New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2018-08-29 17:52:05

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

3D construction - lessons for Mars

US military now using 3D printing techniques:

http://www.foxnews.com/tech/2018/08/29/ … hours.html

Could see that potentially working on Mars - but would probably have to take place under a construction hab to achieve the right temperature, I imagine.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#2 2018-08-29 20:04:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

That is really not a new thing but just trials to tell what it can do with what they need. This is a means to build without using concrete forms to create the walls. The layering we have talked about before in other 3D topics.....

Offline

Like button can go here

#3 2018-08-30 04:33:28

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D construction - lessons for Mars

Yes, I know it's not "new". The advance is in doing this out in the real world under what might not be ideal conditions.

That is really not a new thing but just trials to tell what it can do with what they need. This is a means to build without using concrete forms to create the walls. The layering we have talked about before in other 3D topics.....

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#4 2018-08-30 17:22:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

just did a bump of just some of the cross linking topics for concrete....

Offline

Like button can go here

#5 2018-09-01 10:14:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

Edit note that these are examples of Plot0003

Mars will most likely be of small structures and one shape that would be easily built via 3D could be this onnly larger.

A possible typical dome construction that has above ground and below surface attributes for mars.

Article boast, 3D concrete printer to print a 500-square-foot barracks room in just 40 hours.

Looks like alot of rails to make it work that must be laid down accurately before the system will work.

That is quite the achievement of time and scale but how many hows and what are the energy costs to make what you need to feed this machine with?

This was asked and I have modified it for this topic:

if we stick to concrete and composite construction materials, the cost to live in affordable homes could go down in a dramatic way.

house could be affordably constructed from durable and inexpensive domestically produced aircraft construction materials

or prototypical insulation materials. The composite building materials seem to be much cheaper and more durable than traditional materials.

Mars is very unique to building as we have little natural building materials to make use of. I do think composites will play an important part as well as other aircraft construction techiques.

So of a good question for Mars since these are energy costs but would be possible to do as there are no costs after sending the mining, processing and other such items to be able to use them in the construction process.

Offline

Like button can go here

#6 2019-01-24 19:33:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

lunar base concepts ESA ran a competition, asking: what would you 3D print on the Moon, to make it feel like home? Winning ideas for 3D printing on the Moon

https://www.esa.int/Our_Activities/Prep … o_the_Moon

The 3D printing techniques selected to be the most interesting for lunar exploration – due to their versatility, space-readiness and ability to process a range of materials – are:

Solar sintering which concentrates sunlight to shape lunar soil into a variety of objects – mostly for infrastructure – such as habitat, landing pads and dust protection walls;

Electron Beam Additive Manufacturing which uses a vacuum to create an electron beam that can be used to produce large metal parts;

Fused filament fabrication which has the possibility to create a wide range of materials and has already been tested in low gravity conditions;

Lithography-based ceramic manufacturing which can use lunar soil to create ceramic items with very precise dimensions.

Offline

Like button can go here

#7 2019-03-12 19:05:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

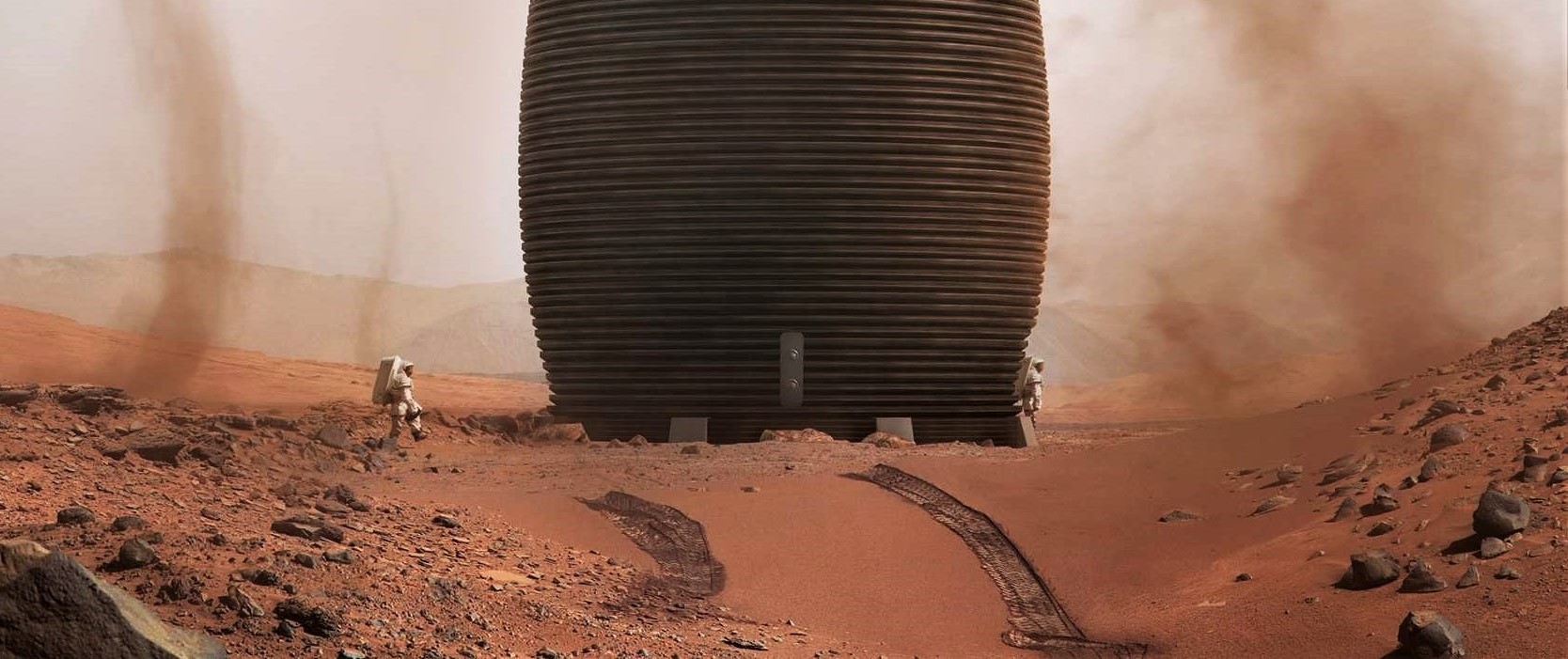

MARSHA:

Teslarati 3D-Printed Mars Habitat could be a perfect for early spaxeX starship colonies, MARSHA

I do https://www.teslarati.com/3d-printed-ma … -colonies/

Thanks for the link to others wanting to print habitats on mars or other places but what they do not go into is the prep side of the equation needed to make the materials to be use for the machinery to utilize it to build with from the insitu resources.

Very cone like indeed...

This is from AI SpaceFactory achieved second place in the latest phase of a NASA-led competition

If I do find the other simular posts I will copy them here so that we will have a list of whom are attempting the technology, the equipment and the materials information of what is targeted for insitu materials.

3D-printed Mars habitat a biorenewable plastic (PLA) reinforced with locally-sourced basalt fiber – also accounts for many of Mars’ shortcomings, as plastics happen to be some of the best materials for radiation shielding per unit of mass. Featuring a duo of PLA shells placing a meter or more of plastic between living areas, MARSHA would permit relatively acceptable radiation levels while avoiding the downsides of locating habitats underground or burying them under several meters of Martian regolith.

NASA's Centennial Challenges: 3-D Printed Habitat Challenge

https://www.nasa.gov/directorates/space … index.html

3D-Printed Habitat Challenge. NASA and its partners are holding a $3.15 million competition to build a 3D printed habitat for deep space exploration, including the agency’s journey to Mars. The multi-phase challenge is designed to advance the construction technology needed to create sustainable housing solutions for Earth and beyond.

https://www.nasa.gov/directorates/space … mpetition/

After two stages where NASA awarded a total of over $1 million to competitors, the final prize was awarded to the top 5 projects.

Something that I would suggest is dropping a unit in one of the analog areas and run the insitu use processes from scratch to see just how hard it is to prepare the raw materials to make it ready for use for the equipment. Measure and test all aspects of it so that we can have better control to what we might find from the earth use.

https://www.3dprintingmedia.network/top … mpetition/

Team Zopherus of Rogers, Arkansas – $20,957.95

AI. SpaceFactory of New York – $20,957.24

Kahn-Yates of Jackson, Mississippi – $20,622.74

SEArch+/Apis Cor of New York – $19,580.97

Northwestern University of Evanston, Illinois – $17,881.10

These are beautiful for sure

A very firmiliar designed floor layout

Offline

Like button can go here

#8 2019-08-10 12:37:59

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

All of the companies doing research and techniques have pushed some things forward as being possible but when would we senbd them to a destination to be used.

Offline

Like button can go here

#9 2019-09-03 09:39:29

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: 3D construction - lessons for Mars

For SpaceNut re topic ...

As time passes, 3D printing technology is improving on multiple fronts.

A newsletter that came my way recently included this update, which (I hope) is pertinent to the Mars project:

White paper: The Fast Radius Guide to Additive Polymers

Fast RadiusYou can make end-use parts with additive polymers. Really. Today's additive materials can do so much more than prototype. The latest white paper from Fast Radius busts common myths about additive, provides a framework for replacing traditional materials with additive polymers, and presents a guide to the mechanical properties of common polymers used in industrial-grade 3D printing.

What I'm noting here is the use of the expression "industrial-grade".

The hobby printers sold in stores or over the Internet are what most folks encounter. I'm deducing the paper above is about something considerably more robust.

(th)

Offline

Like button can go here

#10 2019-09-03 11:34:53

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: 3D construction - lessons for Mars

Interesting. The problem with 3D printing is that molten material is bonded to a solid substrate. This makes it unsuitable for construction of structures the need to take tensile forces, such as pressurised structures, but generally works fine for compressive structures. The problem is even more intractable if ceramic materials are used.

One solution would be to use pre-stressing cables or tendons to provide a compressive force on the structure that balances the pressure within. A cylinder shaped ceramic structure could be reinforced by internal, longitudinal, pre-stressing cables. These would provide enough longitudinal force to balance radial atmospheric pressure through frictional forces between the compressed ceramic materials. Further reinforcement could be provided by external steel locking brackets.

The cables could be made from low carbon steel, glass or basalt fibres or polymers. It would be wise to choose materials that did not creep, although internal cables would be easy to replace.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#11 2019-09-03 11:47:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: 3D construction - lessons for Mars

For Calliban re #10

While noting the validity of your observations about additive manufacturing for many (if not most) use cases, I would like to suggest (if you have time) to put this search string into Google: "3d printed rocket engine"

Progress in printing structures able to withstand tensile forces appears to have taken place, but again, well away from the hobbyist arena.

(th)

Last edited by tahanson43206 (2019-09-03 11:48:14)

Offline

Like button can go here

#12 2019-09-03 17:12:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

Calliban the process do make things that while they stand up to some conditions will need more reinforcing to make them work for the mars condition. The basalt fiber comes to mind for wrapping the outside to give the building strength while epoxy sealants would work to make it air tight. One can also add to the internal layers with aerogel insulation panels and other materials to make it stand up under pressure.

Martian Soil Simulants – Mechanical Properties and Feasibility as Building Blocks

Offline

Like button can go here

#13 2019-10-31 08:37:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,123

Re: 3D construction - lessons for Mars

For SpaceNut for topic in general ...

HP sends me an update about their activities periodically. I'm just one of millions (most likely) recipients of this email, for having registered one of their products.

This latest "newsletter" contained a link to a report on progress with 3D Printing that I am pretty sure has significance for prospects of local manufacturing on Mars.

https://h41369.www4.hp.com/taw/article/ … TAW_002255

Hopefully that link will work for forum readers.

(th)

Offline

Like button can go here

#14 2019-10-31 17:35:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

Thanks for the link as it did work. I have been around 3D printing since early 2000's when cnc and other such machine computer controllers came out. The use of computer stepper contols got better.

The main issue for the printers are the feed stock materials that require a level of processing to be able to use the machines. Depending on the materials you end up with prototyping of form, fit and function in many a case. Then add in additive features to the machining of the object and it can stand in for the real milled parts which do cost and need more time to make usually.

Offline

Like button can go here

#15 2020-07-12 17:20:57

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

The moon might be a bit different for materials to use but the equipment will be very similar.

NASA-backed project could automatically fix 3D printing for Moon bases

NASA is giving Relativity Space $125,000 over six months to further its work.

Offline

Like button can go here

#16 2021-12-30 10:43:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

3-D printing a base on Mars

https://www.designboom.com/architecture … 2-27-2021/NASA was recruiting participants for a year-long simulated mars mission inside the 3D-printed habitat

Offline

Like button can go here

#17 2021-12-30 11:39:44

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: 3D construction - lessons for Mars

This technology seems to have the benefit of being able to produce relatively complex shapes, without the need to first produce sub-components that must then be manually assembled. It can produce components by depositing materials onto surfaces without a mold. That is what printing refers to. But it seems to me that there are a limited number of materials than can be worked in this way. Can we really 3D print steel? How would that even work? Would it be a vapour deposition process? There are some components where 3D deposition would appear to be an inefficient option. If I want a sheet of polymer to make a dome, then it would appear to be more efficient to extrude a thermoplastic through a set of rollers. Printing by deposition would be slow in comparison. If I wanted tables, chairs or a plastic door, why would I 3D print these items instead of just injection molding them? Where does 3D printing start offering benefits beyond other construction methods?

Last edited by Calliban (2021-12-30 11:41:06)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#18 2021-12-30 11:44:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

Metal materials are based off from feed stock in the machines which are building rocket engines and more with the use of additive processes after giving the rough shape by heating and milling what is not needed after depositing them.

Offline

Like button can go here

#19 2022-05-07 12:17:37

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: 3D construction - lessons for Mars

3D printing and thermodynamic modeling help NASA develop a high-flying alloy

https://www.thefabricator.com/additiver … ying-alloy

NASA Develops 1000 Times Stronger Metal Alloy Using 3D Printing

https://www.3dnatives.com/en/nasa-devel … 270420224/

Offline

Like button can go here

#20 2022-05-07 22:46:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,613

Re: 3D construction - lessons for Mars

Important for construction of rockets and other for sure.

Imaginative concepts including a 3D-printed building

https://www.dailymail.co.uk/sciencetech … -Mars.html

Other concepts that have been shared include the 'Mars Case', by Chinese-based firm Open Architecture, and Elon Musk's 'Mars base alpha'

Also but we need a floor slab printed first to make sure it seals to the walls that we print of concrete.

Offline

Like button can go here

#21 2022-10-25 17:19:04

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: 3D construction - lessons for Mars

Relativity Space an American aerospace manufacturing company, seem to be around John C. Stennis Space Center (SSC) is a NASA rocket testing facility in Hancock County, Mississippi, United States, on the banks of the Pearl River at the Mississippi–Louisiana border. Terran 1 is a two-stage, 3D-printed, expendable, small-lift launch vehicle, Terran R is a medium-lift two-stage, fully reusable launch vehicle under development by Relativity Space.

Relativity Space maps path to Terran production at scale with 3D printers

https://www.spacedaily.com/reports/Rela … s_999.html

Relativity Space, the first company to 3D print rockets and build the largest metal 3D printers in the world, today unveiled the latest iteration of its first-of-its-kind proprietary manufacturing platform, Stargate 4th Generation metal 3D printers. These printers will underpin both the development and rate production of Terran R, Relativity's fully reusable, 3D printed rocket that will be capable of launching 20,000 kg to low Earth orbit (LEO).

The newest Stargate printer technology defies traditional printing constraints by moving horizontally as it feeds multiple wires into a single print head to print orbital rockets. Relativity is developing customized software and machine learning techniques to allow these printers to print more complex and significantly larger metal products, with improved print speed and reliability. Stargate 4th Generation printers also radically simplify manufacturing supply chains, as they are capable of printing a rocket with 100x fewer parts in a matter of months.

Offline

Like button can go here

#22 2024-05-19 08:31:29

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: 3D construction - lessons for Mars

How 3D Printing is Revolutionizing the Field of Dental Implants

https://www.mid-day.com/brand-media/tec … plants-869

World's largest 3D printer can print a house in under 80 hours

https://www.wionews.com/videos/worlds-l … urs-719585

The world's largest 3D printer called Factory of the Future 1.0 has been designed to tackle the shortage of homes and construction workers in America.

2023 article

NASA confident of 3D printing houses on the moon by 2040

https://3dprintingindustry.com/news/nas … 40-225318/

Offline

Like button can go here