New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

Pages: 1

#1 2015-12-29 21:27:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,433

Beetroot

Same as the Spirula topic but just with

8. Beetroot

Beetroot is a sweet, tasty and nutritious root crop, and its leaves make a filling, robust spinach-like vegetable. In theory, sugar beet would be heavier yielding, but of little use in space where processing factories are few.Kitchen processing:

Processing sugar beet into sugar water

Small scale farm, experimental plot 1 acre. This guy used a horse drawn plow, operated by hand. Then harvested with another plow, this time pulled by a small tractor. He used a high-end residential kitchen juicer to extract the juice (sugar water). He also built a small scale diffuser, and discusses results.

Small Scale Beet Sugar Production Methods

Offline

#2 2015-12-29 21:29:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,433

Re: Beetroot

Repost:

The second link ends by saying the sugar they made is not saleable. One argument he made was the pump is useful as animal feed. Many people who raise horses will not feed them pump from GMO sugar beets, and the only non-GMO pump is imported from Europe. That's expensive. So a farm that grows its own will produce quality pulp to feed their horses. However, if you can't sell the sugar you may as well feed the animals whole beets. He also said he made a small diffuser, which did work. Ok, so the keys to making quality sugar is to start with quality sugar beets, not fodder beets or some other variety. Yield per acre doesn't matter if the product cannot be sold. Or used on Mars by crew. The other key is to use a real diffuser, not a vegetable juicer. Industrial process to make sugar from beets:

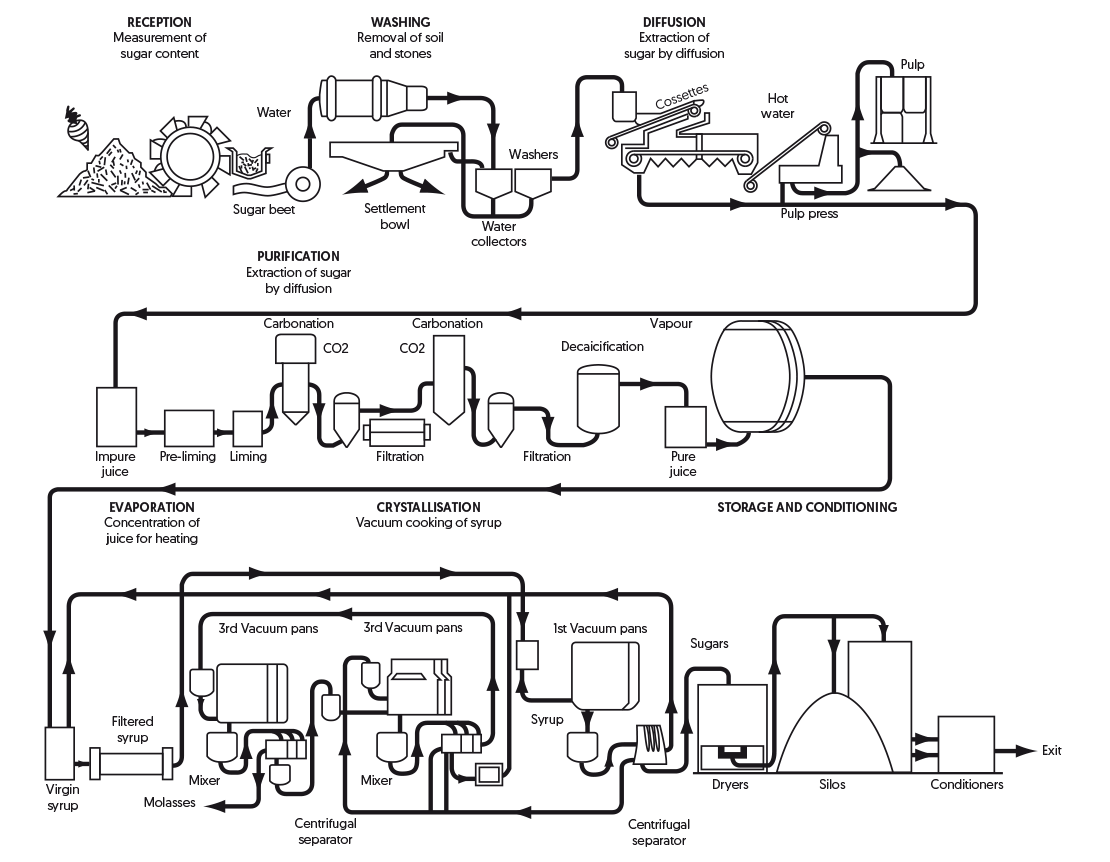

The diffuser uses sliced sugar beets, not crushed or juiced. It's then put in an auger, the auger pushes beet slices in one direction while hot water flows in the opposite direction. The result extracts sugar from the beets without too much "beet flavour". The flow diagram shows a "pulp press", which implies the juicer should have worked. Perhaps post pressing is important. That post processing invovles "liming" which means adding lime (calcium carbonate) to remove beet flavour. Precipitate then has to settle out. The flow diagram then lists "carbonating" which means adding CO2 gas under pressure. Note these post-processing steps are the same for cane sugar. The resulting syrup is then evaporated to make powdered sugar.

You can panic, but if you list all the steps to make bread from flour, the result looks just as complicated. A commercial bakery has a lot of specialized equipment, a household bread maker is a lot simpler. Similarly this process can be scaled down.

One trick:you can't boil syrup, that would burn the sugar, converting it into caramel if not just simply burnt. So syrup is dried under vacuum. That's because water boils a lower temperature at reduce pressure (partial vacuum). Candy makers use this all the time, it allows boiling hard sugar candy dry without burning. I'm sure industrial processes use fancy equipment, but there is a simpler way. Put your hot syrup in a sealed container, with a hose attached. A laboratory glass flask with a rubber stopper will do, but make sure you can get the sugar out when you're done. Instead of laboratory glassware, you could use a glass jug of some sort, and a rubber stopper with hole for a hose from your local store that sells supplies for homemade beer or wine. The hose is then connected to another container, again sealed pressure tight. You could use a laboratory round flask, or just another glass jug with another rubber stopper from the home-brew store. Heat the syrup so it's hot, but not boiling. If the syrup just came from extracting juice from sugar beets, it'll already been hot. Then hold snow against the second container. That will cause water vapour to condense. Be careful to ensure the container with syrup remains hot, while the second container is chilled with snow. The syrup will boil, even through it isn't hot enough to boil, at least not hot enough at normal air pressure. Condensing vapour in the second container will reduce pressure, that pressure reduction is enough to cause hot (but not boiling) water to, well, boil. Candy makers use this trick to boil syrup dry to make hard candy.

Offline

#3 2015-12-29 21:30:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,433

Re: Beetroot

I don't doubt it can be done in a small scale way with limited resource expenditure - but you could say that about a lot of food processing. Surely the early colonists are just going to be way too busy dealing with the essentials of life (secruing water supply, energy production, mining, construction, manufacture and basic food production) to get bogged down in processing relatively small amounts of food. Getting your sugars from fruits and vegetables (i.e. bound up with other nutrients) is known to be a healthy way of eating. Why not get them that way?

RobertDyck wrote:8. Beetroot

Beetroot is a sweet, tasty and nutritious root crop, and its leaves make a filling, robust spinach-like vegetable. In theory, sugar beet would be heavier yielding, but of little use in space where processing factories are few.Kitchen processing:

Processing sugar beet into sugar water

Small scale farm, experimental plot 1 acre. This guy used a horse drawn plow, operated by hand. Then harvested with another plow, this time pulled by a small tractor. He used a high-end residential kitchen juicer to extract the juice (sugar water). He also built a small scale diffuser, and discusses results.

Small Scale Beet Sugar Production Methods

Offline

#4 2015-12-29 21:34:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,433

Re: Beetroot

Some quick links :

http://www.slu.se/Documents/externwebbe … ntonio.pdf

MAXIMUM GROWTH RATE OF SUGAR BEET AS A RESULT OF NUTRIENT SUPPLY, pH AND OTHER ENVIRONMENTAL FACTORS

http://www.gardeningpatch.com/vegetable … -beetroot/

advice on how to grow Beetroot

http://assbt-proceedings.org/ASSBT1946P … rbeets.pdf

Effect of Temperature Upon the Growth Rate of Sugar Beets

http://ucce.ucdavis.edu/files/repositor … -71514.pdf

Sugar Beet Growth Research all factors affecting growth of plants now subject to individual study in controlled environment laboratory Albert Ulrich

Offline

#5 2015-12-30 22:16:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,433

Re: Beetroot

Here is the information to add to our knowledge base for Mars....

Brown Rice and Beet Burger Recipe

presentation goes along way....

Total Hands-On Time: 20 min , Yield: 6 servings

This Brown Rice and Beet Burger Recipe uses a red wine vinegar to bring out special flavor notes.

Ingredients:

• 3 medium beets, scrubbed clean, ends trimmed

• 4 tablespoons olive oil

• 1 red onion, diced

• 1/2 teaspoon salt

• 1 tablespoon red wine vinegar

• 1-1/2 cups cooked black or red beans 1 cup cooked brown rice

• 2 tablespoons chopped fresh parsley

• freshly ground black pepperInstructions:

1. Using the large holes of a box grater or the grater blade of your food processor, grate the beets. (It’s not necessary to peel them first.)2. In a large, lidded sauté pan, heat 2 tablespoons of the oil over medium heat. Add the onion and cook until it softens and begins to look translucent, 6 to 8 minutes. Add the beets and salt and toss to combine. Cover and cook for 10 to 12 minutes, until the beets are completely softened. Add the vinegar, toss to combine, and scrape up the browned bits from the pan with a wooden spoon. Set aside to cool slightly.

3. In a mixing bowl, coarsely mash the beans with a potato masher or fork. Fold in the beet mixture, the rice, parsley, and black pepper to taste. Adjust seasonings. Shape into six patties, flattening to a 1/2 inch thickness.

4. In a sauté pan, heat the remaining 2 tablespoons oil over high heat. Add the patties, in batches if necessary to avoid crowding. They should sizzle—this creates a nice crust. Cook for 1 minute. Reduce the heat to medium and cook for 2 or 3 minutes. Carefully flip the burgers and cook until browned and firm, 4 to 5 minutes longer.

We may not all have a green thumb so we will need all the help we can get.

All About Growing Beets

Types to Try

Red table beets produce edible greens in 35 days, followed by round or cylindrical roots a month later. Leaves from most red beets have red stems and leaf veins similar to red-leafed chard varieties.White, orange and golden beets are prized for their mild, nutty flavor. Because they don’t bleed red juice, these beets are best for roasting with other vegetables.

Storage beets are table beet varieties that excel when grown for fall harvest followed by winter storage in your refrigerator or root cellar.

Mangel beets, often called forage beets or mangel-wurzel beets, grow huge roots weighing from 5 to 20 pounds each that can be used as livestock fodder in winter.

These root vegetables are packed full of beneficial nutrients. They are high in fiber, for one, which is needed for healthy digestion, cholesterol control, blood sugar stabilization, and more.

Beets are also rich in a variety of antioxidants like flavonoids, carotenoids, and phenolic acids, which help fight oxidative damage and prevent various diseases. They contain betalains, which are responsible for red-violet pigmentation, and which have high antioxidant and anti-inflammatory qualities

Simple Beet and Balsamic Salad

3 medium to large beets

1 small onion, thinly sliced

4 to 5 large leafs of basil (or more)

2 tablespoons balsamic vinegar

2 tablespoons red wine vinegar

6 tablespoons extra virgin olive oil

Freshly ground pepper and sea salt

Steam the whole beets until fork tender. When cool enough to handle, scrape off the skins or peel with a knife. (I did this over a layer of paper towels to cut down on the mess.) Julienne the beets and place in a mixing bowl. Add the onion and basil.

In a small bowl, whisk together the vinegars and olive oil, and season with salt and pepper. Pour over the beets and toss to coat. Refrigerate for 30 minutes or longer before serving.

Offline

Pages: 1