New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#76 2021-08-04 07:31:21

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,353

Re: Fixing Americas car industry

3D Printing is potentially a way to make integrated body parts, and experiments have been attempted along those lines.

However, components like wheels, the motor, radiators and moving parts must still be sourced from the global supply chain.

A totally 3D printed car (or much of anything else) seems (to me at least) far in the future.

For SpaceNut ... your reports of discoveries to add to this topic are high on my "look" list when I open the forum each morning.

(th)

Offline

Like button can go here

#77 2021-08-04 11:48:12

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

tahanson43206,

Sourcing a small gasoline engine can be accomplished using domestic generator engine suppliers who produce engines for commercial / landscaping riding mowers. GW's 36hp VW Beetle managed to haul 7,000+ pounds of vehicle and cargo at a top speed of 42mph. For a much lighter vehicle, say 2,000 pounds, it should easily be capable of 75mph with the correct gearing, which is as fast as you can legally drive almost anywhere in the country. The batteries and electric motors available from either primary suppliers or as second-hand parts are all far more expensive, to the point that I don't think they're practical for the immediate future. If the end goal is to provide transportation to low-income people for reasonable cost, then fabrication using community resources and small gasoline generator / mower type engines is probably how it will be done. If the end goal is about ideology over practicality, then low-income people probably can't afford "the solution".

Offline

Like button can go here

#78 2021-08-04 12:45:36

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,353

Re: Fixing Americas car industry

For kbd512 re #77

Taking your post as a starting point, and continuing the theme of 3D printing, I've reconsidered about at least some of the parts ... Wheel rims are just one example of a part that can be 3D printed from/using Iconel, which (I understand) is being used to make rocket engine parts and even major components (ie, tanks).

While I am (reasonably well) acquainted with various kinds of 3D plastic printing, I have not been exposed at all to metal printing, except 5th hand from news reports.

Windows can be made of clear plastic instead of glass, and they don't need to be rolled up with complicated cranks. They can simply be held in sockets by simple screw clamps, and stored on hangers outside the vehicle when conditions are favorable.

There are grades of plastic that seem (to my eye anyway) to be suitable for cushions inside the vehicle.

Gears can be 3D printed, where they are needed, but mass produced gears might turn out to be cost competitive.

I doubt that $1000 for a four person vehicle brand new out the factory door is possible , but that is a target worth considering.

How much is the motor you're thinking about, and can it run on fuels that can be made from non-fossil sources?

That last question is fresh in my mind because of the arrival of a book on manufacture of Methanol, recommended by Calliban for Nuclear is Safe topic.

(th)

Last edited by tahanson43206 (2021-08-04 12:47:13)

Offline

Like button can go here

#79 2021-08-04 18:38:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

Part cost control is only a bit of equation for what it can cost in the end as the assembly by humans is the expensive part.

Four seat anything is 3 seats more than I need in a commuting vehicle of low cost and if you count a place to put things then its a seat for one more.

Aerodynamics is a function of face wind resistance so the second seat needs to be behind the driver so as to keep the wind cutting resistance or drag as low as it can be. Seat needs to incline to lower overall height of the vehicle and high above the ground so that its got clearance.

Offline

Like button can go here

#80 2021-08-04 23:01:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

tahanson43206,

If you want to control cost, then you're going to use existing engines, existing wheel designs, and existing manufacturing methods. A 3D printer to create a small part is nothing like a 3D printer that can create a car chassis or body. The desktop models can be had for a few thousand dollars, whereas the overhead gantry styles range into the millions of dollars. A community center might be able to purchase one, but again, we keep trying to gold-plate what is supposed to be a simple solution to a profound problem. Rich or poor, people need affordable personal transportation so that they can work and live independently. Think about how you can take lemons and make lemonade. That's what we're doing here. We're not going to "reinvent the wheel", because wheels don't need reinvention.

Remanufactured Chrysler 2.4L Tigershark and SRT-4 185hp to 280hp Inline-4s can be had for the same price as a Kohler 36hp lawn mower engine ($3,300). Alternatively, you can purchase a re-manufactured Inline-4 from a plethora of other manufacturers. Honda K-24s, Ford or GM Ecotec, Mazda Skyactiv, and a very long list of others are available for $2K to $4K. All are rock-solid engines, all weigh less than 300 pounds, all produce 150hp to 300hp. Those are all real automotive engines with real automotive durability, for the same price as a lawn mower engine that might never pass automotive emissions standards. I expect the drive train to be $6K to $7K for any practical vehicle. I define practical as a real 4-seat car capable of 75mph that can pass both emissions and crash testing, built to a level of quality that permits many years of faithful service to its owner.

If the 4-bangers don't strike your fancy, there are millions of AMC / Jeep Inline-6 engines that we can convert to EFI and use a modern head design, combined with proven / reliable / inexpensive push-rod driven valve trains. The all cast iron straight 6 of AMC / Jeep fame is around 500 pounds, but it produces lots of torque at low-RPM, which is important for engine longevity. Any engine that revs to the moon will not last very long, because that's how physics works, and high-RPM also leads to increasing friction losses, wear, and decreasing fuel economy.

From looking around online, 4 brand new stamped steel wheels can be had for $100 for my new (to me) 2007 Dodge Charger.

However, for mass-manufacture, check out these steel wheels from China:

Zhejiang Hangtong Machinery Manufacturing Co., Ltd. - 16" Steel Wheels

Only $13.28 per copy and if they all look like that, then they're as good as anything made anywhere else. There are also Silver painted models for $20 to $25 per copy. I prefer black because they're much cheaper and brake dust does nothing to spoil their good looks. The sky's the limit on wheel prices, but a good 16" to 18" steel wheel is good enough for 2,500 to 4,500 pound passenger cars. We're shooting for the lower end of that weight spectrum using all-steel construction.

We need to put together a parts list that includes wiring harness / engine / trans combo, suspension / tires / wheels / brakes combo, and then we need to determine what the cheapest sources are for sheet metal, so that the chassis / body can be fabricated in a community center with welding equipment provided by the center.

I spent tonight looking for air cooled gas and diesel engines for mowers and generators, of the kind used in ersatz cars / trucks in Asia, but they're just expensive crap compared to a real re-manufactured automotive engine that doesn't cost anymore and provides a lot more performance per dollar spent. The shipping from China could be up to 5 times more than the engine itself cost to purchase.

Offline

Like button can go here

#81 2021-08-05 07:55:17

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,353

Re: Fixing Americas car industry

For kbd512 re #80

The community where I live has several maker spaces. One of them is huge. It was funded by a very large grant a couple of years ago. A retired factory was refurbished to hold machines of all kinds, class rooms, and many (ie, lots and lots) of rental offices and work spaces for projects.

Your "build your own car" concept would work in a setup like that. I'm told (by a member who can afford the $50 monthly fee) that the organization survived the Covid crisis thanks to the steady support of people like him, who paid the utility bills. The facility has modern air conditioning, lots of power for every possible need, and the highest Internet available in the region.

One member builds custom motorcycles there, in a space just outside the welding shop.

There are maker spaces like that in major cities around the country (I'm told) ...

There will be meeting of the 3D Printer group next week, and I can present a list you might have ready by then. This is a super practical group (unlike the NewMars forum taken as a culture) so I don't expect much response, but at least I can make the opening pitch.

Regarding 3D Printer capability ... I agree about the cost of equipment capable of creating metal (or even plastic) parts for an automobile.

Shifting gears a bit (pun intended) .... The vast array of mass production facilities on Earth in 2021 are NOT going to be present on Mars.

A manufacturing facility on Mars would necessarily be built upon a framework of metal printing 3D equipment, so designs that ** can ** be made using such printers on Earth are a good idea . I hope they come to pass, and expect they well, because (as Dr. Dartnell reminds us) this advanced civilization is extremely vulnerable. Your concept of how to take advantage of the specializations and economies of scale we have on Earth is sensible and worth supporting, but it is ** only ** available on Earth and during the current epoch.

Follow up at 12:29 local time ....

In thinking about your idea further .... It seems to me quite plausible that there would be citizens in the area who would be interested in building a kit car for a small profit. That profit would be a fraction of what they could earn if they had a job, but it would be ** far ** more interesting because it would follow the model of a few highly regarded manufacturers who used to assemble automobiles with a small team and without automation of any kind.

The challenge I see for someone planning a situation like this is to insure that the parts bolted (or perhaps welded together under supervision) ie, components like the welded frame, arrive crash ready, free of manufacturing defects.

In the Maker Space scenario it is possible to imagine a group purchase, to help to reduce costs, but also to insure a group that is going to tackle assembly is able to secure reinforcement from associates when they hit a snag, whether physically or mentally.

(th)

Last edited by tahanson43206 (2021-08-05 10:38:31)

Offline

Like button can go here

#82 2021-08-05 14:39:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

tahanson43206,

While I agree with the general sentiment that having 3D printing technology is highly desirable and useful, certain products such as sheet steel and steel tubing are pretty foundational to modern society, whereas 3D printing is not. If there is no production of concrete, glass, iron, and steel on Mars, then there will be no human civilization on Mars. It'll be an inordinately expensive science experiment until sufficient energy production / concrete / glass / steel / food production is achieved, and likely to suffer from the effects of basic economics back on Earth. The maintenance of Starship virtually requires a fledgling steel industry on Mars.

There's clearly no shortage of Iron ore and Carbon on Mars, nor any of the alloying metals, so given sufficient energy input, we will have Iron-based metal alloy products beyond Iron powder, which is a good thing. 3D printing will enable maintaining of high pressure / high heat engine components such as Raptor engines or SCO2 gas turbines, combined with radiators and electric generators / motors to produce motive power.

3D printing of nano-particle Iron Oxide infused into pure Iron powder should allow us to make alloys that are both very tough and very hard, without resorting to additional heat treatment processes (what Gamma Alloys has achieved with their Alumina nano-particle infused Aluminum alloys), but getting the grain structure of the metal correct for the intended use case may dictate that subsequent hardening and annealing processes are still required. For example, if we wanted a surface finish even harder than what the nano-particles provide, then a case hardening process may be used to create a component with a very hard surface finish and softer, more ductile core.

Offline

Like button can go here

#83 2021-08-05 15:34:05

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,261

Re: Fixing Americas car industry

Interesting. From Kbd512's post we can identify cornerstone industries for Mars colonisation. If we can develop viable plans for these, colonisation will be achievable.

1. Energy production. Heat (various grades), electricity, synthetic fuels. In previous posts, discussions have revealed the importance of high EROI on Mars, because even the basics of life there are energy expensive. If high growth rates are needed, high EROI is especially important.

2. Steel production. This is important for any structure or component subject to tensile loads. It is especially important for structures and components subject to variable loads, because ductile steels are highly creep resistant. As all structures built on Mars will be pressure vessels, steel will be needed in greater quantities than on Earth. The cold will necessitate greater use of manganese to maintain ductile properties at temperatures far beneath freezing. Ultimately, we need to be able to produce alloy steels with a range of qualities. But good quality (low sulphur, phosphorus, copper, nitrogen, hydrogen), plain low carbon steel is a good place to start and will dominate the total production volumes. To support steel production we need iron ore, heat (1600°C), reducing gas (hydrogen, carbon monoxide, methane, ammonia), alloying elements, ceramics.

3. Concrete. Cement is the single most ubiquitous manufactured material on Earth and the same will be true on Mars. We will need it in compressive structures and buildings. Martian soil is highly basic, suggesting that in some applications, it may form a natural cement when hydrated and compressed. To make cement we would need lime (calcium hydroxide), which is produced on Earth by heating calcium carbonate to 1600°C. The CO2 is driven off. Sand is also a necessary component for concrete. This might be a problem on Mars. On Earth, the sand most useful for concrete is dredged, as it requires uniform shape grains that don't induce point stresses (which can propagate crack growth) in cement films. I am not sure what the solution to this problem will be on Mars.

4. Glass production. Glass may be energetically cheaper than plastics on Mars and is transparent. Transparent, pressurised structures can be formed by inserting glass panes into a steel frame and filling the edges with a sealant. Soda lime glass (90% of manufactured glass) requires 75% high purity silica, 15% sodium oxide, 10% calcium oxide.

5. Food is obvious. Water and nutrients are precursors. We have discussed food production on this board on many occasions. Algae is energetically cheap and could be a nutrient rich additive to processed foods. Vegetable crops require greenhouses or artificial lighting in underground food factories. Grain crops may be difficult to grow without supplementary light. Greenhouses would be pressure shells requiring transparency and tensile strength.

I would add a couple more.

6. Basalt fibre and cast basalt. This will provide more tensile strength per MJ of energy, than steel. It can be used as fibres to add tension strength to pressure shells, thus reducing steel use per cubic metre. Large areas of surface could be made habitable using ETFE sheets, with basalt fibre nets transferring pressure loads to basalt fibre cables, which are then tied to steel piles sunk deep into the ground. Cast basalt can be used to produce hard and strong ceramic components. Basalt bars can reinforce concrete. Fibres may reinforce low melting point metals. Could we produce basalt fibre reinforced concrete? Could basalt fibre ropes replace steel tendons in pre-stressed concrete? Basalt is acid corrosion resistant and highly wear resistant. With basalt lined carbon steel vessels, with external compression stresses to limit crack growth, we could probably build aqueous homogenous nuclear reactors.

7. Polymers. Although energetically expensive on Mars, the durability and properties of polymers make them indispensable to Martian industry. Cable insulation, pressure canopies, domestic appliances, etc. We will need a plastics industry, even if polymers are used more sparingly. I suspect there will be strong drivers to identify fossil methane deposits on Mars if they exist. This will reduce enormously the energy costs of making plastics.

Last edited by Calliban (2021-08-05 16:20:58)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#84 2021-08-05 17:28:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,353

Re: Fixing Americas car industry

For Calliban re #83

SearchTerm:Industry list of key industries for Mars

SearchTerm:Industries

(th)

Offline

Like button can go here

#85 2021-08-07 16:22:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

What I can see is the development of an inline seating arrangement from 1 to 4 seats in length with list of options from economy to luxury with the second option being the side by side seating from 2 to 6 in length with a varying option list as indicated before.

option lists for electric motors size from 350 w to 5,000w or sub 1 liter to 1.5 liter fuel engines, transmission/ gear ratios, air conditioning, sun roof, tire size and width.....and a varying number of drive wheels from 1 to 4 most likely hub motors

Of course other options are for making them hybrid with gas or desiel engines, pedal generators, solar panel pull outs or portable generator along with charging station options.

With the pricing of course dependent on the seat count and options for each design configuration.

Pricing should be from the low single seat near 1500 up to the 6 seat under 10,000

Offline

Like button can go here

#87 2021-08-18 20:23:57

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

SpaceNut,

There are no roads on Mars, which is why the vehicles really need to be tracked, so that within reason, they can simply roll over anything that gets in their way, in much the same way that a tank does.

I don't see an in-line seating arrangement as being practical for American roads, which are too narrow for anything but a pair of motorcycles traveling in tandem and too wide for a much longer in-line seating vehicle to do much more than occupy even more road real estate, increasing traffic congestion. Maybe that could work on Mars, but it would be a very rough ride due to the length of the vehicle. Tight turns on city streets and parking would be the most intractable problems back here on Earth. Some kind of electronic gadget could assure that two longer vehicles can travel in tandem, but the turning / parking / ride quality issues won't have any quick-fixes. Striking something with one front wheel would all but assure a rollover accident as well, and those typically don't end well. The basic steel car chassis design is pretty well optimized for what it does, and all attempts to reduce weight only increase costs.

My own vehicle situation is that my Charger is still down hard. New tires, new brakes, mostly new electronics, but the engine is still not running properly. My fuel injectors are due to arrive at the end of the week. I received 1 new Bosch injector today, illustrating my point about the unsustainable packaging mania that I tried to make to Edward Heisler. Why couldn't they simply ship all 6 at the same time, since they were clearly purchased for a V6 engine? Your guess is as good as mine. To my great surprise, Bosch fuel injectors are "Made in USA". All the plastic on my engine seems to come from Canada. I thought for sure it would come from Mexico, or perhaps China, but I guess not. I think the rubber seals and MLS gaskets were made in Mexico.

Offline

Like button can go here

#88 2021-08-20 19:58:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

A cross between a car and a 3 wheel motorcycle

This would be a summer like use

Offline

Like button can go here

#89 2021-08-21 21:26:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

Ford launching DIY electric car kit for customs

It looks like Ford has a solution for Mustang fans who want an electric car, but aren't into the Mach-E.

The Ford Performance division has announced that it will introduce an electric crate motor for custom car applications at this November's SEMA show in Las Vegas.

The Eluminator borrows its name from Ford's line of Aluminator crate V8s and looks like it was designed to easily swap in for one of them and possibly connect to a standard transmission.

https://www.foxnews.com/auto/ford-musta … ce-edition

The one trade-off for the speed is a reduction in the Mach-E GT's range from 250 miles to 235 miles per charge. Other, less-powerful versions of the Mach-E that will be on sale in the coming weeks have ranges up to 300 miles. The Model Y Performance has been rated by the EPA at 303 miles per charge.

Pricing for the Mach-E GT Performance Edition has not been announced, but the GT starts at $60,500, not including the available $7,500 federal tax credit. The Model Y Performance starts at $59,990, but does not qualify for the incentive.

Offline

Like button can go here

#90 2021-08-25 17:21:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

SpaceNut,

These three-wheel vehicles and electric mopeds are toys for rich people. Those battery powered mopeds might be useful for college kids living on campus who only require "around campus" / "around town" type mobility, but that's about it. They're not a practical form of utility transport for a family. That's why nobody else uses them. Cars and trucks are useful because they're cars and trucks. These vehicles are not stable enough for your average soccer mom to drive like a crash derby car and too heavy to be powered by a prototypical motorcycle engine. Any motor vehicle, irrespective of what powers it, that can't go 75mph and seat 4 adults or 2 adults and 3 kids, with some cargo space, is primarily a toy for rich people. I don't begrudge anyone their toys, but when it comes right down to it, most of us need a practical vehicle for everyday driving.

The one thing I don't quite understand is why so many vehicles are so ridiculously over-powered these days. If you remove the governor off the M1 tank, it will move down a highway at 65mph, even the newest / heaviest versions, which come in around 20hp per ton. They're uncontrollable off-road at speeds greater than 45mph and will easily throw tracks in turns, hence the presence of the governor to control speed. Even that Charger I purchased provides 100hp per ton of total weight with the smallest engine offered, but all the reviewers bashed that engine as being "under-powered". Under-powered for what, exactly? That's 1hp, or 550 pound-feet of torque, to motivate every 20 pounds of weight to start moving. How much more power do you need before it becomes wildly excessive for a street car that's supposed to be a good street car? 0-60 in 2 seconds so you can slam on your brakes the next second after that, by dint of fact that the traffic is not moving that fast and never will? It's an absurd proposition for anything but racing, which is expressly illegal to do on any public road or highway, in all 50 states and nearly any country you care to name off.

Offline

Like button can go here

#91 2021-08-27 10:04:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

Its that price tag that makes it feel like its for the rich as a toy...

I am looking at the cost versus expense for a vehicle use.

It is sad that your yearly earnings can support a 35% purchase in cash or financed whether its used or new for a purchase.

That financed as well as the ownership costs must be less than the 10% of the monthly moneys to pay for having it not to exceed 15% with you needing to replace or repair yearly depending on its aging.

This has nothing to do with being rich or how many you need to transport with one.

Persons in family/household Poverty guideline

For families/households with more than 8 persons, add $4,540 for each additional person.

1 $12,880

2 $17,420

3 $21,960

4 $26,500

5 $31,040

6 $35,580

7 $40,120

8 $44,660

of course state numbers for the table are weighted for cost of living.

ignoring the per person you can buy for $12,880 yearly earnings of just $4,508 with the monthly pay out being for use of $1,288 to $1,932...

Sure the more you earn the more you can afford but there are still lending limits and income stability to consider.

Offline

Like button can go here

#92 2021-09-06 04:26:26

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

I took my Charger to a local repair shop a week ago. It's still not running well. It was a wiring problem as I suspected, but their electronics diagnostics tool did not have the capacity to pinpoint the exact location of the wiring short because it required a software update from Snap-On, so even the computer-controlled diagnostics gadget produced results that are not definitive. Their electronics specialist thinks it's the wiring in the O2 sensor circuit, some of which looks like it's seen better days. I've also been told that this could be a rare case of a Charger with the dreaded TIPM issues. TIPM is an acronym for "Totally Idiotic Power Management", or "Totally Integrated Power Module", as Chrysler calls it. I blame Canada, since that's where all the plastic and electronic crap that failed came from.

Here's what we know now:

1. The fuel pressure regulation system is good.

2. The new fuel injectors I installed are good.

3. The intake manifold vacuum leak is gone.

4. The catalytic converters are good.

5. The EGR valve is good.

6. The PCM appears to be good.

7. The coolant temperature sensor is good.

8. The engine is not mis-firing, which is what the PCM thinks is happening. All coil-overs are firing when they should, the crank position sensor correlates with where the pistons should be in their firing order, and the engine's timing is not off.

9. The mechanical parts of the engine itself appear to be in very good condition.

10. The downstream O2 sensors that I thought were faulty were actually providing correct readings, but they only make it back to the computer intermittently, such as when I step on the gas.

11. Either the electrical wiring or TIPM or PCM is defective in some way, but they can't pin down where it's defective, only that the voltage signals from the O2 sensors are not making it back to the PCM at all times.

12. They hadn't even considered the possibility that exhaust gasket leaks could cause this issue until I pointed it out to them, but that's probably not the issue here.

Almost every electronic gadget on the engine has been replaced, including the PCM. I'm rapidly closing in on $4,000 worth of electronics diagnostics and repairs, around $7,000 in total repair costs, which is more than the vehicle is intrinsically worth according to Blue Book values, but it can't pass inspection until this problem is resolved. No fuses or relays are blown, either, so far as we can tell. Everything electronic, apart from wiring or TIPMs (the car has two of them), is either brand new or operating normally, except the thing won't idle properly because the PCM is freaking out over the O2 sensor readings. The electronics are worth more than the stupid car is. It may as well be a brand new car by the time I'm done with it. This is why I don't think much of modern cars or electronics. Every mechanical part can function nearly as well as the day it came off the assembly line, but you still can't drive the stupid car without functional electronics, which are either difficult to come by or nonexistent, such as the engine wiring harnesses, which I can't obtain a replacement for. For some reason that 15 year old car has more wiring in it than any brand new Cessna 172 on the planet. Little wonder that not even their electronics can figure out what's wrong with it.

Offline

Like button can go here

#93 2021-09-06 13:20:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

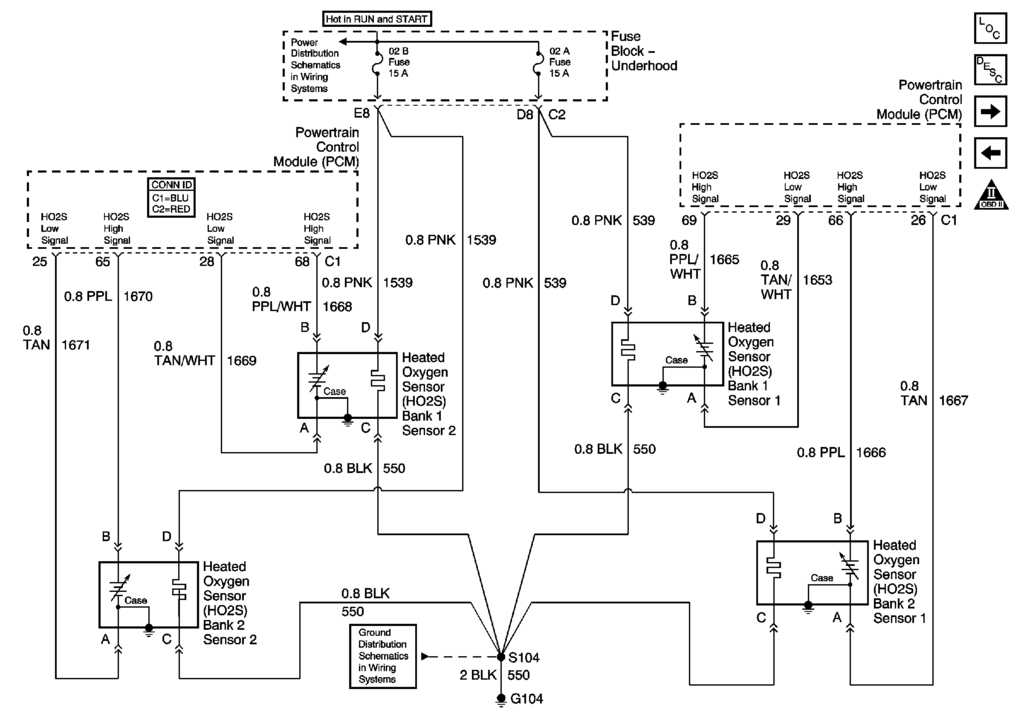

The o2 sensor is a 2 wire most of the time that requires to be above operating temperature to product an analog voltage with regards to it sensing the exhaust being rich or lean. so a zero is really a voltage that is about .8 volts. caution do not measure with a typical meter as you will load the sensors voltage as it require a high impedance input.

The up stream and down o2 units, is used to show that the catalytic convertor is working as the input will be higher than the output side for the sensor values. The computer is looking for a specific difference value to show that its doing the job.

Its also where the EGR valves must return unspent fuel to the intake for reburn conditions if exhaust is rich.

Quite often you are missing grounds when the circuits are not working.

The 4 wire sensors use a preheater element inside to control operations and are less reliant on the engine running temperature of fuel burning correctly.

Some cars also have a manifold air temperature sensor that comes into play for setting the check engine as well.

The computerized gadgets can also send signals to the car commuter so as to test these conditions and you can watch the values change when the engine is running as it will give the car false timing information so as to produce the engine coding for the o2 being faulty.

In NH you can get a waiver if you have put in such funds for inspection so long as all other items will pass.

.

Offline

Like button can go here

#94 2021-09-06 14:52:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

SpaceNut,

Both sets of my O2 sensors are the 4-wire variety on a Chrysler 2.7L DOHC V6. The two white wires are for the heater circuit to heat them to operating temperature faster, the black wire is the signal wire back to the PCM, and I forget at the moment what that black striped gray wire does, but I'm pretty sure that that's the ground wire.

O2 sensors produce their own voltage from the heat generated by the engine exhaust stream (they're miniature thermoelectric generators) so they are not powered by the PCM, but will only provide correct voltage at or above their operating temperature (thus the heater circuit, which is power-side driven by the PCM and used to heat the sensors up faster so the engine can enter closed-loop mode faster), when the reference ceramic O2 sample capsule is not damaged, and the wiring back to the PCM is not damaged.

The O2 sensors only read O2 content in the exhaust, but the assumption is that lower O2 downstream of the catalytic converter(s) means that un-combusted fuel from the engine's exhaust was burned off. The computer constantly trims fuel to the injectors to try to maintain a perfect 14.7:1 AFR.

Yes, the engine computer / PCM allows for monitoring of its output using an OBD II diagnostics port and scanner tool. That's what I was graphing on my scanner, whereupon I saw strange behavior from both downstream O2 sensors (going down to 0.29V when I rev the engine up to 1,500rpm to 2,000rpm, then all the way up to 1.27V (completely out-of-range, indicating faulty sensors, faulty wiring, or faulty PCM interpretation of the data) when the engine idles at 600rpm. The garage I took the car to has a much fancier tool that costs a lot more money than the one I have, along with much more expensive digital volt meters that I don't have access to, plus that all-important lift to get to the wiring beneath the catalytic converters.

Edit:

I don't want to get an emissions waiver, I want my car to run all factory-installed electronic equipment properly. Apart from the money spent, there's no other benefit to having a less-than-well-tuned engine. I want the engine control electronics to function as they should, but I don't have the fancy diagnostics tools to tell me what to repair or replace. I spent a lot of money on new tires, new brakes, new transmission parts, fluid system flushes, but mostly, new electronics and electronics diagnostics to ensure that everything is running properly. I'm prepared to spend more time and money to install new plastic intake and valve cover parts, new air box lower half to replace broken locking tabs, another new set of seals, new hoses, new fuel pump and sending unit / filter. I maintain my cars to the best of my ability because I want them to run reliably. An over-glorified paperweight is of no use to me.

Last edited by kbd512 (2021-09-06 15:06:21)

Offline

Like button can go here

#95 2021-09-06 15:11:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

The wave form on the o2 will follow the timing of each cylinders firing for an oscilloscope. if you were looking at the 2 banks forward they would cycle first one then the other with the output side of the catalytic convertors being nearly the same for a y common exhaust system. Its when its dual exhaust that code is looking for another difference to show a bad convertor. Usually one side or the other sets the code and you have a unique identifier.

It is normal for the o2 to go from one extremes to the other under operation from hard acceleration to idling.

Clearing the saved codes is possible by disconnecting the positive battery terminal and bringing the connector to the ground for 10 seconds to discharge the line. Some cars nominalize the values in a scratch pad for the engine before setting the engine code.

I had one car that changed limit values based mileage as well.

https://smogcheckvacaville.com/chrysler … -monitors/

Offline

Like button can go here

#96 2021-09-06 17:17:47

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

SpaceNut,

Yes, I'm aware of what the waveform and voltages should look like, and both upstream O2 sensors produce the expected waveform and voltage ranges. Only the downstream O2 sensor readings are problematic. I graphed this and consulted the service manual. The 2.7L Charger doesn't have a complete dual exhaust, but it does have the Y-collector you mentioned, which is downstream from the pair of catalytic converters.

The procedure for hard reset of the pair of TIPMs is to disconnect both battery terminals and then connect them together for at least 10 minutes to drain any residual stored power in the various capacitors. The PCM itself will reset almost as soon as you remove power.

Offline

Like button can go here

#97 2021-09-06 17:52:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

So after doing all of the above how soon after hard reset is it that the check engine and codes occur?

Since all that really can cause the failure is a bad convertor....

I have used the no foul spark plug extenders on the o2 sensor in at least one vehicle where the o2 stream was setting a code and it stayed away upon use.

Offline

Like button can go here

#98 2021-09-06 18:19:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

SpaceNut,

After the engine / sensor warm-up period, I think 10+ seconds of continuous operation without proper voltage input should do the trick, but in reality it took several minutes (possibly because of my hard reset), and then the check engine light came back on. To reiterate, the downstream O2 sensor voltages were higher than the upstream O2 sensor voltages- so high that they're completely out of range. Unless you had an exhaust leak introducing atmospheric O2, then the only other ways that could happen is a faulty sensor, faulty wiring (an intermittent open or short to ground), or bad PCM. They looked at the cats and said that the cats are good and not suspected of being part of the problem, nor do I suspect that there's any exhaust leak, because it would smell like engine exhaust. The downstream O2 sensors are providing the correct voltages from the sensor pigtail, but not from the wiring harness. The remaining question is where in the wiring harness.

If the sensor BEFORE the cat reads less O2 (lower voltage) than the sensor AFTER the cat, then if the voltage output of the downstream sensors is correct, meaning the cat is actually doing its job of burning off hydrocarbons, then the only alternative explanation is bad wiring or bad PCM output / read of the sensor data. Alternatively, bad TIPM not routing the voltage to the PCM successfully. TIPM failures causing this problem are not unheard of.

Since both upstream and downstream O2 sensors are actually providing correct output voltages at the pig tails, I presume it's the wiring harness, maybe the TIPMs, but probably not the PCM since the unit is refurbished. I have 2 PCMs for comparison purposes.

Offline

Like button can go here

#99 2021-09-06 18:34:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,850

Re: Fixing Americas car industry

The pcm has a bias or pull up resistor inside for the o2 to work properly. so unless the computer ground is not getting back to the sensor you have an open resistance in the line that would cause the higher voltage as the exhaust has no ground connection. I would agree that it seems to be in the wiring harness. The wiring should go directly to the pcm, without any other inter connection after the one for the sensor.

Grounding the exhaust should not do anything to change the results as the sensor use an isolated ground to make them work.

Typical wiring for chrysler 2 sensor and 4

Offline

Like button can go here

#100 2021-09-09 07:57:08

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,342

Re: Fixing Americas car industry

I have an update for the Charger. After a bunch of piecemeal wiring testing, the tech finally thoroughly tested the wiring, PCM, and TIPMs. The O2 heater circuits work and the voltage / signal from the O2 sensors is making it all the way back to the PCM. Both catalytic converters are dead and the aftermarket O2 sensors need to be replaced with OEM sensors. The tech removed all 4 O2 sensors and the engine ran smooth.

Offline

Like button can go here