted to soft to remove still stuck. Garage owner might attempt to get it free tomorrow otherwise its vise grips and grinding it flush to get the cover off.

Experience with the boxer engine in the subaru makes some of the design choices made questionable for how it's going to fail.

The heads from the engine have been removed and damage to where the head gasket failed is quite discernable to the touch as well as to the unaided eye on the heads and block.

With need to fine sand/remove it's imperfections before putting the new gasket a in. Will also need new stretch bolts for them as well. Of course that means torquing them and letting them set for 24hrs before giving a final torque. This may mean partial assembly for engine to be put back in before doing so.

Offline

Like button can go here

#16 2020-12-18 22:06:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

There were several large posts from kbd512 on how we could make vehicles last longer and perform better

http://newmars.com/forums/viewtopic.php … 74#p174574

http://newmars.com/forums/viewtopic.php … 79#p174579

Gw gave some more sage wisdom on how tough the new England area is on vehicles during the winter salty conditions.

http://newmars.com/forums/viewtopic.php … 91#p174591

Thanks GW for the looking up of the subaru head work. For the Subaru when of the engine size it had early issues with the head gaskets design with materials delaminating causing the failures to occur early. They have redesign them 3 times that I am aware of and even the after market might not live up to the duration expected for life of the car.

this last weekend work on another subaru engine which was out of a vehicle and known to have a coolant failure

Today while it was not so cold I took time on another subaru engine that I got from the mechanic before he scrapped it for metal tonnage 2 months ago. It was stored in my other 2001 escape which has frame issues for why its not useable.

I did finally get to remove the heads to see what the overheating issue was. He had said it was over heating after he had done the gaskets so he simply had gotten another engine and just replaced that vehicles engine as the cheap way out of it costing them more as well as for his time to be reduced by not doing it again.

The gaskets on the drivers side was an original flat metal design generation 1 while the passenger had the 3 ply new subaru gasket which is the 3rd generation design for them.

It was the drivers side gasket that had failed on that engine as the cylinders still had water in them..

So when I get the funds a set of the new subaru 3 ply gaskets are going to be bought for the cars original engine which had the generation 2 composite gaskets that had failed.

Still waiting for more funds to be able to go forward with cleaning up the heads and block surfaces which are needed.

Offline

Like button can go here

#17 2020-12-18 22:06:59

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,546

Re: Internal combustion engines for Mars

Thanks to kbd512 for a post on design of an engine (IC) for Mars .... planning to study it this weekend.

http://newmars.com/forums/viewtopic.php … 54#p175054

SearchTerm:diesel design for Mars

Thanks to SpaceNut for an entire series on the Subaru leak ... Somewhere along the line I had the impression you had pulled the heads and found the gaskets defective, but in reading the posts from today I'm wonder if you ever pulled the heads? My reading of the recent posts gives me the impression you decided to try to keep the car running rather than replace the gaskets.

Another possibility is that you ** did ** replace the gaskets but the engine still leaks.

(th)

Offline

Like button can go here

#18 2020-12-18 22:11:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

I was still finishing last post as you where posting but I had the heads pulled not only on my engine for the outback but as well the one I had to determine how they fail appart to the gasket levels on both.

I since have purchased the 3 layer gaskets for the work and the stretch bolts which were quite a bit close to Christmas to find free to use but I have done it.

Hopefuly after Christmas the process with move forward with getting it back together....

Offline

Like button can go here

#19 2020-12-19 15:04:40

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

In the later posts of the housekeeping topic it was brought up that converting a automobile engine into a house back up generator was possible of which its more than plausible to do.

We talked a bit about the laws for vehicles not registered on a property and how a shed to enclose it may or may not be a safe guard against theft of property. Of course an engine generator is larger than a portable generator in that case so its un likely that it would walk off.

This did tickle my brain and I remembered today a post from kbd512 on the IVF system that ULA uses to power the rockets rather than battery power. so will post in another topic that is better suited to mars.

Offline

Like button can go here

#20 2020-12-19 19:03:39

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,356

Re: Internal combustion engines for Mars

Going back to the DuraMax diesel, the general idea is to set up this engine as a high-output hybrid generator set for use in ground transport vehicles, construction equipment, and backup generators. Rather than using geared transmissions or hydraulics or pneumatics of any kind, it will spin a permanent magnet axial flux electric generator. If it's powering a vehicle, the power will be distributed to hub-mounted electric drive motors, similar to the way NASA's crawler-transporter vehicle operates. If it's powering a base, it will supply electricity to a transformer or other power conversion electronics. Alternatively, the vehicle itself could serve as the backup power supply for a base.

The advantage of this system is the ability to drop complete power packs into different types of heavy duty off-road vehicles and backup generators. Although not as efficient as a fuel cell, it could come reasonably close, as Mercedes F1 racing team has demonstrated with hybrid gasoline engines. The temperatures produced by the engine are not as extreme as solid oxide fuel cells, so an expensive and somewhat fragile ceramic insulation / containment vessel for the fuel cell itself is not required.

Rather than compressed O2 / CH4, it will use LOX / LCH4 and an onboard cryocooler to keep the liquids cold. The engine will run in a partially closed loop, meaning the air intake will draw O2 boil-off from the LOX tank and the fuel injectors will inject CH4 boil-off into the combustion chamber. To improve thermal efficiency, the engine will use exhaust gas recirculation to aid in consuming un-combusted O2 / CH4. The exhaust gases will also help drive the electric generator (the electric generator will be incorporated into the turbochargers or engine), similar to the Mercedes design, charging a small battery pack or super capacitor bank. I can't recall if I called it a V8 or V6 in prior posts, but the Mercedes F1 engine is a 1.6L turbocharged V6.

Engineering Explained - Mercedes Created The World's Most Efficient Racing Engine

Some here are probably wondering why we wouldn't use a gas turbine. Peak thermodynamic efficiency is only achievable within a very narrow band of operation near maximum output. At any lesser power setting, a lot of fuel is expended just to keep the turbine spinning. The obvious problem for ground vehicles and bases is that they rarely have constant power requirements, unlike aircraft and ships. Small gas turbines, for reasons related to aerodynamics, tend to be less efficient than larger units. Larger gas turbines that would be most suitable for constant power output are not well-suited to prototypical ground vehicles, not even tanks, up to 75t or so. The AGT-1500 gas turbine used in the M1 Abrams has relatively reasonable fuel economy at high output (it's rated for up to 1,500hp), in comparison to V8 or V12 turbo diesels capable of similar output, and while it's significantly lighter, it's pretty awful on fuel economy at idle or low output. The problem, of course, is that vehicle engines run at idle or relatively low output levels far more often than they run at maximum output.

If we truly had a 1,500hp / 1MW+ continuous power requirement, then we'd be better off from both a weight and fuel economy standpoint by running a SOXE fuel cell. Due to thermal expansion and contraction, high temperature fuel cells work best while providing continuous output. A 1,500hp / 1.12MW fuel cell would be even lighter than the AGT-1500 and consume far less fuel in operation, but a continuous series of significant power output fluctuations would reduce its expected service life. Perhaps some kind of exhaust gas recirculation within the fuel cell could keep the temperature within the cell relatively constant, but that type of system needs to be designed and tested. Certain types of automotive and light aircraft PEM fuel cells have exhaust recirculation systems to maintain operating temperature and consume un-reacted fuel, but they're operating at temperatures more closely associated with boiling water than the burner inside a jet engine. Anyway, gasoline and diesel engines contend with substantial repetitive power changes a bit better than gas turbines or fuel cells, and they do that while providing relatively consistent fuel burn.

Offline

Like button can go here

#21 2020-12-19 19:33:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

I posted about a converted hybrid changing the gas engine to desiel in the Fixing Americas car industry topic. It was one of those people that did not like the gas engine and perfered the desiel for the hybrid…

edit reply for next post is

Diesels use a glow plug to aid in igniting the fuel but the main question is will it use a lower or high ration of mix for the co + o mix for the chamber compression to be high enough to ignite.

https://en.wikipedia.org/wiki/Wankel_Diesel_engine

seems they never got one to work...

Offline

Like button can go here

#22 2020-12-20 07:32:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,546

Re: Internal combustion engines for Mars

For kbd512 re topic ....

Is there a chance that a CO/O engine would fit into the mix at Mars?

CO/O has been considered for use as a rocket fuel, despite the low ISP.

My understanding is that making CO from CO2 is the simplest of all the chemical energy storage methods available on Mars given the ready availability of the raw material.

I'd like to see designs for vehicles using this combination of fuel and oxidizer.

Images of designs can be stored on imgur.com and posted here using the bbcode links provided by imgur.com.

The size of the tanks for the two gases would be determined by the pressure to be used, and the strength of the material with respect to weight.

A diesel engine (as I understand the distinction) achieves combustion by compressing fuel and oxidizer to the point they self-ignite.

A non-diesel piston engine has less compression, and employs an ignition method such as a spark to cause ignition at the point of maximum compression.

It would be interesting to see development of a plan for development of an indigenous Mars industry using locally sourced materials to make a line of CO/O vehicles for various purposes.

Edit#1: If there is a forum reader (not already registered) who would like to participate in the discussion, there is presently no way (that I know of) for you to request membership in the NewMars forum. I have submitted a request for assistance to the powers that be in the Mars Society. In the mean time, if there is someone in the already registered membership who is interested in this particular topic, please toss a post into the topic.

(th)

Offline

Like button can go here

#23 2020-12-20 10:16:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

2Co + 02 is the output from a moxie unit to save for this desiel style engine as I am not sure about the compression of a gasoline engine with spark to ignite the mix in a chamber

We do have many topics but I am referencing this one Mars Insitu Fuels made from atmosphere, regolith, water

We also could use a fuel cell as well but in either case these have also been suggested for mars rockets specifically for sub orbital hops...

Offline

Like button can go here

#24 2020-12-20 10:30:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,957

Re: Internal combustion engines for Mars

repost

maintenance of a vehicle these days for most mean filling it with gas and waiting until it breaks to bring it to a garage...

Unless we have paents that can teach the skills of checking the oil at each full tank fill up they will eventually have a seazed engine from low oil or dirty oil as they did not change the filter after 3 - 5 thousand miles.

They will not know to look at the overflow coolant resevoir to see if its low before the car over heats.

Checking the break resevoir so as to make sure the fluid is not low as to prevent slidng into another vehicle when breaking.

Or checking the transmission fluid when its warm and running to see if its low so as to keep the can from burning its bands.

Look at the tires for being soft and worn before you have a blow out due to wear through and looking for cupping for alignment issues.Some vehicles need more maintenance than others and if its not garaged its bound to break down sooner from the weather elelments.

Seems this should also be a mars university project to develope the skills needed to make and maintain a mars vehicle....

Offline

Like button can go here

#25 2020-12-20 11:10:35

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,112

- Website

Re: Internal combustion engines for Mars

A compressor for 6 mbar "air" does not look like a compressor for 1000-mbar air here on Earth. It looks more like a hard vacuum pump. Lots of machinery weight and volume, and power draw, for very little throughput rate. As a result, you will not be able to achieve any sort of practical IC engine design for Mars.

You are far better off attempting a battery electric vehicle design, and working the issue of how to keep the batteries charged. Or a fuel cell electric vehicle, and working the issue of how to replenish the reactants. Except for dust storms, Mars has abundant sunshine, at about half the intensities we see here at Earth. The day length is about the same, too, unlike the moon. That cycle affects your battery or reactant tank sizes.

The dust storms are usually only a few days long and don't totally obscure the insolation. You have to plan for that, just like planning for a spate of rainy, cloudy weather here on Earth. But unlike Earth, the really intense planet-wide dust storms on Mars really do totally obscure insolation, for weeks to months at a time. You need a back-up for that. It's most likely nuclear. It's just something you have to do, if you intend on going to Mars for extended times, manned or unmanned.

GW

Last edited by GW Johnson (2020-12-20 11:12:23)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here