New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 Re: Exploration to Settlement Creation » Starship repurposed to make or build what we need » 2026-01-13 16:39:38

I found images of the building of the super dome

Scalable structure that could be made from the cannibalized starships, cut and bend to shape.

#52 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 16:00:43

Human habitat volume requirements vary greatly by mission, with individual private crew quarters needing ~2.1 to 5.4 cubic meters (74-190 ft³) for sleep/privacy (ISS to deep space concepts), while total habitable volume per person ranges from ~25 m³ (zero-g, near-term tech) to over 80 m³ (deep space Mars transit), balancing personal needs, equipment, and life support, with larger volumes preferred for long durations and artificial gravity.

Key Factors Influencing Volume:

Mission Duration & Destination: Longer missions (months/years) demand more volume for psychological well-being and supplies.

Gravity: Microgravity allows for compact designs, while artificial gravity (like spinning habitats) requires much larger volumes to accommodate equipment and normal human movement.

Functionality: Space for sleeping, hygiene, work, exercise, food prep, and communal areas all add up.

Technology: Advanced recycling and life support can reduce storage needs, but equipment still takes space.

Examples by Context:

Current ISS (Microgravity): Individual private quarters are small, around 2.1 m³ (74 ft³), but the overall station is large.

Deep Space Concepts (Future):

Individual Quarters: Aiming for 4 m³ (141 ft³) or more for better psychological health.

Total Habitat: Designs propose anywhere from 25 m³ (zero-g, near-term) to ~80 m³ or more per person for Mars transit, balancing mass and habitability.

Regulatory (Offshore): U.S. Coast Guard requires at least 6 m³ (210 ft³) per crew member in some vessels.

In Summary: There's no single number, but for long-duration deep space, expect requirements to trend towards tens of cubic meters per person for the entire habitat, significantly more than current microgravity quarters, especially if artificial gravity is used.

#53 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 16:00:36

moving to make room

#54 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 16:00:31

Nasa has been planning with a crew of 4 electrical needs for a capsule being provided 10Kw from solar panels but for mars the amount of energy is divided for use for just 2 crewmen for all functions to create.

So a key power requirement is divide for all functions and must be greater than the stated so as to have margin for all personel to make use of it.

All designs must be based on personnel count for all designs for that reason.

Experiments at HI-SEAS analog station the 10 kw array saves to batteries that hold 28.5 kw hrs of energy.

A solar array needs to cover 4500 sq ft on mars while the same on earth is just 525 sq ft for a 10 kw needs to be 40 kw on mars.

Integrated Surface Power Strategy for Mars

NASA's power standards for crewed Mars missions vary significantly by mission phase and scale, ranging from a minimum of ~10 kilowatts (kW) for short surface stays with two crew members to potentially megawatt (MW)-class systems for larger, longer missions with in-situ resource utilization (ISRU) like propellant production, with nuclear power often favored for its reliability, though early missions might use solar/battery systems, with total requirements approaching 160 kWe for some concepts.

Key Power Requirements & Considerations:

Minimum Surface Power: Around 10 kW is considered the baseline for even short (30-day) missions with two crew, covering habitat, life support (ECLSS), and some science/exploration.

ISRU & Larger Crews: Missions involving propellant manufacturing (ISRU) and larger crews (e.g., six people) can push power needs to 40-160 kW or more for activities like producing oxygen and fuel.

Transit/Propulsion: Missions using nuclear electric propulsion (NEP) could require very high power, with some concepts needing 1.9 MWe (megawatts electric) for the journey itself.

Reliability & Redundancy: Critical safety systems demand high availability, often necessitating redundant power sources, like multiple nuclear reactors or large battery/fuel cell backup.

Power Technologies Considered:

Nuclear Fission Systems: Fission power (like Kilopower) is a strong candidate for its mass efficiency and continuous power, providing both electricity and heat, crucial for ISRU and reliability.

Solar Arrays: Roll-out or advanced photovoltaic blankets are an option, but limited by dust, available area, and nighttime needs, requiring significant energy storage.

Energy Storage: Advanced batteries (lithium-ion) and regenerative fuel cells are vital for bridging gaps in solar power or providing backup.

Example Mission Architectures:

Early Missions (2010s Studies): Concepts used two 40 kWe fission systems for 500-day stays, with one primary unit for ISRU and a backup near the habitat.

DRA 5.0 (Design Reference Architecture): Explored options requiring significant power for habitat, science, and ISRU, with pre-deployed cargo landers.

In essence, NASA's power strategy balances mission goals (science, ISRU, crew size) with technology capabilities, leaning heavily towards reliable nuclear systems for higher power needs while integrating robust energy storage for all scenarios

For a Mars garage or any other structure, power systems need reliability in dust and cold, likely combining solar arrays with advanced batteries (like Lithium-ion or supercapacitors) for peak loads and consistent energy, supplemented by Radioisotope Thermoelectric Generators (RTGs) or future Nuclear Fission Reactors for baseline power, especially during dust storms and night, alongside energy storage and distribution systems (PMAD) to manage variable demands for tools and habitat functions.

Primary Power Sources

Solar Arrays (Photovoltaics): Efficient when sunlight is available but challenged by dust accumulation and reduced intensity during Martian winter/storms, requiring regular cleaning.

Radioisotope Thermoelectric Generators (RTGs): Use natural decay of plutonium to generate continuous heat and electricity, providing reliable, long-term power independent of sunlight, excellent for baseline needs.

Nuclear Fission Reactors: For larger, sustained power needs (like industrial processes or larger habitats), small fission reactors offer high power output but require significant shielding for radiation.

Energy Storage & Management

Batteries: Rechargeable lithium-ion batteries (like those used on rovers) handle peak power demands, while advanced alternatives like graphene supercapacitors offer faster charging and wider temperature tolerance.

Power Management & Distribution (PMAD): Essential systems to convert, condition, and distribute power from sources to loads, handling start-up, shutdown, and dynamic events.

Supporting Technologies

Waste Heat Utilization: Nuclear systems produce excess heat, which can be converted to electricity or used for habitat/regolith heating, improving efficiency.

In-Situ Resource Utilization (ISRU): Solar concentrators could use sunlight for heating and 3D printing/sintering, potentially reducing reliance on pure PV cells.

Advanced Motors/Generators: Electric motors are preferred over combustion engines due to simplicity; next-gen storage like supercapacitors could revolutionize rapid power delivery.

Considerations for a Mars Garage or other structures

Dust Mitigation: Systems to clean solar panels and protect equipment from fine dust are crucial.

Thermal Management: Dealing with extreme cold (using waste heat or electrical heaters) is vital for equipment and battery health.

Scalability: A mix of sources (solar for peak, nuclear for baseline) offers the best resilience, from small tools to large fabricators

#57 Re: Human missions » Why Artemis is “better” than Apollo. » 2026-01-12 10:38:00

NASA just switched on a giant solar engine, and it’s headed for the moon

The Gateway, NASA’s upcoming lunar space station, is one step closer to reality as engineers have successfully powered on its solar electric propulsion system, a spacecraft engine designed to orbit and maneuver around the Moon. This achievement marks a major milestone in NASA’s Artemis program, which aims to establish a sustainable human presence on the lunar surface and prepare for future missions to Mars.

Building The Power And Propulsion Element

At the heart of the Gateway lies the Power and Propulsion Element (PPE), developed under the supervision of NASA’s Glenn Research Center in Cleveland, Ohio. Construction and assembly are led by Lanteris Space Systems in Palo Alto, California, where teams have integrated the spacecraft’s main electrical system within protective panels. This ensures the hardware can withstand the harsh environment of deep space.Once fully operational, the PPE will generate up to 60 kilowatts of electricity,enough to supply power for communications, navigation, and orbital adjustments. The engine’s advanced solar electric propulsion allows for continuous, efficient thrust powered by sunlight, offering an innovative alternative to traditional chemical propulsion.

The system’s propulsion capability is built around three 12-kilowatt thrusters developed by L3Harris and four 6-kilowatt BHT-6000 thrusters by Busek. Together, these thrusters provide the necessary maneuverability to maintain the Gateway’s orbit and reposition it as needed for lunar missions. Redwire, another NASA partner, is responsible for the roll-out solar arrays, lightweight, flexible panels that convert sunlight into electrical energy.

This hardware will power not only the Gateway’s core functions but also its visiting spacecraft and future science payloads, forming the energetic backbone of NASA’s next-generation lunar operations.

The Gateway’s Role In NASA’s Artemis Program

The Gateway is a cornerstone of NASA’s Artemis program, which aims to return astronauts to the lunar surface for the first time since Apollo 17. Unlike the International Space Station, the Gateway will not be permanently crewed. Instead, it will serve as a modular outpost, orbiting the Moon in a highly stable near-rectilinear halo orbit (NRHO).This orbit provides ideal access to both the lunar surface and deep space, making it an essential platform for testing life-support systems, radiation protection, and advanced propulsion technologies. Astronauts visiting the Gateway will conduct scientific experiments, prepare landers for surface missions, and evaluate long-duration spaceflight conditions, all critical for future crewed missions to Mars.

NASA envisions Gateway as an international collaboration, involving key contributions from ESA (European Space Agency), JAXA (Japan Aerospace Exploration Agency), and CSA (Canadian Space Agency). Each partner will deliver specialized modules, robotics, and technology to create a truly global platform for exploration.

Engineering A Sustainable Future Beyond Earth

NASA’s decision to rely on solar electric propulsion for the Gateway is both a technological and environmental breakthrough. Unlike conventional rockets, which burn large quantities of fuel in short bursts, this system produces continuous, gentle thrust using electricity derived from sunlight. Over time, it can achieve impressive velocities with minimal resource consumption, an essential feature for long-duration missions far from Earth.The Gateway will also act as a proving ground for autonomous operations, as it will often function without a human crew onboard. This autonomy will be vital for deep-space missions where communication delays make real-time control impossible. The spacecraft’s design prioritizes efficiency, durability, and adaptability, ensuring it can operate safely and independently in lunar orbit for years at a time.

Through its partnership with Lanteris, L3Harris, Busek, and Redwire, NASA is cultivating a powerful ecosystem of innovation that bridges public and private sectors. These collaborations are essential for building the infrastructure required for humanity’s next leap: establishing a permanent foothold on another world.

#58 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 10:21:05

A dome constructed of 304L stainless steel with a 100-meter diameter and 20-meter height is theoretically possible but presents significant engineering challenges, primarily related to managing internal pressure and radiation shielding. The material properties of 304L stainless steel are suitable for the Martian environment, but building at this scale requires novel construction techniques and massive material transport from Earth or extensive in-situ resource utilization (ISRU).

Feasibility and Challenges

Pressure Management: The primary challenge is anchoring the dome against the internal air pressure required for a habitat. A 100m diameter dome would exert tremendous vertical force (around 78,000 tonnes of force), requiring extensive foundation engineering to prevent the dome from lifting off the ground.

Radiation Shielding: A bare metal dome would offer poor protection against high-energy cosmic rays. The structure would need to be covered with a thick layer of Martian regolith (soil) or ice for adequate shielding, potentially adding millions of tonnes of mass and significantly altering the design requirements.

Material Transport vs. ISRU: Transporting the vast amount of steel required from Earth is likely cost-prohibitive. While iron is abundant on Mars, developing the infrastructure to mine the ore, smelt it into iron, and then produce 304L stainless steel plates of sufficient quality and thickness on an industrial scale would be a massive undertaking.

Material Properties: 304L stainless steel performs well in the extreme cold of Mars and is resistant to radiation damage (it doesn't become brittle). However, it offers no radiation shielding for occupants.

Design & Scaling: Domes can be difficult to scale efficiently; as they get larger, the material thickness or strength needed increases disproportionately to handle the pressure, and interior space can be awkward to utilize. SpaceX uses 304L stainless steel for its Starship, which are pressure vessels, demonstrating the material's suitability for containing pressure, but these are smaller in diameter (9m) and use a cylindrical shape with domed ends, which is structurally more efficient for pressure containment than a large architectural dome.

Construction: On-site assembly would require advanced robotics and welding capabilities in a near-vacuum, extreme-cold environment.

Conclusion

While the material properties of 304L stainless steel are suitable for the Martian environment, the engineering challenges associated with building a 100-meter diameter, 20-meter tall habitat-grade dome are formidable. A more practical approach would likely involve a hybrid design using a much thicker layer of local regolith for shielding and using the steel for an internal pressure shell, or building the habitat primarily underground or within lava tubes to utilize the natural shielding of the planet's surface

#59 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 10:20:59

For welding SpaceX Starship's 304 stainless steel, the key equipment involves advanced, high-speed robotic laser welding machines for precise, fast, single-pass welds, replacing slower TIG/MIG methods, though standard TIG/MIG welders (like inverter-based Synergic ARC 304) with appropriate filler (ER308L) and argon gas are used for other stainless work. SpaceX uses specialized systems for deep penetration and heat conduction to minimize warping, enabling lighter, stronger structures quickly.

Cutting and Welding on Mars: Performing precision cutting and subsequent welding in the harsh Martian environment (thin atmosphere, dust, extreme cold) would require specialized, automated tools and techniques. While stainless steel can be welded relatively easily compared to other aerospace materials, doing so robotically in an off-world environment is a significant engineering challenge.

Key Equipment & Techniques for Starship (304 SS)

Robotic Laser Welding: The primary method for Starship rings, offering speed, precision, and minimal heat distortion, allowing thinner sheets.

Heat Conduction Welding: For thin sheets, creating clean welds with little warping.

Deep Penetration (Keyhole) Welding: For thicker sections, creating deep, strong single-pass welds.

TIG/MIG Welders (for general use/prototypes):

Inverter-based MIG/MAG: Machines like the Synergic ARC 304 offer advanced features, high duty cycles, and robust wire feeds.

TIG (GTAW): Known for beautiful, high-quality welds, requiring more skill.

Consumables:

Filler Wire: ER308L is standard for 304 stainless steel.

Shielding Gas: Argon-rich gases are essential for stainless steel welding.

Why the Shift to Laser Welding?

Efficiency: Dramatically speeds up assembly, reducing build times from months to weeks.

Weight Reduction: Enables use of thinner steel by creating stronger, consistent welds, cutting overall mass.

Quality: More precise, consistent welds with less warping than traditional methods.

General Stainless Steel Welding Tips

Cleanliness: Always start with clean stainless steel.

Filler: Use the correct filler (ER308L for 304).

Gas: Use appropriate argon mix.

Duty Cycle: Choose a machine with a high duty cycle for continuous work

SpaceX Starship uses 304L stainless steel, typically in large rolls or sheets for construction, with specific thicknesses around 4 mm (0.156 in), though thinner gauge sheets (like 0.8-1.2mm) are common for various finishes and sizes (e.g., 2000x1000mm, 2500x1250mm) from suppliers. While standard industrial sizes (4'x8', 4'x10') exist, Starship uses large, custom formats for its cylindrical sections, with some reports mentioning rolls over 72 inches wide.

Key Details:

Material: 304L Stainless Steel (low carbon version).

Thickness: Around 4 mm (0.156 inches) for main structure, but thinner for other parts.

Formats: Large sheets or rolls, not small standard sheets.

Standard Sheet Sizes (for general use): 4'x8', 4'x10', 5'x10' (and cut-to-size).

Specific SpaceX Use: Reports mention rolls 1828.8mm (72 inches) wide for building the rocket's body.

So, while standard sizes are common in the industry, Starship uses massive, specific sizes to form its huge cylindrical tanks and body sections.

SpaceX Starship uses 304L stainless steel, typically in large rolls or sheets for construction, with specific thicknesses around 4 mm (0.156 in), though thinner gauge sheets (like 0.8-1.2mm) are common for various finishes and sizes (e.g., 2000x1000mm, 2500x1250mm) from suppliers. While standard industrial sizes (4'x8', 4'x10') exist, Starship uses large, custom formats for its cylindrical sections, with some reports mentioning rolls over 72 inches wide.

Key Details:

Material: 304L Stainless Steel (low carbon version).

Thickness: Around 4 mm (0.156 inches) for main structure, but thinner for other parts.

Formats: Large sheets or rolls, not small standard sheets.

Standard Sheet Sizes (for general use): 4'x8', 4'x10', 5'x10' (and cut-to-size).

Specific SpaceX Use: Reports mention rolls 1828.8mm (72 inches) wide for building the rocket's body.

So, while standard sizes are common in the industry, Starship uses massive, specific sizes to form its huge cylindrical tanks and body sections.

#60 Re: Exploration to Settlement Creation » Mars Medical and Health Monitoring plus of crew » 2026-01-12 10:14:13

Space for patients and staff to make use of carves out square meters for each item and needs specific lighting, Specific OR areas super clean.

Medication security and more to aid in keep crew safe and alive while on mars.

#61 Re: Exploration to Settlement Creation » Mars structure heating requirements » 2026-01-12 10:00:25

While this was started for the large dome of 200m being 120 m tall, that slowing was built over an open pit to gain regolith for brick its use is for all construction that mars requires for men to stay and thrive.

Not just for people Habitats but it also can be for a Mars Garage, Greenhouses, other Biomes ect....

#62 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:57:10

For a Martian habitat at 0.5 bar (significantly higher than Mars's ~0.006 bar average), spherical or cylindrical shapes are optimal for a stainless steel structure, as they efficiently contain internal pressure, with cylindrical shapes often favored for practical construction and use with regolith shielding, using tension members to handle stress, similar to pressurized vessels on Earth.

Why These Shapes?

Spherical: A sphere distributes stress equally in all directions, making it structurally ideal for holding internal pressure against a vacuum or low external pressure.

Cylindrical: Cylinders (especially with domed ends) are practical for larger volumes, offer better usable floor space, and can be buried or covered with Martian soil (regolith) for radiation shielding without collapsing.

Structural Considerations for 0.5 Bar (50 kPa)

Pressure Difference: A habitat at 0.5 bar (50 kPa) has a substantial pressure difference from the Martian surface (around 0.6 kPa), requiring robust structures.

Stainless Steel: While good for strength, stainless steel is heavy, making it costly to transport; however, it's excellent for withstanding pressure.

Tension: The primary force is outward tension. Structural members (like steel bands) wrapped around cylindrical habitats help contain this.

Design Concepts

Buried Cylinders: Building cylindrical habitats within trenches and covering them with regolith provides shielding from radiation and micrometeoroids, using the soil's weight to help counteract the internal pressure, notes Marspedia and NIH.

Domes: Dome-shaped structures (hemispherical) are also efficient for pressure containment, as studied by NASA.

In essence, think of large, pressurized tanks – spheres and cylinders are the best shapes for holding pressure, and adding regolith makes them even more effective Martian habitats

A counter pressure is generally not how an internal atmosphere in a Martian dome would be contained. The force from an internal, human-habitable atmosphere on Mars is immense (around 10 tonnes per square meter), meaning the structure needs sufficient mass and design to resist this tension and prevent it from being lifted off its foundations. The most practical engineering approach for a dome made of Martian regolith bricks involves using the weight of the material itself (or an external regolith covering) to counteract the internal pressure differential.

Internal Pressure Requirements

Mars's Atmospheric Pressure:

The external atmospheric pressure on the surface of Mars is extremely low, averaging only about 0.6 kilopascals (kPa), which is less than 1% of Earth's sea-level pressure. It is effectively a near-vacuum from an engineering perspective.

Human Habitable Pressure:

A human habitat requires a total internal pressure of at least 25 kPa with sufficient oxygen partial pressure to be functional without a pressure suit, or full Earth-equivalent pressure of 101.3 kPa (1 atm) for a standard environment.

Pressure Differential:

The critical engineering challenge is the 100+ kPa pressure differential between the inside of the dome and the outside Martian atmosphere. This creates a massive outward and upward force on the structure.

Structural Considerations for Regolith Domes

Tension vs. Compression:

Domes on Earth are compression structures, meaning their shape naturally handles the force of their own weight pushing down. On Mars, the low gravity and high internal pressure put the dome under tension, trying to tear it apart and lift it from its foundations.

Material Limitations:

Regolith bricks, even advanced "StarCrete" or sintered versions with high compressive strength (up to 72 MPa), have lower tensile strength. Standard bricks and concrete perform poorly in tension.

Design Solution: Weight and Reinforcement:

The primary method to manage the internal pressure is to use a thick layer of regolith as shielding/ballast.

Proposals often suggest using an internal inflatable bladder or a strong internal shell (perhaps with steel or carbon fiber reinforcement) to contain the air.

This internal structure is then buried under several meters of Martian soil/bricks. The sheer weight of this external material provides the necessary "counter pressure" by pushing down and counteracting the upward lift from the internal atmosphere.

In short, the counter pressure is not an engineered force applied externally but rather the passive mass of significant regolith shielding used to anchor the structure to the ground.

#63 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:57:04

Engineered breathable atmospheres for Mars habitats focus on two main approaches: in-situ resource utilization (ISRU) for immediate, localized, or small-scale breathable environments inside habitats, and long-term terraforming to transform the entire planet's atmosphere. Current strategies focus on converting the 95% carbon dioxide (\(CO_{2}\)) Martian atmosphere into oxygen (\(O_{2}\)) using electrical, chemical, or biological methods.

Immediate In-Situ Habitat Strategies For early human missions, breathable air will be generated inside pressurized, sealed habitats or in localized, covered areas: MOXIE (Mars Oxygen In-Situ Resource Utilization Experiment): A technology demonstrator on the Perseverance rover that has successfully converted Martian \(CO_{2}\) into \(O_{2}\) via solid oxide electrolysis, heating gas to 800°C.

Hydroponic Greenhouses: Utilizing plants to take in \(CO_{2}\) and produce \(O_{2}\).Engineered

Microbes: Deploying extremophile microorganisms to convert the atmosphere.S

ilica Aerogel Shields: Placing silica aerogel layers over areas to create a localized, warm, high-pressure "greenhouse" effect that could allow for liquid water and photosynthesis.

Plasma Technology: Using plasma discharge to split \(CO_{2}\) molecules directly from the atmosphere. Long-Term/Global Terraforming Approaches Transforming the entire planet requires raising the temperature to melt polar ice, which in turn thickens the atmosphere.

Engineered Nanoparticles: A 2024 study proposed releasing engineered, iron/aluminum-based, dust-like nanorods into the atmosphere to trap escaping infrared radiation, which could potentially warm the planet by 50°F in decades.

Orbital Mirrors: Placing large mirrors in orbit to focus sunlight on polar caps, triggering the release of frozen \(CO_{2}\) and increasing air pressure.

CFC Importation: Introducing chlorofluorocarbons (CFCs) to Mars to trigger a rapid greenhouse effect. Key Technical and Environmental Challenges Pressure and Density: The current atmosphere is too thin (<1% of Earth's pressure).

Low Oxygen: The atmosphere is 96% \(CO_{2}\) and only 0.1% \(O_{2}\).Radiation: Lack of a global magnetic field poses severe radiation risks to surface life.

Timeframes: Full terraforming could take hundreds to thousands of years.Material Sourcing: Creating a breathable atmosphere requires massive amounts of raw materials, with one proposal requiring, for example, 0.1% of Earth's annual metal production.

Breathable Mixture Goals: The goal for a breathable atmosphere is a mixture that provides roughly 100 millibars of oxygen, allowing humans to work with only light breathing apparatus rather than full, bulky pressure suit

#64 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:56:58

In-situ (on-site) Martian rocket fuels primarily focus on producing methane (\(CH_{4}\)) and liquid oxygen (\(LOX\)), using the abundant atmospheric carbon dioxide (\(CO_{2}\)) and water ice (\(H_{2}O\)) through processes like the Sabatier reaction and electrolysis, significantly reducing launch mass from Earth. Alternative approaches involve biotechnology to create fuels from Martian resources or using carbon monoxide (\(CO\)) and oxygen (\(O_{2}\)) as propellants, leveraging Mars's unique environmental conditions to enable sustainable Mars missions and colonization.

Primary Method: Sabatier Reaction & Electrolysis

Gather Resources: Collect Martian atmospheric \(CO_{2}\) and extract water (\(H_{2}O\)) from subsurface ice/regolith.

Electrolysis: Split water into hydrogen (\(H_{2}\)) and oxygen (\(O_{2}\)).

Sabatier Reaction: React \(CO_{2}\) with the produced \(H_{2}\) to create methane (\(CH_{4}\)) and water.

Oxidizer: The \(O_{2}\) from electrolysis serves as the oxidizer.

Result: This process yields both fuel (methane) and oxidizer (liquid oxygen) on Mars. Key Benefits Cost Reduction: Eliminates the need to transport massive amounts of propellant from Earth.

Mass Leverage: A small amount of imported hydrogen can generate significantly more fuel on Mars.

Resource Utilization: Utilizes abundant Martian resources (\(CO_{2}\), \(H_{2}O\)).

Alternative & Advanced Concepts Biotechnology (Bio-ISRU): Using engineered microbes (like cyanobacteria and E. coli) to convert \(CO_{2}\) into complex hydrocarbons (rocket fuel) and generating excess oxygen, taking advantage of Mars's lower gravity for less energy-intensive liftoffs.

Carbon Monoxide/Oxygen (CO/O2): A propellant combination derived from \(CO_{2}\), potentially offering higher specific impulse, though it still requires a hydrogen source.

Solid Propellants: Research explores creating solid fuels (like aluminum/magnesium-based) from Martian regolith, though less developed. Challenges Power & Infrastructure: Requires significant power for processing and liquefaction.

Efficiency & Reliability: Developing robust, long-term systems for the harsh Martian environment

#65 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:48:23

stay tuned

#66 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:48:13

3D printing of dome-shaped habitats on Mars using basalt-based materials is a leading area of research for in-situ construction. This approach leverages the abundant basaltic rock and regolith found on the Martian surface to create a structurally sound, radiation-shielding building material, eliminating the need to transport heavy materials from Earth.

Construction Techniques

The primary method involves additive manufacturing (3D printing) using robotic systems deployed autonomously before human arrival.

Material Acquisition and Processing: Robots collect basalt rocks and regolith (crushed rock and dust) and process them into a usable feedstock. One method involves melting the basalt in a furnace and pulling it into fibers, which are then combined with a binder.

Binding Agents: To create a cohesive, printable "ink," the basalt material is often mixed with a binder. In various NASA challenges, teams have experimented with:

Polymer composites: Combining basalt fibers with polylactic acid (PLA) or other recyclable plastics, which can potentially be synthesized from plants grown on Mars.

Geopolymers/Cements: Using fast-setting metakaolin geopolymer cement formulations.

Printing Process: The material is extruded layer by layer by a gantry-style or robotic arm printer, building the habitat from the ground up. The dome shape itself is a functional design choice, as the curved walls help to withstand the significant pressure difference between the internal human-habitable atmosphere and the near-vacuum Martian environment.

Advantages of Basalt for Mars Habitats

Radiation Shielding: Cooled basalt has a high density, which provides superior protection from electromagnetic space radiation and micrometeorites compared to more porous materials.

Structural Integrity: Basalt fiber-reinforced composites can be several times stronger than traditional concrete, providing robust structural elements.

Thermal Regulation: The material has a low coefficient of thermal expansion, advantageous for the extreme temperature swings on Mars.

Airtight Seal: Basalt's low permeability makes it suitable for forming the necessary hermetic seal to maintain a pressurized, life-supporting internal atmosphere.

Current Status and Research

Research has largely been driven by competitions like the NASA 3D-Printed Habitat Challenge. While material processing and 3D printing techniques have been successfully demonstrated using Martian regolith simulants on Earth, the practical challenge of establishing the energy-intensive processing equipment (like high-temperature furnaces) on Mars remains a significant engineering hurdle.

For building arch shapes, you can use either tapered/wedge-shaped bricks or standard rectangular bricks. Tapered bricks are specially designed for arches to create uniform mortar joints, while rectangular bricks can be used for a flatter arch, sometimes called a soldier arch. Special shapes like double-tapered arch bricks or bricks with a specific angle (like a 70° skew-back angle for flat arches) are also available for curved elements.

Types of bricks for arches

Tapered or wedge-shaped bricks:

These are the most common for rounded arches. They are tapered to ensure that the mortar joints are of a consistent thickness throughout the depth of the arch.

Double-tapered arch bricks: These are double-tapered in either width or length to form curved features, like an archway or a circular window.

Rectangular bricks (cut or full-size):

Soldier arches:

These are created by placing standard rectangular bricks on their ends, with their long sides set vertically. This type is more of a flat arch and requires support like a lintel or frame.

Flat arches:

Flat arches are often constructed with standard rectangular bricks that are the same size and have parallel sides, sometimes with a specific skew-back angle.

Specialty and pre-fabricated arches: Modern technology allows for pre-fabricated brick arches built to specific dimensions and designs, which can be a cost-effective solution.

Key considerations for size and shape

Uniformity:

The key for most arches is achieving uniform mortar joints for structural integrity. Tapered bricks achieve this, while flat arches often use standard rectangular pieces with a consistent, small mortar joint.

Angle:

For flat arches, a 70° skew-back angle is common for the voussoirs (the wedge-shaped stones used to build the arch).

Customization:

If your design requires specific angles, curves, or a certain rise, you may need to specify custom dimensions or use pre-fabricated arches

#67 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:48:07

Again shape still may change as its never been built as if we are on mars.

It is unknown how fast the mining of ore, processing to be able to cast panels, but to make and weld the frame is also a question. Time and crew size plus equipment causes the build to be pushed across multiple cycles.

Funny we have been there for Cast Basalt

With Basalt melting at temperatures of 1175 - 1350°C, depending on composition.

Similar equipment for other mining operations.

Basalt mining and processing require extremely wear‑resistant, high‑capacity equipment because basalt is one of the hardest and most abrasive natural stones. The core machinery includes drilling/blasting tools, heavy-duty loaders, jaw and cone crushers, VSI sand makers, vibrating screens, and dust‑controlled conveyor systems.

Below is a clear, structured breakdown of the full equipment lineup and process flow, grounded in the latest industry data.

? What Equipment Is Used for Basalt Mining & Processing?

1. Mining / Quarrying Equipment

Basalt is typically extracted from open‑pit quarries.

Extraction Tools

Drilling rigs – for blast‑hole drilling in hard rock.

Explosives & blasting systems – controlled fragmentation of basalt benches.

Hydraulic excavators (30–70 ton) – for loading blasted rock.

Wheel loaders & haul trucks – transport raw basalt to the processing plant.

? 2. Primary Processing Equipment (Crushing)

Basalt’s hardness (Mohs 5–6.5) demands high‑strength crushing machines.

Primary Crusher

Jaw Crusher

Handles large basalt blocks up to 700–1200 mm.

High-strength manganese plates.

Example: C6X Jaw Crusher.

Secondary Crusher

Hydraulic Cone Crusher

Ideal for medium-hard basalt.

Produces uniform, cubical aggregates.

Multi‑cylinder design reduces wear costs.

Tertiary Crusher (Optional)

VSI Sand Maker

Used when producing manufactured sand or highly cubic aggregates.

Common in asphalt and concrete aggregate plants.

? 3. Screening & Sorting Equipment

Vibrating screens (2–4 decks)

Separate crushed basalt into size fractions (e.g., 0–5 mm, 5–12 mm, 12–22 mm).

High-strength screen meshes

Required due to basalt’s abrasiveness.

? 4. Material Handling Systems

Belt conveyors (650–1000 mm width)

Abrasion‑resistant belts and dust‑proof covers.

Hoppers & feeders

Heavy-duty vibrating feeders with wear liners.

? 5. Optional Processing Equipment

Depending on the final product:

For Manufactured Sand

VSI or HVI sand-making machines

Air separators for fine control

For High‑Quality Aggregates

Hydraulic cone crushers (HPT, HP series)

Washing systems (log washers, spiral washers)

For Basalt Fiber Production

Basalt melting furnace

Fiber drawing equipment

Winding machines

? 6. Typical Basalt Crushing Plant Configuration

Based on industry-standard setups:

Stage Equipment Purpose

Feeding Hopper + Vibrating Feeder Regulated feeding of raw basalt

Primary Jaw Crusher First-stage size reduction

Secondary Cone Crusher Produces uniform aggregates

Tertiary VSI Crusher Sand making / shaping

Screening Multi‑deck Vibrating Screen Size classification

Conveying Belt Conveyors Material transport

Example capacity: 250–450 TPH basalt plant with jaw + cone + VSI + screens.

? Tips for Choosing Basalt Processing Equipment

Prioritize wear resistance (manganese steel, ceramic liners).

Use compression crushers (jaw + cone) to reduce wear costs.

Ensure dust suppression for environmental compliance.

Choose variable-speed feeders to stabilize plant output.

For sand production, include VSI or HVI machines.

? Sources

MINEVATE Basalt Crushing & Screening Plant

Liming Heavy Industry Basalt Crusher Overview

Zoneding Basalt Crushing Plant Guide

CCE Online News – Basalt Quarry Equipment Selection

Fote Machinery – Basalt Crushing Process & Machines

Designing interlocking cast‑basalt thick tile panels for use on Mars is a fascinating challenge because it blends planetary engineering, materials science, and in‑situ resource utilization (ISRU). You’re essentially asking: How could we manufacture basalt‑based structural panels on Mars that lock together like giant LEGO blocks and survive Martian conditions?

Let’s build a complete, realistic process from extraction to finished interlocking tiles.

? 1. Basalt as a Martian Manufacturing Feedstock

Basalt is abundant on Mars. It’s chemically similar to terrestrial basalt and ideal for:

Casting into tiles or panels

Melting into basalt fiber

Forming abrasion‑resistant surfaces

Thermal and radiation shielding

Its melting point (~1200–1250°C) is high but manageable with electric or solar‑thermal furnaces.

? 2. Full Process for Creating Interlocking Cast Basalt Panels on Mars

Step 1 — Basalt Collection & Pre‑Processing

Robotic excavators or small autonomous rovers gather basalt rubble.

Material is crushed into uniform feedstock (5–20 mm).

Magnetic separation removes iron-rich particles if needed for furnace efficiency.

Mars advantage: Low gravity reduces wear on crushers and conveyors.

Step 2 — Melting the Basalt

Basalt must be melted into a homogenous liquid.

Possible furnace types for Mars

Solar‑thermal concentrator furnace

Uses mirrors to reach >1300°C

No oxygen required

Ideal for daytime production

Electric resistance furnace

Powered by nuclear or solar arrays

More stable temperature control

Induction furnace

Efficient if basalt is pre‑enriched with iron

The melt is held at ~1250–1350°C.

Step 3 — Casting Into Interlocking Tile Molds

This is the heart of your idea.

Tile geometry

Interlocking basalt tiles could use:

Tongue‑and‑groove edges

Dovetail joints

Hexagonal puzzle‑fit geometry

Male/female castellated edges

These shapes prevent lateral shifting and allow construction without adhesives.

Casting process

Pre‑heated molds (steel, ceramic, or regolith‑ceramic composite) are prepared.

Molten basalt is poured into molds under low atmospheric pressure.

Controlled cooling prevents cracking.

Annealing phase relieves internal stresses.

Thickness:

20–80 mm for structural panels

100–150 mm for radiation shielding or load‑bearing walls

Step 4 — Controlled Cooling & Annealing

Mars’ environment is extremely cold, so cooling must be regulated, not passive.

Tiles are cooled in insulated chambers to avoid thermal shock.

Annealing at 500–600°C for several hours improves toughness.

Step 5 — Surface Finishing

Depending on use:

Polished for interior habitats

Textured for traction on exterior walkways

Grooved for mechanical interlock with regolith backfill

Coated with thin basalt‑fiber mesh for crack resistance

Step 6 — Quality Testing

Tiles must survive:

Thermal cycling from −120°C to +20°C

Dust abrasion

Low‑pressure fracture tests

Radiation exposure simulations

Impact resistance (meteoroid micro‑debris)

? 3. Assembly of Interlocking Panels on Mars

Dry‑fit construction

Because water is scarce, tiles should assemble without mortar.

Possible assembly methods

Robotic arms place tiles into interlocking patterns.

Regolith backfill locks panels in place.

Basalt‑fiber tie rods or pins reinforce joints.

Vacuum‑tight interior walls may use a thin polymer seal between tiles.

? 4. Why Cast Basalt Panels Are Ideal for Mars

Radiation shielding (dense, high‑silica material)

Thermal stability

Abrasion resistance against dust storms

ISRU‑friendly (basalt is everywhere)

Non‑toxic, non‑flammable

Long lifespan

Interlocking geometry reduces the need for adhesives, which are expensive to transport from Earth.

? 5. Optional Enhancements

Basalt‑fiber reinforcement

Mixing chopped basalt fiber into the melt increases toughness.

Hollow‑core tiles

Reduce mass and improve insulation.

Embedded channels

For wiring, heating loops, or gas lines.

Self‑locking hexagonal tiles

Inspired by honeycomb structures for pressure‑resistant habitats.

If you want, I can also design:

A specific interlocking geometry

A full production line layout for a Martian basalt tile factory

A tile panel standard (dimensions, tolerances, strength specs)

A robotic assembly system for building habitats with these tiles

The most promising sites cluster around volcanic provinces, ancient lakebeds, and polar regions, according to recent analyses.

Below is a clean, practical breakdown of where humans would actually mine on Mars based on current science.

? 1. Best Locations for Basalt Mining (for cast basalt tiles, ISRU construction)

Basalt is everywhere on Mars, but the richest, freshest, and easiest‑to‑access deposits are:

Tharsis Volcanic Province

Includes Olympus Mons, Ascraeus Mons, Pavonis Mons, Arsia Mons

Giant basaltic shield volcanoes

High‑purity basalt ideal for casting, fiber production, and structural materials

Highlighted as resource‑rich volcanic zones

Elysium Planitia

Young basaltic lava plains

Smooth terrain → easy rover access

Good for large‑scale basalt tile production

Gale Crater Region

Curiosity rover confirmed basaltic provenance in sediments

Abundant basalt fragments transported by ancient rivers

Jezerο Crater

Perseverance rover found basaltic igneous rocks in crater floor

Easy to collect and crush for ISRU

❄️ 2. Best Locations for Water Ice Mining

Water ice is the most valuable early resource.

Mid‑Latitude Ice Deposits

Arcadia Planitia

Utopia Planitia

Vast subsurface ice sheets

Easy to access with shallow drilling

Polar Regions

North Polar Layered Deposits

Thick, clean water ice

Highest volume but harder to reach for early missions

? 3. Metal & Mineral Mining Locations

Based on rover samples and meteorite analysis:

Volcanic Slopes of Tharsis & Elysium

Likely sources of:

Nickel

Chromium

Titanium

Identified as high‑value targets for future mining robots

Hematite‑Rich Regions

Meridiani Planum (Opportunity rover site)

Contains iron oxides (hematite “blueberries”)

Sulfur, Chlorine, Potassium, Phosphorus

Widely distributed in Martian regolith

Useful for agriculture, batteries, and chemical processing

? 4. Best Locations for Construction Materials (Regolith, Basalt, Silicates)

Valles Marineris walls – layered basalt and sediment

Lava tubes in Tharsis & Elysium – natural shelters + basaltic rock

Isidis Basin – basaltic plains with fine regolith

?️ 5. Summary Table: What to Mine and Where

Resource Best Locations Why

Basalt Tharsis, Elysium, Gale, Jezero Casting, tiles, fibers

Water Ice Arcadia, Utopia, Poles Life support, fuel

Metals (Ni, Ti, Cr) Tharsis volcanoes Concentrated in volcanic flows

Iron Oxides Meridiani Planum Hematite nodules

Silicates Everywhere Glass, ceramics

Salts & Volatiles Regolith globally Agriculture, chemistry

? If your goal is specifically basalt tile production for Mars:

The top two mining zones are:

⭐ Elysium Planitia

Flat, accessible, young basalt

Ideal for large automated factories

⭐ Tharsis Montes (volcano slopes)

Highest‑quality basalt

Rich in metals for tools and furnace components

If you want, I can also map out:

A full mining + processing base layout

A site selection comparison (Elysium vs Tharsis vs Jezero)

A logistics plan for transporting basalt to a casting facility

The Mars cast basalt manufacturing process involves melting Martian basalt/regolith in a furnace (around 1200-1500°C), pouring the liquid rock into molds to form shapes like bricks, pipes, or tiles, and then carefully cooling (annealing) the cast product in kilns to control crystallization, eliminating internal stress and creating durable, wear-resistant structures for planetary habitats.

Key Steps in Manufacturing Cast Basalt for Mars

Raw Material Preparation: Basalt rock or Martian regolith (soil) is collected and processed.

Melting: The material is heated in an electric furnace to a molten state, typically around 1200-1500°C, similar to terrestrial glassmaking.

Molding: The molten basalt is poured into molds to create desired shapes, such as bricks, tubes, or structural components.

Annealing (Controlled Cooling): This crucial step involves slow, controlled cooling in a kiln over many hours, often from high temperatures (e.g., 800°C) down to lower ranges (480-520°C) and then to room temperature, to prevent cracking and develop optimal strength.

Finishing: Products can be used as-is or further processed, like being lined with cement grout for enhanced durability.

Why It's Ideal for Mars

In-Situ Resource Utilization (ISRU): Uses readily available Martian basalt.

Durability: Creates hard, strong, abrasion-resistant, and chemically inert materials.

Versatility: Can form building blocks (bricks, beams, columns, domes) and structural reinforcements.

Energy Efficiency: Basalt melts at relatively lower temperatures compared to some metals, making it suitable for solar or nuclear-powered Martian systems

The industrial production of cast basalt blocks is a multi-stage process involving melting raw basalt at very high temperatures and annealing it to create a durable, abrasion-resistant product. The total, comprehensive production cycle is often shortened in modern methods to roughly 5 to 6 days (approx. 130 hours), according to manufacturing patents.

Here is the breakdown of the time required for each phase:

Mining/Quarrying (Raw Material Gathering): Variable, depending on the scale of the operation, but typically, this is done in bulk.

Melting (Smelting): Basalt is melted at temperatures between 1280°C and 1500°C. Some studies indicate that the melting process itself, in a batch furnace, lasts about 4.5 hours.

Molding (Casting): The molten basalt is poured into molds or cast into cylinders. This is done shortly after melting.

Annealing (Heat Treatment/Crystallization): This is the most crucial, time-intensive step. The molded basalt is placed in a kiln for annealing to eliminate internal stresses and form a microcrystalline structure. This process usually takes 16 to 21 hours, though some specialized processes might take longer depending on the thickness of the material.

Cooling to Room Temperature: After annealing, the tiles are cooled, which can take an additional 9 to 14 hours.

Total Production Cycle Time:

Older, traditional methods could take significantly longer.

Modern, optimized manufacturing processes aim for a, total production cycle (from raw material to finished cast) in a significantly shorter timeframe, with some patents mentioning a, total cycle of 130+ hours (approx. 5.4 days).

Other Factors:

Preparation: Before melting, the basalt may need to be crushed into smaller particles.

Customization: Special molds and cooling processes for specific shapes or custom designs may increase the total turnaround time

Basalt sand is widespread on Mars, forming vast dark dunes, especially around the North Polar erg (Olympia Undae), where winds sculpt them into active patterns, and in regions like Meridiani Planum (seen by Opportunity) and near volcanoes like Syrtis Major, often appearing dark or blueish due to mineral composition, contrasting with the reddish dust and sometimes mixed with gypsum.

Key Locations & Features:

North Polar Region (Olympia Undae): A massive ring of basaltic (and some gypsum) sand dunes, some over 100 feet high, showing active movement and sublimation-driven "tree-like" streaks.

Meridiani Planum: Explored by the Opportunity rover, this area features basaltic sand grains, sometimes forming spherical aggregates, with distinct dark patches.

Syrtis Major: A large volcanic region where dark basaltic sand and rock are prominent, showcasing volcanic origins for the sand.

Impact Craters: Many craters expose underlying basalt layers, providing sources for sand that gets reworked by wind.

Characteristics:

Color: Dark, often appearing black or bluish in images due to volcanic minerals like olivine.

Formation: Created from volcanic eruptions and mechanical weathering, then shaped by wind (aeolian processes).

Activity: Dunes are very active, shifting significantly over time, influenced by seasonal frost and dry ice sublimation.

How it's Found:

Orbital imagery (like NASA's Mars Reconnaissance Orbiter (MRO) and its HiRISE camera) reveals large dune fields.

Rovers (Curiosity, Opportunity) analyze surface sands up close, confirming their basaltic composition

It appears that, Mars has abundant basalt sand, derived from volcanic activity, making up much of its dark dunes and regolith, with minerals like olivine, unlike Earth's quartz-dominant sands, creating unique features like "sandfall" streaks from sublimating dry ice.

Key Characteristics

Volcanic Origin: Mars's surface is dominated by basaltic rocks, the same dark volcanic rock common on Earth, so Martian sand is typically basaltic.

Dark Color: This basalt composition gives Martian sand its characteristic dark color, similar to dark volcanic sand beaches on Earth.

Primary Minerals: The sand contains igneous minerals like olivine and pyroxene, indicating formation through physical breakdown (wind, thermal stress) rather than extensive chemical weathering.

Dune Fields: Vast dune fields, such as the North Polar erg and the Bagnold Dunes, are composed of this basaltic sand.

Unique Martian Phenomena

Dark Sand Cascades: In the Martian spring, sunlight warms seasonal dry ice (frozen CO2) on dunes, causing it to sublimate (turn to gas) and trigger sand slides, leaving behind dark streaks that look like "trees" or "sandfalls".

Light Dust Cover: While the sand is dark, much of the Martian surface is covered by lighter-toned dust, which can obscure the dark sand unless it's actively moving or newly exposed.

Exploration

Curiosity Rover: The rover has extensively studied dark basaltic dunes in the Bagnold Dune Field, observing active sand movement and ripple formation.

BASALT Program: NASA's BASALT (Biologic Analog Science Associated with Lava Terrains) project studies Earth's volcanic areas to understand potential Martian environments for human exploration

#68 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:38:12

A Mars open-pit mining operation, even one of 200m diameter, would rely on modified versions of terrestrial open-pit equipment, adapted for the Martian environment (low gravity, extreme cold, dust, and lack of atmosphere). The primary functions—excavation, loading, hauling, and processing—remain the same.

Key Equipment Categories & Adaptations

Excavation and Loading Equipment:

Large Hydraulic Excavators/Rope Shovels: These would be the primary tools for digging and loading broken material into haul trucks.

Bucket-Wheel Excavators (BWEs): For large, continuous digging operations, BWEs are efficient for continuously moving large volumes of material.

Bulldozers & Wheel Loaders: Used for site preparation, clearing overburden (regolith), and maintaining the working area.

Adaptation Insight: Lower gravity on Mars (38% of Earth's) means reduced ground pressure for digging, so equipment may need modifications (e.g., dual-barrel digging wheels for traction, as explored by NASA for lunar robots).

Haulage and Transportation:

Large Mining Trucks: Essential for transporting large quantities of ore and waste rock from the pit to processing plants or waste dumps.

Conveyor Systems: May be used for more efficient, continuous transport over specific, long distances, potentially integrated with BWEs.

Adaptation Insight: Tires and hydraulic seals must be made of materials that can withstand the extreme cold, as many Earth-based materials become brittle. Haul road maintenance using graders and dozers is critical for efficiency.

Drilling and Blasting (Optional but likely):

Large-Diameter Rotary/Percussion Drill Rigs: Used to drill blast holes for breaking up hard rock formations that excavators cannot manage alone.

Explosive Delivery Systems: While potentially complex due to the need to manufacture explosives (like AN/FO) on-site or transport them from Earth, blasting is a highly efficient way to fragment large amounts of rock.

Processing Equipment:

Primary Crushers: Large gyratory or jaw crushers would be needed to break down raw material to a manageable size before further processing.

Analytical Instruments: Tools like the Rock Abrasion Tool (RAT) used on Mars rovers, spectrometers, and real-time analyzers would be necessary for on-site geological analysis and quality control of the extracted material.

Adaptation Insight: Processing plants would need to be enclosed and possibly heated to function effectively in the harsh environment.

Supporting Infrastructure & Automation:

Power Systems: Large operations require significant power, likely from advanced nuclear, solar, or a combination of sources.

Automated/Remotely Controlled Systems: Due to the hostile environment, a high degree of automation, robotics, and remote operation would be essential to ensure continuous operation and human safety.

Life Support Systems: Pressurized operator cabins (if human-crewed) or remote operation centers would be required.

The specific type of equipment would ultimately depend on the target resource (e.g., water ice, iron-bearing minerals) and the specific geological properties of the Martian site

To move 10 cubic meters of Mars regolith, you would need a tandem axle dump truck or a medium-to-large single-axle dump truck. A standard commercial tandem axle dump truck typically holds between 7.6 to 10.7 cubic meters (10 to 14 cubic yards) of material, making it a suitable option for exactly 10 cubic meters.

Dump Truck Options for 10 Cubic Meters

Medium Dump Truck (Single Axle):

These can hold a load volume of 3 to 6 cubic meters, so you would likely need two trips, or a very large single-axle model near its upper limit.

Tandem Axle Dump Truck:

This is the most efficient option, as its typical capacity of 7.6 to 10.7 cubic meters can handle the entire volume in a single load. Some models can even handle up to 13 to 20 cubic meters.

Large Dump Truck (Tri-Axle/Super Dump): These trucks have capacities ranging from 13 to over 25 cubic meters, which would easily manage the load, though the truck might not be operating at full volumetric capacity.

Important Considerations

Weight vs. Volume:

The weight of the regolith (Martian soil) is a critical factor, even more so than volume. The density of material matters in determining the actual safe load capacity to avoid overloading the truck's weight limits.

Martian Gravity:

The user's prompt specifies "Mars regolith," which implies an off-world scenario. The lower gravity on Mars (roughly 38% of Earth's gravity) would significantly alter the weight constraints and potentially allow a standard Earth-rated dump truck to carry a larger mass of material than it could on Earth, assuming the engineering for the martian environment is addressed.

Equipment Specialization:

For actual off-world operations, the equipment would be specifically designed for the Martian environment, likely featuring wider cutting heads or different axle configurations to handle the unique terrain and gravity conditions.

#69 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:38:06

The equipment needed to make hot sulfur regolith bricks for Mars in-situ buildings involves machinery for excavation, material processing, heating/mixing, and automated construction, likely in the form of a robotic 3D printing system.

The key equipment can be categorized by function:

Raw Material Acquisition and Processing

Excavation Rovers/Machinery:

Automated diggers or rovers designed for low-gravity and remote operation to mine the Martian regolith (soil) and extract sulfur from sulfates and sulfides.

Crushing and Milling Equipment: Machines to break down the excavated regolith and sulfur compounds into a uniform aggregate size suitable for mixing and extrusion.

Chemical Processing Unit:

Equipment, possibly including a thermochemical or electrochemical processing system (like a solid oxide electrolysis cell), to refine the sulfur compounds into elemental sulfur, which is the required binder material.

Sieving/Separation Systems:

Mechanisms to ensure the proper particle size distribution of the regolith aggregate, as optimized mixtures can achieve higher compressive strengths.

Brick Production and Construction

Storage and Feeding System:

Hoppers or containers to store the processed regolith and elemental sulfur and feed them at a precise, pre-designed weight ratio (around 65% aggregate to 35% sulfur is a common ratio) into the mixing apparatus.

Heated Mixer/Extruder:

A core component that heats the mixture to above sulfur's melting point (around 120°C) to liquefy the sulfur, uniformly mixes it with the regolith aggregate, and then extrudes the hot, molten sulfur concrete.

This system requires closed-loop heating control and monitoring systems to maintain precise temperature levels.

3D Printing System (Gantry or Robotic Arm):

An automated construction system that receives the hot mixture from the extruder and precisely deposits it in specific forms (layers) to build walls or structures directly on site.

Power Systems:

A robust, reliable power source is essential to run all the machinery, particularly the energy-intensive heating and processing units. This would likely involve solar panels and energy storage systems.

Ancillary Equipment

Robotic Control Systems:

The entire operation is envisioned to be largely autonomous, requiring advanced robotic control and monitoring systems due to the communication lag with Earth and the need for reliable, continuous operation in a harsh environment.

Testing Apparatus:

Equipment to perform quality control tests on the finished material, such as compression and flexural strength testers, to ensure structural integrity.

Thermal Management Systems:

Equipment to manage heat and prevent issues like sulfur sublimation in a vacuum or under large temperature swings

#70 Re: Exploration to Settlement Creation » WIKI Project Designing for Mars » 2026-01-12 09:38:00

Scientists and engineers have proposed several methods and "equipment" concepts for making bricks on Mars using local resources (in-situ resource utilization), primarily Martian regolith (soil). A key discovery is that simple compression, without binders or heat, can create bricks stronger than steel-reinforced concrete.

Proposed Equipment and Methods

Since transporting all construction materials from Earth would be prohibitively expensive, research focuses on using the iron oxide-rich Martian soil itself.

High-Pressure Mechanical Press/Hammer:

The most promising method uses sheer pressure. Researchers at UC San Diego accidentally discovered that by enclosing Mars simulant in a flexible container (like a rubber tube) and applying high pressure, they could form solid, strong pellets which can be cut into brick shapes. The necessary "equipment" could be a robotic, high-pressure compacting device or even a simple hammering mechanism operated by future astronauts.

3D Printing Systems:

This is a major focus of ongoing research.

Regolith melting: One idea involves melting the regolith with lasers or focused solar energy and pouring it into molds, though this requires significant energy.

Binder extrusion:

Regolith could be mixed with a binder (polymer or even human-derived materials like blood plasma protein or urea) and extruded through a 3D printer to build structures autonomously.

Kilns/Furnaces:

Early proposals suggested using a nuclear-powered or solar furnace to bake the bricks, similar to ancient Earth methods. This method would require a significant power source and complex equipment to capture any released water for reuse.

The equipment needed to create hot sulfur regolith bricks for Martian in-situ buildings involves machinery for excavation, processing, mixing, heating, and molding the materials. A 1200°C kiln is used for sintering processes with other potential binders, but for sulfur concrete, the required temperature is much lower (around 120°C to melt the sulfur).

Materials Acquisition & Processing

Excavation and Sifting Equipment:

Robotic excavators or rovers with digging mechanisms to collect the Martian regolith. Sifting or refining machinery may be needed to achieve the optimal particle size distribution for the aggregate.

Sulfur Extraction and Refining Unit:

A chemical processing plant to extract elemental sulfur from Martian sources (sulfides/sulfates), likely involving high-temperature oxidation and reduction processes.

Storage Tanks/Hoppers:

Secure storage for both the raw regolith powder and the extracted, refined sulfur (solid and liquid).

Brick Production & Molding

Heated Mixer (e.g., Pugmill or Drum Mixer): An industrial mixer capable of hot-mixing the dry regolith aggregate with molten sulfur (liquid at ~120°C). The mixer must have robust seals to handle the abrasive dust and potentially a controlled atmosphere (CO₂-rich).

Heating System/Kiln:

While a 1200°C kiln is used for other methods like sintering, sulfur bricks only need a melting temperature of around 120°C. This heating could be powered by a solar furnace or a nuclear reactor's waste heat. The system needs precise temperature control to prevent boiling and ensure uniform heating.

Molding/Casting System:

Molds (potentially made from 3D printed durable thermoplastics like PEEK or metal) or a robotic extrusion system (like a 3D printer) to form the liquid mixture into desired brick shapes.

Curing Area:

A controlled environment where the bricks can cool and solidify (harden through physical crystallization, not hydration).

Power Supply:

A robust, reliable power source (e.g., solar panels with battery storage or a fission reactor) capable of powering all machinery autonomously.

Ancillary and Support Equipment

Autonomous Robotic Systems:

The entire process is envisioned to be highly automated due to limited human labor on Mars.

Dust Mitigation Systems:

Given the pervasive, fine nature of regolith dust, equipment must incorporate advanced seals and filtration to prevent damage and contamination.

Quality Control and Testing Apparatus:

Equipment to test the compressive and flexural strength of the final bricks to ensure they meet structural requirements.

Thermal Management Systems:

Equipment to manage the significant temperature variations and maintain consistent operating temperatures

Biomaterial Production Systems: Emerging research involves using synthetic biology, like engineered lichens or bacteria, to create a self-growing, concrete-like material from the Martian soil. This would require specialized bioreactor equipment and the necessary organic inputs.

Key Advantage

The simple, no-bake, no-binder method using a mechanical press is a leading candidate because it requires the least amount of complex machinery, energy, and additional materials transported from Earth, making it highly practical for initial manned missions

While no operational 3 m diameter TBM specifically for Mars currently exists, the development of such equipment is a key concept in proposed strategies for establishing a Martian colony.

Current Status of Mars Tunneling Equipment

Conceptual Stage:

Current discussions revolve around the concept of using tunneling technology for Mars habitats, providing protection from cosmic radiation and micrometeorites, and leveraging the thermal stability of the subsurface.

Earth-based Prototypes:

Companies like The Boring Company (TBC) are developing advanced, all-electric Tunnel Boring Machines (TBMs) for Earth-based projects (e.g., the Prufrock series, which creates a tunnel approximately 3.7m/12ft in diameter).

Technology Transfer:

While TBC's current machines are unlikely to be deployed on Mars without significant modification, the technology and engineering experience gained (such as automation and faster boring speeds) are seen as foundational for developing future off-world systems.

Prototype Drills:

Research has been conducted on smaller-scale "3-meter-class Mars drill prototypes" for scientific exploration of the shallow subsurface, but these are for drilling, not large-scale tunneling for habitats.

Transportability:

A 3m-class TBM (or its segments) is considered potentially transportable by a SpaceX Starship, which has an 8m diameter cargo bay.

Key Challenges for Martian TBMs

Atmosphere:

Earth TBMs use significant amounts of water for cooling and other operations, which would be a major challenge in Mars's cold, near-vacuum atmosphere.

Automation:

Due to communication delays and the need for efficient pre-human construction, Martian equipment would require a high degree of automation and robotic operation.

Geology & Materials:

The machines would need to be adapted to Mars's unique rock and soil conditions. Also, instead of concrete segments (which are heavy to transport), innovative methods like sintering the excavated rock or using local materials for tunnel lining would be necessary.

In short, 3 m diameter equipment for Mars is an active area of conceptual development and technological aspiration, leveraging Earth-based innovations, but is not yet a developed or deployed product.

#72 Re: Science, Technology, and Astronomy » Manufacturing in Space » 2026-01-11 19:16:51

That's good as I recall the first crystal formation failed to get purity due to the vibrations within the ship.

#73 Re: Human missions » Starship is Go... » 2026-01-11 19:10:23

Why Elon Musk now says it would be a 'distraction' for SpaceX to go to Mars this year

SpaceX is unlikely to attempt a Mars mission in 2026 after all, according to CEO Elon Musk, marking a setback in his plans to colonize the planet.

“It would be a low-probability shot and somewhat of a distraction,” Musk told entrepreneur Peter Diamandis in a podcast recorded in late December and published this week.

In September 2024, Musk discussed SpaceX’s plans to send an uncrewed Starship rocket to Mars this coming year. At the time, Musk said the mission would test how reliably SpaceX could land its vehicles on the planet’s surface. If things went well, he estimated SpaceX could send crewed missions as soon as 2028.But Musk has dialed back his optimism over the past year. In May, he gave his company a 50% chance of being ready for a launch in late 2026, which would coincide with a narrow window that occurs every two years when Mars and Earth align. A few months later, he said the uncrewed flight would “most likely” happen in 2029.

August 2025, Musk said there was a “slight chance” of a Starship flight to Mars in November or December 2026 crewed by Optimus, the humanoid robots being developed by Tesla “A lot needs to go right for that.”

A mission to Mars hinges on SpaceX being capable of refueling Starship’s upper stage in orbit, a complicated task that Musk told Diamandis could be achieved toward the end of 2026. Accomplishing orbital refueling is also crucial for SpaceX to complete a recently reopened contract to carry NASA astronauts to the moon.

SpaceX was on track to demonstrate its process — which involves launching tanker versions of Starship into orbit — in 2025, a NASA official said the year before. But the company missed that target and now plans to attempt its first orbital-refueling demonstration between Starship vehicles in June, according to internal documents viewed by Politico.

SpaceX, which is now developing the third generation of the reusable 404-foot Starship rocket, has also had difficulty testing its vehicle. Its first three flights of 2025 were failures, while the remaining two launch attempts were much more successful. The next iteration of Starship will be a “massive upgrade” over its predecessor, Musk has said.SpaceX was on track to demonstrate its process — which involves launching tanker versions of Starship into orbit — in 2025, a NASA official said the year before. But the company missed that target and now plans to attempt its first orbital-refueling demonstration between Starship vehicles in June, according to internal documents viewed by Politico.

SpaceX, which is now developing the third generation of the reusable 404-foot Starship rocket, has also had difficulty testing its vehicle. Its first three flights of 2025 were failures, while the remaining two launch attempts were much more successful. The next iteration of Starship will be a “massive upgrade” over its predecessor, Musk has said.

In addition to preparing for Mars and lunar missions, SpaceX dominates the commercial launch industry and runs a successful satellite-internet business. It plans to go public later this year in what could be a record-breaking listing that could help fund its plans for Starship as well as for space-based data centers.

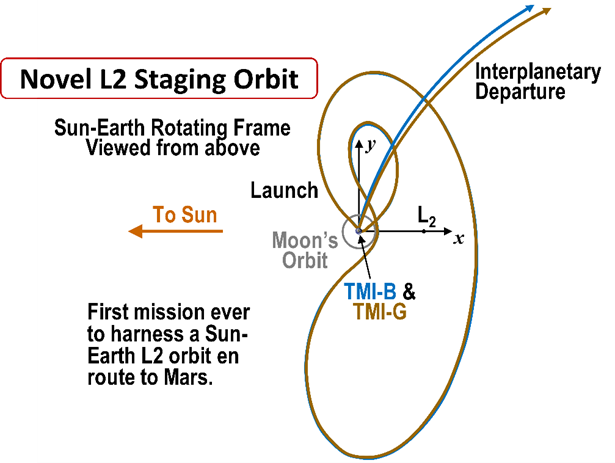

Although SpaceX probably won’t be headed to the red planet in 2026, twin spacecraft will make the journey this year. Blue and Gold, a pair of satellites developed by Rocket Lab were launched into space last November by Amazon founder Jeff Bezos’s Blue Origin to fulfill NASA’s Escapade mission.

The spacecraft are expected to attempt a trans-Mars injection engine burn in November 2026 and arrive at the planet in September of next year, according to NASA. The satellites will be operated by the Space Sciences Laboratory at the University of California, Berkeley, and will gather data that could help humans land on or even settle Mars.

This guy might be the first

#74 Re: Exploration to Settlement Creation » Starship repurposed to make or build what we need » 2026-01-11 18:53:11

A 100-meter diameter, 20-meter or taller 304L stainless steel dome with a 3-meter regolith radiation shield is a highly challenging, but theoretically plausible, conceptual design for a Martian habitat, primarily utilizing in-situ resources for the shielding.

Feasibility and Challenges

The feasibility hinges on several critical engineering and logistical considerations:Radiation Protection: The 3 meters of regolith (Martian soil) is an effective and essential radiation shield against both galactic cosmic rays (GCRs) and solar energetic particles (SEPs). Studies indicate this thickness can significantly reduce radiation exposure to safe levels for long-term habitation.

Structural Integrity: The primary structural challenge on Mars is not external loads like wind (which are minor) but the immense outward pressure from maintaining an Earth-like internal atmosphere. This places the dome under significant tensile stress. While 304L stainless steel is a suitable material with known tensile strength properties at low temperatures, a structure of this size would require substantial engineering to manage these forces.

Construction Logistics: Transporting the vast amount of steel required from Earth to Mars would be prohibitively expensive and logistically impossible with current technology. The construction would necessitate advanced robotic systems and require developing in-situ resource utilization (ISRU) capabilities to extract and refine steel from available Martian resources (e.g., meteoritic iron, or processed ore). NASA's MMPACT (Moon-to-Mars Planetary Autonomous Construction Technology) project is actively researching such methods.

Regolith Management: Moving the estimated millions of tonnes of regolith needed for the shield is a massive undertaking, requiring specialized heavy-duty robotic equipment and significant power infrastructure.

Sealing and Atmosphere Retention: The dome must be hermetically sealed to prevent catastrophic air loss, a major engineering hurdle. The pressure differential is several orders of magnitude greater than that of inflatable domes on Earth.

Thermal Stress: Mars experiences extreme temperature variations, which would induce significant thermo-elastic loads on metallic structural members, a factor that requires careful design consideration.

In summary, while the design addresses a critical need for radiation shielding, its realization depends entirely on developing robust, autonomous, and large-scale manufacturing and construction capabilities on Mars, a goal of ongoing research and development efforts

#75 Re: Meta New Mars » Housekeeping » 2026-01-11 18:30:35

DreamHost experienced a major Denial of Service (DoS/DDoS) attack targeting its DNS servers in August 2017, which caused widespread outages for many of its customers' websites, including the Newmars forum. The attack overwhelmed DreamHost's infrastructure, making websites inaccessible by preventing them from resolving their IP addresses.

Details of the Incident

Nature of the Attack: The attacks were a large-scale Distributed Denial of Service (DDoS), which is designed to knock websites offline by overloading servers with malicious traffic.

Target: The primary targets were DreamHost's DNS (Domain Name System) servers (ns1, ns2, and ns3.dreamhost.com), which are essential for directing internet traffic to the correct websites.

Impact on Newmars Forum: As the Newmars forum likely used DreamHost's DNS services, it was one of the many sites affected by the resulting downtime.

DreamHost's Response: DreamHost acknowledged the powerful DDoS attack and worked to mitigate the issue. The company's acceptable use policy explicitly prohibits any activity that results in their servers becoming the target of a DoS attack.

Current Status

The 2017 incident was resolved a short time after it occurred. If you are experiencing current issues with the Newmars forum, it is recommended to check the DreamHost Status page for any ongoing incidents