New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 Re: Meta New Mars » kbd512 Postings » 2025-07-11 13:14:58

Let's evaluate how using the densest form of Carbon, Carbon Black Powder (CBP), does or does not "work" for rocketry:

The F9B5 booster contains 123,500kg of RP1. We want to evaluate how much CBP is required to deliver equivalent thermal energy, to "know" if CBP's spectacular density of 1,700kg/m^3 can reduce total propellant volume and thus vehicle dry mass.

123,500kg of RP1 * 43MJ/kg = 5,310,500MJ

123,500kg of RP1 / 810kg/m^3 = 152.469m^3 RP1 volume

123,500kg of RP1 / 867kg/m^3 = 142.445m^3 Densified RP1 volume

5,310,500MJ / 32.8MJ/kg (CBP) = 161,905kg of CBP fuel (31% more mass than RP1 for equal thermal output)

161,905kg CBP / 1,700kg/m^3 of CBP = 95.238m^3

161,905kg * 2.67kg of LOX = 432,286.35kg of LOX

432,286.35kg (LOX) + 161,905kg (CBP) = 594,191.35kg of total propellant mass

432,286.35kg LOX / 1,141kg/m^3 = 378.866m^3 LOX volume

432,286.35kg LOX / 1,262kg/m^3 = 342.541m^3 Densified LOX volume

95.238m^3 + 342.541m^3 = 437.779m^3 total propellant volume (CBP Isp is clearly too low, so both mass and volume increases)

Here we can see the effect of low gravimetric energy density on low-Isp high volumetric density fuels. The density of CBP is fantastic, but 32.8MJ/kg is insufficient gravimetric energy density to result in a propellant tank volume reduction for a rocket powered vehicle. The Isp is so low that both propellant mass and volume have increased, as compared with RP1, which means CBP is of no practical use for a SSTO, nor TSTO for that matter. CBP will produce a spectacular amount of thrust as a strap-on hybrid solid rocket booster, much like APCP and HTPB, but the quantity of LOX required is so great that the net effect is to increase the propellant tank volume and thus vehicle dry mass to achieve a given level of payload performance.

Solids are frequently used in conjunction with LH2 to provide that critical but missing thrust at liftoff to "get the rocket moving smartly downrange", as GW puts it. However, solids of the size useful for orbital launches are neither cheap nor rapidly reusable. If the motor casing refurbishment and propellant refill was cheap enough, then we'd figure out an approach for reusability, such as having a stock of motor casings on-hand. Unfortunately, large solids are expensive and time consuming to manufacture, with the propellant poured in multiple batches, so they're more useful for infrequent exploration missions and military weapons than routine orbital launch with a high launch cadence. If CBP was very cheap / easy to produce, and was far less dangerous to transport without an oxidizer mixed into the fuel, then it might have wider utility.

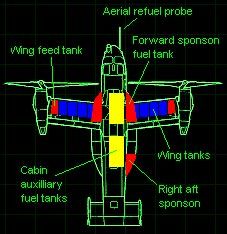

Oddly enough, a German rocket company is working on a hybrid solid rocket uses CBP mixed into Paraffin wax to control burn rate and prevent melting, with LOX as the oxidizer, giving them a solid rocket with a throttle and Isp almost identical to RP1. It's technically interesting because a LOX/LH2 core stage could hold additional LOX to feed the solid boosters, which are essentially inert for transportation purposes and very compact since they lack the oxidizer. LOX is more effective than traditional toxic oxidizers used in solids, such as Ammonium Perchlorate, meaning it increases the Isp of the solid well above what is possible with APCP and HTPB. It would be possible to "ring" a core stage with what are essentially "fuel only" solid rocket boosters, and then to increase the length / height of the core stage to hold more LOX. You could put the LOX in a tank above the booster's fuel grain, but then it's more complex and difficult to recover, or more expensive to discard.

#52 Re: Single Stage To Orbit » SSTO » 2025-07-11 11:09:10

tahanson43206,

Total dry vehicle mass is everything in SSTO world, because it dictates useful payload mass. Using LH2 hinges upon higher thrust-to-weight ratio LH2 fueled engines. The RS-25 and RS-68 engines we presently have are simply not good enough. The density of LH2 is so absurdly low that it increases the dry mass of the vehicle to intolerable levels. Something has to give. There's nothing that can be done to improve the low density of Hydrogen and therefore the mass of the propellant tanks, which represents the bulk of the vehicle dry mass. Either develop LH2 fueled engines that achieve 150:1 or higher TWR or LH2-fueled SSTOs are not practical. If the engines were dramatically lighter for the thrust they provided, then the increased total dry mass of the LH2-fueled option becomes tolerable again. At the end of the day, using LH2 is not materials or energy efficient. Alternatively, use air-breathing SSTOs to delete a healthy percentage of the LOX mass and volume.

I have already proven using simple math (my Total Impulse delivered per unit of total vehicle dry mass calculation for existing rockets that have flown to space many times) that a conventional all-LH2-fueled TSTO booster and upper stage possess a total vehicle dry mass significantly higher than a conventional all-RP1-fueled booster and upper stage, for the payload delivered. 1m^3 of LOX/RP1 delivers 3X greater payload to orbit than 1m^3 of LOX/LH2. This is not debatable. We have all the mass / volume / engine performance figures required to make that determination.

Using LH2, much like Lithium-ion batteries and photovoltaic panels, appears to be more of an ideological obsession than one deferential to incontrovertible energy density math. I think this explains why the Soviets / Russians stuck with RP1 and progressively improved engine performance. They seemed to understand that the most efficient rocket tends to be the one with the lowest dry mass for a given payload to orbit. They dabbled with LH2 and other more exotic propellants, same as America did, but there was no compelling engineering and cost reason to quit using RP1.

#53 Re: Not So Free Chat » Politics » 2025-07-11 10:54:00

President Trump's tariffs are intended to make it cheaper for American businesses to return manufacturing to America. All industrialized nations require robust domestic manufacturing bases. The end goal is to make America self-sufficient so that it does not need to import anything from other countries. If other nations are upset that America's government is now creating conditions favorable to American businesses manufacturing their products here in America, for consumption by Americans, that's their problem.

Rather than treating this as an opportunity to make themselves self-sufficient as well, other nations like Canada are treating it as a pissing contest with President Trump. President Biden's administration was busily implementing the same policies for microchips, munitions to feed the war in Ukraine, and other tech items we feel we need. RobertDyck is upset that Canada will ultimately need to become self-sufficient, even though Canada has the energy, raw materials, education, manufacturing base, and technology to make Canada broadly self-sufficient. It will cost more money to do, but at the end of the day Canadians will have an independent and self-sufficient nation that is uniquely Canadian and not dependent on remaining in the good graces of any other nation.

Maybe Canadians don't think that will ultimately benefit Canada, but I would like the counter-arguments for why it won't benefit Canada. I would also like those arguments from the standpoint of long-term generational prosperity- something that goes beyond the "here and now". A lot of problems have been artificially created by very short-term thinking.

America is now treating our military and economic alliances as, "Let's collaborate if all parties think they're getting fair value for whatever they contribute, or go our separate ways and remain as friends / colleagues if we don't think any particular deal is mutually beneficial."

As an American, I don't want my own fellow Americans to continue to suffer through this systematic "siphoning off of accumulated wealth". I do not want Canadians to suffer, either. I have no bone to pick with Canada or Canadians. That said, my first and most important loyalty and duty is to my fellow Americans. I cannot control how people in other nations view America's imposition of tariffs on foreign-made products. Foreign nations have imposed tariffs on American products for many decades now. If it's good for the goose, then it's good for the gander.

If tariffs are "good / necessary" when Canada applies them to American-made products, then they cannot be "bad / pointless" when America applies them to Canadian-made products, by that very same logic. Regardless or moral valuation on trade policies, what we're presently doing is slowly but surely draining the wealth out of America. That process will inevitably end, so whatever benefits it brought to other nations will end as well.

#54 Re: Meta New Mars » RobertDyck Postings » 2025-07-11 09:59:28

tahanson43206,

In this moment, Canada has a chance to find new (reliable) trading partners.

China will reliably steal intellectual property, reliably attempt to undermine the government and government-civilian relationship of its trading partners, and reliably claim China owns the resources of other nations. That's about all the Chinese government will reliably do.

New residents do not necessarily share the values of the older ones.

This is why they should not be "new residents" to a nation they're seeking citizenship from, until they're ready to accept and share the values of the people they're assimilating into. If part of Mexican culture views learning to speak Spanish as mandatory to assimilation, but I go to Mexico to become a Mexican citizen while refusing to learn the language and respect local customs, the Mexican people are not the problem, I am. Were I to do something like that, it would be a betrayal of public trust in immigrants and an indicator that I never had any intention of becoming a true citizen of Mexico. If there were certain elements of the Mexican government assisting me with my attempt to subvert the Mexican national identity for my own purposes, which can never be moral if that's how I have attempted to change it, then it's a betrayal at an even more fundamental level- the government of a nation at war with its own people.

Establishing a dictatorship from the beginning would appear to be a winning strategy for some cultures.

Please tell me how well China's governance strategy has worked for them. Any system of governance that manages to kill more of its own people than all civilian deaths combined during WWII is a systemic failure in every sense of the word.

#55 Re: Meta New Mars » kbd512 Postings » 2025-07-10 15:08:55

The Rocket Labs Electron rocket is LOX/RP1 TSTO with propellant tanks made entirely from CFRP. It's successfully delivered payloads into orbit 64 times now. The turbopumps are electric and use Lithium-ion batteries to power them. Engine Isp is right up there with the best staged combustion engines, meaning 311s to 343s. I think we can say that it works now.

#56 Re: Meta New Mars » kbd512 Postings » 2025-07-10 14:40:16

tahanson43206,

The propellant tanks could be retained in-orbit to serve as the basis of a propellant depot, but only if all the rockets are taking payloads to the same orbit. Falcon 9 is a general purpose workhorse rocket. If all the payloads Falcon 9 delivers to orbit are going to different orbits, then you're not going to have them all in one place.

You want to "melt down" an engine made from RCC? Why not use it again as an engine?

Using RCC (2g/cm^3) serves two purposes, the first being to greatly reduce engine mass to a value about 1/4 that of stainless (8g/cm^3) or Nickel-Copper (8-9g/cm^3) alloys. The second is that it does not require regenerative cooling to survive the temperatures the engine generates. NASA has tested uncooled RCC engine nozzles burning LH2 / LCH4 / RP1 fuels. They coat the RCC nozzle with UHTCs to prevent oxidation at extreme temperatures. Melting them down is not easy. You need electrical power to do it. Think about it. RCC survives combustion temperatures of LH2 / LCH4 / RP1 fuels without cooling, doesn't melt or disintegrate, and survived multiple firings without refurbishment.

CFRP propellant tanks built strong enough to survive LH2 internal pressurization are also built strong enough to carry LOX and survive 3g accelerations. 52psi vs half that much for LOX and RP1 is an extreme amount of force.

52psi = 36,560kgf/m^3 (drastically more force per unit area than 3g acceleration or aero loads during ascent)

Lockheed-Martin's box-stiffened CFRP tank concept has a 634m^3 capacity, max design pressure of 46.2psi, and it weighed 6,573lbs / 2,981kg. Therefore, the proposed tank mass of 10,710kg is quite realistic as a stage mass (tanks, engine mounts, sensors), and probably gross overkill for 468m^3 of LOX/RP1 tank capacity. I'm talking about loading 518,400kg of propellant in total, and the load is definitely distributed over more than 14m^2, so the idea that this proposed tank somehow isn't strong enough is bunk. It's probably far stronger than it needs to be, yet still a minor fraction of the mass of the original TSTO F9B5 tank mass, less engines.

Sub-scale testing results with the 5.5m diameter tanks:

In other tests, the tank successfully maintained fuels at extremely low temperatures and operated at various pressures. Engineers filled the tank with almost 30,000 gallons of liquid hydrogen chilled to -423F, and repeatedly cycled the pressure between 20 to 53 pounds per square inch -- the pressure limit set for the tests.

30,000 gallons = 113.562m^3 (not too large, but not small, either)

3 different designs from the 3 major aerospace primes. All of them passed all tests.

#57 Re: Meta New Mars » kbd512 Postings » 2025-07-10 12:16:55

As the above comparison shows, our RP1 fueled TSTO is delivering 3X more payload mass per cubic meter of propellant volume, as compared to LH2.

Using the Silverbird Astronautics Launch Vehicle Performance Calculator:

Upgraded Staged Combustion Merlin-powered SSTO

Dry Mass: 17,088kg (40% lighter than Al-2195 tanks using CFRP; Merlin engine mass same as existing engines)

Propellant Mass: 518,400kg (same propellant mass as both stages of F9B5)

Thrust:5,913kN (same as Merlin-1D sea level thrust X9)

Isp: 324 seconds (Merlin-1D converted to staged combustion 360s * 0.9 for time-avg thrust output to orbit)

Launch Site: Cape Canaveral / KSC (USA)

Default Propellant Residuals?: Yes

Restartable Upper Stage?: No

Orbit: 185km by 185km, 45deg inclination

Estimated Payload: 10,654kg; 95% Confidence Interval: 5,704kg to 16,639kg

Why might we still want an expendable SSTO version of Falcon 9?

If we can figure out how to get the engines back, once on-orbit, CFRP tanks could be made 10% lighter than the mass estimate provided here for a single use. Total stage mass could be as little as 14,940kg, with 10,710kg being mostly CFRP. At $100/kg, if we figure on throwing away $1M per launch to discard the propellant tanks while recovering the engines, then I think we can live with that.

For this lighter single-use vehicle...

Estimated Payload: 12,802kg; 95% Confidence Interval: 7,852kg to 18,784kg

For RCC vs stainless and Nickel-Copper engines:

1,057.5kg (engines) + 10,710kg (propellant tanks) = 11,767.5kg dry stage mass

Estimated Payload: 15,970kg; 95% Confidence Interval: 11,023kg to 21,957kg

50% stronger T1200 fiber with CNT-infused resin vs IM7 fiber:

1,057.5kg (engines) + 6,426kg (propellant tanks) = 7,483.5kg dry stage mass

Estimated Payload: 20,254kg; 95% Confidence Interval: 15,310kg to 26,241kg

If we can make the tanks light enough, then at some point we give up on full reusability because it's cheaper to just discard the propellant tanks, collect the engines with a space tug, and return them to Earth using a HIAD. Alternatively, we accumulate some engines in space for use to propel ships to other destinations. Storing RP1 in space is relatively easy.

Someone also recently devised a method to make RCC 100X cheaper than it previously was, so fabricating high-temp engine components from RCC is now a plausible means to greatly reduce engine mass and cost.

SSTO will never be as-performant as TSTO, but the payload performance difference between the partially reusable TSTOs we have today and the expendable SSTOs we could have tomorrow may not be that great. If the cost is lower than the cost of stage recovery, that's still a "win" in my book.

#58 Re: Not So Free Chat » Politics » 2025-07-10 10:31:02

RobertDyck,

If you question whether or not you should state something in an open forum, then maybe you shouldn't. We don't discuss making weapons of mass destruction on this site, whether chemical, biological, or nuclear. Discussion of using nuclear materials for peaceful purposes is fine and ultimately necessary for space exploration.

Edit for clarification:

Discussing what course of action you think the Ukrainians should take to defend their nation is fine, but posting details about making weapons of mass destruction is not.

#59 Re: Meta New Mars » kbd512 Postings » 2025-07-10 00:22:25

tahanson43206,

Using RP1 (kerosene) as the fuel of choice permits rocket vehicle designers to minimize the propellant volume and maximize the total units of thrust generated per unit of engine mass and total vehicle dry mass for an orbital launch vehicle. This feature of RP1 is particularly important for SSTOs, but also important for TSTOs.

Vehicle dry mass scales by engine thrust-to-weight ratio and propellant tank volume, because for any significant payload to orbit, the propellant tank mass represents the majority of the vehicle's total dry mass (engines + propellant tanks). The cube-square law does help limit propellant tank mass increase as the propellant tank volume increases, but the end result will still be heavier propellant tanks and therefore higher vehicle dry mass when substantially less dense propellants, such as LH2, are substituted for RP1, when the goal should be equal or better payload performance with RP1. The vehicle dry mass comparison between Delta IV Medium and Falcon 9 Block 5 outright proves this. This is merely another way of saying that you cannot increase propellant tank volume by 10% or more, on account of LH2's exceptionally low volumetric density, yet still somehow arrive at a lower vehicle dry mass, as compared to RP1.

D4M Booster vs F9B5 Booster Propellant Volume and Tank Mass Comparison

D4M: 450m^3; mass, less engine: 22,110kg

F9B5: 370m^3; mass, less engines: 21,370kg or ~19,370kg without reusability hardware installed

F9B5 tank mass is 87.61% that of D4M

F9B5 tank volume is 82.22% that of D4M

F9B5 payload to orbit is 2.68X greater than that of D4M, but only 2X the gross liftoff mass of D4M

D4M Upper Stage vs F9B5 Upper Stage Propellant Volume and Tank Mass Comparison

D4M: 76m^3; dry mass, less engine 3,189kg; 23,264kg LOX + 3,956kg (561,752MJ) LH2

1X 301kg RL10B-2 engine, 110.1kN, 465.5s Isp; 24.1kg/s mass flow rate

1,129.460580912863071s * 110,100N = 124,353,610N-s

226,770kg total LOX/LH2 (both stages) / 8,510kg = 26.64747kg propellant per 1kg of payload

28,850kg + 3490kg = 32,340kg total dry mass

(447,150,942N-s + 124,353,610N-s) = 571,504,552N-s Total Impulse (both stages)

571,504,552N-s / 8,510kg = 67,157N-s/kg of payload

F9B5: 98m^3; dry mass, less engine 3,450kg; 75,200kg LOX + 33,200kg (1,427,600MJ) RP1

1X 550kg Merlin-1D Vac engine, 801kN, 348s Isp; 236.6kg/s mass flow rate

454.353338968723584s * 801,000N = 363,937,025N-s

518,400kg total LOX/RP1 (both stages) / 22,800kg = 22.73684kg propellant per 1kg of payload

25,600kg + 4,000kg = 29,600kg total dry mass (with booster reusability hardware installed)

23,600kg + 4,000kg = 27,600kg total dry mass (expendable)

(1,178,870,316N-s + 363,937,025N-s) = 1,542,807,341N-s Total Impulse (both stages)

1,542,807,341N-s / 22,800kg = 67,667N-s/kg of payload

Total Propellant Volume Required per kg of Useful Payload

D4M: 526m^3 of total propellant volume; 16.17871kg of payload per 1m^3 of propellant volume

F9B5: 468m^3 of total propellant volume; 48.71795kg of payload per 1m^3 of propellant volume

Total Thrust Required per kg of Useful Payload

D4M: 67,157N-s/kg of payload

F9B5: 67,667N-s/kg of payload

D4M "beats" F9B5, a vehicle pushing 2X as much total mass into the sky, in this one category that doesn't help make the case for LH2 fueled SSTOs, nor TSTOs for that matter. It's fractionally better than RP1 here, meaning you could run the main engine(s) for about 1.5 seconds longer, or less, on a LH2 fueled vehicle before total thrust (an indirect measure of total energy expenditure) per kg of delivered payload equalizes between both vehicles.

Hopefully we now understand how greatly vehicle dry mass affects our vehicle's total energy expended per kg of useful payload. We're getting 3X more payload mass per cubic meter of propellant volume for the F9B5 when we include both stages of the D4M and F9B5 rockets. That's a reasonably good efficiency metric if you ask me. Rather than showing how great LH2 is, we're continuously illustrating how freakishly efficient a modern RP1 fueled vehicle truly is. Even for a TSTO, every little bit of vehicle dry mass increase has a serious effect on vehicle performance.

RP1 has an acceptable Isp (total units of thrust generated per unit of propellant mass expended) for SSTO and TSTO. It's not even close to being "the best", yet LH2's much higher Isp doesn't seem to help improve total vehicle dry mass. Delivery of payload to orbit is primarily a question of Total Impulse delivered per kilogram of vehicle dry mass, and this is where RP1 is a stand-out performer.

RP1 allows the vehicle's propellant tanks to occupy the least amount of physical volume, therefore reducing their mass, amongst all of the common liquid rocket propellants. Amongst the propellants I listed, RP1 (kerosene) is the most widely used energy dense fuel combusted in gas turbine engines. The turbopumps that feed liquid rocket engines are specialized gas turbines capable of force-feeding a tremendous mass of gaseous propellants into the main combustion chamber.

#60 Re: Not So Free Chat » Politics » 2025-07-09 21:03:25

RobertDyck,

President Trump said he would bomb Moscow if Putin threatens to nuke the US again. He certainly has the hardware to do it. It would be a mistake to think he's bluffing. The Iranians certainly know better now. For all their tough talk, they're remarkably quiet now. All the wackos on the radical left said Iran would massacre the US military, that President Trump would start WWIII, and similar unhinged idiocy. Oddly enough, no such thing ever happened.

Ukraine may be capable of developing their own nuclear weapons, but they're not going to have a bomb ready to go in the next week, month, or year.

One reason this war is happening is Putin wants Ukraine's resources and skills back. But he doesn't understand killing them all means he won't get their skills.

I think maybe you don't understand that Putin doesn't care about their skills, which would be why he indiscriminately bombs their cities.

#61 Re: Meta New Mars » kbd512 Postings » 2025-07-09 13:44:58

Calliban,

As an engineer, do you understand all the calculations I presented to evaluate Total Impulse per unit of vehicle dry mass?

tahanson43206,

Let's compute the volumetric energy density efficiencies for the following fuels:

LCH4 (not the same thing as LNG), at 422.8kg/m^3 and 55.5MJ/kg

HTPB (solid propellant), at 920kg/m^3 and 20MJ/kg

N2H4 (Hydrazine), at 1,021kg/m^3 and 19.5MJ/kg

HFO (Heavy Fuel Oil / "Bunker Fuel"), at 1,010kg/m^3 at 41MJ/kg

LH2: 71kg/m^3 * 142MJ/kg = 10,082MJ/m^3

HTPB: 920kg/m^3 * 20MJ/kg = 18,400MJ/m^3

N2H4: 1,021kg/m^3 * 19.5MJ/kg = 19,909.5MJ/m^3

LCH4: 422.8kg/m^3 * 55.5MJ/kg = 23,465.4MJ/m^3

RP1: 810kg/m^3 * 43MJ/kg = 34,830MJ/m^3

HFO: 1,010kg/m^3 * 41MJ/kg = 41,410MJ/m^3

CBP (Carbon Black Powder): 1,700kg/m^3 * 32.8MJ/kg = 55,760MJ/m^3

Volumetric Energy Density of Alternative Fuels Compared with RP1

CBP: 160.092%

HFO: 118.892%

RP1: 100%

LCH4: 67.371%

N2H4: 57.162%

HTPB: 52.828%

LH2: 28.946%

When over 90% of the vehicle's volume is filled with propellant, as is the case for all orbital class rocket vehicles, vehicle dry mass becomes sensitive to propellant density. Since CBP and HFO would pose a severe coking problem for a rocket engine, and HFO is also loaded with Sulfur in most cases, RP1 is the most energy dense and readily available propellant for minimizing vehicle dry mass.

There are no clever "tricks" to skirt around major volumetric energy density differences when fractional improvements in propellant mass efficiency can't overcome volumetric inefficiencies which are multiples of propellants with much higher volumetric energy densities. You need as high an Isp as you can manage, but more importantly, you need sufficient density to minimize vehicle dry mass if you intend to accelerate 100% of the vehicle dry mass, plus the useful payload, to orbital velocities. The only known way to do that is to minimize the vehicle's volume, which is enabled by RP1 and hampered by far less dense propellants like LH2 and LCH4, or propellants with much lower thermal output per unit of mass, such as Hydrazine and solids like APCP and HTPB.

#62 Re: Meta New Mars » Bookmark Bookmarks Find it Again help » 2025-07-09 10:30:31

tahanson43206,

The fuel volume of a LH2 fueled rocket and the comparatively poor engine thrust-to-weight ratio of LH2 fueled engines is increasing the dry mass of the rocket while decreasing Total Impulse per unit of vehicle dry mass. Delta IV requires more vehicle dry mass per unit of payload delivered to orbit. If you were to fabricate the Delta IV from Carbon Fiber and use the highest-Isp LH2 engine available, the RS-25, Delta IV would still have a higher dry mass per unit of payload delivered to orbit, as compared to Falcon 9.

What do I mean by that?:

IF you make Delta IV's propellant tanks from Carbon Fiber, lopping 40% off the dry mass of its propellant tanks

AND

IF you use a pair of even higher Isp / higher thrust / lower total mass (compared to RS-68A) RS-25 staged combustion engines

AND

IF you only fire that pair of RS-25 engines in a hard vacuum where their thrust is highest

THEN

You only generate 45,052 Newton-seconds of thrust per unit of vehicle dry mass for this "upgraded" Delta IV

IF you fire Merlin gas generator engines at sea level, where their thrust is lowest

AND

IF you keep the Al-2195 Aluminum alloy propellant tanks of Falcon 9, which are much heavier than Carbon Fiber

THEN

Falcon 9 Block V still generates 46,050 Newton-seconds of thrust per unit of dry vehicle mass

45,052N-s total thrust per kg dry vehicle mass <-- LOX/LH2 staged combustion / CFRP tanks / engines fired in a vacuum

46,050N-s total thrust per kg dry vehicle mass <-- LOX/RP1 gas generator / Aluminum tanks / engines fired at sea level

If you apply the same engine tech (staged combustion) and propellant tank (CFRP) tech upgrades to LOX/RP1, then it will result in even more Total Impulse per unit of vehicle dry mass. Even if you somehow doubled the engine thrust-to-weight of LH2 fueled engines, you will still get more Total Impulse per unit of vehicle dry mass. Until vehicle dry mass approaches zero, there is quite literally nothing you can physically do to a LH2 fueled rocket powered vehicle solution to make it more effective than RP1 in terms of vehicle dry mass.

Why does this matter so much for a SSTO?

For a SSTO, you NEED as many Newton-seconds (N-s) of total thrust generated per kilogram of dry vehicle mass as you can possibly get. The reason you need that is because you're accelerating the entire vehicle's dry mass, along with the useful payload, from a dead stop on the launch pad to orbital velocity. More N-s per kg dry mass is "more better", and in comparison to a TSTO, it's also "more required".

How did I figure that out using basic multiplication and division?

1. I know how much total propellant mass each rocket holds (in kilograms).

2. I know the mass flow rate per second (in kilograms per second) and thrust generated (in Newtons), for the Merlin-1D, RS-25D, and RS-68A engines, both at sea level and in a vacuum.

Note:

All of those engines have published thrust ratings for sea level and vacuum, as determined by empirical testing on specialized test stands located at Earth sea level, which are capable of simulating a vacuum environment. As you previously discovered, the mass flow rate doesn't change, unless throttle position changes, and the nozzle geometry doesn't change, either. Only the engine thrust output changes as atmospheric back-pressure rapidly reduces with increasing altitude. This, in turn affects Isp (thrust generated by a specific mass flow rate).

Absent real mass flow rate and thrust data, when designing "paper rockets", you may use 90% of Vacuum Isp associated with a given engine propellant combination and combustion cycle. For example, the real life RD-180 engine, an Oxidizer-rich staged combustion engine that burns RP1, has a sea level Isp of 311s and a vacuum Isp of 338s. For comparison, Merlin-1D is only 282s (sl) and 311s (vac).

For a practical SSTO, we need an engine with the thrust-to-weight ratio (TWR) of Raptor with the Isp of the RD-180. I think this is doable, because Raptor uses larger pumps to feed LCH4 (half the density of RP1), yet still achieves 200:1 TWR. Therefore, a RP1 fueled staged combustion engine with a 200:1 TWR should be feasible using the same simplification process that Raptor went through as 3D printing enabled complex component integration without bolting together separate parts. For this "paper engine", we would use 90% of RD-180's vacuum Isp, meaning 304.2s as our flight-averaged Isp. Merlin's flight-averaged Isp is only 279.9s. That provides an 8% "fuel consumption reduction", or in actually, about 8% greater Total Impulse (49,734N-S/kg of dry mass) if vehicle mass stays the same.

3. I divided total propellant mass by mass flow rate per second for all engines, which tells me how many seconds of total firing time I get.

4. I multiplied engine thrust (in Newtons) by total firing time (in seconds), to arrive at Newton-seconds (N-s) of Total Impulse (It).

Note:

If this was a variable value, as would be the case for the solid rocket motors I used as a child, then you have to integrate the result. For a liquid fueled rocket engine this value doesn't change unless the throttle setting changes or the thrust changes, so no calculus is required to compute the result at full rated engine output for a given altitude / atmospheric back-pressure (sea level or hard vacuum). For a real rocket flight where altitude continuously changes throughout the flight, you briefly spin-up the turbopumps, briefly throttle down the engines near Max-Q and then throttle back up again after your vehicle is supersonic, and then throttle down towards the end of the burn to avoid over-acceleration of the vehicle, you must integrate the thrust measurements. On top of that, you need to know what the propellant residuals must be to avoid exploding your engine turbopumps as the propellant tanks run dry. Electric motor driven turbopumps can suck the tanks dry. Combustion driven turbopumps cannot.

5. I divided Newton-seconds of Total Impulse by vehicle dry mass, to determine how much total thrust a given propellant combination would produce per unit of vehicle dry mass, both at sea level and in a vacuum.

The end result of this 5-step exercise illustrated how dramatically higher Total Impulse is for RP1 vs LH2, for a given vehicle dry mass.

#63 Re: Meta New Mars » kbd512 Postings » 2025-07-09 02:37:41

Let's consider the energy efficiency of RP1 vs LH2, purely from an energy consumption per kilogram of useful payload perspective.

D4M = Delta IV Medium (all stages fueled with LH2)

F9B5 = Falcon 9 Block V (all stages fueled with RP1)

Note: D4M is a single Common Booster Core powered by a single RS-68A, with no strap-on solid rockets, and an upper stage powered by a single RL-10. D4M's vehicle dry mass is significantly greater than a F9B5, despite delivering less than half the payload to LEO of a F9B5. Fuel mass for both stages of D4M is 4.9X less than both stages of F9B5, and total propellant mass for the D4M's Common Booster Core is almost exactly 50% that of a F9B5 booster core. One would think that the superior Isp of Hydrogen burning engines and half the propellant mass would translate to a lighter dry stage mass for the D4M Common Booster Core, yet the opposite is true. Both stages of D4M are significantly heavier than both stages of F9B5. Both the propellant tanks and engines of D4M are heavier than the propellant tanks and engines of F9B5.

F9B5 Energy Economics

Fuel Masses: 123,500kg (booster); 34,275kg (upper stage); 157,776kg (total)

157,776kg of RP1 * 43MJ/kg = 6,784,368MJ of total fuel energy

6,784,368MJ / 22,800kg to LEO (fully expended) = 297.56MJ/kg of payload to LEO

297.56MJ / 43MJ/kg = 6.92kg (2.24 gallons of RP1 per 1kg of payload to LEO, at 3.084kg/gal)

D4M Energy Economics

Fuel Masses: 28,400kg (booster); 3,763kg (upper stage); 32,163kg (total)

32,163kg of LH2 * 142MJ/kg = 4,567,146MJ

4,567,146MJ / 8,510kg to LEO (expendable-only) = 536.68MJ/kg of payload to LEO

536.68MJ / 142MJ/kg = 3.78kg (14.12 gallons of LH2 per 1kg of payload to LEO, at 3.733gal/kg)

LH2 vs RP1 Payload-to-Orbit Fuel Efficiency Comparison

536.68MJ/kg (D4M/LH2) / 297.56MJ/kg (F9B5/RP1) = 1.80360

D4M vs F9B5 Payload to Orbit

8,510kg (D4M payload to orbit) / 22,800kg (F9B5 payload to orbit) = 0.37325

D4M vs F9B5 Booster Total Impulse

447,150,942N-s (D4M) / 1,178,870,316N-s (F9B5) = 0.37930

D4M vs F9B5 Booster Dry Mass

28,850kg (D4M) / 25,600kg (F9B5) = 1.126953125

Conclusions

D4M consumes 80% more fuel energy than F9B5 while delivering only 38% as much payload to orbit, with a mass increase of 13% over F9B5. On top of that, D4M also costs more than F9B5, which is why it was retired. If you increase the booster dry mass of the LH2 solution by 338%, using a triple booster core Delta IV Heavy configuration, then you can get 5,990kg more payload to orbit than F9B5.

Key Takeaways

Whatever propellant mass efficiency advantage LH2 provides over RP1, it clearly doesn't translate into lower vehicle dry mass, lower total energy consumption, nor even improved payload performance. If anything, the opposite appears to be true. As the size of the vehicle scales-up to deliver more payload to orbit, that vehicle dry mass problem only gets worse, never better, because materials don't become any stronger as you increase the size of a structure. You will see a relative improvement in vehicle dry mass as you increase the propellant tank diameters, thanks to the cube-square law, yet any LH2 powered vehicle is still going to end up being significantly heavier than a RP1 powered vehicle for the same delivered payload mass.

Even when we compare the total impulse of a notional RS-25 powered D4M operated purely in a vacuum vs a Merlin powered F9B5 operated purely at sea level, the total impulse generated per unit of vehicle dry mass advantage is lopsidedly in favor of F9B5.

If you invoke a D4M with Carbon Fiber propellant tanks with only 60% of the mass of the actual historical D4M's Aluminum propellant tanks, powered by a pair of lighter and higher-Isp RS-25D engines, you will still fail to generate a total impulse per unit of dry vehicle mass figure that's higher than a Merlin powered F9B5, constructed primarily of Al-2195 alloy. That's how horrendously awful LH2 is as a fuel choice for a SSTO or TSTO.

Total impulse generated per unit of dry vehicle mass, not propellant mass, is the figure of merit that either makes or breaks SSTOs, and the primary reason why there are none. That figure of merit is either sky-high, as it would be for a RP1 fueled rocket with Carbon Fiber propellant tanks and staged combustion engines, or SSTO doesn't work.

#64 Re: Not So Free Chat » Politics » 2025-07-08 20:34:26

Yuri,

Giving Ukraine nuclear weapons may also give Putin the pretext he needs to justify nuking Ukraine. Are you absolutely certain that he and his lackeys are rational actors? If you misjudge his willingness to use nuclear weapons, then Ukraine won't exist as a nation following the exchange. Give this outcome the serious thought it deserves, because it's a real possibility.

#65 Re: Not So Free Chat » Chat » 2025-07-08 09:33:34

My personal take on Russian armor is that their T-72 is a roughly correct design, but even their frontal armor is ineffective against modern sabot and shaped charge rounds, their fire control system needs modernization, and their thermal imagers used to surveil the battlefield and acquire targets are woefully inadequate. The 125mm smoothbore cannon is adequate, but their sabot rounds could be improved. I would prioritize the improved thermal imager and fire control upgrades.

Here's how I would overhaul a NATO tank program:

1. Give up on sabot rounds for direct penetration of modern composite armor. Kinetic penetrator rounds do work, but the extreme heat involved rapidly "burns out" the barrels through erosion caused by hot high pressure gases, especially the latest and greatest sabot rounds, which renders accuracy unacceptable after far fewer rounds fired. Barrel life has seen a steep decline with successive "improved penetration" versions of the M829 "silver bullet" sabot round and similar analogs. M256 L44 cannon barrels are now seeing service lives in the low thousands of rounds at most. Each M829 now costs as much as a subcompact car. The Tungsten penetrators fielded by other NATO nations have only made the barrel erosion problem worse, because those require extra velocity to equal the performance of our DU penetrators, which is why you see longer L55 barrels on the latest version of the Leopard 2, prompting Rheinmetall's experimentation with 140mm caliber guns. Either way, the gun tubes are becoming unwieldy in urban warfare scenarios and if we're increasing caliber to 140mm, then why not use 155mm and call it a day?

2. Standardize on 155mm caliber for all towed artillery pieces, self-propelled guns, tank main guns, naval guns, and airborne gunships. The US Army discovered long ago, much to its chagrin, that their tanks were nowhere near as well protected against 155mm artillery shells as they thought they were, whether fired at high angle or low angle, whether air burst above the tank or allowed to make contact and detonate. Air burst 10m to 20m above the target proved to be the most destructive, but direct hits also rendered the target tanks inoperative as tanks. 155mm did not penetrate the frontal armor, but splinters from the shells punched right through the main gun tube of the target tanks, totally wrecked their optics and radio antennas, completely sheared off parts of the running gear (road wheel bogies and tracks), and punched through the engine deck in airbursts, setting fire to the vehicle after destroying the engine beneath the thinner engine deck armor. Given that the M48 and M60 tanks used in the test were no longer usable as tanks, and would require depot level repairs to return to service, I'd say that still counts as a "kill". No modern Russian or NATO tank would fare any better when hit with 155mm. The M776 cannon that equips the M777 towed howitzer is a L39 weapon that weighs 3,700lbs for the barrel and breech, about 6,370lbs in total when configured as an artillery cannon. The M256 L44 cannon that equips the Abrams weighs 8,330lbs. The L55 cannon of the Leopard 2 weighs 9,170lbs I would reduce the M776 cannon's length to L29, same as ye olde M109s, and Charge 4 to reduce the length of the breech and recoil.

3. Cease and desist with loading up every imaginable type of weapon and round of ammo aboard every vehicle. The sheer quantity of equipment we try to cram into each vehicle is, in point of fact, driving the horrendous cost and weight of our tanks and other armored vehicles. A tank should have its driver and vehicle commander located inside the hull and nobody inside the turret, which implies an autoloader for the main gun, a high quality thermal imager, panoramic fiber optic cameras that provide a 360 degree view of the battlefield without having the crew constantly expose themselves, a top notch fire control computer, and a battery of grenade launchers for smoke and HE or buckshot for close-in vehicle defense. It doesn't need multiple machine guns in different calibers, a small caliber automatic cannon, Javelin missile launchers, and partridge in a pear tree. The more people and weapons you stuff into a tank, the higher its silhouette becomes, which makes it easier to spot from the ground by casual observation, and the heavier yet more vulnerable you make the vehicle and people in it, simply because you cannot adequately armor the top and sides of a tank with a gigantic 3-man turret.

For a tank to support infantry assaults, you need a big gun that fires powerful shells, mostly to deal with light vehicles and dug-in infantry using fragmentation effects. You can and will fire that $15K M829 "silver bullet" at a Toyota pickup truck if that's all you have, and it will do what it does, but to what end? Whether or not it can outright "punch through" opposing tanks is largely irrelevant unless you're fighting hordes of tanks over open ground. Even if you are, that's what Javelins and airborne tank destroyers are for. What's the point of deploying infantry and combat drones in support of armored ground vehicles if you're not going to use all of their strengths to deliver asymmetric counter-attacks to defeat opposing forces? The western world has an unhealthy ongoing fascination with the idea of "dueling" and "aces". War is, "We're using everything we have against everything our enemy has." It's not, "We're going to defeat your tank with our superior tank in one-on-one combat." You get "quality" not only from technological superiority, but also from exhaustive realistic training, well-maintained equipment with plentiful spares, local numerical superiority, and the element of surprise.

My concept of "useful combat drones" involves small-ish (~750lbs) remotely-piloted fixed wing piston engine aircraft that can fly at speeds up to 200mph or so for up to 1 hour, and drop a single 155mm glide bomb shell on enemy armor or field fortifications. If the air defense threat is minimal, perhaps Apaches and Warthogs can fulfill our "airborne tank destroyer" doctrinal role to protect our combined armor / infantry advances. Apache and Cobra gunships ultimately replaced the M18 and M36 tank destroyers of WWII, as well as armored cavalry scouts for most missions, but now those roles appear ready to assign to small combat drones. I would retire the Apaches and Warthogs at this point because the threat posed by radar-aimed autocannon and shoulder-fired missiles to piloted close air support assets is far too great against a peer level adversary. Afghanis may not have any Stingers. Russia and China, however, have thousands of them. Flying at treetop level against them is a better than average way to lose good men and machines on every mission. When, not "if", some of our combat drones get shot down, we build more and our drone operators live to learn from their failures since they weren't aboard the machines that were shot down.

We'll use trucks and cargo ships to transport / fuel / arm / repair our combat drones. We'll launch them from gun-based catapults that use fuel and compressed air in conjunction with the high-low pressure principle our 40mm grenades use for "soft launch". We'll recover them with nets so we don't need runways. This worked well for drones of that approximate size carried aboard American battleships used during Gulf War I to spot the fall of rounds from the 16 inch guns.

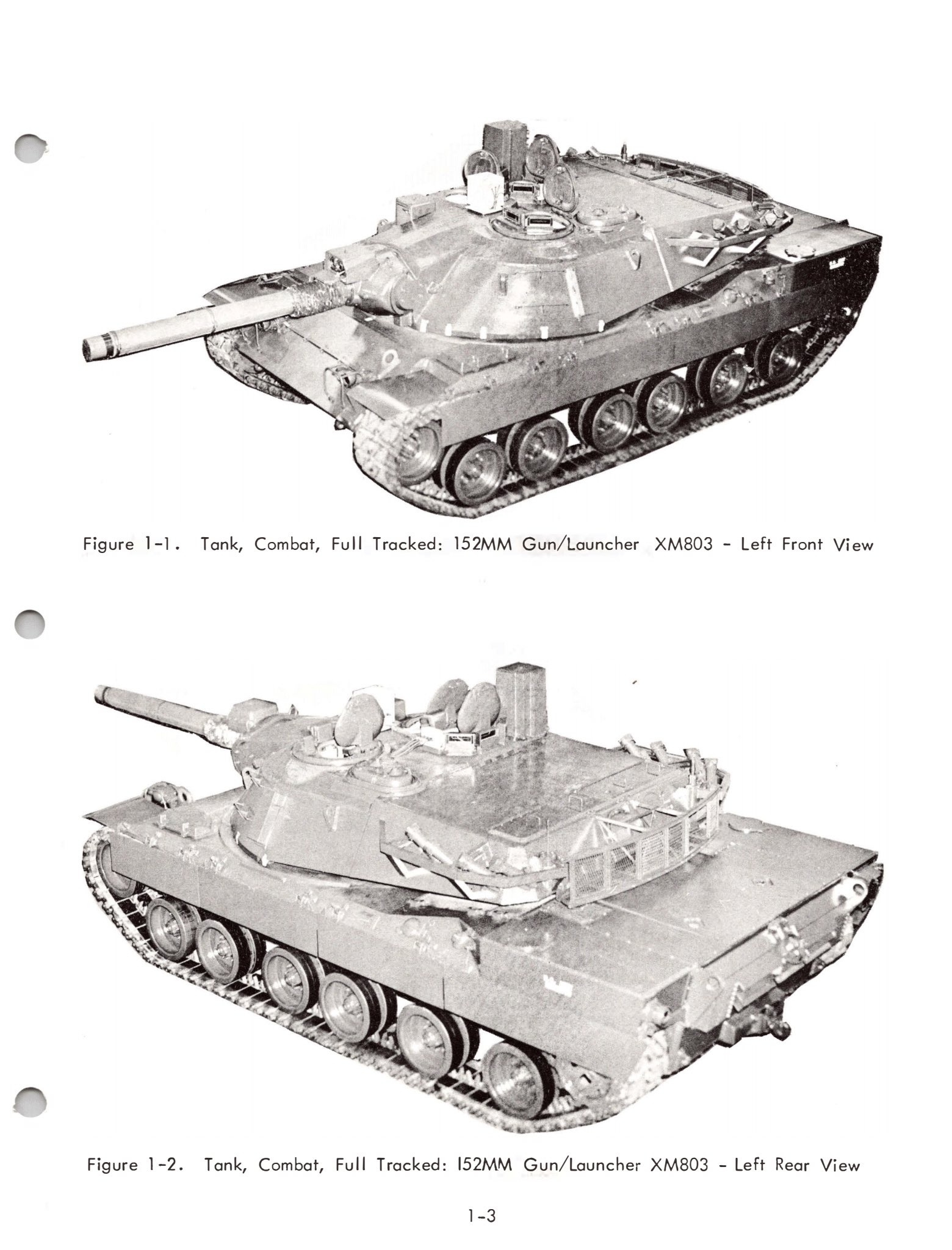

The XM-803 (forerunner to the M1 Abrams, equipped with a 152mm rifled gun):

This is what we need to get back to, but without the oversized / overweight 3-man turret, meaning only 2 men in a highly protected hull compartment. We must use electro-optical sensors to surveil the battlefield instead of exposing tank crews to enemy small arms and artillery fire while they're actively operating their tank. The entire point of putting them in a tank was to protect them so they could focus on neutralizing targets that are holding up infantry advances. Keeping all their hatches open, because they're still using their eyeballs to observe, has become a highly lethal anachronism. This new tank concept deals with enemy field fortifications and infantry by direct-firing 100lb HE shells at them. When you start direct-firing 155s at people, then everyone gets down, or everyone dies.

The infantry themselves will start manning self-mobile 30mm cannons that the Apaches previously carried, using small arms for close range self defense only. As they advance, their first objective is to tear apart light vehicles, machine gun nests, mortar pits, and infantry formations using HEI cannon shells. The Chinese are sure to fight island defense campaigns in the South Pacific roughly the same way the Japanese did during WWII, because there's not many viable alternatives to what the Japanese did, even with modern weapons.

This new way of fighting is firepower-based, rather than a specialized / limited supply weapon for this / that / the other. Most ground targets can be dealt with using 155s. Anything that requires a JDAM or bunker buster or cruise missile will be delivered by F-35s, B-21s, B-52s, ships, and submarines. Missiles will be used sparingly, mostly limited to attacking enemy air defense systems, ships, and aircraft. There are not enough of these advanced weapons, we cannot easily and rapidly produce more, and huge amounts of resources are captured in their production, stockpiling, and maintenance. Iron bombs and artillery shells can be manufactured by the millions for comparatively little cost, especially if the shell bodies or bomb casings are stockpiled without filling them with explosives.

We need all services to adopt 155mm. L29 155s for our tanks to minimize barrel length / weight / recoil force, L39 155s for our towed M777s and M109s, perhaps a few L52 M777ERs for niche applications, and 58 caliber 155s for the US Navy to replace their less effective 5 inch Mk54 guns. When everyone is using 155, figuring out logistics becomes rather easy. You need 155 shells and their modular propellant charges. For longer shots, we'll splurge on Excalibur munitions so we don't burn out the barrels while "firing for effect". All the services have spent mad money on special application guns. The US Navy spent "stupid money" trying to make a 155 fly 100 miles. Each 110lb guided shell cost $1M, as much as a Tomahawk cruise missile that flies 1,500 miles with a 1,000lb warhead. A 58 caliber cannon can still reach out 40 miles or so with a $50K guided shell. That would have been a very useful capability for the US Navy to have aboard ships, because it roughly doubles engagement range over the standard 5inch L62 Mk54 gun. That would put the ship that fired it over the horizon, against most islands.

The objective of this program is to build lots of guns and shells, not "special guns" that require their own "special shells". Since 155 works for the Army and Marine Corps, it works for the Navy, too. Heck, we're going to figure out how to mount 155s in Spectre gunships so we can shell people from the air as well. Against adversaries like Russia and China, more shelling equals "more better". Russia is not wrong, as it pertains to their liberal use of artillery. They don't call artillery the "King of Battle" for nothing. The fact of the matter is that a 100lb HE shell is adequate to kill most military targets, if accurately delivered. Bunkers, ships, and certain kinds of area targets like runways are the only kinds of targets that require more powerful guided bombs and missiles or torpedoes.

#66 Re: Single Stage To Orbit » SSTO - Mathematical Analysis Gravity vs Stages » 2025-07-07 15:22:08

tahanson43206,

In reviewing Posts #33 and #34, it seems to me that kbd512's hypothesis has never been tested.

I'll bet that kbd512's hypothesis has never been tested.

It's not a hypothesis. It's gas expansion physics in action. I clearly didn't explain it in a way you understood, so I'll try to do a better job.

All kinds of pictures, videos, diagrams, and explanations of testing engines under vacuum conditions, here at sea level:

Scott Manley - Defying Atmosphere - How Rocket Engines Get Tested In A Vacuum Before Going To Space

In the portion of his video showing ignition of the Space Shuttle Main Engines on the pad, that "wavy looking blue flame pattern" you see dancing around the engine nozzle exit is actually a visual indication of the flow separation phenomenon that GW is constantly telling people about, although it mostly falls on deaf ears. The RS-25 engines are over-expanded at sea level to the maximum extent permissible without destroying the engines from the flow instability that flow separation causes. If that wavy blue line (flow separation) were to venture a little further up into the engine nozzle, it would rapidly tear the nozzle apart, destroying the engine in the process. Thankfully, the RS-25's engineers figured out "where the line was", and how not to cross it. That means the nozzle's expansion ratio is actually optimized for an altitude far above sea level, but not to the point that it damages the engine nozzle.

Both sea level-optimized engine nozzles and vacuum-optimized engine nozzles are tested in altitude simulation test stands, at sea level.

That's how engine designers confirm how much thrust a sea level engine nozzle will produce at 100,000ft, for example.

NASA White Sands Test Facility

From the article:

I had the exciting experience of a behind-the-scenes tour of NASA’s White Sands rocket engine Test Facility in Las Cruces, NM. The most notable engine tests were on the Apollo Command Module rocket engine and the Lunar Module (LM) Ascent and Descent engines in the 60s.

The first rocket engine test occurred here on September 22, 1964; this NASA facility in Las Cruces, NM has performed development and certification testing of space propulsion systems for manned and unmanned spacecraft in the cold void of outer space.

During my exclusive tour, I was able to experience what it was like there in the 1960s when the Apollo program was in full swing. Later, I also experienced the present day rocket engine test facilities and actually got a chance to go inside one of the Test Stands (TS) where active rocket engine testing under a vacuum is performed today for NASA and its contractors.

...

NASA’s vacuum test stands simulate a propulsion system’s intended operating environment. This enables engineers/scientists to verify how a particular propulsion system will operate when it is put into service at a particular altitude level, even in the cold void of space. When a propulsion system is installed inside one of these enclosed test stand chambers, the chamber is evacuated to simulate altitude conditions. A vacuum is maintained during rocket engine firing within a sustained pressure environment of that which the spacecraft will experience in space.

...

I'm going to attempt to explain this again, so please bear with me.

Specific impulse (Isp) is units of thrust (such as Newton-seconds) generated for a given number of units of mass flow rate (such as kilograms of propellant fed through the engine per second). If the mass flow rate stays the same while the thrust generated by that mass flow increases, then your Isp increases. This happens for virtually all sea level rocket engines as they ascend through the Earth's atmosphere.

The kinetic energy or force produced by gas expansion from combusting a specific number of mass units of any given oxidizer / fuel combination does not change one iota, whether you're located at Earth sea level or in a hard vacuum. Hydrogen still delivers 142MJ/kg of thermal energy when completely combusted with Oxygen, whether you're located where the pressure of the atmosphere is 14.7psi, here at Earth sea level, or in deep space where there is zero atmospheric pressure. When turbopumps in a rocket engine are spun-up to 100% of their rated power output, it doesn't matter if they're operated at Earth sea level or 100,000ft. If their mass flow rate is 500kg/s at full rated output, then it's 500kg/s, regardless of atmospheric pressure.

The only thing that does change, between Earth sea level and a hard vacuum, is the thrust generated by the engine in the absence of thrust-robbing atmospheric back-pressure. Every rocket engine is attached to an exhaust gas expansion nozzle of some type, to include "aerospike" engines that use ambient atmospheric pressure as part of their "expansion nozzle design". The explanation regarding why the exact same nozzle design produces more thrust at lower atmospheric pressure, which occurs at higher altitudes than mean sea level on any planetary body with an atmosphere, is that the engine nozzle is expanding the exhaust gas to some given pressure value. If the pressure of the expanded gas is less than ambient pressure (over-expansion), then you lose thrust, and possibly destroy the engine from flow instability if the pressure from the expanded gas is low enough. If it's more than ambient pressure (under-expansion), then you also lose thrust. The ideal expansion value is the same pressure as the surrounding atmosphere, when atmospheric pressure is present. A fixed nozzle geometry can only have "ideal expansion" at some given atmospheric pressure value, which is fairly closely tied to altitude. There is no such thing as a completely optimal "vacuum nozzle expansion ratio" because the nozzle would be infinitely large and infinitely massive when the ambient pressure is zero.

At Earth sea level, there are approximately 14.7 pounds of air pressure "pushing back on" the exhaust gas trying to escape from the nozzle, over every square inch of the expansion nozzle's exit plane area. You're basically "losing" quite a bit of kinetic energy from the expanding gas because the back-pressure from the atmosphere is robbing power by slowing down the expanding gas. By the time you reach 33,000ft, this atmospheric back-pressure has dropped to about a third of the pressure at sea level, because atmospheric pressure at 33,000ft is about 1/3rd of what it is at sea level. Since there is less force from Earth's atmosphere "pushing back on" the expanding gas exiting the rocket engine's nozzle, the same expanding gas generates more force / thrust. Since Isp is force generated for a given mass flow rate, and mass flow rate doesn't change at all, so long as the engine's throttle setting hasn't been changed, the end result is higher Isp, from the exact same nozzle and mass flow rate.

Hopefully that was a more complete explanation, but feel free to continue your own research.

#67 Re: Science, Technology, and Astronomy » Google Meet Collaboration - Meetings Plus Followup Discussion » 2025-07-06 17:44:51

tahanson43206,

I've still seen no response to the fact that RP1 very clearly provides a lot more Newton-seconds of total impulse per unit of dry stage mass, as compared to LH2. A Falcon 9 Block V booster core with sea level Merlin-1D gas generator engines and the reusability hardware attached still delivers 48% more Newton-seconds of total impulse, per kilogram of dry stage mass, using sea level thrust / Isp values, as compared with a pair of RS-25D staged combustion engines attached to a notional re-powered Delta IV Common Booster Core, when the basis of comparison is with the RS-25D's Vacuum thrust / Isp figures.

For any rocket, Newton-seconds of total impulse per unit of dry stage mass determines how much payload you can deliver to orbit. More total impulse per unit of dry stage mass is "more better", especially for a SSTO, which is carrying the entire vehicle mass all the way to orbit with the useful payload.

#68 Re: Not So Free Chat » Chat » 2025-07-06 17:28:15

RobertDyck,

The handheld jammers that work on FPV drones don't work against our guided missiles and bombs. That's part of what I meant about cheap and low cost drones coming with serious operating limitations that extend beyond range and speed, which are important but don't guarantee a "kill".

The Iranians, Russians, and presumably the Chinese have all tried to jam our Predator and Global Hawk drones, without much success. That's the difference between a small FPV drone and a multi-million dollar combat drone that has long range sensors and can fire missiles or drop bombs. Short of shooting it down, you're not going to interfere with the operator's comms link, decoy it, or jam its sensors. It's basically a miniature fighter jet. We miniaturized the radar that the F-18 uses, it still has the full capabilities of the older/larger system installed aboard F-18s, to include range and attack modes, and then stuffed it into the nose of our XQ-58 combat drones. Jamming a handheld drone is one thing. Jamming the F-18's radar is another. The Iranians have shot one down with SAMs, but since those drones have few defensive capabilities and move at modest speeds, that's not terribly difficult to do.

Operation Spiderweb was brilliant, but as you noted, probably will never be repeated. After you expose that kind of vulnerability, the enemy will respond. They're evil, not stupid.

All tanks are quite vulnerable to top attack because they have nothing but a thin sheet of armor steel on the top of their turrets, usually no more than an inch thick. Virtually any kind of HEAT warhead is guaranteed to penetrate, with catastrophic results. There's nothing magical about the Abrams in this regard. In American use, tanks are supported by infantry, artillery, and air support. In the Ukraine War, lack of infantry support leaves them vulnerable to the kinds of attacks which are simply not realistic when fighting against US or NATO forces. American and British tanks are much heavier than the tanks used by other nations because they're designed to shrug off hits to the frontal armor during an armored assault. Most kinds of anti-armor weapons are ineffective against Abrams and Challenger over the frontal arc.

The Abrams sent to Ukraine do not include the full armor package that the US Army uses. In point of fact, all foreign-operated Abrams do not include the American heavy armor package. Most people don't know that, but the Saudis, for example, have complained about this. The tanks we sent to the Ukrainians are also about 20 years old, so they lack the latest electronic upgrades to the fire control system. They were given the best ammo we have, though, fully capable of penetrating the frontal armor of the latest Russian tanks. Despite being older, both the fire control system and radios are superior to any Russian tank. Even the Russians admitted this. If operated correctly, the gun is accurate and the sabot round will punch through opposing tanks using pure kinetic energy. The crushing weight, voracious appetite for fuel, and complexity are its drawbacks. As a fighting vehicle, it's as good as anything else out there- not better, but just as good.

Phalanx are designed to automatically engage both airborne and seaborne threats. For seaborne threats, however, we typically use our more powerful manually operated 25mm Bushmaster chain guns mounted to the main deck, using SAPHEI shells. Phalanx are typically loaded with DU penetrator sabot rounds to punch through airborne anti-ship missiles. The onboard radars are powerful enough to track the tiny outgoing shards of metal, as well as the inbound missile. Unlike Russian CIWS, the Phalanx are self-contained weapon systems with their own on-mount power source. There's no deck penetration for external system components. Nominally, power is externally supplied by the ship. Phalanx are also integrated into the AEGIS Combat System so they can receive target prioritization and advanced warning of inbound missiles from more powerful radars such as SPY-1 and now SPY-6. We mount them high in the superstructures of our warships so that they can aim both up and down.

Naval drones with sufficient combat capability to deal with enemy aircraft and ships will be expensive by their very nature. I would be very cautious about extrapolating useful and repeatable capabilities on the basis of a handful of data points because we don't know how many of these attacks were thwarted in various non-kinetic ways or outright failed due to defensive action on the part of the Russian Navy. As a general rule, Russian Navy training and ship material readiness condition are awful. Moskva reportedly put to sea with a non-functional air search radar, something no other adequately resourced naval force would ever do. As offensive weapons, seaborne drones might be more cost effective than massed missile attacks, though. Since they attack right at the waterline, they can be highly effective in sinking ships in the traditional way.

As far as the Neptune missile attack on the submarine is concerned, this would be why stealth and opsec are so critical to successful submarine operations. This also strikes me as a non-repeatable offensive action unique to the Ukraine War, due to proximity. If they did this to three or more submarines, then I would reconsider its use as an effective military tactic.

#69 Re: Science, Technology, and Astronomy » Electric flight » 2025-07-06 16:25:44

How would I attempt to produce one of these "eVTOL" machines if I was running the development team, with an eye towards achieving production of a practical electric aircraft that uses a lot less fuel?

1. Use a Jet-A / kerosene burning high temperature Solid Oxide Fuel Cell (SOFC) that directly consumes kerosene, without prior reformation into Hydrogen gas, instead of electro-chemical batteries of any description. There are no batteries in existence that are worth the cost, mass, volume, operating temperature limitations, and numerous operational challenges involved, such as the total lack of charging infrastructure and sufficient electric power generating capacity for recharging them. That would be the absolute best place to start working on an "all-electric" society. Provide the electricity first, rather than excuses for why it's not available, and then we'll pursue electrification of vehicles.

I've seen credible (independently tested and verified) 1,500Wh/kg figures posted for single-use Aluminum-air batteries that the Israelis experimented with here in America, installed in electric cars that drove over 100,000 miles in total. Experimentation lasted a number of years until it became apparent that there was no economical solution for recharging them. The process for recharging them is the same process used to smelt fresh Aluminum metal from Alumina ore (oxidized Aluminum), meaning 10X as much input energy is used to re-separate the Oxygen from the Aluminum as the batteries can actually store / output. The batteries were easily swapped for fresh ones, by design, but the battery would last for two weeks to a month in a BEV under normal daily driving, and then the Alumina dust had to be emptied from the battery casing and recycled at the factory. There was some minor disassembly involved, but no messy liquid or gel electrolyte as such. The battery had to be "re-manufactured" (not quite the right word since it was more like rebuilding a fuel cell than true re-manufacturing) using fresh Aluminum metal "dust". The parts of it that I saw made me think it could be done outside of a factory environment, but only with appropriate equipment. To my untrained eye, it did not appear to be dangerous, merely time consuming and a little messy. I think a mechanic with appropriate training could do the job, but I'm not an expert so go talk to the experts if you need a better evaluation.

To this day, no readily rechargeable Lithium-ion battery comes within a country mile of Aluminum-air's gravimetric energy density. Amprius has developed a 500Wh/kg and 1,300Wh/L Lithium-ion cell, which is a real commercial product you can buy with money, not a lab prototype or future promise. This tech ought to be a boon for portable electronics, but they're fixated on BEVs and other inappropriate uses for batteries.

I see lots of enthusiasm for batteries because they're neat toys for electrical engineers to tinker with, but there's little acknowledgement of the fact that nobody knows how to solve their fundamental energy density and recharging problems. We need an order of magnitude energy density improvement. General Motors continues to be correct in their assertion that 2,500Wh/kg batteries are necessary for practical BEVs that perform similarly to gasoline fueled vehicles in all respects, with similar curb weight and cost. For aviation, we need battery energy density to almost match hydrocarbon fuel energy density. That prospect is much further into the future, assuming it's possible.

Let's compare that with hydrocarbon fuels (BTU/gal figures provided by "The Engineer's Toolbox" website):

Gasoline: 125,000BTU/gal or 36,634Wh/gal; 6lbs/gal avg; 13,461Wh/kg

Kerosene: 135,000BTU/gal or 39,565Wh/gal; 6.8lbs/gal avg; 12,827Wh/kg

Diesel: 139,000BTU/gal or 40,737Wh/gal; 7lbs/gal avg; 12,830Wh/kg

Modern turbocharged direct-injected liquid-cooled gasoline automotive engines are 35% to 45% thermally efficient, which means they convert 4,711Wh/kg to 6,057Wh/kg of energy from their gasoline into mechanical power output.

Micro gas turbines, less than 0.5MW, are typically pretty horrendous when it comes to fuel efficiency, usually 20% or lower thermal efficiency. Small gas turbines, 0.5MW to 25MW will be about 30% thermally efficient, such as the T406 that powers the V-22, so 3,848Wh/kg can be converted into mechanical horsepower output using kerosene as the fuel. Medium-sized gas turbines, 25MW to 75MW, are about 40% thermally efficient. LM2500 gas turbines or equivalents typically power warships, cruise ships, and large offshore oil drilling platforms. Large natural gas fired gas turbines, in the 75MW to 500MW range, can approach 50% thermal efficiency. All of that is simple cycle efficiency without significant recuperation, although it is increasingly common to use recuperators in marine applications and gas turbine power plants, which can improve combined cycle efficiency up to about 65%.

Diesel engines that power semi-trucks, construction equipment, and ships are now up to 50% thermally efficient without doing anything too spectacular or expensive. Unlike gas turbines, which are most thermally efficient only at max power output, diesels are typically highly efficient across most or nearly all of their operating power band. Warships smaller than aircraft carriers frequently use diesels to economically steam at speeds up to 15-20 knots, then use gas turbines to pour on the power to attain that last 10-15 knots of their flank speed. Steaming at 30 knots typically requires about 8X more power than steaming at 20 knots. Delivering that much additional shaft power using diesel engines alone makes the propulsion plant impractically large and heavy. To the best of my knowledge, nobody uses geared steam turbines any more, except in conjunction with naval nuclear reactors, because marine steam boilers are also very heavy and take up too much space inside the hull. For ships designed to move at significant speed, medium-sized marine gas turbines have become the power plant of choice for virtually all conventionally powered warships and cruise ships. Cargo and tanker ships typically use a single very large diesel engine powered by bunker fuel / residual fuel oil.

SOFCs can be 50% to 85% thermally efficient, dependent on type, so 6,414Wh/kg to 10,903Wh/kg of mechanical work output can be extracted from kerosene or diesel fuel. That's 4 to 7 times as much energy per unit weight as the most energy dense single-use Aluminum-air battery cell. For an electric aircraft, that translates into 4 to 7 times less "fuel" weight, or 4 to 7 times greater useful payload-to-distance for the same "fuel" weight. Practically speaking, there is no physical way to increase the size and weight of the aircraft by 4 to 7 times and retain the same energy usage efficiency. Increasing an aircraft's physical size increases the aerodynamic drag because you need more wing area to make it fly, as well as more power. Apart from takeoff power, which typically is significantly greater than cruise power, power required is a function of the drag force generated at the design cruise speed.

The only reason Joby Aviation's S4 can fly 150 miles using its 125kWh battery pack (I've recently learned that the actual production vehicle will be equipped with a 150kWh pack, though range remains unchanged) is that most of its flight time is spent in forward flight. However good they are at hovering, all helicopters, regardless of what powers them, are incredibly inefficient "forward flight machines". As a general rule of thumb, you can fly 2 to 4 times further using a purpose-built fixed wing aircraft, or merely one better optimized for forward flight than one using a purpose-built rotary wing, with half as much horsepower, at the same takeoff weight.

Joby Aviation's S4 2.0 pre-production prototype, with its 4,000lb MTOW, has an installed power of 1,899hp (6X 236kW max output 28kg electric motors, each motor driving a 5-bladed composite constant speed propeller). Direct competitors to S4, Robinson's R44/R66 (270hp) and Bell's Model 206 JetRanger (400hp), do not require anything approaching the S4's power output figure because they're purpose-built helicopters with main rotors providing dramatically greater swept area. The S4's stated service ceiling is 15,000ft, presumably in forward flight. The R66 service ceiling is 14,000ft. The JetRanger can reach 20,000ft. Induced drag must be horrendous with 30 propeller blades, which explains why the S4's top speed is only 200mph, while the lack of swept area explains why the S4 requires 1,900hp to hover. With optimal blade length for hovering, the R66 can still fly 400 miles. From a mission fulfillment standpoint, the S4 looks like a brute force approach to what should be a more elegant solution, meaning either an electric V-22 facsimile or a real electric helicopter. Anyone who thinks a 1,900hp VTOL machine will require dramatically less maintenance than a 270hp VTOL machine is in for a rude surprise.

Thousands of R44/R66 and JetRanger models, as well as thousands of examples of similarly capable foreign helicopter designs, have been operated within the confines cities for many decades now- the exact operational environment where these new S4 eVTOL vehicles are supposed to "make a splash" by providing a vastly more economical air taxi service. That's the only way for these all-electric air taxi services to become profitable. Forgive me, but this entire concept looks like Moller Sky Car 2.0. Dramatically larger sums of money have been invested into the S4 in comparison to the Sky Car, but there's no clear market for thousands of electric V-22s that cost as much as a gas turbine powered helicopter to purchase. Given the sheer numbers of helicopters already operating within cities, fuel and maintenance costs alone cannot possibly be the only reasons why most people are not flying to work every day.

When people say "beyond oil", I don't know what kind of nonsense they're spouting off, unless they mean nuclear power. If we had a miniature fusion reactor we could stuff into an aircraft, that would be ideal. Unfortunately, we don't have any of those.

The RR300 gas turbine that powers the R66 burns 23 gallons per hour, so let's do some basic math to see if a SOFC and electric motor can deliver equivalent power output for less total mass.

RR300 gas turbine engine weighs about 91kg, can generate 270hp for takeoff and 224hp at max continuous power, and burns about 23gph in cruise flight, when installed in the R66.

23gph = 909,995Wh of thermal energy input

224hp (max continuous power for the RR300) = 167,036.8W

167,036.8W / 909,995Wh = 18.36% engine thermal efficiency in cruise flight

That explains why nobody uses a gas turbine less than about 550hp for conventional aircraft. The fuel burn rate is too high.

Let's use Joby Aviation's electric motors.

236kW = 316hp, so 1X of Joby's electric motors is sufficient to power the R66 and it weighs 28kg.

We'll use 5kW/kg as our SOFC's power-to-weight value and 70% as our efficiency figure, since both values have already been demonstrated in a singular SOFC design developed by NASA.

270hp = 201,339W

201,339W / 5,000W/kg = 40kg

68kg is the mass of our fuel cell and electric motor combination. This combination is looking like a rather promising for our electric R66, because it's lighter than the mass of the gas turbine engine it's replacing.

The R66's max fuel capacity is 73.6 gallons, which weighs 500lbs / 227kg.

167,036.8W / 0.7 (SOFC's electrical conversion efficiency) = 238,624W

238,624W / 39,565Wh/gallon = 6 gallons per hour

The RR300 powered R66 can fly for just over 3 hours before it's out of fuel.

We're going to carry 20 gallons / 136lbs of fuel to provide 3 full hours of flight at max cruise speed, plus a reserve of 2 gallons.

R66 empty weight is 1,290lbs and MTOW is 2,700lbs. We'll assume our "eR66" has an identical empty weight as the gas turbine model because our power plant mass is so close that we're unlikely to save a lot of mass on the fuel cell and electric motor. Technically, we're 23kg lighter than the gas turbine, but we'll presume that 23kg covers any electric power cabling, power inverters, or other unanticipated mass increases.

With full fuel, our eR66 only weighs 1,426lbs, which leaves us with 1,274lbs of useful load. That means each of the 5 occupants could weigh 254.8lbs. However, the real R66 is only rated to carry 1,200lbs, so we have a full fuel / full occupancy aircraft, which is simply not possible with the gas turbine engine because 73.6 gallons of fuel weight cuts into our useful load weight. Regardless, we can now fly a full occupancy aircraft for 3 full hours while burning only 18 gallons of fuel vs 69 gallons of fuel. Our fuel burn rate is reduced by 3.83X, as are our CO2 emissions for people who care about that. On top of that, we made our electric "eR66" a "practical electric aircraft" which is "more useful" than the original gas turbine R66.

In comparison to Joby Aviation's S4, we're consuming 273,912Wh of energy for equivalent flight distance with equivalent payload. That means we're consuming about 82.6% more energy. The explanation for that is pretty simple, though. First, batteries are more efficient than fuel cells. Second, as previously stated, rotary wing aircraft require about 2X more power than aircraft which are optimized for forward flight.

2. Use air-cooled brushed direct current direct drive electric motors with permanent magnets. Brushed DC motors are capable of high torque at low rpm, which is ideal for an aircraft application. The utter lack of solid state power electronics and software required to control the fuel cell and electric motors dramatically simplifies the entire power plant design problem. Could you theoretically achieve greater absolute efficiency with electronically controlled systems? Probably, but then you have to pay for all the additional electronic components and software, which pile on weight / cooling issues / purchase cost / maintenance cost at a breathtaking rate. When I say "I'm designing an electric aircraft", that statement is precisely what I mean. I do not mean, "I'm designing an oversized electronic remote controlled toy that humans can ride around in."

Those brushes will have to be replaced on a regular basis, which is annoying, but so what? Carbon brushes are dirt cheap mechanical parts that a human being can visually inspect for imminent failure using ye olde Mk I Mod 0 eyeball. Nobody can "eyeball" a microchip or other solid state electronic device to evaluate when or even if it might fail. I need a very expensive piece of electronic support equipment to tell me that.

My mission here is to produce an affordable, maintainable, and demonstrably "better", in every sense of the word, "electric aircraft". That objective is incompatible with retaining standing armies of engineers engaging in pointless "make work" projects. I consider all battery operated aircraft much larger than children's RC toys to be pointless endeavors. My aircraft won't have electronic motorized door handles, "just because we can". While I pay my electrical engineers, they're going to do something demonstrably useful for aviation. Anyone who needlesly increases the weight of our airframes by attempting to use batteries for inappropriate uses will promptly be shown the door.

3. Decide if what we're building should be a true helicopter or an electrically-powered V-22 facsimile. All the oddball eVTOL designs I've seen do not improve upon range, speed, or payload-to-distance over true helicopters or V-22 facsimiles or fixed wing aircraft, which means they're not "good aircraft". The one market I see for eVTOL of the variety developed thus far, that seems almost entirely ignored, is as a "rapid response" air ambulance or firefighter delivery vehicle that can near-instantly liftoff and head towards the scene of an emergency. Most emergency response vehicles do not get "used and abused", 24/7/365, the way commercial aircraft are. They're meticulously maintained but infrequently used. When used, they need to be ready to go, post-haste. This is where a battery operated eVTOL really would be a meaningfully better aircraft, purely for its ability to rapidly respond. You don't need to wait 5 to 10 minutes for the engines to spin up and pre-flight checklist completion. You flip the switch and it's ready to lift off seconds later.

#70 Re: Not So Free Chat » Chat » 2025-07-06 15:04:21