New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#76 2016-01-08 09:35:48

- Antius

- Member

- From: Cumbria, UK

- Registered: 2007-05-22

- Posts: 1,003

Re: 3D Printers

JoshNH4H wrote:Well, it would be useful because, oddly enough, while cast basalt has a strength of approximately 10 MPa, Basalt Fibers have a tensile strength of 4500 MPa. Big difference, no? Making a composite of these two materials could very easily result in a new material with much improved tensile properties. I can't comment on the reasons for this difference. This is similar in concept to the Reinforced Carbon-Carbon composite used on the Space Shuttle. That one is Graphite and Carbon Fiber, IIRC.

I'm not sure what particular uses this material would have, if it were possible to fabricate, but surely it is always useful to have a higher-strength analogue to the usual construction materials available, in case it is needed.

I see. 10 MPa is really crappy, though. It makes me doubt about the usefulness of cast basalt. And plain basalt still needs too much heat for being a usable matrix, I fear. Imagine a steel wire. Drown it into smelted steel. Not sure it will survive & keep its properties.

My uneducated guess is that basalt fiber is strong because of internal chemical orientation of molecules. That one would be destroyed by excessive heating.

JoshNH4H wrote:I don't doubt that the colony will need to have machining capabilities. I was just thinking in terms of ways to minimize the cost of the models, seeing as Iron production on Mars will be akin to Aluminium production on Earth in that it will be quite energy intensive. Cast basalt production will use much less energy, but it's not really machinable, it would have to be covered in something that is. I'm not sure what a cost benefit would show, and I guess it doesn't really matter seeing as these will probably be one use anyway.

But thermosets won't be cheap either, I fear. Here I go again with my mantra : molding is not something easy, neither cheap, for such a small-scale society. It's not magic reproduction of pieces, & requires a lot of investment.

Who says you need to use the same minerals for both fibre and binder? Take a look at this:

http://hyperphysics.phy-astr.gsu.edu/hb … trock.html

How about olivine fibres in a Feldspar binder?

Offline

#77 2016-01-08 17:38:33

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 3D Printers

Well all things degrade over time - indeed the degrading of plastics in our oceans is a serious issue. I think bioplastics would be useful on Mars in the early colony particularly with respect to producing things such as grow-bags for plants, food processing and parts for various kitchen and farm utensils.

This link suggests durable bioplastics are feasible:

http://sciencelearn.org.nz/Innovation/I … ioplastics

louis wrote:Energy intensity is not an issue for a small colony on Mars - per capita energy generation on Mars will be absolutely huge and the element required to produce plastic relatively small.

Your link says ordinary plastics biodegrade - so not sure what your point is.

I think the key issues are "usefulness" and "labour input".

Ok, I'll accept that. "Labour input" is a good measure. My point is you want durable goods, not something disposable. The link also emphasized the distinction between biodegradable and compostable. In the 1990s, "biodegradable plastic" was normal petroleum plastic with some starch mixed in. The starch would decompose, but plastic didn't. Not useful. Bioplastic is compostable. But my point is it isn't durable, so you have to replace it. Bioplastic makes great flatware for a picnic or quick meal from a cart vendor on the street, but a Mars colony will want durable goods.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

#78 2016-03-20 16:18:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

SpaceNut wrote:Dexter2999 the image on the right could be a hill side construction using the very hill side to mine the insitu resource to actually make the glass, steel and mars cement needed to create it but until we can land the equipment it will have to wait untill raw man power can perform the tasks of construction and building of such structures.

Oh, I am sure that any "artistic" structure will require humans there.

But robots are capable of a whole lot. I think our perspective is more the limit. And that perspective will most likely have to change.

We can't build everything here and carry it with us. It just isn't practical. So, drones will be needed to find and stockpile resource materials. Iron, certainly, but why not have them also creating stores of oxygen, nitrogen, and water?

Speaking of practical, how many engineers and architects are actual builders? Large scale projects currently require large scale workforces to construct. Traditional methods just don't seem to make sense.

New methods are needed. New ideas. Or at least new application of existing ideas. Here are some video links to some interesting tech.

Ten houses printed in 24 hours in China

https://www.youtube.com/watch?v=SObzNdyRTBsSpider like 3D printing

https://www.youtube.com/watch?v=GNg8HtcDUF8This one is using styrofoam as forms for concrete construction

https://www.youtube.com/watch?v=p3v6VgiM5hYExpandable structure Hoberman sphere at LSC

https://www.youtube.com/watch?v=IN5AgauUpPAOr modular construction inspired by Buckminster Fuller

https://www.youtube.com/watch?v=1Bn2o-xyS6MRemember this? XANADU (now torn down)

https://www.youtube.com/watch?v=36lNS1ruK4sEDIT: I just think we can and need to take a look at existing ideas and see if can't extrapolate them into something more advantageous.

Thanks for the utube video's are there actual links to the companies and or written process documents?

I noticed many other video's on the pages as the relate but many had very negative comments to them...

The 3 D printing Idea is something to consider once we can process mars to use it in the printers....

Offline

#79 2016-03-21 00:51:02

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Well all things degrade over time - indeed the degrading of plastics in our oceans is a serious issue. I think bioplastics would be useful on Mars in the early colony particularly with respect to producing things such as grow-bags for plants, food processing and parts for various kitchen and farm utensils.

This link suggests durable bioplastics are feasible:

http://sciencelearn.org.nz/Innovation/I … ioplastics

Some items you would want to be durable, others you may want to have break down.

Interesting stuff with filaments made from organic sources like hemp and algae

https://www.youtube.com/watch?v=1-gjJRsLDP0

https://www.youtube.com/watch?v=zFbkKYtIKPY

Conversely, some things you want to be very durable. Like this jet engine.

https://www.youtube.com/watch?v=dRQB1SY4d6U

Offline

#80 2016-03-21 01:02:04

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Thanks for the utube video's are there actual links to the companies and or written process documents?

I noticed many other video's on the pages as the relate but many had very negative comments to them...The 3 D printing Idea is something to consider once we can process mars to use it in the printers....

Well, the "Spider" video was done not by a company but as part of a university challenge. The cement printing, I didn't find that particular company but here is a link to another company.

http://www.totalkustom.com/

Companies that do the styrofoam formed cement construction,

http://www.quadlock.com/

http://reddiform.com/

http://www.smartblock.com/

The Hoberman sphere and B.Fuller domes have been around for...what 50 years? Both genius BTW. Those are the kinds of things most of the rest of us can only aspire to.

Offline

#81 2016-03-21 16:54:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

Thanks for the links they are interesting but there is not much given in the way of how large the system is or of the mass that it would be to send to mars even if its sent in pieces.

The other is that it appears to be a wet type that fast drys which would be a problem for mars with the low quantity of water and colder temperatures that would effect the concrete / cement setup....

The cement so far proposed is a sulfur base mixture but that is one that is not going to be odor free....

Offline

#82 2016-03-21 23:13:59

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Thanks for the links they are interesting but there is not much given in the way of how large the system is or of the mass that it would be to send to mars even if its sent in pieces.

The other is that it appears to be a wet type that fast drys which would be a problem for mars with the low quantity of water and colder temperatures that would effect the concrete / cement setup....

The cement so far proposed is a sulfur base mixture but that is one that is not going to be odor free....

Okay, scale is a variable.

But how about this as a theoretical?

Say you have bots that are able to harvest the iron from the surface and a bot that can use that with a laser for 3D printing truss work?

Truss is not particularly tall, but rather you have say an 18" height and width but a run of 20'? Then stand up the pieces and lash them together with cables (or other printed pieces) and you have made yourself a gantry to move the business end of the printer about.

Now this gantry could also in theory be wrapped in a plastic perhaps much like you tent a house for fumigation.

And even a noxious odor cement...would the odor travel towards the higher pressurized interior or gravitate to the exterior?

Can that structure be coated with an interior sealant? Plastic sheeting? The sheeting works with it in a symbiotic relationship like rebar works with cement. Rebar makes cement stronger. Cement protects rebar from oxidation. Similarly, cement could protect plastic from exterior elements, sandstorms and radiation, while the plastic would protect the cement from interior humidity and keeps the noxious fumes out.

There is also the recent article about CO2 based cement. However I don't know the science.

Truthfully, I don't nuthin' 'bout nuthin'.

But I have a fair track record among friends of looking at existing tech and forecasting what is to come, an amateur futurist if you will.

I don't know the first thing about chemistry, but it seems that most of what I have ever heard/read is that the majority of functions will require air, water, or heat/energy to garner a chemical reaction to convert what is available to what we need (or at least what we currently know we need) on Mars.

I really believe in the necessity to have a bot that can refine and print the iron present on Mars. It will be THE FUNDAMENTAL material to build structures, but also to create tanks that can store oxygen, water, possibly nitrogen. It makes much more sense to have stockpiles of necessities on hand rather than have to rely on making things AFTER humans arrive.

Last edited by Dexter2999 (2016-03-21 23:30:28)

Offline

#83 2016-03-22 16:49:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

So to keep this on the 3D printer and not the side topic of Materials to build with I am going to continue in Domed habitats... - ...size, materials, and more

Then the part about robotic processing and mining ......

Offline

#84 2016-03-22 23:24:17

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Sorry, I often get off on tangents.

It is difficult for me to separate what the goal object is from the materials and tools.

3D printers can make a variety of items from a variety of materials and the potential is very exciting. Permanent items, biodegradable items, tools, parts, or whole structures, but it all hinges on materials, need, and conditions will vary as well.

Offline

#85 2016-03-23 17:05:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

No problem Dexter2999 with the slight tangent as its very common buts its important to just have the conversation....

The 3D printer media feed stock is really coming to age lately with metals being used in rocket engines and such....we just need forward thinking people to make use of them in other ways.....

Offline

#86 2016-03-24 20:25:29

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

Actually we need to plan before we go to Mars or the science returned will not have targeted the mysteries that we wanted to have answered. We will not have the correct mineral deposits checked for future missions.

Devising a machine that can scoop and build what we need from a 3D printer would be great but all seem to need quite a bit of processing of the media that is feed into the machine to be able to perform the miracle of building what we need.

So the question is do we send a robotic mission or 2 to the same site to build what we need and then go as we can make use of much smaller landers and just move the support systems from them into the newly create habitas built by the 3 D printers or do we just go for it with way more small landers or some other method to garrantee success....

Offline

#87 2016-03-24 20:39:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

http://www.shapeways.com/blog/archives/ … Shape.html

http://www.dezeen.com/2013/05/21/3d-pri … int-shift/

British company uses 3D printing to make stone buildings out of sand D-Shape's printers use a special inorganic binder and ordinary sand as the only raw materials. The non-epoxy binder is composed of two parts — sand is mixed with a solid catalyst, and the mixture is then exposed to a liquid binding agent.

http://foundrymag.com/moldscores/patter … printing-0

Offline

#88 2016-03-24 21:54:06

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Excited about this article, but still with reservations. 3D printing transparent glass.

Offline

#89 2016-03-25 20:24:00

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

From link

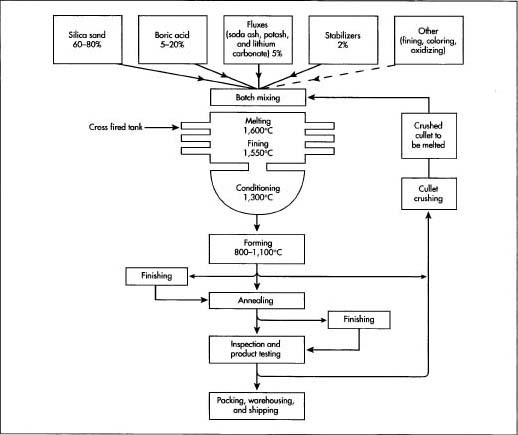

The machine prints soda lime glass, a family of glasses used in everything from water glasses to windows. But glasses like Pyrex could in principle be printed this way too, albeit at much higher temperatures

https://en.wikipedia.org/wiki/Soda-lime_glass

http://www.cmog.org/article/chemistry-glass

Soda-lime glass, most common form of glass produced. It is composed of about 70 percent silica (silicon dioxide), 15 percent soda (sodium oxide), and 9 percent lime (calcium oxide), with much smaller amounts of various other compounds. The soda serves as a flux to lower the temperature at which the silica melts, and the lime acts as a stabilizer for the silica.

A low-thermal-expansion borosilicate

https://en.wikipedia.org/wiki/Pyrex

According to glass supplier Pulles and Hannique, borosilicate Pyrex is made of Corning 7740 glass and is equivalent in formulation to Schott Glass 8830 glass sold under the "Duran" brand name.[11] The composition of both Corning 7740 and Schott 8830 is given as 80.6% SiO2, 12.6% B2O3, 4.2% Na2O, 2.2% Al2O3, 0.1% CaO, 0.1% Cl, 0.05% MgO, and 0.04% Fe2O3,

Offline

#90 2016-03-25 21:04:20

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,926

- Website

Re: 3D Printers

You know, for windows you wouldn't use 3D printing. A flat, rectangular pane can be made the traditional way. Which raises the question: how do you make a window? I believe modern windows are "float glass", meaning molten glass floated on liquid tin. Is there a better way? The medieval way was use glass blowing to make a big bottle, then while it's still molten, roll it on a table to make a cylinder, cut ends off, then cut along the length of the cylinder and unroll. The result was a flat pane. But manipulating a molten cylinder by hand will cause areas to sag. And of course the bottom surface is only as flat as the table. Is there a smaller scale method that doesn't require a factory with a giant tank of molten tin, and yet produces a window as smooth as modern glass?

As for goblets (drinking glasses): I image you would 3D print a mould, then use that to mould a set. Then you don't need a specialized 3D printer for glass. Modern bottles are made by a machine that blows glass into a mould.

This is an episode of a TV program that shows how factories make stuff. Different intro and different narrator than episodes in Canada, but looks like the same series. I noticed a second YouTube video that appears identical, but the narrator has a UK accent. Do they have different narrators for each country? Anyway, this could be scaled down.

How it's Made - Glass bottles

::Edit:: Cylinder blown sheet glass

Last edited by RobertDyck (2016-03-25 22:41:08)

Offline

#91 2016-03-25 22:03:39

- Dexter2999

- Member

- Registered: 2016-03-08

- Posts: 20

Re: 3D Printers

Well, the reservations I had sprung from reading that the 3D printed glass will work at 1000 degrees C. The idea of silica fused glass seemed exciting because silica is apparently abundant on Mars. However, the additive that brings the melting point down to 1000 degrees from 2000 degrees , I believe I read was sodium-bicarbonate, does not appear to be abundant...or even present from what have read so far. Bicarbonates in general are on the rare side.

Anyway, the higher temp of the silica fused glass indicates that it wouldn't be a candidate for printing. The print heads would be subject to the higher temps and dips would lead to clogging.

Aside from this, printing a window seems wildly impractical. Perhaps a something along the line of like a deco-block? Something that allows light but offers privacy could be a potential product. And if combined with a CNC removal process, to provide smooth finishes, more common items or lab glass.

But for large scale "flat glass" like a window it may be better to stick to more traditional methods.

Last edited by Dexter2999 (2016-03-25 22:04:25)

Offline

#92 2016-03-25 22:23:41

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,926

- Website

Re: 3D Printers

Mars has calcite in soil and rocks, and CO2 in atmosphere. There's salt in soil. On Earth, sodium bicarbonate is made by the Solvay process.

overall: 2 NaCl + CaCO3 → Na2CO3 + CaCl2

Sodium bicarbonate is baking soda, so there are food uses.

Offline

#93 2016-03-26 09:15:29

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,904

- Website

Re: 3D Printers

Depending on how transparent the window has to be... could it be sintered from glass beads? Put the beads in a flat mould, heat them, and press down evenly to press them into a flat shape. I imagine that would be the glass transition temperature? For soda-lime glass, that's ~600 degrees c, according to wikipedia.

Use what is abundant and build to last

Offline

#94 2016-03-26 11:18:44

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,926

- Website

Re: 3D Printers

Depending on how transparent the window has to be... could it be sintered from glass beads?

Should work. You have to worry about voids or air spaces. If there are any, then you get translucent or "frosted" glass, not a transparent window. To make it transparent, you really need to melt it.

I keep wondering how Surmet makes ALON? It's sintered from powder. I believe the powder is ground to fines, but everything I read says others who tried to duplicate the process always end up with material that has voids. That makes it translucent, not transparent. Do they use vacuum to suck air out, then use a multi-ton press to crush the powder while it's heated? And it has to be extremely hot, surface of powder grains has to melt to fuse together.

But you said not just fines, but beads. That means larger voids. Here's a YouTube video of sintering glass beads. Notice they form a butterfly shape, then sinter the beads together. They don't even try to change the beads from their round shape.

Wikipedia: Float glass

Float glass uses common glass-making raw materials, typically consisting of sand, soda ash (sodium carbonate), dolomite, limestone, and salt cake (sodium sulfate) etc. Other materials may be used as colourants, refining agents or to adjust the physical and chemical properties of the glass. The raw materials are mixed in a batch process, then fed together with suitable cullet (waste glass), in a controlled ratio, into a furnace where it is heated to approximately 1500 °C. Common flat glass furnaces are 9 m wide, 45 m long, and contain more than 1200 tons of glass. Once molten, the temperature of the glass is stabilised to approximately 1200 °C to ensure a homogeneous specific gravity.

The molten glass is fed into a "tin bath", a bath of molten tin (about 3–4 m wide, 50 m long, 6 cm deep), from a delivery canal and is poured into the tin bath by a ceramic lip known as the spout lip. The amount of glass allowed to pour onto the molten tin is controlled by a gate called a tweel.

Tin is suitable for the float glass process because it has a high specific gravity, is cohesive, and is immiscible with molten glass. Tin, however, oxidises in a natural atmosphere to form tin dioxide (SnO2). Known in the production process as dross, the tin dioxide adheres to the glass. To prevent oxidation, the tin bath is provided with a positive pressure protective atmosphere of nitrogen and hydrogen.

The glass flows onto the tin surface forming a floating ribbon with perfectly smooth surfaces on both sides and of even thickness. As the glass flows along the tin bath, the temperature is gradually reduced from 1100 °C until at approximately 600 °C the sheet can be lifted from the tin onto rollers. The glass ribbon is pulled off the bath by rollers at a controlled speed. Variation in the flow speed and roller speed enables glass sheets of varying thickness to be formed. Top rollers positioned above the molten tin may be used to control both the thickness and the width of the glass ribbon.

Once off the bath, the glass sheet passes through a lehr kiln for approximately 100 m, where it is cooled gradually so that it anneals without strain and does not crack from the temperature change. On exiting the "cold end" of the kiln, the glass is cut by machines.

Could this be scaled down as a batch? Instead of a continuous ribbon, a single window pane? I'm thinking of something for an early Mars settlement; not a science mission, but the first permanent settlers. The Mars Homestead Project assumed 12 settlers. Could we make windows for a greenhouse by scaling down this processes?

Older methods:

Broad sheet glass

It is made by blowing molten glass into an elongated balloon shape with a blowpipe. Then, while the glass is still hot, the ends are cut off and the resulting cylinder is split with shears and flattened on an iron plate. The quality of broad sheet glass is not good, with many imperfections and mostly translucent.

It is created with a similar process to broad sheet, but larger cylinders are produced by swinging the cylinder in a trench. The glass is then allowed to cool before the cylinder is cut. The glass is then re-heated and flattened. The result is much larger panes and improved surface quality over broad sheet.

In this manufacturing process glass is blown into a cylindrical iron mould. The ends are cut off and a cut is made down the side of the cylinder. The cut cylinder is then placed in an oven where the cylinder unrolls into a flat glass sheet.

Offline

#95 2016-03-26 11:36:43

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,926

- Website

Re: 3D Printers

Earliest: Roman glass - Tesserase and window glass

Shards of broken glass or glass rods were being used in mosaics from the Augustan period onwards, but by the beginning of the 1st century small glass tiles (tesserae) were being produced specifically for use in mosaics. These were usually in shades of yellow, blue or green, and were predominantly used in mosaics laid under fountains or as highlights.

Around the same time the first window panes are thought to have been produced. The earliest panes were rough cast into a wooden frame on top of a layer of sand or stone, but from the late 3rd century onwards window glass was made by the muff process, where a blown cylinder was cut laterally and flattened out to produce a sheet.

Last edited by RobertDyck (2016-03-26 11:37:18)

Offline

#96 2016-03-27 09:43:50

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,904

- Website

Re: 3D Printers

For a greenhouse, we don't need transparent glass, just translucent glass that let's the majority of light through. If we get 90% of the light transmitted, and it's all scattered, that's not a problem - and in fact might be a benefit.

Use what is abundant and build to last

Offline

#97 2016-03-31 20:05:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

Commercial printer now by Lowes and California-based startup Made In Space....

'Hardware Store in Space': Lowe's Wants to Send Commercial 3-D Printer to ISS

Roughly 30% of parts on the ISS can be 3-D printed from the reading on the subject, which is not all that bad... But we can do better....

Offline

#98 2016-04-04 19:36:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

New 3-D printing process could lead to construction on Mars and the Moon

Selective Separation Sintering (SSS), a new 3D-printing process by USC Viterbi professor’s invention, uses lunar and Martian dust to develop material for a zero-gravity environment

The NASA competition mandated that competitors use materials found on the Moon and Mars — regolith or crushed basalt rock — to develop a cement-like building material without water in a zero-gravity environment.

Using synthetic material created by the Johnson Space Center that mirrors the existing gravel and material available on the Moon and Mars, Khoshnevis and his team developed “a robotic fabrication process” that uses high melting-point ceramics such as magnesium oxide (readily available on the Moon and Mars) and ordinary regolith (planetary soil) to produce tiles that could withstand the heat and pressure of exhaust plumes of landing spacecraft.

SSS, Khoshnevis said, “is a novel powder-based additive manufacturing method that can build parts of various scale out of polymers, metals, ceramics and composites.”

Here is the why this method...

SSS is a powder-based method ideal for building smaller-scale objects such as interlocking tiles and bricks, as well as a large array of functional objects such as metallic parts.

“SSS is the only powder-based process that can effectively work in zero gravity condition and as such it is ideal for use in the International Space Station for fabrication of spare parts and tools,” Khoshnevis said.

The research team plans to further test the SSS process in a vacuum chamber of USC’s Astronautics Rocket Lab and NASA’s Kennedy Space Center facilities. The engineers hope to collaborate with local aerospace companies in the Los Angeles area.

Offline

#99 2016-04-04 20:12:15

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,926

- Website

Re: 3D Printers

But the Moon and Mars have gravity. The material is on those bodies. Constructing a landing pad would be done on the body. So why zero gravity?

Offline

#100 2016-04-04 20:40:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,428

Re: 3D Printers

yup National Labratory (ISS) is not on the moon or Mars where we need to be doing this work....

Offline