New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#2176 2025-09-04 15:18:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

The tile material sure did not standup to the entry but a shuttle tile system would require lots more prep time. The transpiring would mean thicker metals to widthstand the boiling pressure between the layers that would hold the water or other working fluids.

Offline

Like button can go here

#2177 2025-09-05 10:01:45

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Starship is Go...

Does anyone outside SpaceX really know what those so-called "metallic tiles" really are? I have not heard, myself.

They would appear to have worked well enough on Flight 10. And fewer tiles seem to have been lost on Flight 10, although that judgement is affected by the better camera coverage on Flight 10. I think the tiles on Flights 4, 5, and 6 were some kind of ceramic. But details like that were rarely given out.

Those are the four (flights 4, 5, 6, and 10) that have actually made it back through entry, descent, and landing. Flights 1, 2, and 3 were destroyed before ever reaching space. Flights 7, 8, and 9 were destroyed because they were tumbling out of control when they entered.

The worrisome thing from Flight 10 was the sudden creation of a hole in the engine bay skirt, in a process that appeared to be explosive, to the camera. Nobody yet seems to know what that was. It is the unknowns like that, which are the most worrisome things.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#2178 2025-09-05 15:13:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

AI Overview

The Bestagons: Starship's Upgraded Heat Shield

Starship currently uses black, hexagonal ceramic heat shield tiles, likely a derivative of the TUFROC material, mounted on a stainless steel hull, to protect it from re-entry temperatures. For the future, SpaceX is exploring a metallic heat shield technology that utilizes the spacecraft's liquid methane to perform film cooling.Current Ceramic Tiles

Composition: The tiles are made of a toughened, porous, fibrous ceramic material, possibly a version of the TUFROC (Toughened Unipiece Fibrous Reusable Oxidation-Resistant Ceramic) used on other spacecraft.

Color: They are black to help radiate heat away from the vehicle more quickly.

Structure: The tiles are mounted directly onto Starship's stainless steel body.

Function: They are designed to withstand the extreme temperatures of atmospheric re-entry and can be reused for multiple missions.

Future Metallic Heat Shield

Concept:

SpaceX is developing and experimenting with a metallic heat shield system.

Mechanism:

This system incorporates tiny holes in the metallic plates. During re-entry, the liquid fuel (water or methane) seeps through these holes, creating a film that carries away heat and prevents the underlying metal from melting.

Advantages:

Metallic shields offer greater durability, are easier to manufacture in larger sections, and are simpler to repair or replace than ceramic tiles.

Material:

While experimental, the material used for this project is expected to be a heat-resistant alloy or stainless steel.

AI Overview

Starship SN9's Heatshield : r/SpaceXLounge

Starship's metal tiles are composed of SpaceX's proprietary "30X" stainless steel alloy, an evolution from commercially available 301 and 304L grades, featuring custom refinements with potentially higher chromium content for improved corrosion resistance and strength. This proprietary alloy was developed in-house to overcome limitations of previous materials, and while its exact composition is undisclosed, it is an austenitic stainless steel tailored for the extreme conditions of spaceflight.Evolution of Starship's Materials

Early stages:

Initially, Starship used commercially available stainless steel alloys, such as 301 and 304L.

Transition to proprietary alloy:

SpaceX eventually transitioned to a custom alloy, internally designated "30X," for the vehicle's construction.

Current material:

The current standard for Starship and the Super Heavy booster is this proprietary stainless steel.

Characteristics of the "30X" Alloy

Proprietary development: The "30X" alloy is a custom formulation developed by SpaceX.

Enhanced performance: It incorporates custom refinements and potentially higher chromium content than standard grades, leading to increased resistance to corrosion and degradation.

High-strength properties: The material is an austenitic stainless steel designed to withstand the harsh conditions of space launch and re-entry.

Why Stainless Steel for Starship?

Cost-effectiveness:

Stainless steel is relatively inexpensive compared to other high-strength materials like titanium.

Machinability:

It is easier to machine and work with, which is crucial for constructing large structures like Starship.

Cryogenic strength:

Stainless steel maintains its strength at cryogenic temperatures, essential for spaceflight operations.

Resilience:

The alloy's ability to form a protective oxide layer prevents corrosion and degradation, even after multiple missions

Offline

Like button can go here

#2179 2025-09-05 17:10:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

Based on recent SpaceX flights, the white residue on Starship's nose cone after reentry is from ablative insulation material that became exposed to the high heat of atmospheric entry. This occurred in areas where SpaceX deliberately removed some of the protective tiles for testing.

For example, after a late August 2025 flight, SpaceX CEO Elon Musk confirmed that the discoloration was the result of a thermal protection system experiment.

The purpose of the experiment

Testing different heat shield designs: SpaceX has been experimenting with various thermal protection configurations. On recent flights, the company has intentionally removed some of Starship's heat shield tiles to test different materials, including metallic tiles, and to see if other systems can compensate for missing tiles.

Exposing the insulation: In the areas where the tiles were removed, the underlying white ablative insulation was directly exposed to the high-temperature plasma of reentry.

Creating a white vapor deposit: The extreme heat caused some of this insulation material to vaporize. This vapor then re-condensed as a white coating on the cooler sections of the nose cone.

A different kind of test

The ablative insulation that appeared white after reentry is a departure from the polished steel Starship prototypes. For certain operational versions, like the Human Landing System (HLS) for the moon, a white thermal coat will be used. This is done to reflect sunlight and help with temperature regulation while in space. However, the post-reentry white residue is a byproduct of a specific experimental process, not the intended final coloration

AI Overview

Starship turned orange after re-entry due to experimental metallic heat shield tiles that oxidized, forming iron oxide. This orange color is a result of these metallic test tiles reacting with atomic oxygen in the atmosphere at high speeds, while white patches were from deliberately removed tiles exposing white insulation. This discoloration indicates the success of these new metallic tiles and insulation testing during Flight 10, with Elon Musk confirming the phenomenon was intended to observe these materials.

Details of the Orange Coloration

Metallic Test Tiles:

The primary cause of the orange coloration was the use of experimental metallic heat shield tiles on the flight.

Oxidation:

These metallic tiles, likely stainless steel, oxidized rapidly during re-entry at Mach 25, reacting with the atmospheric oxygen to form a distinct orange, iron oxide layer.

Intended Experiment:

SpaceX deliberately placed these metallic tiles in specific areas and intentionally removed some ceramic tiles to expose the underlying insulation.

White Areas and Insulation

Deliberate Removal:

The white areas seen on Starship are from areas where the standard ceramic heat shield tiles were intentionally removed to test the white insulation beneath.

White Insulation:

This insulation, made of heat-resistant composites, was designed to withstand re-entry temperatures and reflect heat. Unlike the metallic tiles, it did not contain easily oxidizable metals, causing it to retain its white color.

Significance of the Event

Testing and Reusability:

The orange discoloration is not a sign of failure; rather, it's a visual indication of SpaceX's ongoing material science experiments to develop and test new thermal protection systems for future Starship missions, aiming for increased reusability.

Confirmation of Success:

Elon Musk confirmed that the heat shield tiles largely stayed attached, suggesting the latest upgrades are performing well, despite the unusual colors.

Offline

Like button can go here

#2180 2025-09-05 17:11:15

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

Offline

Like button can go here

#2181 2025-09-05 20:02:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,499

Re: Starship is Go...

Hypersonic Materials and Structures

All those new materials and fabrication methods under T&E 10 years ago are now fairly standard for reentry TPS. Starship could be using any of those new TPS materials, most likely some combination of them.

Offline

Like button can go here

#2182 2025-09-05 23:43:50

Re: Starship is Go...

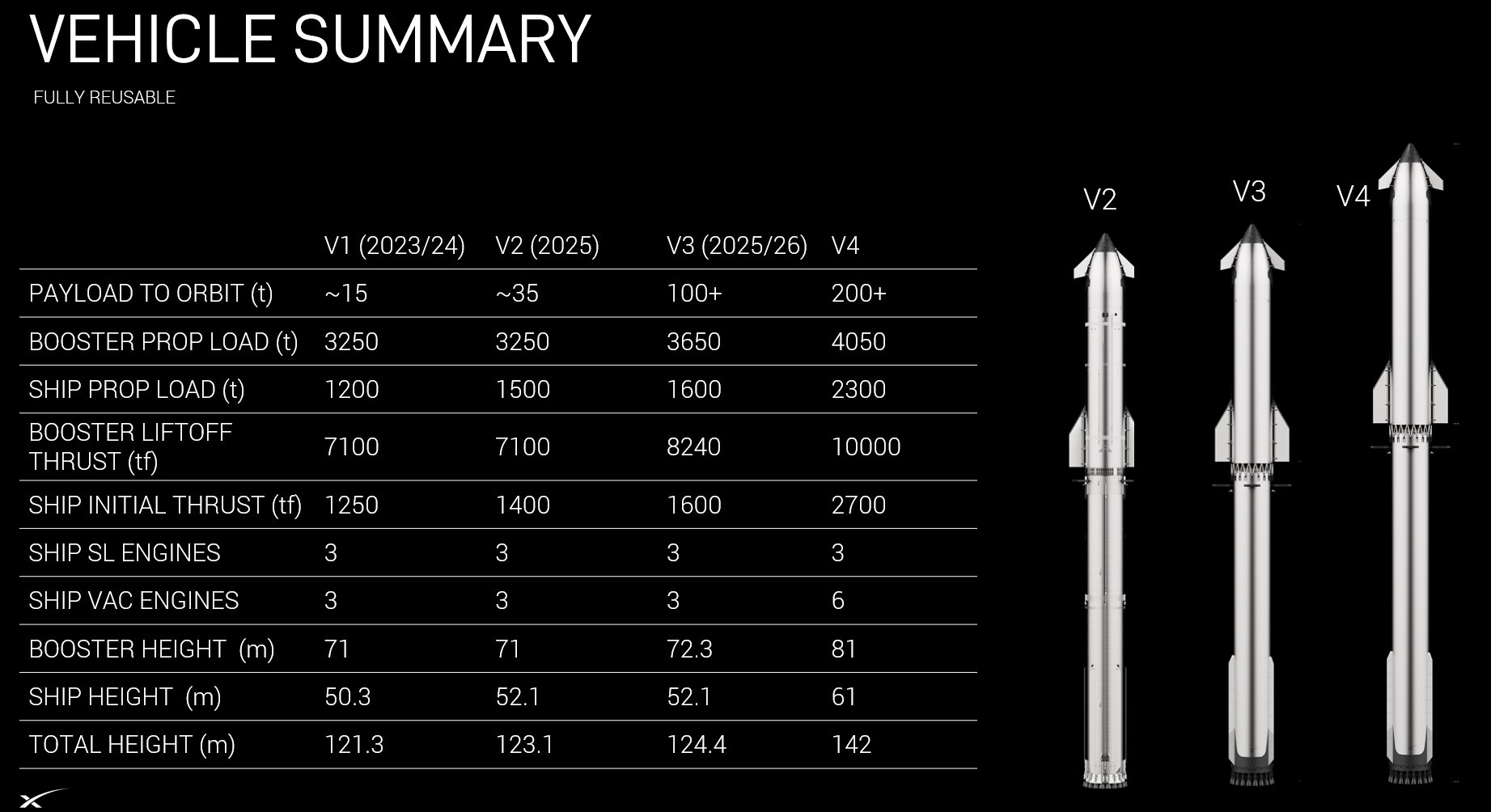

SpaceX spent billions developing Starship version V1 getting a rocket 10 times the size of the Falcon 9 and it wound up having less payload than the Falcon 9.

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2183 2025-09-06 00:46:09

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,280

Re: Starship is Go...

Well, I am not sure I understand your intention, but...

Isn't that like saying VOID is no good because in grade school, he was unable to hold a full-time job?

But so, far my impression is that SpaceX has self-funded, by providing value and attracting investors. Yes, they have gotten some grants from the government, but have also provided support for National Security, and so then also provided protection for NATO, and ultimately the E.U.

Reptiles may on occasion eat their young. But the higher the life form, supposing that humans are rather high, then the more resources are invested in childhood for a higher quality result.

The probable offshoots from Starship when it grows up will be enormous, and Europe will benefit from it as well.

Ending Pending ![]()

Last edited by Void (2025-09-06 00:52:05)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#2184 2025-09-06 12:10:06

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Starship is Go...

Beware the AI-generated results. It is confusing the hull construction materials with the heatshield materials.

All I know for sure is that earlier flights used some sort of ceramic tiles, probably resembling the outer layer of a Tufroc tile. The stainless steel hull can accept a higher temperature from the inward conduction through the denser ceramic, while the aluminum hull of X-37B could not; that's why the Tufroc tiles on the nose and leading edges of X-37B were two-layer, with a lower density underlayer. The denser outer ceramic can take a higher temperature, so they make it black to radiate away heat efficiently.

Somewhere along the line the last few flights, SpaceX has transitioned to what Musk termed a "metallic tile", whatever that really means. It's still put on the hull as tiles, you can see the joints. But I have no clue what they are actually made of, or how. Neither does anyone else outside SpaceX, near as I can tell. And the AI's certainly do not know. They don't even comprehend the question properly.

As for whether this was all worth it, 4 out of 10 mission successes all the way through reentry, and 7 out of 10 partial successes that made it into space at all, is actually a pretty damned good track record for a development flight test program of an advanced vehicle design that really pushes the state of the art rather hard. Complaining about low payload masses out of rapidly-evolving still-highly-experimental vehicles strikes me as grasping at straws for something to complain about!

I think they did really good on Flight 10, and pretty good all through the testing, even with the spectacular failures. The early histories of Atlas, Titan, Juno, Jupiter, Thor, and several others was actually rather similar. It's just what happens when you push the state of the art hard, with experimental flight testing the only real way to get credible results.

GW

Last edited by GW Johnson (2025-09-06 12:22:08)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#2185 2025-09-06 16:54:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

The colors of the starship reminds me of the wind tunnel testing Nasa would do on a model. So this method is pretty ugly.

Offline

Like button can go here

#2186 2025-09-06 22:58:22

Re: Starship is Go...

It would be like spending all the money they did on the Falcon 9 and winding up with a rocket of less payload than the Falcon 1. We would say they took a bad engineering approach to the development of the larger rocket.

Bob Clark

Last edited by RGClark (2025-09-06 23:02:17)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2187 2025-09-07 07:49:57

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,280

Re: Starship is Go...

https://en.wikipedia.org/wiki/Troll_doll

Image Quote:

SLS Block 1 can lift 95 Tons, after all that money.

But it is Apples and Oranges. I think it is becoming apparent that Stainless Steel was a good choice, as it helps with the Heat Shield, (Probably).

I think S. Steel with the foundation and several other features added to it could make it reusable. Probably not per hour usable, but in the beginning reasonably reusable.

V3 100+ in 2025/2026, (We hope).

I think it has not even been realized how valuable "Expendable/Not Really" is going to be as well.

??? 250+ Tons: "Expendable/Not Really".

Ending Pending ![]()

Last edited by Void (2025-09-07 07:57:03)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#2188 2025-09-07 09:14:24

Re: Starship is Go...

It would be like NASA spending billions on the Saturn V to take man to the Moon. And the Saturn V they came up with had less payload than the Gemini-Titan that could only get the Gemini capsule to LEO.

Bob Clark

Last edited by RGClark (2025-09-07 16:34:38)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2189 2025-09-07 09:30:49

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,280

Re: Starship is Go...

I want to make sure that I do not profess to be proficient at rocket science, but if you can tolerate that, then we can talk.

Dr. Zubrin wants a "Mini-Starship". That would have one sea level and one vacuum engine.

I think Rocket Lab could eventually make a Moonship that could be carried to orbit or suborbital and could then go to the Moon.

I think Stoke Space might be able to upsize their NOVA ship.

So, then beyond what SpaceX plans to do with their 1st and 2nd stages to make money and to send the 2nd stage to Mars, these options may emerge.

And I speculate on 2 options:

1) Do, an "Expendable/Not Really" on the 2nd stage to get the "3rd" stage poised to do it's maximum capability. I don't really consider this to be expendable unless you de-orbit the 2nd Stage. The materials of the 2nd stage may be of some value in LEO.

2) Do suborbital with the 2nd Stage and land it. Send the "3rd" stage to orbit from suborbital. This then reduces the amount of heating for the 2nd Stage. But you probably need a deal with someone on the other side of the planet for landing and launching the Starship. (Maybe not the Superheavy).

One thing that interests me a lot is the idea of a Rocket Lab Carbon 3rd Stage to send robots to the Moon.

In that case you could use the Carbon from one ship to make Methane for another ship to take off from the Moon. That presumes the Lunar water is accessible to make the Methane with.

Probably with the advent of robots on the Moon, the total number of humans needed on the Moon would be small. Mostly for research.

So, I have high hopes for the space industry in the future, if we can keep the white-collar old-world type cannibals from eating the profits.

Ending Pending ![]()

I see Saturn V could lift about 150 tons to LEO to stage a Moon mission. I think that is going to be in reach. That and more.

Ending Pending ![]()

Last edited by Void (2025-09-07 09:45:01)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#2190 2025-09-08 12:23:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,073

Re: Starship is Go...

Inspired by recent (September 2024) discussion of alternatives to stainless steel for construction of large spacecraft, I asked Google to estimate the mass of a fully loaded Starship system ready to launch:

AI Overview

A fully loaded Starship and Super Heavy has a total mass of approximately 5,000,000 kg (5,000 metric tons) before launch. This total consists of the Super Heavy booster, the Starship upper stage, the onboard propellant, and the payload.

Breakdown of the total mass

Super Heavy booster: Approximately 3,675,000 kg when fully fueled with liquid methane and liquid oxygen.

Starship upper stage: Approximately 1,300,000 kg when fully fueled.

Total mass: When stacked and fully fueled, the combined vehicle is about 5,000,000 kg at liftoff.

Note: The total mass can vary depending on the specific Starship variant and the amount of payload carried.

In a recent post in the Google Meeting topic, kbd512 estimated the thickness of the stainless steel wall of Super Heavy as 4 mm.

Whatever the thickness may be, the entire 5,000,000 Kg must be born by the edge of the Super Heavy wall that is in contact with the launch platform.

Whatever the thickness, it is clearly able to support 5,000,000 Kg, so the compression strength of stainless steel has not been exceeded.

Diamond is the form carbon takes when subjected to sufficient pressure.

I asked Google to write a short summary of diamond making using high pressure, and it came back with news of a low pressure way to make diamond, in addition to the requested pressure values.

A new method of making diamonds doesn't require extreme pressure

Artificial diamonds are typically made using the HPHT method, which requires extremely high pressures, around 5 to 6 gigapascals (GPa), or about 50,000 to 60,000 times atmospheric pressure, to replicate natural diamond formation conditions. However, a newer low-pressure method called Chemical Vapor Deposition (CVD) can produce diamonds at or near atmospheric pressure, although it is not considered a "high-pressure" technique.

High-Pressure High-Temperature (HPHT) Method

Pressure: Approximately 5 to 6 gigapascals (GPa).

Temperature: Around 1,400 to 1,500 degrees Celsius.

Process: This method replicates natural diamond formation by subjecting carbon to intense heat and pressure in a controlled environment.

Equipment: Involves large presses that can weigh hundreds of tons to achieve the necessary pressure.

Chemical Vapor Deposition (CVD) Method

Pressure: Significantly lower, often near atmospheric pressure.

Temperature: Lower than HPHT, around 1,025 degrees Celsius.

Process: Carbon-rich gas is used to grow diamond crystals, often layer by layer, onto a diamond seed.

Equipment: Does not require the massive high-pressure equipment of HPHT.

A New Atmospheric Pressure Method

A new technique has been developed that synthesizes diamonds without extreme pressure.

This method uses a liquid metal alloy of gallium, iron, nickel, and silicon exposed to carbon-rich gases like methane.

It can produce diamonds at normal atmospheric pressure and cooler temperatures than HPHT.

To round out this post about material able to hold 5,000,000 kg, here is a short summary by Google of the stainless steel that is thought to be in use by SpaceX:

The specific compression strength of the proprietary "30X" stainless steel used in the SpaceX Super Heavy rocket isn't publicly disclosed, but it's a high-performance, cold-rolled stainless steel alloy developed to withstand extreme conditions. While standard 304L stainless steel has a yield strength of roughly 200-250 MPa and a tensile strength of around 500-700 MPa, the 30X alloy is significantly stronger, especially at cryogenic temperatures. The cold-rolling process increases its strength to be much closer to its tensile strength, a key factor for the rocket's structural integrity.

Why this alloy is used:

High Strength at Cryogenic Temperatures:

The chrome-nickel content in the 30X alloy increases its strength by 50% at the very cold temperatures found in space, without becoming brittle.Heat Resistance:

The stainless steel also performs well under the high-heat conditions of atmospheric re-entry.Cost-Effectiveness and Workability:

Compared to materials like carbon fiber, stainless steel is significantly cheaper to produce and easier to work with, which is crucial for the rapid, high-volume production needed for Starship.Durability for Rapid Turnaround:

Its robust nature allows for quick refurbishment between launches, a core principle of SpaceX's design.Strength Considerations:

The high compression loads on the lowest part of the rocket are handled by this strengthened stainless steel.While the specific numbers are proprietary, the material was chosen and optimized to exceed the capabilities of standard stainless steel grades for this application.

(th)

Offline

Like button can go here

#2191 2025-09-08 16:03:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

Each stage also has seperate 100mT fuel for return to earth landing in header tanks.

o build the fuel tank and structure of Starship, SpaceX manufactures stainless steel rings, assembles them into larger sections with domes, and stacks these sections vertically. Advanced robotic welding, internal stiffeners, and a common bulkhead are key to integrating the tank's pressure vessel with the overall vehicle structure.

Manufacturing steel components

Steel coils: The process begins with delivery of 11-ton coils of 3.97 mm (0.156 in) thick stainless steel to the Starbase production facility.

Forming rings: Robotic machinery unrolls and forms the steel into 9-meter diameter circles, then welds them into continuous rings that are 1.83 meters (6 ft) tall.

Fabricating domes: Tank domes, which act as the top and bottom caps of the tanks, are made from stamped and welded steel panels. This includes the crucial common bulkhead that separates the liquid oxygen (LOX) and liquid methane (CH4) tanks.

Welding and assembly

Robotic welding: SpaceX uses advanced robotic welding techniques, including laser, electron beam, and friction-stir welding, to join the steel sections. This ensures high-precision, stronger welds compared to earlier manual welding.

Section stacking: Individual rings are stacked and welded into larger barrel sections. Domes are integrated into these sections, often on the ground, before final vertical stacking.

Vehicle stacking: A Starship's assembly progresses from the top down. Sections like the nosecone and header tanks are added to the common dome section, which is then joined to the main tank and engine sections.

Integrating structural integrity

Internal stiffeners: Internal stringers (axial reinforcements) and baffles are welded inside the tanks. This improves the vehicle's structural rigidity, prevents the propellant from sloshing, and allows the structure to support its own weight without internal pressure.

Common bulkhead: A highly optimized, mass-saving common bulkhead serves as the top of the LOX tank and the bottom of the CH4 tank, eliminating the need for a separate tank wall between them.

Engine thrust structure: The aft dome of the LOX tank is integrated with a heavily reinforced thrust puck. This specialized structure transfers the immense thrust from the Raptor engines directly into the vehicle's frame during flight.

Testing and completion

Proof testing: After the structure is assembled, it undergoes cryogenic proof testing, where it is filled with liquid nitrogen and pressurized beyond flight levels. This confirms the vehicle's structural integrity at cryogenic temperatures.

Engine installation: Following successful testing, the Raptor engines are installed, along with plumbing, avionics, and flight-control surfaces like the flaps.

Thermal protection system: The heat shield tiles are then attached to the exterior of the vehicle to protect it during atmospheric re-entry

https://www.teslarati.com/spacex-starsh … rage-tank/

Fuel tank as part of structure

Offline

Like button can go here

#2192 2025-09-09 07:14:06

Re: Starship is Go...

Everyday Astronaut suggests a single launch architecture for a Moon mission using an expendable Starship as the launcher, so eliminating the SLS, and using Blue Moon as the lander, and the Orion as the capsule:

Everyday Astronaut @Erdayastronaut

Call me pessimistic, I honestly think the only way to get humans back on the moon in this decade is likely a single launch approach, but not with SLS. SLS's TLI capacity is insufficient. Honestly, make an expendable Starship upper-stage with a Saturn V style clamshell stage adapter to house a fully fueled Blue Moon Lunar Lander inside and an Orion Capsule on top.

Booster might even be able to be caught and still get all that mass on a TLI with a dedicated expendable upper stage. If not, just ditch the booster for maximum performance, who cares, that's a drop in the bucket compared to even a single RS-25. It could literally be demonstrated in less than one year from today on the Starship side.

Without needing a refueling architecture from Blue Moon, it also simplifies that development process. A stage adapter for Orion is very simple.

Make no mistake, orbital refueling is the future and will be what makes these things more sustainable, but if we're in a race to beat China to the moon, the first return to the moon could be done on a very accelerated timeline without relying on such lofty milestones and infrastructure.

Maybe I'll do a video breaking down this and other options when I finish my other video.

https://x.com/Erdayastronaut/status/1965141937931120910

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2193 2025-09-09 08:49:12

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Starship is Go...

From AIAA's "Daily Launch" email newsletter for Tuesday, 9 Sept 2025:

Space

SpaceX test fires next Super Heavy booster for Starship's 11th upcoming launch

The company performed a static test fire of the Super Heavy booster slated for Starship's 11th launch. Secured to the launch stand at SpaceX's Starbase manufacturing and test facility in Texas, the booster, B15, fired its 33 Raptor engines for about 10 seconds Sunday, Sept. 7.

I did not follow the link to Space.com to see if there was a projected date for the launch yet. I'd hazard the guess of early October. I think they still need to static-test the ship, and it might still be in fitting-out. Last I heard it was another Block 2, not the newer block 3 that uses Raptor-3 engines.

GW

Last edited by GW Johnson (2025-09-09 08:49:23)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#2194 2025-09-09 15:02:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Re: Starship is Go...

The current SpaceX Starship and Super Heavy booster have a stainless steel hull thickness of approximately 3.97 mm (0.156 in), and are constructed by welding together rings of stainless steel. This design marked a major shift from early carbon composite concepts for the rocket, which was originally known as the Big Falcon Rocket (BFR).

History of the Starship/BFR design

Initial carbon composite design: In 2018, early concepts for the BFR were built using carbon composites. At the time, early prototype sections were estimated to be between 12 and 25 mm thick.

Switch to stainless steel: Later in 2018, SpaceX announced the switch from carbon composites to stainless steel for the entire Starship and Super Heavy structure. Elon Musk cited reasons including lower cost, increased strength at cryogenic temperatures, and the ability of stainless steel to handle high temperatures.

First stainless steel prototypes: The first stainless steel prototypes used 301L stainless steel. Following pressure tests and iterative improvements, the alloy was updated to 304L stainless steel.

Evolution of hull thickness: The earliest steel prototypes, such as Starship SN1, were built with a 3.97 mm thickness. An anecdote from Elon Musk's biography describes his decision to push for thinner 4 mm tank walls over the nervous objections of engineers. Later, test articles like SN7.2 were briefly experimented with even thinner 3 mm steel, but recent production vehicles have remained at the 4 mm thickness.

Construction and thermal protection

Construction process: The 9-meter diameter hull is manufactured by rolling sheets of stainless steel into rings, which are then stacked and welded together.

Integrated structure: The stainless steel hull acts as both the external skin and the propellant tanks for the vehicle's liquid methane and liquid oxygen.

Heat shield for re-entry: While the steel can withstand high temperatures, the side of the Starship that faces the wind during re-entry is covered with approximately 18,000 hexagonal ceramic tiles for additional thermal protection.

Continuous development: SpaceX continues to iterate on the design and materials used. Following flight test 4, upgraded heat shield tiles were installed on the flight 5 Starship, along with a secondary ablative layer underneath the tiles for added protection against overheating

Offline

Like button can go here

#2195 2025-09-09 22:17:54

Re: Starship is Go...

Former NASA administrator Jim Bridenstine also saying U.S. unlikely to win race back to the Moon against China because of the too complex multi-refueling approach to a lander:

Ex-NASA chief revealed the Real Problem with SpaceX Starship to get back to the Moon while China

https://youtu.be/eA1uS4SgAwU

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2196 2025-09-10 02:25:21

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,280

Re: Starship is Go...

So, my prize is the Panama Canals that SpaceX may be able to create with Superheavy/Starship, or white collar elites that I am allowed to admire from a distance?

The claim discredits SpaceX, which has done what is almost magic to get to the point that those Panama Canals can be built, and yet does not mention Blue Origin. Why doesn't blue origin get pillory?

This looks like another Sputnik moment. As P. Zeithan said, a beeping grapefruit that put America into a panic.

Then the process was to beat the children as they were not worthy. Only the white-collar elites are worthy!

The pity is that true talent in blue collar is adopted by the white-collars, to give them credentials to display. Otherwise, the white-collars are a bunch of blabbermouth, ninny people who hire thugs to keep the blue-collars in line.

I am a witness to the classrooms produced. If you can answer a question in 1 or less seconds, then teacher rewards you. That is a form of capability. But intelligence may require time, maybe as much as a lifetime. But the game is to produce a magic show to the public where the Elites can award, certificates of intelligence or whatever to the anointed.

It is simply a way for the white collars to own the definition of intelligence.

And then there is "Homo-Erectus". Why does our culture favor the breeding of the human race back into Homo-Erectus?

A tall dominant man is the one who will be more likely to be given a magic wand, from the white collars to be benefited with wealth and mating privileges. But to my knowledge in 2 million years Homo-Erectus never went into space.

The Romans and other white collars like them spent centuries breeding our people into wonderful farm animals. Clever farm animals.

But no, the elites want their fancy boys instead.

But every once and a while we get a champion, one who has the keys to open the doors locked to most of us, and that champion has a magnificent mind. A fabulous but not perfect person.

I think you know who I am referring to.

And there is a wonderful princess in this story also, thanks be to God for that.

Ending Pending ![]()

Last edited by Void (2025-09-10 02:31:54)

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#2197 2025-09-10 07:52:18

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Starship is Go...

I still do not understand what the "metallic tiles" really are, but I did find this on LinkedIn. It is an evaluation by a NASA official (Gerstenmaier) that was reposted by another NASA figure (Yoon). It would appear that the booster flies its return a bit better than the CFD models would indicate. The gap fillers he talks about are put in there with what amounts to a caulking gun. Very labor intensive. The Dragon heat shield is the ablative PICA-X. - GW

Found on LinkedIn Wed 9-10-2025

Steven Yoon Steven Yoon • 1st1stNASA, air mobility, space explorationNASA, air mobility, space exploration9h • 9 hours ago • Visible to anyone on or off LinkedIn

Lessons from the last Starship Flight

Bill Gerstenmaier, a SpaceX executive in charge of build and flight reliability, presented the findings Monday at the American Astronautical Society's Glenn Space Technology Symposium in Cleveland.

“The metal tiles... didn't work so well," he said. “They oxidized extremely nice in the high oxygen environment.”

“In most of the tiles, there are fairly large gaps, and that's where we're seeing the heat get through and get underneath."

“The white patch was caused by heat seeping between gaps in the tiles and eroding the underlying material, a thermal barrier derived from the heat shield on SpaceX's Dragon spacecraft.” Technicians also intentionally removed some tiles near Starship's nose to test the vehicle's response.

"So, what that's showing us is that we're having heat essentially get into that region between the tiles, go underneath the tiles, and this ablative structure is then ablating underneath. So, we learned that we need to seal the tiles."

Not great, but SpaceX officials think they have a solution. Near the top of the ship, amid the patch of white, engineers noticed a few darker areas.

“We call it crunch wrap," Gerstenmaier said. "It's like a wrapping paper that goes around each tile, and then... these tiles are mechanically held in place. They're snapped in by a robot.” Using this "crunch wrap" material could seal the spaces between the tiles without using gap fillers.

Gerstenmaier also briefly mentioned the results of experiments with Starship's Super Heavy booster on the most recent test flight.

SpaceX engineers noticed the booster's performance on descent in flight doesn't match predictions from computer models or wind tunnel tests. In ground experiments, the booster encounters unstable buffeting as it slows below the speed of sound.

Based on those results, "[we] should not be able to do what we do with our maneuver coming back with a booster, but we've been able to essentially show through flight that we have more stability than either CFD (Computational Fluid Dynamics) or the wind tunnels show that we have.”

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#2198 2025-09-10 14:12:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,460

Offline

Like button can go here

#2199 2025-09-11 09:27:01

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,144

- Website

Re: Starship is Go...

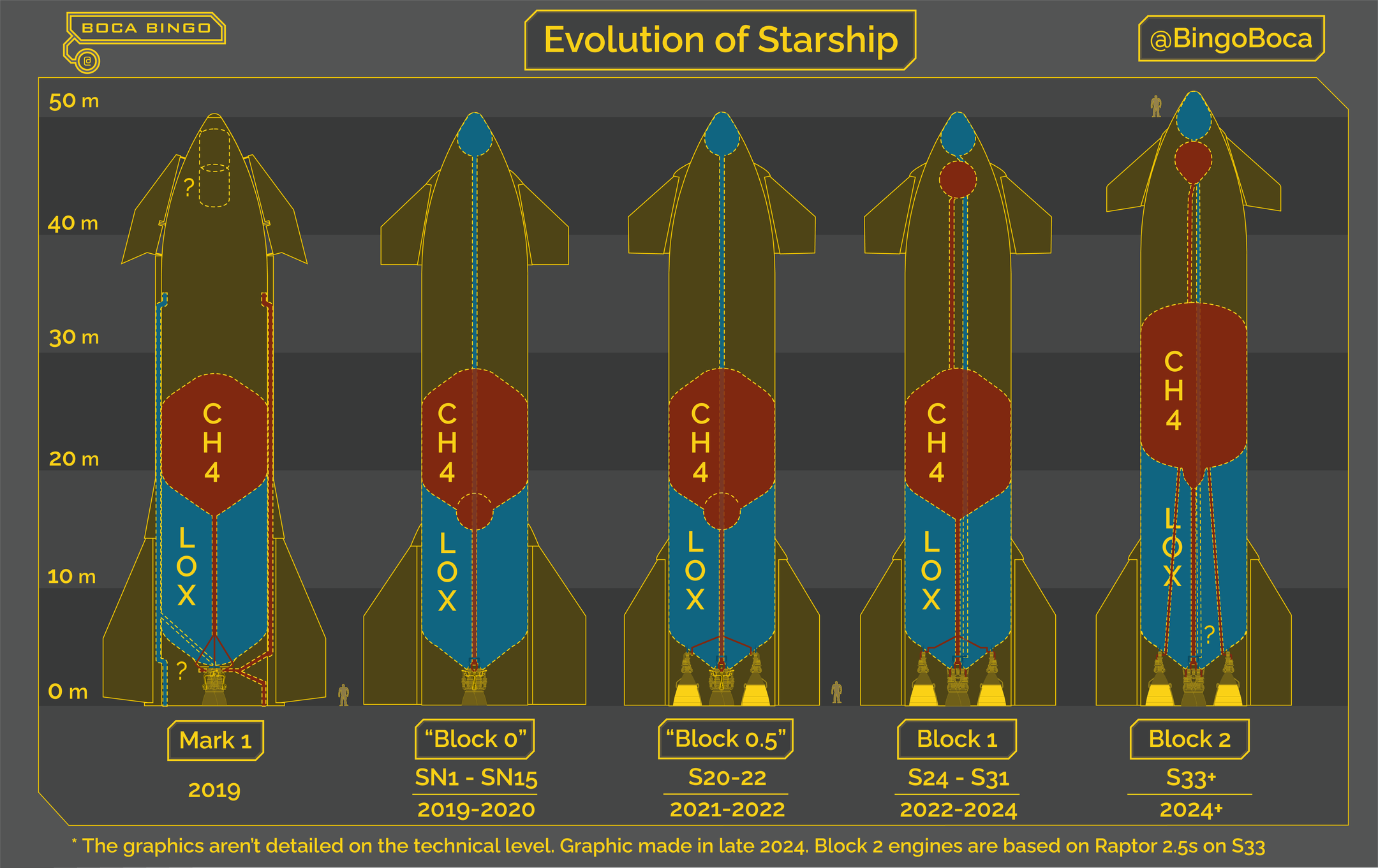

Interesting diagrams. Thanks, Harold.

GW

Update 9-14-2025: I see in Spacenut's diagrams of Starship the evolution of the tankage dome designs, away from conical shapes, toward spherical-segment shapes, except under the bottom tank. There they need the conical shape to serve as an efficient load path (one of multiple paths) for engine thrust forces to reach the outer tank shell. Between the anti-slosh baffles (not shown), and whatever thrust truss supports there are, there's probably enough stiffness to keep the cone shape from ballooning-outward into "round", at only around 100 psi tank pressures. Too high a pressure, and the cone is where the burst failure is most likely to initiate.

Last edited by GW Johnson (2025-09-14 09:28:30)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#2200 2025-09-21 06:30:29

Re: Starship is Go...

U.S. Is Losing Race to Return to Moon, Critics Say, Pointing at SpaceX.

The company’s Starship rocket, which has suffered a series of recent test explosions, is still years away from being ready for the mission, former NASA executives say.

The SpaceX Starship rocket has exploded during three of its four recent tests, and its current version can carry only a fraction of its promised payload into orbit.

By Eric Lipton

Reporting from Washington

Sept. 20, 2025

Elon Musk has a history of making promises to rapidly deliver technological breakthroughs, only for them to end up taking longer than predicted or to fail to materialize.

Among these are his promises for fully autonomous self-driving cars or tunnels under Los Angeles to solve traffic congestion. Now some federal government officials worry that his pledges for landing astronauts on the moon will suffer similar delays.

That is why one of the largest federal contracts Mr. Musk has ever secured is now under intense scrutiny: a multibillion agreement with NASA for this crewed mission to the moon, the first in more than five decades.

https://www.nytimes.com/2025/09/20/us/p … -race.html

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here