New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#101 2014-11-24 22:23:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,625

Re: Indoor farming update

Its time to get back to life support....

Mars Life Support Systems

http://marsjournal.org/contents/2006/00 … 6_0005.pdf

Radiation Effects and Shielding Requirements in Human Missions to the Moon and Mars

http://marsjournal.org/contents/2006/00 … 6_0004.pdf

Offline

Like button can go here

#102 2014-11-25 00:07:57

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Indoor farming update

There is a maximum concentration for each diluent gas in the high pressure environment, to allow zero pre-breathe. Again, "pre-breathe" means breathing pure oxygen for a defined period of time in order to expel dissolved diluent gas from the blood. Necessary to reduce diluent gas in the blood to the level necessary for decompression without that gas "evolving" out of solution. Tiny bubbles of gas in the blood will block blood flow, causing starvation to tissues fed by that blood vessel. This can cause necrosis of the tissues affected. Said necrosis is most common in joints, causing permanent joint damage that results in movement problems. That's commonly called "the bends". And yes, there is a maximum amount of each gas to allow for decompression without causing "The Bends".

I have already quoted the ratio of partial pressure of nitrogen in the higher pressure environment to total pressure in the lower pressure environment. There is a different ratio for each gas. The US Navy has already performed experiments to determine those ratios. For nitrogen, it's 1:1.2. I don't have the figure for argon, but GW Johnson's calculation sounds reasonable to me.

And yes, the US Navy uses multi-gas mixtures to avoid toxicity at high pressure. That's used for deep diving. But they also worked out ratios necessary to work with these gasses. That includes maximum partial pressure of each gas in the higher pressure environment to permit decompression without time in a decompression chamber. The US Navy worked out all sorts of protocols for decompression; most of which are not applicable to Mars. This ratio of 1:1.2 is.

A different ratio for each gas dose not mean their is no COUPLING between them. Think about what is happening in the body, each gas is dissolving out based on PP difference between the dissolved gas and the free gas, that means you have a bubble formation rate that is at minimum the sum of what each would be alone, so your already at higher rates then with one gas, but it will likely be worse, the nitrogen bubble has low argon PP, so argon wants to enter it, and the argon bubble has low nitrogen PP so nitrogen wants to enter it, your going to get mixed gas bubbles that form easily and grow rapidly.

This study is also a nice one dealing with the whole EVA/HAB atmosphere problem, http://marsbase.org/sites/default/files … 0Units.pdf

I've been asking you or GW to back up that wish/dream/hope of yours with some actual hard research data. You know what would be needed before people are sent into harms way, if the research doesn't exist say so and admit that you don't know how to make a space-craft atmosphere. Your willingness to accept 'reasonable' calculations which are based on wishing that the decompression sickness works the way you want it to is just intellectual laziness, prove the theory and only then do the calculations become worth anything.

I've been searching quite a bit and nothing I've found supports your position, this abstract for a paper in fact seems to bust the idea http://www.pubfacts.com/detail/2999061/ … es-in-rats. The result looks to be just what I was expecting, the inert gases are all coupled and your R ratio for zero-prebreathing is just the weighted average of the gases thus mixes have no advantage over simply using the best gas. Argon was worse then N2 and He was the best. If we can find the acceptable R for a O2/He mix then you can design an atmosphere around that.

Last edited by Impaler (2014-11-25 05:17:24)

Offline

Like button can go here

#103 2014-11-25 08:35:17

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Indoor farming update

Impaler, you already admitted you still haven't read "The Case For Mars". I could cite my entire library, but start with that book.

Offline

Like button can go here

#104 2014-11-25 08:51:47

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,394

- Website

Re: Indoor farming update

SpaceNut: interesting paper. I notice they have water allotment for urinal flush. Is that necessary? Many different designs are possible. The Space Shuttle and Space Station use air flow. They don't have a "urinal", at least not like a public washroom in North America. They have a nozzle on the end of a hose.

Equipment then separates air flow from liquid urine. That liquid then flows through a smaller tube to the Urine Processing Assembly. I imagine the systems for a science mission or exploration mission would be very similar to ISS. Mars has gravity, and the Mars Direct habitat is designed to use artificial gravity for transit to Mars, but operation in zero-G should be possible as a backup. Besides, that removes any water requirement for flush.

A permanent Mars base or settlement would be different. It could be designed to require gravity. And water can be processed, then used to feed plants in a greenhouse. But urine and feces cannot be used directly; they have to be broken down by bacteria before being used to water food crops. Urea in urine has to be broken down into ammonia (or dissolved ammonium), then converted to nitrite (one oxygen atom to each nitrogen), then converted to nitrate (two oxygen per nitrogen). Food crops require nitrate. Breaking down like this requires at least a septic tank. The GreenCELSS Task Force looked at a composting toilet, which performs the same task but doesn't use any flush water at all. You have to shovel the, um, result into the soil of a garden. A grey water system requires more water, but more automated.

Last edited by RobertDyck (2014-11-25 11:53:06)

Offline

Like button can go here

#105 2014-11-25 11:51:19

- Void

- Member

- Registered: 2011-12-29

- Posts: 9,340

Re: Indoor farming update

But why not keep the Ammonia, since it is a useful chemical that is hard to make.

Is it possible that the root of political science claims is to produce white collar jobs for people who paid for an education and do not want a real job?

Offline

Like button can go here

#106 2014-11-25 17:33:55

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Indoor farming update

Impaler, you already admitted you still haven't read "The Case For Mars". I could cite my entire library, but start with that book.

Yes, but I have read the whole Mars Trilogy by Kim Stanly Robinson which is much better. You see I can tell the difference between a research paper (like the ones I've been linking too) and a work of science-fiction which is what CFM basically is, even NASA DRM's (which I've studied) are a huge step up from CFM, though still highly speculative. If actual research by people who are experts in their field disagree with something Zubrin was pondering about well outside of his field of expertise (nuclear engineering) then I'll go with the real research every time. CFM is not a bible and I do not need to read it refute you on technical points where your in clear contradiction to real research. I've had to do that repeatedly as you try to grab a hold of some factoid and try to run without anything more then hand-waving away the difficulties.

Last edited by Impaler (2014-11-26 04:30:56)

Offline

Like button can go here

#107 2014-11-27 21:33:05

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Indoor farming update

Another point in favor of stacked artificial lighting set up like that in the OP.

Adjustable shelving heights for the growing racks, a batch of crops spends most of it's life-span at far less then it's final mature height and plants in artificially lit situations generally benefit from having the light source brought to just a few inches from their top most leaves. So having a kind of accordion cycle in which a succession of crops are grown with the racks moving further apart until a mature crop in harvested and it's rack is replanted and the space above it redistributed to the others. This arrangement should be able to produce another rough doubling of overall volumetric density.

Their is also the advantage of being able to temporarily move a pocket of space around to facilitate human examination (LED's generally switch to white light levels to do this so the human eye can see the plants normally) and harvest of the tray, as this is a very short term activity the space could literally be 'borrowed' from other levels by momentarily compressing them to below optimum levels, the leaves of other levels might just brush the LED's and if need be they can be shut off for a few minutes to do this without any real damage to . The picked tray of plants would then be immediately re-sown without removing it from the vertical system.

The mechanical system to move the levels would likely be some kind of cog-wheel and locking-pin that engages with a vertical rail, 4 rails and 4 cogs per level. Each moving shelf would have LED's in the bottom of it and likely a ventilation system that both cools the LED's and blows across the plants to develop robust stems, the top of the shelf is a flat waterproof surface and the growing tray is a fully separate system that simply sits on top of it. The lights, fans and servos for the cogs are all powered and controlled by a single wire running to a simple plug in another vertical column dedicated to electrical power, the wire simply has sufficient slack to accommodate the maximum range of movement of the shelf. Growing tray water systems are likewise supplied by flexible tubes emanating from a vertical plenum with sufficient slacks to accommodate movement, pumps located in the plenum and under computer control do all watering meaning the tray systems and watering systems are kept separate. All the system parts disassemble into compact forms, the shelves, stack flat, the rails can be bundled and then snap into floor plates, the electrical and water plenums likewise bundle, growing trays should nest. Throw in some central water/nutrient/air handling systems and any growing media/fertilizer and you have a full turn-key system. A simple unpressurized cargo container should be able to hold all that and, the only thing not included are the seeds which may need to be pressurized and chilled and radiation protected so I would basically treat the seeds as 'crew' for logistical purposes aka they get to ride the fast-transit and all the protection of biological systems that we can manage, fortunately they are so small we will hardly notice them tagging along with the crew.

The whole system when packaged should be just a small fraction of it's final volume, so it will pair very well with an inflatable structure such as a Bigelow/TransHab system, as these system become progressively more mass/volume efficient the bigger they get I think something on the 1-2k m^3 may be what's desired (for both growing and living space), as this is just an empty pressure vessel it should mass . The inflatable might not be the traditional cylinder that's been the go too choice for in-space human habitation, rather a planetary surface a more rectangular shape is better, a Quonset hut style shape may be a good compromise as a tall vertical space is not much of a problem as the 25ft vertical space in the OP's link indicates. The human harvest is the only issue and I'd mitigate the danger of a ladder by using a kind of flat topped staircase that fits in the aisle, these are fairly standard in warehouses and are fairly idiot proof, worst case tumble down a staircase is much better then falling off a ladder.

Offline

Like button can go here

#108 2014-11-28 14:05:51

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,172

- Website

Re: Indoor farming update

I've looked at the reference Impaler supplied above. The various values of acceptable R seem to be related to shorter pre-breathe and higher risk vs longer pre-breathe and lower risk, with the fundamental assumption being "it's a two-gas system". I looked for, but didn't see anything about relevant R values for a 3-gas system. So, I think that the issue of a multi-gas system is still open. That's a very good report Impaler provided, and I downloaded it for more "digestion".

Heliox for deep diving has been known for a long time. The trouble with helium is "Donald Duck voice". Argon and nitrogen get toxic if their pressures get too high, which should not be a problem for space habitats. Not sure about the others, but I'd guess neon is OK if not to much is used.

The suggestion I have offered is use nitrogen first, then as much argon, helium, and neon as you dare with each. No one dissolved partial pressure is any higher than their partial pressure in the habitat atmosphere (each a minor fraction of the total pressure), and those are just lower numbers with a multi-gas system. That has to restrict bubble formation relative to a single diluent situation, where the diluent partial pressure is instead a major fraction of the total pressure.

I don’t think the NASA guys who wrote that report considered that possibility, so their report does not rule the multi-gas approach out. The “other gases” for them were all trace constituents. As for “alveolar oxygen”, that’s what I am calculating when I allow saturated water vapor at body temperature to displace part of the “dry” habitat atmosphere (or suit atmosphere) inspired into the lungs.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#109 2014-11-29 06:30:21

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Indoor farming update

Great post Impaler - some v. interesting ideas.

If the trays can be moved mechanically though, do we need any ladder or staircase for harvesting? Of course, you might get mechanical failure.

I do agree that one of the key tasks required with respect to a human mission is to undertake an absolutely thorough health and safety analysis. Injuries must be kept superficial and minimal. Everything from cooking to harvesting to mining to life support systems and exploration will need to be analysed to nth degree.

And/or, I wonder if you can have an inflatable staircase?

Another point in favor of stacked artificial lighting set up like that in the OP.

Adjustable shelving heights for the growing racks, a batch of crops spends most of it's life-span at far less then it's final mature height and plants in artificially lit situations generally benefit from having the light source brought to just a few inches from their top most leaves. So having a kind of accordion cycle in which a succession of crops are grown with the racks moving further apart until a mature crop in harvested and it's rack is replanted and the space above it redistributed to the others. This arrangement should be able to produce another rough doubling of overall volumetric density.

Their is also the advantage of being able to temporarily move a pocket of space around to facilitate human examination (LED's generally switch to white light levels to do this so the human eye can see the plants normally) and harvest of the tray, as this is a very short term activity the space could literally be 'borrowed' from other levels by momentarily compressing them to below optimum levels, the leaves of other levels might just brush the LED's and if need be they can be shut off for a few minutes to do this without any real damage to . The picked tray of plants would then be immediately re-sown without removing it from the vertical system.

The mechanical system to move the levels would likely be some kind of cog-wheel and locking-pin that engages with a vertical rail, 4 rails and 4 cogs per level. Each moving shelf would have LED's in the bottom of it and likely a ventilation system that both cools the LED's and blows across the plants to develop robust stems, the top of the shelf is a flat waterproof surface and the growing tray is a fully separate system that simply sits on top of it. The lights, fans and servos for the cogs are all powered and controlled by a single wire running to a simple plug in another vertical column dedicated to electrical power, the wire simply has sufficient slack to accommodate the maximum range of movement of the shelf. Growing tray water systems are likewise supplied by flexible tubes emanating from a vertical plenum with sufficient slacks to accommodate movement, pumps located in the plenum and under computer control do all watering meaning the tray systems and watering systems are kept separate. All the system parts disassemble into compact forms, the shelves, stack flat, the rails can be bundled and then snap into floor plates, the electrical and water plenums likewise bundle, growing trays should nest. Throw in some central water/nutrient/air handling systems and any growing media/fertilizer and you have a full turn-key system. A simple unpressurized cargo container should be able to hold all that and, the only thing not included are the seeds which may need to be pressurized and chilled and radiation protected so I would basically treat the seeds as 'crew' for logistical purposes aka they get to ride the fast-transit and all the protection of biological systems that we can manage, fortunately they are so small we will hardly notice them tagging along with the crew.

The whole system when packaged should be just a small fraction of it's final volume, so it will pair very well with an inflatable structure such as a Bigelow/TransHab system, as these system become progressively more mass/volume efficient the bigger they get I think something on the 1-2k m^3 may be what's desired (for both growing and living space), as this is just an empty pressure vessel it should mass . The inflatable might not be the traditional cylinder that's been the go too choice for in-space human habitation, rather a planetary surface a more rectangular shape is better, a Quonset hut style shape may be a good compromise as a tall vertical space is not much of a problem as the 25ft vertical space in the OP's link indicates. The human harvest is the only issue and I'd mitigate the danger of a ladder by using a kind of flat topped staircase that fits in the aisle, these are fairly standard in warehouses and are fairly idiot proof, worst case tumble down a staircase is much better then falling off a ladder.

Last edited by louis (2014-11-29 07:12:35)

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#110 2014-11-29 18:50:36

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Indoor farming update

GW: I was only able to read the Abstract of the rat experimental paper http://www.pubfacts.com/detail/2999061/ … es-in-rats, it looks to be navy research rather then NASA and it's quite old 1985. But it really dose look like it shuts the door on multi-gas mixes evading the R value the way your hoping it will. We really should try to find the body of that paper to get the raw data and see if their has been any followup in the subsequent decades.

It looks like the best possible R value could be achieved with Heliox and it could be enough to close the circle and get the needed ZPB & Fire safety, the voice stuff is annoying but when compared to the operational safety and LOC dangers being reduced is it really that bad? Deep divers have decided it is a worth doing, perhaps the fact that divers are not expected to appear on national TV making comments about 'great leaps for all mankind' is the reason they get to breath safer but sound sillier.

Personally I think the technical improvement of the suit glove will simply take this whole issue off the table and we will see suits at higher and higher pressure and more conservative R values used. The 1.2 value is still going to give a 1-2% chance of the bends per ZPB EVA, NASA finds that level acceptable, if suit tech keeps improving then you can and should become more conservative and lower R to 1.0 which results in virtually no bends at all even amongst totally un-acclimated individuals.

I would not be surprised if habitat pressure even goes higher then Sea-level equivalent to give EXTRA fire-hazard protection, the ability to use a greater variety of materials in the habitat area would be on great value, especially when you consider the idea of ISRU materials being used to make things that go in the habitat. The ISRU mats are generally going to be of simpler molecular structure and thus simpler to manufacture. The more fire-proof a material is the more heavy elements it generally contains (like PFCE) with Chlorine in it and the more complex it is to make even here on earth. In an essentially incombustible atmosphere it would be safe to use things like bamboo grown in a greenhouse as a primary building material.

louis: I'm assuming that shelves can't move past each other and that the growing plants on each level would get crushed if we tried to compress all the lower shelves to bring a high shelf down to ground level. I imagine each shelf moving within a ~6 foot range, not because of any limit in their cog-rail system, but simply to prevent crushing of plants. Now if you really wanted to go with some kind of loop system, a bit like thouse ovens that donuts rise in then you could bring any shelf to ground level but that would complicate things on many levels, mechanical, electrical and watering. I think the simpler approach may be desirable here, particularly when the first system is likely to be no more then 6-8 foot tall, the 25 foot tall towers are a good deal further out and aren't needed until your feeding dozens or hundreds I think. I'd imagined stair-cases being made of carbon-fiber or aluminum, nothing sounds less safe then an inflatable ladder, the ultimate vertical farm perhaps uses a picking robot that brings trays down and to a human work area, much like a modern warehouse or distribution center.

Offline

Like button can go here

#111 2014-11-29 19:37:42

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Indoor farming update

louis: I'm assuming that shelves can't move past each other and that the growing plants on each level would get crushed if we tried to compress all the lower shelves to bring a high shelf down to ground level. I imagine each shelf moving within a ~6 foot range, not because of any limit in their cog-rail system, but simply to prevent crushing of plants. Now if you really wanted to go with some kind of loop system, a bit like thouse ovens that donuts rise in then you could bring any shelf to ground level but that would complicate things on many levels, mechanical, electrical and watering. I think the simpler approach may be desirable here, particularly when the first system is likely to be no more then 6-8 foot tall, the 25 foot tall towers are a good deal further out and aren't needed until your feeding dozens or hundreds I think. I'd imagined stair-cases being made of carbon-fiber or aluminum, nothing sounds less safe then an inflatable ladder, the ultimate vertical farm perhaps uses a picking robot that brings trays down and to a human work area, much like a modern warehouse or distribution center.

Not sure I have quite grasped your proposal - I was indeed of the view you were thinking more of something like a donut rack system.

One question: does it have to be automated? Is there any reason why a person on the ground couldn't activate movement of the racks on a chain system.

I agree about the first trial only being 6-8 feet high.

Robots are coming on at speed, much faster than most people realise and of course the high cost of robots would be irrelevant for the early Mars missions, so robots might well have a part to play.

I am not sure an inflatable ladder is necessarily dangerous. It could be built with inflatable guard sides, so that the worst that happens is you bounce down to the (inflated) bottom. I think stability for useful work rather than safety would be the key limiting factor. What we call "bouncy castles" in the UK have really high inflatable sides BTW.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#112 2014-11-29 21:41:21

- Impaler

- Member

- From: South Hill, Virginia

- Registered: 2012-05-14

- Posts: 286

Re: Indoor farming update

Yes a manually operated system with a little hand-turned crank could work just as well and might be the simpler thing. My thought was if were already running a lot of power to the LED's it's fairly simple to throw some servo-motors on-top of that and let it all be computer controlled. It comes down to the amount of crew time your willing to expend on working the garden though I guess the shelf adjustments do not really amount to much time if the system is easy to use (flip a locking lever, spin crank, re-lock lever). Lights should probably remain under full computer control as plants need to have a specific 'diet' of light through their growth cycle as well as their periodic 'sleep' darkness periods and it would be a waste of time to have people constantly making these little adjustments when they are so predictable.

The sides of the ladder were never what concerned me, it was the hard ground. If your putting an inflatable in contact with the ground as in the bouncy-castle (we have them here in the US too) I don't think it's got the mobility to go around the greenhouse anymore as I'd always imagined very narrow aisle of ~1m wide. Which brings up another point, why not compress that aisle space when not in use? Much like the large book-cases with cranks you see on the side at archival libraries. That would give yet another 100% volumetric efficiency improvement if the shelves and aisle are the same width (I think this means were at ~1% of the footprint of the sun-lit farm by now), though at the cost of significantly heavier ground railings and probably the need for a cement floor. Also at this density I'm quite sure that heat dissipation is a BIG problem, even if the LED's were perfectly efficient the inefficiencies within the plants chloroplasts themselves would be turn most of the input energy into heat which they must dissipate to the air generally by transpiration resulting in a sauna like environment. Their will need to be a lot of air-handling to take this greenhouse air out to the rest of the habitat where it can hopefully fulfill the heating needs their. It might even be more heat then the rest of the habitat can dissipate and we need to dump it (the heat not the air) too the outside environment. And on top of that you have moisture handling needs too, a big condenser is going to be needed to dry the air so the plants can be supplied with dry enough air for them to continue to transpire the water that they are being fed to from the condenser so at least we should be glad that it's a closed loop.

Offline

Like button can go here

#113 2014-12-25 22:01:28

Re: Indoor farming update

Others have pointed this out. That heat loss is slow due to Mars thin atmosphere. I talked about a double wall inflatable greenhouse, with pressure between the walls that is lower than the greenhouse interior, but higher than Mars ambient. That allows pressure alone to hold its shape. And Bruce MacKenzie pointed out you can monitor pressure of that gap to detect leaks. If pressure falls, the outer envelope has a puncture. If pressure rises, the inner one does.

An old "Case for Mars" paper talked about an aluminized Mylar curtain drawn over the ceiling at night to reflect radiant heat back in. I suggested the same coating that NASA uses for spacecraft/station windows. That coating is vacuum deposited thin layers of gold, nickel, and silver oxide. Only silver is oxidized. The combination of metals reflect UV and IR, but let over 80% of visible light through. This has been commercialized, but window manufacturers only use silver oxide because they only care about IR. Earth's ozone layer takes care of UV. NASA calls it "spectrally selective", commercial companies use brand names "Heat Mirror" or "Low-e". And this coating can be "tuned" to reflect more long wave IR from warm things like the floor or furniture, and less short wave IR from very hot things like the Sun. That difference causes net heating. Of course window manufacturers use this for Canada or northern states, and reverse the short/long bias for net cooling for sale to southern states.

At one point I suggested both the coating and curtain, but some Mars Society members question whether we need the curtain if we have the "spectrally selective" coating.

I also talked about bubble wrap to insulate the floor. With a rigid plastic walking surface on top of the bubble wrap, to ensure bubbles don't burst. Fill the gap of the greenhouse with argon gas, and fill the bubble wrap with argon as well. That conducts less heat than air. Some commercial window companies fill sealed casement windows with argon.

But one engineer, Janyce Wynter, questioned whether a double layer greenhouse envelope was necessary. She pointed out majority of heat loss would be to the ground. So I asked to see the numbers. She couldn't provide me with that. I still haven't found anyone who knows how to calculate heat transfer. I want to see the numbers.

Coincidentally this was my final project in one of my classes. My powerpoint can be found here:

https://docs.google.com/presentation/d/ … sp=sharing

Note that convection was assumed to have a coefficient h of 12 W/m^2K (Which I calculated to be optimal). This is doable with a fairly low pressure, although the equations typically used to calculate convective heat transfer coefficients are not very accurate, especially because I had to use equations made for a sightly different geometry (Apparently convective heat transfer between two parallel plates at a different temperature is not common enough to merit equations in my textbook).

The writeup is here:

-Josh

Offline

Like button can go here

#114 2014-12-26 16:19:23

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,172

- Website

Re: Indoor farming update

Hi Josh:

Look in your heat transfer textbook in the chapter about "free convection". I think you'll find what you need. It's calculated quite different from the more-standard "forced convection" that more folks know about.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#115 2014-12-26 19:26:54

Re: Indoor farming update

Sure, but the correlations for free convection aren't all that good either ![]()

In this case, the Raleigh number is at about the maximum number where the correlation works (1e12) and my numbers aren't exact, but it looks like the convective heat transfer coefficient will be between 0.1 and 1 W/m^2K (My calculations showed 0.4 but this is a bit of an abuse of the correlation and the relevant thermophysical properties change pretty quickly with slight changes in temperature). Anyway, what my numbers are showing is that convective heat transfer is enough, but it needs to be forced convection. That's good, because that means you can control the rate of heat transfer with fans circulating the air within the layers to obtain the right value for the convective heat transfer coefficient.

-Josh

Offline

Like button can go here

#116 2015-01-24 16:54:49

- JCO

- Member

- Registered: 2015-01-22

- Posts: 35

Re: Indoor farming update

Yes a manually operated system with a little hand-turned crank could work just as well and might be the simpler thing. My thought was if were already running a lot of power to the LED's it's fairly simple to throw some servo-motors on-top of that and let it all be computer controlled. It comes down to the amount of crew time your willing to expend on working the garden though I guess the shelf adjustments do not really amount to much time if the system is easy to use (flip a locking lever, spin crank, re-lock lever). Lights should probably remain under full computer control as plants need to have a specific 'diet' of light through their growth cycle as well as their periodic 'sleep' darkness periods and it would be a waste of time to have people constantly making these little adjustments when they are so predictable.

The sides of the ladder were never what concerned me, it was the hard ground. If your putting an inflatable in contact with the ground as in the bouncy-castle (we have them here in the US too) I don't think it's got the mobility to go around the greenhouse anymore as I'd always imagined very narrow aisle of ~1m wide. Which brings up another point, why not compress that aisle space when not in use? Much like the large book-cases with cranks you see on the side at archival libraries. That would give yet another 100% volumetric efficiency improvement if the shelves and aisle are the same width (I think this means were at ~1% of the footprint of the sun-lit farm by now), though at the cost of significantly heavier ground railings and probably the need for a cement floor. Also at this density I'm quite sure that heat dissipation is a BIG problem, even if the LED's were perfectly efficient the inefficiencies within the plants chloroplasts themselves would be turn most of the input energy into heat which they must dissipate to the air generally by transpiration resulting in a sauna like environment. Their will need to be a lot of air-handling to take this greenhouse air out to the rest of the habitat where it can hopefully fulfill the heating needs their. It might even be more heat then the rest of the habitat can dissipate and we need to dump it (the heat not the air) too the outside environment. And on top of that you have moisture handling needs too, a big condenser is going to be needed to dry the air so the plants can be supplied with dry enough air for them to continue to transpire the water that they are being fed to from the condenser so at least we should be glad that it's a closed loop.

For the issue of the ladder, a number of commercial vertical farms us sets of rotating shelves. The reason for this is it simplifies watering the plants. Rather than having irrigation on each shelf you have a trough at the stack and each shelf rotates through it. I believe this is to provide a more natural cycle of saturation and aeration of the growth medium. This might make adjusting the shelf height more complicated but it may be possible to make a system that did both. With a rotating rack attention to any one shelf is easily done when it is near the floor.

For the heat issue, rather than venting atmosphere would it be more effective to pump it into a "basement" where the martian permafrost could act as a heat sink.

Offline

Like button can go here

#117 2016-04-08 17:08:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,625

Re: Indoor farming update

Well my plan was to make the Moon into a giant O'Neill colony complete with Earth gravity. the Moon's lack of an atmosphere allows for this. A cheaper alternative is just to live with Lunar gravity and build a giant tower at the poles. You have a vertical sky scrapper, it receives direct sunlight, it could even rotate once every 24 hours on a turn table, each level allows entry of more sunlight through windows. One can have vertical farms for growing food and creating oxygen.

Here is a terrestrial version of that same idea. On the Moon, their is no atmosphere for the sunlight to pass through, It is just as intense as at the Moon's equator, the main difference is at the poles, you have 24-hour access to sunlight for all 30 lunar hours of the month. You can rotate your vertical farm to produce night and day for various sections of your vertical farm. The Moon provides the gravity. My feeling is, since a mile high tower is possible on Earth, on the Moon it would be 6 miles high using conventional construction materials, if you allow 10 feet per floor, that would give you 3168 levels of this sky scraper.

I agree that verticle farming is perfect for the moon's polar location....

On could use light piping glass to allow for the suns rays to be brought around to the dark side of the tower and to use blinds to simulate the night and day time of day by opening or closing the sun side of the towers light pipes.

Offline

Like button can go here

#118 2016-04-09 12:21:50

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 4,000

- Website

Re: Indoor farming update

Why waste sunlight? You can alternate which areas are lit, instead.

Use what is abundant and build to last

Offline

Like button can go here

#119 2016-04-09 15:45:16

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: Indoor farming update

Tom Kalbfus wrote:Well my plan was to make the Moon into a giant O'Neill colony complete with Earth gravity. the Moon's lack of an atmosphere allows for this. A cheaper alternative is just to live with Lunar gravity and build a giant tower at the poles. You have a vertical sky scrapper, it receives direct sunlight, it could even rotate once every 24 hours on a turn table, each level allows entry of more sunlight through windows. One can have vertical farms for growing food and creating oxygen.

http://tse3.mm.bing.net/th?id=OIP.M3663 … =4&pid=1.1

Here is a terrestrial version of that same idea. On the Moon, their is no atmosphere for the sunlight to pass through, It is just as intense as at the Moon's equator, the main difference is at the poles, you have 24-hour access to sunlight for all 30 lunar hours of the month. You can rotate your vertical farm to produce night and day for various sections of your vertical farm. The Moon provides the gravity. My feeling is, since a mile high tower is possible on Earth, on the Moon it would be 6 miles high using conventional construction materials, if you allow 10 feet per floor, that would give you 3168 levels of this sky scraper.I agree that verticle farming is perfect for the moon's polar location....

On could use light piping glass to allow for the suns rays to be brought around to the dark side of the tower and to use blinds to simulate the night and day time of day by opening or closing the sun side of the towers light pipes.

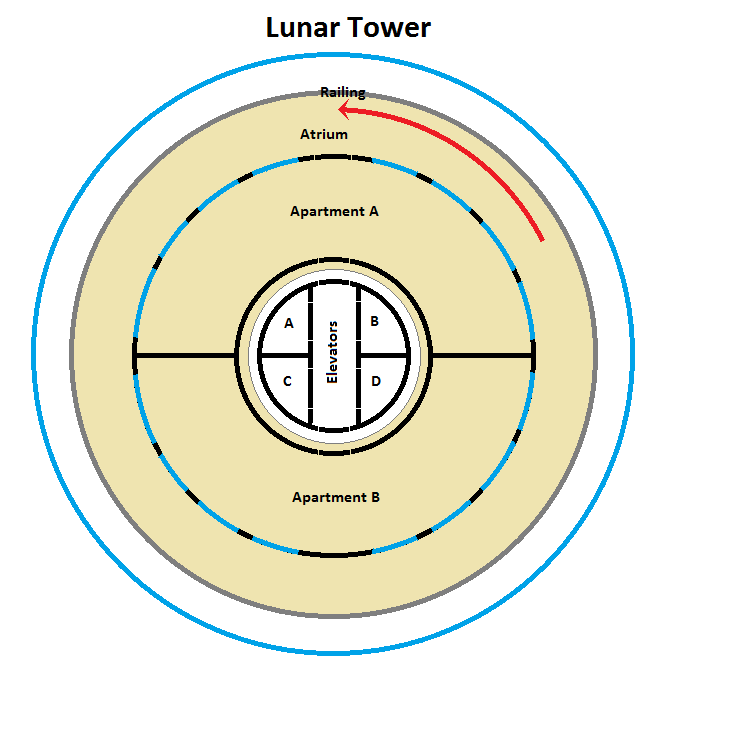

One could also have a fixed tower that does not rotate, and put each individual floor in a turn table so that it rotates within the tower once every 24-hours. I think that would be easier that rotating the entire tower. One could also put an elevator bank in the center of the tower, so people can get to different floors. I would suggest two apartments for each level. Each apartment in a cylindrical tower taking up half the floor space minus that reserved for the elevators. The two apartments would rotate around an axis centered on the elevators. Each apartment would have 180 degrees of window space. Half the time the Sun would shine through, half the time you would get an excellent view of the Earth through your living room window. The windows would open to an atrium, that is the turntable would have two apartments on it those apartments would have windows, that you could open. Beyond the windows is an atrium, some garden space, perhaps a few trees, and beyond that a panoramic window to space.

Offline

Like button can go here

#120 2016-04-09 20:31:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,625

Re: Indoor farming update

I search to se if its practical and found that we have them here on earth... ‘Rotating Tower’ – World’s First Building in Motion

Construction is scheduled to be completed by 2010

Each floor will be able to rotate independently. This will result in a constantly changing shape of the tower. Each floor will rotate a maximum of 6 meters (20 ft) per minute, or one full rotation in 90 minutes.

These Buildings Can Actually Move by Rotating

Offline

Like button can go here

#121 2016-04-10 06:32:26

- Tom Kalbfus

- Banned

- Registered: 2006-08-16

- Posts: 4,401

Re: Indoor farming update

Probably the one on the bottom is closest to what I have in mind, though a lot taller! It would be sheifed inside a glass building that does not rotate, its purpose is to keep the pressure within. Each rotating section would be within a compartment maybe 30 feet tall with a floor to prevent people who flip over the rail from falling 6 miles within the outer glass building. A 30-foot fall within an atmosphere under lunar gravity, would have the same impact energy as falling 5 feet on Earth. Those railings I depicted, obviously won't prevent people from jumping over them if they wanted, they are just something to hold onto, to prevent people from accidentally falling over the edge.

If this building was on the Moon, you could jump from the third floor quite easily, landing on your feet and avoiding harm.

Offline

Like button can go here

#122 2017-01-26 20:34:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,625

Re: Indoor farming update

The farm that runs without sun, soil or water Well, almost no water. AeroFarms, the company behind the venture, say they will use 95% less water than a conventional outdoor farm. A massive indoor vertical farm is about to open in the US and it grows baby leaves and herbs using a method which requires no sunlight or soil and next to no water.

Long rows of LED tubes shed light at the exact wavelength each plant needs to thrive. Instead of soil, the plants are grown on a cloth made from recycled materials, and their roots are misted with a solution of nutrients.

The company says their method is superior to more commonly used indoor farming techniques like aquaponics and hydroponics, which require much more water, and that the plants taste the same, or even better, than their conventionally grown counterparts.

Offline

Like button can go here

#123 2017-01-27 03:12:30

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: Indoor farming update

Even a small meteorite would jeopardize this entire structure. The rocket reaction from a leak, multiplied by the enormous leverage provided by a 10,000 metre high enclosure would probably destroy the envelope. It has to be shorter and the pressure containment has to be subdivided.

Offline

Like button can go here

#124 2017-01-27 11:34:15

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,172

- Website

Re: Indoor farming update

I see no reason why it couldn't be subdivided. It is an intriguing concept. With its own lighting, it could become a buried item.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#125 2017-01-27 19:23:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,625

Re: Indoor farming update

I do agree that under the right size step for each module section from mission to mission that each having interlocking connecting doors that can be auto sealed from one chamber to the next would be ideal....Have a scantuary chamber inside each module to allow for safety incase the modules section seal before a crew man can get out of a section allowing for rescue by putting a space suit in each for the size of a crew that would be working in the greenhouse units.

Offline

Like button can go here