New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-05-25 17:55:14

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Miniature ITV for Mars Flyby and Exploration Missions

I'm starting this topic to discuss the technology for minimal risk / minimal complexity crewed Mars flyby and exploration missions using a miniaturized version of the 500 passenger Interplanetary Transport Vehicle (ITV), transporting an exploration crew of up to 4 human crew per ship plus 4 robotic crew members to assist with maintaining the ship and potentially dangerous tasks such as EVAs.

The same basic design principles would apply, albeit to a much smaller and simplified ship design that uses an appropriate mix of electric and storable chemical propulsion systems to complete exploration missions. A colonization class (c-ITV) requires advanced Solar Thermal or Nuclear Thermal propulsion to contain propellant / launch costs. An exploration class (e-ITV) can use simpler near-term propulsion solutions that won't work at the scale required for colonization. The e-ITV program will feature many of the programmatic elements of a colonization campaign, but at a smaller scale.

To the extent feasible, vehicle fabrication methods, propulsion systems, computer control systems, and mission architecture will only feature mature or highly refined systems. This means the major mission elements and associated systems as a whole must constitute an engineering exercise, rather than a clean sheet developmental program. As an example, for a propulsion system to be used, it must have already flown in space at least once. Novel applications of existing tech are fine, but if you want to develop a brand new "clean sheet" engine design, that's a separate development program that won't become part of this program until it flies in space.

ITV Design Characteristics:

Counter-Rotation Artificial Gravity

Counter-rotation minimizes gyroscopic precession effects. A motor of some kind can spin the two habitation spaces in opposite directions, likely varying speeds just a little, using accelerometer sensors to provide feedback, to help minimize the destabilizing effect of small mass imbalances between both sets of rotors. The destabilizing effect of rotating only in one direction complicates the operation of propulsion systems or requires deployment of tethers to connect a habitation module to an upper stage mass. A rigid "baton" design could and probably would also work, but batons typically become heavier the longer they are, to resist deformation caused by the artificial gravity induced by spinning them. If the baton is much stronger than it needs to be, because it was originally designed as a rocket vehicle's upper stage, then it's also much heavier than it needs to be, so more propulsive power and propellant are required.

CFRP Primary Structures

We can use automated tape-winding machines to deposit very thin (70g/m^2) layers of Carbon Fiber pre-preg onto a mold using a laser to secure and partially cure the tape in place. Since Boeing's autoclaves are large enough for all the major hull parts to fit, a complete curing process can be utilized for a full density / full hardness / minimum porosity hull. Composite parts produced this way have a density on-par with Magnesium, at 1.7g/cm^3. A 1m^2 panel of CFRP material 10mm thick is therefore 17kg/m^2, or 42.5kg/m^2 at 25mm thick. Excluding end domes, a 4.5m OD 10m long module with 25mm thick walls weighs 11,883kg. The 4.3m OD 8.5m long Destiny module, which was primarily Al-2219-T87, had a mass of 14,515kg for comparison purposes.

We'll use the same IM7 fiber and Cycom 5320-1 resin system which has proven so resistant to O2 and H2 permeation in NASA's Composite Cryogenic Tank Demonstrator program. CFRP LH2 tanks were constructed using automated tape winding laying fiber onto collapsible molds with alternating 70g/m^2 and 140g/m^2 IM7 fiber layers, to speed up the tape winding process. Those tanks were not vacuum bagged and autoclaved, yet they held pressure and resisted H2 / LH2 permeation, at pressures up to 58psi, and were less than 10mm thick. That particular fiber and resin system combination is CTE-matched such that temperature extremes had little effect on durability.

For fire resistance, the hull's interior can be lined with Carbon-X fabric, affixed in place using CFRP rods woven into the fabric, so no adhesives or metallic fasteners are required. The exterior MMOD protection layers should be a combination of Kevlar and Nextel. A Vectran outermost layer will reflect sunlight and resist atomic Oxygen attack in LEO.

Extensive use of fabrics and composites, which contain a lot of Carbon and Hydrogen, will reduce the secondary radiation dose associated with Galactic Cosmic Rays (relativistic ionized particles) striking thin-walled metallic structures. Some protection from the intense proton storms produced by Solar Particle Events (SPEs) and Coronal Mass Ejections (CMEs) will be provided as well. Additional protection using food and water crew provisions will still be required for adequate protection from the most powerful solar storms.

Storable Chemical and Solar Electric Propulsion (SEP) Systems

After the initial Trans-Mars Injection (TMI) burn performed with cryogenic liquid propellants, Mars Orbit Capture, Mars Orbit Transfer, Low Mars Orbit station-keeping, Trans-Earth Injection, Earth Orbit Capture, Earth Orbit Transfer, and Low Earth Orbit insertion burns will be performed using an appropriate combination of storable chemicals and electric thrusters. The crew need not remain aboard the ITV during the spiral into LMO, from TMI, nor to LEO, on the way back to Earth from Mars. Direct entry with appropriate vehicles is acceptable. SEP using Argon ($35/kg) or Iodine ($61/kg) propellants can deliver 2,000s Isp. Both Argon and Iodine are dramatically less expensive and more plentiful than Xenon ($3,000/kg) and Krypton ($2,100kg to $4,800/kg). Iodine is very dense and can be stored as a liquid with modest heating applied. Storable chemicals like Hydrazine ($78.50/kg) or HAN ($200/kg to $350/kg) or Ammonia ($0.73/kg) can deliver up to 600s Isp using ArcJet thrusters. Thrust levels for all propellants mentioned are very modest, on the order of 10s of mN/kW of input electric power, but Isp ranges from 580s to 2,000s.

Conventional NTO/MMH or NTO/HAN can provide high thrust for impulsive maneuvers, with Isp ranging between 340s and 350s when used by pump-fed engines. Small electric pumps can generate extreme pressures for brief periods of time, such as the Rutherford engine used by the RocketLabs Electron small satellite launch vehicle. Better still, these pumps can suck the tanks dry without exploding, unlike conventional turbopumps, so there is no residual / unusable propellant left. In normal turbopump-fed chemical rocket engines, 2% to 3% of the propellant mass is unusable because attempting to use the pump to extract that last bit of propellant would cause pump cavitation, swiftly followed by rapid unscheduled disassembly.

Whenever Zero Boil-Off (ZBO) technology is truly ready for space flight applications, then LOX/RP1 with electric pumps provides the best Density Impulse and Total Impulse characteristics for a given propellant tank and engine hardware mass, at the expensive of propulsive efficiency. LOX/LCH4 or LOX/LH2 are highly desirable for in-space propulsion if sufficient tank insulation and cryocooler power is available, but the greater dry mass fraction of LCH4 or LH2 fueled stages vs RP1 stages for equivalent Delta-V (ΔV), up to about 4.5km/s per increment.

At 465.5s, using LH2 fueled RL-10B-2 engines, possibly 470s using greater nozzle expansion ratios, we might get a 15% to 20% payload performance advantage over RP1 fueled engines, for equal in-space propulsion stage mass. Unfortunately, LH2 ZBO tech is still in active development and nowhere near ready for crewed missions.

The last page of that document seems to indicate that we still have another 5 to 10 years of developmental work before ZBO systems for LH2 is ready to go. It's a complex bit of tech. Every listed piece of tech in the chart on the last page needs to be at TRL7 or higher, preferably TRL8, before we stake human lives on it. That takes time, money, and a coherent development effort with parallel development of stages designed to capitalize on it.

Offline

Like button can go here

#2 2025-05-25 18:42:28

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

This post is reserved for an index

Definition of acronym ITV: Interplanetary Transport Vehicle (from post #1)

Index:

(th)

Offline

Like button can go here

#3 2025-05-28 17:00:25

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

I think we should pursue a modified minimum risk mission that uses existing air and water recycling technologies that we already paid through the nose to develop:

Minimum Risk Deep Space Habitat and Life Support

I think the technological risk associated with using regenerative life support is greatly over-played. ISS wouldn't have been habitable for 20+ years if the tech didn't work.

The next generation life support tech, specifically the Amine Swingbed CO2 Scrubber and Ionomer Waste Water Processor have been quietly doing an even better job aboard ISS, using a lot less power and suffering fewer system casualties, for over 2 years now. They're much closer to closed-loop systems, drastically lighter / more compact, and they've had very few teething problems. If the ionic liquid CO2 scrubber experimentation pans out, the total amount of power both systems consume will be under 1kWe for a crew of 4. The total power requirement should be 2.5kWe or less. That means photovoltaic array deployment mechanisms are not required. Waste heat management radiators can be fixed / hull-integrated designs as well.

600W - Counter-Rotation Motors (CRMs)

400W - Skylab Control Moment Gyros (for 8 CMGs at normal operating rpm)

Source:

[url=https://ntrs.nasa.gov/api/citations/19790007076/downloads/19790007076.pdf]NASA TM-78212 - 25 kW POWER MODULE UPDATED

BASELINE SYSTEM - December 1978 - Page Labeled 39 in lower right-hand corner[/url]

800W - Carbon Dioxide Removal by Ionic Liquid Sorbent (CDRILS) System

Source:

Scale-up of the Carbon Dioxide Removal by Ionic Liquid Sorbent (CDRILS) System

Novel Liquid Sorbent CO2 Removal System for Microgravity Applications

60W - Ionomer Waste Water Processor (Direct, Single Cycle, or Dual Cycle)

Development of Ionomer-membrane Water Processor (IWP) technology for water recovery from urine

Demonstration of a Full Scale Integrated Membrane Aerated Bioreactor- Ionomer-Membrane Water Purification System for Recycling Early Planetary Base Wastewater

140W - Avionics / flight computers, electronics, communications, sensors (redundant mobile chips using power-over-fiber sensors)

2kWe is a very modest amount of power for 4 crew members. That can be supplied by hull-integrated thin film arrays. Additional power can be stored in Lithium-ion batteries.

Last edited by kbd512 (2025-05-29 01:44:12)

Offline

Like button can go here

#4 2025-05-28 19:18:04

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Miniature ITV for Mars Flyby and Exploration Missions

The NASA science mission portion of what NASA does has been gutted. They will not even complete the missions already out there.

The NASA manned mission stuff is going to be greatly changed. Trump wants flags-and-footprints on the moon and on Mars, but nothing else. Once he gets that, no more NASA anything. Look to see SLS and Orion killed after the Srtemis-2 flight around the moon. And Gateway is toast, too.

That future loss of NASA contracts is really where the new baby rift between Musk and Trump is coming from. Musk's NASA contracts will dry up when that happens. DOD will not make up the difference, not with the likes of that incompetent Hegseth in charge of it. Musk knows that.

It's already just barely started over DOGE, with Musk essentially complaining that Trump's "big beautiful bill" does not kill enough Americans for lack of cuts to health care, social security, etc.

GW

Last edited by GW Johnson (2025-05-28 19:22:28)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#5 2025-05-28 19:29:19

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Miniature ITV for Mars Flyby and Exploration Missions

Getting back to the proper topic here, what is needed is vehicles assembled in circular LEO at a space station facility that does both assembly work and propellant fill/refill work. You do it in circular LEO at fairly low inclination to make it reachable from the surface at the least launch dV.

There needs to be a space tug or multiple tugs based at that same facility. The tugs take the interplanetary craft to just below escape, so that a much smaller departure dV is demanded of the interplanetary craft, while the tug itself stays in an extended ellipse, and returns unladen to the station in LEO for reuse. That leaves more dV available for the interplanetary craft to enter low Mars orbit, should that be desired. Direct landings require less dV, but are not reusable. The direct landing dV is not as much less than the enter-LMO dV as most people think. Why? Aerobraking cannot do it all!

BTW, the same basic idea also works for lunar missions.

GW

Last edited by GW Johnson (2025-05-28 19:30:52)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#6 2025-05-30 01:06:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

GW,

Your complaints about Elon Musk, President Trump, and DOGE are duly noted, but this topic is about ITV technologies for exploration class Mars missions. There is a political topic for politics.

I think space tugs and propellant depots are a splendid idea, but again, this topic is about ITV technologies. I think we're already in agreement that all real exploration missions thus far have begun in LEO. At this point, I would be pleased with any crewed mission to another planet, including a fly-by mission, irrespective of what orbit it starts in or what propulsion tech it uses. A fly-by mission would at least demonstrate that our ITV is mission capable and that the crew is no worse for wear after the mission.

Propulsion is obviously a very important part of making all interplanetary missions possible, and I understand your affinity for those systems, which I share, but do you have any specific ideas on how we can create a more practical long-duration in-space vehicle to carry exploration crews to Mars?

I've already mentioned some of my ideas:

1. Counter-rotation sidesteps the precession and loss-of-control issues with artificial gravity.

2. Composites fabricated by robotic tape winding machines can create durable yet light vehicle hulls with excellent volume-to-mass ratios.

3. SEP, storable chemicals, and CMGs can provide adequate in-space propulsion and maneuvering after achieving escape velocity using already available cryogenic chemical propulsion upper stages.

Maybe we'll have ZBO tech perfected in another 5 to 10 years so that long duration on-orbit storage of cryogens becomes a more practical proposition. ZBO tech development began over 25 years ago. I think the required insulation tech is ready to apply, but not much else is. My understanding is that insulation alone, and perhaps some modest cryocooler hardware to re-liquefy small amounts of boil off as compared to LH2, is sufficient for LOX and LCH4. Unfortunately, NASA is dead set on using LH2. If the daily loss rates weren't so high I understand the potential benefits from using LH2. Thus far, long-term LH2 storage has proven to be a very tough nut to crack.

4. Rather than trying to store absolutely everything because we're afraid of equipment failures, capitalize on the excellent progress being made on low-temperature / low-power / high reliability CO2 scrubbers and water filtration systems. I see these technologies as "de-risking" the mission, rather than adding risk. Highly efficient air and water recycling is a mission enabler. We already spent the money to develop this tech to a very high degree of reliability and readiness, so we may as well use it. The mass reduction from water recycling alone is key. IWPs provide a very consistent 98% water recycling rate. CO2 recycling would provide another significant mass reduction.

There are near room temperature processes for CO2 splitting that leaves pure elemental Carbon dust floating on top of Gallium metal as the Gallium strips the O2 from CO2. An electrostatic attraction process could remove the Carbon dust for storage, although even mechanical separation methods appear to work. Heating the metal to 500C to 700C in a vacuum is sufficient to release 2 of the 3 Oxygen atoms. Hydrogen gas will strip the remaining Oxygen, producing water and Gallium metal. By the end of the mission we have 546kg of elemental Carbon from the respiration of 4 crew members. Human feces is 40% to 55% Carbon, so an additional 200kg to 275kg of Carbon could be recovered. This recovered Carbon is one of the important precursor materials for synthetic fibers, plastics, and rubbers.

5. Use the most modern avionics suite and sensors we have, because the reduction in power consumption and heat rejection are incredible. Power-over-fiber combined with optical chips is a radiation hardened by design computing environment. Some researchers here have already built a fully optical computer that performs all the necessary logic functions of legacy Silicon-based CPUs, to include RAM, but it does this with a 100GHz clock cycle. Some simpler designs are operating at up to 800GHz. That's 200 to 300 times faster than Silicon-based CPUs. Even a very modestly capable CPU with a clock cycle that fast can still perform the same functions as more sophisticated Silicon-based chips. The result is orders of magnitude power reduction.

Photonic crystal displays can render painting-on-paper quality colors. In the tech world, there's a recently established "fetish" for near-infinite color range and quality that looks as if the image was inked onto a piece of paper, even though it's been rendered onto a clear piece of glass.

Optical computers have been tested using specialized lasers and particle accelerators to withstand radiation doses in the range of 10s of megarads- a near-instant lethal dose for the crew. There's even been some talk of putting optical computers inside the cores of fission reactors, or at least ones operated at steam generating temperatures, as integrated monitoring and control systems. That makes them highly resistant to both damage and upset from normal radiation fluence ranges found in space.

Offline

Like button can go here

#7 2025-05-30 06:35:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

Quoting from Post #1:

ITV Design Characteristics:

Counter-Rotation Artificial Gravity

Counter-rotation minimizes gyroscopic precession effects. A motor of some kind can spin the two habitation spaces in opposite directions, likely varying speeds just a little, using accelerometer sensors to provide feedback, to help minimize the destabilizing effect of small mass imbalances between both sets of rotors. The destabilizing effect of rotating only in one direction complicates the operation of propulsion systems or requires deployment of tethers to connect a habitation module to an upper stage mass. A rigid "baton" design could and probably would also work, but batons typically become heavier the longer they are, to resist deformation caused by the artificial gravity induced by spinning them. If the baton is much stronger than it needs to be, because it was originally designed as a rocket vehicle's upper stage, then it's also much heavier than it needs to be, so more propulsive power and propellant are required.

It seems to me there is a germ of a good idea buried in Post #1.

That idea is to use two counter rotating batons to provide artificial gravity for crew while retaining rotational stability.

The technical difficulty of achieving those dual objectives is clear from the text above.

This post is about the operational challenges that would face the commander of an expedition using this technique.

The challenges are not unique to the counter rotating baton idea, but they are more severe.

The issue this post seeks to address is the difficulty of exerting force along the axis of rotation, in order to make necessary adjustments to the trajectory of the vehicle.

An ordinary folding umbrella is a practical example of technology applied to solve the problem I am addressing in this post. A modern umbrella is an example of extreme engineering developed over many decades to deliver great strength at the least possible cost of materials or mass.

The designer of a single Baton ship, or a multiple Baton ship as described in this topic will provide for transfer of force along the axis of rotation to the masses at the extreme ends of the baton structure.

In the case of the modern umbrella, strength is achieved by use of tension and compression working together to keep the tips of the umbrella where they need to be to perform their function.

If anyone ever actually builds the counter-rotating baton ship envisioned by this topic, that individual will have demonstrated mastery of the physics that umbrella designers have mastered over centuries.

This topic would benefit greatly with addition of diagrams that illustrate the ideas in play.

(th)

Offline

Like button can go here

#8 2025-05-30 07:17:23

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,271

Re: Miniature ITV for Mars Flyby and Exploration Missions

See here for a potential power source.

https://newmars.com/forums/viewtopic.ph … 59#p231959

It would be neat to have a reusable ITV that can be assembled from the payload of 1-2 Starship launches. We could say 1 launch for the basic vehicle structure. The second launch for propellant, reactor and consumables.

Last edited by Calliban (2025-05-30 07:19:56)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#9 2025-06-01 20:59:09

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

For Calliban re #8

Thanks for your contribution to kdb512's topic for a minimal 4 person expedition to Mars orbit!

Here is an attempt to capture the essence of the idea, given the huge volume of words and equations already published.

(th)

Offline

Like button can go here

#10 2025-06-02 16:56:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Miniature ITV for Mars Flyby and Exploration Missions

What real world experiments have been done

Space tethers

Offline

Like button can go here

#11 2025-06-02 18:19:52

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

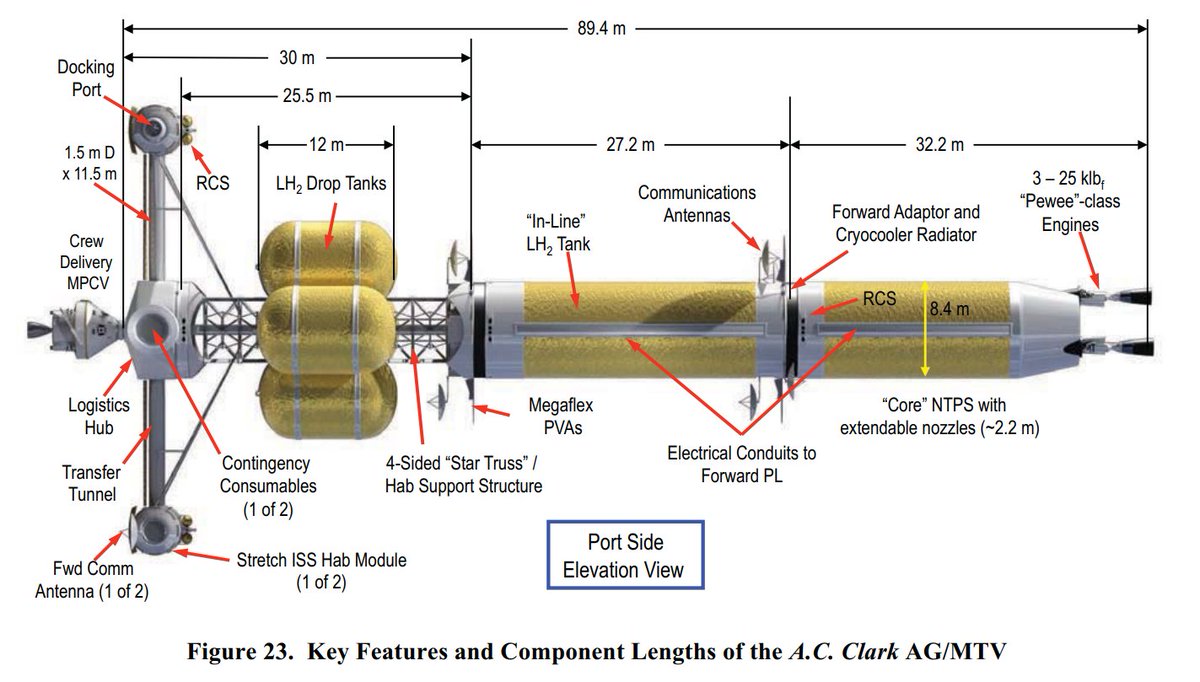

Imagine one of these ships had 2 sets of habitation modules rotating in opposite directions:

NASA has already designed the simplified form of it with 1 pair of rotating habitation modules rotating in 1 direction. Imagine that we had a second pair rotating in the opposite direction.

Please see Page 8 of this document (look at the actual page numbers on the page, not what the PDF says the page number is):

Conventional and Bimodal Nuclear Thermal Rocket (NTR) Artificial Gravity Mars Transfer Vehicle Concepts

AN ARTIFICIAL GRAVITY CONCEPT FOR THE MARS TRANSIT VEHICLE

The "Lunar Gateway" has been designed as a purpose-built Mars Transit Vehicle that also happens to be a good miniature space station:

Gateway Lunar Habitat Modules as the Basis for a Modular Mars Transit Habitat

I've heard lots of people claim that the Lunar Gateway is a waste of time and money, yet NASA is quite literally designing and building it to support a crew of 4 people for up to 500 days in deep space without resupply, possibly more, use nearly closed-loop life support that doesn't hog too much electrical power or generate too much heat, have a solar storm shelter, incorporate artificial gravity, and use a combination of chemical and electric propulsion so as not to blow out the mass budget. It's an Exploration class ITV by any other name, but wait... They actually call it that, because that's what it's really designed to do.

People like Dr Zubrin make a claim that goes like, "Hey, you know, with your capsule and my lunar lander and their giant rocket, we could do a lunar mission." However, these people are talking to each other, via systems engineers, and there are systems integration engineers who take all the bits and pieces and transform them into coherent working vehicle designs with specific missions in mind.

This long duration interplanetary transport vehicle concept dates back more than 20 years. That's how long NASA has wanted to build it, but didn't have the budget, or the giant rocket, or various other important bits like closed-loop life support that is durable and reliable. We're almost there now.

Offline

Like button can go here

#12 2025-06-02 20:10:52

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

One of the most recent refinements to NASA's ITV design:

NASA’s Moon to Mars (M2M) Transit Habitat Refinement Point of Departure Design

Abstract

As NASA prepares for the next human footsteps on the lunar surface, the Agency is already looking ahead to systems that will enable a sustained human presence on the lunar surface and mission to Mars, including a lunar Surface Habitat (SH) and Mars Transit Habitat (TH). This paper describes the latest NASA government reference design for the TH and how it will support NASA's Moon to Mars human exploration architecture. First, it will serve as a test and demonstration platform in lunar orbit, demonstrating capabilities required for long-duration microgravity human spaceflight as part of the lunar-Mars analog missions. Then, the TH will serve as a major Mars exploration element to support crew habitation during their transit from the Earth’s orbit to Mars and returning safely before TH’s return to a lunar orbit. This paper will cover several considerations contributing to the latest habitat design refinement, including the TH's concept of operations, system functional definition, subsystem assumptions, notional interior layouts, a detailed mass and volume breakdown, and identify future trade studies and analyses required to close identified technology/development/architecture gaps.

Offline

Like button can go here

#13 2025-06-02 20:17:37

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

A high level slide deck to go along with the document from Post #12:

Transit Habitat Concept and Mars Analog in Cislunar Orbit

Offline

Like button can go here

#14 2025-06-02 21:07:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

Moon to Mars (M2M) Habitation Considerations A Snap Shot As of January 2022

The following NASA Technical Memorandum (TM) is intended to provide a snapshot in time of NASA’s current considerations (ground rules and assumptions, functional allocations, logistics) for habitation systems for the lunar surface (non-roving) and Mars transits. As NASA continues to refine the reference designs to meet the needs of an evolving architecture, it is expected that this information will also be updated as a result. Where appropriate, relevant publicly released documents will be referenced to provide further detail.

Offline

Like button can go here

#15 2025-06-03 06:26:04

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

One of the references included in posts 11-14 refers to an observation about rotation in space (The Dzhanibekov effect).

I asked Google for citations, and it came up with a number, including a NASA video illustrating the flipping effect.

AI Overview

Learn moreWhy Do Tennis Rackets Tumble? The Dzhanibekov Effect ...

The Dzhanibekov Effect: What Is It and How It Works - YouTube

rotational dynamics - What would it feel as a human being to ...

Tennis racket (Dzhanibekov) effect: torque-free rotational ...

Investigate the Dzhanibekov Effect with a Simulation App

Can the Earth flip over? The Dzhanibekov Effect | by Space ...View all

The Dzhanibekov effect, also known as the tennis racket theorem, is a phenomenon in rigid body dynamics where a rotating object with three distinct moments of inertia, particularly in microgravity, unexpectedly flips its orientation when spinning around its intermediate axis. This effect, named after Soviet cosmonaut Vladimir Dzhanibekov who first observed it in space, is due to the instability of rotation about the intermediate axis.

Elaboration:

Rigid Body with Three Moments of Inertia:The Dzhanibekov effect applies to objects that have three different moments of inertia around their principal axes of rotation. Examples include tennis rackets, T-handles, and wingnuts.

Intermediate Axis Instability:

When such an object spins around its intermediate axis, it experiences a flip in its orientation. This is because the intermediate axis of inertia is unstable, meaning it is less resistant to changes in its rotational direction than the other two principal axes.Microgravity and the Effect:

The Dzhanibekov effect is most pronounced in microgravity (like in space) because there are no external forces like gravity to stabilize the rotation.Discovery:

Cosmonaut Vladimir Dzhanibekov first observed this phenomenon while in space in 1985.Tennis Racket Theorem:

The Dzhanibekov effect is also known as the tennis racket theorem because it was later observed and explained using the behavior of a flipping tennis racket.Tennis racket theorem - Wikipedia

The tennis racket theorem or intermediate axis theorem, is a kinetic phenomenon of classical mechanics which describes the movemen...Wikipedia

Internal dissipation in the Dzhanibekov effect - ScienceDirect

ScienceDirect.com

Why Do Tennis Rackets Tumble? The Dzhanibekov Effect Explained… | COMSOL Blog

Sep 1, 2020Wikipedia

https://en.wikipedia.org › wiki › Tennis_racket_theoremIt has also been dubbed the Dzhanibekov effect, after Soviet cosmonaut Vladimir Dzhanibekov, who noticed one of the theorem's logical

consequences whilst in ...People also ask

Can Dzhanibekov's effect happen to Earth?

What is the Dzhanibekov effect in math?

What is also dubbed the Dzhanibekov effect?

Why do spinning objects in space flip?

Feedback

Can the Dzhanibekov Effect celestial bodies, like Earth's ...Physics Stack Exchange

https://physics.stackexchange.com › questions › can-the...

Mar 22, 2024 — The Dzhanibekov Effect does apply to some of our neighbours like asteroids and Pluto's moon Nix, for example. With regard to magnetic pole ...Top answer:

The weight distribution of earth is not very symmetric at all, especially when taking the polar ...

Why Do Tennis Rackets Tumble? The Dzhanibekov Effect ...COMSOL

https://www.comsol.com › blogs › why-do-tennis-racke...

Sep 1, 2020 — The Dzhanibekov effect is also called the intermediate axis theorem or tennis racket theorem. Tennis rackets also have three easily identified ...

Videos14:49

YouTube · Veritasium

The Bizarre Behavior of Rotating BodiesYouTube · Veritasium

Sep 19, 2019

10 key moments in this video

From

00:37

Wingnut flipping

From

02:12The 3 ways to spin a tennis racquet

From

03:41

Examples of half-twist

From

04:08

Spinning ring

From

04:40

History of the intermediate axis theorem

From

06:36

Explanation

From

09:31

Conclusion

From

12:16

Maximum Moment of Inertia

From

13:06

Earth's rotation

From

13:57

LastPass Sponsor Message0:31

Dzhanibekov effect demonstration in microgravity, NASA ...6:58

YouTube · Strongly Connect

The Dzhanibekov Effect: What Is It and How It Works

YouTube · Strongly Connect

Sep 20, 20235 key moments in this video

11:51

YouTube · GetAClass - Physics

The Dzhanibekov effectYouTube · GetAClass - Physics

Feb 17, 2024

3 key moments in this video

Feedback

View all

(th)

Offline

Like button can go here

#16 2025-06-03 15:37:09

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Miniature ITV for Mars Flyby and Exploration Missions

Didn't I already tell everyone that spin is stable only about the min and max moment of inertia axes? This has been in engineering dynamics texts for over a century now.

There, I said it in 2 sentences. The AI needed a whole page.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#17 2025-06-03 18:06:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

Let's get back on track!

kbd512 has proposed dual counter-rotating batons.

GW Johnson has proposed single batons, and it turns out so has NASA.

Rather that getting sidetracked with issues that have been solved in past decades or centuries, let's see if we (NewMars forum) can make some progress in defining a feasible vessel similar to the NASA example, with kdb512's dual rotating batons.

One of the NASA examples showed force structures holding the rotating structure against propulsion forces. Let's add that to the drawing.

It looks to me as though the NASA example shows a lot of thought by a team that was given the opportunity to try to design an exploration vehicle that could actually survive a trip to Mars and back. Let's build on that example, adding the counter rotating habitat idea.

(th)

Offline

Like button can go here

#18 2025-06-04 17:36:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

This post contains an image of kbd512's ITV concept, prepared by GW Johnson.

For kbd512 ... GW says this is a "first cut" ... please provide guidance for details of how you would build and operate the vehicle.

The NASA study you showed us seems to me to contain a lot of the elements that would be needed.

(th)

Offline

Like button can go here

#19 2025-06-04 18:19:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

tahanson43206,

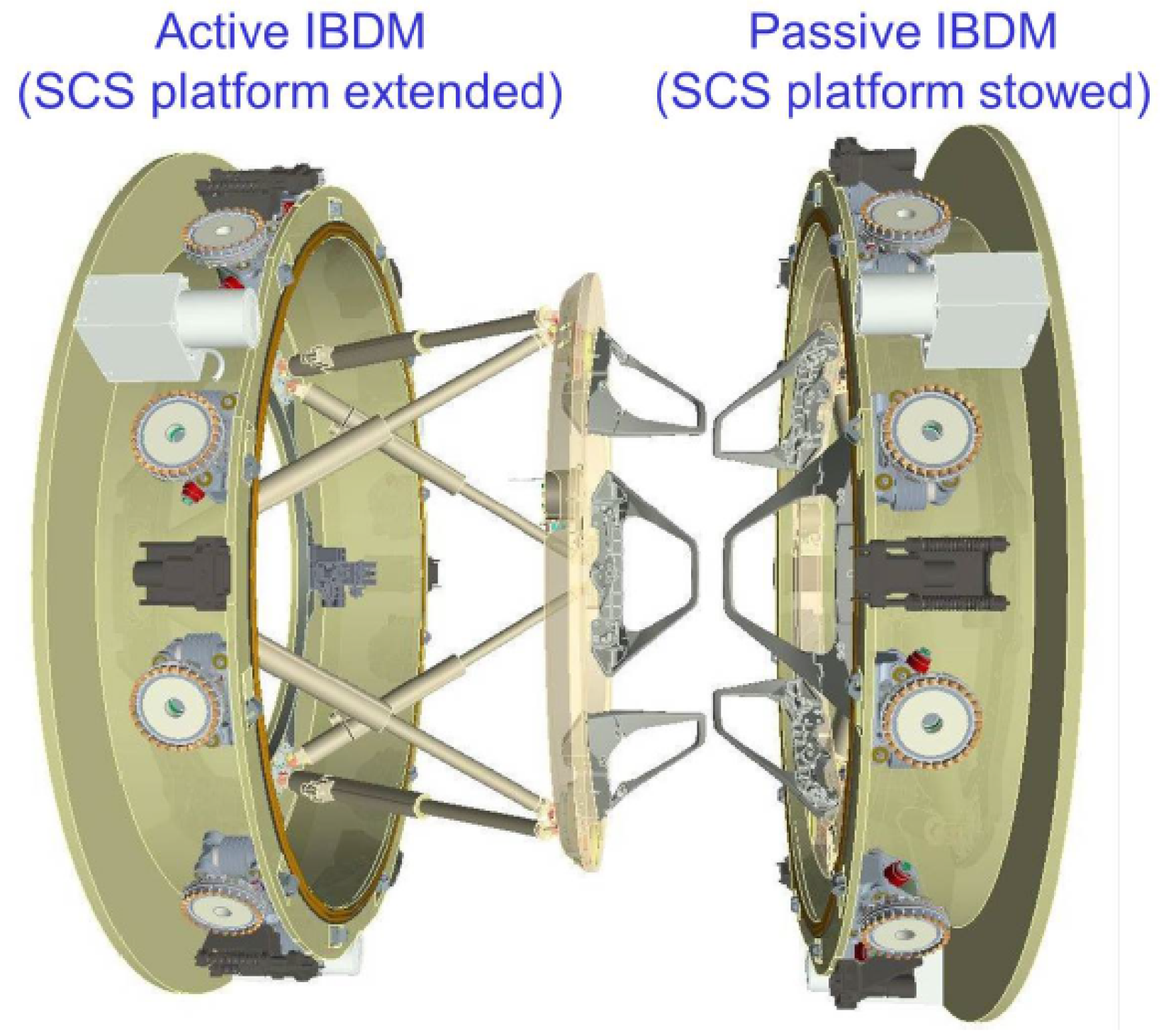

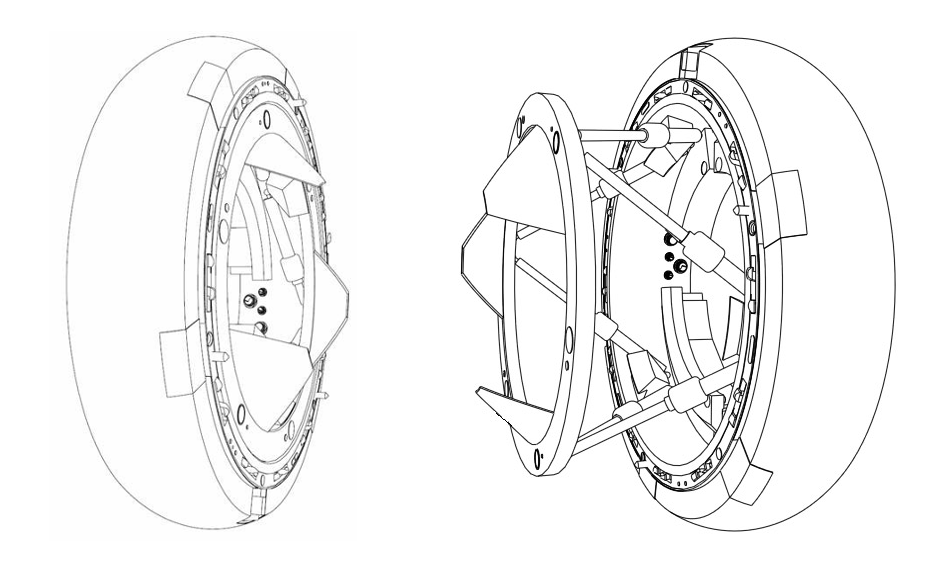

YES! There we go! That's the basic idea.

To prevent the gas leaks GW is concerned about, my "idea", if you will, was that both rotating modules would be completely sealed and if you wanted to transfer people between modules then you would "spin down" both units and then attach a "docking ring" between the two rotating units to allow people to pass between them.

There's a part of the "docking module" on ISS and/or visiting spacecraft that "extends" or "retracts" when docking occurs. I will post a picture of it below. The same basic system would be used here to connect both rotating units for personnel transfer, first in LEO to transfer to the ITV from a Dragon / Orion / Starliner / Dreamchaser / Soyuz, then in LMO to transfer to a descent capsule (probably a Dragon with SuperDraco thrusters to effect a propulsive soft landing on Mars, and once again in LEO or near Earth (direct entry) to depart the ITV via a capsule for splashdown in the ocean.

NASA Low Impact Docking System:

NASA DOCKING SYSTEM (NDS) USERS GUIDE

Low Impact Docking System (LIDS)

Visualize a flexible seal running around the circumference of the extensible portion of that docking mechanism, likely the same materials used to construct a standard space suit.

Offline

Like button can go here

#20 2025-06-05 06:37:58

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

Post #19 includes several links to related documents ...

The excerpt below is from the User's Guide...

The HCS contains 12 pairs of docking hooks that provides the structural integrity while

the two vehicles are hard mated. Each hook pair has both an active and a passive

hook. The 12 active hooks on the active-NDS engage with the passive hooks on the

opposing passive-NDS interface to perform the hard capture function.

The next time we get a chance to see a docking at the ISS, I presume we would see this system in operation, or at least the outer surface of the docking system as the arriving vehicle shows video. The drawings also show magnetic devices that (presumably) hold the surfaces together while the mechanical locks engage.

The User's Guide includes the word "androgynous" to describe the system.

A truly androgynous system would have active and passive hooks on both sides of the engagement. It appears the two systems automatically secure themselves so there are a total of 24 locks in place after the procedure completes. I would expect there to be sensors able to confirm that locks have been achieved.

The writers of Star Trek never bothered with details like how docking systems worked. It was (and is) preposterous to suppose docking systems from different species would "just work". However, the details of docking mechanisms would have detracted from the story line.

I would like to offer the observation that the mass of these mechanisms will be significant, so the number of these systems deployed on a vehicle will be determined by design teams trying to achieve the maximum functionality possible with the smallest possible mass.

Comments by other members who have the time to study the NASA documentation shown by kbd512 would be welcome.

(th)

Offline

Like button can go here

#21 2025-06-05 14:36:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,502

Re: Miniature ITV for Mars Flyby and Exploration Missions

This post is reserved for an updated image from GW Johnson.

The image shows the problem of forces at work in a vessel configured to operate as kbd512 has described.

image here >>

(th)

Offline

Like button can go here

#22 2025-06-05 17:55:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Miniature ITV for Mars Flyby and Exploration Missions

Remember wear factors on things that rotate in space the ISS solar array came to mind.

AI Overview

Learn more

The rotation of the International Space Station's (ISS) solar wings, specifically the Solar Alpha Rotary Joints (SARJ), can experience wear and tear over time.

Mechanism of Wearout:

The SARJ mechanisms are large rotating joints that orient the solar arrays towards the sun to maximize power generation.

They rotate continuously and slowly, completing one full rotation per orbit (approximately every 90 minutes).

This constant rotation puts stress on the bearing surfaces and can lead to wear, especially if proper lubrication or design specifications are not met.

Issues Encountered:

Lubrication Failure: In 2007, the starboard SARJ suffered a lubrication failure, resulting in severe damage (spalling) to one of the bearing surfaces.

Increased Drag Torque and Vibrations: This issue manifested as high drive motor current draw and increased structural vibrations near the joint.

Kinematic Design Vulnerability: Investigations revealed that the anomaly was caused by a combination of kinematic design vulnerability, inadequate lubrication, and manufacturing flaws.

Mitigation and Repairs:

Cleaning and Lubrication: To mitigate the damage, astronauts performed spacewalks to clean and lubricate the affected bearing surfaces.

Component Replacement: Worn and damaged components were replaced in orbit.

Improved Lubrication: Space-compatible grease was applied to improve lubrication and reduce friction.

Lessons Learned: The experience led to improved practices in designing, manufacturing, and testing mechanisms for use in the space environment.

Impact on Solar Arrays:

While the SARJ issues primarily affect the rotating joint mechanism, the solar arrays themselves are also subject to degradation over time.

Environmental factors like radiation, contamination, and micrometeoroid impacts can contribute to the degradation of the photovoltaic cells.

The original solar arrays were designed for a 15-year service life and have been replaced multiple times to ensure adequate power generation for the station.

In conclusion, the rotation of the ISS solar wings, specifically the SARJ, has encountered wear and tear issues primarily due to lubrication failures and design vulnerabilities. These issues have been addressed through repairs, lubrication, and component replacement, and the lessons learned have been incorporated into future designs. The solar arrays themselves also experience gradual degradation from environmental factors, necessitating periodic replacemen

Offline

Like button can go here

#23 2025-06-06 01:47:24

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,350

Re: Miniature ITV for Mars Flyby and Exploration Missions

I think composite structures are going to have less difficulty resisting the forces applied to them than light alloys. For starters, composites have sky-high stiffness (resistance to bending / deformation) and tensile strength, as compared to 2xxx series Aluminum alloys and 3xx series stainless steels. Coefficients of Thermal Expansion are much lower for Carbon-based composites than they are for virtually any suitable metal alloys, so temperature deltas across areas of the structure exposed to full Sun vs shadow are far less. Composites don't corrode from atomic Oxygen attack in LEO, so that's not much of a consideration, either.

We can make fairly thick composite structures from very thin layers of Carbon Fiber tow / roving / tape material, such as IM7 fiber, because the composite's density falls somewhere between 1.5g/cm^3 and 2g/cm^3, with 1.7g/cm^3 to 1.8g/cm^3 being the most probable value for an IM7 fiber composite consisting of 60% fiber fill and 40% resin matrix. Magnesium is 1.737g/cm^3. The strongest Magnesium alloy I could find would yield around 50.75ksi. IM7/5320-1 fiber/resin yields between 245ksi (compression) and 270ksi (flexure). Maraging steel yields between 250ksi and 350ksi, dependent upon the steel's heat treatment, and it's density is around 8g/cm^3, or 4.7X less mass for the bulk composite for similar strength to C300 maraging steel. The big and small of this matter is that we have an exhaustively proven aerospace composite combination available at affordable prices. When used to fabricate cryogenic propellant tanks, the cost of the finished product was 25% to 30% below the cost of a comparable Al2195. Most of the cost of composites is the energy consumed to create the materials. The tape winding fabrication process takes place over a matter of weeks (typically 1-3 weeks, maybe 5 weeks for complex parts), and is no more time consuming than the months of milling and welding Al2195 "potato chips" into finished structures. The curing process then takes place over the next month or two, but involves very little touch labor and no movement of the part or structure. Additional painting or coating processes may be required, perhaps a fluoropolymer sealant to inhibit absorption of moisture, for example.

Hexcel HexTow IM7 Carbon Fiber Material Properties

Fiber Density: 1.78g/cm^3

Cytec CYCOM 5320-1 Epoxy Resin System Material Properties

CYCOM 5320-1 is a toughened epoxy resin prepreg system designed for vacuum-bag-only (VBO) or out of autoclave (OOA) manufacturing of primary structural parts. Because of its lower temperature curing capability, it is also suitable for prototyping where low cost tooling or VBO curing is required.

CYCOM 5320-1 handles like standard prepreg, yet can be vacuum bag cured to produce autoclave quality parts having very low porosity. It offers mechanical properties equivalent to other 350°F (177°C) autoclave-cured toughened epoxy prepreg systems after a 350°F (177°C) post-cure. The laminate can support a freestanding post-cure after an initial low temperature cure. The material can also be cured under positive pressure in an autoclave or press.

CYCOM 5320-1 Cured Resin Density: 1.31g/cm^3

NCAMP 5320-1 Resin System Processing Documentation:

Cytec, a Syensqo Company 5320-1

NCAMP NMS 818 Carbon Fiber Specifications Documentation Repository for Qualified Materials:

NMS818 Carbon Fiber Specifications

NCAMP NMS 818/8 Fiber Specification for Hexcel HexTow IM7 Unidirectional Fiber Tape:

Document No.: NMS 818/8 Revision N/C, February 8, 2013 - for NMS 128/2 IM7 8552 Unitape

60% Fiber Fill: (1.068g/cm^3) + 40% Cycom 5320-1 Resin (0.524g/cm^3) = 1.592g/cm^3

I prefer to use 1.7g/cm^3 as my bulk density "fudge factor figure" in lieu of the manufacturer's exact stated material properties. If I use 1.7g/cm^3, then I know I'm not going to end up with a primary structure component with greater mass than what I intended. If the component ends up modestly lighter, that's fantastic. If not, then I'm still covered. Since the mechanical properties of this IM7 fiber used in conjunction with the 5320-1 resin system are so well defined, relative to many other composite materials, we can have high confidence in the mechanical properties of the components fabricated from this combination. One of the major complaints engineers have about working with composite materials is not knowing exactly what they're getting. I think that problem is mostly solved by using this combination. We're not getting as much strength or as much stiffness as we possibly can, but we are getting a good mix of properties suitable for this application.

One underappreciated aspect of selecting these fabrication materials is just how thick our parts can be at reasonable mass. If our parts range in thickness between 10mm and 25mm, we're going to have exceptional resistance to deformation relative to much thinner cross-section Aluminum alloys, with tensile strength very comparable to maraging steel. The only mass-comparable structural metal alloys similar in density to composites are Magnesium alloys, none of which begin to approach the tensile strength of maraging steel. The relationship between moment of inertia and resistance to bending / deflection under load means doubling the thickness of a part doesn't increase stiffness by only 2X, it's 8X as stiff. If we were limited by the yield strengths and masses of structural metal alloys, this would quickly increase mass to impractical levels. Thankfully, we're not.

Offline

Like button can go here

#24 2025-09-23 17:30:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Miniature ITV for Mars Flyby and Exploration Missions

Mars flyby Mission Architecture of Spacecraft

by Vimana Notion Design Team India

Offline

Like button can go here

#25 2025-09-24 14:12:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Miniature ITV for Mars Flyby and Exploration Missions

A fully fueled Starship carries 1,200 metric tons of propellant (liquid methane and liquid oxygen) in its tanks. Earth departure for the 40 mt cargo needs to get to mars.

For a Mars mission carrying a 40-metric-ton payload, a Starship uses approximately 676 metric tons of fuel for the Earth departure burn after being fully refueled in Earth's orbit. The vehicle is powered by Raptor engines that burn liquid methane and liquid oxygen.

A staship fully loaded at earth orbit with fuel and just a 40mt cargo still requires for a propulsive landing more than I had thought due to the mass of the ship of 85mt for the early versions.

For a propulsive landing on Mars with a 40-ton payload, a SpaceX Starship would need approximately 30 to 40 tons of methalox propellant for the final landing burn. The Raptor engines use sub-cooled liquid methane (CH₄) as fuel and liquid oxygen (LOX) as the oxidizer.

Assuming all goes well with a landing is the question leaves quite a bit of fuel still in the ship once on mars surface.

To return to earth from mars with just 10 mT of cargo needs.

For a Starship with an 85-metric-ton dry mass and a 10-metric-ton payload to return from Mars, it would need approximately 340 metric tons of fuel synthesized on the Martian surface. The overall mission requires significant fuel production and refueling in low Earth orbit (LEO)

total fuel load at earth= 1200 mt

departure = 676 mt

landing = 40 mt

return launch = 340 mt

----------------------------

required 1056 mt

Offline

Like button can go here