New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#76 2022-12-19 07:17:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For Calliban re #75

Void appears to have found an article about achieving solar reflector heating greater than 400 Celsius.

Void posted encouraging news about improved performance of solar trough systems:

http://newmars.com/forums/viewtopic.php … 10#p204210

(th)

OK ... the article was quoted in Fahrenheit...

Quote:

The team is confident that the new aerogel will enable parabolic trough solar power systems to heat a circulating fluid up to 1,300 degrees Fahrenheit. They also envision a modular, scalable system that could be deployed widely across industrial sites.

I have a feeling that kdb512 will like this one also. I recall him having some affinity for solar thermal.

Google says that 1300 Fahrenheit is 704 Celsius.

Is that enough improvement to make a difference?

Something else to consider is the tradeoff of mechanical adjustment of the trough orientation vs a permanent orientation.

Unlike with a process driven by hydrocarbon fuels, which can be made steady and persistent over long periods, a solar heated process would be subject to constant variation.

Update a bit later .... another consideration is the cost of the aerogel component.

(th)

Offline

Like button can go here

#77 2022-12-19 08:33:00

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,281

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

According to Wiki, the highest temperature reaction in the copper-chlorine process, takes place at 500°C.

The four reactions in the Cu–Cl cycle are listed as follows:

2 Cu + 2 HCl(g) → 2 CuCl(l) + H2(g) (430–475 °C)

2 CuCl2 + H2O(g) → Cu2OCl2 + 2 HCl(g) (400 °C)

2 Cu2OCl2 → 4 CuCl + O2(g) (500 °C)

2 CuCl → CuCl2(aq) + Cu (ambient-temperature electrolysis)

Net reaction: 2 H2O → 2 H2 + O2

A temperature of 530°C on the solar thermal side, allows for a modest temperature drop across heat exchangers.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#78 2022-12-19 09:18:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The link provided by Void was to: https://cleantechnica.com/2021/11/29/ne … ower-ball/

I've just returned from reading the article.

The process of separating Oxygen and Hydrogen is not mentioned, so it is possible the ideas of Calliban might work in this situation, while attention is focused elsewhere.

The article ** does ** make the point that both Calliban and kbd512 have been making, that existing industrial processes make heavy use of petroleum products for heating.

The focus of the article seems to be adapting existing industrial process to the (proposed) solar trough systems.

However, ** both ** kbd512 and Calliban have pointed out that the existing infrastructure works well with hydrocarbon fuels, the investment has been made, and the existing equipment and systems would continue working well for years to come if a new supply of hydrocarbon fuels becomes available.

I'm hoping that it will turn out that production of hydrogen and oxygen works even better at 700 Celsius than it does at lower temperatures? I am hoping someone in the group of active posters will describe how a trough design could deliver hydrogen and oxygen from a tube running along a trough?

If the input is sea water, I would expect the design would deal efficiently with separation of non-water suspended material from the arriving flow. That material represents a valuable set of atoms which deserve to be processed separately to make useful products.

Punch line: There is money available from government to perform research that will enhance national interests.

If it can be shown that trough solar dedicated to production of hydrocarbon fuels is a more effective (and efficient) use of taxpayer monetary units, then funds may be available to support construction of a demonstration facility.

(th)

Offline

Like button can go here

#79 2022-12-19 13:23:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

It's not an affinity for any one particular energy system or process per se, it's a recognition that we're not going to build thousands of nuclear reactors in 10 years, we're not going to produce hundreds of millions of non-recyclable electronic devices that require going nuts with burning fossil fuels to make them (playing a shell game with global emissions isn't changing anything), and the efficiency of converting photons into heat is much better than the efficiency of converting them directly into electricity. Since nothing made by humans lasts forever, a statement particularly true of electronics, I also recognize that Iron (steel), Aluminum, and even concrete have direct recycling methods that produce more metal and concrete of the same quality as the recycled materials.

The processes for converting electronics back into raw materials to then create new electronics are practically non-existent. In theory, we have processes to do electronics recycling, but all of them are so energetically unfavorable that we only do that when we have no other choice in the matter. In practice, all the electronics and batteries go to the landfill. The more highly integrated the electronics become, the less possibility of fixing them and putting them back into service.

Electronics are only particularly efficient at computation. Any device that requires computation excels when more / better electronics and software are added to it. When used to generate or store electrical power, electronics are universally short-lived single-use devices that are great at creating waste products but otherwise very poor at making or storing significant amounts of power. Efficiency needs to be put into context. An electrical device that's 100% efficient but stores 1/10th of the power you require is not all that efficient in the final analysis because it still requires at least 10X more material and some orders of magnitude more energy input to actually make a device that does what you need it to do. This is accurately reflected in prices. This is why an iPhone costs $1,000 while a gasoline powered car, which weighs as much as 2,000 iPhones (or more), can be had for $10,000 to $20,000. This is in spite of the fact that iPhones are mass-produced more than any model of car in a given model year. If you scale-up all the technology inside an iPhone and then apply it to a car, the only possibility is a much more expensive car with a much greater embodied energy cost.

A subcompact Tesla Model 3 without government subsidies costs $60,000 to buy, to achieve the same driving range as a Chevy Spark that costs $15,000. After 10 years of driving a 35mpg subcompact car using $5/gallon gasoline, you still paid half as much to purchase and drive a Chevy Spark 14,263 miles per year (average number of miles driven by the average American driver), as you did driving a Tesla Model 3. California says a Tesla is overall 23% more efficient at using energy than equivalent gasoline-powered models. A 23% well-to-wheels efficiency increase doesn't justify spending 4X more than you would on a subcompact Chevy / Mazda / Toyota with a gasoline engine.

Money, in this case, is a proxy for the cost of energy (to make and drive a 4-seat subcompact car). The cost of oil changes is a farcical addition to the cost of the gasoline car. If it costs $100 per oil change, done every 3,000 miles, then you added $4,754.33 to the total ownership cost. Since a Tesla's tires don't last 1 year in many cases, according to a Service Manager who works for Tesla, and certainly won't last 2 years, all the oil changes don't add up to the weight of rubber involved in replacing the Tesla's tires. That issue is one of a small car with small tires that weighs as much as a full-sized truck, and can only be solved by using bigger / heavier tires or making the car lighter. The same issue applies to my wife's Escalade. All the marketing BS in the world can't change the fact that the thing weighs 3 tons and the tires wear out faster because of it's immense weight. You paid a minimum of $5,000 and as much as $10,000 for tires for the Tesla, so whatever oil change savings you received were immediately consumed by paying for new tires once per year, two years at most. It's a different kind of petroleum product being exchanged, but that's all (about 5 gallons of used motor oil per year vs 100 pounds of fresh rubber- yet another bad energy trade made by people who can't do basic math). Most of the used motor oil gets recycled / re-manufactured into new motor oil. Most of the used tires get chopped up and burned in incinerators (on top of that, some people call this "green energy").

A solar thermal power plant checks a lot of boxes, which is why I proposed using it. It's not because I'm enamored with a particular solution. If someone makes a photovoltaic cell that produces equivalent power over the same time frame (50 years or more) and is easily recyclable into a brand new photovoltaic cell when the time inevitably comes to do that, then let's make a bunch of photovoltaics. I'm far less interested in the technology used than I am in the end result- affordable and usable on-demand power for everyone that doesn't contribute to global CO2 emissions.

Everyone else seems far more enamored with their favorite idea while ignoring all the problems involved with implementing it. I already know what the problems are with my idea. The main problem is that the 392 billion dollars squandered by our money squandering party, the Democrats, would've paid for fuel synthesis plants providing 2/3rds of the gasoline we presently consume. If we added the money squandered on COVID to the money squandered on the "Climate Change Action Bill", then it would've paid for synthesizing well over 100% of our total demand, which means we could start exporting fuels to our European allies to address the problems created by their money squandering Democrats. Nobody in Europe would be asking, "Hey, where is our electricity and natural gas coming from?" That problem would've been adequately addressed.

1. It's feasible to build without invoking any magical new technology that doesn't exist or only exists in a lab at demonstrator scale. We're continually told how urgent our "climate problem" is. It's not obvious to me that it is urgent, based upon what I see the people asserting that we have a dangerous problem are actually doing. The politicians think throwing money at R&D is the solution, but are they building anything to provide alternative energy or behaving any differently? Absolutely not. From the 392 billion we just spent on "climate action", I can all but guarantee everyone that not one lousy dollar will produce a power plant that does anything meaningful to address "the boogeyman". If the boogeyman is adequately addressed, then there's no bludgeon for your pandering troglodytes to use to get you to do what they want.

If the problem is real and urgent, despite the fact that none of the morons we've voted for behave as though it is, then goofing off with low energy density electronics which replaced 2% of the total primary energy supply in 50 years, or asserting that we'll rapidly build new reactors, is wasting time we don't have. Climate change is being treated as another stupid and pointless Chinese fire drill, intended to cause almost completely ignorant observers to confuse accomplishment with all the activity they see happening. Activities that cost money but don't generate solutions are worse than doing nothing.

2. The power plant requires few advanced degrees to operate, mostly limited to degrees in petrochemical engineering. The material science for the catalysts is complex, but it's reasonably simple to keep the plant up and running. People in Mongolia / parts of China / most of Africa still need energy to eat, and their emissions still count towards the total, even if none of our self-absorbed finger waggers see it, and their energy will come from somewhere. If you want them to stop burning wood and coal and poop, then they need a viable energy alternative. There are vanishingly few people with nuclear engineering degrees ready and waiting to operate thousands of advanced new reactors, and educating them is a 4 to 8 year process AFTER they receive a high quality primary education.

3. Solar thermal uses very common and easy-to-extract Earth-abundant elements. The quantities of materials involved, while fairly high, do not represent thousands of years of mining output at current extraction rates. In other words, we can feasibly source the metal ores required without turning half the planet into a giant strip mine or a toxic chemicals dump filled with old and broken electronics and batteries.

4. It's made from recyclable materials that pose no significant engineering challenges to recycle in a energy and therefore monetary cost-effective manner. Steel / Aluminum / concrete are not particularly toxic, nor do they require toxic processing to effectively recycle. More importantly, we already do recycle these materials in mass quantities because it's quite profitable and energy-favorable to do so.

5. The technology set I wish to use minimizes energy conversions. The more energy conversions that must take place, the more energy is lost to the conversions. The alternative mass-produced photovoltaics or wind turbines are incredibly energy intensive to make, there's still no other viable energy storage mechanism at human civilization scale, apart from hydrocarbon fuels, and any intermittent energy source used as a substantial portion of the primary energy supply WILL require energy storage. Storing the energy as fuels does away with all the additional but presently non-existent equipment required to transport and use electricity. The batteries we presently have are woefully incapable of storing enough power to matter. You eventually arrive at the inescapable conclusion that we're either going to keep doing what we've been doing, and keep getting the same results that lead you back to "the boogeyman", or something has to give.

If you want to quit drilling for more fossil fuels, then you actually have to provide a like-kind replacement for gasoline and diesel and kerosene. Even if all you want to do is make more electronics and batteries with the fuel, the energy to do that doesn't come from other electronics. Batteries don't make other batteries. Photovoltaics don't make other photovoltaics. All the plastics, fibers, and metals used to create wind turbines, certainly don't come from other wind turbines.

Do we have any batteries that store 45MJ of energy per kilo?

If not, then your options are to synthesize that stuff from scratch using CO2 from the air and heat from the Sun, or you can keep digging it out of the ground, or you can try to cut off the people who needed that energy, who will eventually deem the people who did that to them, "annoying", and then they will do what society normally does to annoying people (imprison or exile or execute them). I'm a proponent of not returning to medieval ways of treating people.

Some acceptance of basic math and science is required. The energy math doesn't favor electronics and batteries. We have them and they do what they do, but they're not a like-kind replacement for oil and gas and may never be. If new inventions come along to prove me wrong, then great, we'll start using them. I have a feeling that even if they do, lots of energy will still be required to make them.

Some belief that people are more valuable than fantasy-based ideas is required. If the concern for Earth and its future suitability for animal and plant habitation is not thinly disguised anti-humanism (hatred of humanity and thinking that humans are the root of all problems), then if you see an insurmountable problem, you stop insisting on doing something a certain way and bypass the problem entirely. Solar thermal to fuel is bypassing the emissions problem entirely. It replaces oil and gas extraction with atmospheric CO2 and water extraction. If the planet and all life on it recycles CO2 and water, then we can do that as well. If magical new electronics come along that last for decades with no appreciable degradation, then of course we'll start using those when they become available. Today is not that day.

Some understanding that energy doesn't simply materialize into readily usable forms is required. Basically, making anything worthwhile is rather complicated, so the simpler your energy supply chain is, the more resistant it is to external factors throwing it into disarray.

Using more "money to perform research" is equal to saying, "I don't want to do anything constructive to solve my own conundrum while hoping that my favorite electronics-based solution suddenly becomes far less energy-intensive and far more affordable." We don't need any more research into thumb-twiddling. We need to start building technically feasible energy systems. Thumb-twiddling doesn't solve any problems. Scientists can spend entire lifetimes tinkering with technology.

If we have an actual urgent problem, then we can afford to make a few mistakes building pilot-scale plants. The P-51 didn't go from cocktail napkin sketch to flying prototype in 102 days by obsessing over every little detail. They built one first, figured out what its flaws were, then mass produced a lot more of them. They were still highly imperfect, but good enough to kill nazis. Endless goofing off with minor variations on the same theme then occupied the engineers and scientists while our assembly line workers were able to get on with the task of building the machines required to win the war.

If the war is against continually increasing CO2 emissions because everything is extracted and nothing is recycled, then take stock of what a viable solution dictates. You have to close the loop on CO2 recycling. The power to remove the CO2 can only come from an energy source equal to or greater than what created it.

Offline

Like button can go here

#80 2022-12-19 14:56:10

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,281

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

According to this article, silica aerogel remains stable up to 900°C.

https://www.researchgate.net/publicatio … silica_sol

Most chemical plant benefits from scale economies. Thermal losses become smaller with increasing scale. Chemical attack is a surface area phenomena, but flow rates are proportional to reactor volume. Thermal energy storage becomes more practical with increasing scale, because heat loss scales with surface area, but heat content scales with volume. So going big with the chemical plant makes a lot of economic sense.

If we are going to insulate the trough oil pipes, then it makes sense to plumb the output of individual solar thermal farms into insulated heat mains, that deliver several GW of heat to a large thermochemical plant. The heat mains can be carbon steel pipes, insulated with much cheaper rockwool. Oil is compatible with low carbon steel. Corrosion is not an issue. And carbon steel is cheap and easy to weld. The oil involved does not require pressurisation. So the steel pipes can be thin walled, hot rolled and seam welded.

The copper-chlorine process involves decomposition of hydrogen chloride at almost 500°C. There is no mention of what pressure this will require. Even stainless steel will take a hammering in HCl at that temperature. One option is glass lined reactor vessels. For that to work, we must avoid pressure and thermal cycles. Heating rates must be slow. Ideally, we switch the reactor on and do not switch it off again for fifty years.

I will read up on the Cu-Cl cycle and post more when I have.

Last edited by Calliban (2022-12-19 15:27:28)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#81 2022-12-19 20:20:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

We know that the trough and central pipe work it's a question for what we are going to make use of for the collecting fluid that dictates what else is being done with that level of heat. Not to mention if we are using that heat directly for other processes.

Insulation is on the outgoing side of the plumbing and must not be placed on the collector surface. If there is a need to do so, then make it a vacuum inside it to keep heat from being lost through conduction like the evacuated tube which could be ALON or other silica of choice.

Offline

Like button can go here

#82 2022-12-25 21:14:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re #81 .... There appear to be more than one way to use a solar trough ... Your post appears (as I read it) to cover methods that involve flowing fluid through a pipe at the focus of the Sun's rays.

I'm interested in kbd512's original idea of making hydrocarbon fuel using solar power, and specifically Solar Trough systems.

Recently, Calliban reminded us that hydrogen can be produced directly from solar power, and specifically from Solar Trough designs.

I would like to see a small (not a gigantic many acre sized) solar trough design able to produce a kilogram of hydrogen in a single Earth day.

In hopes of helping our members to contribute to design of such a system, I asked Bing for some help.

Here are some snippets Bing seems to "think" might apply to the request:

A solar hydrogen panel is a device for artificial photosynthesis that produces photohydrogen directly from sunlight and water vapor utilizing photocatalytic water splitting and thus bypasses the conversion losses of the classical solar–hydrogen energy cycle where solar power is first harvested with solar panels and only then to converted to hydrogen with electrolysis plants.

Solar hydrogen panel - Wikipedia

en.wikipedia.org/wiki/Solar_hydrogen_panel

en.wikipedia.org/wiki/Solar_hydrogen_panel

Was this helpful?

People also ask

Could solar panels produce hydrogen gas on site?

How do solar panels split water?

How do hydrogen photovoltaic panels work?

How much solar energy can be converted into hydrogen?

Feedback

Solar Panel Splits Water to Produce Hydrogen - IEEE …https://spectrum.ieee.org/solar-panel-prototype...

WebMar 13, 2019 · A small but growing number of facilities are producing “green” hydrogen using electrolysis, which splits water molecules using electricity—ideally from renewable sources such as wind and solar.EXPLORE FURTHER

Global web icon

Hydrogen From Water - 3 Production Methods - The Green O…

greenoptimistic.com

Global web icon

Scientists invent a solar panel that produces hydrogen - Inha…

inhabitat.com

Global web icon

(PDF) Hydrogen Production Using Solar Energy - ResearchGate

researchgate.net

Global web icon

World's First Home Hydrogen Battery Powers Your House fo…

goodnewsnetwork.org

Global web icon

Belgian scientists develop solar hydrogen panel – pv magazi…

pv-magazine.com

Recommended to you based on what's popular • Feedback

Solar Panel Splits Water To Produce Hydrogen - DS New Energy

https://www.dsneg.com/info/solar-panel-splits...

WebJan 11, 2021 · Solar panels are multiplying on rooftops and in gardens worldwide as …Videos of solar Panel Splits water To Produce hydrogen

bing.com/videos

(3) Photocatalytic water splitting to produce solar hydrogen on a large scale

Play (3) Photocatalytic water splitting to produce solar hydrogen on a large scale

1:28:50

(3) Photocatalytic water splitting to produce solar hydrogen on a large scale

2.7K views · 6 months ago

(th)

Offline

Like button can go here

#83 2022-12-26 19:24:07

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut, here is another "conversation" with Google ...

Google, please see if you can find a design for a solar trough system that converts water to hydrogen and oxygen gas

About 638,000 results (0.90 seconds)

Simple "Electrolysis" using sunlight! (turns water into fuel)https://www.youtube.com › watch

3:59

Solar Hydrogen/Oxygen Generator DIY - Simple "Electrolysis" using ... school science experiment and is totally safe. one can imagine if this ...

YouTube · desertsun02 · Aug 28, 20145 key moments in this video

Missing: Google, design trough systemDesign and performance assessment of a solar-to-hydrogen ...https://www.sciencedirect.com › science › article › pii

by S Coulibaly · 2022 · Cited by 2 — This work investigates the techno-economic performance of the proposed system which recovers the waste heat from molten carbonate fuel cell and uses solar ...Scientist Devises a Solar Reactor to Make Water and Oxygen ...https://www.solarpaces.org › solar-reactor-makes-water-...

Oct 26, 2017 — With the successful test of this solar reactor design, Denk has achieved the first step, creating H2O on the Moon using solar thermal energy.

How solar thermochemistry generates the greenest hydrogenhttps://www.solarpaces.org › csp-efficient-solar-split-h2...

Dec 16, 2022 — Solar heat at about 800 C makes the water (H2O) split into hydrogen (H2) and oxygen (O). SK: Could today's natural gas plants be converted in ...Hydrogen and Oxygen Production via Water Splitting in a ...https://www.mdpi.com › ...

by S Tosti · 2021 · Cited by 3 — According to thermodynamics, this process exhibits conversions of practical interest at very high temperatures and needs efficient separation ...Methodologies for the Design of Solar Receiver/Reactors for ...https://www.mdpi.com › ...

by MA Murmura · 2020 · Cited by 6 — Thermochemical hydrogen production is of great interest due to the potential for significantly reducing the dependence on fossil fuels as energy carriers.People also ask

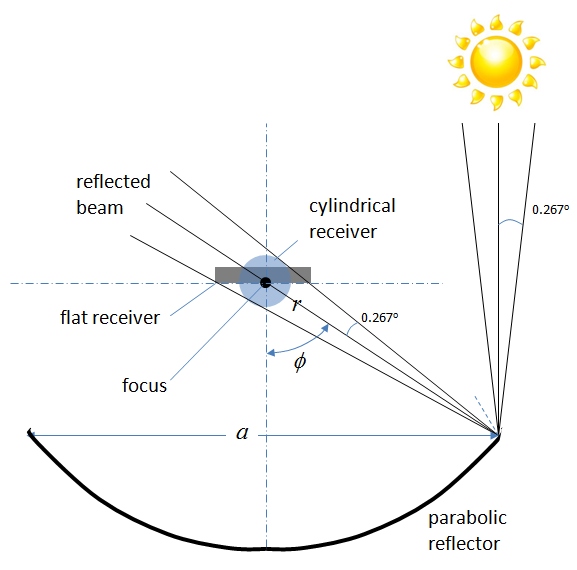

How does a solar trough work?

Can you produce hydrogen from solar energy?

How do you generate electricity from hydrogen gas?

What are the two types of solar energy conversions?

FeedbackSolar energy conversion - Physics Today - Scitationhttps://physicstoday.scitation.org › doi

If solar energy is to become a practical alternative to fossil fuels, we must have efficient ways to convert photons into electricity, fuel, and heat.Solar Trough Systems - NRELhttps://www.nrel.gov › docs › legosti

In addition to operating on solar energy, the. SEGS plants are configured as hybrids to oper- ate on natural gas on cloudy days or after dark. Natural gas ...Missing: Google, design water hydrogen oxygen

Concentrating Solar Power Best Practices Study - NRELhttps://www.nrel.gov › docs

by M Mehos · 2020 · Cited by 62 — maintenance of existing concentrating solar power (CSP) parabolic trough and power ... systems, but it is not clear if they have been designed correctly, ...

(th)

Offline

Like button can go here

#84 2022-12-26 19:47:01

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Water being broken down will require a membrane, catalyst, to stop the oxygen from recombining with the hydrogen in the pipe.

The 800 C is just where moxie operates to breakdown 2co2 into 2co and o2 with a membrane as well.

While we understand these, they are not commercially off the shelf.

https://solartechadvisor.com/parabolic- … ollectors/

Here is the system that tracks but as you can see its the central line that gets hot at the top while the return is under it closer to the reflector that makes steam temperatures.

Offline

Like button can go here

#85 2022-12-27 10:26:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

A solar dish is similar but different

https://www.solartronenergy.com/solar-c … ator-work/

This indicates a 9 meter dish will give a x 1000 times for a temperature of 800'c but what is the size of the conversion surface.

other engineering books

https://www.sciencedirect.com/topics/en … centrators

https://www.instructables.com/Solar-Concentrator/

Author made use of CD-ROMs for the reflective surface and created the shape to hold them. with the mention of another project

I built this https://www.instructables.com/id/CERC-Green-Solar-Oven/, which worked incredibly well (325 degrees F) but I feel it's severely limited by the use of tinfoil as a reflective surface.

of course, the reflective shape is also part of the concentration levels and lots of details for that

https://www.e-education.psu.edu/eme812/node/557

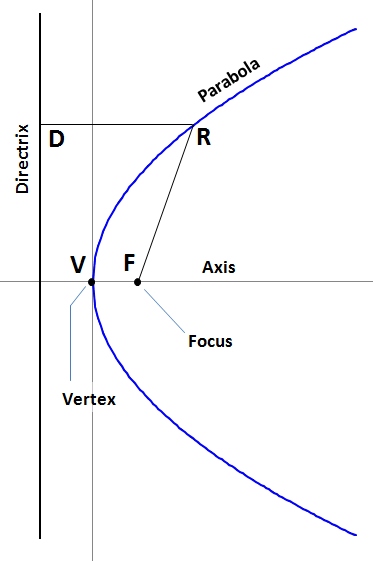

y2=4fx

Offline

Like button can go here

#86 2022-12-28 18:00:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The concentration point is a pipe that appears to be about 1-2 inches at most.

Went back to find information or images that give a scale of sorts to how large they are.

https://www.nrel.gov/csp/concentrated-solar-heat.html

So roughly a 2-meter diameter trough based on the man's average height.

software development tool

https://sam.nrel.gov/

It appears that the pair is 4 x 6meter section

locations where Troughs are present

https://solarpaces.nrel.gov/by-technolo … lic-trough

Offline

Like button can go here

#87 2022-12-28 19:40:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

What is common to all working fluids is the pipe flow rates. It comes down to the diameter and length of the pipe which is chosen as well as the materials cable of the temperature delta's that we are looking at. It's that temperature rise that is Sensores so that we know what we have after a period of time which aids in getting the work out of the system that we desire.

https://www.omnicalculator.com/physics/pipe-flow

https://www.gigacalculator.com/calculat … ulator.php

That said once we have a number then we need a pump that can handle the condition set up. Which has a check valve or electrical shutoff to keep back pressure from heating to cause a switch of flow direction.

https://highperformancehvac.com/boiler- … pe-sizing/

Flow Rates – Boiler Piping Flow & Pipe Sizing Chart

Pipe Size Flow Rate for Copper Flow Rate for Steel

½” 1 ½ GPM (Gallons per Minute) 2 GPM (Gallons per Minute)

¾” 4 GPM (Gallons per Minute) 4 GPM (Gallons per Minute)

1” 8 GPM (Gallons per Minute) 8 GPM (Gallons per Minute)

1 ¼” 14 GPM (Gallons per Minute) 16 GPM (Gallons per Minute)

1 ½” 22 GPM (Gallons per Minute) 25 GPM (Gallons per Minute)

2” 45 GPM (Gallons per Minute) 50 GPM (Gallons per Minute)

2 ½” 85 GPM (Gallons per Minute) 80 GPM (Gallons per Minute)

3” 130 GPM (Gallons per Minute) 140 GPM (Gallons per Minute)

4” 300 GPM (Gallons per Minute)

Offline

Like button can go here

#88 2022-12-28 20:06:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

pipe dream of 800c or less as the answer is https://www.thenakedscientists.com/arti … and-oxygen

2,000 c plus....this requires a lot smaller reaction area than a trough, so this becomes this

Offline

Like button can go here

#89 2022-12-29 08:36:11

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re nrel .... your recent posts have included images from nrel....I was curious to learn more about this agency...

https://www.nrel.gov/csp/work-with-us.html

My first impression is that our proposed little plant to make a kilogram of hydrogen would (surely) look like pretty small potatoes to the scientists and engineers in this organization. Then I decided to investigate anyway....

Work With Us

The interaction of the National Renewable Energy Laboratory (NREL) with industrial, university, and government partners is the key to moving advanced concentrating solar power (CSP) technologies into the marketplace and the U.S. economy. We provide opportunities to use our facilities, develop technology partnerships, and license our technology.

On the NREL campus, South Table Mountain (upper right) provides testing with the High-Flux Solar Furnace and the Outdoor Optical Efficiency Test Loop, and the Field Test Lab (middle) houses the Advanced Optical Materials Labs.

Using Our Facilities

To help advance research and/or strengthen a product's marketability in CSP, several of our facilities or tools are available to industrial, university, and government researchers. We can also provide experienced staff to help conduct testing at the facilities, or you can perform the testing on your own. The NREL facilities include the High-Flux Solar Furnace, Large-Payload Solar Tracker, and the three specialized laboratories at NREL (Advanced Optical Materials Lab, Advanced Thermal Storage Materials Lab, and Optical Characterization Lab. To learn more, contact the CSP Research Staff.

Developing Technology Partnerships

NREL offers a variety of technology partnership agreements to help you gain access to our research expertise in CSP, including our laboratory and modeling and analysis capabilities. You can:

Work collaboratively with us on a CSP research project through a Strategic Partnership Projects Agreements.

Submit a proposal in response to any active solicitation for assisting NREL with a CSP research and development activity.

Licensing Our TechnologyYou can license any available patented CSP technology. For more information, see NREL's technologies available for licensing.

National Renewable Energy Laboratory

About

Research

Work with Us

News

Careers

Contact Us

Visit

Subscribe to NREL

Accessibility

Disclaimer

Security and Privacy

Site Feedback

Content Editors

Developers

EmployeesAlliance for Sustainable Energy, LLC U.S. Department of Energy

The National Renewable Energy Laboratory is a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, operated by the Alliance for Sustainable Energy LLC.

(th)

Offline

Like button can go here

#90 2022-12-29 08:47:44

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut ... FYI .... contact form submission to nrel

NewMars.com/forums is affiliated with the Mars Society. We've been discussing/thinking about settlement of Mars for over 20 years. I am a (junior) moderator (tahanson43206). I'm encouraging discussion of a number of technologies, and one of them may be of interest to someone in the large membership of nrel (staff/affiliates).

As an exercise, we (small group of posters) are thinking about what it would take to make a kilogram of hydrogen in one Terrestrial day, using a set of equipment that I will list below. We'd (certainly ** I ** ) would appreciate any assistance/advice/pointers that anyone might care to provide.

Proposed system:

1) Solar trough with fluid flow (many examples of nrel research are inspiration)

2) Stirling Engine to collect energy from heated fluid

3) Electric generator to feed battery

4) Battery to even out current flow to electrolysis unit over 24 (Earth) hours

5) Electrolysis unit and associated product collection and storage subsystems

6) Whatever I've overlookedIn my role as (junior) moderator, I monitor the organization email address and encourage membership.

We have 18,370 renovated email addresses that we have recovered from spammers who dropped them off over 20+ years.(th)

Note ... I had to remove content from the above original, to meet the 750 character limit.

(th)

Offline

Like button can go here

#91 2022-12-29 09:00:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re above inquiry at NREL ...

The key concept I am hoping will interest (someone?) at NREL is the compact nature of the project, and it's potential to be replicated thousands or millions of times.

The Earth's surface (including oceans) receive a predictable quantity of sunlight, so it should be possible to imagine small installations such as the one described above located at various points on the Earth's surface, where water is available, making/collecting hydrogen and oxygen at the rate of one kilogram per Earth day.

At this point, I have no idea what the dimensions of a system would be to produce one kilogram of hydrogen per day, because every component is inefficient, and the inefficiencies are chained, so the entire system would be ridiculously inefficient.

If a system efficiency of 1% is achieved, I would be amazed.

(th)

Offline

Like button can go here

#92 2022-12-29 10:40:55

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

posted about hydrogen in the solar fuel topic.

Of course, my light house tower is the trough vertically rather than horizontally and of course I am unsure if I need high levels of heat save or volume of it for winter heating use which would change the design from a single tube capture to multiples in the reflection refocused zone of the system.

positioning the collector

https://builditsolar.com/SiteSurvey/site_survey.htm

Offline

Like button can go here

#93 2022-12-29 11:49:32

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re topic development ...

This post is to add a specification for a Solar Trough system to collect 1 Kg of Hydrogen in a single Terrestrial Day.

Your observation that 8 Kg of Oxygen would be produced caught me a bit by surprise, because I have(had) lost track of that mass ratio.

To repeat information you already provided, here is a Quora take on the question:

Showing results for Given a kilogram of hydrogen how much oxygen is needed to make water

Search instead for Given a kilogram of hydrogen how much oxygen isneeded to make waterHow much water is required to produce 1 kg of hydrogen?

https://www.quora.com › How-much-water-is-required-to...

Mar 17, 2017 — In general, it takes about 50 kiloWatt hours of energy to electrolyze 9 kilograms (also 9 liters) of water to produce 1 kg of hydrogen (H2) and 8 kg of oxygen ( ...

3 answers

· 9 votes: Thanks for A2A. The method of production of Hydrogen , in here shall be supposed as ...

If water is split into hydrogen and oxygen, how much ...

11 answers

Mar 7, 2018

How much hydrogen gas is released from one liter ...

3 answers

Oct 20, 2016

How many KGS of hydrogen is required to produce 1 ...

2 answers

Jul 16, 2018

How much oxygen and hydrogen gas can be ...

3 answers

May 12, 2018

More results from www.quora.com

So the specified system would take in 9 kg of water (9 liters) and produce gas as output.

In practice, more than 9 liters of water would be needed due to presence of suspended materials and due to inefficiencies in processes.

The detail I'd like to add in this post is to make the system portable.

I'm not sure how large the system will end up being, but it can be mounted on a light weight (probably aluminum) frame with wheels large enough to traverse farm fields, and moved into working positions on fields that are harvested and ready for winter.

Millions of acres of land in the United States (and probably elsewhere) are potentially available for this secondary income stream.

Thus, the complete system would include:

***add list >>

Proposed system:

1) Solar trough with fluid flow (many examples of nrel research are inspiration)

2) Stirling Engine to collect energy from heated fluid

3) Electric generator to feed battery

4) Battery to even out current flow to electrolysis unit over 24 (Earth) hours

5) Electrolysis unit and associated product collection and storage subsystems

6) Wagon frame and wheels for deployment in fields

7) Whatever I've overlooked

(th)

Offline

Like button can go here

#94 2022-12-29 12:09:09

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Business practice and companies that already have these fields will be the navigation of laws and regulations to achieve even a modest level for home use let alone to become a provider of a service to manufacture the energy as a combined roadblock to success. It's one of the reasons for why solar arrays are not more broadly used.

Here's why the U.S. electric grid isn't running on 100% renewable energy yet

I hear that but we have always done it that way statement coming in the article. We are at the point where demand for energy from providers are nearing that break even with lots of buts since location for setup changes the initial cost and so does that energy from others.

we have seen the maps for solar in that out west is the best for them

and for wind its more coastal in nature.

which brings up what the article is calling out in scaling up the grid with support for these sources with batteries along with other storage methods

The final issue is the connections and grid that has caused fires and failures to occur and paths below ground require deforesting the paths to allow for them to be built.

The northern pass was defeated when hydro was to bring power through NH.

here is how the landfills would set up an array so as to not disturb the soils that cap them

As for hydrogen elevating the water temperature going into the electrolysis machine does lower the energy required to split it into hydrogen and oxygen. That said doing the same for the source of co2 would be also implied.

Offline

Like button can go here

#95 2023-01-16 18:53:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

repost from another topic.

I have seen this compound reflector before on the tech groups on yahoo and it is intended for thermal liquid heat obsorbtion. It would damage the solar cells.

product like this one

http://www.gogreenheat.com/collector%20data%20sheet.htm

Compound Parabolic Hydronic Solar Collectors

Up to 30% more efficient than standard evacuated tube collectors

http://images.wikia.com/solarcooking/im … berger.pdf

COMPOUND PARABOLIC CONCENTRATORS FOR SOLAR WATER HEAT

PASTEURIZATION: NUMERICAL SIMULATION

Best one for all the calculations is at this site

http://www.powerfromthesun.net/Book/cha … ter09.html

More on solar concentration

The motion of the sun is why we need to mount a system on an 2 axis system to follow the sun has to do with direct ray use at the focal point.

http://digitalcommons.calpoly.edu/cgi/v … ext=bmedsp

Design, Construction, and Test of a Miniature Parabolic Trough Solar Concentrator

https://wims.unice.fr/xiao/solar/diy-en.pdf

Manual making of a parabolic solar collector

HCPV Solar Parabolic Solar Concentrator Technology

We have talked about high temperature PV cells in a few topics and this companies seems to be where we need solar to be.

Concentrating photovoltaic (CPV) technology uses optics such as lenses or curved mirrors to concentrate a large amount of sunlight onto a small area of solar photovoltaic (PV) cells to generate electricity. CPV multi-junction solar cell efficiencies of 46% are being reached compared to conventional solar power tower steam engine efficiency of 14% and average PV panel efficiency of 15%. Solartron works with CPV manufacturers and solar power plant project developers and provides a state-of-the-art parabolic solar concentrator for use with CPV multi-junction solar cell modules.

Making a dish seems to be probable.

So making solar concentrated would be possible

I think that due to low Martian gravity, and winds that are far less of a problem, it can be made from lighter materials. This Spacenut also suggested.

But for the parabolic mirror, I am thinking Styrofoam, with a reflective coating. The other surfaces may need a protective coating as well.

If Styrofoam, is not strong enough, then embed a wire mesh in it.This then being lighter, the supporting structures can also be lighter. And of course that was obvious to the other members as well.

I am usually worried about the consumption of Copper and Aluminum, so I would like to avoid that when alternatives exist, or at least reduce the amount of consumption. We do have Chromium, Iron, and Titanium available in the sand dune materials, and of course from other sources.

Sounds like we could do this...

Offline

Like button can go here

#96 2023-01-18 21:03:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Based on the knowledge gained from my site survey and weather cloud / bad weather days we will need to pick a location in the red zone for the isolation map above in post 94 first image.

Yes, the ability to track the sun just increases the throughput of the designed system daily amounts even with a single axis design.

Offline

Like button can go here

#97 2023-01-19 07:55:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,925

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For SpaceNut re recent discussion ....

A time tested way to deal with shortage of something in one location is to import it from another location where it is abundant.

Generally, the mechanism for acquiring something of value from a location where it is abundant is to offer something in exchange.

In this case, since this topic is about making solar trough devices, it is possible to imagine you might build a solar trough on your premises, and trade it with someone who lives where solar power is abundant, in return for a percentage of the value produced by the trough.

There are folks in the American South who have lots of (relatively) unproductive land where solar power is abundant.

A trade relationship between those who can make solar troughs, and those who can employ them with success, would seem possible.

(th)

Offline

Like button can go here

#98 2023-01-19 08:58:24

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

I like that panel orientation in Post #94. That's a clever use of less material to achieve the desired end result (single-axis tracking with optimization over the Sun's position in the sky for most of the year). We can probably do the same thing with trough-style panels. We can see what the problem is with using photovoltaics, though. That site looks brand new, yet the panels are already quite dirty. One of the panels has been deformed and is most likely no longer functioning as well or possibly at all. A piece of steel can be bent back into the proper shape. A Silicon wafer was never designed to be bent, and is about as brittle as a potato chip.

Offline

Like button can go here

#99 2023-01-20 18:30:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

To maximize my site's ability to use a horizontal trough Mine would be several smaller sections possibly 1 or 2 m diameters that would have rows on a stepped slope arrangement to all for each row of troughs to get full sunlight going into each as the sun would rise to that peak high noon period of the day. As my images show putting them behind a fence at the road point towards the sun on the small slope is about all that I can do.

I would need to do experiments with say a 1-meter section to test what I could expect for temperatures and volumes of the working fluid.

Today and for the next few days my location will have very poor to no solar energy available as its snowing each of the days. I got about 5 or 6 inches just today from the start of the storm last night at about 8pm.

Offline

Like button can go here

#100 2023-04-18 22:02:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,276

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

One issue for a system here in NH is the half of the year where temperatures can drop below 40'F causing a collector working fluid to freeze.

One would need to provide heat during those periods of time until the collector is collecting more than what is needed to keep it from freezing during periods of low sun or severe cold temperatures. This would make it harder to do steam power generation as the out bound exit of the turbine would tend to freeze up overnight. Might a turbine shed and a catching system to recirculate the water make sense. If the source water is also coming from an artesian well that is collocated for the source water?

Offline

Like button can go here