New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2017-06-01 06:50:12

- Oldfart1939

- Member

- Registered: 2016-11-26

- Posts: 2,488

Re: Designing the best greenhouse demonstrator for Mars

If we're going through the efforts to put anything underground, it should be human sleeping quarters. Based on the Martian Sol, this will automatically reduce the accumulated GCR exposure significantly. Based on the recently released GCR exposure data for the BEAM habitat on the ISS, the Bigelow structure doesn't do much for cosmic radiation attenuation.

Last edited by Oldfart1939 (2017-06-01 06:54:31)

Offline

Like button can go here

#52 2017-06-01 11:22:40

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,083

- Website

Re: Designing the best greenhouse demonstrator for Mars

Be careful interpreting radiation measurements from BEAM on ISS. It was designed with a 6 inch hull thickness to be equivalent to an ISS module in terms of radiation protection. B330 is the "deep space" module design, with an 18-inch hull thickness. It doesn't pack up as tightly, but provides 3 times the shielding, and even better micrometeroid protection.

It's awfully hard to find specifics, as Bigelow has removed a lot of construction specifics from its website recently. But as near as I can tell, these hulls are many multiple layers of Kevlar and Vectran, within a white cloth cover, and surrounding an internal bladder and restraint system. The white cloth cover controls both sunlight and atomic oxygen exposure. The Kevlar is basically the bulletproof vest, and the Vectran is the same radiation shielding as Vectran garments for nuclear workers.

Looks like a pretty smart design to me, and 3 times BEAM's radiation shielding is what Bigelow proposes for use outside low Earth orbit. He is basically waiting around for NASA to get comfortable with it, and already has designs for spacecraft modules, space stations away from Earth, and surface habs for moon and Mars. I saw some hints of my proposal: dock some end-to-end and spin that baton for spin gravity. Bigelow says adding floors to stand on is a "nothing" sort of problem to solve.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#53 2017-06-01 19:13:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Some of the articles talk about creating shield via 3D printing of materials in various thickness to test with in the Beam unit.

Offline

Like button can go here

#54 2017-06-14 10:14:12

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,267

- Website

Re: Designing the best greenhouse demonstrator for Mars

Greenhouses at night are a different matter. A greenhouse at a temperature of 288K (15C) will radiate heat into the Martian sky at a rate of 390W/m2. It is doing that 24 hours per day. During the day, it will gain an average of about 300W/m2 for the 12 hours that the sun is about the horizon.

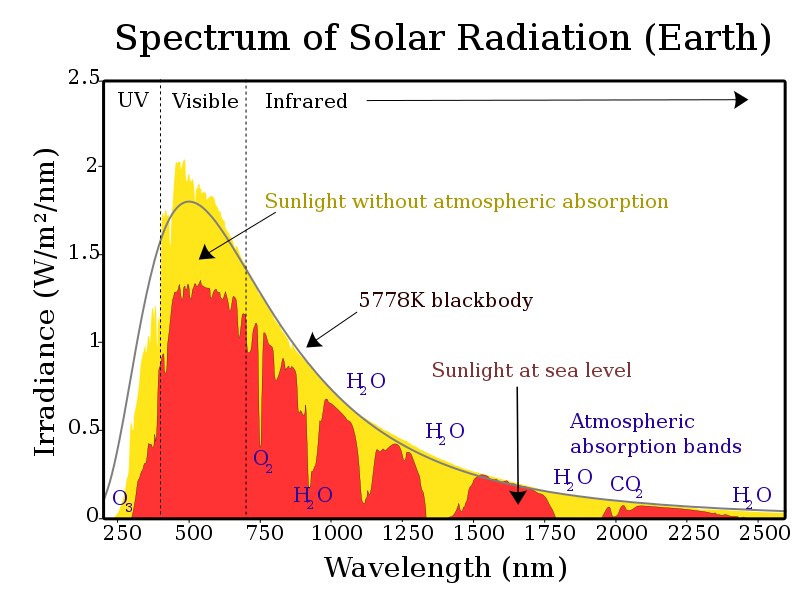

Excellent! Actual numbers. Now how will that change with spectrally selective coating? NASA uses vacuum deposited gold, nickel, and silver oxide to block UV and control IR. That technology has been commercialized, sold under the brand name "low-e". Low-e coatings use only silver oxide, they don't need to block UV because Earth's atmosphere has the ozone layer. Transmittance with commercial coatings looks like this. Graph line 5 is spectrally selective low-e glazing.

![]() This may be backwards. Transmittance at 0.5 micrometer (500 nm, green) wavelength is about 85%. Transmittance just above 1.0 micrometers (1,000 nm) is about 10%. Transmittance above 2.0 µm rises to 40%, and about 2.3 µm to 47%. Warm objects like the floor emit long wave IR. Extremely hot objects like the sun emit short wave IR. This appears to have the net effect of keeping radiant heat out. We need to keep it in.

This may be backwards. Transmittance at 0.5 micrometer (500 nm, green) wavelength is about 85%. Transmittance just above 1.0 micrometers (1,000 nm) is about 10%. Transmittance above 2.0 µm rises to 40%, and about 2.3 µm to 47%. Warm objects like the floor emit long wave IR. Extremely hot objects like the sun emit short wave IR. This appears to have the net effect of keeping radiant heat out. We need to keep it in.

The red line is roughly room temperature: 300°K = 26.85°C = 80.33°F.

Offline

Like button can go here

#55 2017-06-14 10:34:15

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,267

- Website

Re: Designing the best greenhouse demonstrator for Mars

A couple papers about spectrally selective coatings:

Spectrally selective coatings on glass: solar-control and low-emissivity coatings

Glazing and Coatings - BRIMEE

quoting the second paper

3.10.3.4.1 Doped metal oxides

Low-e coatings based on doped metal oxides comprise a host lattice (usually In2O3,SnO2, or ZnO) that is doped by metal or halide atoms. The most common representatives of this group of films are tin-doped indium oxide (In2O3:Sn, usually called ITO), fluorine-doped tin oxide (SnO2:F, usually called TFO), and gallium-doped zinc oxide (ZnO:Ga, usually called GZO). Doping is accomplished either by adding a higher-valence metal, by replacing some oxygen with fluorine, or by oxygen vacancies. The compounds mentioned above have wide enough band gaps to allow considerable transmission in the visible and doping is feasible to a level high enough to render the materials IR reflecting and electrically conducting. In doped metal oxides, the degree of doping determines the position of the transition wavelength (λΤ): the higher the doping, the more metal-like the films are and λΤ appears at lower wavelengths. However, in these films, doping cannot be brought to a sufficiently high level required for solar control, their λΤ usually lies in the near IR and, thus, doped metal oxide coatings are used mostly for thermal insulation. The main advantage of the doped metal oxides, compared to metal-based films, is the chemical and mechanical stability, which allows their use on glass surfaces exposed to ambient conditions. This is why these films are referred to as ‘hard coatings’.The development of these materials has reached maturity, and numerous commercial products are available in the market for windows and other architectural applications. Most of these films are prepared by spray pyrolysis and their typical thickness is on the order of 10−1 μm. Typical properties of such coatings are as follows: Tlum ≈ 90%, Tsol ≈ 75%, ε ≈ 0.20.

Although doped metal oxide coatings are well established, intense research activity continues in the field. The research effort is directed toward the development of alternative host materials and dopants, as well as multiphase mixtures of known materials, in order to improve various properties of the coatings, such as electrical conductivity, optical transmission, hardness, and adherence. Some of the combinations reported in the literature are the following: ITO:ZnO, ITO:Ti, In2O3–ZnO (IZO), In2O3:Ti, In2O3:Mo, In2O3:Ga, In2O3:W, In2O3:Zr, In2O3:Nb, In2-2xMxSnxO3 with M being Zn or Cu, ZnO:(Al,F), ZnO:B, ZnO(Ga,B), Zn0.9Mg0.1O:Ga, and many others.

Offline

Like button can go here

#56 2017-07-06 19:10:02

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Well here is something that would aid an above ground greenhouse...

These Transparent, Solar Power-Generating Windows Are the World's First

Trying to make large buildings energy-neutral, companies are taking advantage of building windows' surface area to harvest solar energy.

So double pane design from image:

The windows have solar cells installed in the edges at a specific angle that allows the incoming solar light to be efficiently transformed into electricity. The windows could generate 8 to 10 watts of power, according to Grapperhaus.

"This enables the user to charge a phone per every square meter [11 square feet] two times a day,"

Ya not many cell phones on mars but its still power being generated for use....

Offline

Like button can go here

#57 2019-11-27 20:47:31

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

This is a fact for any mars food growth as there is no open environment on mars which means we are in a protective area...Using controlled environment food production to solve food shortages

There needs to be a high degree of automation not only to the growth but for the prep to the shelf for the consumption of its bounty.

Offline

Like button can go here

#58 2019-11-27 20:57:26

- louis

- Member

- From: UK

- Registered: 2008-03-24

- Posts: 7,208

Re: Designing the best greenhouse demonstrator for Mars

This was what got Musk going - NASA's refusal to take his greenhouse demonstrator project seriously:"OK I'll build me my own rocket!"

Let's Go to Mars...Google on: Fast Track to Mars blogspot.com

Offline

Like button can go here

#59 2019-11-28 07:21:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,189

Re: Designing the best greenhouse demonstrator for Mars

For SpaceNut ... the idea of a design competition is on my mind this morning, and I was interested to see that you have brought back a topic which explicitly includes the word design in the title.

Without going back to read the entire set of 58 posts, I am unable to know if any ** real ** design elements were offered by anyone. I sure hope so.

This forum is a potential treasure trove of useful work plans for future Mars expedition planners, all of whom have access to this forum thanks to the Mars Society Open Information Sharing policy.

What someone could do, if they have the time and energy, and motivation, is to collect the wisdom and insights from the topic in a single post, organized to maximize the benefit to an individual with capital to invest in a greenhouse demonstrator.

(th)

Offline

Like button can go here

#60 2019-11-28 14:24:14

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

The demonstrator lander has 2 choices for food growth at a minimum of which the real issue is square footage for what crop types, mass of the lander with its payload since we are only at a Red Dragon retro propulsion lander with 2 mT of what ever we would want to take within the small internal cubic demensions.

That said what are the ideal methods and the associated mass for either.

With power coming from an RTG or solar panels simular to the ATK fans of which 2 to 4 panels with comparible batteries. So what are we using for an amount of brought along water since this is not intended to be an insitu for these. Only that we can automate the growth to the greatest degree possible and have food without a hands on approach.

Offline

Like button can go here

#61 2019-11-30 22:19:11

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

A good rule of thumb is to use a minimum of 50 watts of light per square foot of course plants thrive in full sun, but can adapt to partial shade Minimum sun – 5 hours. Low-light plants should receive between 10 and 15 watts. So natural light of 430 w m^2 is plenty for mars to grow food with.

https://www.firsttheseedfoundation.org/ … -Light.pdf

Now a 60w light bulb that is LED for the colors that favor food growth will be about 8 to 10 watts to give the same range of lighting energy.

NASA designs an inflatable greenhouse for Mars

/cdn.vox-cdn.com/uploads/chorus_image/image/54458283/space_greenhouse_nasa_lunar_mars_university_arizona_2.0.jpg)

The prototype modules, a long cylinder measuring 18 feet long and 7 feet in diameter, are designed to help create an artificial ecosystem with plants feeding off the carbon dioxide exhaled by astronauts and astronauts breathing in the oxygen from the plants

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/8410897/space_greenhouse_nasa_lunar_mars_university_arizona_1.jpg)

Offline

Like button can go here

#62 2019-12-12 17:36:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Here is a twist on such a technology...but when it comes to mars we will want to make use of daily sunlight just as much as we will artificial.

Punching holes in opaque solar cells turns them transparent

Existing transparent solar cells tend to have a reddish hue and lower efficiency, but by punching holes that are around 100 um in diameter (comparable in size to a human hair) on crystalline silicon wafers, it allows light through without coloring. The holes are then strategically spaced, so the human eye is unable to "see" the pattern. The best solar cells on the market have an efficiency of over 20 percent. The transparent neutral-colored solar cell that the research team developed demonstrated long-term stability with a high-power conversion efficiency of 12.2 percent. The next step for the team is to scale up the device to 25 cm2 (3.88 in2) and increase the efficiency to 15 percent. Furthermore, most windows are vertically placed, which causes light to hit the windows at a low angle. When hit by low angle light, the electrical current in conventional cells drops nearly 30 percent, while transparent solar cells reduce less than 4 percent--allowing it to utilize solar energy more efficiently.

http://dx.doi.org/10.1016/j.joule.2019.11.008

Research Report: "Neutral-Colored Transparent Crystalline Silicon Photovoltaics"

This makes it ideal for solar concentrated light to pass as well as to get the energy from the reflected light. This is a benefit to a natural lighted greenhouse as the panels now become part of the construction and not extra mass to supply energy.

Offline

Like button can go here

#63 2019-12-17 16:34:52

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

http://bigidea.nianet.org/wp-content/up … -et-al.pdf

Low Pressure Greenhouse Concepts for Mars:

Atmospheric Composition

Offline

Like button can go here

#64 2019-12-17 19:02:22

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,189

Re: Designing the best greenhouse demonstrator for Mars

For SpaceNut re #63

From the paper cited:

We need to determine by

experimentation the cost of maintaining particular

conditions, and what effect different conditions would

have on plant productivity.

That is what I am proposing.

All the test modules should be set up by professional contractors under the supervision of top tier academic research organizations.

The results should then be collected in a rigorous fashion and collated for delivery to a master database.

Out of a profusion of tests there should arise a clear picture of which plants would do best under what circumstances.

Clearly the optimum solution would be a set of plants which meet human needs and which grow happily in an all CO2 atmosphere, with the minimal number of trace gases needed to sustain healthy growth.

Touching some of the links you have gathered in the past day tells me that much of the needed research has been done, so the standards for a large scale mass research project would appear to be in place.

With appropriate management of the campaign, I am hoping members of the general public would be willing to fund modules in the $500 range for the education of family members as well as for the contribution to the Mars project, as well as for the contribution to the well being of the Earth population as a whole.

As a reminder of kbd512's idea which was the inspiration for the present initiative, the greenhouse would be operated at ** Earth normal ** pressure, NOT Mars normal pressure. The advantage is that the human worker can visit the facility without a pressure change, and by donning only an oxygen/air mask instead of a full body suit of some kind.

(th)

Last edited by tahanson43206 (2019-12-17 19:02:59)

Offline

Like button can go here

#65 2019-12-17 20:19:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Chamber size and design for natural or LED needs mass delivery dimensioning to be able to say we can deliver the unit or not.

If it were me I would use a spent Dragon cargo unit size for early mars cargo and crew men to mars for initial testing size. Once the cargo is out and setup we can build the connecting tunnels to make this design work. Connect them to each other via a pressure tunnel so that we can go into all connected units which are growing food as indicated to reduce need for space suits.

So far a collection of gas levels and heat plus light intensities seem to change how the plants grow and behave for nutritional content.

The above link is a nasa project which as of yet has need seen the light of funding to go to mars...

We also know that we can do just fine in less air pressure as well for pure to mixed oxygen levels so in a chamber tunnel situation we may also have less pressure for the plant growth as well which will save on initial energy to fill the area to make it viable for a greenhouse with shirt sleeve access.

Offline

Like button can go here

#66 2019-12-18 12:49:46

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,189

Re: Designing the best greenhouse demonstrator for Mars

For SpaceNut re #65 ...

Your comments in this post appear (to me at least) to open the door to another option, which may well have been discussed earlier in the forum archive.

The advance of robotic waldos is sufficient already to permit entirely robotic "workers" inside the greenhouse on Mars, which would completely eliminate the issue of trying to accommodate the human workers as well as the plants.

The gas mixture, gas pressure, gas temperature and lighting can ALL be optimized for the plants, and the human operators can work from comfort, just as military drone operators do today, or industrial truck operators in Australia.

Air locks for movement of items into and out of the greenhouses would still be needed, but the volume could be much less than would be true if humans had to make the trip. A "special" air lock for humans could be included in the design for emergencies.

(th)

Offline

Like button can go here

#67 2019-12-18 18:06:48

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Offline

Like button can go here

#68 2020-01-08 21:07:08

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

Lots of good information in this Farming and the geography of nutrient production for human use: a transdisciplinary analysis

The variety of crops and of livestock as well as fish biomes but not how much land or energy for each are required. Lest we forget we have hugh biomes of forest and oceans with which we would not live with as well.

So data from FOOD, LAND, POPULATION and the U.S. ECONOMY

At least 1.2 acres per person is required in order to maintain current American plus Currently the 400 gallons of oil equivalents expended to feed each American ...

Its actually more when we include the other resources which make these other food possible along with the breathable air and materials we take for granted.

Lets call it 2 acres and that converts to 8093.71 m^2 for just 1 person....or 90 meters on a side...

https://www.metric-conversions.org/area … meters.htm

So now what is the energy that we need for solar light...

Goggling mars greenhouse floor thermal insulation for heat lose calculations reference materials

Will read more tomorrow for these links

https://www.greenhousemag.com/article/t … heat-loss/

Conductive heat loss = SA x U x TD

Infiltration heat loss = 0.02 x V x C x TD

http://www.marshome.org/files2/Hublitz2.pdf

ENGINEERING CONCEPTS FOR INFLATABLE MARS SURFACE GREENHOUSES

https://farm-energy.extension.org/wp-co … tation.pdf

Greenhouse Energy Efficiency (Heating)

Offline

Like button can go here

#69 2020-01-09 18:25:25

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

For a well insulated for lose of thermal heat, sealed from leaks of pressure and covered at night clear material it just meets the goal without enhancement from reflection if its stays warm enough inside.

I think long before we will build we will bring and the simplest to bring is the vehicle for crew and cargo to convert to the chamber for food growth. If we want natural light we bring a top hatch lense unit to allow for the light to concentrate from its shape and then to spread out once on the inward side of the hatch lense assembly.

Once that is done then use a space foam insulation of a roll of good fiber insulation to wrap the capsule or cargo landers hull on the outside before burying it then connect to power, water supplies and plant the crop.

.

Offline

Like button can go here

#70 2021-04-22 17:04:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

bump

Offline

Like button can go here

#71 2021-06-11 14:36:46

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Designing the best greenhouse demonstrator for Mars

Food, experiments, and tardigrades headed to International Space Station

https://www.fox13news.com/news/spacex-n … rgo-launch

NASA website - Fruits for Their Labor

https://www.nasa.gov/missions/science/m … house.html

Offline

Like button can go here

#72 2021-06-11 16:07:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

So how many square feet are we requiring with a mixed crop growth that will be capable of feeding men a good nutritious variety of foods from the start....

That one key thing is what we really do not have a good handle on as its got to be big....

Offline

Like button can go here

#73 2022-07-13 16:34:28

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Designing the best greenhouse demonstrator for Mars

The Crazy Real-Life Story Of Biosphere 2

Offline

Like button can go here

#74 2024-11-27 21:02:39

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,189

Re: Designing the best greenhouse demonstrator for Mars

I just read this topic from the top.... it is loaded up with interesting content.

RobertDyck contributed significantly, and SpaceNut was in good form back in the day.

Void got ticked off at SpaceNut ... SpaceNut apologized. Minor kerfluffle, but it does show how some care in wording is worth the time.

Terraformer pitched in, as did Oldfart1939.

in the modern era (ie, 2024) we have possibilities contributed by Calliban, for use of acetate to feed plants without photosynthesis, and Chinese making starch out of water and CO2.

I was curious to see what this topic contained, because I am interested in how a diet might come together if Calliban's suggestions were implemented on a large scale.

(th)

Offline

Like button can go here

#75 2025-09-26 16:39:30

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,804

Re: Designing the best greenhouse demonstrator for Mars

https://www.designindaba.com/articles/c … and-beyond

https://www.nasa.gov/science-research/l … -on-earth/

The lists that follow should be part of the crops that such a demonstrator

A "NewMars lunar inflatable garden" does not refer to a specific, named project but describes an inflatable greenhouse concept being developed by NASA and others, primarily the University of Arizona. These Bioregenerative Life Support Systems (BLSS) use plants to create a sustainable, closed-loop environment for long-duration space missions, including future outposts on the Moon or Mars.

Core life support systems

Air revitalization: Plants use photosynthesis to absorb the carbon dioxide exhaled by astronauts and convert it into breathable oxygen. This process is more sustainable and autonomous than relying on oxygen tanks or physiochemical scrubbers alone.

Water recycling: Water vapor released by plants through transpiration is collected and purified. This system, along with recycling wastewater from the crew, provides clean water for drinking and irrigation.

Food production: The garden grows fresh, nutritious food, supplementing the freeze-dried and pre-packaged meals typically consumed on missions. This provides essential vitamins and minerals and improves crew morale.

Waste management: Biological waste, including inedible plant biomass and human waste, can be recycled. Microorganisms in the BLSS break down the waste into nutrients that are then used to feed the plants.

Inflatable garden design

Radiation shielding: The Moon has no atmosphere or magnetosphere to protect against space radiation. Inflatable greenhouse prototypes are designed to be covered with a layer of lunar soil (regolith) after deployment to shield the plants from harmful cosmic rays.

Artificial lighting: With the garden buried for protection, plants are grown under controlled LED lights. These lights are highly energy-efficient and provide the optimal light spectrum for photosynthesis. Some concepts also explore using rotating mirrors to direct natural sunlight into the buried greenhouse.

Hydroponics: To save weight and avoid using alien soil, plants are grown using a hydroponic system. Nutrient-rich water is circulated directly over the plant roots, which are typically supported by a cable-based system.

Durable materials: The inflatable structures are made from high-strength, flexible materials that can be compactly stowed for launch. The material for NASA's LIFE (Large Integrated Flexible Environment) habitat, which includes a garden system, is made of Vectran, a fiber stronger than steel.

Benefits beyond physical survival

Psychological well-being: For long, isolated missions, exposure to greenery, gardening, and fresh food has a significant positive impact on the mental health of astronauts. It creates a connection to Earth and a sense of normalcy.

Increased sustainability: The closed-loop nature of the BLSS reduces dependence on resupply missions from Earth. This minimizes launch costs and makes long-duration missions to distant locations like Mars more feasible

40 mt payload content food for a crew of 4 journey.

For a four-person Mars mission, the food tonnage would be between 6.6 and 15 tons, depending on the total mission duration and whether resupply missions or local food production are used. The total mass includes the food itself plus the necessary packaging. Key factors influencing food tonnage Mission duration

A Mars mission is typically estimated to be a round trip of 2 to 3 years, with a stay on the Martian surface. The total mass of food required is a direct product of the mission length.

Average daily mass:

A standard estimate for space food is about 1.83 kg (4 lbs) per astronaut per day.Total food mass calculation: Assuming a 2.5-year (912.5-day) mission, the total food tonnage for four astronauts would be calculated as follows:

1.83 kg/person/day * 912.5 days * 4 astronauts =6,680 kg

This equals about 6.7 metric tons.Mission architecture

The overall mission plan significantly affects the food tonnage that must be launched from Earth.All prepackaged:

If all food is launched from Earth, the tonnage would be at the high end of the estimate, especially if extra supplies are included for safety margins or emergencies. Some proposals suggest sending supply caches to Mars ahead of the crew.Partial local production:

Integrating local food production, such as growing crops in a Martian habitat, could dramatically reduce the amount of food that needs to be carried. A diet supplemented with fresh vegetables and other produce could significantly lower the initial launch mass.Food type

The composition of the food is a critical variable. Freeze-dried vs. whole food: Freeze-dried or dehydrated food contains much less water, making it far lighter to transport than whole food.Packaging: Packaging, while individually light, adds up over the course of a multi-year mission. Innovations in lighter, more efficient packaging could contribute to reducing overall tonnage. Contingency supplies Mission planners must also account for potential issues and emergencies.Buffer stock: A contingency supply of food is often included to cover mission extensions or unforeseen problems, adding significant mass to the total payload. For a 4-person, 900-day mission, a 500-day contingency supply could add over 10 tons of mass.

Example calculation

Here is a breakdown of a potential scenario for a four-person, 2.5-year (913-day) Mars mission. Daily food intake per person: 1.83 kgTotal crew-days:4 people * 913 days=3,652 person-days

Total food mass: 3,652 person-days * 1.83 kg/person/day=6,698 kg

Base food tonnage: Approximately 6.7 metric ton

Perishable food items are foods that will spoil, decay, or become unsafe to eat if not kept refrigerated or frozen, including meats, poultry, seafood, dairy products, eggs, cooked leftovers, and most fresh fruits and vegetables, especially those that are cut, chopped, or lack a hard outer skin.

Meat, Poultry, and Fish

Raw meats: such as ground beef, steaks, lamb, and pork.

Poultry, like fresh chicken, turkey, and duck.

Fish and seafood, including fresh fish, shrimp, lobster, and all types of shellfish.

Deli meats, which are processed and sliced.

Dairy and Eggs

Milk, cream, and yogurt.

Cheese, including soft and hard varieties.

Butter .

Eggs .

Fruits and Vegetables

Most fresh fruits and vegetables are perishable, particularly those without a hard skin like berries, tomatoes, and lettuce.

Cut or chopped produce, as this increases the rate of decay.

Cooked Foods and Leftovers

Any cooked leftovers, such as stews, cooked rice, and prepared meals.

Prepared salads: and other dishes containing perishable ingredients.

Other Perishables

Drinks with live bacteria, like some juices.

Sauces and dips: (like hummus, pesto, and sour cream), once opened.

Some baked goods, especially those with dairy or cream.

Non-perishable food items are shelf-stable and do not require refrigeration, including canned goods (fruits, vegetables, meats, soups, beans), dried goods (rice, pasta, oats, dried fruit, nuts, seeds, jerky, dried beans), shelf-stable milk and juices, and pantry staples like peanut butter, honey, cooking oil, sugar, and crackers.

Canned & Pouched Foods

Proteins: Tuna, salmon, chicken, and beans.

Vegetables: Corn, green beans, carrots, and other vegetables.

Fruits: Peaches, pineapple, applesauce, and other fruits.

Soups & Stews: Meat-based, vegetable-based, and other ready-to-eat options.

Dried & Grains

Grains: Rice, oats, pasta, and couscous.

Legumes: Dried beans, lentils, and peas.

Snacks: Nuts, seeds, dried fruits (raisins, apricots), trail mix, jerky, and granola bars.

Pantry Staples

Spreads: Peanut butter, jelly, and other nut/seed butters.

Sweeteners & Sauces: Honey, sugar, syrup, and jarred pasta sauces.

Oils: Vegetable oil and other cooking oils.

Baking Ingredients: Pancake mix and powdered milk.

Beverages: Shelf-stable powdered milk, bottled water, and juice boxes.

Other Shelf-Stable Items Crackers and melba toast, Ready-to-eat meals (like MREs), and Hard candies

Offline

Like button can go here