New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 Yesterday 16:23:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

WIKI Project Designing for Mars

NOT A DISCUSION TOPIC

Project design is the crucial early phase of outlining a project's "why" and "what"—defining goals, scope, resources, deliverables, and success criteria before detailed planning—to create a strategic blueprint for stakeholders, often using visuals like flowcharts to align teams and guide execution. It establishes the conceptual foundation, differing from detailed project planning which focuses on "how" tasks get done.

Key components

• Goals & Objectives: What the project aims to achieve (SMART goals are ideal).

• Scope & Deliverables: Boundaries of the project and tangible outputs.

• Methodology & Strategy: High-level approach and chosen processes.

• Resources & Budget: People, tools, budget estimates, and constraints.

• Success Criteria & KPIs: How success will be measured.

• Risks: Potential issues and mitigation strategies.

Purpose

• Alignment: Gets everyone (team, stakeholders) on the same page.

• Foundation: Creates a clear, agreed-upon path before detailed work begins.

• Visualization: Uses tools (Gantt, Kanban) to make strategy transparent.

• Buy-in: Secures stakeholder approval for the overall direction.

Process steps (simplified)

1. Define the core problem/opportunity.

2. Establish clear goals and SMART objectives.

3. Identify key deliverables and success metrics.

4. Map out required resources and budget.

5. Identify potential risks and constraints.

6. Create visual aids (flowcharts, mockups) to communicate the design.

7. Get stakeholder feedback and approval.

Project design provides the strategic "why" and "what," leading into the detailed "how" of project planning, with outputs like project charters and plans built upon this initial framework

Project design concepts are the foundational ideas, principles, and high-level plans guiding a project, defining its goals, structure, and key features before detailed planning, using visuals like flowcharts and mood boards to align stakeholders on the 'why' and 'what,' ensuring a shared vision for success. Key elements include defining outcomes, identifying stakeholders, exploring options (like sustainability or accessibility), and establishing success criteria, serving as the blueprint for later execution.

Core Components of Project Design Concepts

• Goals & Objectives: What the project aims to achieve (e.g., "sleek and minimalist" for a phone).

• Target Audience & Problem: Who it's for and the problem it solves.

• Scope & Deliverables: What's included and what will be produced (e.g., sketches, prototypes, reports).

• Guiding Principles: Overarching ideas like sustainability, accessibility, or efficiency.

• Visuals & Mood Boards: Mood boards, sketches, flowcharts to convey aesthetics and process.

How They Work

1. Early Stage: Happens before detailed planning or charter development.

2. Blueprint: Creates a broad overview (the "what" and "why").

3. Exploration: Involves generating and evaluating multiple design options.

4. Stakeholder Alignment: Gets buy-in by presenting choices and setting expectations early.

Examples of Design Principles & Concepts

• Product: "Safe and reliable" (car) or "Intuitive user experience" (app).

• Architecture: Integrating local culture, sustainability, or maximizing natural light.

• Process: Using Agile principles or a specific project management methodology

In essence, a project design concept is the strategic "big picture" that transforms abstract goals into a tangible vision, guiding the entire project from its inception to successful completion.

Project design phases generally move from understanding the problem to creating detailed solutions, often covering Programming/Pre-Design, Schematic Design, Design Development, Construction Documents, Bidding, and Construction Administration, though models vary (like the AIA's 5 phases or broader project management cycles). Key stages define scope, develop concepts, produce technical drawings, select builders, and oversee building, ensuring a structured path from idea to reality.

Here's a common breakdown, blending architectural and project management steps:

1. Programming/Pre-Design (Problem Seeking): Define project goals, needs, budget, site analysis, and scope.

2. Schematic Design (Concept): Develop broad concepts, sketches, and basic layouts to explore possibilities.

3. Design Development (Refinement): Flesh out the chosen schematic design with materials, systems, and detailed plans.

4. Construction Documents (Technical Drawings): Create detailed blueprints and specifications for construction.

5. Bidding/Negotiation: Solicit and select contractors.

6. Construction Administration (Building): Oversee the building process, ensuring it matches the design.

Variations & Other Models:

•

Engineering:

Includes research, feasibility, concept generation, detailed design, and production planning.

•

Design Thinking:

Focuses on empathy, defining problems, ideating, prototyping, and testing (Discover, Define, Develop, Deliver).

•

Project Management Lifecycle:

Broader stages like Initiation, Planning, Execution, Monitoring & Control, and Closure.

No matter the model, the goal is to break a complex project into manageable steps, moving from abstract ideas to concrete results

Offline

Like button can go here

#2 Yesterday 16:23:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

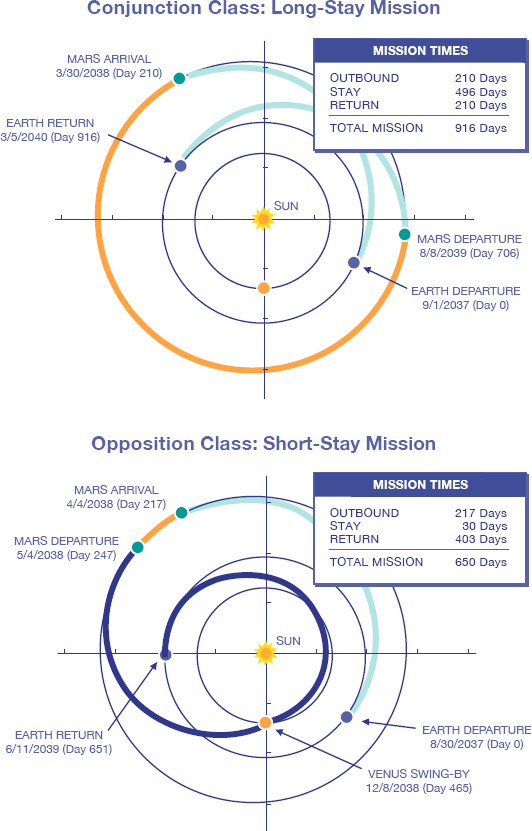

Mars missions for human spaceflight are primarily categorized into two types based on their trajectories and duration: Conjunction-class (long-stay) and Opposition-class (short-stay). Missions are constrained by the relative orbits of Earth and Mars, with launch windows occurring roughly every 26 months (the planets' synodic period).

Conjunction-class missions are generally favored in many studies because they offer significantly more time for surface exploration at a lower fuel cost and reduced crew exposure to the risks of prolonged zero-gravity and deep-space radiation.

Opposition-class missions, while having a shorter overall mission duration, require more advanced propulsion and expose the crew to more time in space and harsher conditions.

Mission Cycles

Launch Windows: Due to the relative orbits of Earth and Mars, launch windows (times of minimum energy transfer) open approximately every 26 months, or 780 days.

Optimal Windows: The specific energy requirements and travel times vary over a larger, roughly 15-year cycle, with certain windows offering the most optimal conditions (e.g., opposition occurring when Mars is closest to the Sun).

Solar Cycle: Mission planning must also consider the approximately 11-year solar cycle. Launching during a solar minimum helps mitigate the risks from solar storms and radiation exposure to the crew

NASA Space Mission Life Cycles

NASA project life cycles are divided into two primary phases: Formulation and Implementation.

Formulation Phase (Planning and Technology Validation)

Pre-Phase A: Concept Studies and Mission Definition - Broad ideas are produced and alternatives for missions are analyzed to confirm the mission need and feasibility.

Phase A: Concept and Technology Development - The feasibility of the suggested system is determined, and initial requirements and architecture are developed to establish a baseline for funding.

Phase B: Preliminary Design and Technology Completion - The project is defined in enough detail to establish an initial baseline and mitigate technical and programmatic risks.

Implementation Phase (Building, Launch, and Operation)

Phase C: Final Design and Fabrication - The system design is finalized, and hardware fabrication and assembly begin.

Phase D: System Assembly, Integration & Test, Launch - The system is assembled, integrated, tested, and prepared for launch/deployment.

Phase E: Operations and Sustainment - The mission is actively flown, and data is analyzed and sustained.

Phase F: Closeout - The system is retired after meeting its operational objectives.

This structure allows managers and stakeholders to assess technical progress and make informed decisions at key decision points (KDPs) separating each phase

Offline

Like button can go here

#3 Yesterday 16:24:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Designing a Mars mission involves defining clear goals (e.g., find life, establish presence), setting specific objectives (e.g., collect samples, test life support), choosing mission types (robotic, human, precursor cargo), and detailed planning for technology, logistics (launch, propulsion, landing), science operations, and risk management, all within budget and schedule constraints, following a phased approach like NASA's Moon to Mars strategy.

Types of Mars Missions

Robotic Landers/Rovers: Focus on remote science (habitability, past life, geology), sample collection (Perseverance), and preparing sites for humans (e.g., Mars 2020).

Cargo Missions: Pre-position supplies, habitats, and infrastructure before human arrival (e.g., NASA's 2033 plan).

Crewed Missions (Opposition/Conjunction Class): Long-duration missions with humans, requiring advanced life support, propulsion, and significant pre-placed assets.

Orbiter Missions: Study Mars from orbit, mapping, atmospheric analysis, and supporting surface operations (e.g., Indian Space Research Organisation's MOM).

Goals & Objectives

Overarching Goals: Discover past/present life, understand Mars's evolution, learn to live and work on other planets, prepare for sustained human presence.

Science Objectives: Identify key measurements, samples, landing sites for specific science campaigns (e.g., searching for biosignatures).

Technology Objectives: Develop and demonstrate new systems for propulsion, life support, surface power, entry/descent/landing (EDL).

Planning & Design Principles

Objective-Based Approach: Start with the "what" (goals/objectives) and work backward to design the "how".

System of Systems: Integrate various elements (launch vehicles, transit habitats, landers, surface assets) into a cohesive architecture.

Constraints: Design within strict mass, power, budget, and schedule limits.

Phased Approach: Utilize precursor robotic missions to pave the way for human exploration (Moon to Mars Strategy).

Risk Management: Address environmental factors (radiation, dust, communication lag) and engineering challenges.

Key Planning Stages & Elements

Define Science & Exploration Goals: What do we want to learn/achieve?.

Develop Mission Architecture: How will we get there and operate (split vs. single launch, propulsion, vehicles)?.

Technology Development: Build necessary tech (e.g., advanced engines, habitats).

Mission Operations: Plan for launch windows, transit, landing, surface activities, and sample return.

Instrumentation & Site Selection: Choose instruments and landing spots to meet objectives.

Collaboration & Public Engagement: Work with partners (international, industry) and build support

Offline

Like button can go here

#4 Yesterday 16:24:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Project design for exploratory missions involves defining clear objectives, assembling diverse expert teams, developing concepts of operation (ConOps), conducting trade studies (AoA), identifying risks, and iteratively planning detailed activities using specialized software, all within structured life cycles (like NASA's) to move from initial ideas to a flight-ready plan, focusing on flexibility and measurable success. Key steps include envisioning, building minimum viable products (MVPs) for testing, deploying, observing, and deciding whether to cancel or productize the concept, all while managing constraints and contingency needs.

Key Stages & Activities

Concept & Definition (Envisioning):

Define Purpose & Objectives: Establish clear, SMART (Specific, Measurable, Attainable, Relevant, Time-bound) goals (e.g., scientific discovery, tech advancement).

Stakeholder Engagement: Involve science experts, engineers, project managers, and users to capture needs and goals.

Develop ConOps: Outline how the mission will operate, from launch to data collection.

Design & Analysis (Build & Observe):

Trade Studies (AoA): Evaluate alternatives for systems, trajectories, and operations.

Technology Development: Test hypotheses through building and deploying MVPs (Minimum Viable Products).

Risk Identification: Classify and identify initial technical risks.

Software Tools: Utilize tools like NASA's GMAT for trajectory design or SPICE for observation planning.

Planning & Iteration (Deploy & Productize):

Detailed Planning: Create specific activity plans, including contingency plans (e.g., backup Trajectory Correction Maneuvers - TCMs).

Flexibility: Use flexible plans that allow for adjustments (e.g., MAPGEN for Mars rovers).

Testing & Validation: Perform operational readiness tests (ORT).

Iterative Cycles: Loop back to refine plans based on observations and actual constraints.

Core Principles

Iterative & Adaptive: Plans evolve to meet changing constraints and priorities.

Data-Driven: Observation and measurement guide decisions.

Cross-Disciplinary: Success requires integrating science, engineering, and operations.

Risk Management: Proactive identification and mitigation of risks are crucial.

Example Frameworks

NASA's Lifecycle: Moves from concept to formulation, development, and operations.

Disciplined Agile (DA): Uses an exploratory lifecycle with envision, build, deploy, observe, and cancel/productize phases.

The primary project design goals for Mars construction management are centered on sustainability, self-sufficiency, safety, and efficient resource utilization due to the extreme and isolated environment. These goals ensure human survival, scientific advancement, and a foundation for a potential long-term settlement.

Key design goals include:

Survival and Safety

Radiation Protection: Designing structures, often buried or semi-buried, that provide robust shielding from the high radiation levels in the Martian environment.

Environmental Protection: Protecting crew, hardware, and electronics from extreme temperature variations, atmospheric differences, and micrometeorites.

Structural Integrity and Pressurization: Engineering buildings capable of withstanding the internal pressure of a breathable atmosphere within the thin Martian atmosphere, managing associated tensile stresses.

Reliable Life Support Systems: Integrating robust and redundant life support systems (oxygen generation, water recycling, waste management) to create a self-sustaining environment.

Resource and Efficiency

In-Situ Resource Utilization (ISRU): Minimizing the mass of materials transported from Earth by leveraging local Martian resources (regolith, basalt, water ice, etc.) for construction, which is a major cost and logistics driver.

Additive Construction (3D Printing): Utilizing autonomous or semi-autonomous 3D printing technologies to build infrastructure (landing pads, habitats, roads) with minimal human involvement and using local materials.

Energy Efficiency and Generation: Designing systems that require minimal energy consumption for material processing and operations, while integrating reliable surface power sources, such as nuclear power.

Functionality and Habitability

Scalability and Adaptability: Designing initial systems that can be incrementally expanded and modified to meet the needs of a growing population with minimal recurring development effort.

Maximizing Interior Space and Habitability: Creating functional layouts that maximize usable space and provide a psychologically comfortable living and working environment to support long-duration missions and a healthy work-life balance.

Support for Science and Operations: Ensuring infrastructure supports a wide range of activities, including scientific research, testing, and eventual industrialization, beyond just basic survival.

Autonomy: Developing construction hardware and processes that can operate autonomously or be managed with minimal oversight from Earth, given the communication delays and operational challenges.

These goals require collaboration across multiple disciplines, including civil and aerospace engineering, architecture, and material science, often utilizing advanced technologies and rigorous project management methodologies to control cost, schedule, and risk. NASA's Moon to Mars Planetary Autonomous Construction Technology (MMPACT) project is actively developing many of these capabilities on the Moon as a stepping stone for future Mars missions

Living and Working on Mars

Oxygen

The Mars Oxygen In-Situ Resource Utilization Experiment, or MOXIE, is helping NASA prepare for human exploration of Mars by demonstrating the technology to produce oxygen from the Martian atmosphere for burning fuel and breathing.

Food

Astronauts on a roundtrip mission to Mars will not have the resupply missions to deliver fresh food. NASA is researching food systems to ensure quality, variety, and nutritional values for these long missions. Plant growth on the International Space Station is helping to inform in-space crop management as well.

Water

NASA is developing life support systems that can regenerate or recycle consumables such as food, air, and water and is testing them on the International Space Station.

Power

Like we use electricity to charge our devices on Earth, astronauts will need a reliable power supply to explore Mars. The system will need to be lightweight and capable of running regardless of its location or the weather on the Red Planet. NASA is investigating options for power systems, including fission surface power.

Spacesuits

Spacesuits are like “personal spaceships” for astronauts, protecting them from harsh environments and providing all the air, water, biometric monitoring controls, and communications needed during excursions outside their spaceship or habitat.

Communications

Human missions to Mars may use lasers to stay in touch with Earth. A laser communications system at Mars could send large amounts of real-time information and data, including high-definition images and video feeds.

Shelter

An astronaut's primary shelter on Mars could be a fixed habitat on the surface or a mobile habitat on wheels. In either form, the habitat must provide the same amenities as a home on Earth — with the addition of a pressurized volume and robust water recycling system.

Offline

Like button can go here

#5 Yesterday 16:25:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Project design goals for Mars construction center on sustainability, autonomy, and protection, focusing on using local resources (regolith) via 3D printing, pre-fabrication, and robotics to build habitats resistant to radiation, dust, and extreme temperatures, ensuring life support while minimizing Earth-based supplies and maximizing habitat modularity and long-term functionality for crew safety and expansion.

Core Design Goals

1. In-Situ Resource Utilization (ISRU):

• Use Regolith: Harvest Martian soil (regolith) as the primary building material for 3D printing structures.

• Create Building Materials: Develop methods (like laser sintering) to turn regolith into strong, durable construction materials (e.g., ceramic-like structures).

2. Autonomy & Robotics:

• Autonomous Construction: Deploy robotic swarms to excavate sites, print structures, and prepare habitats before astronauts arrive.

• Versatile Robots: Use robots with interchangeable tools for various tasks, including printing, sensing, and repair.

3. Environmental Protection:

• Radiation Shielding: Design structures with thick regolith shells or underground placement to shield against cosmic radiation.

• Thermal Management: Build to withstand extreme temperature fluctuations.

• Dust Mitigation: Incorporate robust designs and materials to handle corrosive Martian dust.

4. Sustainability & Efficiency:

• Minimize Earth Cargo: Reduce reliance on Earth by building with local materials.

• Energy Efficiency: Optimize shapes and use materials to minimize energy needed for construction.

• Waste Repurposing: Recycle waste into new furniture or parts using 3D printing.

5. Habitability & Modularity:

• Modular Design: Create connectable habitat units for easy expansion and resource sharing.

• Zoned Interiors: Separate wet (lab, kitchen) and dry (bedroom, workstation) areas for efficient resource use.

• Pressurized Cores: Use inflatable or prefabricated modules for the core pressurized areas, covered by the 3D-printed regolith shell.

6. Long-Term Viability:

• Durability & Repairability: Design components for long operational lifetimes and ease of onsite repair.

• Scalability: Create systems that can grow from initial outposts to larger settlement

Offline

Like button can go here

#6 Yesterday 16:26:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Mars settlement projects typically progress through phases from initial robotic exploration and small outposts (Pre-settlement) to permanent, growing settlements with developing infrastructure (In-settlement), culminating in self-sufficient, potentially terraformed societies (Post-settlement), focusing first on establishing basic life support, resource utilization (ISRU), energy, and habitats before expanding to a city-like presence with economic independence. Key stages involve robotic reconnaissance, crewed landings, building propellant plants, establishing habitats, developing local agriculture, mining, and transitioning to self-sufficiency, requiring advances in transportation, closed-loop life support, and energy systems.

Key Phases & Stages

1. Pre-Settlement (Robotic & Early Outpost):

• Robotic Reconnaissance: Detailed surveys, sample collection (e.g., Perseverance), testing technologies for fuel/oxygen production from the atmosphere.

• Cargo Pre-Deployment: Sending autonomous cargo, including fuel production equipment, before human arrival.

• First Crewed Missions: Establishing a rudimentary base, completing the propellant plant for return fuel, and testing life support.

2. In-Settlement (Permanent & Growing Colony):

• Infrastructure Development: Building habitats, mining water, growing crops, creating power systems (solar/nuclear).

• Resource Utilization (ISRU): Extracting and processing Martian resources (water, metals, minerals) for construction and fuel.

• Population Growth: Increasing crew sizes, developing a local economy, and establishing governance.

3. Post-Settlement (Self-Sufficiency & Beyond):

• Industrial Independence: Scaling up mining, manufacturing (3D printing, metals, plastics) to reduce Earth reliance.

• Societal Development: Growing into towns/cities, developing unique Martian culture, governance, and potentially independent political structures.

• Terraforming (Long-Term): Modifying the environment to create breathable air and habitable zones, a highly speculative long-term goal.

Key Technologies & Goals

• Transportation: Reliable, efficient Earth-Mars transport (e.g., SpaceX Starship).

• Life Support: Perfecting closed-loop systems for air, water, and food.

• Energy: Sustainable power generation (solar, nuclear).

• ISRU: Water extraction, atmospheric processing for fuel/oxygen, material processing.

• Habitats: Durable, radiation-shielded shelters (surface and underground)

Offline

Like button can go here

#7 Yesterday 16:27:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Mars settlement projects, like SpaceX's vision, progress through phases: pre-settlement (outposts), in-settlement (permanent bases), and post-settlement (self-sufficient society), aiming for crewed landings in the late 2020s/early 2030s and self-sufficiency by mid-century, requiring massive initial cargo (Starships carrying 100+ tons) for habitats, life support, and resource utilization (ISRU) like water and fuel production from Martian air and ice, with the ultimate goal of a large, self-sustaining population.

Phases of Development (Conceptual)

1. Pre-Settlement (Exploration & Outpost)

• Focus: Robotic missions, establishing basic infrastructure, resource identification (water ice, minerals).

• Key Tech: Advanced rovers, ISRU (In-Situ Resource Utilization) for oxygen/methane (fuel/air).

• Timeline: Current robotic exploration, early cargo missions (late 2020s).

2. In-Settlement (Permanent Base)

• Focus: First human landings, establishing initial habitats, expanding resource production (ISRU, agriculture), reducing Earth dependency.

• Key Tech: Habitable modules, power systems, water processing, basic manufacturing.

• Timeline: First crewed landings (early 2030s), developing permanent presence.

3. Post-Settlement (Self-Sufficient Society)

• Focus: Large-scale population, full industrialization, economic self-sufficiency, cultural development.

• Key Tech: Advanced manufacturing, large-scale life support, robust local economy, potential for terraforming elements.

• Timeline: Decades-long process, aiming for self-sufficiency by 2050+.

Timeline & Mass Estimates (SpaceX Example)

• Early Missions (2020s-2030s): Cargo & Crew via Starship (100+ tons capacity).

• Cargo: Essential for habitats, initial supplies, ISRU equipment.

• Crew: Small groups (4-10+), increasing over time.

• Self-Sufficiency: Goal by 2050, requiring a million people using numerous Starships over many launch windows (every ~26 months).

Mass Requirements & Challenges

• High Mass: Water, air (oxygen/nitrogen), fuel, food, equipment, habitats.

• ISRU Critical: Extracting water ice and using atmospheric CO2 for oxygen and methane fuel (CH4) is essential to reduce launch mass from Earth.

• Example: Water is heavy; a Starship (100 tons payload) could carry enough water for 20 people for years, but continuous resupply is needed.

In essence, Mars settlement requires a phased approach, leveraging current tech like Starship for massive cargo delivery, transitioning from outposts to permanent bases, and finally, fostering self-sufficiency through local resource utilization to support a growing population

Offline

Like button can go here

#8 Yesterday 16:27:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

In-situ (Latin for "on-site" or "in its original place") in the context of Mars construction refers to the practice of using local Martian resources, rather than transporting all materials and equipment from Earth. This is officially called In-Situ Resource Utilization (ISRU).

The core concept is "living off the land" to drastically reduce the enormous cost and logistical challenge of sending supplies across vast distances from Earth.

The idea that you would have no equipment at all is generally not feasible; some minimal, specialized equipment and robotic systems would be sent from Earth to act as the initial "factories" and "builders". How ISRU Addresses the "No Equipment" Constraint (Relatively) The goal is to minimize the mass and volume of material that must be launched from Earth, not to eliminate equipment entirely. Specialized, compact, and often autonomous, equipment would be sent first to leverage local materials.

The strategy involves: Sending minimal, critical machinery: Instead of sending heavy raw materials like concrete or steel beams, lightweight robotic equipment, 3D printers, and processing hardware are sent.

Utilizing local materials: The robots would use abundant Martian resources, primarily the soil (regolith) and atmosphere, to produce usable products.

Automated construction: The construction process would likely be managed by autonomous or semi-autonomous robots before humans arrive, allowing for the creation of habitats and infrastructure in advance.

Examples of In-Situ Resources for Construction With specialized equipment,

Mars offers several resources: Regolith (Martian soil): This can be used as a primary building material. Processes like sintering (fusing with heat) or mixing with binding agents (like an epoxy or sulfur) can create bricks, ceramics, and concrete-like structures for radiation shielding and general construction..

Water ice: Found below the surface, water is a critical resource. Once extracted, it can be used for life support (drinking water, growing food), split into hydrogen and oxygen (for breathing air and rocket propellant), or used in industrial processes.Atmospheric \(\text{CO}_{2}\): The Martian atmosphere is mostly carbon dioxide. Equipment like the MOXIE experiment on the Perseverance rover can extract oxygen from the atmosphere for life support and as an oxidizer for rocket fuel.

Basalt: Basaltic rocks are abundant and can be processed into glass or glass fibers, which have good insulating properties and can be used for construction. Essentially, "in-situ construction" is the practice of building with what you have on Mars, which is crucial for long-term sustainability and survival when resupply from Earth is nearly impossible

Basalt is a very hard, abrasive rock, so its processing for 3D printing requires robust, industrial-grade crushing and grinding machinery to produce the necessary fine powder or granule sizes. Typical crushing sequences involve multiple stages of specialized equipment, rather than a single machine.

Equipment for Basalt Crushing

A multi-stage process is typically used to break down large basalt rock into fine powder or granules suitable for applications such as fiber production or as an aggregate in 3D printed concrete.

Primary Crushing: Jaw Crushers

Purpose: The first stage of size reduction for large, raw basalt pieces.

Description: Jaw crushers are built strong with a deep crushing chamber to handle large, tough lumps of rock effectively, reducing them to sizes manageable by the next stage (e.g., from a meter down to a few inches).

Secondary/Tertiary Crushing: Cone Crushers or Impact Crushers

Purpose: To further reduce the basalt to a more uniform, smaller aggregate size (e.g., down to 0-40mm).

Description:

Cone crushers are highly recommended for hard, abrasive materials like basalt due to their durability and efficiency in producing a uniform, cubic product with lower wear rates than impact crushers.

Impact crushers can also be used, especially for shaping the material into a cubical form, but they tend to experience higher wear when processing hard basalt.

Fine Grinding (Milling): Ball Mills or Vertical Roller Mills

Purpose: To achieve the fine, micron-level powder needed for specialized 3D printing material composites, fillers, or fiber production.

Description: These machines use balls or high pressure to pulverize the basalt into the extremely fine particles required for additive manufacturing processes.

Screening and Classifying Equipment

Purpose: To sort the crushed material by size and ensure the final product meets the required specifications for 3D printing projects.

Description: Vibrating screens are used after each crushing stage to separate the desired product sizes from oversized material, which is then recirculated for further crushing. Air classifiers or washers may also be used to remove impurities and achieve specific material properties.

Considerations for 3D Printing Projects

Particle Size and Shape: 3D printing requires a consistent and specific particle size distribution (PSD). The equipment used must be able to produce material within narrow tolerances.

Material Abrasiveness: Basalt is highly abrasive, with a Mohs hardness of 5-9. Equipment must have heavy-duty construction and wear-resistant liners (e.g., tungsten carbide components) to withstand the wear and tear.

Scale: For hobbyist or small-scale projects, small-scale jaw crushers might be available, though they are primarily industrial machines. For industrial 3D printing applications (e.g., large-scale additive construction using basalt-based concrete), a full production line is required.

Companies like Rubble Master, Zoneding Machine, and FTM Machinery manufacture industrial basalt processing equipment, and platforms like Alibaba.com list a variety of crushers and mills

A comprehensive iron ore processing and steel production facility on Mars would require an integrated suite of mining, comminution, beneficiation, and refining equipment. A 200-meter diameter is a massive scale, likely referring to the entire facility's footprint rather than a single piece of equipment, and would enable significant production capacity.

Required Equipment: The equipment would function in a sequence from raw material extraction to finished product, much like on Earth, but adapted for the Martian environment and the use of in-situ resources.

1. Mining and Raw Material Handling Excavation and Loading: Robotic rovers and excavators with magnetic systems could collect iron-rich regolith or access concentrated ore deposits.

Transportation: Robust, self-driving transport systems (e.g., heavy-duty rovers or a rail system) to move ore from the mine to the processing plant.

Crushing and Grinding: Equipment such as jaw crushers, hammer mills, and ball mills would be needed to break down the iron ore into fine particles for processing.

2. Beneficiation and Concentration Sizing and Screening: Vibrating screens and classifiers to sort particles by size.

Separation: Magnetic separators are key for iron ore beneficiation, potentially complemented by flotation equipment, to increase the iron concentration in the ore.

Dewatering/Filtration: Equipment like filter presses or vacuum filters would be necessary if wet processing is used, to remove water from the concentrated ore.

3. Iron & Steel Production Martian steelmaking would likely favor direct reduction or electric arc furnaces over traditional blast furnaces due to the lack of abundant coking coal and the availability of atmospheric \(\text{CO}_{2}\) and water ice for reactants/power generation.

Ore Agglomeration: Pelletizing or sintering machines to form the fine concentrate into larger, usable pellets.

Reduction Reactors/Furnaces:Direct Reduction Kiln: Equipment to reduce iron oxides using hydrogen and/or carbon monoxide derived from Martian resources.

Electric Arc Furnace (EAF): An EAF would melt the sponge iron (produced from direct reduction) and allow for the controlled addition of carbon (extracted from the Martian atmosphere's \(\text{CO}_{2}\)) and other alloying elements to produce specific steel grades.

Continuous Caster/Molds: Machinery to form the molten steel into basic shapes (e.g., billets, slabs) for further processing.

Ladle Furnace: Used for final refining of the steel.

4. Manufacturing and Finishing Rolling/Finishing Mills: Large mills to shape the raw steel into plates, sheets, beams, or pipes.

Additive Manufacturing (3D Printing): Metal powder bed fusion or directed energy deposition machines could use the produced steel powder for on-site fabrication of parts and infrastructure. Infrastructure and Support Equipment Power Systems: The entire process requires enormous amounts of power, suggesting large-scale nuclear fission reactors or extensive concentrating solar power (CSP) fields and storage systems.

Gas Processing Plant: A complex system involving electrolysis cells (like NASA's MOXIE technology) and chemical reactors (e.g., Sabatier reaction) to produce the necessary oxygen, hydrogen, and carbon monoxide from the Martian atmosphere and water ice.Habitat and

Maintenance Facilities: Pressurized environments, repair shops, and storage facilities for personnel and spare parts.Fume Extraction Equipment: Systems to manage and clean process gases, essential for operational efficiency and safety in a closed environment

Offline

Like button can go here

#9 Yesterday 16:28:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Mars in-situ regolith mining equipment involves robotic excavators (like RASSOR/Razer), drilling/microwave probes for volatiles, and processing units for extracting water, metals (iron/steel), and oxygen, using systems like Solid Oxide Electrolysis Cells (SOEC) (MOXIE heritage) and 3D printing for construction materials, with key technologies focusing on automation, heat recycling, and handling abrasive Martian dust for ISRU (In-Situ Resource Utilization).

Key Equipment & Technologies

Excavation & Collection:

Robotic Excavators/Rovers: Systems like RASSOR 2.0 and Razer use counter-rotating drums or buckets for digging in low gravity, designed for high volume and autonomous operation.

Microwave Probes: Non-excavation method to heat subsurface ice, turning it into vapor for collection, reducing mass/cost of heavy machinery.

Processing & Extraction (ISRU):

Water/Volatiles: Extraction from regolith via microwave sublimation or drilling, followed by purification (membranes, distillation) and electrolysis to produce hydrogen (fuel) and oxygen (life support).

Metals & Oxygen: Systems (like MMOST) use electrolysis and reduction processes (e.g., using H₂/CO) to extract iron, steel, and oxygen from iron oxides in regolith.

Sifting/Refining: Machinery to achieve optimal particle size for construction aggregates, often involving heating and mixing with binders like sulfur.

Manufacturing & Construction:

3D Printers: Use processed regolith (sintered, mixed with binders) to build structures, reducing reliance on Earth-imported materials.

Sulfur Concrete Units: Heated mixers (pugmills) to combine regolith aggregate with molten sulfur (around 120°C) for bricks.

Key Processing Units:

Solid Oxide Electrolysis Cells (SOEC): Efficiently split water and CO₂ into constituent gases (H₂, O₂, CO) for chemical processing.

Heated Mixers/Kilns: For creating construction materials like sulfur concrete or sintering regolith.

Challenges & Considerations

Automation: Mining must be fully robotic and autonomous due to distance and communication delays.

Abrasion: Martian dust is highly abrasive, requiring robust seals and durable components.

Power & Logistics: Requires reliable, renewable power and efficient transport/storage systems.

High-Fidelity Simulants: Accurate testing relies on materials like MGS-1C (clay-rich) and MGS-1S (sulfate-rich) to mimic real Martian conditions.

Example System (Conceptual)

An integrated system might include a Razer excavator, feeding a processing unit that uses SOECs and heat recycling to produce oxygen, water, and metal powders, with a 3D printer using these materials to build habitats.

To build with Mars regolith, milling equipment (like vibratory/planetary ball mills) reduces particle size, while separation methods use techniques like laser sintering, cold sintering (CSP), polymer binders, or microwave systems to bind or melt regolith into structures, often requiring 3D printers for shaping, aiming for materials like bricks, shielding, or metal parts from extracted elements like iron/titanium. Key processes involve size reduction (milling) and consolidation (sintering/binding) to create usable materials like "Mars concrete" or fused components, with focus on robotic, energy-efficient systems.

Milling Equipment & Processes

Ball Milling (Planetary/Vibratory): Used to reduce particle size (PSD) of raw regolith simulant, with planetary mills being faster but roller banks better for large slurries.

Sieving: Separates milled particles into specific size ranges (e.g., 60-mesh).

Separation & Consolidation Technologies

Laser Sintering: Uses high-power lasers to melt and fuse regolith into solid layers, creating paving or structural elements.

Cold Sintering (CSP): Binds regolith with water/alkaline solutions at low temperatures (under 250°C) and pressure, forming strong bricks or blocks.

Polymer Binders: Mixes regolith with polymers (made from Martian CO2/water) for 3D printing concrete-like materials.

Microwave/Solar Sintering: Alternative methods to use focused energy for hardening regolith.

Metal Extraction: Processes like carbonyl metallurgy or vapor deposition extract iron and other metals for 3D printing steel parts.

Additive Manufacturing & End Products

3D Printing (Extrusion/Powder Bed): Deposits processed regolith/binders layer-by-layer, building structures like domes, habitats, tools, or rebar.

Products: Sintered bricks, concrete-like blocks, radiation shielding, metal components (rebar, gears, tools), and coatings.

Key Considerations

In-Situ Resource Utilization (ISRU): The core principle, maximizing use of Martian soil.

Energy Efficiency: Focus on low-energy methods like cold sintering.

Robotics: Automation is crucial for mining, milling, and construction

Final product sizes and applications

0–5 mm: Manufactured sand for concrete, dry-mix mortar, asphalt mix

5–10 mm: High-grade road base, permeable concrete

10–20 mm: Municipal projects, ready-mix concrete plants

20–31.5 mm: Railway ballast, highway base, mass concrete

>31.5 mm: Returned for re-crushing to ensure proper gradation

Offline

Like button can go here

#10 Today 09:38:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Scientists and engineers have proposed several methods and "equipment" concepts for making bricks on Mars using local resources (in-situ resource utilization), primarily Martian regolith (soil). A key discovery is that simple compression, without binders or heat, can create bricks stronger than steel-reinforced concrete.

Proposed Equipment and Methods

Since transporting all construction materials from Earth would be prohibitively expensive, research focuses on using the iron oxide-rich Martian soil itself.

High-Pressure Mechanical Press/Hammer:

The most promising method uses sheer pressure. Researchers at UC San Diego accidentally discovered that by enclosing Mars simulant in a flexible container (like a rubber tube) and applying high pressure, they could form solid, strong pellets which can be cut into brick shapes. The necessary "equipment" could be a robotic, high-pressure compacting device or even a simple hammering mechanism operated by future astronauts.

3D Printing Systems:

This is a major focus of ongoing research.

Regolith melting: One idea involves melting the regolith with lasers or focused solar energy and pouring it into molds, though this requires significant energy.

Binder extrusion:

Regolith could be mixed with a binder (polymer or even human-derived materials like blood plasma protein or urea) and extruded through a 3D printer to build structures autonomously.

Kilns/Furnaces:

Early proposals suggested using a nuclear-powered or solar furnace to bake the bricks, similar to ancient Earth methods. This method would require a significant power source and complex equipment to capture any released water for reuse.

The equipment needed to create hot sulfur regolith bricks for Martian in-situ buildings involves machinery for excavation, processing, mixing, heating, and molding the materials. A 1200°C kiln is used for sintering processes with other potential binders, but for sulfur concrete, the required temperature is much lower (around 120°C to melt the sulfur).

Materials Acquisition & Processing

Excavation and Sifting Equipment:

Robotic excavators or rovers with digging mechanisms to collect the Martian regolith. Sifting or refining machinery may be needed to achieve the optimal particle size distribution for the aggregate.

Sulfur Extraction and Refining Unit:

A chemical processing plant to extract elemental sulfur from Martian sources (sulfides/sulfates), likely involving high-temperature oxidation and reduction processes.

Storage Tanks/Hoppers:

Secure storage for both the raw regolith powder and the extracted, refined sulfur (solid and liquid).

Brick Production & Molding

Heated Mixer (e.g., Pugmill or Drum Mixer): An industrial mixer capable of hot-mixing the dry regolith aggregate with molten sulfur (liquid at ~120°C). The mixer must have robust seals to handle the abrasive dust and potentially a controlled atmosphere (CO₂-rich).

Heating System/Kiln:

While a 1200°C kiln is used for other methods like sintering, sulfur bricks only need a melting temperature of around 120°C. This heating could be powered by a solar furnace or a nuclear reactor's waste heat. The system needs precise temperature control to prevent boiling and ensure uniform heating.

Molding/Casting System:

Molds (potentially made from 3D printed durable thermoplastics like PEEK or metal) or a robotic extrusion system (like a 3D printer) to form the liquid mixture into desired brick shapes.

Curing Area:

A controlled environment where the bricks can cool and solidify (harden through physical crystallization, not hydration).

Power Supply:

A robust, reliable power source (e.g., solar panels with battery storage or a fission reactor) capable of powering all machinery autonomously.

Ancillary and Support Equipment

Autonomous Robotic Systems:

The entire process is envisioned to be highly automated due to limited human labor on Mars.

Dust Mitigation Systems:

Given the pervasive, fine nature of regolith dust, equipment must incorporate advanced seals and filtration to prevent damage and contamination.

Quality Control and Testing Apparatus:

Equipment to test the compressive and flexural strength of the final bricks to ensure they meet structural requirements.

Thermal Management Systems:

Equipment to manage the significant temperature variations and maintain consistent operating temperatures

Biomaterial Production Systems: Emerging research involves using synthetic biology, like engineered lichens or bacteria, to create a self-growing, concrete-like material from the Martian soil. This would require specialized bioreactor equipment and the necessary organic inputs.

Key Advantage

The simple, no-bake, no-binder method using a mechanical press is a leading candidate because it requires the least amount of complex machinery, energy, and additional materials transported from Earth, making it highly practical for initial manned missions

While no operational 3 m diameter TBM specifically for Mars currently exists, the development of such equipment is a key concept in proposed strategies for establishing a Martian colony.

Current Status of Mars Tunneling Equipment

Conceptual Stage:

Current discussions revolve around the concept of using tunneling technology for Mars habitats, providing protection from cosmic radiation and micrometeorites, and leveraging the thermal stability of the subsurface.

Earth-based Prototypes:

Companies like The Boring Company (TBC) are developing advanced, all-electric Tunnel Boring Machines (TBMs) for Earth-based projects (e.g., the Prufrock series, which creates a tunnel approximately 3.7m/12ft in diameter).

Technology Transfer:

While TBC's current machines are unlikely to be deployed on Mars without significant modification, the technology and engineering experience gained (such as automation and faster boring speeds) are seen as foundational for developing future off-world systems.

Prototype Drills:

Research has been conducted on smaller-scale "3-meter-class Mars drill prototypes" for scientific exploration of the shallow subsurface, but these are for drilling, not large-scale tunneling for habitats.

Transportability:

A 3m-class TBM (or its segments) is considered potentially transportable by a SpaceX Starship, which has an 8m diameter cargo bay.

Key Challenges for Martian TBMs

Atmosphere:

Earth TBMs use significant amounts of water for cooling and other operations, which would be a major challenge in Mars's cold, near-vacuum atmosphere.

Automation:

Due to communication delays and the need for efficient pre-human construction, Martian equipment would require a high degree of automation and robotic operation.

Geology & Materials:

The machines would need to be adapted to Mars's unique rock and soil conditions. Also, instead of concrete segments (which are heavy to transport), innovative methods like sintering the excavated rock or using local materials for tunnel lining would be necessary.

In short, 3 m diameter equipment for Mars is an active area of conceptual development and technological aspiration, leveraging Earth-based innovations, but is not yet a developed or deployed product.

Offline

Like button can go here

#11 Today 09:38:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

The equipment needed to make hot sulfur regolith bricks for Mars in-situ buildings involves machinery for excavation, material processing, heating/mixing, and automated construction, likely in the form of a robotic 3D printing system.

The key equipment can be categorized by function:

Raw Material Acquisition and Processing

Excavation Rovers/Machinery:

Automated diggers or rovers designed for low-gravity and remote operation to mine the Martian regolith (soil) and extract sulfur from sulfates and sulfides.

Crushing and Milling Equipment: Machines to break down the excavated regolith and sulfur compounds into a uniform aggregate size suitable for mixing and extrusion.

Chemical Processing Unit:

Equipment, possibly including a thermochemical or electrochemical processing system (like a solid oxide electrolysis cell), to refine the sulfur compounds into elemental sulfur, which is the required binder material.

Sieving/Separation Systems:

Mechanisms to ensure the proper particle size distribution of the regolith aggregate, as optimized mixtures can achieve higher compressive strengths.

Brick Production and Construction

Storage and Feeding System:

Hoppers or containers to store the processed regolith and elemental sulfur and feed them at a precise, pre-designed weight ratio (around 65% aggregate to 35% sulfur is a common ratio) into the mixing apparatus.

Heated Mixer/Extruder:

A core component that heats the mixture to above sulfur's melting point (around 120°C) to liquefy the sulfur, uniformly mixes it with the regolith aggregate, and then extrudes the hot, molten sulfur concrete.

This system requires closed-loop heating control and monitoring systems to maintain precise temperature levels.

3D Printing System (Gantry or Robotic Arm):

An automated construction system that receives the hot mixture from the extruder and precisely deposits it in specific forms (layers) to build walls or structures directly on site.

Power Systems:

A robust, reliable power source is essential to run all the machinery, particularly the energy-intensive heating and processing units. This would likely involve solar panels and energy storage systems.

Ancillary Equipment

Robotic Control Systems:

The entire operation is envisioned to be largely autonomous, requiring advanced robotic control and monitoring systems due to the communication lag with Earth and the need for reliable, continuous operation in a harsh environment.

Testing Apparatus:

Equipment to perform quality control tests on the finished material, such as compression and flexural strength testers, to ensure structural integrity.

Thermal Management Systems:

Equipment to manage heat and prevent issues like sulfur sublimation in a vacuum or under large temperature swings

Offline

Like button can go here

#12 Today 09:38:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

A Mars open-pit mining operation, even one of 200m diameter, would rely on modified versions of terrestrial open-pit equipment, adapted for the Martian environment (low gravity, extreme cold, dust, and lack of atmosphere). The primary functions—excavation, loading, hauling, and processing—remain the same.

Key Equipment Categories & Adaptations

Excavation and Loading Equipment:

Large Hydraulic Excavators/Rope Shovels: These would be the primary tools for digging and loading broken material into haul trucks.

Bucket-Wheel Excavators (BWEs): For large, continuous digging operations, BWEs are efficient for continuously moving large volumes of material.

Bulldozers & Wheel Loaders: Used for site preparation, clearing overburden (regolith), and maintaining the working area.

Adaptation Insight: Lower gravity on Mars (38% of Earth's) means reduced ground pressure for digging, so equipment may need modifications (e.g., dual-barrel digging wheels for traction, as explored by NASA for lunar robots).

Haulage and Transportation:

Large Mining Trucks: Essential for transporting large quantities of ore and waste rock from the pit to processing plants or waste dumps.

Conveyor Systems: May be used for more efficient, continuous transport over specific, long distances, potentially integrated with BWEs.

Adaptation Insight: Tires and hydraulic seals must be made of materials that can withstand the extreme cold, as many Earth-based materials become brittle. Haul road maintenance using graders and dozers is critical for efficiency.

Drilling and Blasting (Optional but likely):

Large-Diameter Rotary/Percussion Drill Rigs: Used to drill blast holes for breaking up hard rock formations that excavators cannot manage alone.

Explosive Delivery Systems: While potentially complex due to the need to manufacture explosives (like AN/FO) on-site or transport them from Earth, blasting is a highly efficient way to fragment large amounts of rock.

Processing Equipment:

Primary Crushers: Large gyratory or jaw crushers would be needed to break down raw material to a manageable size before further processing.

Analytical Instruments: Tools like the Rock Abrasion Tool (RAT) used on Mars rovers, spectrometers, and real-time analyzers would be necessary for on-site geological analysis and quality control of the extracted material.

Adaptation Insight: Processing plants would need to be enclosed and possibly heated to function effectively in the harsh environment.

Supporting Infrastructure & Automation:

Power Systems: Large operations require significant power, likely from advanced nuclear, solar, or a combination of sources.

Automated/Remotely Controlled Systems: Due to the hostile environment, a high degree of automation, robotics, and remote operation would be essential to ensure continuous operation and human safety.

Life Support Systems: Pressurized operator cabins (if human-crewed) or remote operation centers would be required.

The specific type of equipment would ultimately depend on the target resource (e.g., water ice, iron-bearing minerals) and the specific geological properties of the Martian site

To move 10 cubic meters of Mars regolith, you would need a tandem axle dump truck or a medium-to-large single-axle dump truck. A standard commercial tandem axle dump truck typically holds between 7.6 to 10.7 cubic meters (10 to 14 cubic yards) of material, making it a suitable option for exactly 10 cubic meters.

Dump Truck Options for 10 Cubic Meters

Medium Dump Truck (Single Axle):

These can hold a load volume of 3 to 6 cubic meters, so you would likely need two trips, or a very large single-axle model near its upper limit.

Tandem Axle Dump Truck:

This is the most efficient option, as its typical capacity of 7.6 to 10.7 cubic meters can handle the entire volume in a single load. Some models can even handle up to 13 to 20 cubic meters.

Large Dump Truck (Tri-Axle/Super Dump): These trucks have capacities ranging from 13 to over 25 cubic meters, which would easily manage the load, though the truck might not be operating at full volumetric capacity.

Important Considerations

Weight vs. Volume:

The weight of the regolith (Martian soil) is a critical factor, even more so than volume. The density of material matters in determining the actual safe load capacity to avoid overloading the truck's weight limits.

Martian Gravity:

The user's prompt specifies "Mars regolith," which implies an off-world scenario. The lower gravity on Mars (roughly 38% of Earth's gravity) would significantly alter the weight constraints and potentially allow a standard Earth-rated dump truck to carry a larger mass of material than it could on Earth, assuming the engineering for the martian environment is addressed.

Equipment Specialization:

For actual off-world operations, the equipment would be specifically designed for the Martian environment, likely featuring wider cutting heads or different axle configurations to handle the unique terrain and gravity conditions.

Offline

Like button can go here

#13 Today 09:48:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Electric drive heavy earth-moving equipment for Mars requires robust, cold-resistant components (motors, actuators, hydraulics with special fluids/seals) and power sources (batteries, potential nuclear), leveraging electric motors for efficiency in thin atmosphere, with concepts like track systems (Mars Crawler) for modularity, adapting proven Earth mining tech (Tesla motors, Bobcat designs) for extreme Martian conditions (low temp, near-vacuum), focusing on electric actuation over hydraulics where possible.

Key Design Considerations for Mars:

Power & Propulsion:

Electric Motors: Preferred due to the lack of oxygen for combustion engines.

Power Sources: Batteries (lithium-ion) and potentially radioisotope thermoelectric generators (RTGs) for remote power.

Cold Operation: Motors need thermal management, potentially sealed systems, as air cooling is inefficient in Mars' thin atmosphere.

Mechanical Systems:

Hydraulics: Require specialized low-vapor-pressure fluids and durable polymer seals to prevent brittleness and evaporation in extreme cold and low pressure.

Actuators: Electric actuators (like piezoelectric) are being developed for precision and reliability in space.

Materials: Lighter, stronger materials like titanium alloys might replace steel for structural components, reducing mass.

Chassis & Mobility:

Tracked Systems: Offer stability and can distribute weight effectively on loose regolith (Mars Crawler concept).

Suspension: Similar to existing rovers (e.g., rock-bogie systems) for uneven terrain.

Modularity: Interchangeable tools (buckets, drills) on a base platform (Mars Crawler) for versatility.

Operational Environment:

Temperature Extremes: All components must function from cold to frigid temperatures.

Low Pressure: Affects fluid dynamics and heat transfer; systems need to be sealed or adapted.

Dust: Seals and mechanisms must resist pervasive Martian dust.

Inspiration from Earth & Space:

Mine Loaders: Models like large electric mine loaders provide power and robustness, adaptable for road grading and heavy lifting on Mars.

Electric Conversions: Companies converting Bobcat loaders to all-electric show potential for Mars applications.

Spacecraft Tech: Precision actuators from rovers like Perseverance demonstrate technology for reliable space operation.

Example Concepts:

Mars Crawler: A track-based platform with modular attachments (e.g., 3D printers, digging tools) run by powerful electric motors.

Electric Tractors: Powerful electric units similar to large mine loaders, capable of pulling heavy freight trains or grading roads

Offline

Like button can go here

#14 Today 09:48:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

3D printing of dome-shaped habitats on Mars using basalt-based materials is a leading area of research for in-situ construction. This approach leverages the abundant basaltic rock and regolith found on the Martian surface to create a structurally sound, radiation-shielding building material, eliminating the need to transport heavy materials from Earth.

Construction Techniques

The primary method involves additive manufacturing (3D printing) using robotic systems deployed autonomously before human arrival.

Material Acquisition and Processing: Robots collect basalt rocks and regolith (crushed rock and dust) and process them into a usable feedstock. One method involves melting the basalt in a furnace and pulling it into fibers, which are then combined with a binder.

Binding Agents: To create a cohesive, printable "ink," the basalt material is often mixed with a binder. In various NASA challenges, teams have experimented with:

Polymer composites: Combining basalt fibers with polylactic acid (PLA) or other recyclable plastics, which can potentially be synthesized from plants grown on Mars.

Geopolymers/Cements: Using fast-setting metakaolin geopolymer cement formulations.

Printing Process: The material is extruded layer by layer by a gantry-style or robotic arm printer, building the habitat from the ground up. The dome shape itself is a functional design choice, as the curved walls help to withstand the significant pressure difference between the internal human-habitable atmosphere and the near-vacuum Martian environment.

Advantages of Basalt for Mars Habitats

Radiation Shielding: Cooled basalt has a high density, which provides superior protection from electromagnetic space radiation and micrometeorites compared to more porous materials.

Structural Integrity: Basalt fiber-reinforced composites can be several times stronger than traditional concrete, providing robust structural elements.

Thermal Regulation: The material has a low coefficient of thermal expansion, advantageous for the extreme temperature swings on Mars.

Airtight Seal: Basalt's low permeability makes it suitable for forming the necessary hermetic seal to maintain a pressurized, life-supporting internal atmosphere.

Current Status and Research

Research has largely been driven by competitions like the NASA 3D-Printed Habitat Challenge. While material processing and 3D printing techniques have been successfully demonstrated using Martian regolith simulants on Earth, the practical challenge of establishing the energy-intensive processing equipment (like high-temperature furnaces) on Mars remains a significant engineering hurdle.

For building arch shapes, you can use either tapered/wedge-shaped bricks or standard rectangular bricks. Tapered bricks are specially designed for arches to create uniform mortar joints, while rectangular bricks can be used for a flatter arch, sometimes called a soldier arch. Special shapes like double-tapered arch bricks or bricks with a specific angle (like a 70° skew-back angle for flat arches) are also available for curved elements.

Types of bricks for arches

Tapered or wedge-shaped bricks:

These are the most common for rounded arches. They are tapered to ensure that the mortar joints are of a consistent thickness throughout the depth of the arch.

Double-tapered arch bricks: These are double-tapered in either width or length to form curved features, like an archway or a circular window.

Rectangular bricks (cut or full-size):

Soldier arches:

These are created by placing standard rectangular bricks on their ends, with their long sides set vertically. This type is more of a flat arch and requires support like a lintel or frame.

Flat arches:

Flat arches are often constructed with standard rectangular bricks that are the same size and have parallel sides, sometimes with a specific skew-back angle.

Specialty and pre-fabricated arches: Modern technology allows for pre-fabricated brick arches built to specific dimensions and designs, which can be a cost-effective solution.

Key considerations for size and shape

Uniformity:

The key for most arches is achieving uniform mortar joints for structural integrity. Tapered bricks achieve this, while flat arches often use standard rectangular pieces with a consistent, small mortar joint.

Angle:

For flat arches, a 70° skew-back angle is common for the voussoirs (the wedge-shaped stones used to build the arch).

Customization:

If your design requires specific angles, curves, or a certain rise, you may need to specify custom dimensions or use pre-fabricated arches

Offline

Like button can go here

#15 Today 09:48:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

The concept of using a Starship cargo lander as a long-term habitat on Mars, sometimes called a "caretaker" or base camp, is central to {Link: NASA and SpaceX's Mars colonization vision, involving converting the massive lander into a livable base after its initial cargo delivery, with conceptual studies exploring how to offload and configure these huge structures, potentially using other Starships or specialized equipment for setup.

Key Concepts & Plans

Starship as Lander & Habitat: Starship's enormous payload capacity (up to 150+ metric tons) allows it to deliver not just supplies but also become a primary habitat on Mars after landing.

NASA's Common Habitat Architecture: NASA studies, like the "Common Habitat," envision using SLS core tanks or Starship-derived modules as large, long-duration habitats, leveraging the work on Starship landers for delivery and setup on the Moon and Mars.

Phased Deployment: Early cargo Starships land, offload equipment, and then potentially serve as initial shelters, with later, larger modules or converted Starships forming the core of a permanent base.

Deployment & Setup: A major challenge is getting the habitat off the lander and onto the surface, with studies exploring cranes, jib systems, or even other Starships to maneuver and position these massive structures.

Caretaker Role: The lander itself, or a dedicated Starship habitat, would provide immediate shelter, life support, and a base of operations, acting as a "caretaker" until larger, purpose-built habitats are established.

How it Works (Conceptual)

Launch & Transit: A modified Starship carries cargo and/or habitat components to Mars.

Landing: The Starship performs a powered landing on Mars.

Habitat Activation: The vehicle is configured (potentially by another Starship or robotic systems) to become a habitable zone, with internal decks, life support, and living quarters.

Expansion: Subsequent Starship deliveries bring more components to build out a larger, more permanent base around the initial lander habitat.

This approach leverages Starship's unique capabilities to drastically reduce the complexity and cost of establishing a long-term human presence on Mars

Offline

Like button can go here

#16 Today 09:56:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

In-situ (on-site) Martian rocket fuels primarily focus on producing methane (\(CH_{4}\)) and liquid oxygen (\(LOX\)), using the abundant atmospheric carbon dioxide (\(CO_{2}\)) and water ice (\(H_{2}O\)) through processes like the Sabatier reaction and electrolysis, significantly reducing launch mass from Earth. Alternative approaches involve biotechnology to create fuels from Martian resources or using carbon monoxide (\(CO\)) and oxygen (\(O_{2}\)) as propellants, leveraging Mars's unique environmental conditions to enable sustainable Mars missions and colonization.

Primary Method: Sabatier Reaction & Electrolysis

Gather Resources: Collect Martian atmospheric \(CO_{2}\) and extract water (\(H_{2}O\)) from subsurface ice/regolith.

Electrolysis: Split water into hydrogen (\(H_{2}\)) and oxygen (\(O_{2}\)).

Sabatier Reaction: React \(CO_{2}\) with the produced \(H_{2}\) to create methane (\(CH_{4}\)) and water.

Oxidizer: The \(O_{2}\) from electrolysis serves as the oxidizer.

Result: This process yields both fuel (methane) and oxidizer (liquid oxygen) on Mars. Key Benefits Cost Reduction: Eliminates the need to transport massive amounts of propellant from Earth.

Mass Leverage: A small amount of imported hydrogen can generate significantly more fuel on Mars.

Resource Utilization: Utilizes abundant Martian resources (\(CO_{2}\), \(H_{2}O\)).

Alternative & Advanced Concepts Biotechnology (Bio-ISRU): Using engineered microbes (like cyanobacteria and E. coli) to convert \(CO_{2}\) into complex hydrocarbons (rocket fuel) and generating excess oxygen, taking advantage of Mars's lower gravity for less energy-intensive liftoffs.

Carbon Monoxide/Oxygen (CO/O2): A propellant combination derived from \(CO_{2}\), potentially offering higher specific impulse, though it still requires a hydrogen source.

Solid Propellants: Research explores creating solid fuels (like aluminum/magnesium-based) from Martian regolith, though less developed. Challenges Power & Infrastructure: Requires significant power for processing and liquefaction.

Efficiency & Reliability: Developing robust, long-term systems for the harsh Martian environment

Offline

Like button can go here

#17 Today 09:57:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

For a Martian habitat at 0.5 bar (significantly higher than Mars's ~0.006 bar average), spherical or cylindrical shapes are optimal for a stainless steel structure, as they efficiently contain internal pressure, with cylindrical shapes often favored for practical construction and use with regolith shielding, using tension members to handle stress, similar to pressurized vessels on Earth.

Why These Shapes?

Spherical: A sphere distributes stress equally in all directions, making it structurally ideal for holding internal pressure against a vacuum or low external pressure.

Cylindrical: Cylinders (especially with domed ends) are practical for larger volumes, offer better usable floor space, and can be buried or covered with Martian soil (regolith) for radiation shielding without collapsing.

Structural Considerations for 0.5 Bar (50 kPa)

Pressure Difference: A habitat at 0.5 bar (50 kPa) has a substantial pressure difference from the Martian surface (around 0.6 kPa), requiring robust structures.

Stainless Steel: While good for strength, stainless steel is heavy, making it costly to transport; however, it's excellent for withstanding pressure.

Tension: The primary force is outward tension. Structural members (like steel bands) wrapped around cylindrical habitats help contain this.

Design Concepts

Buried Cylinders: Building cylindrical habitats within trenches and covering them with regolith provides shielding from radiation and micrometeoroids, using the soil's weight to help counteract the internal pressure, notes Marspedia and NIH.

Domes: Dome-shaped structures (hemispherical) are also efficient for pressure containment, as studied by NASA.

In essence, think of large, pressurized tanks – spheres and cylinders are the best shapes for holding pressure, and adding regolith makes them even more effective Martian habitats

A counter pressure is generally not how an internal atmosphere in a Martian dome would be contained. The force from an internal, human-habitable atmosphere on Mars is immense (around 10 tonnes per square meter), meaning the structure needs sufficient mass and design to resist this tension and prevent it from being lifted off its foundations. The most practical engineering approach for a dome made of Martian regolith bricks involves using the weight of the material itself (or an external regolith covering) to counteract the internal pressure differential.

Internal Pressure Requirements

Mars's Atmospheric Pressure:

The external atmospheric pressure on the surface of Mars is extremely low, averaging only about 0.6 kilopascals (kPa), which is less than 1% of Earth's sea-level pressure. It is effectively a near-vacuum from an engineering perspective.

Human Habitable Pressure:

A human habitat requires a total internal pressure of at least 25 kPa with sufficient oxygen partial pressure to be functional without a pressure suit, or full Earth-equivalent pressure of 101.3 kPa (1 atm) for a standard environment.

Pressure Differential:

The critical engineering challenge is the 100+ kPa pressure differential between the inside of the dome and the outside Martian atmosphere. This creates a massive outward and upward force on the structure.

Structural Considerations for Regolith Domes

Tension vs. Compression:

Domes on Earth are compression structures, meaning their shape naturally handles the force of their own weight pushing down. On Mars, the low gravity and high internal pressure put the dome under tension, trying to tear it apart and lift it from its foundations.

Material Limitations:

Regolith bricks, even advanced "StarCrete" or sintered versions with high compressive strength (up to 72 MPa), have lower tensile strength. Standard bricks and concrete perform poorly in tension.

Design Solution: Weight and Reinforcement:

The primary method to manage the internal pressure is to use a thick layer of regolith as shielding/ballast.

Proposals often suggest using an internal inflatable bladder or a strong internal shell (perhaps with steel or carbon fiber reinforcement) to contain the air.

This internal structure is then buried under several meters of Martian soil/bricks. The sheer weight of this external material provides the necessary "counter pressure" by pushing down and counteracting the upward lift from the internal atmosphere.

In short, the counter pressure is not an engineered force applied externally but rather the passive mass of significant regolith shielding used to anchor the structure to the ground.

Offline

Like button can go here

#18 Today 09:57:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: WIKI Project Designing for Mars

Integrated Surface Power Strategy for Mars

NASA's power standards for crewed Mars missions vary significantly by mission phase and scale, ranging from a minimum of ~10 kilowatts (kW) for short surface stays with two crew members to potentially megawatt (MW)-class systems for larger, longer missions with in-situ resource utilization (ISRU) like propellant production, with nuclear power often favored for its reliability, though early missions might use solar/battery systems, with total requirements approaching 160 kWe for some concepts.

Key Power Requirements & Considerations:

Minimum Surface Power: Around 10 kW is considered the baseline for even short (30-day) missions with two crew, covering habitat, life support (ECLSS), and some science/exploration.

ISRU & Larger Crews: Missions involving propellant manufacturing (ISRU) and larger crews (e.g., six people) can push power needs to 40-160 kW or more for activities like producing oxygen and fuel.

Transit/Propulsion: Missions using nuclear electric propulsion (NEP) could require very high power, with some concepts needing 1.9 MWe (megawatts electric) for the journey itself.

Reliability & Redundancy: Critical safety systems demand high availability, often necessitating redundant power sources, like multiple nuclear reactors or large battery/fuel cell backup.

Power Technologies Considered:

Nuclear Fission Systems: Fission power (like Kilopower) is a strong candidate for its mass efficiency and continuous power, providing both electricity and heat, crucial for ISRU and reliability.

Solar Arrays: Roll-out or advanced photovoltaic blankets are an option, but limited by dust, available area, and nighttime needs, requiring significant energy storage.

Energy Storage: Advanced batteries (lithium-ion) and regenerative fuel cells are vital for bridging gaps in solar power or providing backup.

Example Mission Architectures: