New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2026-01-18 11:57:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

project design to produce water on mars system for science mission size

Designing a Mars water production system for science missions involves extracting subsurface ice or hydrated minerals, processing them (heating/microwave), and collecting the vapor, using methods like drills (Coiled Tubing), heated regolith extraction (C.R.A.T.E.R.), or Rodriguez Wells, focusing on reliability, low mass, power efficiency for tasks like life support (ISRU) and propellant, with key components including drills, heaters, condensers, storage, and potentially atmospheric processors for oxygen/methane.

Core Concepts & Technologies

In-Situ Resource Utilization (ISRU): The overarching goal is using local Martian resources (water ice, atmospheric CO2) to create needed consumables (water, oxygen, methane fuel).

Extraction Methods:

Drilling: Using drills (like the Mars Ice Drill or Coiled Tubing) to reach buried ice, potentially melting it in situ.

Regolith Heating: Heating Martian soil (regolith) to release bound water molecules (e.g., 200-500°C).

Rodriguez Well (Rodwell): A method using a well to access large subsurface ice deposits, especially glacier-like forms.

Processing & Collection:

Microwave Heating: Efficiently freeing water from soil.

Condensers: Cooling water vapor to collect liquid water.

Storage: Tanks for storing extracted water.

Atmospheric Processing (for oxygen/methane): Using the Sabatier process (CO2 + H2 → CH4 + H2O) to make fuel, creating water as a byproduct.

System Design for Science Missions (Scalable)

Targeting: Use orbital data to find shallow subsurface ice or hydrated minerals, crucial for accessibility.

Excavation/Drilling Unit: A robust, potentially semi-autonomous system (e.g., drill with air/water jets) to reach the ice/hydrated material.

Processing Unit:

Heating Element: For regolith (microwaves/resistive heating) or sublimating ice.

Separation/Condensation: Capturing water vapor.

Collection & Storage: A reliable system to meter and store the water in tanks, potentially with internal heating/cooling loops.

Power & Control: Solar/RTG power, autonomous controls for simple operations, and telemetry for remote monitoring.

Integration (Optional): Link to a life support system (like CHRSy) for crewed missions or propellant production.

Example Project Elements (Student/Small Scale)

C.R.A.T.E.R. System (Colorado School of Mines): A conveyor belt system to feed Martian soil into a microwave-heated casing for water extraction.

Mars Ice Drill (FAU): A drill to penetrate ice, heat it, and pump water to the surface for collection

Designing a Mars water system for a science mission (e.g., 3-6 crew) involves In-Situ Resource Utilization (ISRU) like extracting subsurface ice (drilling/melting) or atmospheric vapor, combining with water recycling (ISS-style) for reliability, and using systems like Sabatier reactors for propellant/oxygen production, all needing redundancy and significant power (160kW+) for a ~1.5 yr stay, balancing mass/cost with crew needs for drinking, hygiene, science, and crucial life support. Key Design Components & Technologies Water Sourcing (ISRU)Subsurface Ice Extraction: Drilling (e.g., Coiled Tubing method) to access buried ice, followed by melting.Atmospheric Extraction: Capturing water vapor from the Martian atmosphere.Waste & Recycling: Advanced systems to recover water from urine, humidity, and hygiene, similar to ISS but with higher reliability for Mars.Water Processing & StoragePurification: Filtration, reverse osmosis, distillation, and UV treatment.Storage: Durable tanks (FRP, PEX) with anti-freeze/heating to prevent freezing, plus distribution piping.Water for Propulsion & Life SupportSabatier Reactor: Uses imported Hydrogen (\(H_{2}\)) and Martian Carbon Dioxide (\(CO_{2}\)) to create methane (\(CH_{4}\)) fuel and water (\(H_{2}O\)).Electrolysis: Splits water into Hydrogen and Oxygen, providing breathable air and rocket propellant (for ascent/return). Crew Size & System Implications Crew Size (e.g., 3-6): Impacts total water needed (drinking, hygiene, food prep, science), influencing habitat volume, water processing capacity, and ISRU system scale.Mass & Cost: ISRU dramatically cuts Earth-launched mass by using local resources, making missions feasible and more autonomous.Reliability: Higher redundancy and robust systems are critical due to the long travel time and inability to quickly resupply if systems fail. Example Mission Scenario (6 Crew) Pre-deployed Cargo: Habitat, ISRU plant, Descent/Ascent Vehicle (DAV) sent ahead.Crew Transit: Transported in a separate vehicle, potentially using water electrolysis for propulsion.Surface Operations: ISRU system extracts water, processes it, and stores it; water is used for life support and creating propellant for return. Key Considerations for Science Missions Power: Significant power (160kW+) needed for ISRU, life support, and thermal control.Science Payload: Water use for scientific experiments (e.g., hydroponics, sample processing) must be budgeted.Planetary Protection: Strict protocols for handling potential Martian microbes

Water Extraction from Martian Soil

The topic we have

ISRU Technology Development for Extraction of Water from the Mars Surface

Offline

Like button can go here

#52 2026-01-18 12:07:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Exploration sized

Designing a Mars water production system for a crew of 4-6 involves a multi-pronged approach: In-Situ Resource Utilization (ISRU) from Martian soil/ice, highly efficient water recycling (up to 98%+ on ISS) for transit, and robust storage/treatment systems, requiring advanced drills/miners, Sabatier reactors, electrolysis units, filtration (RO/Forward Osmosis), and storage tanks (FRP/PEX) with nanotechnology for a 1.5-2.5 year mission to meet hygiene, metabolic, and fuel needs. Crew size (often 4-6) dictates scale, with larger crews needing more redundancy and capacity, but fewer crew (e.g., 3) significantly reduces mass/cost, influencing system design. Key System Components & Design Principles Water Sourcing (ISRU):Regolith Extraction: Drills/heaters (like Mars Ice Drill concept) to extract water vapor from Martian soil (regolith) or subsurface ice.Atmospheric Extraction: Condensing atmospheric water vapor, though less direct than soil extraction.Chemical Conversion (Sabatier/Electrolysis): Using imported hydrogen and atmospheric \(\text{CO}_{2}\) to make methane fuel and water (\(\text{H}_{2}\text{O}\)), then electrolyzing water for breathing oxygen/rocket oxidizer.Water Production & Processing:Water Recovery System (WRS): Similar to ISS, recycling urine, humidity condensate, hygiene water with high efficiency (near 98%).Treatment: Reverse Osmosis (RO), Forward Osmosis (FO), distillation, and advanced filtration for purification.Storage: Lightweight tanks (Fiber-Reinforced Plastic - FRP, crosslinked Polyethylene - PEX) with leak detection, heating to prevent freezing.Life Support Integration:Metabolic Water: Generated from food/fuel (like the movie The Martian's concept using rocket fuel, though ISRU is preferred).Hygiene Water: Separate loop with efficient recovery and reuse. Crew Size Considerations (4-6 Astronauts) 6 Crew (Conjunction Class Mission): Longer stays (18 months surface), higher demand for water, requires larger ISRU units, more robust recycling, significant water storage redundancy.4 Crew (Transit/Surface): Lower overall demand, potentially simpler systems, but still needs high reliability for long durations (400-500 days transit + surface stay).Smaller Crew (3): Significantly reduces mass/cost/complexity, making larger ISRU systems more feasible or requiring less overall capacity, but fewer hands for maintenance. Mission Profile Example (6 Crew, ~2.5 Years Total) Transit (9-12 months): Relies heavily on recycled water, backup supplies (30+ metric tons if all water carried).Surface Stay (18 months): ISRU becomes critical for sustaining hygiene, metabolic needs, and propellant production for return.Key Design Goal: Minimize water mass from Earth; maximize ISRU & recycling to make the mission feasibl

Offline

Like button can go here

#53 2026-01-18 12:08:24

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Colony or settlement sized

Designing a Mars water system for a crew of 4-6 (initial) to dozens (colony) relies on In-Situ Resource Utilization (ISRU), primarily extracting water from Martian soil/ice via heating or microwave drilling, supplemented by high-efficiency closed-loop recycling of hygiene/wastewater, plus atmospheric water harvesting (like MARRS), all integrated with habitats (MHUs) and power (solar/nuclear), ensuring redundancy for survival and growth.

1. Water Sources & Extraction (ISRU)

Subsurface Ice/Hydrated Minerals: The main source; systems heat regolith (200-500°C) or use microwave energy down boreholes to vaporize water, then collect and condense it.

Atmospheric Water: Systems like MARRS (Mars Atmospheric Resource Recovery System) capture water vapor from the thin Martian atmosphere.

2. Water Processing & Recycling (Life Support)

ECLSS (Environmental Control and Life Support Systems): Highly reliable systems (similar to ISS) to recycle water from urine, humidity, and hygiene.

Bioregenerative Systems: Using algae or plants (in greenhouses/hydroponics) to further purify water and produce food, reducing Earth dependence.

3. System Design for Different Crew Sizes

Early Missions (4-6 crew): Focus on robust, high-reliability closed-loop systems with significant storage (1000+ days' supply) and initial ISRU capability.

Colony (Growing to 20+): Requires large-scale, scalable ISRU plants, modular habitats (MHUs) with extendable capacity, and robust power generation (solar/nuclear).

4. Key Components & Concepts

ISRU Hardware: Mobile units (like Honeybee Robotics' MISWE) for exploration and extraction.

Habitat Modules (MHUs): Inflatable structures with integrated water processing, living areas, and crop growth zones.

Power: Thin-film solar arrays or small nuclear reactors to power extraction and life support.

Redundancy: Critical for survival; backup storage, parallel systems, and emergency escape routes within habitats.

5. Water Needs Estimation

Baseline: Around 0.6-0.7 kg/person/hour (consumption, hygiene, plant growth) in a gravity environment, with high reclamation.

Plants: Require additional water (approx. 0.003 kg/hr/person) not easily reclaimed.

Example Design Framework (for a growing colony)

Initial Landing: Crew of 4-6 with pre-deployed ISRU hardware and life support units.

Expansion (Year 2+): Increase crew (6, 12, 24 per mission) using new missions, deploy larger ISRU facilities, establish larger crop areas, and build more habitat clusters.

ISRU Integration: Automated systems extract water, feed it to storage, processing units, and greenhouses, ensuring continuous supply

The Mars Homestead Project, led by the Mars Foundation and founded by Bruce Mackenzie, focuses on designing the first permanent settlement on Mars using local materials (In-Situ Resource Utilization - ISRU) to support a growing colony. The project emphasizes expanding beyond Earth-dependent exploration to a self-sufficient colony through agricultural and industrial development, rather than just short-term survival.

Key Aspects of the Mars Homestead Colony-Sized Approach

Initial Settlement Structure: The initial base is designed to support up to twelve individuals, eventually growing into a larger, permanent manufacturing community.

ISRU and Life Support: The core concept is "Don't Manage Scarcity; Exploit Abundance," utilizing Martian regolith, water ice, and the atmosphere (CO2) for fuel, construction, and life support.

Construction Methods: The project proposes building habitats by mining and processing local materials, including brick-making, utilizing volcanic caves, or using pressurized, excavated spaces.

"Linear City" Design: Inspired by Paolo Soleri, the layout focuses on constructing along the edge of a mesa or landform to allow for easy expansion.

Energy Generation: The design incorporates nuclear power plants and surface-based solar arrays to power mining, refining, and manufacturing operations.

Common Themes in Associated Presentations

"To Arrive, Survive & Thrive!": A common presentation title from the Mars Foundation (2006) focusing on the mission to design, fund, build, and operate the first permanent settlement.

Technical Papers: Numerous presentations have been given at Mars Society Conventions (e.g., Bruce Mackenzie, 22nd Annual Convention) focusing on the structural architecture, such as "lava casting" (an ISRU approach using local soil for structural elements).

Development Stages: Presentations often detail the progression from landing and initial shelter to a self-sustaining, growing, and thriving colony.

For a detailed look at the slides, you can view the 2006 overview presentation or search for Bruce Mackenzie's presentations on the Mars Society YouTube channel

Mars Homesteads colony plan to recycle waste

Dead link marshome.org site now gone

Related topic Sewage treatment

Offline

Like button can go here

#54 2026-01-18 12:08:40

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

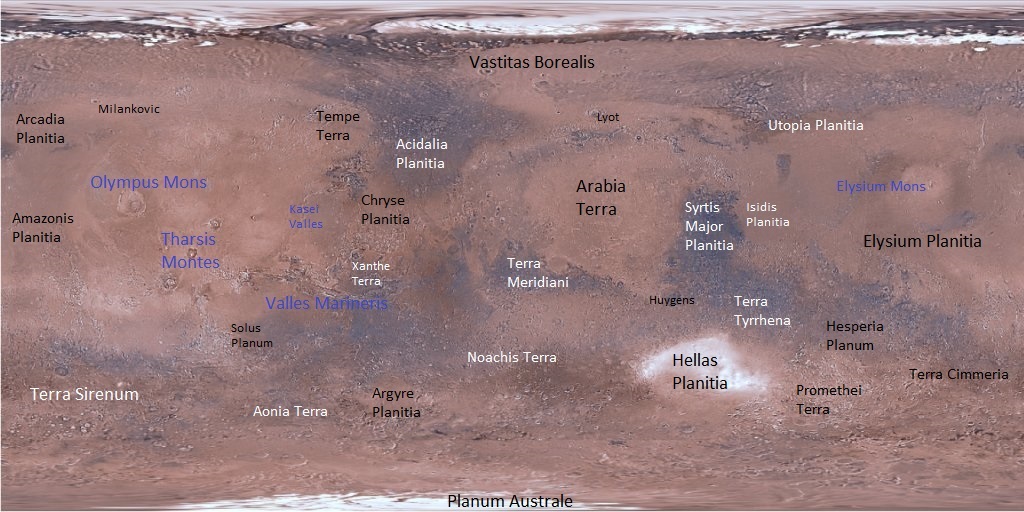

High-concentration iron ore locations on Mars are found in areas rich in hematite, like Meridiani Planum (famous for "blueberries"), Vallis Marineris, and Utopia Planitia, with the whole planet covered in iron-rich dust, though mining quality requires locating purer deposits. Martian iron exists as abundant hematite (\(Fe_{2}O_{3}\)), easily found in regolith and concretions, and also as metallic nickel-iron meteorites, providing resources for potential In-Situ Resource Utilization (ISRU) to produce steel.

Key Locations & Forms of Iron Meridiani Planum: Known for abundant hematite spherules ("blueberries") found by the Opportunity rover, indicating past water activity that concentrated the ore.Utopia & Amazonis Planitia: Maps show high iron content in these mid-latitude regions.Vallis Marineris & Sinus Meridiani: Detected as deposits of coarse-grained, grey crystalline hematite.

Meteorites: Nickel-iron meteorites litter the surface, offering a direct source of metallic iron that doesn't oxidize easily in Mars' atmosphere. How It Can Be Used for Steel Hematite Reduction: Martian regolith (soil) and hematite deposits are rich in iron oxide (\(Fe_{2}O_{3}\)). Researchers are exploring processes like pyrolysis (heating the dirt to 1000°C) under Martian conditions to extract metallic iron.Metallic Iron Source: The nickel-iron meteorites can be melted down, potentially alloyed with other elements, and cast.

Challenges: While iron is abundant, creating quality steel requires finding concentrated, pure deposits and overcoming challenges like the low-oxygen Martian atmosphere for processing. In Summary: Mars is iron-rich, with rich hematite deposits (like the "blueberries" at Meridiani Planum) and common meteorites providing raw materials. Future colonists could use these local resources to establish an "Iron Age," though significant processing will be needed to extract and refine the metal for steel production

Iron ore is exceptionally abundant on Mars, generally found as iron oxides (magnetite, hematite) in the red dust and surface regolith. High-concentration deposits are primarily located in the northern lowlands spanning from Utopia Planitia to Amazonis Planitia, as well as within Acidalia Planitia. Hematite-rich areas suitable for mining include Meridiani Planum, Valles Marineris, and Aureum/Iani Chaos. Here is a breakdown of how to locate, extract, and convert Martian iron into stainless steel.

High-Concentration Iron Locations on Mars Meridiani Planum: Known for large, concentrated deposits of gray, crystalline hematite (\(Fe_{2}O_{3}\)), particularly small spherules known as "blueberries".Valles Marineris & Chaos Terrains: These areas show signs of ancient water activity that concentrated iron oxides.

Northern Lowlands (Utopia/Amazonis Planitia): Identified by orbital gamma-ray spectrometers as having the highest concentrations of surface iron.Impact Craters (Southern Highlands): High-grade ore systems likely exist in the subsurface, exposed by large crater impacts.

Meteorites: Nickel-iron meteorites are relatively common on the surface, offering a source of high-grade, pre-reduced iron that does not require smelting. How to Make Steel on Mars Since conventional coal-based smelting (coke) is not available, Martian steel production will rely on hydrogen reduction or electric processes. Mining and Concentration: Magnetic processing and sieving can be used to separate iron-rich dust from the regolith.

Reduction (Extracting Iron):Hydrogen Reduction: Hydrogen (produced via electrolysis of Martian water ice) can be used to remove oxygen from iron oxide at roughly 800°C.

Direct Electrolysis: Using heat and electricity to break the bonds between iron and oxygen.Pyrolysis: Heating iron-rich regolith to 1000°C–1400°C to extract iron and create alloys.

Carbon Addition: To turn iron into steel, carbon is necessary. This can be sourced from the atmospheric \(CO_{2}\).Electric Arc Furnace (EAF): The resulting iron can be melted with carbon in an electric arc furnace to produce steel. How to Make Stainless Steel Stainless steel requires iron alloyed with chromium (usually 10.5% or more) and often nickel or molybdenum for corrosion resistance.

Obtain Alloying Elements:Chromium/Nickel: These are essential for stainless steel. While iron is abundant on Mars, finding high concentrations of chromium may require targeted prospecting in volcanic, hydrothermal regions (e.g., Tharsis region).

Recycling: Initial stainless steel production may rely on recycling the high-grade stainless steel from landing vehicles (e.g., SpaceX Starship).

Refining (AOD/VOD Process): The molten iron is transferred to a converter, such as an Argon Oxygen Decarburization (AOD) converter, where oxygen and argon are blown through the melt to reduce carbon content and add chromium/nickel.

Casting and Shaping: The refined molten stainless steel is cast into slabs or billets and shaped into sheets, pipes, or beams.

Key Challenges Energy Consumption: Producing steel requires massive amounts of power, requiring a large-scale solar or nuclear power infrastructure.

Gravity Constraints: Smelting in low gravity (0.38g) requires specialized machinery, likely centrifuges, to separate impurities from the metal.

Refractory Materials: Furnaces need specialized lining to withstand temperatures up to 2200°C

Offline

Like button can go here

#55 2026-01-18 12:08:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

cooling or dehumidiation

For a structure with a 200 m (656 ft) diameter and 120 m (394 ft) tall parabolic dome, standard High-Volume, Low-Speed (HVLS) ceiling fans, typically with diameters up to 7.3 meters (24 feet), would be used in a calculated array to provide effective air circulation. Multiple fans, rather than a single massive fan, are required due to the immense size of the space.

Step 1: Calculate the Floor Area and Assess Fan Coverage The floor area of the dome is a circle with a radius of 100 m:\(\text{Area}=\pi \times \text{radius}^{2}=\pi \times 100^{2}\approx 31,416\,\text{m}^{2}\,(338,166\,\text{ft}^{2})\)A single large HVLS fan (e.g., 7.3 m diameter) typically covers between 900 and 1,500 square meters. For cooling purposes, the coverage area is roughly five times the fan's diameter for large-blade fans, but for destratification (air mixing in very high spaces), it can be up to ten times.

Step 2: Determine the Number and Placement of Fans Given the vast area, an array of fans is necessary. The general guideline is to space fans a distance equal to at least one fan diameter apart, or up to three times the diameter depending on the manufacturer and application. For consistent coverage, a grid pattern is ideal. For such a massive, open space, consulting with an HVLS expert for a custom layout drawing is crucial. The number of 7.3-meter (24-foot) fans could range from 21 to over 30 to cover the entire area effectively, depending on specific airflow requirements and building obstructions.

Step 3: Consider Ceiling Height and Fan Mounting The 120 m (394 ft) ceiling is extremely high. While fans perform well when mounted between 6 and 12 meters (20 to 40 feet) above the floor, longer downrods might be needed to position the fans within the occupied zone for optimal air movement. The fans must also maintain safe clearance from the floor (at least 3 m or 10 ft) and other structural elements.

Answer: For a parabolic dome ceiling with a 200 m diameter and 120 m height, multiple HVLS fans with diameters typically ranging from 6.1 meters to 7.3 meters (20 to 24 feet) would be required. The exact number and strategic placement of fans, likely exceeding two dozen units, should be determined through a professional airflow study to ensure uniform air circulation and temperature control

Commercial 7m (7-meter) fans refer to large industrial fans, often HVLS (High-Volume, Low-Speed) ceiling fans, used for cooling vast spaces like warehouses, factories, malls, and arenas, providing massive airflow (measured in CFM) for comfort and energy efficiency in huge commercial areas. You'll find them as massive ceiling units or powerful pedestal/wall-mounted fans designed for serious air movement, not typical home use, with high CFM ratings (thousands) for effective cooling.

Key Characteristics:

Size & Type: Look for HVLS fans (often 7 feet or more in diameter) or large pedestal/wall fans, not standard residential ceiling fans.

Airflow (CFM): Measured in Cubic Feet per Minute; higher CFM means more air moved, crucial for large spaces (e.g., 7000+ CFM is common).

Applications: Warehouses, factories, gyms, shopping centers, agricultural buildings, and large event spaces.

Benefits: Better air circulation, reduced heat, improved comfort, and energy savings over traditional AC in large buildings.

Where to Find Them:

Home Improvement Stores: The Home Depot offers large industrial ceiling fans.

Online Marketplaces: Alibaba.com has many manufacturers for 7m industrial fans.

Specialty Retailers: Amazon.com (for large pedestal/wall fans) and industrial fan suppliers.

When searching, use terms like "HVLS fan," "industrial ceiling fan," "large commercial fan," or specify CFM and diameter (like 7ft or 7m) for best results

Offline

Like button can go here

#56 2026-01-18 12:08:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

We launched the evening with discussions of kbd512's vision of a ring/dome habitat

SpaceNut joined in with numerous suggestions for materials and procedures.

We settled on a population to serve: 1000

That is a nice round number to work with. SpaceNut agreed to consult his AI friends to see if any of them can work out the requirements for all the equipment needed to sustain that population.

We are in need of fresh water and sewerage systems, and the equipment to recover fresh water from the sewerage.

SpaceNut is in an industry that deals with humans in closed life support environments.

Hopefully he will be able to help kbd512 size the complex.

Kbd512 gave us an expectation that some support systems would be inside the building and some outside.

Offline

Like button can go here

#57 2026-01-18 19:55:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

make a building that can house 1,000 crew is just a multiplier for what needs to be setup for all space requires from power, life support, greenhouse, medical care, ect these are not established for mars or for the moon in there entirety.

Picking any number to support any person is going to fail for any construction when quotative numbers are not proven.

That's like saying you only need 8 gallons of water to drink for the whole mission with none on the other end once you are there.

Ignoring facts of who, what, where, when and more 20 questions are blank.

The facts of mars for plumbing are going to be below the structures floor but inside the pressurized area hull of 0.1 M with depth of the floor depends on materials and where there is more floors above. ceiling are 2 meters tall with lighting 0.05M, electrical 0.05M, HAVC 0.3m set aside to keep these out of the way of the people with in. This layout repeats for the next and so on.

That means the proposed 125m³ per pressurized volume for each family of 4 is a rectangle of 2.5 m tall with 5 m wide x 10 m long.

1,000 crew / 4 means 250 such rooms but that is not all of the internal requirement as hall ways are need on both side of these so that is 2.5 M x 1 M wide x 2 x 250 x 10 M = 62,500 cubic meter for living space regardless of shape for sleeping quarters.

Private Hygiene: 25 m³ per crew. 2.5 m x 2.5 m x 4 m

Exercise/Equipment: 9 m³ per crew.

Health/Medical Area: per crew. For long-term, permanent, or expanding settlements, the available volume can increase through local construction (e.g., using regolith for radiation shielding), but the initial landing, transit, and surface habitats will likely operate close to the minimum 25 m³/person requirement with total are for the medical suite 4645 to a max of 9290 square meters

Offline

Like button can go here

#58 2026-01-18 19:55:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

more dummy pages

Offline

Like button can go here

#59 2026-01-19 06:52:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Establishing a 1,000-person colony on Mars requires a significant, dedicated gym facility—estimated at 3,000–5,000 square meters—to mitigate muscle atrophy and bone density loss in 38% gravity. Given the high-intensity daily exercise requirements (equivalent to 2+ hours per person on the ISS), this facility would likely consist of multiple, specialized pressurized structures rather than a single room.

Gym Facility Requirements (1,000 Personnel)

Total Area: ~3,000–5,000 square meters (based on 3–5 sq/m per person for a "station" or commercial standard).

Equipment Density: Roughly 10–30 sq/ft (1–3 sq/m) per piece of equipment for comfort, or 20–50 sq/ft for strength training.

Core Equipment: Advanced Resistive Exercise Device (ARED) for strength, Treadmill 2 (T2) with vibration isolation for running, and Cycle Ergometer (CEVIS) for cardio.

Design Consideration: The facility should be part of a larger pressurized "city" complex, likely utilizing 3D-printed Martian concrete domes or inflatable modules, according to NASA-sponsored habitat studies.

Key Design Elements for Mars Gyms

Gravity Countermeasures: Because Mars has lower gravity, the equipment must allow for daily, high-intensity workouts to prevent long-term health degradation.

Equipment Type: Compact, multi-use devices like the ROCKY (Resistive Overload Combined with Kinetic Yo-Yo) device are necessary to save space.

Psychological Benefit: Beyond physical health, dedicated gym space is essential for mental well-being and reducing the feeling of being "cooped up".

Construction: The gym area would be built using 3D-printed regolith (Martian soil) structures, which provide necessary shielding against radiation.

Space Context & Comparisons

ISS: Current gym equipment for 3-6 crew members takes up roughly 850 cubic feet.

CHAPEA (Mars Simulation): A 1,700-square-foot habitat includes a dedicated, yet small, area for fitness.

Starship Transport: A 100-person transport ship is designed with a volume of roughly 1,000+ cubic meters, with a smaller portion allocated for exercise.

For a 1,000-person colony, the gym would not be a single room, but a large, multi-zone facility, potentially divided into specialized areas for cardio, free weights, and rehabilitation

Offline

Like button can go here

#60 2026-01-19 06:52:16

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

more dummy pages

Offline

Like button can go here

#61 2026-01-20 16:30:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Structural metal methods for possible use with structures on mars.

The Orion capsule features an aluminum isogrid/orthogrid structure designed for maximum strength-to-weight efficiency, featuring complex machining, with specific structural requirements including:

Grid Structure: The structure consists of machined aluminum panels (isogrid or orthogrid), which are assembled into rings for the pressurized crew cabin and other sections.

Skin/Web Thickness: Analysis of similar, high-strength aerospace applications indicates skin pocket thickness is driven by buckling requirements during re-entry. While not providing a single definitive number for the entire capsule, typical aerospace isogrid designs often involve thin skins (e.g., < 0.04 inches/1.0 mm) with significantly thicker integral ribs (sometimes up to 8mm or more, or "> 0.32 inch") for reinforcement.

Weldland Thickness: In structural analyses of similar metallic structures, weldlands (areas where panels are welded together) are designed with a minimum thickness of 0.25 inches to maintain structural integrity.

Manufacturing Tolerances: The panels are precision-machined, with components for the SLS/Orion system (like the adapter) featuring a "lightweight" design to reduce weight while preserving structural integrity, as noted in the manufacturing of the Orion Stage Adapter.

The orthogrid web thickness is primarily determined by buckling stability and strength requirements during high-load scenarios

Offline

Like button can go here

#62 2026-01-20 16:30:39

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Isogrid stainless steel manufacturing for Mars habitats leverages additive manufacturing (3D printing) with in-situ resources (ISRU), like Martian iron ore, to create strong, lightweight panels for structural support, potentially using techniques like Directed Energy Deposition (DED) for metal alloys, reducing Earth launch mass by printing parts on-site. This approach, focusing on robotic construction and modular designs with materials like regolith or steel powder, aims to enable autonomous habitat creation and repair, enhancing mission robustness and self-sufficiency for long-term Martian bases.

How it works

Material Sourcing: Martian iron ore (regolith) can be processed to create steel powder, replacing imported materials.

Additive Manufacturing: DED 3D printing is used to build intricate isogrid structures, fusing metal powder layer by layer.

In-Situ Production: Robots build panels autonomously on Mars, creating walls and components for habitats.

Gradient Alloys: Researchers are exploring gradient alloys, like transitioning from Invar to stainless steel, for specific properties like thermal expansion.

Benefits for Mars habitats

Reduced Mass: Eliminates the need to launch heavy building materials from Earth, lowering costs.

Autonomous Construction: Robots can build habitats before crew arrival, increasing safety and efficiency.

Enhanced Reliability: On-site manufacturing allows for creating spare parts, supporting self-repair and growth.

Structural Efficiency: Isogrids provide high strength-to-weight, ideal for pressurized environments.

Key technologies & concepts

ISRU (In-Situ Resource Utilization): Using local Martian materials.

DED (Directed Energy Deposition): A 3D printing method for metals.

Robotic Construction: Autonomous assembly and printing.

Modular Design: For easier maintenance and replacement of components.

Current Status & Future

NASA and partners are actively researching and prototyping these methods, with testbeds like Mars Dune Alpha demonstrating 3D-printed habitats and technologies for ISRU construction showing high Technology Readiness Levels (TRLs) for future mission

Offline

Like button can go here

#63 2026-01-20 16:30:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

A 1,000-crew, self-sustaining Mars habitat utilizing a ring-shaped, Quonset-hut design made of stainless steel offers a durable, high-volume, and potentially scalable solution to extraterrestrial habitation. By leveraging a curved structural form, the habitat distributes pressure efficiently while allowing for modular construction using materials suitable for the harsh Martian environment, such as stainless steel (analogous to Starship technology).

Structural & Design Concepts

Quonset Hut Shape: The semi-circular cross-section is ideal for pressure vessels, as it distributes stress uniformly. Large-scale, curved metal arches provide high durability and resistance to exterior pressure loads.

Ring Configuration: A ring shape allows for a modular, expandable colony where segments can be added, and it provides a circular, continuous loop for efficient, self-contained, and self-sufficient living spaces.

Dimensions & Pressure: To house 1,000 crew members, a large-radius ring (likely over 500 meters in diameter) would be required to provide sufficient living, working, and agricultural space. The 0.5 bar pressure (roughly half Earth's sea-level pressure) is a common, manageable target for reducing structural load compared to 1 bar while still allowing human comfort.

Materials: Stainless steel is a prime candidate due to its high strength, relatively low cost, and durability, especially under the extreme temperature fluctuations on Mars. It also allows for easier welding/fabrication using robots (such as "Atomic Liberation of Propellant and Habitat" (ALPH) units).

Sustainability & Life Support (In-Situ Resource Utilization - ISRU)

A self-sustaining colony requires producing resources on-site to minimize resupply from Earth:

Shielding: To protect against radiation and potential, albeit low, atmospheric leakage, the stainless steel structure would likely need to be covered by 1-2 meters of Martian regolith.

Food Production: Hydroponic or aquaponic systems, potentially using processed Martian regolith, would be integrated into the habitat, perhaps in specialized greenhouse segments of the ring.

Water & Air: Local water ice could be mined to supply water for drinking, cleaning, and electrolysis to produce oxygen for breathing and hydrogen for fuel.

Construction Materials: While the initial structure uses transported or on-site fabricated steel, subsequent expansion could utilize 3D-printed materials made from local basalt fiber and binders.

Safety and Operational Factors

Pressurization Risk: The 0.5 bar pressure differential requires robust construction to avoid explosive decompression, with particular attention to airlocks and structural seams.

Modular Safety: The ring structure should be segmented with pressure-tight, closable doors (airlocks) to allow for sealing off damaged sections without affecting the entire colony.

Energy Generation: The colony would require massive solar arrays and, most likely, compact nuclear reactors to sustain the 1,000-person population, greenhouses, and processing machinery.

This configuration provides a sustainable, long-term habitat that combines the proven, rugged design of a Quonset hut with modern, material-efficient, and self-reliant Mars technologies.

Offline

Like button can go here

#64 Yesterday 11:30:21

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Mars settlement projects typically progress through phases from initial robotic exploration and small outposts (Pre-settlement) to permanent, growing settlements with developing infrastructure (In-settlement), culminating in self-sufficient, potentially terraformed societies (Post-settlement), focusing first on establishing basic life support, resource utilization (ISRU), energy, and habitats before expanding to a city-like presence with economic independence. Key stages involve robotic reconnaissance, crewed landings, building propellant plants, establishing habitats, developing local agriculture, mining, and transitioning to self-sufficiency, requiring advances in transportation, closed-loop life support, and energy systems.

Key Phases & Stages

1. Pre-Settlement (Robotic & Early Outpost):

• Robotic Reconnaissance: Detailed surveys, sample collection (e.g., Perseverance), testing technologies for fuel/oxygen production from the atmosphere.

• Cargo Pre-Deployment: Sending autonomous cargo, including fuel production equipment, before human arrival.

• First Crewed Missions: Establishing a rudimentary base, completing the propellant plant for return fuel, and testing life support.

2. In-Settlement (Permanent & Growing Colony):

• Infrastructure Development: Building habitats, mining water, growing crops, creating power systems (solar/nuclear).

• Resource Utilization (ISRU): Extracting and processing Martian resources (water, metals, minerals) for construction and fuel.

• Population Growth: Increasing crew sizes, developing a local economy, and establishing governance.

3. Post-Settlement (Self-Sufficiency & Beyond):

• Industrial Independence: Scaling up mining, manufacturing (3D printing, metals, plastics) to reduce Earth reliance.

• Societal Development: Growing into towns/cities, developing unique Martian culture, governance, and potentially independent political structures.

• Terraforming (Long-Term): Modifying the environment to create breathable air and habitable zones, a highly speculative long-term goal.

Key Technologies & Goals

• Transportation: Reliable, efficient Earth-Mars transport (e.g., SpaceX Starship).

• Life Support: Perfecting closed-loop systems for air, water, and food.

• Energy: Sustainable power generation (solar, nuclear).

• ISRU: Water extraction, atmospheric processing for fuel/oxygen, material processing.

• Habitats: Durable, radiation-shielded shelters (surface and underground)Mars settlement projects, like SpaceX's vision, progress through phases: pre-settlement (outposts), in-settlement (permanent bases), and post-settlement (self-sufficient society), aiming for crewed landings in the late 2020s/early 2030s and self-sufficiency by mid-century, requiring massive initial cargo (Starships carrying 100+ tons) for habitats, life support, and resource utilization (ISRU) like water and fuel production from Martian air and ice, with the ultimate goal of a large, self-sustaining population.

Phases of Development (Conceptual)

1. Pre-Settlement (Exploration & Outpost)

• Focus: Robotic missions, establishing basic infrastructure, resource identification (water ice, minerals).

• Key Tech: Advanced rovers, ISRU (In-Situ Resource Utilization) for oxygen/methane (fuel/air).

• Timeline: Current robotic exploration, early cargo missions (late 2020s).

2. In-Settlement (Permanent Base)

• Focus: First human landings, establishing initial habitats, expanding resource production (ISRU, agriculture), reducing Earth dependency.

• Key Tech: Habitable modules, power systems, water processing, basic manufacturing.

• Timeline: First crewed landings (early 2030s), developing permanent presence.

3. Post-Settlement (Self-Sufficient Society)

• Focus: Large-scale population, full industrialization, economic self-sufficiency, cultural development.

• Key Tech: Advanced manufacturing, large-scale life support, robust local economy, potential for terraforming elements.

• Timeline: Decades-long process, aiming for self-sufficiency by 2050+.

Timeline & Mass Estimates (SpaceX Example)

• Early Missions (2020s-2030s): Cargo & Crew via Starship (100+ tons capacity).

• Cargo: Essential for habitats, initial supplies, ISRU equipment.

• Crew: Small groups (4-10+), increasing over time.

• Self-Sufficiency: Goal by 2050, requiring a million people using numerous Starships over many launch windows (every ~26 months).

Mass Requirements & Challenges

• High Mass: Water, air (oxygen/nitrogen), fuel, food, equipment, habitats.

• ISRU Critical: Extracting water ice and using atmospheric CO2 for oxygen and methane fuel (CH4) is essential to reduce launch mass from Earth.

• Example: Water is heavy; a Starship (100 tons payload) could carry enough water for 20 people for years, but continuous resupply is needed.

In essence, Mars settlement requires a phased approach, leveraging current tech like Starship for massive cargo delivery, transitioning from outposts to permanent bases, and finally, fostering self-sufficiency through local resource utilization to support a growing populationEstablishing a Mars propellant plant to refuel a Starship for a return trip likely requires several cargo missions, with estimates suggesting 2 to 6+ ships to deliver necessary infrastructure (solar panels, mining equipment) and initial fuel stocks. While some scenarios suggest 3-4 ships can enable a return via in-situ resource utilization (ISRU), initial, safer approaches might use 6+ tankers to establish necessary infrastructure.

Seems that we are not going to our landing site of Korolev Crater

SpaceX is planning to land multiple uncrewed Cargo Starships on Mars as early as 2030, with a focus on locations in the northern lowlands, such as Arcadia Planitia, which are rich in subsurface water ice. While the Korolev Crater is a notable, 82-kilometer-wide, ice-filled feature, it is located at 73° North latitude, which is generally outside the prime, lower-latitude, or mid-latitude zones (closer to the equator for solar power) favored for initial,, easier landings.

Key Aspects of Multiple Cargo Starship Landings on Mars:

Landing Locations: SpaceX has downselected candidate sites, primarily focusing on Arcadia Planitia, Deuteronilus Mensae, and Phlegra Montes. These areas offer flat, low-elevation, and less rocky terrain, reducing the need for extensive obstacle avoidance.Challenges and Strategy: Landing requires high precision due to the thin atmosphere, necessitating a "belly-flop" maneuver followed by a vertical landing using legs. The ships are designed to land at least 6–9 engines to generate sufficient braking force.

Landing Procedures: Multiple Starships are expected to land in close proximity (within a few kilometers of each other) to build up an initial outpost.

Infrastructure Setup: The initial cargo missions will land equipment, including tools to extract water from ice for propellant production (using the Sabatier process) and for creating breathable oxygen.

Why Not Directly in the Center of Korolev Crater?

Latitude and Solar Power: Korolev Crater is at a high northern latitude (73°N), whereas early missions require closer to the equator (under 40° latitude) for consistent solar power and better thermal management.Terrain: The center of the crater is a 1.8-kilometer-deep, 60-kilometer-wide mound of solid water ice. While this is ideal for resources, it is a massive glacier, not a "level surface" in the sense of a stable, rocky landing pad, making it unsuitable for heavy, vertical-landing rockets.

Therefore, multiple Starships would likely land on the level plains of Arcadia Planitia or adjacent to large, accessible ice deposits rather than inside the Korolev Crater itself, even though that crater is a significant source of iceInfrastructure Requirements: A fully operational plant capable of producing 1,000+ tons of propellant (methane and oxygen) for a return journey requires substantial power, estimated at 5 GWh, needing ~250 metric tons of equipment, equivalent to 2+ fully loaded cargo Starships.

Fuel Mining & Production: The process involves extracting water ice and capturing \(CO_{2}\) from the atmosphere.

Alternative/Interim Methods: Rather than immediate, full ISRU, early missions might rely on landing 3-4 Starships, where 3 are drained to fuel 1 for the return trip, or using 4-6 ships to establish a rudimentary plant.

Scale: SpaceX aims to send at least 2 uncrewed cargo ships before the first crewed mission to set up power, mining, and life support. Ultimately, the number of ships depends on the efficiency of the ISRU plant, the power capacity installed, and the willingness to risk the first crew's return capability

Water source from Korolev Crater

Based on current SpaceX Mars mission architecture, establishing a propellant plant on Mars to refuel a Starship for a return journey, utilizing water ice, requires a multi-stage, cargo-heavy operation. Initial Setup Phase: To establish the necessary propellant plant (Sabatier reactors, mining equipment, solar arrays) at a location like Korolev Crater, early, uncrewed missions would need to land several cargo Starships (potentially 2–5) containing roughly 100+ tons of equipment each.Propellant Production Requirement: To refuel a single Starship for a return journey, the plant must produce approximately 1,200 metric tons of propellant (methane and oxygen).Operational

Requirement: While early estimates suggested 1–2 cargo ships worth of equipment could start production, a more robust and faster turnaround (within one synod, or 26 months) likely requires at least 3-4 cargo ships to be active to ensure enough power and water processing capability to produce the ~1,200+ tons of fuel. In summary, to start a plant, 2-5 dedicated cargo Starships are required to land the equipment, with at least 3-4 of them acting as operational plant components/fuel depots to reliably produce enough fuel for one return trip.

Key considerations: Water Source: Korolev Crater is an ideal, high-latitude location (\(73^{\circ }\text{N}\)) with large, accessible, near-surface water ice deposits, reducing the need for deep drilling.

Power: The limiting factor will be the mass of solar panels or nuclear reactors required to power the electrolysis process to turn that water into hydrogen, requiring significant cargo mass for power generation.

Launch Windows: These cargo ships must arrive at least one, if not two, synodic periods (26–52 months) before the crew arrives, to ensure the tanks are full

Landing multiple SpaceX Starships on the level surface of the Korolev Crater on Mars to avoid damaging its 1.8 km thick, 60 km wide water ice mound is feasible but requires careful landing site selection and operational procedures. The Korolev Crater is an ideal destination for future missions because its deep basin acts as a natural "cold trap," creating a permanent, stable, and protected reservoir of ice, with air above it being significantly colder and heavier than the surrounding atmosphere.

Strategies for Non-Destructive Landing

To avoid melting or destroying the ice, landings must be carefully managed to minimize heat and debris:

Distance from Ice Mound: Landings should occur on the outer edges of the crater floor or on the flat plains outside the crater rim, rather than directly on the central ice mound, to prevent heat-induced sublimation or contamination.

Controlled Descent & Landing: Starship uses controlled, vertical landings powered by its Raptor engines, allowing it to precisely target non-ice zones.

Landing Pad Development: Initial cargo missions would likely need to prepare a, stable, and possibly paved, or reinforced landing surface on the Martian regolith to prevent the engines from creating a large, dangerous, and erosive crater beneath them.

Engine Exhaust Management: While the Raptor engines operate for a short time, they still produce high heat and pressure, so landing on prepared, rocky, or flat, non-ice areas is crucial to prevent the ice from "melting" or being covered in soot.

Environmental Considerations

The "Cold Trap" Stability: The ice in the Korolev Crater is protected because the cold air above it acts as a shield from surrounding warm air, meaning a small amount of disturbance will not immediately cause the entire ice mound to melt.

Impact of Multiple Landings: Multiple landings would require extensive site surveys and careful planning to ensure the cumulative, long-term impact on the local environment is kept to a minimum.

Potential Contamination: The use of methane/oxygen fuel is relatively clean, producing less soot than other rockets, but still produces CO₂ and water vapor, which could potentially contaminate the pristine, untouched ice.

By landing on the periphery of the crater's interior or on the surrounding plains, multiple cargo Starships can safely deliver supplies to the edge of this vast water resource without destroying the unique geological feature

The Korolev Crater on Mars, located in the northern lowlands at 73°N latitude and 165°E longitude, features a remarkably smooth, flat, and dome-shaped surface in its central region. This topographically uniform area is a 1.8-kilometer-thick, 60-kilometer-wide mound of permanent water ice.

Topographic Features and Data:

Smooth Center: The central, ice-filled floor of the 82-km-wide crater acts as a natural "cold trap," creating a flat, bright, and smooth surface.

Elevation: The crater floor lies approximately 2 kilometers below its rim.

Topographic Profile: Color-coded topographic views (such as those from the High Resolution Stereo Camera on Mars Express) show the central ice mound as a relatively high-altitude, flat deposit, whereas the surrounding area is characterized by the rugged, steep crater walls.

Composition: The flat surface is not snow, but a massive deposit of water ice, with a volume of approximately 2,200 cubic kilometers, that remains stable year-round.

The smooth, ice-filled depression is surrounded by the dune fields of Olympia Undae, further distinguishing the flatness of the crater floor from the surrounding terrain

AI seems to not understand being not landing inside the crater on the ice.

Trying to land outside of the crater but on flat smooth surface:

Landing outside the immediate topographical map area of the Korolev Crater on Mars (located at 73°N, 165°E in the northern lowlands) allows for access to smooth, flat terrain within the broader Planum Boreum or the nearby Olympia Undae region. These areas are characterized by extensive, low-lying northern plains.

Recommended Smooth/Flat Areas Outside Korolev Crater

Planum Boreum (Northern Polar Plain): The Korolev Crater is located on this vast, relatively flat expanse. The plains surrounding the 2-kilometer-high crater rim offer extensive flat, solid ground suited for landing.

Olympia Undae: Located just north/northeast of Korolev, this dune field wraps around part of the north polar cap. While it is a dune field, the boundary regions between the plains and the dunes offer relatively smooth, accessible terrain.

Northern Lowlands (General): The region surrounding Korolev is part of the northern lowlands, which are characterized as being much smoother and lower in elevation than the southern hemisphere. These areas are often favored for landing due to having fewer obstacles and lower topographical variation.

Key Topographical Features in the Area

Rim Elevation: The rim of Korolev Crater stands approximately 2 kilometers above the surrounding Plains.

Surface Composition: The terrain immediately surrounding the crater is typical of the northern high-latitude plains, often covered in seasonal frost and dust.

Accessibility: The region is considered a "cold trap" and is a primary target for finding water-ice and studying polar climate history.

The surrounding northern plain, specifically the area within the Mare Boreum quadrangle (specifically away from the crater rim), provides a flat, stable surface

Offline

Like button can go here

#65 Yesterday 11:49:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,372

Re: WIKI Project Designing for Mars

Another view of the Korolev

Offline

Like button can go here