New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#76 2018-03-03 16:31:04

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,330

Re: Mars Cart

I like that, and I am not trying to do a topper here.

3D printed motor: (So, two ways)

http://www.instructables.com/id/3D-Printed-DC-Motor/

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#77 2018-03-03 17:13:52

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Cart

Great video. I've noted before that electric motors are relatively simple and could be produced by an early colony largely from ISRU materials. 45 Kws is pretty powerful - enough to run a car I think!

This is how one might make a motor or generator from insitu materials 45Kw DC Brushless motor construction

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#78 2018-03-03 17:18:15

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: Mars Cart

Some interesting concepts here. Tracked vehicles are less likely to get stuck in soft terrain than wheeled vehicles. But they are heavier and less energy efficient.

I wonder if a hybrid electric vehicle could be a good option for Mars. A short range 40km battery, which can be charged with roll-out solar panels. An IC engine mounted to a generator for when greater speed and power are needed or when traveling close to the poles. Wheels could be some kind of fibre reinforced polymer.

Offline

Like button can go here

#79 2018-03-04 04:34:01

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Mars Cart

For Mars service an IC engine isn't likely to work. You have to carry oxidant as well as fuel. Atmospheric CO2 could be used but you need a fuel that won't coke your engine up. Better to use a Sterling or Brayton engine (external combustion) if you want to use the CO2 as an oxidiser, as a coked up heat exchanger is relatively easily switched and/or cleaned.

I posted elsewhere about self heated tires by filling them or compounding them with radioactive elements. I prefer the filling option because it is renewable and can be adjusted for different missions. An alpha or beta emitter might be best to restrict penetration of the particles, and it would need to be a volatile compound so that a puncture or leak would dissipate rather than create a concentration of your radioisotope. I still prefer tracks if they can be done, though.

Offline

Like button can go here

#80 2018-03-27 20:21:28

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

http://www.ecmweb.com/content/selecting … efficiency

Motor ratings and nameplates are standardized in terms of horsepower and speed, with no mention of torque. However, you can relate horsepower and torque with the following equation: Horsepower = Torque (lb-ft) x rpm/5250

http://www.kylesconverter.com/power/foo … horsepower

calculate the peak power and torque produced by an electric motor

Offline

Like button can go here

#81 2018-03-28 21:31:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

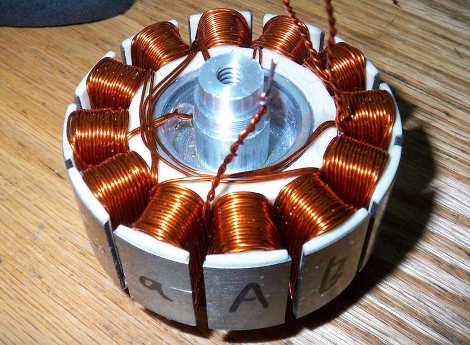

Pancake motor coil winding video's

http://www.nmbtc.com/step-motors/engine … ng-theory/

Lynch motor winding Axial Field Permanent Magnet DC Motor With Powder Iron Armature

https://www.revolvy.com/main/index.php?s=Lynch%20motor

The Physics of Permament Magnets

http://onlinepubs.trb.org/onlinepubs/ar … report.pdf

https://www.tu-braunschweig.de/Medien-D … f_2006.pdf

Offline

Like button can go here

#82 2018-03-29 19:25:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

http://uav.ece.nus.edu.sg/~bmchen/cours … motors.pdf

http://www.electric-cars-are-for-girls. … motor.html

http://www.machinedesign.com/motorsdriv … mdc-motors

HIGH SPEED PERMANENT MAGNET SYNCHRONOUS MOTOR / GENERATOR DESIGN FOR FLYWHEEL APPLICATIONS

Permanent magnet axial-flux generator with toroidal winding

Offline

Like button can go here

#83 2018-03-30 20:34:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

The simularities of a pancake permanent magnet generator and of a motor aka axial flux are something that will be a somewhat simple construction for the early conlony on mars. Not to meantion something that we may need to learn how to fix.

Project home page with links on the left side for building the other parts.

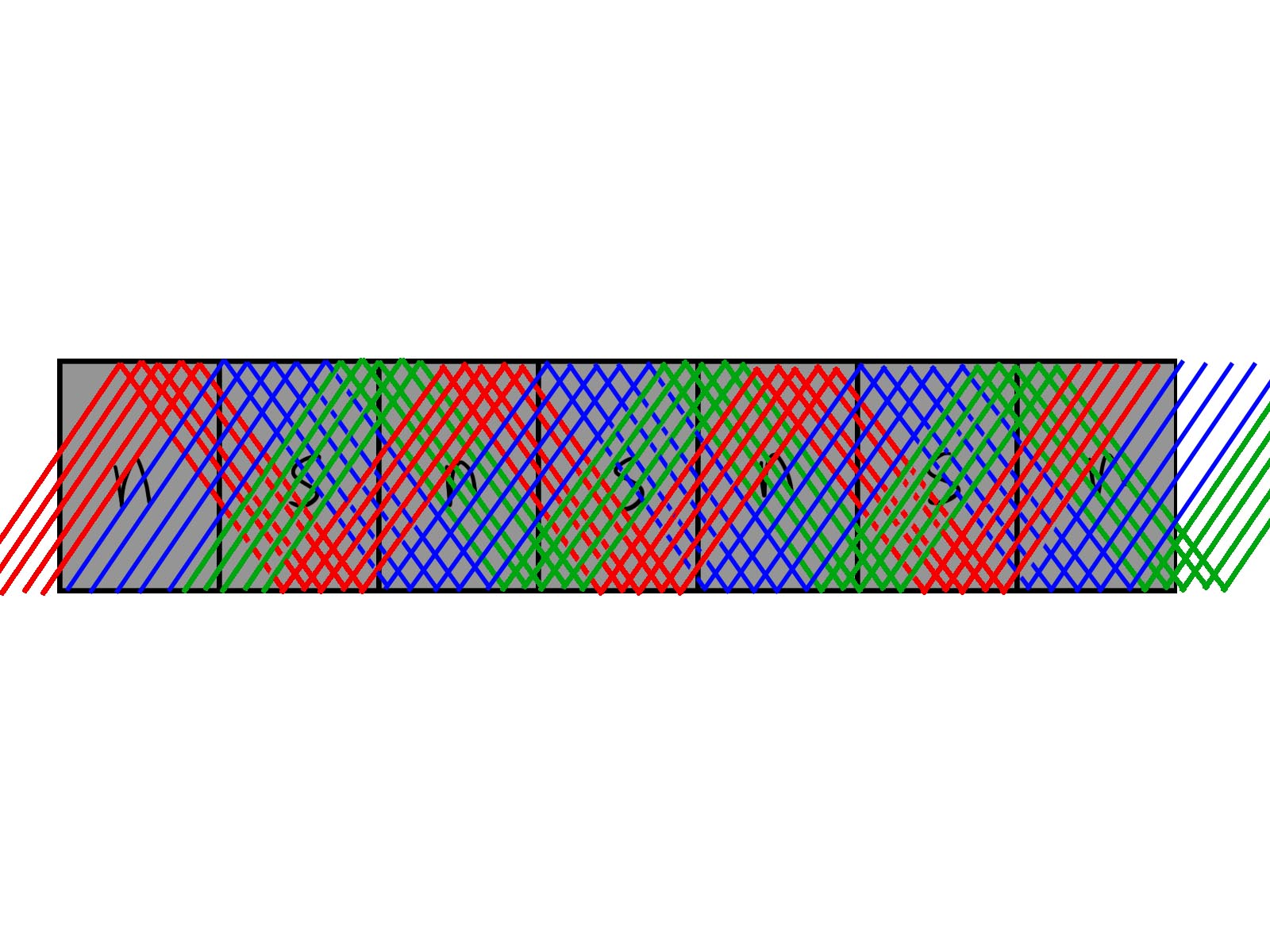

How to make the Stator while this is for a windmill its the same generator that is designed for low RPM rotation to achieve power. Since we are coverting the AC to dc the rotation speed the frequency will not be an issue as we are not looking to sync it up for regular power appliances. The DC would be then fed into a charger circuit that would charge batteries.

The magnet rotor plate construction will allow for multiple stators and plates to be used to build up higher levels of wattage as needed. The axial flux design uses 2 of these plates to create the feild path north to south for each coil and then swaps south to north on the other plate.

The generators output is about 48 Volts with a max 30 amps for the approximate output of around 1200 watts at around 140 RPM with the output wattage going up with the increase of RPM.

https://ashwoodselectricmotors.com/perm … ux-motors/

Building a triple stator axial flux motor has lots of the actual construction

Offline

Like button can go here

#84 2018-03-30 21:30:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Permanent Magnet Spiral Motor for Magnetic Gradient Energy Utilization: Axial Magnetic Field in a Wankel design...

Experiments with Spiral Magnetic Motors

https://www.freeenergyplanet.biz/energy … ngine.html

http://www.cheniere.org/misc/wankel.htm

Simular as the other motor design in that a stackup of platters offset by the phase count relative to the platter count or 360' / 3 for 3 platters or 120' seperation of energy to make the rotation happen.

https://evmc2.wordpress.com/2011/12/29/ … gy-motors/ links on left side of page of other topics.

Wire Size, AWG and Funny Numbers

Electric Motor HP Ratings (and Other Secrets of the Universe) vs Gas

Basic Motor Types: PMDC, BLDC, AC Induction, Synchronous and Series DC

NEW PMAC 38 kW Liquid-Cooled 120V Motor (from Electric Motorsport)

Axial vs Radial Flux: Simple as Pie. Or cake. Or Pancake. Motor.

Conversion Table Reference: RapidTables

Electric Motor Power (Really Simple) and HP Ratings

Motor Starting Torque (Peak Stall Torque) and Motor Types

Offline

Like button can go here

#85 2018-03-31 18:46:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

http://www.emic-bg.org/files/Electric_M … Drives.pdf

Continuing to do research into how one can build motors and generators for the given applications of making things move. Battery research will come later as cost is the key to being able to do this on a little bit of money.

My homemade bicycle motor, version 1

The key to understanding motors and generators http://allianceorg.com/pdfs/Magnet_Tutorial_v85_1.pdf plus the creation of the magnets to make it all happen. The processing of ore to magnets are contained within the pages.

Offline

Like button can go here

#86 2018-04-01 09:15:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

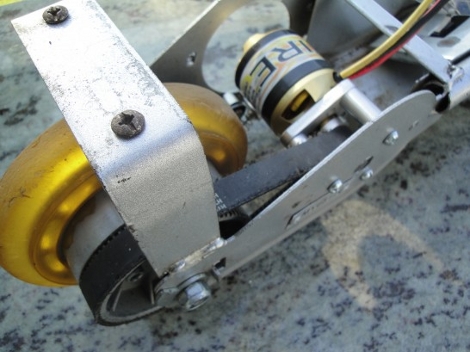

Tire wheel hub motor design

http://lati-solar-car.wikispaces.com/fi … +Sheet.pdf

Sinjce we will need to make the insitu magnets I would look for materials in the remnant field areas for this.

How magnets are made

https://www.quora.com/How-does-one-make … nt-magnets

Something to make not of is that while the same design for a generator and a motor can be done the actual difference for 3 phase delta or wye wiring is a generator will use more magnets than coils of wire versus usually 4 to 3 per phase while in a motor you will use less magnets than the coil count even for that same wiring. For a generator we need rectifing diodes to change the AC to DC while for the motor we will pulse the phase winding in sequence to make the motor move.

http://www.completepowerelectronics.com … ldc-motor/

https://www.digikey.com/en/articles/tec … or-control

BLDC motor stator is the same as what would be the generator with the amount of magnets changing.

Offline

Like button can go here

#87 2018-04-01 15:33:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Brushless DC Motors – Part I: Construction and Operating Principles

Brushless DC Motors--Part II: Control Principles

https://www.hurricanewindpower.com/axia … rator-24V/ this is a pancake or axial generator that will output 24v at 30 to 40 rpm or give at full rpm 2.4kw.

Not recogmending product only listing for how many sizes are available

Offline

Like button can go here

#88 2018-04-02 19:14:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Here is a page to help with coil to magnet counts and how many turns will be in the coils to create and\ approximate voltage output.

Winding Scheme Calculator

http://chemandy.com/calculators/round-w … ulator.htm

Offline

Like button can go here

#89 2018-04-07 08:39:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

So You Want to Build an Electric Car

If when designing the motor the choices are for in the hub or on the end of an transaxle or axle and then again at the end of the transmission.

http://www.ebikeschool.com/geared-hub-m … ub-motors/

Gearless (direct drive) hub motors

gut of a small motor for a hub

Geared hub motors

For those that do not want to build here is a site that show examples for what the pricing of what can be https://www.diyebikestore.com/c/hub-motor_0388 not endorsing just information.

Motors can also be belt or chain drive to the wheel as well as geared.

https://hackaday.com/2009/10/18/1480w-s … ad-trauma/

So many choices of how to make motion need to now study and research motor controllers

http://kellycontroller.com/Permanent-Ma … roller.php

it appears voltage source is a value that is fixed for the purchase and design

Offline

Like button can go here

#90 2018-04-07 11:30:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

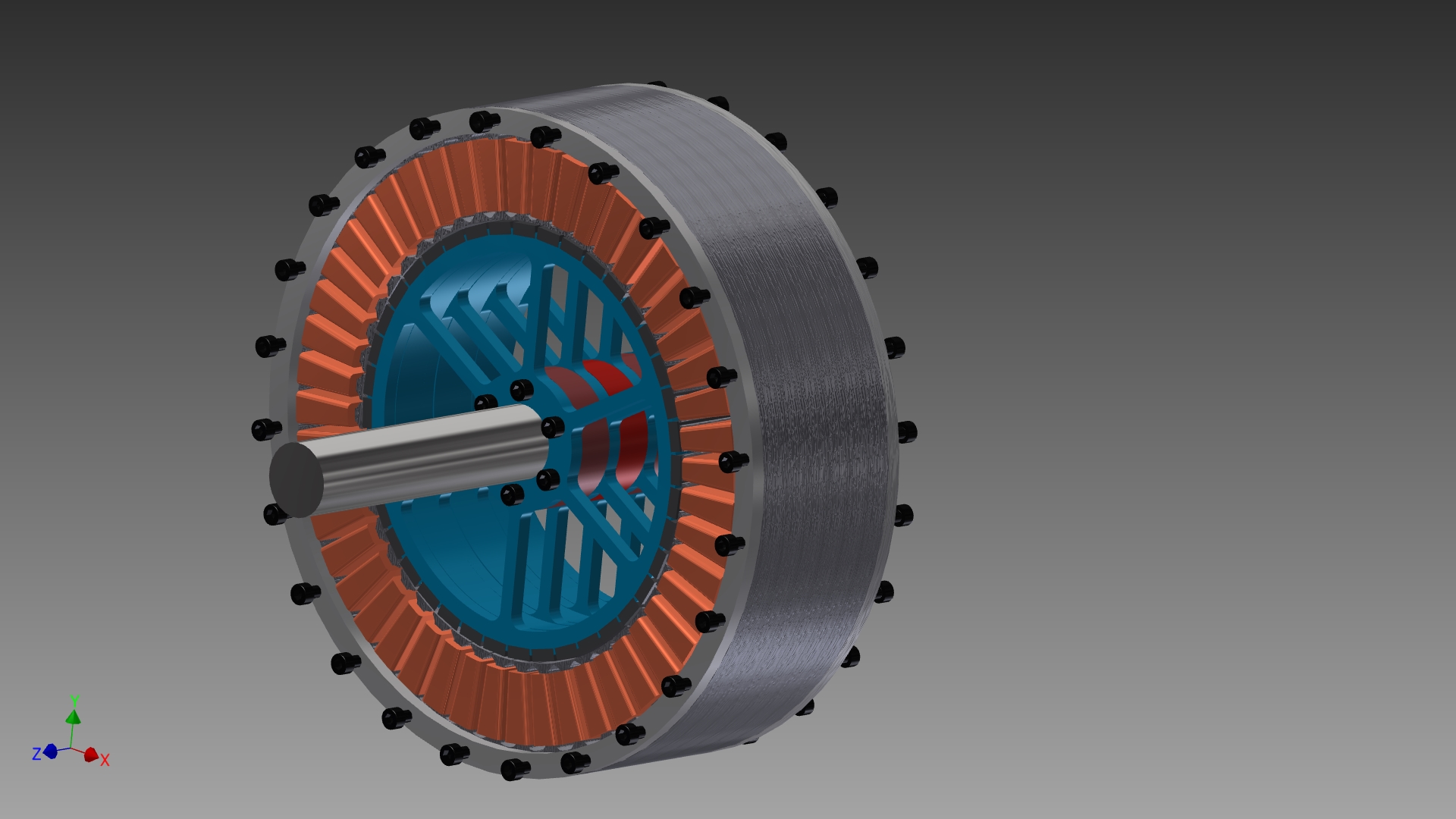

One of the main objectives with the permanent magnet design is they would require no brushes for the motor to operate. Another is how to cool the motor and how much torque willbe required for the speed that you will want to move at. The design images from post 99 are magnets on the outside while this one will be on the inside of the motor which makes it good for an axle design.

45KW Bushless motor design

Motor controllers are inAC or DC type of which the permanent magnet is sort of a cross between both as its a pulsed DC which makes it move.

Offline

Like button can go here

#91 2018-04-07 21:03:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Single phase DC brushless motors would use something like this

http://www.onsemi.com/pub/Collateral/TND6041-D.PDF

http://www.ti.com/lit/an/sprabz0/sprabz0.pdf

http://www.hobbyprojects.com/M/Motor_Controls.html

Offline

Like button can go here

#92 2018-04-09 19:39:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Was reading today about speed and mass of a vehicle in that the power coming form the battery are and is the factor to which controls this to a greater level. The voltage as it rises will make it such that we can go faster under a set mass and that the torque for a greater mass drives the current load required from a battery up. Its this combination and the watt hour rating in ampere hours that matter for the usefill time period of use of the battery pack design.

Offline

Like button can go here

#93 2018-04-16 21:23:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Offline

Like button can go here

#94 2018-04-21 11:58:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Electric Car Motors: Horsepower

Weight to power ratio:

When you're selecting electric car motors, 8hp (continuous) for every thousand pounds of finished, loaded vehicle weight. That means figure in the car's curb weight - along with the load of batteries, corn-fed American passengers, and the trunk full of camping equipment. Seth sez: "More horsepower is required for higher speeds, heavier vehicles, and steeper terrains."

Electric Motor Rating:

They're rated at their maximum efficiency, which is designated "continuous", although they are capable of short bursts of power 2-4 times greater than their continuous rating (without damaging the motor), called "peak".

Voltage and Horsepower:

The horsepower goes up with the voltage. Motors are rated, not only "continuous" and "peak", but at a given voltage, as well. There's no way to figure an EV motor's horsepower without knowing the voltage of the system.

Over- and Under-powered Motors:

No worries if you get a motor that's a little oversized for your car, that's what the controller is for. The tradeoff is that you're wasting weight on motor that you could be spending on batteries. If you get a motor that's a little undersized, though, the challenge is keeping it cool enough.

The Need for Speed:

If you like to drive on the freeway, you'll need more horsepower per pound. Seth says it takes four times the horsepower to go 70mph than it does to go 35mph.

Air Drag Coefficients and Frontal Area Calculation: Coefficient of Drag

http://www.wallaceracing.com/Calculate% … 0Speed.php

Offline

Like button can go here

#95 2018-04-22 07:36:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Pancake flat motrors and generators

Another very interesting design

I have seen a number of builds using metals and even wood to make up various parts of the generators and motors in permanent magnet builds.

Offline

Like button can go here

#96 2018-04-25 19:17:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Permanent Magnet Synchronous Motor (PMSM) Drive brushless direct current (BLDC) motor http://www.cypress.com/file/106186/download

MODELING AND SIMULATION OF PERMANENT MAGNET SYNCHRONOUS MOTOR DRIVE SYSTEM

Offline

Like button can go here

#97 2018-04-26 21:25:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Offline

Like button can go here

#98 2018-04-28 17:32:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,516

Re: Mars Cart

SpaceNut,

The rovers don't need to travel at high speed. Speed is inherently dangerous, whether you're on Earth or Mars. It's not any kind of a race and speed kills. Limit top speeds to 50kph or less for crewed vehicles, and 25kph or less for regolith collection rovers. There's no significant drag to concern ourselves with on Mars, either. Whether the Mars-bound vehicle in question is shaped like a brick or a bullet, if it's powered by an electric motor then it will move at the same speed and consume the same amount of electrical power.

Offline

Like button can go here

#99 2018-04-28 19:37:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,595

Re: Mars Cart

Low speed in MPH 15 to the upper limit 31 which is determined via the mass we are moving at torque delivered to the wheels from the batteries. The pulse rate to the coils in the motor is the speed to which we are moving from the power source. That pulse rate changes with size of the wheel and the voltage level that can be provided with the current that makes each magnetic force to push against the magnet in the rim since the coils are kept stationary. With the only drag is the rotation of force that must move a vehicle up over any rocks as the tire rotates as that will require more torque to the wheel to make that happen which is more current to the coils via more pulses.

Motor determening factors are: strength of the magnets, how many magnets are placed around the stator to the size of the wire for the coils, how many coils are used, how many phases are spread around the stator ect....

Offline

Like button can go here

#100 2018-04-29 03:53:31

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Mars Cart

Two more items to consider are cooling and dust sealing.

No device can be 100% efficient. Expect about 95-97% for a good electrical machine, so 3-5% of the input power must be dissipated to somewhere. If the machine is stalled, eg by coming up against a rock it can't climb 100% of the input power gets converted to heat. Martian atmosphere is not going to be brilliant for this cooling because its density is so low, so you may have to use a lot of it! Then you will need cooling fans.

Dust will contain iron, so expect a build up around anything with leaking magnetic fields. Also it will be very fine and penetrating, leaving the proverbial Arizona road dust in the shade. Positive pressurisation with clean gas is probably the best option for excluding it from machine casings. Now you need pressurising fans and very good self cleaning filters, or a couple of bottles of gas. Maybe cabin gas leak-off could be used on manned machines.

Offline

Like button can go here