New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-01-07 18:26:44

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Pure Carbon burned with pure Oxygen Analysis

The purpose of this topic is to give an idea proposed by kbd512 in early 2025 a chance to receive consideration.

I am hoping this topic will attract contributions that are entirely composed of facts. This is NOT a topic for speculation. We have hundreds if not thousands of topics where speculation is welcome and enthusiastically supported by NewMars members.

In offering this topic, I note that (to the best of my knowledge) there exists on Earth NO example of a production combustion system that runs on pure carbon. The reasons are numerous, but one of the chief reasons is that carbon comes bundled with hydrogen on Earth, thanks to photosynthesis carried out over millions of years. In late 2024 and early 2025, kbd512 proposed what looks like an attractive chemical fuel combination for mobile equipment on Venus. Pure carbon and pure oxygen can be made from CO2, and there is an abundance of CO2 on Venus.

In a quick scan of the Internet offerings regarding delivery of carbon in a carrier such as water, I learned that this idea has been explored in the past, but as nearly as I can tell, none of the early enthusiasm persists into the present time.

The issue at hand (as I understand it) is the difficulty of moving pure carbon into a combustion chamber and performing efficient combustion.

This topic is offered for NewMars members who might like to dive deep into this problem to see if there might be a solution.

For SpaceNut... here are the existing topics that contain the word Carbon in the title. I did not see a good match for this new topic.

Forum Replies Last post

Spring Energy Storage Carbon Nanotube Competitive Safe by tahanson43206

Science, Technology, and Astronomy 1 2024-08-04 22:07:43 by tahanson43206Fuel Depot on Phobos - Ship Carbon and Water - Make methane and LOX by tahanson43206

Projects 1 2024-06-18 08:08:56 by tahanson43206Ocean Desert Fertilization Methods, Food, Fuel, and Carbon Abatement by Void

Life support systems 4 2024-03-19 12:24:58 by VoidCarbon and Carbon Monoxide by JoshNH4H

Life support systems 24 2024-03-10 13:57:57 by SpaceNutCarbon Monoxide - a way to power Mars? by louis [ 1 2 3 4 ]

Human missions 80 2023-11-18 19:56:34 by SpaceNutCarbon and Water Shipped as Reactants >> Methane and Oxygen by tahanson43206 [ 1 2 ]

Interplanetary transportation 42 2023-11-18 14:20:25 by tahanson43206Carbon Capture on Earth may apply to Mars by tahanson43206

Science, Technology, and Astronomy 11 2023-11-17 20:55:46 by SpaceNutGas Turbine uses Hot Carbon Dioxide - Ideal for Mars by tahanson43206

Science, Technology, and Astronomy 10 2023-09-07 14:46:45 by tahanson43206eFuel Plants - E-Fuel - Generic - Synthetic carbon based fuel by tahanson43206

Science, Technology, and Astronomy 4 2023-05-05 22:00:32 by SpaceNutPlastic Car Automobile Truck Diamond Carbon No Metals by tahanson43206

Science, Technology, and Astronomy 12 2023-04-11 23:18:34 by SpaceNutCarbon Nanotubes by tahanson43206

Science, Technology, and Astronomy 2 2022-04-12 22:04:11 by SpaceNutA Carbon Capture method which may generate power. Mericulture too. by Void

Science, Technology, and Astronomy 1 2022-02-02 12:55:26 by tahanson43206A happy Carbon loving future. by Void [ 1 2 3 ]

Not So Free Chat 59 2020-04-05 22:07:13 by SpaceNutBurning silane in carbon dioxide to give carbon monoxide? by knightdepaix

Planetary transportation 2 2018-12-27 21:58:34 by SpaceNutResearchers invent novel catalyst to convert carbon dioxide by Scott Beach

Science, Technology, and Astronomy 3 2017-05-05 21:27:18 by Dave_DucaSpace Carbon Dioxide Cloud to Reduce Global Warming by Dook

Science, Technology, and Astronomy 7

(th)

Offline

Like button can go here

#2 2025-01-07 18:31:41

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Re: Pure Carbon burned with pure Oxygen Analysis

This post is reserved for an index to what I hope will be substantial and useful contributions by NewMars members.

The idea of feeding pure carbon into a combusion chamber with pure oxygen seems (to me at least) attractive in a number of respects. However, it appears that practical execution of this simple idea has never been attempted on Earth, or if it has, the records are going to take a bit of effort to find.

(th)

Offline

Like button can go here

#3 2025-01-07 19:36:20

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Re: Pure Carbon burned with pure Oxygen Analysis

Soot

Soot is composed largely of unburned carbon. A quick Google for soot generated a great number of citations.

Humans have been dealing with soot for a long time.

kbd512's idea would appear to be practical in the sense that citations about soot seem to agree that it can be burned off.

My knowledge of computer printers is limited, and consists primarily of changing printer cartridges.

Those cartridges are filled with finely ground carbon, and that carbon is (apparently) drawn to a metal drum by electrostatic charge where letters are called for by the print plan. It occurs to me that a film of carbon powder might be delivered to a combustion chamber using a variation of this method.

(th)

Offline

Like button can go here

#4 2025-01-07 21:00:52

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Re: Pure Carbon burned with pure Oxygen Analysis

I asked ChatGPT4o to "think" about the Venus problem, and it came back with several ideas I had not considered:

Project Overview: Carbon and Oxygen Combustion on Venus

Objective: To explore the feasibility of using the abundant CO₂ in Venus’ atmosphere to produce fuel and oxidizer for machinery operating on the planet, focusing on the controlled delivery of pure carbon to a combustion chamber.

Key Challenges

1. Environmental Conditions on Venus

Extreme surface temperatures (~475°C / 900°F).

High atmospheric pressure (~92 Earth atmospheres).

Corrosive atmospheric components (e.g., sulfuric acid traces).

2. Controlled Carbon DeliveryEnsuring precise and reliable feeding of carbon to the combustion chamber under Venusian conditions.

Overcoming potential issues like particle clumping, material degradation, and mechanical failure.Proposed Carbon Delivery Methods

1. Electrostatic Handling of Carbon Powder Principle: Use electrostatic charges to attract and transport carbon particles, similar to a laser printer.

Challenges: Electrostatic behavior may be affected by Venus' dense, high-temperature atmosphere.2. Auger Screw Feeder Principle: Use a rotating screw to transport carbon powder or pellets.

Advantages: Reliable and mechanically simple.

Challenges: Requires materials resistant to Venusian conditions.3. Fluidized Bed Feeding Principle: Suspend carbon particles in a gas flow for smooth delivery.

Advantages: Minimizes clumping and enables precise feeding.

Challenges: Optimizing gas flow for Venus' environment.4. Pelletized Carbon Delivery Principle: Use compact carbon pellets fed by a hopper or conveyor system.

Advantages: Robust against clumping and high-pressure conditions.

Challenges: Manufacturing pellets on Venus.5. Magnetic Carbon Handling Principle: Manipulate magnetic carbon particles using magnetic fields.

Challenges: Ensuring magnetic properties and handling high temperatures.6. Mechanical Vibratory Feeder Principle: Use vibrations to deliver carbon particles or pellets in a steady flow.

Advantages: Minimal moving parts in contact with material.

Challenges: Adapting for Venus’ gravity and environmental conditions.Next Steps

1. Develop Prototypes on Earth

Test various carbon delivery systems under controlled conditions.

Simulate Venus-like environments where possible.

2. Material SelectionInvestigate high-temperature, corrosion-resistant materials (e.g., ceramics, tungsten).

3. Model DynamicsCreate computational models for carbon particle behavior and system reliability.

4. Implement Feedback MechanismsUse sensors to monitor carbon flow rates and prevent blockages.

Conclusion

This project aims to address a critical component of enabling machinery to operate on Venus by delivering pure carbon reliably to a combustion chamber. With innovative engineering solutions and careful consideration of Venus' unique challenges, this idea could open new possibilities for exploring and utilizing the planet’s resources.

(th)

Offline

Like button can go here

#5 2025-01-08 07:24:51

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Re: Pure Carbon burned with pure Oxygen Analysis

I useful addition to this topic would be a comparison of the pure carbon/oxygen vision with more common combinations with hydrogen on Earth.

Comparison might include (for a given mass of fuel (such as one kilogram))

Energy stored

Temperature of combustion

Storage form (solid vs liquid)

Method(s) of energy recovery as useful work

Related factors might include:

Energy required to prepare a particular combination

Technology/procedures required to prepare a particular combination

Advantages of a particular combination

Most if not all of the studies have been done, so this collection might include links and brief summary text

(th)

Offline

Like button can go here

#6 2025-01-08 13:18:44

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,292

Re: Pure Carbon burned with pure Oxygen Analysis

The energy density of pure carbon is respectable, at 32.7MJ/kg. That is about 2/3rd of diesel.

https://en.m.wikipedia.org/wiki/Energy_density

The problem is that carbon is a solid. It cannot be pumped in the way that liquids and gases can. Fuel could be fed into a boiler using conveyors. Alternatively, the carbon could be stored in a gassification oven. The fuel would be heated to 500°C and controlled quantities of oxygen fed into the chamber. The oxygen will react with the carbon to produce CO, which can then be burned in an ICE.

Last edited by Calliban (2025-01-08 13:25:36)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#7 2025-01-08 14:47:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,051

Re: Pure Carbon burned with pure Oxygen Analysis

For Calliban re #6

Thank you for adding to this topic! I assume you do not have time to read everything kbd512 writes. He has proposed Carbon/Oxygen as the fuel/oxidizer for mining equipment on Venus. The carbon would be obtained from CO2 in the atmosphere of Venus. You have addressed one possible way of delivering carbon into the combustion chamber of a machine on Venus. However, I think an augur might be a better bet for a small tractor sized machine. A conveyor belt might be a good choice for a larger fixed installation, such as a rock crusher.

I don't know which is better ... burning to CO or all the way to CO2. I'm hoping you and kbd512 can figure that out.

Also, I ** think ** that for Venus, kbd512 is contemplating an SCO2 turbine. I can't help you with that. You would have to allocate about a week to read all of Kbd512's posts about that. (or you could just ask him for a concise summary).

In any case, thanks for giving this topic an interesting addition.

(th)

Offline

Like button can go here

#8 2025-01-08 22:23:47

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,467

Re: Pure Carbon burned with pure Oxygen Analysis

Calliban,

Is there any reason why fine Carbon powder cannot be fed through a spray nozzle with CO2 and O2?

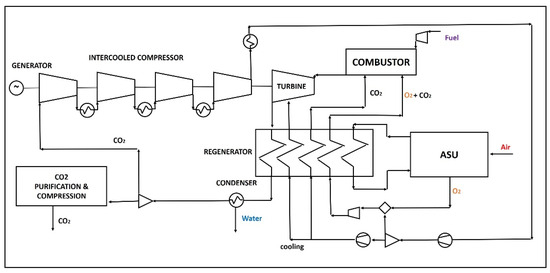

Every powder coating operation uses compressed air to coat parts with fine powder. That's essentially what they're doing in the Allam-Fetvedt cycle sCO2 power plants using coal dust and concentrated O2. 95% of what gets fed into the burner is hot CO2, mixed with a little bit of coal dust and a little bit of nearly-pure O2 from an air separator unit powered by the low temperature side. Reliably supporting combustion has not proven to be particularly problematic, although the pressures and temperatures involved are quite high. Heat from combustion is recycled into both the combustor can and the tubes containing the sCO2, just before being fed into the first stages of the power turbine.

Allam Cycle Presentation:

ADVANCED COAL-FIRED POWER CYCLES

Allam-Fetvedt Cycle Presentation using sCO2:

ALLAM-FETVEDT CYCLE

The Allam-Fetvedt is the novel supercritical carbon dioxide (sCO2) power cycle which is used to reduce emissions. It utilizes a highly recuperated cycle with oxy-combustion of carbon fuels and a high-pressure supercritical CO2 working fluid to absorb all emissions by design. Liquid water and a stream of ultra-pure, pipeline-ready CO2 are the sole by-products.

We're building a 300MWe Allam-Fetvedt cycle power plant here in Texas. Above presentation includes TRL diagram. The fuels of choice are natural gas and coal-water slurry, IIRC.

Allam Cycle Zero Emission Coal Power

Cycle Diagram:

Possible Co-Product Synthesis (Fertilizers) with Allam Cycle:

Offline

Like button can go here

#9 2025-01-08 22:47:27

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,467

Re: Pure Carbon burned with pure Oxygen Analysis

From the document pertaining to what 8 Rivers Capital is financing:

NET Power is supporting multiple 300MWe facilities that are under development for commissioning in the early 2020s. These commercial natural gas facilities will overcome any remaining scale-up challenges for the coal system by demonstrating the full-scale cycle and the 550MWth turbine, same as will be used by the coal Allam Cycle.

This seems to be the fundamental difference between the Allam Cycle and a simpler RCBC power plant:

1. Fuel compressor delivering gas to the combustor at the elevated turbine inlet pressure, an order of magnitude higher than conventional, air-breathing combustion turbines

2. ASU with O2 compression. O2 is pre-mixed with a portion of the recycle CO2 before being compressed and delivered to the combustor as oxidant. Industrial quality oxygen at 99.5% purity is specified to minimize the introduction of inerts. This requires, in addition to the normal O2-N2 separation, an added O2-Ar separation, at incrementally higher capital and auxiliary power cost. Achieving this level of purity is well within the capability and experience of existing ASU providers.

3. Heat-recovery system to collect and provide miscellaneous thermal resources, including ASU compressor heat, to the working fluid.

It's more complex, involves a lot more plumbing and recuperation, but it's also about 60% thermally efficient after all plant losses are accounted for. Very few other power cycles can make that same claim. There might be certain portions of the cycles that are very thermally efficient, but overall steam is a poor working fluid choice, however familiar we might be with using it.

My hope is that with additional operational experience, we can start using molten metals as our working fluids.

Offline

Like button can go here