New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Re: Meta New Mars » Housekeeping » 2025-09-15 14:45:56

In the Admin, options the ser ver is blank but I do not remember if there was one.

SMTP server address

The address of an external SMTP server to send emails with. You can specify a custom port number if the SMTP server doesn't run on the default port 25 (example: mail.myhost.com:3580). Leave blank to use the local mail program.

still researching

sent other information to you.

AI Overview

PHPMailer is a popular, open-source library for sending emails in PHP applications. It provides a robust and feature-rich way to send emails compared to the native mail() function in PHP, offering support for SMTP, attachments, HTML emails, and more secure handling of email sending.

Key features and uses of PHPMailer:

SMTP Support:

PHPMailer allows sending emails through an SMTP server, which is generally more reliable and secure than using the local mail() function. This is crucial for ensuring email deliverability and avoiding spam filters.

HTML Emails:

It facilitates sending emails with rich HTML content, including images and styling, for a more engaging user experience.

Attachments:

PHPMailer makes it easy to attach files to emails, such as documents, images, or other media.

Authentication and Encryption:

It supports various authentication methods and encryption protocols (SSL/TLS) for secure communication with SMTP servers.

Error Handling:

PHPMailer provides comprehensive error reporting, making it easier to diagnose and troubleshoot issues during email sending.

Flexible Recipient Management:

It allows setting multiple recipients, including CC and BCC, as well as reply-to addresses.

Using PHPMailer in a project typically involves:

Downloading and Including:

.

Obtaining the PHPMailer library (e.g., from GitHub or via Composer) and including the necessary files in your PHP script.

Instantiating PHPMailer:

.

Creating an instance of the PHPMailer class.

Configuring SMTP Settings:

.

Providing details for your SMTP server, including host, port, authentication credentials (username and password), and security settings (SSL/TLS).

Setting Sender and Recipient Information:

.

Specifying the sender's email address and name, as well as the recipient(s).

Composing the Email:

.

Setting the email subject, body (plain text or HTML), and adding any attachments.

Sending the Email:

.

Using the send() method to dispatch the email and handling potential errors.

Troubleshooting PHPMailer issues often involves:

Verifying SMTP server settings: Ensuring the host, port, and authentication details are correct.

Checking network connectivity: Confirming that your server can connect to the SMTP host.

Reviewing error logs: Examining PHPMailer's error messages for clues about the problem.

Consulting documentation and community resources: Referring to the official PHPMailer documentation, GitHub page, and online forums (like Stack Overflow or specific hosting/framework forums) for solutions to common issues.

#2 Re: Meta New Mars » Housekeeping » 2025-09-14 14:48:53

The username and the banned are 2 seperate tables of information.

The usernames are also linked to the user profile table which contains the email and other information.

There are some usernames that should not be removed as these would not follow simple rules.

The list of banned have 490 ish usernames that can be converted if we would desire to remove them from the banned.

The user profiles will need the username changed as well as the email content as well as putting it into the inactive list.

Changing the username to the group to inactive first does not change it from the banned as it remains banned as its the table of control for that user.

I see that poster seemed to be spamming a link of the same for every discusion as to why it got banned.

#3 Re: Science, Technology, and Astronomy » Firefly Launch » 2025-09-13 14:55:34

NASA Confirms Private Spacecraft Successfully Lands on the Moon

NASA’s recent confirmation of Firefly Aerospace’s Blue Ghost Mission 1landing on the Moon signifies a transformative moment in the realm of space exploration. The private American spacecraft successfully touched down near Mons Latreille in Mare Crisium, marking a milestone for NASA and its commercial partners.

Firefly Aerospace’s Blue Ghost 1mission represents not just a significant technological achievement but also an important step toward NASA’s long-term lunar exploration plans. The Blue Ghost spacecraft, launched from Florida in January 2025, touched down on the Moon’s surface after a carefully orchestrated sequence of maneuvers involving a cruise, approach, and powered descent phase. Landing in the Mare Crisium region near Mons Latreille, an area with ancient volcanic significance, this location was chosen for its scientific value, offering insights into lunar crustal chemistry and thermal history.

“This incredible achievement demonstrates how NASA and American companies are leading the way in space exploration for the benefit of all,” said NASA’s acting Administrator Janet Petro. This success is also critical for the development of NASA’s Artemis program, which envisions sustainable exploration of the Moon and beyond. The mission’s instruments, designed to support Artemis objectives, include payloads focused on navigation, lunar dust analysis, heat flow measurement, and other crucial data-gathering technologies.

A key component of Blue Ghost 1’ssuccess lies in NASA’s Commercial Lunar Payload Services (CLPS) model. This initiative enables private companies to carry out lunar deliveries rather than having NASA build and operate every spacecraft themselves. By using competitive task orders and indefinite delivery contracts, NASA is able to reduce costs and expedite technological development. This approach helps spread the risk of failure across multiple flights and encourages rapid innovation in the space sector.

The Blue Ghost mission, being only the second commercial soft landing on the Moon, demonstrates the potential of the CLPS model. This framework allows private companies like Firefly Aerospace to contribute significantly to the broader goals of space exploration while simultaneously improving cost efficiency and speeding up the testing of new technologies. By leveraging private sector expertise and resources, NASA is fostering an ecosystem that can deliver critical hardware and data to the Moon sooner than traditional government-funded missions would allow.

The payloads aboard the Blue Ghost 1 spacecraft carry critical instruments designed to provide data that will advance our understanding of the Moon’s surface and subsurface properties. One of the standout instruments is a subsurface drill capable of penetrating about 10 feet (3 meters) into the lunar surface. This drill is designed to gather important data about the Moon’s thermal gradient and heat flow, which will help refine models of lunar crust thickness and its volcanic history.

Additionally, the spacecraft carried a range of other scientific instruments, including a lunar soil sampler and a magnetotelluric sounder. The sampler is designed to collect lunar regolith (soil) using gas-based methods, which is an energy-efficient alternative to traditional robotic arms with moving parts. This technique could potentially simplify future lunar missions, reducing the need for complex machinery.

One of the most notable payloads is theLunar GNSS Receiver Experiment (LuGRE), which successfully demonstrated that weak GPS and Galileo signals can be acquired and tracked on the Moon’s surface. This could revolutionize navigation during future lunar missions by allowing landers to operate more independently, with less reliance on Earth-based tracking systems. This would be particularly beneficial for smaller lunar missions that don’t have the resources for full-scale tracking systems.

Lunar dust presents one of the most persistent challenges for future lunar missions, as it can cling to equipment, damage moving parts, and even pose risks to astronauts’ health. The Blue Ghost mission’s research into dust behavior focuses on how it interacts with electric fields, particularly near the Moon’s terminator (the line between day and night). During the lunar dawn and dusk, the sunlight at low angles creates electric fields that can lift fine grains of dust, creating a phenomenon that could affect equipment and operations.

In addition to dust research, the thermal properties of the Moon are also a key focus.The Blue Ghost spacecraft’s drill will probe the thermal gradient at depths of several feet, helping scientists better understand heat flow from the Moon’s interior. This data could reveal more about the Moon’s volcanic activity, crustal composition, and overall thermal history.

Furthermore, by analyzing the behavior of the spacecraft’s instruments during the lunar twilight, scientists will gather valuable data that could help refine future designs for lunar rovers, spacesuits, and seals, all of which need to withstand the Moon’s harsh conditions.

The success of Blue Ghost 1is a testament to the growing role that private companies are playing in lunar exploration. NASA’s partnerships with companies like Firefly Aerospace show how public-private collaborations are accelerating the pace of innovation and reducing the costs associated with space missions. As companies gain more experience and repeat flights, they will continue to refine their technology, which in turn will reduce mission costs and shorten timelines.

The Blue Ghost mission not only marks a pivotal achievement for Firefly Aerospace but also contributes to the larger effort to build a sustainable human presence on the Moon. As more private companies enter the space race, they will help create a thriving ecosystem for lunar exploration, making it possible to scale operations more rapidly and efficiently.

#4 Re: Life support systems » Excess Oxygen » 2025-09-13 14:49:26

New liquid air storage system bottles electricity on demand, producing 10 tons daily

Korean researchers have unlocked a new way to bank clean energy and turn it back into power on demand.

Scientists at the Korea Institute of Machinery and Materials (KIMM) have developed Korea’s first homegrown Liquid Air Energy Storage system, which uses surplus electricity to chill air into liquid, store it, and later release it to generate power.

The team recently achieved the production of up to 10 tons of liquid air per day, representing a significant milestone in advancing the technology toward large-scale commercial viability.

Power on demand

When the grid has more electricity than it needs, the surplus is used to cool air to extremely low temperatures until it becomes liquid. This liquid air is stored in insulated tanks like a giant energy reserve.When demand spikes, the air is warmed again. As it rapidly expands about 700 times its liquid volume, the pressure drives turbines to generate electricity.

When demand spikes, the air is warmed again. As it rapidly expands about 700 times its liquid volume, the pressure drives turbines to generate electricity.

Led by Principal Researcher Dr. Jun Young Park, the KIMM team designed two key components entirely in-house.

A turbo expander that spins faster than 100,000 revolutions per minute and a cold box equipped with multi-layer insulation and a powerful vacuum to keep air at cryogenic temperatures.

These innovations enabled Korea’s first successful air liquefaction test for energy storage. It shows that liquid air storage can work using domestic technology.

“This is an essential step for Korea’s renewable future,” said Dr. Park. “Large-scale energy storage is the missing piece and our work shows LAES can deliver it without geographical limits.”

Most large-scale storage today relies on pumped hydro or compressed air. Both can be effective but they require mountains, valleys, or underground caverns. They also come with environmental trade-offs.

Liquid air avoids those problems. It can be built almost anywhere which makes it a flexible option for cities and industrial hubs. It also comes with added benefits. The extreme cold can be tapped for industrial cooling, and waste heat from factories can be reused to make the process more efficient.

A global race

Korea is not the only country chasing this technology. Companies in the UK, China, and the United States are already exploring liquid air as a storage medium. What makes KIMM’s achievement stand out is that it is fully homegrown.That is a critical step for Korea’s plan to build an energy superhighway to carry renewables across the nation.

The current system is modest compared to the country’s power needs. But its successful operation is proof of concept. If scaled up, bottling air could become one of the cleanest and most versatile ways to store renewable energy.

For now, it is still early days. But in a world desperate for long-duration storage, Korea’s breakthrough shows that the future of power might be hiding in plain sight.

#5 Re: Business Proposals » Mechanical Windmills » 2025-09-13 14:41:32

The life of man changed as energy store allowed for constant supply of what we needed. Its that storage that allowed for a change in our behaviour, no longer at the mercy of inconsistancy that solar, wind, even stream or river sourced energy input.

#6 Re: Interplanetary transportation » Concurrent (nested) Habitat rings » 2025-09-13 14:29:37

Nice html and the brackets from the copy paste of the AI outputted page.

#7 Re: Science, Technology, and Astronomy » Coil gun vs Rail gun military and civilian applications » 2025-09-11 17:12:59

#8 Re: Single Stage To Orbit » SSTO History Atlas and other single stage launchers » 2025-09-10 14:52:00

#9 Re: Human missions » Space Initive Launch Vehicle » 2025-09-10 14:45:18

The Space Shuttle That Never Flew: Lockheed’s LS-200

n 1966, the United States Air Force and Lockheed introduced the Star Clipper concept. At the time, it was “an Earth-to-orbit spaceplane based on a large lifting body spacecraft and a wrap-around drop tank.”

After 1966, NASA began a space program that included a permanently manned space station, a small base on the moon, and the hopes of a soon-to-be crewed mission to Mars. This is where the concept of a “logistics vehicle” emerged in order to lower the cost of space station operations. The vehicle’s role would be focused on changing crews on the space station on a weekly basis.

In 1967, a whole-day meeting was arranged to evaluate the logistics vehicle concept. The Air Force and NASA had already joined forces on a study of existing technologies in the “Integrated Launch and Re-entry Vehicle” project, or ILRV. The meeting resurfaced the ILRV research calling on the same industry partners to present different logistics vehicle concepts.

That’s when Lockheed submitted Star Clipper while General Dynamics introduced their Triamese and Chrysler SERV. Soon, NASA’s own teams joined in on the fun supporting mostly the “classic” flyback design.

Then in 1971 something happened that changed everything and brought the Star Clipper to the forefront. The maximum development budget was reduced by 50% by the Office of Management and Budget, going from a whopping $10 billion to a mere $5 billion.

This is when the Star Clipper became the most viable option as the costs for a stage-and-a-half design were much lesser because it involved the engineering of only one spacecraft. Despite this, in the end, it was not Lockheed’s version that would eventually be chosen to be built, but North American Aviation’s take on the concept.

#10 Re: Meta New Mars » GW Johnson Postings and @Exrocketman1 YouTube videos » 2025-09-10 14:19:57

almost sounds like they are just butting the tiles edges to each other rather than using a gap filler material.

#11 Re: Business Proposals » Mechanical Windmills » 2025-09-10 14:14:45

it could also be made to drive pistons for air compressing as well.

#12 Re: Meta New Mars » Housekeeping » 2025-09-10 14:13:46

todays post show in images how its not a single layer of materials in use.

#14 Re: Science, Technology, and Astronomy » Puzzle to Solve: Strength of Super Heavy Booster Wall » 2025-09-10 14:10:14

#15 Re: Business Proposals » Mechanical Windmills » 2025-09-09 17:00:56

I am reminded of those old westerns that I saw as a kid with the praire covered with them.

A western water pump windmill is a device powered by wind to draw water from a well and pump it to the surface, typically used on farms and ranches in the American West to provide water for homes, livestock, and crops. Key features include a tower, a rotatable tail for facing the wind, a self-governing mechanism to adjust sail area in high winds, and a pump rod connecting to a piston in a cylinder at the bottom of the well. Daniel Halladay's 1854 invention was the first commercially successful American model, revolutionizing settlement of the Plains by making water independence possible.

How it Works

1. Wind Capture:

The wind spins the mill's blades, which are designed to catch the wind and rotate the mechanism.

2. Self-Regulation:

A tail vane turns the mill into the wind. In strong winds, the mechanism automatically turns the blades partially out of the wind to prevent damage.

3. Pump Operation:

The rotational energy is transferred down the tower by a connecting rod to a pump.

4. Water Lift:

A piston on the end of this rod moves up and down, drawing water from the well to a storage tank or another location.

Historical Significance

Settlement:

Water pump windmills made settlement on the Great Plains and other parts of the West possible by providing a reliable, independent water source.

Agricultural Expansion:

They allowed farmers and ranchers to expand operations by watering large numbers of livestock and irrigating crops without being tied to natural water sources.

Iconic Status:

Windmills became a symbol of the American West, reflecting the ingenuity and hard work of homesteaders.

Key Innovations

Daniel Halladay (1854):

.

Invented the American-type windmill, which was smaller, cheaper, and self-governing, making it practical for settlers.

Materials:

.

Early models were primarily wood, but later versions incorporated metal blades and components, leading to increased durability and use.

Self-Governing Mechanism:

.

This feature allowed the windmill to function reliably in a wide range of wind speeds by automatically adjusting the sail's angle or size

#16 Re: Human missions » Starship is Go... » 2025-09-09 15:02:19

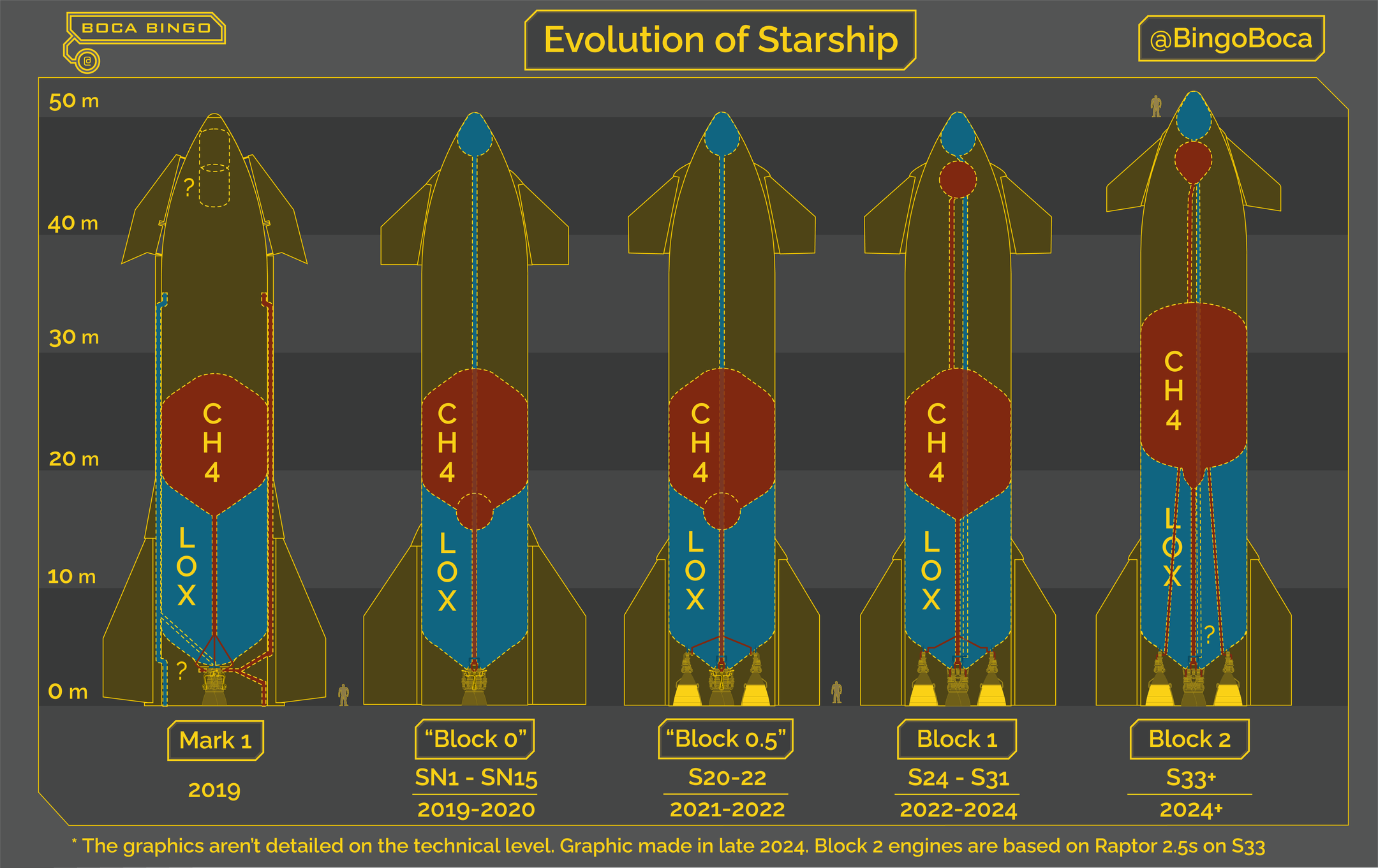

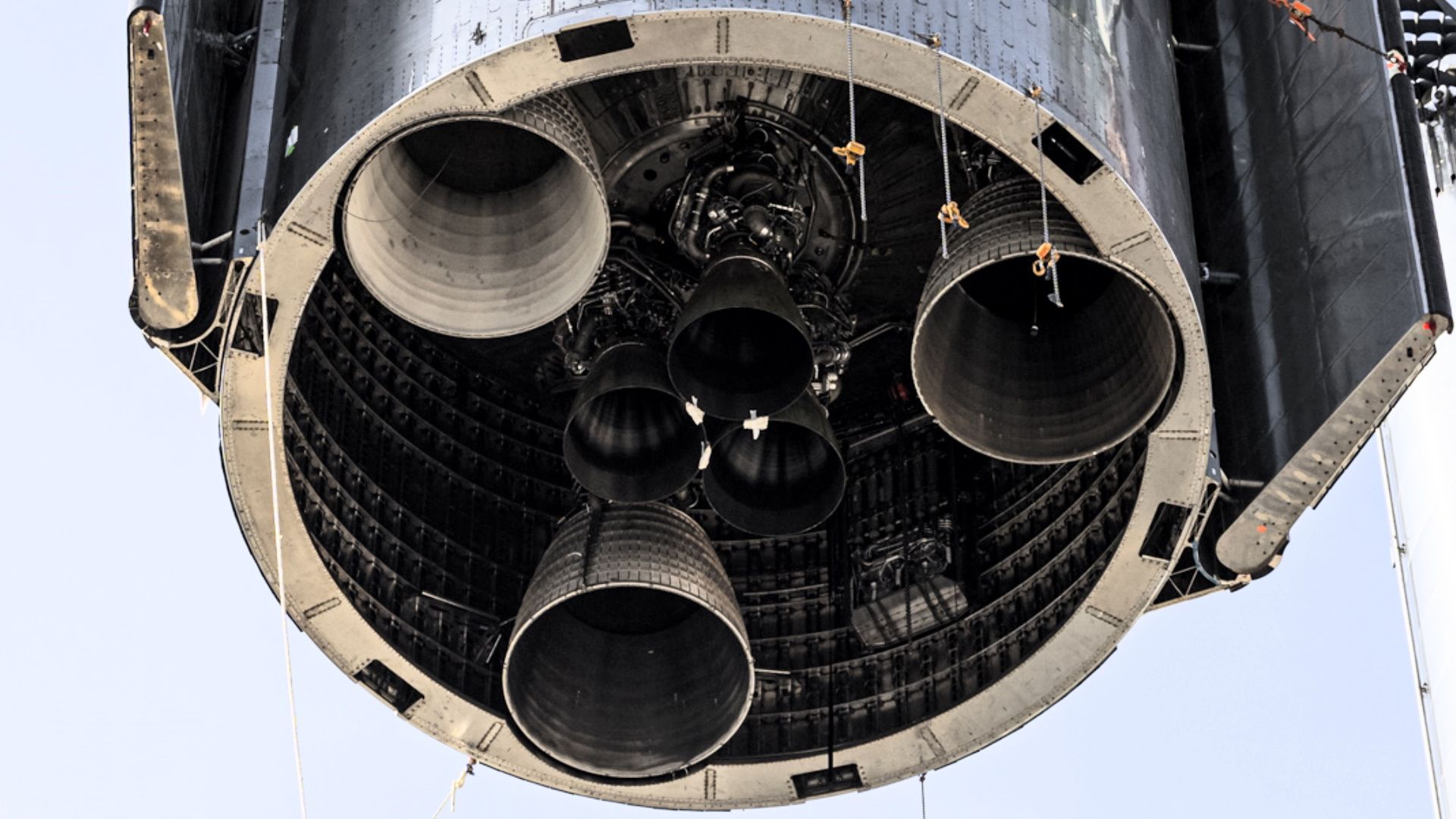

The current SpaceX Starship and Super Heavy booster have a stainless steel hull thickness of approximately 3.97 mm (0.156 in), and are constructed by welding together rings of stainless steel. This design marked a major shift from early carbon composite concepts for the rocket, which was originally known as the Big Falcon Rocket (BFR).

History of the Starship/BFR design

Initial carbon composite design: In 2018, early concepts for the BFR were built using carbon composites. At the time, early prototype sections were estimated to be between 12 and 25 mm thick.

Switch to stainless steel: Later in 2018, SpaceX announced the switch from carbon composites to stainless steel for the entire Starship and Super Heavy structure. Elon Musk cited reasons including lower cost, increased strength at cryogenic temperatures, and the ability of stainless steel to handle high temperatures.

First stainless steel prototypes: The first stainless steel prototypes used 301L stainless steel. Following pressure tests and iterative improvements, the alloy was updated to 304L stainless steel.

Evolution of hull thickness: The earliest steel prototypes, such as Starship SN1, were built with a 3.97 mm thickness. An anecdote from Elon Musk's biography describes his decision to push for thinner 4 mm tank walls over the nervous objections of engineers. Later, test articles like SN7.2 were briefly experimented with even thinner 3 mm steel, but recent production vehicles have remained at the 4 mm thickness.

Construction and thermal protection

Construction process: The 9-meter diameter hull is manufactured by rolling sheets of stainless steel into rings, which are then stacked and welded together.

Integrated structure: The stainless steel hull acts as both the external skin and the propellant tanks for the vehicle's liquid methane and liquid oxygen.

Heat shield for re-entry: While the steel can withstand high temperatures, the side of the Starship that faces the wind during re-entry is covered with approximately 18,000 hexagonal ceramic tiles for additional thermal protection.

Continuous development: SpaceX continues to iterate on the design and materials used. Following flight test 4, upgraded heat shield tiles were installed on the flight 5 Starship, along with a secondary ablative layer underneath the tiles for added protection against overheating

#17 Re: Science, Technology, and Astronomy » Puzzle to Solve: Strength of Super Heavy Booster Wall » 2025-09-09 14:58:33

It appears that the tank wall and hull walls are each of the same thickness to which the sregnth comes from the connecting area of both as it rises from the ground skyward.

The current SpaceX Starship and Super Heavy booster have a stainless steel hull thickness of approximately 3.97 mm (0.156 in), and are constructed by welding together rings of stainless steel. This design marked a major shift from early carbon composite concepts for the rocket, which was originally known as the Big Falcon Rocket (BFR).

History of the Starship/BFR design

Initial carbon composite design: In 2018, early concepts for the BFR were built using carbon composites. At the time, early prototype sections were estimated to be between 12 and 25 mm thick.

Switch to stainless steel: Later in 2018, SpaceX announced the switch from carbon composites to stainless steel for the entire Starship and Super Heavy structure. Elon Musk cited reasons including lower cost, increased strength at cryogenic temperatures, and the ability of stainless steel to handle high temperatures.

First stainless steel prototypes: The first stainless steel prototypes used 301L stainless steel. Following pressure tests and iterative improvements, the alloy was updated to 304L stainless steel.

Evolution of hull thickness: The earliest steel prototypes, such as Starship SN1, were built with a 3.97 mm thickness. An anecdote from Elon Musk's biography describes his decision to push for thinner 4 mm tank walls over the nervous objections of engineers. Later, test articles like SN7.2 were briefly experimented with even thinner 3 mm steel, but recent production vehicles have remained at the 4 mm thickness.

Construction and thermal protection

Construction process: The 9-meter diameter hull is manufactured by rolling sheets of stainless steel into rings, which are then stacked and welded together.

Integrated structure: The stainless steel hull acts as both the external skin and the propellant tanks for the vehicle's liquid methane and liquid oxygen.

Heat shield for re-entry: While the steel can withstand high temperatures, the side of the Starship that faces the wind during re-entry is covered with approximately 18,000 hexagonal ceramic tiles for additional thermal protection.

Continuous development: SpaceX continues to iterate on the design and materials used. Following flight test 4, upgraded heat shield tiles were installed on the flight 5 Starship, along with a secondary ablative layer underneath the tiles for added protection against overheating

#18 Re: Human missions » Starship is Go... » 2025-09-08 16:03:47

Each stage also has seperate 100mT fuel for return to earth landing in header tanks.

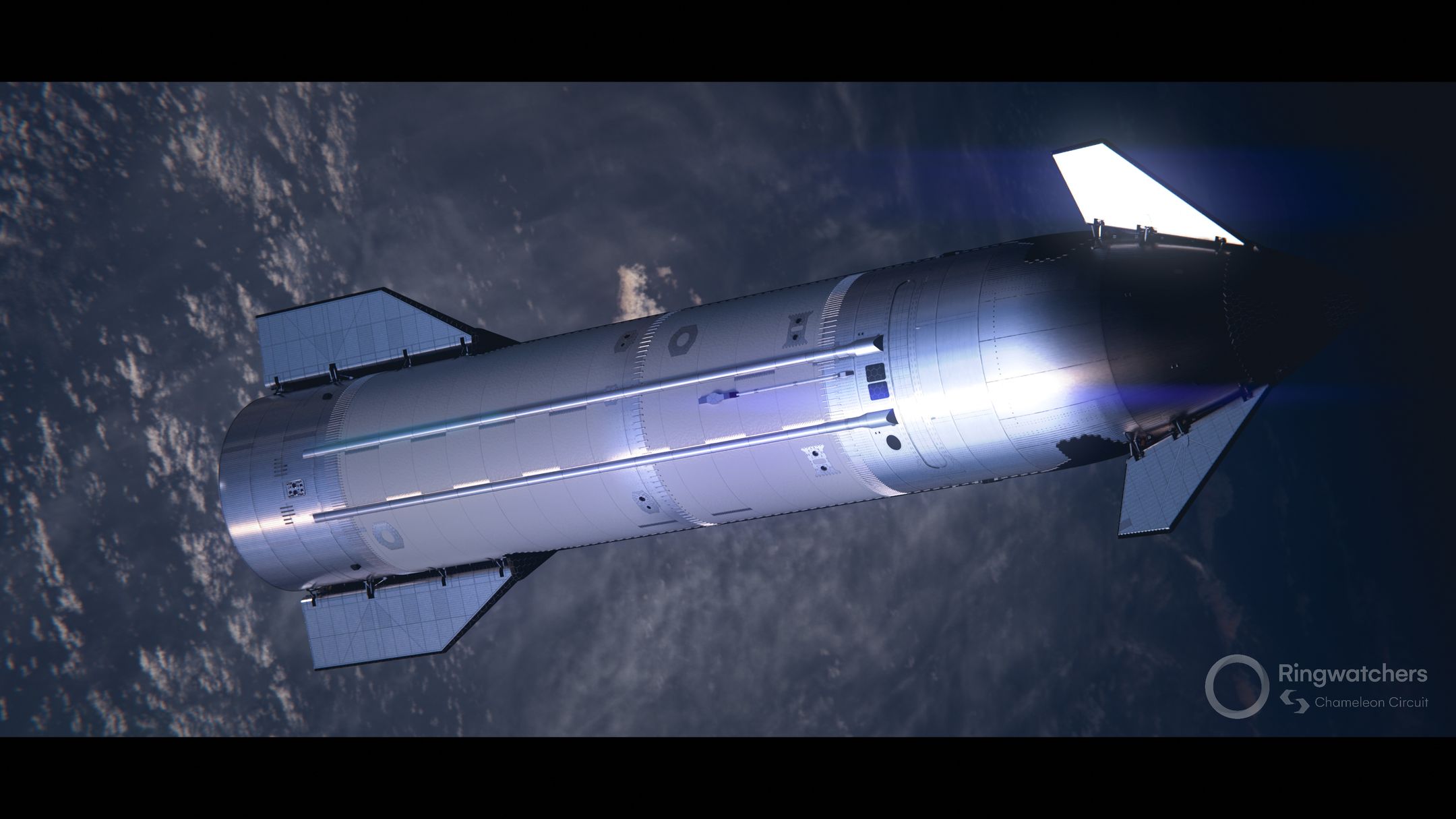

o build the fuel tank and structure of Starship, SpaceX manufactures stainless steel rings, assembles them into larger sections with domes, and stacks these sections vertically. Advanced robotic welding, internal stiffeners, and a common bulkhead are key to integrating the tank's pressure vessel with the overall vehicle structure.

Manufacturing steel components

Steel coils: The process begins with delivery of 11-ton coils of 3.97 mm (0.156 in) thick stainless steel to the Starbase production facility.

Forming rings: Robotic machinery unrolls and forms the steel into 9-meter diameter circles, then welds them into continuous rings that are 1.83 meters (6 ft) tall.

Fabricating domes: Tank domes, which act as the top and bottom caps of the tanks, are made from stamped and welded steel panels. This includes the crucial common bulkhead that separates the liquid oxygen (LOX) and liquid methane (CH4) tanks.

Welding and assembly

Robotic welding: SpaceX uses advanced robotic welding techniques, including laser, electron beam, and friction-stir welding, to join the steel sections. This ensures high-precision, stronger welds compared to earlier manual welding.

Section stacking: Individual rings are stacked and welded into larger barrel sections. Domes are integrated into these sections, often on the ground, before final vertical stacking.

Vehicle stacking: A Starship's assembly progresses from the top down. Sections like the nosecone and header tanks are added to the common dome section, which is then joined to the main tank and engine sections.

Integrating structural integrity

Internal stiffeners: Internal stringers (axial reinforcements) and baffles are welded inside the tanks. This improves the vehicle's structural rigidity, prevents the propellant from sloshing, and allows the structure to support its own weight without internal pressure.

Common bulkhead: A highly optimized, mass-saving common bulkhead serves as the top of the LOX tank and the bottom of the CH4 tank, eliminating the need for a separate tank wall between them.

Engine thrust structure: The aft dome of the LOX tank is integrated with a heavily reinforced thrust puck. This specialized structure transfers the immense thrust from the Raptor engines directly into the vehicle's frame during flight.

Testing and completion

Proof testing: After the structure is assembled, it undergoes cryogenic proof testing, where it is filled with liquid nitrogen and pressurized beyond flight levels. This confirms the vehicle's structural integrity at cryogenic temperatures.

Engine installation: Following successful testing, the Raptor engines are installed, along with plumbing, avionics, and flight-control surfaces like the flaps.

Thermal protection system: The heat shield tiles are then attached to the exterior of the vehicle to protect it during atmospheric re-entry

https://www.teslarati.com/spacex-starsh … rage-tank/

Fuel tank as part of structure

#19 Re: Meta New Mars » Housekeeping » 2025-09-08 15:59:12

https://newmars.com/forums/admin_bans.php

enter * in the username box and hit submit to get the list

these are the banned users but they are not a group, each user is removed from the banned table only 1 at a time.

https://newmars.com/forums/admin_users.php

enter * in the username box and hit submit to get the list

this shows the Title/Statuss and those are inactive, members ect including the banned identies.

you can change the group to inactive but it is still a banned user if not removed from the individual under the first list.

The users m* that were change have not had info changed for the profile. I think we would still want to change the username and default the email to keep it locked out in the profile.

#20 Re: Human missions » Human Business and flight plan for mars » 2025-09-07 18:13:35

How much food and water do you need for a one-year stay on Mars?

Nutritionists recommend that you drink at least eight 8-ounce glasses of water a day. Let's say you might be a tad thirstier. So for a two-year mission, a person would need about 456 gallons (1,726 liters) of water.

If you want to be a minimalist about it, you can get your calories from white sugar, your fat from vegetable oil, your protein from protein powder and your fiber from bran. In this case, each person on the two-year journey would need:

602 pounds (274 kilograms) of sugar

133 pounds (60 kilograms) of vegetable oil

96 pounds (43 kilograms) of protein

40 pounds (18 kilograms) of fiber

If you formed all of those ingredients into bars or kibble, you would need about 880 pounds, or 400 kilograms, of food per person. When you buy dog food at the grocery store, a typical large bag holds 20 pounds (9 kilograms). So you would need 44 large dog-food-sized bags to keep one person alive for two years.

Bad example but the point is we are going to need to solve it for 3 different legs and staging of what we need.

https://en.wikipedia.org/wiki/Space_food

https://ift.onlinelibrary.wiley.com/doi … 10.01982.x

The different forms in which food is provided include the following:

1

Thermostabilized—this process, also known as the retort process, heats food to a temperature that renders it free of pathogens, spoilage microorganisms, and enzyme activity. NASA thermostabilized products include pouched soups, sides, desserts, puddings, and entrees.2

Irradiated—irradiation is not typically used to process foods to commercial sterility. However, NASA has received special dispensation from the Food and Drug Administration (FDA) to prepare 9 irradiated meat items to commercial sterility (FDA 2009).3

Rehydratable—both commercial and internally processed freeze-dried foods are included in the NASA food provisions and then rehydrated during the mission using the potable water supply. Rehydratable foods are typically side dishes, such as spicy green beans and cornbread dressing, or cereals. Ambient and hot water are available to the crew for rehydration of these items.4

Natural form—natural form foods are commercially available, shelf stable foods. The moisture of the foods may range from low moisture (such as almonds and peanuts) to intermediate moisture (such as brownies and dried fruit), but all have reduced water activity, thus inhibiting microbial growth. These foods help to round out the menu by providing very familiar menu options, additional menu variety, and foods requiring no preparation time.5

Extended shelf life bread products—items, such as scones, waffles, tortillas, and dinner rolls, can be formulated and packaged to give them a shelf life of up to 18 mo. Like the natural form foods, breads add to menu variety and address crewmembers’ desire for familiarity.6

Fresh food—foods such as fresh fruits and vegetables, which have a short shelf life, are provided on a limited basis, more for psychological support than as a means to meet dietary requirements.7

Beverages—the beverages currently used on the International Space Station (ISS) and the Space Shuttle are either freeze-dried beverage mixes (such as coffee or tea) or flavored drinks (such as lemonade or orange drink). The drink mixes are weighed and then vacuum sealed inside a beverage pouch. In the case of coffee or tea, sugar or powdered cream can be added to the pouch before sealing. Empty beverage pouches are also provided for drinking water.

#21 Re: Human missions » Human Business and flight plan for mars » 2025-09-07 16:07:28

Only 13 pages but full of information

Human Mars Mission Design – The Ultimate Systems Challenge

Mars Landing Vehicles: Descent and Ascent Propulsion Design Issues

AI Overview

For a two-manned Mars mission, food and supplies must cover a multi-year journey, including six months of transit each way and a long stay on the surface. Astronauts would rely on a hybrid system: a supply of packaged, shelf-stable food and advanced regenerative systems for producing fresh food, recycling water, and managing waste.Food system

The food system must be nutritious, reliable, and varied to prevent "menu fatigue," which can lead to inadequate calorie intake.

During transit (approx. 6 months each way)

Packaged meals: The crew would rely on food similar to that on the International Space Station (ISS), but with a shelf life of three to five years. Examples of current space foods include thermostabilized pouches, rehydratable meals, and intermediate-moisture items like nuts and crackers.Menu variety:

Menus are typically on a weekly rotation to provide variety and psychological comfort. Food scientists at NASA's Space Food Systems Laboratory develop and test space foods for nutritional value, taste, and safety.

Nutritional supplements: Vitamins and minerals, particularly Vitamin D, Vitamin K, and calcium, are crucial for mitigating bone and muscle loss in microgravity.Low-sodium food:

To prevent excessive calcium excretion, a negative effect of high sodium intake, space food is being reformulated to reduce sodium content.On Mars' surface (approx. 18 months)

In-situ food production:

Crew members would grow crops in a specialized habitat to supplement pre-packaged meals. This provides fresh produce, reduces reliance on Earth, and offers psychological benefits.Potential crops:

NASA's analog missions test crops like leafy greens, herbs, and small fruits. The European Space Agency (ESA) has also researched staple crops such as potatoes, wheat, and soybeans.Food processing:

A Martian galley would allow astronauts to process and cook the harvested ingredients.Waste management:

Used food packaging must be efficiently managed since there is no way to incinerate it. Lighter materials with sufficient barrier properties will be used.Supplies and equipment

In addition to food, a Mars mission requires highly reliable and efficient life support systems, medical gear, and crew equipment.

Life support and environmental controlWater recycling systems:

Closed-loop systems are essential for recycling water from urine, wastewater, and humidity. Water can also be extracted from Martian soil and ice.Atmosphere revitalization:

Regenerative systems would scrub carbon dioxide (CO2) from the air and use it to produce oxygen (O2). Crop growth would also contribute to oxygen production.Radiation shielding:

Specialized gear or materials are needed to protect the crew from high radiation exposure during transit and on the Martian surface.Temperature control:

Reliable systems for managing temperature and humidity inside the habitat.Health and hygiene

Medical kit:

A lightweight, compact, but comprehensive medical kit is necessary. Researchers use predictive models to determine the most likely health issues and prioritize supplies.Exercise equipment:

Compact exercise gear, such as resistance bands, is vital for combating muscle atrophy and bone loss in a low-gravity environment.Personal hygiene:

Toothbrushes, wet wipes, and sanitizer. Water-conserving systems are essential for laundry and personal cleaning.Mission and surface exploration

Spacesuits:

Extravehicular Activity (EVA) suits are required for surface exploration and emergencies.Power systems:

Reliable and lightweight power sources, such as fission surface power systems, are needed to power all equipment.

Communication: Equipment for constant communication and navigation.Scientific equipment:

Tools and instruments for research and exploration

#22 Re: Human missions » Stoke Space » 2025-09-07 15:56:25

#23 Re: Human missions » Starship is Go... » 2025-09-06 16:54:34

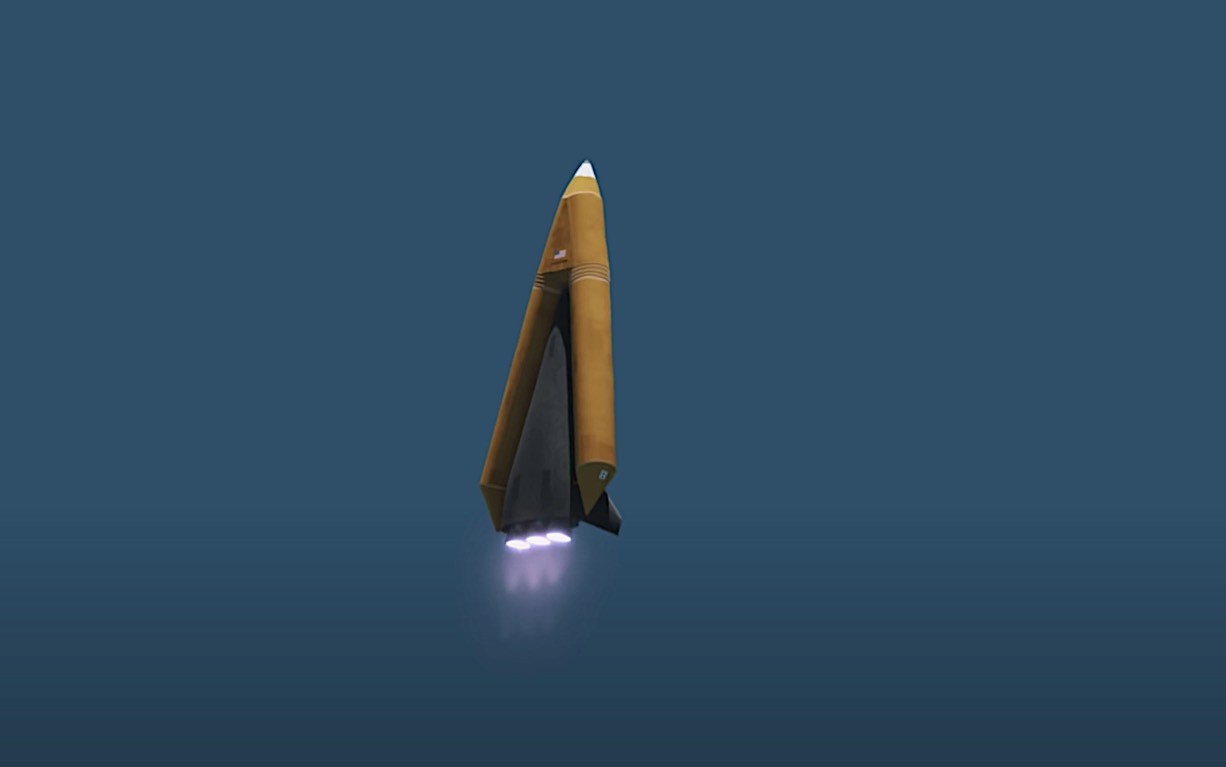

The colors of the starship reminds me of the wind tunnel testing Nasa would do on a model. So this method is pretty ugly.

#24 Re: Science, Technology, and Astronomy » Drag Aerodynamic » 2025-09-06 13:10:35

its why going with a large heat shield diameter for mars is favored for getting more to the surface of mars as mass also plays into the equation.

#25 Re: Not So Free Chat » Huricane season 2025 » 2025-09-05 17:22:37

Starting to get wild and crazy.

Gulf on alert for hurricanes during 2nd half of September