New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#226 2023-03-09 05:45:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

This is interesting.

https://solar.lowtechmagazine.com/2008/ … works.html

We have already discussed transportation using canals and water filled pipelines. Small rail vehicles travelling through pipes or ducts would be much quicker and energy consumption comparable. These could be propelled pneumatically, by maintaining an air pressure difference between the front and rear of a vehicle. The rolling resistance of mine carts on rails is about 0.002, according to wiki. That means that a pressure difference of 10KPa between the front and rear of a vehicle with a 1m2 cross section area, could push 500 tonnes. That assumes the track is perfectly level of course. Wind turbines along the duct, could be used to generate LP air at say +0.1 bar relative pressure, and suction at -0.1 bar relative pressure. By opening and closing flaps, we would set up travelling waves, that our rail vehicles would ride.

The ducts would be concrete or brick, with inner dimensions perhaps 1m x 1m. Rails would be carbon steel, as would the wheels and chassis of the vehicles. Simple disc brakes would be remotely controlled (some electronics there). The wind turbine towers would be made from stone, bonded with cement or clay. The sails would be wooden, bolted to a steel hub and steel shaft driving a compressor, which exhausts into a verticle brick lined shaft, that enters the top of the tunnel. Air flow into the tunnel is controlled by rotating flap valves. Speed can be controlled by varying the opening of the valves or by applying brakes.

We could build ducts like this to transport goods between towns and cities, or between docks, mines, quarries and factories. Very good in situations where you need to transport a lot of heavy goods from point to point. Locally, for smaller packages over distances of 10 miles, compressed or liquid air powered trucks could be used. Cargo bycicles are also possible for distributing goods around towns. Ropeways carrying goods over short to medium distances could be suspended from poles and driven by drirectly coupled verticle axis wind machines, gravity or even human powered. The freight is carried in suspended baskets. We could even build small rail ducts that carry goods across towns. Over short distances, we could use furnicular systems using pumped water to adjust counter weights, with cables pulling the vehicle where it needs to go. Even gravity powered systems would work over short distances.

Last edited by Calliban (2023-03-09 05:56:26)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#227 2023-03-09 07:20:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Calliban re #226

Thank you for that link to the lengthy and detailed report on a variety of historical and present day alternatives to surface transport of goods.

It seems to me that creating a new city from scratch (as on Mars) is a way to build in such concepts from the start. Mars may have a natural advantage since habitation needs to be underground for radiation protection.

However, as humans are forced away from coasts by climate change in coming decades, there will be opportunities to start over, and building such low-tech-high-tech hybrid systems is most affordable at the beginning. Even right now, Saudi Arabia is building a huge new city in the desert. I don't know any of the details, except (if memory serves) that the city is laid out as a linear structure.

Human beings being what they are, it is necessary to plan ahead for terrorism. The low tech systems need to be built with every high tech sensor system that can be imagined.

Admission of items to the system through input ports must be managed with utmost vigilance.

It's too bad that's the way it is, but ... that's the way it is, so we might as well get used to it.

(th)

Offline

Like button can go here

#228 2023-03-09 08:32:15

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Reasonable security arrangements are needed, commensurate to risk. I think it depends upon what is being transported and where stuff is coming from and going to. I cannot imagine it being too problematic to x-ray sealed packages entering the system.

I would imagine that small guage rail freight transportation like this would be electrically powered. A conductor rail will deliver low voltage DC to the vehicle and motors will propel it forward. I have talked about a lot of low tech, non-electrical systems over the past couple of days, because I wanted to explore what was possible if we find ourselves without the materials needed for electrical systems and had to live on renewable energy, using very basic materials. It turns out that quite a lot is possible and we could probably adapt whilst retaining a reasonable living standard. But the solutions would involve big changes to our way of life. They require community cooperation, long term planning and a high degree of collectivism. It could be done. I'm not sure that it would be done.

Last edited by Calliban (2023-03-09 08:34:40)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#229 2023-03-09 08:45:54

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

This article discusses the use of direct mechanical wind power throughout the ages.

https://solar.lowtechmagazine.com/2009/ … mills.html

Of most interest are some Dutch experiments to improve the efficiency of conventional wind mills in the 1930s. They were able to double the work output of the turbine, by redesigning sails. We have even better technology today. CFD has been used to optimise blade design. So net energy return could be much better than a traditional machine. Important factors for making wind power sustainable are to use low embodied energy materials, like wood and stone; build the machines to last, with regular maintenance and to use mechanical power, rather than trying to electrify everything.

If machines are built to modest sizes, then blades can be made from wood, either carved or laminated. This is important because wood can be grown and harvested to make new blades. Epoxy glues tend to be used for glass or carbon fibre composites. But given that wood fibres are inherently weaker, perhaps we can use a more sustainable glue material to produce laminate blades? We can then burn retired blades for heat. A thin polymer coating would make the blades water proof.

Last edited by Calliban (2023-03-09 08:51:00)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#230 2023-03-09 20:07:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

From post that I last made to this one is full of lots of good discussion, but we keep glossing over the fact that the rise of energy requirement is not abating but continue to rise with each passing day causing an increase of fuels or other sources to keep growing in use as prices change for each ever increasing as well.

The use of hot fluids that are stored is just as viable as they were and still are with the steam boilers of yesteryear. The difference is we are trading coal that fires the boiler for 2 tanks of a differential temperature engine power creation source instead.

Offline

Like button can go here

#231 2023-03-10 04:27:41

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Scientists Have Developed a Way to Make Wood as Strong as Steel

The new process used here has two steps. First, natural wood is boiled in a mix of sodium hydroxide and sodium sulphite, which is actually similar to the process made to create wood pulp for paper.

Next, the wood goes through a compression phase to collapse the walls between individual cells. Heat is added to encourage new chemical bonds while the wood continues to be compressed.

Sodium, water, sulfur. All abundant elements. I suspect it will last a lot longer than regular wood as well, given the absence of small spaces for moisture and microorganisms to get to work. Of course, there's going to be a size limit to the process, so whether we can make blades for windmills this way I do not know.

Use what is abundant and build to last

Offline

Like button can go here

#232 2023-03-10 07:49:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Scientists Have Developed a Way to Make Wood as Strong as Steel

The new process used here has two steps. First, natural wood is boiled in a mix of sodium hydroxide and sodium sulphite, which is actually similar to the process made to create wood pulp for paper.

Next, the wood goes through a compression phase to collapse the walls between individual cells. Heat is added to encourage new chemical bonds while the wood continues to be compressed.

Sodium, water, sulfur. All abundant elements. I suspect it will last a lot longer than regular wood as well, given the absence of small spaces for moisture and microorganisms to get to work. Of course, there's going to be a size limit to the process, so whether we can make blades for windmills this way I do not know.

Good find Terraformer! Even if there are limits to the size of wooden pieces that can be treated, presumably it can be applied to laminates that can then be glued into a composite of any size. We could build blocks big enough for large blades in this way and machine them into shape using a CNC milling machine. Once done, we would coat them with a thin layer of epoxy to prevent any water ingress. The epoxy resin could be mixed with fine titanium dioxide dust. This would absorb UV light, reducing age related degradation of the coating.

Another thing we could do is build machines with four blades instead of the usual three. This allows for reduced rotation rate and also a more balanced symetry, reducing both blade stress and vibration. I see no reason that blades treated and designed in this way cannot last for fifty years. With four blades, we have a machine with slightly higher capital cost. But life span would be much greater.

Another option that would allow us to build larger wind mills, is to build stone or brick towers with steel tendons or stressing cables running down sleeves within them. These allow taller towers to absorb bending stresses with height to diameter ratio that would not be possible with entirely compressive structures. But the big advantage over a pure steel tower is that steel ropes can be replaced individually, without decommisioning the whole tower. A steel tower is usually finished after 20-30 years, due to corrosion and fatigue. But a stone tower can last for centuries and just swap over cables every 20 years.

As we are building for longevity, the design of the turbine hub and gearing is important. This research paper suggests that for steel gears with low stress factor, effective lifetime can be as high as 1E10 cycles.

https://www.researchgate.net/publicatio … tigue_life

If each rotation of our four bladed turbine takes 2 seconds on average, that equates to a gear life of about 600 years. I think the key to achieving sustainability is to make things that don't need to be replaced for a very long time. Whilst we can recycle materials, this takes energy and labour, with more energy and labour then needed to build something new. But if something can just be maintained for centuries, with small amounts of regular maintenance, it will always be more efficient in terms of energy and materials, than a slightly cheaper device that needs to be replaced every 20 years.

I think the same can be true with a district heating system. The pumps are moving parts, that need replacement on a timescale of decades. But the tanks, pipes and boreholes should only need building once and they can be used for centuries. A town based thermal store for cooking, could also last for many centuries. Much as we still have castles from the 12th century, our descendants should be able to use thermal stores that we build even a millenia from now. The key to living on diffuse energy is for each generation to pay maintenance costs, but only occasional replacement costs. That way, the large embodied energy needed in things like wind machines and energy storage, becomes affordable.

Last edited by Calliban (2023-03-10 08:16:13)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#233 2023-03-10 13:07:48

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Terraformer and Calliban ....

Thanks to both of you for the combination of your discovery and evaluation of potential...

I have difficulty trying to think of tags that might work for folks who want to find this discussion months or years from now, but I definitely think it has long term value.

I'll try a couple of ideas and welcome additions that our members may suggest...

SearchTerm:Wood compressed strong as steel

SearchTerm:Windmill blades made of wood

SearchTerm:Tower stone with steel cable tension

For Calliban ... I was mildly surprised you did not mention using this "artificial" wood for the frame of the wind tower.

For all ... I'm wondering if this new kind of artificial wood might become a familiar consumer product, similar to the PVC "wood" that I use for all external projects these days. PVC is slightly more expensive, but I expect it to last for as long as I do, in those applications where it has outdoor duty.

(th)

Offline

Like button can go here

#234 2023-03-12 03:23:07

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

TH, quite right. We have well maintained wooden structures that are centuries old. And wood is a renewable material. I wonder if the the new process would work on straw and other crop residues as well? In arable places, a lot of this ends up being burned in biomass powerplants. If we can make a strong particle board out of it, then we have a renewable material for cladding and flooring.

Last edited by Calliban (2023-03-12 03:27:30)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#235 2023-03-12 18:39:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

‘Fitting a heat pump has been an expensive waste of time’

Last year, I installed an air-source heat pump in a Grade II listed, off-grid cottage I’ve been renovating in a small village in Hampshire.

Offline

Like button can go here

#236 2023-03-12 20:30:15

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For SpaceNut re #235 .... you presented that lady's story without comment.

She reported difficulty finding a contractor, and that she was unhappy with the contractor who agreed to do the work.

My reservation would be about going with an air sourced design, instead of investing in a ground loop system.

It is possible there might be a case to be made for an air source system, in a given locality, or perhaps based upon budget.

I note that the lady was eligible for government funding (grants) but apparently she missed one opportunity.

She may have earned more from the attention getting piece you quoted, than she spent on the installation.

(th)

Offline

Like button can go here

#237 2023-03-13 02:58:46

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

tahanson43206,

Installing a heat pump that performs the way it's expected to is an engineering project which requires actual engineering expertise, to include site-specific knowledge of local conditions over time. It cannot be done successfully in a repeatable manner without prior knowledge. It makes no difference if the heat pump is using the air or the ground as the cold sink. The question then becomes, "How can I, someone who is not knowledgeable about heat pump systems, determine if someone else I've never met, is knowledgeable about such systems?" One of the very first things the person who we ultimately hired to install our home solar system did, was to present his credentials as an electrical engineer with more than 10 years of experience designing and installing those systems for commercial and residential sites in Texas. You don't have to be an electrical engineer to successfully install a home solar system, but you do need to have the prior knowledge of someone with their expertise.

If this woman wanted to spend a bunch of money to reduce her power bills, then the best investment she could've made is better insulation. The way in which insulation affects a building's power consumption for heating and cooling is very easy for someone without much engineering expertise to understand. If you double the insulation value of the materials used in an existing structure, then you cut the energy required to heat or cool said structure by about half. No other investment into energy efficiency is as effective or guaranteed to work or long-lasting, regardless of local conditions. This principle works equally well in Texas or Arizona as it does in Alaska or Maine.

There's a radio show that I listen to here on the weekends, Texas Home Improvement with Jim Dutton. One of the most frequent recommendations given to people looking to lower their power bills, is to improve their home's insulation. Texas homes, even most of the new ones, are frequently built with almost non-existent insulation in the walls and giant but cheaply made windows that leak heat like a sieve. If you want to cut power consumption, then you do a much better job of insulating it than the contractors who built the homes.

I installed a new door leading to our garage to replace the one destroyed by our home invader. The effect of better sealing and the better insulation of the door, which was designed as an exterior vs interior door, was immediately obvious. The inside of the new door is cold to the touch in the summer, whereas the old door was warm. Since I'm not trying to air condition our garage, that was a fairly significant change.

Offline

Like button can go here

#238 2023-03-13 04:00:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For kbd512 re #237

Your contribution to Void's topic contains several helpful observations, but I would like to focus this post on the benefits of improving insulation you mentioned.

For all who might have similar success stories to share ... please post them here.

A lot of specific suggestions (like a replacement door with insulating properties) can add up to big savings.

(th)

Offline

Like button can go here

#239 2023-03-13 04:04:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For all in connection with SpaceNut's post about the dissatisfied purchaser of an air source heat pump.

My guess/expectation is that an air source heat pump is cheaper than a ground loop heat pump, and it may be satisfactory in some locations.

My guess/expectation is that a ground loop heat pump is a better bet in the long run, but don't have specific data to substantiate that view.

(th)

Offline

Like button can go here

#240 2023-03-13 04:46:08

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Qualified tradesmen are in short supply in the UK. This is partly due to lack of sufficient apprenticeship schemes. But there is huge demand from new build housing projects. This is more lucrative than taking on piece work. My father in law has had to wait sevedal months to get his boiler replaced.

Installing a heat pump will be expensive because achieving good efficiency means heating at low temperature. With a gas boiler, safety is the only limit to radiator temperature. The boiler could put water through the system at 100°C. But safety limits temperature to 60°C. With a heat pump, achieving a good coefficient of performance requires that water temperature is as low as possible. To get the same rate of heat transfer out of lukewarm radiators requires a much larger radiator surface area. If I were building new, I would run heating pipes through the walls and under the floors. Improved insulation and eliminating drafts are definitely a better way of mitigating this in an already built house. But there are practical limits when your house is ancient, as many houses are in the UK. My house was built in 1865, about the time of the US civil war. I could clad the outside walls with insulation, but it would be one hell of a job.

Ground source heat pumps will give a much better COP, but they require that you have sufficient space for the heat transfer coils. A lot of UK houses don't have enough space around them. They also require specific ground conditions. The obvious problem with air source, is that your heat loads are highest when the air is coldest. The UK would really benefit from a programme of district heating. If each house is using a heat pump, then the water that distributes the heat could actually be cold at say 10°C. As the UK is an island, we could use seawater mains to distribute heat through towns. The only insulation needed is that provided by the dirt above and around the buried pipes. Interseasonal heat storage using boreholes is an attractive idea. It also allows district heating to be introduced more incrementally, at a street level, rather than having to build a single network covering an entire town.

Last edited by Calliban (2023-03-13 05:01:36)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#241 2023-03-13 05:22:00

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

The key to living on diffuse energy is for each generation to pay maintenance costs, but only occasional replacement costs. That way, the large embodied energy needed in things like wind machines and energy storage, becomes affordable.

How can we best use our dwindling stock of fossil fuels to build infrastructure for the future? Grand Contour Canal, perhaps? Whilst the diesel for the machines is still somewhat affordable. It will take thousands of years to erode away without maintainence (of course, the failure of a lock would probably drain it sooner than that, and the artificial gorge colonised by trees...). America has the Mississippi; whilst we have the coasts, maybe an internal network would be preferable, less vulnerable to weather.

Use what is abundant and build to last

Offline

Like button can go here

#242 2023-03-13 16:36:52

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Terraformer,

Locks and canals require gigantic diesel-fueled machines to dredge out a channel at least big enough for a barge, and then you need enormous amounts of power to pump water into and out of the canals.

If you're already building gigantic wind turbines, then how about a cable car system?

The cargo could be dropped right down the shaft of a wind turbine tower, via cable / elevator.

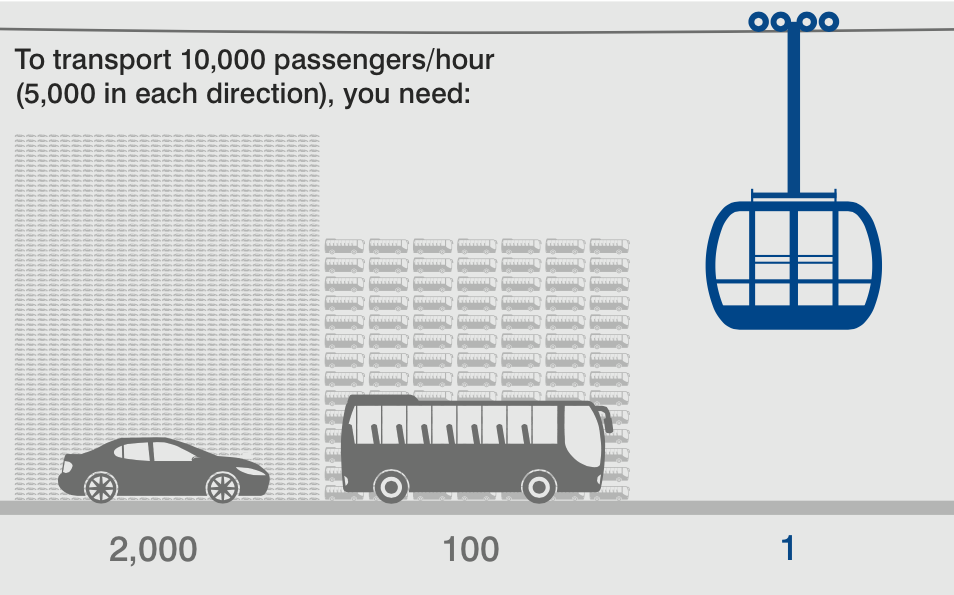

Cable cars can be incredibly efficient. They do require electricity to run, but I think they even beat trains for energy efficiency. I don't know of much else that can do that. Barges and trains are pretty close to each other until you start transporting bulk goods like ore and coal, but cable cars are better than both for other kinds of goods like food, beverages, clothing, pharmaceuticals, electronics, small appliances- all the stuff society uses which is not terribly heavy but high-value. Cable cars should make theft more difficult than trains or trucks. They're very low cost, they don't require a lot of real estate, and they can operate for decades. Severe storms can stop them from running, though.

Offline

Like button can go here

#243 2023-03-13 17:08:50

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Oh, I'm all for suspension railways, both passenger size and for small cargo transport around towns. Somewhat more work than a cable car, but faster and I think more comfortable, and can be put into trains for energy savings. Unlike trains they're surrounded by air on all sides, which afaict is a benefit when it comes to reducing air resistance? Crayon and envelope calculations suggest we could transport people for very low amounts of electricity.

And I'm all about cheaper transport. Stopping decline is not enough. I want Britain to have more heat, cheaper goods transport, the ability to send packages neighbourhood to neighbourhood swiftly and affordably, and cheap passenger travel. Mere survival is insufficient.

Use what is abundant and build to last

Offline

Like button can go here

#244 2023-03-13 20:26:20

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Terraformer,

I think cable cars come pretty close to beating walking, so far as energy efficiency is concerned, certainly over longer distances. I'm not sure how you can do much better than that.

Offline

Like button can go here

#245 2023-03-14 12:49:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Repost by tahanson43206

From ChatGPT topic: This is the last of a series of discussions around design of a solid state geothermal harvesting system. We heard back from a manufacturer of Seebeck devices, and their equipment bottoms out at 160 Kelvin. This means that LN2 is not acceptable, because LN2 boils at 77 Kelvin.

Upon rereading the above, I realized that Nitrogen might work well as a gas, if the goal is to provide cooling for Seebeck devices.

ChatGPT considered Sulfur Dioxide and Carbon Dioxide.

For the time being, I decided to show the CO2 results, because CO2 is abundant on Mars, and it is unwelcome on Earth, so using it for worthwhile projects would presumably be welcomed by those who want CO2 out of the environment.

hello again!

Hello! Welcome back! How can I assist you today?We are working on a cooling system that will operate at 6 atmospheres, using Carbon Dioxide as a working system. The CO2 will be cooled to 160 Kelvin, to meet the requirements of equipment, per the manufacturer specifications. I am concerned about the stability of the system at 160 Kelvin. If you can, please show the range of pressure we must maintain before CO2 freezes solid at 160 Kelvin.

Sure, I can help you with that. The triple point of carbon dioxide (the temperature and pressure at which all three phases - solid, liquid, and gas - coexist in thermodynamic equilibrium) is approximately 5.2 atmospheres (517 kPa) and 216.6 Kelvin.

At a pressure of 6 atmospheres (600 kPa), the saturation temperature of CO2 is about 218.3 Kelvin, which is above the triple point temperature. Therefore, at a pressure of 6 atmospheres, CO2 will exist as a gas at 160 Kelvin.

However, you mentioned that you are concerned about the stability of the system at 160 Kelvin. At 160 Kelvin, the heat transfer fluid will be quite cold and may present challenges for some materials used in the system, particularly if they become brittle at low temperatures. You should ensure that all materials used in the system are compatible with the operating conditions and do not become brittle or otherwise degraded at low temperatures.

As for the pressure range you must maintain to prevent CO2 from freezing, since the temperature is below the triple point temperature, solid CO2 (dry ice) can form if the pressure drops below a certain value. The exact pressure at which this will occur depends on the temperature and the initial pressure.

At 160 Kelvin, the pressure below which CO2 will freeze solid can be calculated using the Clausius-Clapeyron equation. Assuming that the enthalpy of sublimation of CO2 is approximately 25 kJ/mol, the pressure at which solid CO2 will form at 160 Kelvin is approximately 3.7 atmospheres (375 kPa). Therefore, you should maintain the pressure of the system above this value to prevent solid CO2 from forming.Thank you !! The range between 6 atmospheres and the danger point of 3.7 atmospheres looks reasonable to me. Electronic controls should be able to keep the pressure close to 6 atmospheres at all times, but there is apparently some leeway before the CO2 freezes. Meanwhile, the entire system is to be bathed in heat, so the expectation is that the CO2 will boil back to gas as heat arrives. The risk of freezing appears to be acceptable if pressure is kept above 5, with a "normal" setting of 6 atmospheres.

It sounds like you have a good understanding of the situation. Yes, keeping the pressure within the range of 5-6 atmospheres should prevent solid CO2 formation, and it's great that the system will be bathed in heat to ensure the CO2 remains in the gas phase. As long as the electronic controls are able to maintain the pressure within the desired range, and all materials in the system are compatible with the operating conditions, the cooling system should function as expected. Good luck with your project!

I'll copy this post over to a topic where it is a better fit.

The purpose of this topic is to show interactions with ChatGPT.

(th)

Offline

Like button can go here

#246 2023-03-14 12:53:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

This question is for kbd512 primarily, but all are welcome to comment as you might be inspired ...

The low end of the Seebeck devices is given as 160 Kelvin, per the manufacture, who wrote back by email.

After a long session with ChatGPT trying to find a liquid that is stable at 160 Kelvin, and after posting a copy of the result above, i realized that Nitrogen might work just fine as a coolant at 160 Kelvin.

Do you think that idea sounds reasonable? Nitrogen at 160 is still a gas, but it should flow as needed past the cold ends of the Seebeck devices.

(th)

Offline

Like button can go here

#247 2023-03-14 13:04:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

tahanson43206,

There are plenty of refrigerant loops that could operate at or above 160K. Freon 12 (CH2F2) freezes at -311F/83K. If I were you, I'd stay away from the very edge of the TEG's performance envelope. A better question to ask the manufacturer would be about their device's ability to thermal cycle over a given temperature delta before it cracks or otherwise fails.

Offline

Like button can go here

#248 2023-03-14 13:16:43

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

This is a follow up to #247

It appears that a geothermal system with Nitrogen gas as the coolant can operate at 2.31 atmospheres.

If Nitrogen enters the system at 160 Kelvin, it will be heated to 513 Kelvin by the Earth, which will increase the pressure to 2.31 atmospheres.

Therefore, after 2.31 atmospheres is reached, the new cool Nitrogen must be forced into the system at 2.31 atmospheres.

Comments/corrections are wecome.

(th)

Offline

Like button can go here

#249 2023-03-14 18:03:54

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

Terraformer,

I think cable cars come pretty close to beating walking, so far as energy efficiency is concerned, certainly over longer distances. I'm not sure how you can do much better than that.

Far off topic I know, but this youtube video talks about the last aerial ropeway in Britain.

https://m.youtube.com/watch?v=6RiYXI1Tfu4

At one time, there were hundreds. The ropeway carries shale from a quarry to a brickworks. There is no power source other than gravity - the quarry is at a higher elevation than the brickworks. A very elegant solution. No one would think to build something like this today. The default solution nowadays would be diesel powered trucks. It wouldn't even occur to people to use something like this. One thing I did note is that the cable is replaced every six years. For an inch thick cable that is miles long, that is a non-trivial expense.

Gravity power is a bit of a niche solution, that will only be applicable if you happen to be carrying goods down a gradient. We could create our own gradient between towers, but would then need to lift goods up the tower. The hoists could be electrically driven. An even simpler solution would be to mount vertical axis wind turbines onto the top of the hoists so that the wind drives them directly, with the shaft directly attached to the hoist. We could do this without even any gearing, with the hoist turning at the same rate as the turbines. A brake would be needed to prevent overspeed in high wind.

San Fransisco has street railways that are as far as I know, unique in the world. Street cars are pulled along by a cable under the road, which winds around hoists at each end of the route. Something like this could allow clean transportation without even electricity, by adjusting the weight of counterweights at each end. The easiest way of doing this is to adjust the weight of a water tank that descends into a pit and is attached to the hoist. When the train sets off in a particular direction, water is added to the tank at that end and drained out of the tank at the other. To move, the train driver just releases the brakes and lets gravity do its work. Water that drains into the pit is returned to a tank topside using either an electric or mechanical wind pump. An entirely mechanical system.

Last edited by Calliban (2023-03-14 18:19:29)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#250 2023-03-14 18:34:16

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Geothermal and Geothermal Battery (Changed Title 12/21/23)

For Calliban re #249

Does gravity stored energy count as "Geostored" .... I'm not sure. This is Void's topic, so he would be the final judge.

If it ** does ** then your post is on topic! I appreciated your historical reminders, and look forward to seeing the video soon.

Update after seeing the video: Thanks for showing us that link! I watched with some admiration as the workers managed the loading and unloading of the line. The line is (apparently) the last in England, and in 2036 it will be retired and demolished for safety reasons.

I wonder how they splice that wire rope so it is secure for 6 years of heavy duty service.

(th)

Offline

Like button can go here