New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2017-01-05 19:57:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

100 colonist production greenhouse

Lets for a moment think ahead into the future when we can do this..is ..for Lake Matthew Team - Cole's and other big dreamers that we have here that have adapted to thinking smaller or small to mini or nano.

Let the topic which states a case that we are able to land such a vehicle with nuclear power plants for power and able to build a substantial size greenhouse for food production for the 100 colonists that now exist on Mars.

This would be what Musk is thinking of build for such a scale for transport of 100 colonist to the surface of Mars.

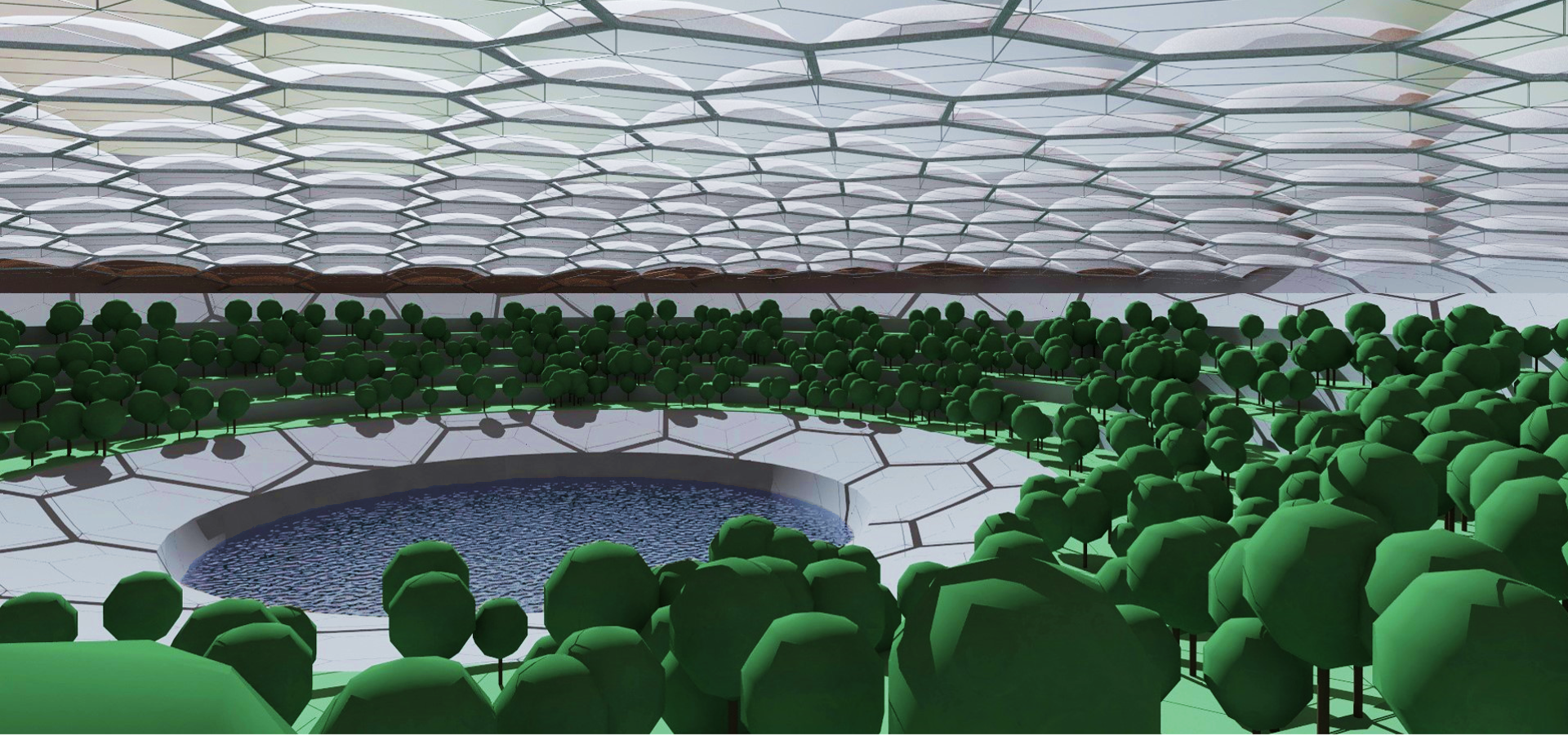

of which the greenhouse would take on this appearance.

LMT 300-m water-roof dome is notionally a modular titanium polygon / ETFE foil cushion structure. That structure (including anchoring system) comes in around 0.1 kg/m3.

Lake Matthew Team has a larger, self-sufficient greenhouse in mind, for that same first mission.

Habitat rough geometry, as enabled by Lake Matthew micro-environment. Subaqueous dome, 300m scale.

The martian surface presents saltation abrasion, hard UV, electrical discharge, corrosive salts and an uncertain flux of cm-scale iron meteorite bullets. Maybe you've accounted for these and other problems, but you'd want to be sure your greenhouse could survive them.

Offline

Like button can go here

#2 2017-01-05 19:59:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

I just completed another calculation, and we definitely need to include a floor. Pressurization of my structure would lift it off the deck in a heartbeat. I'm now including an additional floor area of 6963.6 meters^2, of a substantially heavier polymer coated Kevlar fabric. I'm guessing an 12 kg per meter^2 weight. Add 83,562 kg to my initial weight of the structure; this is minus and airlocks or support equipment (sprinklers, LED lighting, etc.). I believe there is also a discussion of the materials used on another thread? Mainly, we need a transparent south facing "window,' which can only be of a polymer film.

Bullet Time

RobertDyck wrote:A greenhouse must be transparent. I suggest PCTFE film, sold under the brand name Clarus, made by Honneywell. It's a fluoropolymer film.

Cool. Clarus is a great cryogenic polymer.

I see that PCTFE is used in coatings and containers, but I haven't seen it used as a suspended architectural fabric. Can you help locate examples? Or is there some limitation of PCTFE that makes ETFE preferable for

greenhouse architecture?RobertDyck wrote:Note: micrometeorites don't reach Mars surface. Regular meteorites will, but micrometeoroids burn up in Mars atmosphere. The burn up about 30km above the surface. On Earth they burn up about 100km above the surface. How deep into the atmosphere depends how large the meteoroid. So an inflatable habitat on Mars doesn't need the micrometeoroid shield of BEAM.

Lake Matthew Team - Cole wrote:Right, but micrometeorites scale only to 2 mm. I was focused on the cm-scale iron meteorites, which do penetrate the atmosphere and impact at the speed of... well, of bullets. That flux is uncertain at present. Greenhouse "bullet protection" is needed unless/until the bullet flux is found to be too slight to worry about.

Offline

Like button can go here

#3 2017-01-05 20:04:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Max Yield

Oldfart1939 wrote:What we should be concentrating on for crops is a set of products which have very short times from planting to maturity, combined with maximum caloric and vitamin output. There are lots of books about farming for survival that indicate the most efficient crops for the colony situation. Turnips are a quick crop. Root crops can be co-planted alongside taller crops to make maximum use of the space available. Radishes, beets, and carrots are good sources of essential vitamins, in addition to providing taste variety. Swiss chard is a heavy producer, and is semi-perennial. The turnip greens are also a decent food. Look into short growing season hybrids developed for use in the northern tier of states and Canada. Vine squashes can be planted in conjunction with other crops too. Every square centimeter needs to be productive, both above ground and below ground. Add in sweet potatoes in place of white potatoes for variety and vitamin A production.

Sounds good. Given the expense and difficulty of constructing greenhouse space, superb crops are needed, with careful co-planting for efficient use of space, and many other tweaks for max yield.

Chard is good, yes. Turnips are yucky.

In one exercise I roughed out an intensive garden, augmented with prawn-and-tilapia aquaculture. Scale: 8 acres of garden, 1 acre of aquaculture. Location: 40 South. Lighting: 60% PPF light transmission, for 9 months of useful sunlight per Mars year, plus LEDs. LED supplement and extended growing seasons notionally match yields to terrestrial garden yields (with exception of wheat, per above).

In this scheme the garden and aquaculture produce roughly 210 million calories per Mars year: self-sufficiency for an initial crew of 100.

The plots: (link to full-res image)

I didn't attempt a Perfect Day / Thrive synthetic dairy plant in that scheme, because I can't quantify the plant's yield. I imagine it could boost calorie production significantly.

Can you recommend some other breakout crops or methods, to make big improvements in yield? E.g., some especially short-season (<60d) hybrids?

Offline

Like button can go here

#4 2017-01-05 20:05:49

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Wheat

RobertDyck wrote:Wheat yield in Canada is 3 tons per acre in Quebec...

Under optimal field conditions you can get over 6 tons per acre, but the greatest yield ever recorded was achieved in a NASA high-irradiance experiment. Bugbee and Salisbury 1988 got 20 tons per acre: enough wheat for 36,000 loaves.

That's 69 million calories from one harvest on one acre. I think that's the yield record for any crop species, and an attainable goal for a settlement attempting calorie self-sufficiency.

A notional greenhouse acre plot:

- 2000 wheat plants/m2

- summer sunlight + 6 MW power, 16 hr/sol, spectrum-optimized LEDs

- curtain-box (red mulch) surrounding plot, to maximize useful PPF and prevent eye damage

- PPF 200 mol/m2d (~4x typical terrestrial field)

Terraformer wrote:It's important to note that Wheat is a C3 crop, so yields are significantly limited by the availability of CO2. In a Martian greenhouse, that's not going to be the limiting factor.

Yes, and they noted that CO2 enrichment "makes a slightly higher maximum [photosynthetic] efficiency possible". They noted some other mods that might also boost yield beyond their own:

- raising planting density (e.g., from 2000 to 4000 plants/m2)

- optimizing hydroponic water potential and hydroponic root-zone environment

- balanced nutrient uptake

- longer photoperiod for increased nitrogen assimilation

- and of course, higher PPF. The published figures present yields that have not yet plateaued even at the highest experimental PPF (150 mol/m2d).See Fig. 8 for the growth rate that's "potentially achievable". Clearly there's room for improvement, and some methods for attempting improvement. And who knows, combining these methods with focused genetic engineering might lift growth rate beyond the rate that was potentially achievable back in 1988. 100 million calories per acre might not be possible, but it's not obviously impossible.

Offline

Like button can go here

#5 2017-01-05 20:06:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Milk Without Cows

RobertDyck wrote:The reason for transporting calves instead of adult cattle, is it reduce launch mass. But the first herd would have to be calves weaned from milk, because there won't be any milk for the first ones.

Actually, there's a workaround for milk. The Perfect Day animal-free dairy process is a traditional fermentation process, yeast on sugar, which seems suitable for a greenhouse. Its Buttercup GM yeast produces the milk proteins, then the process adds sugar and "plant fats, vitamins and minerals" for the final milk product.

Vitamins and minerals can be shipped as minor cargo. The sugar can be obtained very efficiently from beets. The "plant fats" can be merely monounsaturated fats from algae, such as Thrive Culinary Algae Oil. Given that algae is an efficient oil producer, the Thrive algae oil could be produced in greenhouse algae tanks, alongside the Perfect Day yeast fermentation tanks.

True dairy products, without cows. Very useful!

Estimation

It would be interesting to estimate the calorie production rate, in a greenhouse synthetic dairy-and-fat "cottage industry" plant. However I don't yet know enough about the Perfect Day and Thrive processes to attempt the estimate. Are there any useful manufacturing details in the public domain?

Offline

Like button can go here

#6 2017-01-05 20:07:18

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Ferment and Fertilizer

RobertDyck wrote:The key ingredient in cheese is casein. It's milk protein. If someone has made genetically modified yeast to produce it, then there are already processes to make every major type of cheese from it.

Right, that's what the Buttercup GM yeast does. Then once it outputs the casein protein, normal dairy processes make cheese and other tasty products.

I don't know Buttercup yield, the factor that determines viability for a small greenhouse plant. I'd expect yield to be excellent - after all, it's an optimized commercial GM fermentation process - but I don't have a number yet.

RobertDyck wrote:Minerals: humans can metabolize calcite as source of calcium...

...humans also require magnesium for bone.

We explored in situ production of calcium, magnesium and other nutrients as bulk fertilizer, at the NasaSpaceFlight forum. One tech that seemed to meet the need for calcium and magnesium fertilizer was the Calera CO2 sequestration process, aka ABLE: Alkalinity Based on Low Energy. It's a commercial process that efficiently extracts calcium and magnesium cations from basalt - a rock which is of course abundant on Mars.

Alternately, a Zero Liquid Discharge (ZLD) plant could also extract those cations from brine, as part of the standard ZLD precipitation sequence:

1. iron via oxidation & pH increase

2. magnesium via pH increase

3. calcium and phosphorous via pH decrease, then alkaline agent

4. potassium via temperature decrease

Additional potassium and phosphorus could be recovered from stalk-and-greens composting, which would also provide free heat for the Calera reactor.

Nitrate can also be produced efficiently in the greenhouse. As envisioned, a nitrogen gas-separation membrane is coupled to a small plasma nitrate production plant.

Other methods could be used of course, and you've broached some others in forum. I just note that these particular ISRU methods could likely produce, altogether and efficiently, over 90% of the fertilizer required for a hydroponic greenhouse. That's significant only because fertilizer tonnage would be very expensive if shipped as cargo, or else very hard-won if recovered through complex ECLSS waste reprocessing.

Offline

Like button can go here

#7 2017-01-05 20:08:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Flow

Oldfart1939 wrote:...a real "chemical engineering" type process flow sheet needs to be developed...

Would it make sense to start with a high-level ZLD water flow chart? Many of the greenhouse's essential products, starting with water itself, could be made efficiently by a ZLD plant. A water flow chart concisely relates the various ZLD solution inputs, outputs, devices and modes, with brief annotations and maybe color-coding. Example: Figure 3. Water Flow Chart.

Some of the ideas we've discussed at NMF have already been implemented commercially in ZLD plants. For example, perchlorate removal - so important to Mars regolith/brine treatment - is actually a well-known commercial process: insert an electrodialysis stack into the ZLD chain and the problem is solved. Adding each vital component to the ZLD water flow chart, where appropriate, could pull NMF ideas together, and in a form that's easily communicated.

After, something similar might be done for the gas/cryogenic plant, and perhaps the ECLSS plant (which might be too complex for more than a partial chart of the most vital ECLSS flows).

The life support items with in the habitat would have this recycling system in place but using a simular system as put forth for processing the water extracted from soil, regolith ice brime concentration would be the way to utilize this in making water for the greenhouse....

Oldfart1939 wrote:You're thinking about technology far beyond what the FirstMars pioneers will be using. The processing equipment you have envisioned will all come from Earth, or by Mars manufacture after the basics are covered.

ZLD is just water treatment. How would you expect the crews to treat raw freshwater or brine, anyway? It's a core task requiring efficient, reliable tech. ZLD seems appropriate.

And when you consider the fact that ZLD output gives a series of useful fertilizers, well, I don't know why you'd design a Mars greenhouse - even the first greenhouse - without it.

Offline

Like button can go here

#8 2017-01-05 20:10:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

ZLD

Oldfart1939 wrote:I'm not saying that it's not a good system. Just the amount of mass required seems to be excessive for the early efforts at colonization. Your system would be 2nd Generation technology.

? This little ZLD unit processes 24,000 liters per day. Fits on a flatbed.

You might consider the tech and its uses, before diving into those greenhouse process flows. Could save some time and trouble.

Sorry about having to move the post:

Lake Matthew Team - Cole wrote:SpaceNut wrote:...the power noted on page 2 is 1,835 kilowatts which will not be possible on a first mission...

That's cleaning 404 gallons per minute.

What flow rate are you imagining for the first mission? Maybe scale your ZLD power need accordingly.

That is a lot of water which will not be needed from what I can see on first missions as we do not have that much water going with a crew to even drink let alone shower with.....

Current life support unit that takes in sweat, humidity, urine ect...onboard the ISS

Oldfart1939 wrote:...that unit probably weighs in at something around 3 to 5 tons? The size and mass of such a unit is far beyond the early settlement's importation capacity to afford...

You realize a 4 ton cargo is less than 1% of an ITS payload, right?

For a mission-critical life-support system, np. Do at least get familiar with the tech.

Offline

Like button can go here

#9 2017-01-05 20:11:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Fertilizer Delivery

RobertDyck wrote:I had also argued for soil agriculture instead of hydroponics. The reason is hydroponics requires liquid nutrients. Where do those come from? Yes, hydroponics can produce more from a given crop area, but what does it take to produce those liquid nutrients?

Well, the methods of a previous post might help. For example, the notional plasma nitrate plant gives nitrate in solution. It should be a very energy-efficient way to make a liquid N fertilizer, far more efficient than ammonia and/or ammonium nitrate production, to best of my knowledge.

As for delivery:

One might attempt automated "garden printing". That is, one could install an automated pump-grid network on the ceiling, with a sprayer at each node. Each sprayer covers a garden sector. An IoT soil sensor is planted below each sprayer. When a sensor detects a soil imbalance, a custom fertilizer solution is calculated, measured out, and routed through the pump-grid, to the sprayer overhead.

Conceptually it's a bit like a stationary print head. CLICKETY-CLICKETY-PUMP-PUMP-PUMP. Liquid fertilizer delivered.

Scaling (e.g. Ca/Mg scaling) within the grid pipes could be a problem. One fix: deliver that fertilizer as dry pellets, perhaps taking a page from Amazon delivery and drone-dropping it. The drone circles the soil sensor while pouring pellets through its rotors. BRRRRRRRRRRRRRWHUP. Solid fertilizer delivered.

Re: substrate:

This gardening scheme assumes no appreciable nutrients in the planting substrate itself (for simplicity and safety). Therefore it's a hydroponic scheme, where the substrate is inert and ideally pH-neutral. One possible source of such a substrate would be rinsed sand, perhaps augmented with a little shredded compost matter for water retention.

Offline

Like button can go here

#10 2017-01-05 20:13:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Milliferanauts

Oldfart1939 wrote:Another species we need to consider introducing in each of these greenhouses is honey bees.

A keystone species, surely. And actually they adapt to spaceflight very well. (STS-41C beehive video at 8:00.)

In conclusion, the bees in the orbiter BEM fared quite well in outer space, managing by mission's end to adapt perfectly to microgravity. The crew noted in the log book that "...by Day 7, comb well developed, bees seemed to adapt to 0-g pretty well. No longer trying to fly against top of box. Many actually fly from place to place." This adaptation may indicate a certain "learning" capacity on the part of the bees.

Milliferanauts are ready when we are.

Has anyone here contemplated Elon Musk's proposal of bringing settlers to mars 100 at a batch, and the impact that has on supply side of things? Calorie counting aside, a normal person has a 2 % body weight daily food intake for weight maintenance, and 2.5 % to 4 % or more with heavy activity; i.e. doing farming or construction. Running some rough numbers, supplies from Earth will be a major source of food for the first 3 years after new arrivals begin consuming supplies. Taking the FAA guideline for the average passenger weight on an airliner, 170 pounds, that calculates to a minimum of 340 pounds per day for sedentary activity, or double that if they are all going to be engaged in construction or say an average of 500 pounds per day for an average set of activity levels. Before they arrive, I would expect there to be a 3 year supply of food on hand, which calculates to 547,500 pounds of food. Add in the base building advance party of maybe 20 to 50 workers, there's another supply/logistics problem of having 273,750 more pounds stockpiled. His interplanetary transport system is going to be busy bringing food, much more so than additional colonists. Some SERIOUS WORK needs to be accomplished before massive colonization begins. There's a distinct need for a serious agriculture base before overloading the system with more mouths.

As I mentioned in another post--an initial exploration party of 7 is ideal; enough hands to get something done, and not just wandering around doing science. Need to begin the agricultural experiments with a wide variety of test crops in a smallish greenhouse, and get some serious structures capable of shielding from Solar flares. Finding and developing a reliable water supply; bringing a small Nuclear reactor on line, etc. Other suggestions of using artificial light for agriculture are nicely discussed in Robert Zubrin's "Entering Space." Too high a power requirement!

Oldfart1939 wrote:Has anyone here contemplated Elon Musk's proposal of bringing settlers to mars 100 at a batch...? I would expect there to be a 3 year supply of food on hand, which calculates to 547,500 pounds of food. Add in the base building advance party of maybe 20 to 50 workers, there's another supply/logistics problem of having 273,750 more pounds stockpiled. His interplanetary transport system is going to be busy bringing food...

Well, 30 tons of MREs can get a 100-man crew through 500 days of greenhouse construction, assuming robotics/telerobotics do most of the heavy lifting. The boring menu would motivate the crew to get the greenhouse ice cream factory up and running asap.

Offline

Like button can go here

#11 2017-01-05 20:15:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Known Unknowns, Etc.

SpaceNut wrote:Another topic suggestion area for soil type and conditioning for agriculture:

Soil Manufacture on Mars

Sewage treatment

Building Soil with Salt Marshes

Building soil

Mars regolith analogThere are some very creative ideas in those threads. Focusing on soil, I find that many of the creative ideas for soil manufacture seem to introduce more unknowns than they remove. For example, the idea of blending waste streams into the soil could introduce unpredictable fluctuations in toxins, microbes, pH and nutrient loads. On Earth, soil microbes are diverse and abundant, and their metabolisms help the soil manage fluctuations. But on Mars, most of the beneficial soil microbes would be absent unless explicitly cultivated. Perhaps fluctuations could be managed by the greenhouse crew, but it would seem to be a worrisome job. It's just more unknowns.

Hydroponics removes unknowns by simplifying the soil down to an inert substrate, such as pH-neutral rinsed sand. In a greenhouse with ISRU fertilizer, sterile nutrients are added in a controlled manner, again removing unknowns. A microbiome isn't required and can be suppressed, to remove even more unknowns. For example, a plasma nitrate plant makes hydrogen peroxide as a byproduct. That hydrogen peroxide is added to the liquid nitrate fertilizer to kill off soil pathogens without harming the plants. (Conceivably this treatment could remove a further unknown: hypothetical Mars exo-pathogens. Microbes evolved under martian anoxic conditions really shouldn't like sudden peroxide oxygen baths.)

To my mind the removal of unknowns is a main reason to aim for a hydroponic greenhouse, one having no more organic matter in the substrate than may be necessary for water retention. A little cellulose could be adequate.

But am I missing something? Is there good reason to convert sand substrate into a soil that's rich in organics, microbes, worms, etc., in this unique circumstance?

RobertDyck wrote:Mars doesn't have sand.

Does have sand.

RobertDyck wrote:Hydroponics has more "unknowns" than soil.

Martian soil and dust contain some known toxins: perchlorates, chromium, silicate dust and gypsum dust come to mind. Other toxins may exist, but have yet to be isolated. Now, you can eliminate those known and unknown toxins, and eliminate soil variability generally, by using rinsed, inert sand as the substrate. That is, the hydroponic substrate.

But to your mind, does that simplification introduce more soil variability, toxins, or unknowns?

Oldfart1939 wrote:I have issues with the concept of using hydroponics. It's certainly possible for certain varieties of plants, but totally unfeasible for grain crops such as wheat, barley, oats, rye...etc. It's very difficult to harvest from hydroponic containers, at least in any quantity.

"Containers"? That's a misapprehension. The LMT scheme grows half-acre plots. No containers. It's only hydroponic because it uses inert bedding substrate. There's no obvious need for a complex soil. Or is there?

Managing Greenhouse pH with Nitrogenous Fertilizers

Oldfart1939 wrote:Another reason I mention the chickens is the benefit of chickensh*t, which is mostly composed of Uric Acid.

Urea is one of the first and easiest ECLSS extracts. Membrane separate, sterilize, done.

Both ECLSS urea and greenhouse plasma nitrate could be produced efficiently, using little electrical power. The urea could complement the nitrate: urea lowers soil pH, nitrate raises soil pH. As envisioned in practice: The IoT fertilizer software alters the urea/nitrate mixture for pH effect, and routes each mixture through the pump-grid "printer" to the plots, for easy pH balancing throughout the greenhouse.

They don't need the chicken uric acid.

Mass Matters?

SpaceNut wrote:What we still need to nail down is the mass for the soil trays plus what depth sizes as that's crop dependant, support structure for trays not at ground level, quantity of hydroponic tubing for solution delivery plus other parts...

I understand hydroponic substrates are commonly about 0.5 m deep. Crops with shallow roots might get 0.3 m. If the substrate is just sand, the mass is ISRU, and largely irrelevant.

Hydroponic tubing and widget mass adds up, but here again mass is only truly limiting if you're hauling it from Earth. Many plastics can be used for piping etc., so why not manufacture the hardware via ISRU plastic + injection molding? For example, if the methane plant produces excess methane, you might use that excess as feedstock for an AirCarbon PHA plastics plant. Alternately, you might make PE plastic more efficiently from a GM cyanobacterial plant.

Other options? An ISRU plastics industry would have many uses beyond hydroponics, and if fully developed it could knock very significant mass off the cargo flights. What are promising methods?

Offline

Like button can go here

#12 2017-01-05 20:51:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

I think the grand dream forgets that mars will be a little bit like the american old wild west area and while we do have the rovers and orbital observation being made there is so much still that we do not know for Mars and a safe long term colony to exist.

Space Colonies Will Start Out Like the Wild West, Grow Family-Friendly

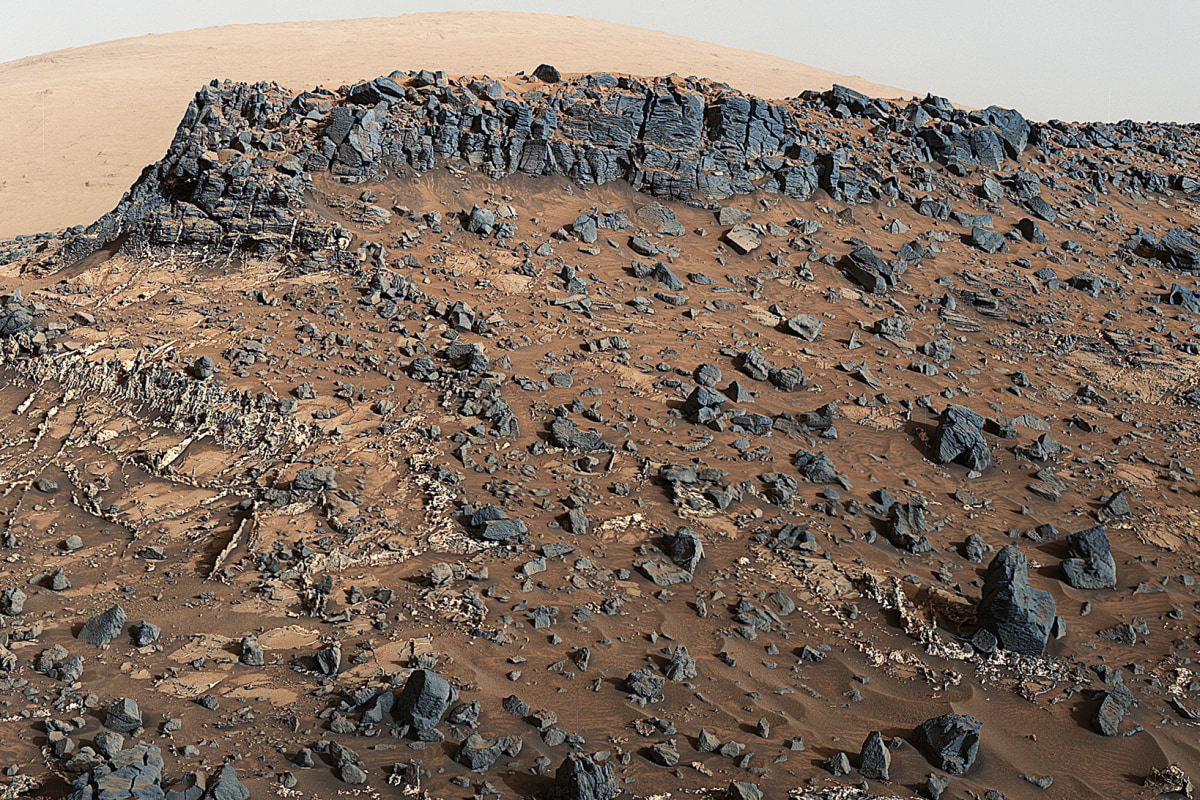

With much of mars looking more like this image:

Offline

Like button can go here

#13 2017-01-06 19:16:46

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: 100 colonist production greenhouse

I wouldn't bother with natural light greenhouses. Just use aerogel inflatable farm habs powered by PV panels and methane generators (methane being produced by PV power from Mars air and water). Alternatively use RTG generators.

This would allow you to have multiple crop tray layers within one hab. Maybe 4 or 5 layers. Focus mainly on short growing period crops with good all round nutrition. Bean shoots are good. With many plants you will be able to get several crops per (earth) year. You will need feed but after the colony is established the colony can look to creating its own soil or feed.

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#14 2017-01-06 20:44:56

- IanM

- Member

- From: Chicago

- Registered: 2015-12-14

- Posts: 276

Re: 100 colonist production greenhouse

I'll have to agree with Louis in using multiple tray layers in lieu of/addition to "conventional" in-regolith agriculture, if only to maximize efficiency of area cultivated until the colony is sufficiently developed.

The Earth is the cradle of the mind, but one cannot live in a cradle forever. -Paraphrased from Tsiolkovsky

Offline

Like button can go here

#15 2017-01-06 22:41:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

The other topics that we have it was Lake Matthew Team - Cole that said we were thinking to small, I do remember a time when that our discusion where much along the same lines as what Lake Matthew Team - Cole was thinking, one where we had unlimited power to spare with all the down mass to our hearts desire. Of which the members here did try to reign in the big idea of grandure in that a touch of reality that we are really still small with limits of cash and size for the dreams of Mars.

Mars is a rough and hard core world that will be a battle to gain the toehold and foothold for man to stay but much like all far off lands were we have courage and strength which will be by our side as we did set out with our limited resources and carve out a place for man to exist on another planet in our small little universe that we live in.

I like the RTG generated heat and constant power level but I know little about the amount of shielding that we need for a mars useage. It could be a simple as digging a hole and placing it into it to give the crew the shielding that will be needed from it.

Sure te crop trays can could be on the ground for the deepest of depth for those large root crops but for the more shallow growing which could use less than 6 " depth we will need to solve the mass issue for raising the trays in order to make use of the most of the greenhouse verticle space.

Offline

Like button can go here

#16 2017-01-06 22:56:36

- Lake Matthew Team - Cole

- Member

- Registered: 2016-12-21

- Posts: 119

- Website

Re: 100 colonist production greenhouse

...Lake Matthew Team - Cole that said we were thinking to small, I do remember a time when that our discusion where much along the same lines as what Lake Matthew Team - Cole was thinking, one where we had unlimited power to spare with all the down mass to our hearts desire. Of which the members here did try to reign in the big idea of grandure in that a touch of reality that we are really still small with limits of cash and size for the dreams of Mars.

Oh, I think the current situation is better than that. The ITS is coming together, and it will haul 450+ tons of cargo per flight. One ITS cargo is more than enough for the two Lake Matthew domes, totaling ~4,000,000 m3 of space. A second ITS cargo of solar panels can power the domes and much more, with max 45 MW electrical power. Why not anticipate the coming scale, and calculate accordingly?

Btw, did you see that Elon Musk was at Trump Tower again today? What do you think was on the agenda? ![]()

Last edited by Lake Matthew Team - Cole (2017-01-06 23:12:13)

Offline

Like button can go here

#17 2017-01-06 23:02:58

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,489

Re: 100 colonist production greenhouse

I haven't read that many older posts--going back months and years--but I saw in passing a suggestion that we build into a hillside for the greenhouse; that suggested to me building in terraced steps to maximize the light gain on the crops. Some crops are compatible with being grown on trellises, such as vine type peas and green beans, and I've seen cucumbers grown that way, too. Kiwi fruit needs trellises, as do grapes. The vertical pitches walls could have built-in trellises for maximum growing space utilization. I have also heard that vine squashes can be grown in that manner too.

Offline

Like button can go here

#18 2017-01-06 23:37:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Not sure that Elon Musk at Trump Tower would mean that he would want to be the head of Nasa thou.....

Offline

Like button can go here

#19 2017-01-07 05:19:06

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,360

- Website

Re: 100 colonist production greenhouse

I saw in passing a suggestion that we build into a hillside for the greenhouse

You might be referring to my post. If so, the Mars Homestead Project - Hillside Settlement was to be built into the side of a hill. However, the greenhouse was to be built on flat ground in front of the hill. I could post an image, the project had a professional architect and an artist. I was quite proud of the group. But that project assumed we would start with 12 settlers, then double to become 24. This discussion is about 100 colonists. And your idea of a greenhouse itself built into a hill has merit too.

Offline

Like button can go here

#20 2017-01-07 05:40:06

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: 100 colonist production greenhouse

Not sure that Elon Musk at Trump Tower would mean that he would want to be the head of Nasa thou.....

(reply in new thread - Apollo 8, redux - Human Missions)

Use what is abundant and build to last

Offline

Like button can go here

#21 2017-01-07 09:33:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Thanks for doing that....

Offline

Like button can go here

#22 2017-01-07 09:34:26

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,489

Re: 100 colonist production greenhouse

The idea of building into a hillside for the greenhouse would allow for use of vertical growth across the back walls, and allow more efficient utilization of the available sunlight. My late wife was a gardener and had every garden catalog imaginable. From our study of such, the vine type peas and green beans are much heavier bearers of crop than the bush varieties, in addition to allowing easier harvesting--no "stoop" labor. If the Bobcat-type front loader became available early-on, building this would require less glassed-in area if the soil face could be simply plasticized. This could also result in less heat loss during Martian nights, as well as becoming a decent passive solar heat capture. What we're looking for, in the case of a 100 colonist system is the most efficient utilization of every square meter of horizontal growing area, so why not "go vertical" as well?

Offline

Like button can go here

#23 2017-01-07 09:42:23

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

A terraced approach so long as a favorable allignment with the sun is possible....

Offline

Like button can go here

#24 2017-01-08 04:27:33

- elderflower

- Member

- Registered: 2016-06-19

- Posts: 1,262

Re: 100 colonist production greenhouse

Life support systems need to be split and need to produce storable surpluses. Something is likely to go wrong so each section should be totally independent, maybe even built some distance apart. You don't want it all going south at once.

Fallback is initially iron rations shipped from earth but at the 100 colonist level this would require a lot of transportation, which should be given over to equipment, machinery, structural materials, chemicals etc that cannot be produced locally. Number of launches will be limited. There is not likely to be spare capacity.

Offline

Like button can go here

#25 2017-01-08 10:02:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,280

Re: 100 colonist production greenhouse

Daily nutritional Iron could be as simple as swallowing a martian blueberry from what we have found for surface iron, just crush and powder it to allow for purification.....

So we can also have a seperate greenhouse that faces northernly for when in summer on a southern mountain wall....But I do agree that each terrace level should be sealable from the next for just in case emergencies of shell penetration.

The "100 colonist level this would require a lot of transportation," "to equipment, machinery, structural materials, chemicals" of which careful step by step planning would aid in lowering what we do need from earth as we can make these on mars if we send the right items first for making them insitu....

Items for insitu processing and manufacturing to make:

Glass

Plastic

Refined Metals collection(scoops,dozers ect),transport and processing

Metal forming shape(other than hammers) equipment

Machining,welding,lifting(crane) equipment

So can the same furnace or ovens for metal refining be used for glass?

Making the equipment useable for other needs will make what we need to send from earth's list smaller.

Offline

Like button can go here