New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2021-11-22 18:18:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Luois, I think a target minimum day count of 365 is the worst case for showing that we can achieve the quantity by time a first crew would get there. I think this was the 30 - 40 % of fuel we would require for a fast return on a crewed mission.

Calliban, we also have electrical for assist to that initial and following needed shaft RPM under load of the compressor which we can also make use of from a Stirling generator depending on design of 10kw - 40 kw. I am think of an inline baffled expansion tank to get the water out of the super critical co2 that we are generating.

https://www.grc.nasa.gov/www/k-12/airplane/ctmatch.html

https://files.asme.org/igti/knowledge/a … /13051.pdf

Introduction to Gas Turbines for Non-Engineers

https://www.irjet.net/archives/V2/i8/IRJET-V2I8121.pdf

ANALYSIS OF INLET AIR TEMPERATURE EFFECT ON GAS TURBINE COMPRESSOR PERFORMANCE

Offline

Like button can go here

#102 2021-11-22 18:59:17

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

I accept we would have to build in a margin of error = say 10-20% outage. But I think 345 days/sols is unreasonably short.

Luois, I think a target minimum day count of 365 is the worst case for showing that we can achieve the quantity by time a first crew would get there. I think this was the 30 - 40 % of fuel we would require for a fast return on a crewed mission.

Calliban, we also have electrical for assist to that initial and following needed shaft RPM under load of the compressor which we can also make use of from a Stirling generator depending on design of 10kw - 40 kw. I am think of an inline baffled expansion tank to get the water out of the super critical co2 that we are generating.

https://www.grc.nasa.gov/www/k-12/airplane/ctmatch.html

https://files.asme.org/igti/knowledge/a … /13051.pdf

Introduction to Gas Turbines for Non-Engineershttps://www.irjet.net/archives/V2/i8/IRJET-V2I8121.pdf

ANALYSIS OF INLET AIR TEMPERATURE EFFECT ON GAS TURBINE COMPRESSOR PERFORMANCE

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#103 2021-11-22 19:05:14

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

Nope.

Fully understand the issue and parameters.

It's just I think 365 days/sols is unreasonably short. On any mission you are going to have at least 500 sols before you return. Bear in mind also, that some fuel production could take place robotically on the cargo Starships that land some two years before the main arrival. Eg you might have a water vapour extractor that splits off oxygen and hydrogen etc - that could give you a head start.

For Louis re #99

Thank you for an excellent question.

It provides an opportunity for clarification.

The fuel must be prepared and in storage ** before ** a human leaves Earth.

The scenario you are imagining is that a crew would land on Mars without having return fuel already in place.

No prudent mission planner would take such a risk.

To the best of my knowledge (admitting it is limited) NO responsible author has suggested sending a crew to Mars without already having the return fuel and oxidizer in place.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#104 2021-11-22 19:32:12

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For Louis....

The mission planner needs to be sure the tanks are full before the manned mission takes off from Earth

Assuming a two year cycle (I understand the actual interval is not exactly two years) ...

The ship to make fuel departs and takes 6 months to reach Mars.

The next launch window is two years from the launch above.

But the crew vessel needs months to prepare for launch.

If the fuel/oxidizer manufacturing process is complete after one year, then the crewed vessel has six months of worry free time to prepare.

If the fuel/oxidizer process takes the 500 days you seem to think acceptable, then the crewed mission has just 50 days to be sure the fuel is ready.

It seems to me wiser (more prudent) to plan to complete the fuel/oxidizer manufacture in less time rather than more time, in this situation.

Here are the numbers:

730 days (two year interval assumed)

180 days flight time for fuel manufacturing system to land on Mars (that is an optimistic number)

365 days for the manufacturing to complete

185 days for the crewed mission to prepare for launch

In your scenario:

730

180

500

50 days for crew to complete preparations

180-50 >> 130 days are wasted if the mission has to be terminated because the fuel is not ready.

In both cases, I'm assuming a minimum of six months are needed to prepare for a human mission.

Mission planners are likely to want the fuel/oxidizer reader sooner rather than later.

(th)

Offline

Like button can go here

#105 2021-11-22 20:09:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

The real issue for starship in order to get the payload to mars upward from the 200 mt for 2 ships which will not fit until you go a slow travel to mars of 200 to 300 days which is closer to 400 mT for the 2 ships. Which cuts into the operation time on the surface if they land successfully at all.

post 10 is the mass reference less the equipment to mine or collect co2 and it operates just 10 hours of each day

Working to get enough knowledge to give quantity proof of co2 being captured by indirect means as well as for direct via heat expressions of expansion.

https://www.carbon-dioxide-properties.c … esweb.aspx

https://www.grc.nasa.gov/www/k-12/airplane/compexp.html

https://docs.lib.purdue.edu/cgi/viewcon … text=iracc

Characteristics of CO2 Trans-critical Expansion Process

https://www.csb.gov/assets/1/6/appendix … .pdf?16444

Thermal Expansion Estimates

Natural Gas Liquids

https://www.aidic.it/cet/13/32/089.pdf

Phase Transition and Volume Expansion in CO2-Expanded Liquid Systems

https://pangea.stanford.edu/ERE/pdf/IGA … pruess.pdf

N THE FEASIBILITY OF USING SUPERCRITICAL CO2 AS HEAT TRANSMISSION FLUID

IN AN ENGINEERED HOT DRY ROCK GEOTHERMAL SYSTEM

https://www.engineeringtoolbox.com/CO2- … _2017.html

Ideal gas law: PV = nRT

P: Pressure

V: Volume

n: number of moles

R: product of Boltzmann constant and Avogadro constant (8.314)

T: Temperature

n = PV / RT

Offline

Like button can go here

#106 2021-11-25 17:56:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

The amount of wash gas after feeding the chamber is going to be greater than the volume of the chamber in size.

Chamber is currently a 5m x 2m x 20cm high with the period of time heat is 5 minutes.

Martian atmosphere has a pressure of 6.518 millibars or 0.095 psi.

Mars air temperature is quite cold during the evening and closer to zero during the day.

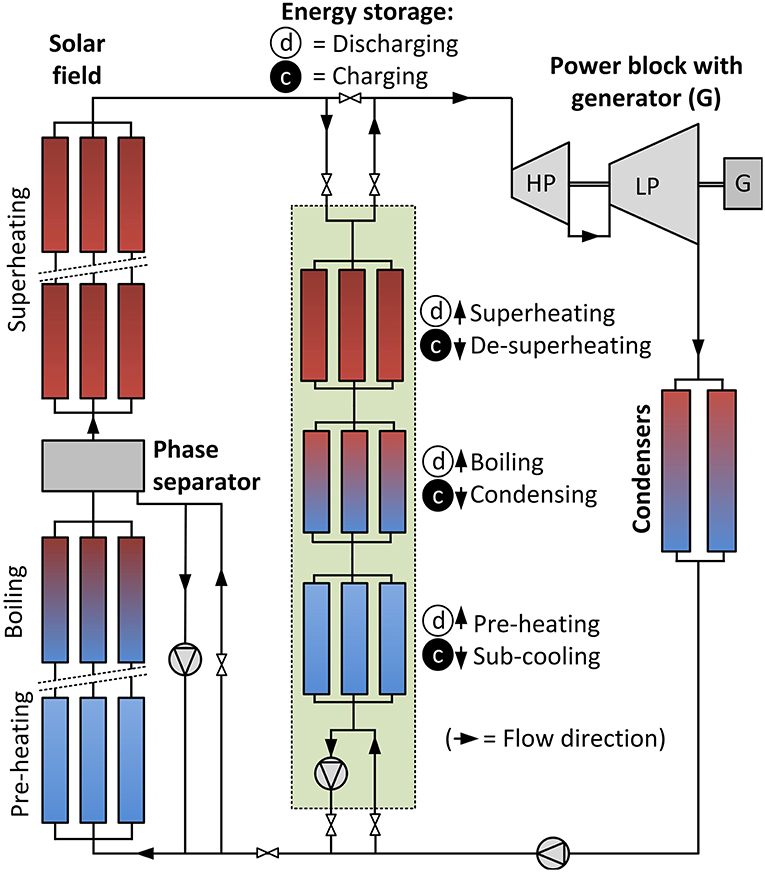

The baking oven has a fan blade system spinning to feed air into the heating chamber and as the water is liberated and the internal pressure build we are creating an inlet for a steam turbine to make use of to create a power for the next shaft to form a compressor that takes in more mars air and blends it with the exhaust from the steam turbine to be pumped into the storage tank.

The typical Steam system generation system (for example, in boilers or waste heat recovery systems), where it reaches a high temperature, around 400°C to 600°C seems ideal for the first outlet of the water from the baking chamber. Normally this has a electrical power generator connected top that shaft but for this design we will want to send that created torque and rotation to the next stage of the mars atmosphere unit.

one pound of steam at 800 degrees has a certain amount of work in it; to produce the same amount of work at 400 degrees, you need a much greater amount of water.

Liberated from the baking is 9 kg of steam along with the wash gas from mars atmosphere.

https://en.wikipedia.org/wiki/Steam_turbine

The inlet side of the turbine is the high pressure side while the exhaust is the low pressure side. That exhaust steam and wash gasses are supplied to the condenser that cools out the water to feed into a separate tank while the gas continues on to its pressure liquidation stage.

https://www.epa.gov/sites/default/files … rbines.pdf

There are many types of turbines which could end up in the final design.

https://www.sciencedirect.com/topics/en … se-turbine

There may also be gear boxes to change speed for torque in the system

Offline

Like button can go here

#107 2021-11-25 19:00:29

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

Before I accept your claim that humans will be on Mars for only 18 months I need a citation from you. This has always been closer to my understanding:

"To produce the power for one load in 26 months would require just under one megawatt of continuous electric power."

https://en.wikipedia.org/wiki/SpaceX_Mars_program

A period of something like 2 years has always been my understanding of how long humans will need to be on the surface before they return.

Maybe I've got this wrong but we need to bottom it out since there are swings and roundabouts to a shorter or longer period.

For Louis....

The mission planner needs to be sure the tanks are full before the manned mission takes off from Earth

Assuming a two year cycle (I understand the actual interval is not exactly two years) ...

The ship to make fuel departs and takes 6 months to reach Mars.

The next launch window is two years from the launch above.

But the crew vessel needs months to prepare for launch.

If the fuel/oxidizer manufacturing process is complete after one year, then the crewed vessel has six months of worry free time to prepare.

If the fuel/oxidizer process takes the 500 days you seem to think acceptable, then the crewed mission has just 50 days to be sure the fuel is ready.

It seems to me wiser (more prudent) to plan to complete the fuel/oxidizer manufacture in less time rather than more time, in this situation.

Here are the numbers:

730 days (two year interval assumed)

180 days flight time for fuel manufacturing system to land on Mars (that is an optimistic number)

365 days for the manufacturing to complete

185 days for the crewed mission to prepare for launchIn your scenario:

730

180

500

50 days for crew to complete preparations180-50 >> 130 days are wasted if the mission has to be terminated because the fuel is not ready.

In both cases, I'm assuming a minimum of six months are needed to prepare for a human mission.

Mission planners are likely to want the fuel/oxidizer reader sooner rather than later.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#108 2021-11-25 20:18:37

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

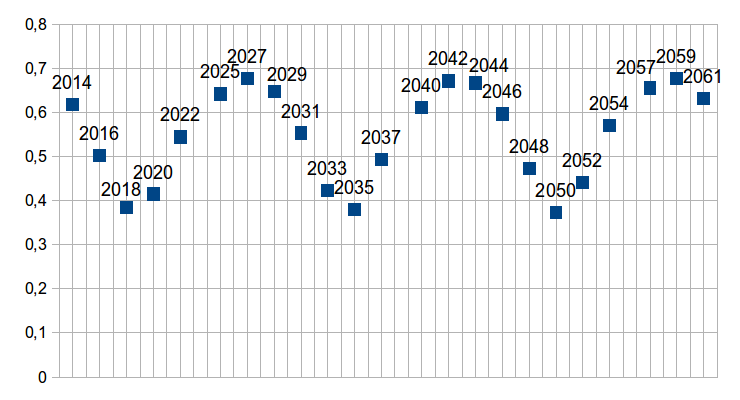

Part of the issues is the mission times change with payload mass going to Mars and back. Some of the choices come back to human stay time and cargo delivery expectations in between what we want for cycles.

https://marspedia.org/Mars_mission_duration

How Long Does It Take To Get To Mars?

Notice the duration spent getting there can vary.

Part of the issues is a bulked up cargo ship taking the maximum time to land means the next ship going fast transit gets less time to setup and show progress for making the fuel before we launch the crew.

The minimum-energy launch windows for a Martian expedition occur at intervals of approximately two years and two months (specifically 780 days, the planet's synodic period with respect to Earth) and sending an extra heavy starship cargo is not minimum energy so the time to mars will be longer.

Offline

Like button can go here

#109 2021-11-25 20:43:58

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

OK but this is about the minimum period for a stay on Mars by humans on a return mission that allows for Starship refuelling.

Your links don't address that. I have always understood it to be something like 18 months to 2.5 years.

Part of the issues is the mission times change with payload mass going to Mars and back. Some of the choices come back to human stay time and cargo delivery expectations in between what we want for cycles.

https://marspedia.org/Mars_mission_durationHow Long Does It Take To Get To Mars?https://miro.medium.com/max/700/0*9RC7GkSPljVlZuQI

Notice the duration spent getting there can vary.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#110 2021-11-25 21:27:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Just talking about the Launch windows to Mars opened approximately every 2.14 years (26 months) is only part of the answer.

That same day is also the return home with the same time in both directions but since mass coming home is less the window for duration will shift.

Here is the next launch windows

As the distance increase so does the fuel need for the set mass which means if we load up a mission heavier the time to mars gets longer.

http://clowder.net/hop/railroad/EMa.htm

Offline

Like button can go here

#111 2021-11-27 18:47:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Shifting time for surface to Orbital mechanics topic.

So back to a question on how fast can we heat water to 500 c to make use of it as steam power rotation to turn a compressor for mars air collection.

https://en.wikipedia.org/wiki/Superheated_water

How to Calculate Time to Heat Water

Using the formula Pt = (4.2 × L × T ) ÷ 3600 you can calculate the time it takes to heat a specific quantity of water from one temperature to another temperature. Once you have calculated the thermal power used to heat the water, as represented by Pt in the above equation, divide this number by the heater element rating to find out how long it would take to heat your water.

Calculate Kilowatt-HoursCalculate the kilowatt-hours (kWh) required to heat the water using the following formula: Pt = (4.2 × L × T ) ÷ 3600. Pt is the power used to heat the water, in kWh. L is the number of liters of water that is being heated and T is the difference in temperature from what you started with, listed in degrees Celsius.

Solve for Thermal PowerSubstitute in the appropriate numbers into the equation. So imagine you are heating 20 liters of water from 20 degrees to 100 degrees. Your formula would then look like this: Pt = (4.2 × 20 × (100-20)) ÷ 3600, or Pt = 1.86

Offline

Like button can go here

#112 2021-11-27 20:24:28

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

This article dealing with radiation risks makes the following reference to:

"an ~3-year Mars mission (transit and surface stay)"

https://www.nature.com/articles/s41526-020-00124-6

This has always been my understanding.

If we take an average transit time of 14 months (2 x 7 months each way) that would equate to a surface stay duration of 22 months - and that has always been my understanding of what is a pretty standard surface stay duration time.

22 months is about 670 days. I always remember the duration being in that range.

So 365 days is an absurdly low figure and can be put to one side.

I think in the past, on the principle of margins of safety, I have thought you should plan for maybe a period of 500 sols to produce your required rocket fuel. This allows for an unexpected malfunction of 100 sols or more. Of course a solar powered facility would have to factor in dust storm risk as part of its overall architecture. Malfunction refers more to an unexpected breakdown in the facility operation.

Anyway I think we can junk the 365 days nonsense.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#113 2021-11-27 21:38:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Shifting time for surface to Orbital mechanics topic.

Offline

Like button can go here

#114 2021-11-28 09:56:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut .... what is the status of this topic?

You have some readers who appear not to understand this topic is (or at least I ** think ** it is) dedicated to designing an automated system to prepare fuel and oxidizer for a manned expedition. All talk of making fuel ** after ** a landing is just hot air.

The fuel and oxidizer for a return ** must ** be in place before the expedition leaves Earth

That is why the 365 Day/Sol timeline is needed ... I have explained the timeline in previous posts, and hope that it stands up to review by knowledgeable members. what might be done ** after ** a landing to make fuel and oxidizer is independent of what SpaceNut has undertaken.

For SpaceNut ... are you ready to create a single, concise post that provides the detailed equipment specifications a funder would need to buy from Earth based suppliers? If you have, I must have missed it.

My understanding of your venture here is to harvest water that is physically (and not chemically) embedded in the regolith, and to do so with sufficient vigor to deliver a ship's worth of fuel and oxidizer in one Earth year.

Your concise summary would (I presume) include:

1) power supply

2) regolith gathering equipment

3) regolith baking equipment (and associated volatiles collection equipment)

4) water electrolysis equipment and associated gas collection equipment

5) CO2 harvesting (compression) equipment and related storage equipment

6) methane manufacture using Carbon and Hydrogen collected above

7) oxygen collection from step 4 and related cooling and storage equipment

9) manifest of all of the above for delivery in a small fleet of vessels able to land on unimproved surfaces

10) anything I've missed that is needed to insure success

After all the research you've done in posts to this point, I'm hoping a concise summary/shopping list will just flow smoothly from your keyboard.

It is time to name names: We need to provide names of vendors who can provide the equipment needed. We don't need to invent anything, or hire a consulting firm to create a white paper. This ** should ** be work that has been done on Earth already.

(th)

Offline

Like button can go here

#115 2021-11-28 10:25:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Yes you have given me an outline or wish list and until I know enough about what we do not have in the equipment design its still a thought process.

I also have the previous list in post 88 as well to add to the content of any paper as well.

post # 52 shows scalability of thermal generation plus electrical unit with example of baking chamber just thermal not electrical to keep heat levels high enough to drive cold Regolith to temperature quickly

"Power" is not just electrical but in this case use of the thermal to do needed work by the equipment.

post # 50 give ex. what I think can be modified to scale for the base design for prototyping of course extend it to dump as it rotates for return on the down ward slope so that it enters the hopper.

"Regolith gathering" needs a robust prototype to test in a mars analog situation

Post # 81 shows the wait state hopper that controls the filling of pan description for baking with sensors to control processing

ex image of the hopper image needs to be part of the prototype for integration to complete unit

post # 52 shows scalability of thermal generation plus electrical unit with example of baking chamber just thermal not electrical to keep heat levels high enough to drive cold Regolith to temperature quickly

"Regolith baking" needs a prototype to test in a mars analog situation

post #10 second image shows the wash gas and water to be pressure to gathering pump for flow to main storage tank via cooling

"Water and co2 collection harvesting" still in process of a combined section of design on a single machine

Designing co2 compressor post # 1 caliban notes to make use of thermal steam to drive turbine that shaft connects to the compressor that adds co air to the collected cooled wash gas from the baking cooling section.

post # 92 shows a typical total unit less currier transport such that we do not introduce time delay correction to keep unit gather and processing regolith

designed transport system post #67 introduced for the "Water and co2 collection harvesting" unit to the base processing inistu processing plant

Processing plant of collected and harvested go to the base line to affirm remaining shipped system to mars must meet the power requirements of mars made in post #10

Offline

Like button can go here

#116 2021-11-28 10:45:59

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut .... hopefully all your hard work will lead to a finished product, which (in this case) is a precise shopping list for a funder.

It seems to me unhelpful to worry about expense, mass or anything else that might occur to someone working on a project like this.

By worrying about extraneous concerns, such a person might self-edit to the point of never accomplishing anything.

** After ** the precise equipment list is published, ** then ** all the critics will show up to second-guess individual equipment choices.

It is completely within the realm of possibility that a well researched shopping list could be published in a major pubic journal, and certainly in a limited distribution special interest publication.

Please consider making a first draft and posting it here so it can receive the close attention that members can provide when they are inspired.

Time is flying .... please consider having a draft posted this (Earth) year.

Edit: While preparing for this post, I ran across a report of a study done at JPL under ? Murray ? to determine how to make fuel if you bring Hydrogen along. That is very similar to the method of Zubrin in his published work.

Your plan (as I understand it) is to pull water from the regolith, CO2 from the air, and to make all needed fuel and oxidizer without bringing anything except equipment from Earth. That plan ** might ** have unique qualities that would (or at least ** could **) be of interest to actual mission planners around the world.

(th)

Offline

Like button can go here

#117 2021-11-28 11:00:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

The big thing is to stay with in the mass limits of 300 mT on each starship which brakes up the mass to duplicate deliveries to make throughput possible.

Post 10 first image give everything else that is not part of the processing plan for mass and power systems required to make it happen.

these are 80 mT each which makes 300 mT of fuel for the mars year so a minimum of 2 on each ship gives margin of production.

The reason is the hydrogen processing unit operates only 10 hours a day since that design was solar powered. That is where I depart and use nuclear to make it possible to do more with the full clock of a mars sol.

So a starships mass payload so far is 160 mT of mathane plant plus the mass for the gathering processing plant equipment unit that is not on that slide. That is the items I am working to bring about for use on the surface.

I believe I gave a value of the gathering processing plant equipment unit as being 3 for each starship to be built to stay under the 140 mT limit. So total unit mass is 140 mT / 3 = for the maximum value to stay under for the total gathering units delivery which includes the surface transport product mover.

That places 6 units going after 1200 sq meters of regolith to get the needed water from that is delivered back to the starship to make into methane.

Key aspects are to integrate the parts needed for the nuclear thermal as parts to be used in the structural processing gathering units pieces.

At this time we are ignoring the taking of seed hydrogen to mars as that is another trade off study to do since boil off is such an issue to get to mars.

Equation for water if we are depending on seed Hydrogen CO2 + H2 → CO + H2O (The Reverse Water-Gas Shift Reaction) which means we are targeting an even greater amount of mars air to make use of.

A more stable hydrogen source would be to send Ammonia NH3 to mars as we can use the decomposed Nitrogen to aid in atmospheric building.

Offline

Like button can go here

#118 2021-11-28 14:58:32

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #117

My interest here is to (try to) see you through to a successful published plan that will stand up to NASA level scrutiny.

With that in mind, and NOT disagreeing with anything posted so far, can you point to a reference for your opening line in #117?

Is there something published by SpaceX that says they are expecting to place 300 Mt gently on Mars?

There must be or you would not have used that figure.

(th)

Offline

Like button can go here

#119 2021-11-28 17:17:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

post by [GW Johnson]Spacenut:Using the best available data off SpaceX's website (propellant mass and engine thrusts) and Wikipedia (inert mass guesses), plus my own reverse-engineering of the Raptors, I had reverse-engineered the performance estimates for Starship to Mars, and posted this stuff on my "exrocketman" site. Because the inert masses are just speculation, so is the performance. But to the extent those inert masses are realistic, so are the performance estimates. I had found max payload deliverable to Mars over 200 tons (and possibly as high as 300 tons) from a min-energy Hohmann transfer (average 8.5 months one-way). That is larger than I estimated as the max delivery to LEO for Starship/Superheavy.

Delivery to Mars is lower on a faster trajectory, of course. But it is generally still larger than what could be ferried up to LEO, even for the 4.3-month trip. It takes a LOT of tankers to fully fuel Starship in LEO to the full 1200 tons of propellant. But, if you reduce payload delivered, you can reduce the propellant load required, and thus the number of tankers. I got a reasonable number of tankers at 100 tons delivered.

Spacex has yet to think their way through this landing leg/landing pad design for rough, soft ground. Compounding that is that we must ASSUME how strong that soft rough ground is, there being no ground truth data for soil bearing strength, despite decades of landers and rovers. I have seen nothing yet on any of these prototypes to suggest they have a credible landing leg design for these purposes. Which will show up as a catastrophe the first time one of these has to make an off-site emergency landing right here on Earth.

I would hazard the guess that maybe we should send our letter proposal to Musk at Spacex, with the addition that a 5-meter drill is available from Deltion, but they are closing in 28 days. Maybe that'll prod them off dead center on this issue. Otherwise, I dunno.

GW end quote

I may be a bit over realistic in the 300 mT but I can make it with less for each ship its just going to need the entire system reviewed once we have a function item that is sell able to reduce and optimize for mars use.

We also get a bit of a methane lox kick start with the left over landing fuels as that some where in the 10% range for each ship out of the header tanks which is 100 mT for fuel.

Offline

Like button can go here

#120 2021-11-28 17:57:24

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #119

Thanks for finding the 300 Mt estimate.

Could I offer a suggestion? Please see if you can keep the chunks of your plant at 100 Mt or less.

If it turns out 300 Mt is both possible and practical, you (or rather, Mr. Musk) can combine sections of your plant.

Otherwise, the chunks can be shipped in as many vessels as are needed.

I'd like to see a shopping list, similar to what your family would put together for the weekly grocery restock.

The list might be set up with needed data, such as:

1) Item name

2) Mass of item

3) Volume of item

4) Length of item

5) Width of item

6) Depth of item

It would seem reasonable (to me at least) to use the published dimensions of the Starship freight configuration as a guide.

You may have to design (or select) machinery to fit within the published freight compartment dimensions.

(th)

Offline

Like button can go here

#121 2021-11-28 18:04:42

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Mars Water regolith soils 1 foot depth only

The heading for this topic is "Life support systems - Mars Water regolith soils 1 foot depth only"

It's not what you appear to imagine.

Mission duration is crucial to how one plans for fuel prep. You keep citing 365 days as surface duration of the Mission for some reason but it's completely false and you don't seem able to accept that. The average appears to be something like 670 days.

For SpaceNut .... what is the status of this topic?

You have some readers who appear not to understand this topic is (or at least I ** think ** it is) dedicated to designing an automated system to prepare fuel and oxidizer for a manned expedition. All talk of making fuel ** after ** a landing is just hot air.

The fuel and oxidizer for a return ** must ** be in place before the expedition leaves Earth

That is why the 365 Day/Sol timeline is needed ... I have explained the timeline in previous posts, and hope that it stands up to review by knowledgeable members. what might be done ** after ** a landing to make fuel and oxidizer is independent of what SpaceNut has undertaken.

For SpaceNut ... are you ready to create a single, concise post that provides the detailed equipment specifications a funder would need to buy from Earth based suppliers? If you have, I must have missed it.

My understanding of your venture here is to harvest water that is physically (and not chemically) embedded in the regolith, and to do so with sufficient vigor to deliver a ship's worth of fuel and oxidizer in one Earth year.

Your concise summary would (I presume) include:

1) power supply

2) regolith gathering equipment

3) regolith baking equipment (and associated volatiles collection equipment)

4) water electrolysis equipment and associated gas collection equipment

5) CO2 harvesting (compression) equipment and related storage equipment

6) methane manufacture using Carbon and Hydrogen collected above

7) oxygen collection from step 4 and related cooling and storage equipment

9) manifest of all of the above for delivery in a small fleet of vessels able to land on unimproved surfaces

10) anything I've missed that is needed to insure successAfter all the research you've done in posts to this point, I'm hoping a concise summary/shopping list will just flow smoothly from your keyboard.

It is time to name names: We need to provide names of vendors who can provide the equipment needed. We don't need to invent anything, or hire a consulting firm to create a white paper. This ** should ** be work that has been done on Earth already.

(th)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#122 2021-11-28 19:18:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

get over the value and contribute. A mars optimize time is using the same mass and same values to derive that consistent time on mars surface which meant the same delta v for leaving earth each time. Where the lower that delta v is the longer that time to mars will be.

Which implies that mass fraction thing which I am sure you have read that relates to the engines and fuels burn duration.

https://ttu-ir.tdl.org/bitstream/handle … sequence=1

https://en.wikipedia.org/wiki/Hohmann_transfer_orbit

https://www.oca.eu/images/LAGRANGE/page … rs/TTV.pdf

That first value is due to the longer time to get to mars fully loaded to the max with the first cargo mission with a follow up crew if we make the goal. Giving time to unload and set up operation tele-robotically to start grooming the Regolith for the water and co2 to star making fuel. Until you harvest the daily processing capability you got nothing to get home with.

Offline

Like button can go here

#123 2021-11-29 19:41:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

Planning is working with what you know to be true and not guessing or using a wish list of what you do not have the truth for.

An ability to venture into the unknown with a poor plan makes for a chance for failure but if that failure is with no men on board, then we can just build more as that is the musk way.

For all others that may not work for them.

If the Drill landing site mission gives the data with a small funding and the answers give truth to what we wish for, then we are able to change the plan to know that we will not fail and that we will not need to crash an burn a few to get it right.

Offline

Like button can go here

#124 2021-12-04 14:23:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Mars Water regolith soils 1 foot depth only

For SpaceNut re #123 ... That post is interesting, but I don't know what to make of it.

Are you designing a plan for harvesting water from the regolith, or doing something else?

If you ** are ** working on a plan, it needs to keep advancing at a pace that works for you.

It needs to end up with a shopping list of equipment, a set of precise procedures for the equipment to follow, and guidelines for the team that is going to launch everything.

That's more than a single person can handle, so it would make sense to enlist helpers who share an interest in this particular very specific mission.

(th)

Offline

Like button can go here

#125 2021-12-04 15:13:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Mars Water regolith soils 1 foot depth only

The drill mission would give characteristics of the site that the planned water harvesting machine. This makes for a design that is not a wish list or wishful thinking but a planned response. The bonus is in the add ins that make it gather atmosphere, and hauls it back to the insitu processing unit where the water, co2 is turned into methane and oxygen.

All the other shopping for the insitu processing unit are making methane and oxygen are well known and its just work to make it more efficiently as well as requiring less power and mass to accomplish in the time to volume requirement.

I am currently in thermal driven turbines and compressors to get the need numbers and design information required for the topic. It may be possible to use the water as a steam turbine drive since we have the heat or supply a loop for thermal energyt from the reactor core to drive a closed loop.

Offline

Like button can go here