New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2021-08-11 09:29:51

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Tim Dodd and Elon Musk tour and interview Pt. 3

Offline

#2 2021-08-11 09:46:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,431

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Oldfart1939,

Thanks for posting this.

Offline

#3 2021-08-11 15:41:19

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 5,459

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

It sounds like he is planning on launching from the shore. Maybe moving to the oil rig later if he has to, but only if he has to.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

#4 2021-08-11 16:04:49

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,431

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

He's very clear that launching from the oil rigs is a backup plan and that SpaceX's first order of business is a successful orbital launch and reentry with Starship. It's always cheaper / easier to launch from onshore than offshore. That's pretty much a given. If there's no other option, or if the payload performance demands an offshore launch from an equatorial location, then you switch to offshore launches. If the rocket is big enough, and Starship Super Heavy is very nearly there, then it'll have to be launched offshore as well, because no onshore launch location in North America is far enough away from population centers to receive FAA / EPA approval. That's why Nova could not be launched from KSC, thus NASA went with Saturn V for their first lunar program.

Offline

#5 2021-08-11 16:32:57

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Musk commented in segment 2 that they are looking into a water deluge system for sound suppression.

Offline

#6 2021-08-11 18:17:52

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Not even North Dakota?

He's very clear that launching from the oil rigs is a backup plan and that SpaceX's first order of business is a successful orbital launch and reentry with Starship. It's always cheaper / easier to launch from onshore than offshore. That's pretty much a given. If there's no other option, or if the payload performance demands an offshore launch from an equatorial location, then you switch to offshore launches. If the rocket is big enough, and Starship Super Heavy is very nearly there, then it'll have to be launched offshore as well, because no onshore launch location in North America is far enough away from population centers to receive FAA / EPA approval. That's why Nova could not be launched from KSC, thus NASA went with Saturn V for their first lunar program.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

#7 2021-08-11 18:19:01

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

I'm not surprised. I am pretty sure they will have something pretty innovative to offer for noise suppression.

Musk commented in segment 2 that they are looking into a water deluge system for sound suppression.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

#8 2021-08-11 19:29:30

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,811

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

When Saturn 1B launched from LC-34 the vibration it produced caused damage. That was just a concrete ring with tiny metal wedge on the concrete pad dead center beneath the rocket to encourage sideways flow. The rocket was relatively close to the pad. That told them they needed a noise suppression system of some sort, especially the even larger Saturn V. That's when the deluge system was invented. Saturn V was also close to the ground, relative to its size. But it had moulded flame trenches and deluge. When Saturn 1B was used to launch astronauts to Skylab, they built a "milking stool" for the Mobile Launcher for LC-39. The shear distance of engines from the flame trench reduced force of exhaust on the ground, hence sound reflection etc.

Notice the orbital launch platform is high up in the air like the Saturn 1B milking stool.

Offline

#9 2021-08-12 09:22:43

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

https://www.youtube.com/watch?v=2S1qKpCK5Vg

Overlook the annoying computer voice--this is about the new side by side refueling idea.

Offline

#10 2021-08-12 09:43:54

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,811

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

https://www.youtube.com/watch?v=2S1qKpCK5Vg

Overlook the annoying computer voice--this is about the new side by side refueling idea.

Doesn't sound like a computer voice, it's a person. He does mispronounce the word "integral".

Offline

#11 2021-08-12 10:01:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,167

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

The video does NOT discuss the details that have been considered in this forum.

The animation shows what side-by-side fuel delivery might look like, but there is no hint of spinning or ullage thrusters.

The animation is probably speculation by an artist, based upon hits from Musk tweets.

Fortunately, this forum has members who can predict with near certainty what would be required for this concept to work.

(th)

Offline

#12 2021-08-12 10:09:44

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Here's more from Teslarati:

https://www.teslarati.com/spacex-elon-m … g-details/

Last edited by Oldfart1939 (2021-08-12 10:10:39)

Offline

#13 2021-08-12 11:26:19

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 5,459

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

You have to understand that these informational postings are coming from outside observers who are technically untrained for the most part. They hang on every tweet as well as every press release. Tweets and press releases are just not very reliable as real sources of information.

Example: making the inference that the distance to Mars vs the moon makes for a larger Mars refilling requirement than the moon. Actually, the reverse is true, because it is delta-vee requirements, not distance covered (or trip time) that sets refill requirements. These guys don't understand that. At least some of us here on these forums do understand. We've heard of, and used, the rocket equation.

I honestly don't know whether side-by-side will be better than tail-to-tail docking for refilling. I do know there is a way to cut the refill requirements for the moon mission by getting clever with where you do most of the refilling. It ain't 16 tankers. And Mars is far less at 6 or 7 tankers. I've already explored this and posted my results. And that's coming from someone well-trained technically to get such numbers.

There ain't gonna be any trick bladders with cryogenic propellants. These tanks will be the same free-surface designs that they are now. The same as they were on every cryogenic-fueled rocket back to Goddard's liquid oxygen/gasoline design in 1926. That means there will be acceleration produced by an ullage thruster of some kind during any propellant transfer operation, and during any engine relight operation, while in zero-gee.

Your only wiggle room is exactly where and how you will get that ullage thrust force. Otherwise, this problem is the same as it was with the Saturns half a century ago. Nothing about those physics, or the associated engineering tradeoffs, has changed.

GW

Last edited by GW Johnson (2021-08-12 11:34:48)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

#14 2021-08-12 11:33:54

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

This is mainly all good PR for SpaceX. Nothing more than filler for these daily posters.

Offline

#15 2021-08-12 11:50:36

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,167

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

For GW Johnson .... Thanks for continuing to invest in the collection of valuable insights in this forum.

We (administrators/moderators) learned recently that Mars Society has indeed been noting the quality of some of the conversations.

With that in mind, and noting that Elon has hired the best folks he could find to help him solve the refueling problem, please think about how ** you ** would handle refueling, if you were suddenly (like yesterday) presented with Elon's decision to forget the tail-docking and go for side by side refueling.

You have made clear that your inclination is to use ullage thrusters, so I would expect you'll be thinking along those lines. However, you may well have a surprise for the readers, as you consider the physics of the situation.

Something I'd like to toss into the ring at this point, is that with recent improvements of ion thrusters, it is no longer necessary to depend exclusively on chemical propulsion.

How thrusters would be deployed to expedite fluid transfer while not disturbing the orbit in LEO more than absolutely necessary will be fun for us to learn, and (most likely) challenging for you to describe so we can understand it. However, your track record is pretty good, so I am guardedly hopeful.

(th)

Offline

#16 2021-08-12 12:00:38

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 5,459

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

There should be some attitude thruster quads dispersed about the ship for attitude control. These are placed for both angular control about 3 axes, and also translation capability along 3 axes. Those will likely be at least similar to the Draco thrusters they use for that purpose on Dragon. Which means they are bladdered tanks with the room-temperature storables NTO and MMH, pressure-fed to a very simple thruster chamber that has no moving parts, other than propellant on/off valves.

Whichever thrusters point in the direction needed for the ullage thrust you desire, those you fire for the refill events (or for the re-ignition events). You size the thruster propellant tanks for the burn time totals you think you need, at the flow rates the thrusters draw. Those burn times include all the refill and reignition ullage events, plus all the anticipated attitude control budgets.

Simple as that, and just as hard as you might fear, to actually do.

In another thread, I pointed out that these ullage burns do affect your orbital path. But if you orient the cluster to burn across the orbit instead of along it, your perigee and apogee are unchanged. Only your orbit plane changes, but because of the low delta-vee and high orbital velocity, it changes by something only down in the .001 radian range. And if you reorient 180-out for each successive tanker refill, those tiny changes add to zero.

GW

Last edited by GW Johnson (2021-08-12 12:06:59)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

#17 2021-08-12 14:08:23

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,811

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

There ain't gonna be any trick bladders with cryogenic propellants. These tanks will be the same free-surface designs that they are now. The same as they were on every cryogenic-fueled rocket back to Goddard's liquid oxygen/gasoline design in 1926. That means there will be acceleration produced by an ullage thruster of some kind during any propellant transfer operation, and during any engine relight operation, while in zero-gee.

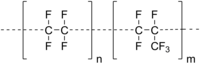

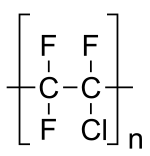

Do you have any experience with fluoropolymers at cryogenic temperatures? Specifically PCTFE and FEP? PCTFE is sold in the United States by Honeywell under brand names Clarus and Aclar, Clarus is targeted to military and aerospace applications. FEP is sold by DuPont under brand name Teflon FEP. There are other manufacturers in the world, but the point is the service temperature in technical documents published by the manufacturers. If you don't believe they can operate under service temperatures as published, please tell me what experience with these specific materials supports that conclusion.

Bladder vs ullage is a trade-off of propellant expended to produce acceleration vs mass of the bladder. There's also the issue that acceleration will change orbit. And how will that acceleration affect coupling the two vehicles while connected?

Offline

#18 2021-08-12 14:29:28

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Robert-

I suspect that the bladders could be useful additions to the tanker-only versions of Starship, using the bladders to squeeze out the propellants into the receiving Starship. There will undoubtedly be arguments over additional mass needed but will not be a throwaway item and will be reused as much as the service lifetime will allow. I'm familiar with these polymers only in passing, but they should work fine especially for the (l) Me, and probably for the LOX as well.

Offline

#19 2021-08-12 14:49:37

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,811

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Oldfart1939, Thank you. That's what I was trying to say. I have samples, but only 8.5"x11", and I don't have any access to cryogenic liquids to see how they respond. I can only go by manufacturer's technical document. But the point is I'm trying to say bladders could be used for tankers, to transfer propellant in zero-G.

Could also be used for propellant tanks for ullage thrusters, if Elon uses LCH4/LOX for ullage thrusters instead of MMH/N2O4. In the interview he talked about using residual pressure in the tanks for cold gas thrusters. Interesting optimization, but limited. For satellite delivery, Starship need only achieve orbit, open its door to release payload, then immediately return to Earth. For that role, residual pressure could be enough. Not as if it's going to loiter in orbit like Space Shuttle did. Dragon currently rendezvous with ISS, and stays attached for extended time. So that method wouldn't work for Dragon. But for Starship, fine.

Offline

#20 2021-08-12 15:20:59

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 5,459

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Robert:

I can't say I have any familiarity with the PCTFE specific products you mentioned. I do have familiarity with a thin film made of FEP teflon, that is the same material used as Saran Wrap, and was the isolator film used between the silicone liner and HTPB propellant in the ASALM-PTV integral booster design (I worked on that). We acid-etched that teflon film to turn it from a release agent into a surface we could bond to.

I don't know, but my first impression from the product acronyms is that both the products you mentioned are more-or-less teflon plastic: fluorine-carbon plastic materials. Like glass, in very thin form, they are flexible. Made thick, they are inflexible hard plastics. Teflon in quarter to half-inch thicknesses is really stiff and hard, you cannot deform it with your hands. It breaks before it has much strain at all. But in 10 mil film form, it reshapes all over the place as cling wrap. I also used the same FEP teflon in quarter-inch to half-inch thickness as hard plastic structural parts, as part of an aircraft towed decoy about 1985. Hard as rock and almost brittle as glass. At 70 F.

You will not be making bladders reshaping hundreds of tons of propellant with very thin film. It would take thousands of layers to be strong enough for the forces involved: that is just not a practical thing to do. If you make those parts, say, a quarter inch thick, it will be hard-as-a-rock and totally inflexible to the touch: not a bladder at all.

And you can't do it as woven fibers to create flexible fabric, like we do with glass. The same porosity problem ensues as with glass fiber fabric, and also the ceramic fabrics. While both strong and flexible, they leak like a sieve. Nextel 312 fire curtain cloth is almost 20% open-area porous. I can actually see through it, held at the right distance from my eyes, looking right through the pores past the woven fibers.

About the only "way out" would be strong woven FEP fabric, "sealed" with layers of thin FEP film. But only if the film didn't burst over the fabric pores while conforming to the woven fibers. It would have to be a hell of a tight weave. Which reduces fabric flexibility.

I could be wrong, but the problems I describe are probably why no one has ever flown a cryogen-fueled rocket with bladder-lined tanks. And these materials have been around in one form or another for decades. The ASALM work with FEP teflon dates to 1978-1980.

GW

Last edited by GW Johnson (2021-08-12 15:29:50)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

#21 2021-08-12 18:57:50

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,384

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

In the worst case scenario, these polymers could be used as seals between a moveable bulkhead and the fluid being pushed by the gas pressure utilized.

Offline

#22 2021-08-12 19:48:56

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,167

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

For OF1939 ...

One of the neat things about this debate is that we will know the solution within a (relatively) short time ... Whatever technology or procedure is needed MUST be developed shortly after SpaceX achieves LEO with Starship, because it is key to everything else that SpaceX might want to do.

We already have on record GW Johnson's suggestion to use ullage thrusters, which can be used with either the side-by-side refueling method or the end-to-end method.

I like your suggestion because it seems so simple compared to all the alternatives. A simple pressure piston advanced by gas pressure against cryogenic liquid eliminates the need for pumps. The fact that some liquid can squeeze past the rim of the piston seems of little consequence, if the vast majority of the liquid is gently moved out of the tanker into the waiting Starship.

SearchTerm:Piston refueling strategy

SearchTerm:Refueling strategy

SearchTerm:Orbital refueling

Edit at 21:53 local time

https://www.teslarati.com/spacex-elon-m … g-details/

ByEric RalphPosted on August 12, 2021

After a much-anticipated GAO denial of Blue Origin and Dynetics protests over NASA’s decision to solely award SpaceX a contract to turn Starship into a crewed Moon lander, an in-depth (but heavily redacted) document explaining that decision was released on August 10th.Aside from ruthlessly tearing both companies’ protests limb from limb, the US Government Accountability Office’s decision also offered a surprising amount of insight into SpaceX’s HLS Starship proposal. One of those details in particular seemed to strike an irrational nerve in the online spaceflight community. Specifically, in its decision, GAO happened to reveal that SpaceX had proposed a mission profile that would require as many as 16 launches to fully fuel a Starship Lander and stage the spacecraft in an unusual lunar orbit.

After around 24 hours of chaos, confusion, and misplaced panic, SpaceX CEO Elon Musk finally weighed in on the GAO document’s moderately surprising indication that each Starship Moon landing would require sixteen SpaceX launches.

First, SpaceX will launch a custom variant of Starship that was redacted in the GAO decision document but confirmed by NASA to be a propellant storage (or depot) ship last year. Second, after the depot Starship is in a stable orbit, SpaceX’s NASA HLS proposal reportedly states that the company would begin a series of 14 tanker launches spread over almost six months – each of which would dock with the depot and gradually fill its tanks....

(th)

Offline

#23 2021-08-12 23:09:11

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 7,811

- Website

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

Pulling out my samples of film... I have Tefzel 100CLZ, 200CLZ, 500CLZ. And Teflon FEP 100A, 200A, and 500C. These are 1 mil, 2 mil, and 5 mil thicknesses respectively. They're from DuPont. I also have PCTFE 1.0 mil, 2.0 mil, and 4.0 mil thickness. These are from Tekni-Films, a division of Tekni Plex Inc. You're right, the Teflon FEP is clingy, like Saran wrap. However, PCTFE is not.

FEP is Fluorinated Ethylene Propylene. It's a co-polymer of ethylene and propylene with all the hydrogen atoms replaced by fluorine.

PCTFE is Polychlorotrifluoroethylene. It's a polymer of ethylene with 3 of the 4 hydrogen atoms replaced by fluorine, the 4th with chlorine.

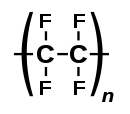

By the way, regular "Teflon" is Polytetrafluoroethylene (PTFE). That's a polymer of ethylene with all 4 hydrogen atoms replaced by fluorine. Goretex is the same polymer, just made by a different company.

Although FEP is a transparent film, and it produces static electricity that causes it to cling like Saran Wrap, it's not the same polymer. Saran Wrap was polyvinylidene chloride (PVDC). The Wikipedia article says Dow Chemical included other monomers. However, in 2004 it was changed to polyethylene due to "problematic chlorine content". Saran Wrap is not a fluoropolymer.

Today's Saran Wrap is no longer composed of PVDC in the United States, due to cost, processing difficulties, and environmental concerns with halogenated materials, and is now made from polyethylene. However, polyethylene has a higher oxygen permeability, which in turn affects food spoilage prevention. For example, at 23 °C and 95% relative humidity polyvinylidene chloride has an oxygen permeability of 0.6 cm³ μm m−² d−¹ kPa−¹ while low-density polyethylene under the same conditions has an oxygen permeability of 2000 cm³ μm m−² d−¹ kPa−¹. For that reason, packaging for the meat industry still may use PVDC-containing films, as a barrier layer.

Your point is well taken about forces over such a large tank. The solution for an inflatable greenhouse for Mars is strapping at regular intervals. That means the film doesn't have to withstand forces over the entire surface, just over the square of film between straps. A bladder could do the same thing. Bond the film to a fishnet mesh. Holes or gaps in the fishnet could be quite large. Film inside, fishnet outside.

Offline

#24 2021-08-13 00:53:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 7,431

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

This PTFE film doesn't have to withstand huge forces if you don't subject it to such forces. The bladders can remain inside enlarged landing propellant tanks nested within the larger primary propellant tanks. Gas pressure from residual propellant inside the primary tanks can be used to slowly apply force to the PTFE bag around the propellants in the header tanks. The bag will squirt its propellant contents out of the header tanks and into the primary propellant tanks of the receiving Starship.

Similar to aerial refueling on Earth, the Starship Tanker variant will extend a short boom / Canadarm, lock into the receptacle on the receiving Starship, and use residual propellant pressure to slowly transfer propellants. One propellant will be transferred at a time, with enough time between transfers for purging residual propellant in the line to vacuum or to pressure the tanks of the receiving Starship.

Rather than risk contaminating or damaging the delicate solar panels, both Starships will use onboard Inline-Six spark-ignited engines that burn natural LOX/LCH4 boiloff, same as ULA is doing with LOX/LH2 to eliminate Helium COPVs and Lithium-ion batteries. ULA's design is an all-Aluminum liquid (glycol) cooled flat-head variant of a high performance Roush Racing engine. The cold oxidizer and fuel are used to cool the engine prior to injection via a heat exchanger. A small amount of siphoned gas is also circulated through the heat exchanger to re-pressurize the tanks. ULA's engine is only 26hp or 26kW, I forget which (doesn't matter anyway). The net result is that the pair of engines are significantly lighter than Lithium-ion batteries, less propellant is lost from running the engines than would otherwise result from boiloff, and the entire setup is both very compact and very tightly integrated with the overall vehicle design.

A picture of the engine is present in page 13 of the ULA report below (from 2012):

ULA - Integrated Vehicle Fluids A Combined Propulsion & Power System for Long Duration Spaceflight

Edit: Fixed link line break issue

Analytical Studies of the Integrated Vehicle Fluids (IVF) Technology from NTRS (2017):

Numerical Modeling of an Integrated Vehicle Fluids System Loop for Pressurizing a Cryogenic Tank

The mature technology integration with the upper stage, 6 years later (2018):

ULA - Advanced Cryogenic Evolved Stage

Starship would simply be a much more powerful version of this concept:

CREATING A SPACETUG FOR SPACE EXPLORATION BY MODIFYING THE ULA COMMON CENTAUR UPPER STAGE

Crap all over ULA if you must, but they still have people working there with excellent ideas. Whether or not management takes eons to use them is a different story. When you're aboard Starship, you're sitting inside the world's largest / fastest flying gas tank. It would be great to have much smaller engines onboard to use some of that during orbital operations. The solar panels are absolutely required for the transit to Mars, but are best kept protected while zipping through that shooting gallery we call Low Earth Orbit.

IIRC, Astronaut Sunita Williams has quite a bit of experience with fluid flow from experimentation aboard ISS. Someone should probably talk to her, given how many different experiments she carried out with fluid flow in a micro gravity environment.

Anyway, I think Robert's idea, in conjunction with ULA's idea, has merit to it. PTFE can be gas permeable, fluid impermeable, and it retains some flexibility down to -200C from actual testing with various cryogenic liquids. Perhaps some kind of novel collapsing structure is required, but this is doable. Maybe we can use a giant syringe technique with a thin PTFE seal against the sides of the inner tank. Note that I did not say that any of this is simple or easy, merely doable.

Last edited by kbd512 (2021-08-13 11:10:06)

Offline

#25 2021-08-13 05:42:28

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 17,167

Re: Tim Dodd and Elon Musk tour and interview Pt. 3

For kbd512 re #24

SearchTerm:Syringe Giant - on orbit refueling tanker concept

OF1939 - Your contribution of using one of these carbon based materials as a "piston ring seal" is noted by readers.

Because some of the SpaceX engineering team ** must ** be working hard on preparing for the tanker versions of Starship, ** and ** the "Fuel Depot" version, we are being prepared by these discussions for whatever surprise SpaceX has in store for the global audience. I think it is highly unlikely anyone from SpaceX pays any attention to this forum, or would admit it if they did, but ** we ** can celebrate which ever vision comes closest to the actual design that ends up in LEO.

(th)

Offline