New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2024-05-30 06:08:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

SSTO History Atlas and other single stage launchers

This topic is inspired by an observation of RobertDyck...

There was a time, early in the history of development of space launch vehicles, when the possibility of using more than one stage was still a concept to be developed. All experience up to that time had been with single stage vehicles.

RobertDyck's insight is that launchers like the Redstone and Atlas may have had the capability of reaching orbit on their own.

The purpose of this topic is to offer NewMars members a place to contribute posts about that early period, and any launchers that might have come close to meeting the Wikipedia definition of an SSTO.

The criteria I am looking for include:

1) The vehicle must reach orbit

Reaching orbital altitude is not sufficient for this topic. The vehicle must have reached a stable low Earth orbit that persisted for at least one circuit of the Earth before drag brought it down.

2) The vehicle must discard NOTHING on the way to orbit.

Here is the Wikipedia definition:

AI Overview

Learn more

…

According to Wikipedia, a single-stage-to-orbit (SSTO) vehicle is a spacecraft that can reach orbit from a planet's surface without discarding any major parts, such as engines, fuel tanks, or wings. SSTO vehicles are designed to reach orbit intact so they can be reused for future launches, which could lower costs and increase the frequency of launches. The term "SSTO" usually refers to reusable vehicles, but not always. For example, Project Orion is an SSTO vehicle that is not a reusable launch vehicle.Wikipedia

Single-stage-to-orbit - WikipediaA single-stage-to-orbit (SSTO) vehicle reaches orbit from the surface of a body using only propellants and fluids and without expending tanks, engines, or other major hardware. The term usually, but not exclusively, refers to reusable vehicles.

Simple Wikipedia

Single-stage-to-orbit - Simple English Wikipedia, the free encyclopediaA single-stage-to-orbit (abbreviated as SSTO) is a hypothetical spacecraft. It can reach space from the surface of a planet without expending major pieces of the craft (such as engines, fuel tanks, or wings).

New Space Economy

Single-Stage-to-Orbit (SSTO): Pioneering the Future of Space Exploration – New Space Economy

May 31, 2023Wikipedia

Category:Single-stage-to-orbit - WikipediaSingle Stage To Orbit vehicles are vehicles capable of reaching orbital velocity and altitude from the Earth's surface without dropping off any hardware. Single stage to orbit vehicles are not necessarily Reusable launch vehicles, e.g. Project Orion.

Generative AI is experimental.

Show moreA single-stage-to-orbit (SSTO) vehicle reaches orbit from the surface of a body using only propellants and fluids and without expending tanks, engines, or other major hardware. The term usually, but not exclusively, refers to reusable vehicles.

Single-stage-to-orbit - Wikipedia

Wikipedia

https://en.wikipedia.org › wiki › Single-stage-to-orbit

(th)

Last edited by tahanson43206 (2024-05-30 07:06:00)

Offline

Like button can go here

#2 2024-05-30 06:09:30

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: SSTO History Atlas and other single stage launchers

This post is reserved for an index to posts that may be contributed by NewMars members over time.

(th)

Offline

Like button can go here

#3 2025-07-26 07:47:40

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: SSTO History Atlas and other single stage launchers

This post is an attempt to capture current status of the SSTO concept... This one is as of 2025/07/26

I asked Google's Gemini to review the history and current status of the field... It appears to have missed one or two initiatives, but it caught some I had not heard of, or missed as SSTO concepts...

Conversation with Gemini

Inventory of SSTO Initiatives - Hi Gemini! Thank you for your assistance with many previous requests! I'm hoping this one will be on the easy side. A small international forum has members who are interested in the SSTO problem. To the best of your knowledge SSTO has not been achieved on Earth, but early ATLAS flights came close, by discarding engines to save weight. There are two categories of interest. Expendable vs Fully Reusable are the two categories. Expendable appears to be achievable, and reusable is far more attractive, and far more difficult. To help our members keep up with developments world wide, I'm hoping you might see what you can find along these lines. We are aware of the renewed British initiative, based upon earlier work they have done.

***

Thank you for the kind words and for your interesting question. The pursuit of Single-Stage-to-Orbit (SSTO) vehicles has a long and fascinating history, and as you've noted, it continues to be an area of significant research and development. The distinction between expendable and fully reusable SSTO is a crucial one, as it defines the core challenge and potential reward of the technology.Here is an inventory of current and historical SSTO initiatives, categorized as you requested.

Fully Reusable SSTO Initiatives

This category represents the "holy grail" of space access, aiming for aircraft-like operations with minimal turnaround time and cost. The primary challenges are the extreme mass fraction requirements (the ratio of a rocket's propellant to its total mass) and the need for a propulsion system that can operate efficiently from sea level to orbit.

Skylon (United Kingdom): This is the initiative you mentioned. Reaction Engines Ltd. (REL) is developing the Skylon spaceplane, a vehicle that would use a novel engine called the Synergetic Air-Breathing Rocket Engine (SABRE). The SABRE engine is the key to the concept, as it would function as a jet engine, breathing air from the atmosphere, up to Mach 5.5, and then switch to a closed-cycle rocket engine using onboard liquid oxygen to reach orbit. This hybrid approach significantly reduces the amount of oxidizer the vehicle needs to carry, thus improving the mass fraction. While the Skylon vehicle itself has not been built, REL has received significant funding from the UK and European Space Agency to develop and test the core technologies of the SABRE engine, including its pre-cooler, which is a major technological hurdle.

NASA's X-33 and VentureStar (United States): While a historical program, it is essential to mention this one due to its significant influence. The X-33 was a sub-scale technology demonstrator for a proposed fully reusable SSTO vehicle called VentureStar. The program, led by Lockheed Martin in the 1990s, aimed to use a unique lifting body shape and a linear aerospike engine, which is an altitude-compensating rocket engine. The project was ultimately canceled in the early 2000s due to technical challenges and cost overruns, particularly related to the vehicle's composite liquid hydrogen fuel tank. The legacy of X-33 continues to inform modern SSTO research.

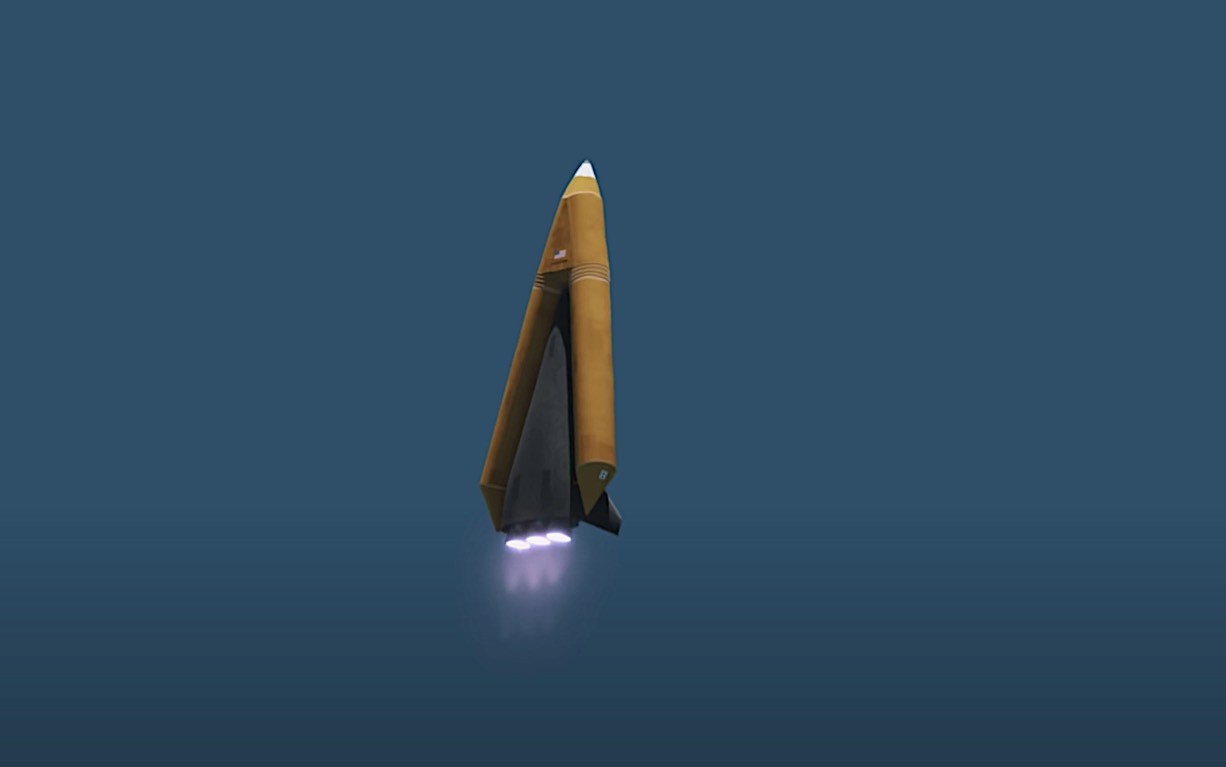

Delta Clipper (DC-X/DC-XA) (United States): Another influential historical program, the Delta Clipper was a prototype for a vertical-takeoff, vertical-landing (VTVL) SSTO. Developed by McDonnell Douglas, the DC-X and its successor, the DC-XA, successfully demonstrated rapid reusability and VTVL capabilities in the mid-1990s. The program showcased the potential for quick turnaround times, with one flight taking place just 26 hours after the previous one. The concepts and lessons learned from the Delta Clipper program are highly relevant to the VTVL approaches being explored by companies today.

Stoke Space (United States): This is a more recent and active initiative. Stoke Space is developing a "fully and rapidly reusable" rocket. While it is a two-stage-to-orbit (TSTO) rocket, its second stage is designed to be fully reusable and land on its own, which is a significant step toward the SSTO goal. The company is particularly focused on creating a reusable upper stage with a novel heat shield and a "full-flow staged combustion" engine.

Expendable SSTO Concepts

While not as commercially attractive as fully reusable systems, expendable SSTOs are considered by some to be technically feasible with existing or near-term technology. The challenge is still the mass fraction, but without the added weight of landing gear, thermal protection systems for reentry, and other recovery hardware. The primary goal would be to simplify the launch process and eliminate the need for complex, multi-stage separation events.

Historical "Thought Experiments": Throughout the history of rocketry, engineers have conducted studies to see if existing hardware could be reconfigured for an expendable SSTO mission. For example, some analyses in the late 20th century explored the possibility of using the Saturn S-IVB stage or the Space Shuttle's External Tank (ET) as a single stage with upgraded engines. While not leading to actual hardware, these studies demonstrated that with a high enough mass fraction, an expendable SSTO is theoretically possible. However, the payload would be very small, and the cost would be high, undermining the purpose of the design.

Conceptual Designs and Research: Most modern work on expendable SSTO is at the conceptual level, often in academic or government research papers. These studies typically explore new materials and propulsion technologies that could improve mass fraction sufficiently to make an expendable SSTO viable for a specific, niche mission, such as launching a small payload or a crew capsule without the complexity of a multi-stage system. However, the commercial and economic case for such a vehicle is very weak compared to reusable systems.

In summary, the focus of the space industry has overwhelmingly shifted towards fully reusable vehicles, with multi-stage reusable rockets like those from SpaceX leading the way. The dream of a fully reusable SSTO, however, lives on through projects like Skylon and in the ongoing research into advanced propulsion and materials. The path to an expendable SSTO is theoretically clearer but lacks the compelling economic argument needed to justify its development in the current market.

Inventory of SSTO Initiatives - Hi Gemini! Thank you for your assistance with many previous requests! I'm hoping this one will be on the easy side. A small international forum has members who are interested in the SSTO problem. To the best of your knowledge SSTO has not been achieved on Earth, but early ATLAS flights came close, by discarding engines to save weight. There are two categories of interest. Expendable vs Fully Reusable are the two categories. Expendable appears to be achievable, and reusable is far more attractive, and far more difficult. To help our members keep up with developments world wide, I'm hoping you might see what you can find along these lines. We are aware of the renewed British initiative, based upon earlier work they have done.

Here's the plan I've put together. Let me know if you need any changes before I start researching.

SSTO Initiatives: Global Inventory and AnalysisResearch Websites

(1) Define the core concepts of Single-Stage-To-Orbit (SSTO) and the fundamental engineering challenges associated with achieving it.

(2) Differentiate between expendable and fully reusable SSTO approaches, outlining the technical distinctions, advantages, and difficulties inherent in each category.

(3) Identify historical and current global initiatives, projects, and research efforts focused on achieving SSTO, including those that came close to the goal or were foundational in the field, such as early ATLAS flights.

(4) For each identified SSTO initiative, categorize it as primarily pursuing an expendable or a fully reusable design based on its stated objectives and technical specifications.

(5) Conduct a focused investigation into the renewed British SSTO initiative, detailing its current status, technological approach, and any recent developments or partnerships.

(6) For each significant SSTO initiative (both historical and current, expendable and reusable), gather comprehensive information on:

(a) the organizations or entities leading the effort

(b) the specific technologies, design concepts, or propulsion systems being developed

(c) the current development status, key milestones achieved, and projected timelines

(d) any reported major challenges, breakthroughs, or funding status.

(7) Synthesize the gathered information to provide an overview of the worldwide progress in SSTO development, highlighting emerging trends, significant hurdles, and the overall feasibility outlook for both expendable and fully reusable categories.

Analyze Results

Create Report

Ready in a few mins

The last time I tried this Gemini went away and never came back.

(th)

Offline

Like button can go here

#4 2025-07-26 08:39:03

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: SSTO History Atlas and other single stage launchers

Following is a full Research Report done by Google's Gemini on 2025/07/26...

The post below shows what you get if you select the "export" option. I will post a simple copy in the next post.

Inventory of Single-Stage-to-Orbit Initiatives1. Executive SummaryThis report provides a comprehensive overview of Single-Stage-to-Orbit (SSTO) initiatives worldwide, distinguishing between historical concepts and current developments, particularly focusing on expendable versus fully reusable approaches. The pursuit of SSTO is fundamentally driven by the promise of drastically reduced space launch costs, primarily through the elimination of hardware jettisoning and the maximization of vehicle reusability.1Despite its compelling allure, no Earth-launched SSTO vehicle has yet achieved orbital velocity. This persistent challenge stems primarily from the "tyranny of the rocket equation," a fundamental physical constraint that necessitates an exceptionally high propellant mass fraction for any single-stage vehicle attempting to reach orbit from Earth's surface.2 This constraint imposes extreme engineering demands on every component, particularly regarding mass efficiency.Historically, projects such as the McDonnell Douglas DC-X/DC-XA, Lockheed Martin X-33 VentureStar, and Roton demonstrated critical technologies and operational concepts, but ultimately encountered significant technical and economic hurdles that led to their cancellation.5 The Atlas rocket, while a groundbreaking design, employed a "stage-and-a-half" configuration, which involved discarding engines during ascent, thus not qualifying as a true SSTO. This design choice highlights early pragmatic compromises in rocket engineering to overcome the inherent difficulties of single-stage flight.9Current global efforts represent a renewed push to overcome these long-standing challenges through diverse technological pathways. Notable initiatives include the UK's Invictus program, which leverages the advanced SABRE engine technology originally developed for Skylon; Radian One's novel horizontal launch system incorporating a rocket-powered sled; and Polaris Aerospace's focus on aerospike spaceplanes. These projects are exploring various methods to improve mass efficiency and propulsion performance.11A critical distinction is evident in the contemporary landscape: while true SSTO remains a formidable technical goal, the broader industry focus is increasingly shifting towards fully reusable launch systems, even if these systems employ multiple stages. This pragmatic shift is largely influenced by the demonstrated success of reusable multi-stage systems, such as those developed by SpaceX, which have achieved significant cost reductions and operational efficiencies. These multi-stage reusable vehicles are proving to be economically competitive and often more readily achievable than strict SSTO designs, driving a re-evaluation of the most effective path to low-cost space access.112. Introduction: The Enduring Quest for Single-Stage-to-OrbitDefining Single-Stage-to-Orbit (SSTO) and its Aspirational Role in Space AccessSingle-Stage-to-Orbit (SSTO) refers to a space vehicle engineered to reach Earth orbit from its surface without jettisoning any hardware components during its ascent. This implies that the entire vehicle, including its engines and propellant tanks, remains intact from liftoff through orbital insertion.1 The core vision driving SSTO development is the drastic reduction of space launch costs. By eliminating the need to discard expensive hardware, SSTO promises to enable complete vehicle reuse, fostering greater investment in the space sector, facilitating more frequent launch experiments, and ultimately paving the way for a future of low-cost private space access.1 The ultimate aspiration for many SSTO proponents is a vehicle that could operate much like a conventional winged aircraft, taking off and landing horizontally, thereby eliminating the need for complex and costly vertical launch infrastructure.2While the concept of SSTO has been successfully demonstrated from celestial bodies with significantly weaker gravitational fields and negligible atmospheric pressure, such as the Moon (achieved by the Apollo program's Lunar Module) and various robotic spacecraft of the Soviet Luna program, it has yet to be realized from Earth.2 Earth's formidable gravitational pull and dense atmosphere present unique and exceptionally challenging engineering obstacles that have historically proven difficult to overcome.The Fundamental Challenge: "The Tyranny of the Rocket Equation"The Tsiolkovsky rocket equation is a cornerstone mathematical principle in aerospace engineering that defines the fundamental performance limits of any rocket. It establishes a direct relationship between a rocket's maximum change in velocity (delta-v), the effective exhaust velocity of its engines, and the ratio of its initial total mass (including propellant, often referred to as wet mass) to its final mass (after propellant is expended, or dry mass).3 This equation illuminates the profound challenge inherent in achieving SSTO from Earth.For a single-stage rocket to attain the necessary delta-v to reach Low Earth Orbit (LEO) from Earth's surface, which is approximately 9,700 meters per second (accounting for gravity and aerodynamic drag losses), an extraordinarily high proportion of its initial mass must be dedicated to propellant. For example, with a typical effective exhaust velocity of 4,500 m/s, approximately 88.4% of the vehicle's initial total mass must be propellant.3 This leaves a mere 11.6% of the initial mass for all other critical components, including the structural mass (such as the engine, control and guidance systems, tankage, and supporting structures) and the payload itself.3This severe mass budget is precisely what is often referred to as the "tyranny of the rocket equation" for SSTO. It mandates that every component of the vehicle, from its engines to its thermal protection system and internal structures, must be engineered to be incredibly lightweight while simultaneously possessing the strength and robustness to withstand the immense forces of launch, the extreme temperatures of hypersonic flight, and the stresses of re-entry. This challenge is further compounded by the additional mass requirements for reusability, such as landing gear, more durable structures, and thermal protection systems designed for multiple missions.5 This fundamental physical constraint explains why multi-stage rockets became the dominant paradigm in space launch. By shedding empty tanks and engines during ascent, multi-stage vehicles effectively improve the mass ratio for subsequent stages, making the achievement of orbital velocity significantly more feasible for a given initial mass and engine performance.4 Overcoming this inherent mass efficiency challenge is the primary driver behind many innovative SSTO design choices, including the development of air-breathing engines (which reduce the need for onboard oxidizer), highly efficient propulsion systems like aerospikes, or external launch assists like sleds. Each of these solutions aims to either reduce the required propellant mass fraction or provide initial energy without expending internal propellants, thereby making the stringent 11.6% dry mass budget for a practical payload more attainable.3. Historical Context: Early Visions and DemonstratorsPioneering Concepts and Theoretical DesignsThe aspiration for Single-Stage-to-Orbit vehicles gained prominence in the early 1960s, giving rise to numerous visionary designs that pushed the boundaries of aerospace engineering. These early concepts, though largely theoretical, were instrumental in exploring the possibilities and identifying the immense challenges of SSTO.Among the most prolific proponents was Philip Bono, an engineer at Douglas Aircraft Company, who championed various SSTO designs. He proposed the One Stage Orbital Space Truck (OOST) as an expendable SSTO concept, alongside a reusable counterpart named ROOST.5 Bono's later designs, such as the Douglas SASSTO from 1967, continued to explore vertical takeoff and landing (VTOL) SSTO configurations.5Another ambitious early concept was NEXUS, proposed by Krafft Arnold Ehricke in the early 1960s. NEXUS was envisioned as a colossal reusable launch vehicle, with a projected diameter exceeding 50 meters and the capability to lift up to 2,000 short tons into Earth orbit, primarily intended for missions to the outer Solar System.5 In 1979, Rockwell International unveiled the Star-Raker, a concept for a 100-ton payload heavy-lift spaceplane designed for horizontal takeoff and landing. This vehicle would have utilized a multi-cycle airbreather ramjet/cryogenic rocket engine system, combining LOX/LH2 rocket engines with turboramjets.5 Other notable early concepts included ROMBUS (Reusable Orbital Module, Booster, and Utility Shuttle), Ithacus (a sub-orbital military transport derived from ROMBUS), Pegasus (a passenger and payload transport), and Hyperion (which proposed using a sled to build up speed before liftoff to conserve fuel).5 These pioneering designs, despite never being constructed, were crucial in establishing the theoretical framework and highlighting the formidable engineering hurdles associated with SSTO.Key Demonstrator Programs and Their Lessons LearnedOver time, the theoretical concepts evolved into experimental programs aimed at demonstrating key SSTO technologies. These demonstrators provided invaluable practical experience, even when they did not achieve their ultimate goals.McDonnell Douglas DC-X/DC-XA: Vertical Take-off and Landing (VTOL) Proof-of-ConceptThe Delta Clipper Experimental (DC-X) was an uncrewed prototype of a reusable single-stage-to-orbit launch vehicle, developed by McDonnell Douglas in collaboration with the United States Department of Defense's Strategic Defense Initiative Organization (SDIO) from 1991 to 1993. Funding was subsequently continued by NASA until 1995.7 The DC-X was a one-third-scale prototype, standing 12 meters high with a 4.1-meter diameter, specifically designed to demonstrate vertical takeoff and landing (VTOL) capabilities, subsonic maneuverability, and airplane-like supportability and maintainability.7 Its design drew inspiration from Philip Bono's earlier SASSTO vehicle.7The DC-X completed a total of 12 flights—eight under McDonnell Douglas and four under NASA as the DC-X/A—between 1993 and 1996.7 The project was ultimately canceled after a test flight of the DC-XA in 1996 resulted in a fire, though it had successfully demonstrated the critical VTOL capabilities and rapid turnaround operations.7 The program's philosophy of "fly a little, break a little" emphasized rapid prototyping and gaining practical experience with fully reusable, quick-turnaround spacecraft.7 This approach proved instrumental in demonstrating the technical feasibility of precise vertical takeoff and landing for reusable rockets, a capability that has since become a cornerstone of many modern launch systems, most notably SpaceX's Falcon 9. The DC-X's legacy lies in validating a key operational mode essential for future reusable spaceflight.Lockheed Martin X-33 VentureStar: Suborbital Demonstrator and its Technical HurdlesIn 1996, NASA selected Lockheed Martin to develop and fly the X-33 test vehicle, a half-scale, suborbital reusable spaceplane demonstrator, measuring 69 feet long and 77 feet wide with a gross liftoff weight of 285,000 pounds.6 The X-33's primary objective was to validate advanced technologies for a new full-scale reusable launch vehicle concept known as VentureStar, which was intended to be a true SSTO vehicle.6 The X-33 featured a distinctive lifting body shape, was powered by two XRS-2200 linear aerospike rocket engines (delivering 410,000 pounds of thrust at liftoff), and incorporated a durable metallic thermal protection system (TPS).6 The program aimed for an ambitious cost reduction, seeking to lower the cost of sending payloads to space from approximately US10,000perpoundtojustUS1,000.11The X-33 program was canceled in 2001 before any test flights were conducted, primarily due to a failure during testing of its complex cryogenic liquid hydrogen tank.6 While the program did not achieve its flight objectives, it did accomplish significant successes in areas such as rapid flight hardware design, subsystem testing, and the development and testing of aerospike engines.20 The cancellation of the X-33, despite successful development of individual subsystems like the aerospike engines, illustrates the profound difficulty of scaling and integrating complex systems. The extreme mass fraction requirements of SSTO mean that every component, particularly large, lightweight cryogenic tanks, must perform flawlessly under immense structural and thermal stresses. The failure of even one critical, complex component can derail an entire ambitious program. This experience underscores that scaling up from a demonstrator to a full orbital vehicle introduces new, often unforeseen, engineering challenges that compound the inherent difficulty of SSTO. The X-33's fate serves as a significant lesson for SSTO development, emphasizing that the challenge extends beyond designing individual components to ensuring their reliable and robust integration within an extremely tight mass budget, especially for reusable systems.Roton: A Unique Approach to Reusability with a Rotary Engine and Helicopter LandingThe Roton was a piloted commercial space vehicle design developed by Rotary Rocket Company in the late 1990s.8 It was conceived as a fully reusable, single-stage-to-orbit (SSTO) Vertical Take-off and Landing (VTOL) spacecraft, designed to transport up to 3,200 kg to LEO with a target price of $7 million per flight (in 1999 dollars).8The Roton featured several distinctive innovations. It was initially planned to use a novel rotary engine and, uniquely, a helicopter rotor system mounted on top for a controlled, pilot-directed landing.8 The rotor system would autorotate during descent and utilize tip rockets for a soft touchdown.8 The design called for an empty weight under 5% of its gross takeoff mass, a figure described as "very challenging" even for an expendable rocket, let alone one carrying a crew, rotor system, and thermal protection.8 This requirement directly illustrates the extreme demands imposed by the "tyranny of the rocket equation" on SSTO designs. The project was ultimately canceled in 2000 due to persistent technical challenges and insufficient investment.8The "Stage-and-a-Half" Atlas Rocket: Clarifying its Design and Why it Wasn't a True SSTOThe Atlas rocket family, which originated with the SM-65 Atlas Intercontinental Ballistic Missile (ICBM) in the late 1950s, is sometimes mentioned in discussions of SSTO due to its unique design.9 The Atlas employed an unusual "stage-and-a-half" or "parallel staging" configuration.9 During ascent, two outboard booster engines, along with their supporting structures, were jettisoned. The central sustainer engine and the vehicle's propellant tanks continued to fire throughout the remainder of the ascent.9This design, as explicitly stated, meant that the original versions of the Atlas did jettison hardware during ascent. Therefore, it was technically not a true SSTO vehicle, despite being referred to as "stage and a half".10 This design choice was a pragmatic engineering solution to the challenges posed by the rocket equation. By shedding the mass of two engines once they were no longer needed at higher altitudes, the Atlas effectively improved its mass ratio for the remainder of the ascent without incurring the full structural complexity and potential failure points of a traditional serial multi-stage separation. It achieved some of the performance benefits of staging, such as reducing the total vehicle weight for a given payload and delta-V, or allowing for a larger payload from the same initial vehicle 18, while simplifying the overall vehicle structure compared to a fully staged rocket. The Atlas's design highlights an early recognition of the immense difficulty of achieving SSTO from Earth. Engineers sought intermediate solutions to improve performance and mass efficiency under existing technological constraints, rather than pursuing a pure SSTO ideal at all costs. This historical example underscores that design choices in rocketry often involve finding optimal compromises between performance, complexity, reliability, and cost. The "stage-and-a-half" approach demonstrates that even partial staging can yield significant benefits, a lesson that continues to influence modern reusable multi-stage designs.4. Expendable vs. Fully Reusable SSTO: Technical and Economic DistinctionsDetailed Technical Definitions of Each CategoryTo clarify the landscape of space launch, it is essential to define the categories of expendable and fully reusable systems, particularly within the context of Single-Stage-to-Orbit (SSTO).An Expendable SSTO would, by the strict definition of SSTO, reach orbit without jettisoning any hardware during ascent.1 However, the term "expendable" would imply that the vehicle is discarded after a single use. Given the extreme technical difficulty and inherently high development costs associated with SSTO designs 5, building such a complex vehicle only to discard it after one mission would be economically unfeasible and environmentally unsustainable.22 Consequently, in practical aerospace discourse, the term "SSTO" is almost invariably associated with the concept of reusability.A Fully Reusable SSTO represents the pinnacle of this aspiration. Such a vehicle would not only reach orbit without jettisoning any components but would also return its entire structure to Earth for refurbishment and subsequent missions.1 The primary projected advantage of this approach is the complete elimination of hardware replacement costs, which are inherent in expendable launch systems.5Advantages and Disadvantages of Expendable vs. Fully Reusable Systems (General Rocketry Context)To fully appreciate the challenges and motivations behind SSTO, it is helpful to consider the broader advantages and disadvantages of expendable versus reusable systems in general rocketry, as these principles largely apply to the SSTO debate.Multi-Stage Rockets (often expendable, or partially reusable):Advantages: Multi-stage designs significantly reduce the total vehicle weight required to achieve a given payload capacity and delta-V, or conversely, enable a larger payload for the same initial vehicle size.18 By shedding empty tanks and engines, these systems dramatically improve the mass ratio for subsequent stages, making the attainment of orbital velocity more achievable.4 This approach also allows for higher maximum velocities for a given vehicle and can decrease the required specific impulse of engines.18Disadvantages: Multi-stage rockets are inherently more complex due to the multiple separation events, engine ignitions, and intricate control systems required during ascent.18 This increased complexity can lead to decreased reliability due to a greater number of potential failure points.18 From an economic perspective, the discarding of costly engines, avionics, and other hardware with each flight results in significantly increased recurring costs.18Fully Reusable Systems (including SSTO and reusable multi-stage):Advantages: The primary projected advantage of fully reusable systems is the elimination of hardware replacement, which is a major cost driver in expendable launch systems. This promises drastically reduced recurring costs per launch.5 The prevailing belief among investors and developers is that reusing system elements will ultimately prove more economical than continually manufacturing and discarding expensive components.23Disadvantages (specific to Fully Reusable SSTO):High Non-Recurring Costs: The design, development, research, and engineering (DDR&E) costs for reusable SSTO systems are substantially higher than for expendable systems.5 This is attributed to the extreme technical challenges that must be overcome, assuming these issues can be resolved at all.Extreme Technical Complexity: A reusable SSTO demands an exceptionally robust vehicle capable of surviving numerous round trips into space. This requires breakthroughs in advanced materials, innovative construction techniques for sustained high-speed atmospheric flight, and sophisticated thermal protection systems for re-entry.5 Propulsion systems must also maintain high efficiency across an enormous range of altitudes and speeds.5Mass Penalties: The features necessary for reusability, such as landing gear, robust structures designed for multiple flights, and extensive thermal protection, add significant inert mass to the vehicle.5 This further exacerbates the "tyranny of the rocket equation," making it even more challenging to achieve the necessary mass fraction for orbit with a meaningful payload.5 For instance, while kerosene tanks can represent as little as 1% of their contents' weight, hydrogen tanks often must weigh 10% of their contents due to hydrogen's extremely low density and cryogenic nature, significantly impacting overall vehicle design and thrust-to-weight ratios.5High Maintenance: Reusable SSTO vehicles are likely to require a significantly higher degree of regular maintenance and refurbishment between flights to ensure safety and reliability, which adds to operational costs.5Low Payload Fraction: Rocket-powered SSTO vehicles are characterized by very high mass ratios and consequently very low payload fractions. For example, the payload might be around 1-2% for an Equatorial LEO, falling to as low as 0.25% for a Polar orbit.24 This limited payload capability has historically been a major disadvantage, hindering their development.24The Economic Viability Debate: SSTO vs. Multi-Stage Reusable SystemsA lively debate persists regarding the economic merits and drawbacks of reusable versus expendable systems.23 The central question is whether the substantial investment and technical hurdles of reusability, particularly for SSTO, are ultimately "worth it".23The current economic landscape of space launch is rapidly evolving. The emergence and success of highly reusable rockets, particularly from companies like SpaceX, have fundamentally altered the cost equation. These multi-stage reusable systems have driven down the cost of reaching low Earth orbit (LEO) to approximately US$3,000 per kilogram.11 This development presents a significant challenge for SSTO systems to compete economically, even if they achieve technical feasibility.While a true SSTO vehicle conceptually offers the ultimate efficiency in hardware reuse by discarding no parts whatsoever, the extreme technical difficulty and associated monumental development costs 5 mean that a partially reusable or fully reusable multi-stage system can achieve sufficient cost reductions to be economically viable sooner and more reliably. These multi-stage systems, by strategically shedding mass, can achieve better payload fractions and greater operational flexibility. The market is demonstrating that the "perfect" solution (a true SSTO) is often superseded by a "good enough" solution (a highly reusable multi-stage system) that delivers significant, demonstrable cost savings. Companies are prioritizing achievable reusability that provides substantial, proven economic benefits over the theoretically ideal, but practically elusive, single-stage design. This explains why the focus of companies like Stoke Space is on "100% reusable rockets" but not necessarily strict SSTO 16, as their designs incorporate a reusable upper stage. The economic competitiveness of SSTO is therefore no longer just against traditional expendable rockets but against increasingly efficient and proven reusable multi-stage systems. This raises the bar for SSTO to not only be technically feasible but also demonstrably economically superior to its multi-stage reusable counterparts, which is a formidable challenge in the current market.The following table provides a comparative overview of different launch system categories, highlighting their technical and economic trade-offs:Table 1: Comparison of Expendable vs. Fully Reusable Launch SystemsCriteriaExpendable Multi-stage (e.g., Atlas V)Reusable Multi-stage (e.g., Falcon 9/Starship)Theoretical Expendable SSTOFully Reusable SSTO (e.g., Skylon concept)Technical ComplexityModerate to High (complex staging)High (staging, re-entry, landing, refurbishment)Very High (extreme mass ratio, propulsion)Extremely High (all SSTO challenges + reusability)Development Cost (DDR&E)ModerateHigh to Very HighVery HighMonumentally High 5Recurring Cost per FlightHigh (discarding costly hardware) 23Low (reusing costly hardware)Extremely High (discarding entire complex vehicle)Potentially Very Low (no hardware replacement) 5Reliability (general)Established (many flights)Improving (complex operations, but proven)Unproven (inherent challenges)Unproven (inherent challenges, high maintenance) 5Mass Ratio/Payload FractionGood (staging improves effective mass ratio) 4Good (staging allows for better payload)Extremely Challenging (88.4% propellant) 3Extremely Challenging (1-2% LEO, 0.25% Polar) 24Turnaround TimeN/A (expendable)Rapid (days to weeks)N/A (expendable)Targeted Rapid (e.g., 48 hours for Radian One) 11Propulsion System RequirementsOptimized for stagesOptimized for stages, re-entry burns"One engine for all altitudes" 5"One engine for all altitudes," highly efficient 5Thermal Protection RequirementsLess critical for discarded stagesCritical for reusable stagesExtremely critical for entire vehicle 5Extremely critical for entire vehicle, multi-flight 5Current Market CompetitivenessDeclining (due to reusable options)Highly Competitive (e.g., ~$3,000/kg to LEO) 11Not viableChallenged by reusable multi-stage systems 115. Current Global SSTO-Relevant Initiatives and DevelopmentsThe quest for Single-Stage-to-Orbit continues globally, with several initiatives exploring diverse technological pathways to overcome the inherent challenges. These projects often leverage advancements in materials, propulsion, and operational concepts.The Renewed British Initiative: Invictus and the Legacy of SkylonSkylon's Original Vision and the SABRE Engine TechnologySkylon was a series of conceptual designs for a reusable SSTO spaceplane, developed by the British company Reaction Engines Limited (REL).5 Its revolutionary design centered on the Synergetic Air-Breathing Rocket Engine (SABRE), a combined-cycle, air-breathing rocket propulsion system.5 The core innovation of the SABRE engine was its "pre-cooler" system, engineered to cool incoming air from over 1,000°C to ambient temperature in less than 1/20th of a second.14 This capability was designed to allow the engine to utilize atmospheric oxygen during the initial phases of flight, significantly reducing the mass of onboard oxidizer required. At higher altitudes and speeds (e.g., Mach 5.4 at 26 kilometers), the engine would then transition to using internal liquid oxygen for the final rocket burn to achieve orbital velocity (Mach 25).14Skylon was envisioned as a hydrogen-fueled aircraft that would take off from a conventional runway. It was designed to carry substantial payloads, such as 17 tonnes of cargo to LEO or 11 tonnes to the International Space Station.25 The project aimed for an exceptionally low launch cost of approximately £650 per kilogram to LEO, a dramatic reduction from the estimated average of £15,000 per kilogram using conventional methods in 2011.25Status of Reaction Engines Ltd. and the Transition to the Invictus ProgramReaction Engines Ltd. conducted critical tests of SABRE engine components in 2012 and 2024, demonstrating the viability of the pre-cooler technology.25 Despite securing significant investment from major aerospace firms like BAE Systems, Boeing, and Rolls-Royce 25, and receiving funding from the European Space Agency (ESA) 14, the company unfortunately faced cash-flow issues and entered administration (a form of bankruptcy) in October 2024. This led to the official cancellation of the Skylon project itself.25However, the cancellation of the full Skylon vehicle did not signify the end of its core enabling technology. The SABRE engine's precooler system, a breakthrough in hypersonic propulsion, has found a new purpose. The European Space Agency (ESA) announced in July 2025 that this technology would be leveraged in their new Invictus research program.13 This transition illustrates that even when a large-scale, integrated aerospace project fails to reach its ultimate, grand vision, the fundamental technological advancements made during its development can be incredibly valuable. The precooler, for instance, is a critical component for air-breathing hypersonic flight, regardless of whether it is integrated into a full SSTO vehicle. This represents a strategic pivot, where the focus shifts from the grand vehicle concept to the maturation and application of key enabling technologies. This pattern of technology transfer, repurposing, and re-initiation is vital for progress in high-risk, long-term research and development fields like advanced space access, ensuring that significant investments in ambitious projects are not entirely lost. Instead, their sub-components or underlying scientific breakthroughs can contribute to future, perhaps more incremental or diversified, advancements.Invictus's Focus on Hypersonic Flight and its Potential for Future Orbital ApplicationsThe Invictus program, led by the consulting firm Frazer-Nash and involving partners such as Spirit AeroSystems and Cranfield University, aims to develop a Mach 5+ spaceplane by early 2031.13 While its immediate objective is to demonstrate hypersonic flight capabilities at the edge of space, the underlying air-breathing propulsion technology could potentially lead to future orbital launch applications.14 The "renewed British initiative" is therefore not a direct continuation of the Skylon SSTO dream as a complete vehicle, but rather a pragmatic and strategic pivot to develop a key enabling technology for a broader range of hypersonic and potentially future orbital applications. This highlights the long-term, iterative, and often fragmented nature of aerospace innovation, where foundational research can find new life even after initial program cancellations.Radian One (USA): Rekindling Spaceplane AmbitionsSeattle-based Radian Aerospace is actively pursuing the Radian One project, a single-stage-to-orbit spaceplane designed for horizontal launch and return to Earth.11 This initiative is explicitly aimed at revolutionizing the economics and logistics of space travel by making it more akin to conventional airline operations.A key innovation of Radian One is its plan to replace traditional vertical launches with a unique rocket-powered sled system.11 This sled is designed to accelerate the spaceplane along a two-mile rail, reaching speeds of Mach 0.7 (537 mph) before the spaceplane's own engines ignite to propel it into orbit.11 This novel approach is specifically intended to "address the 'tyranny of the rocket equation'" by providing significant initial acceleration without consuming onboard propellant, thereby reducing the required propellant mass fraction for the vehicle itself.11 This directly relates to the concept of "launch assists" as a strategic engineering solution. By gaining a significant portion of its initial velocity and kinetic energy externally, the vehicle reduces the required delta-v from its onboard propulsion system. This, in turn, allows for a lower propellant mass fraction for the vehicle, potentially enabling a higher payload fraction or more robust reusability features, making the overall SSTO design more feasible. Launch assist mechanisms represent a pragmatic approach to circumventing the fundamental mass fraction challenge of SSTO. They offload a portion of the energy requirement from the vehicle's internal systems, making the design less constrained by the need for ultra-lightweight structures and extreme engine efficiency across the entire flight profile. This suggests a potential future for SSTO where the "single-stage" concept might implicitly include significant ground-based launch infrastructure. It highlights a shift from purely onboard solutions to integrated system solutions that leverage external energy input to achieve orbital access, blurring the lines of what constitutes a "single stage" in a broader operational context.The Radian One spaceplane is designed for high reusability, targeting up to 100 missions with a rapid 48-hour turnaround time between flights.11 Once in orbit, it is intended to function similarly to the Space Shuttle, deploying payloads such as satellites and performing missions like Earth observation and defense applications.11 While technically promising, the economic viability of Radian One remains a "significant question," particularly due to the intense competition from reusable multi-stage rockets from companies like SpaceX, which have already driven down LEO costs to approximately US3,000perkilogram.[11]RadianAerospacehassecuredUS27.5 million in seed capital, with the final project cost expected to be in the hundreds of millions.11Polaris Aerospace MIRA (Germany): Advancing Aerospike TechnologyPolaris Aerospace, a company based in Germany, is actively developing the MIRA Supersonic-Hypersonic aerospike spaceplane platform, with the explicit aim of achieving Single-Stage-to-Orbit flight.12 Following a crash of the MIRA I prototype, Polaris is preparing to fly two new, identical prototypes, MIRA II and MIRA III. These new airframes feature 30% more wing area and incorporate significant design improvements based on lessons learned from the MIRA I. While these demonstrators are constructed from fiberglass, Carbon Fiber Reinforced Polymer (CFRP) is planned for their commercial products.12The core technology of the MIRA aircraft is its utilization of an aerospike rocket engine (specifically, the AS-1 LOX/Kerosene linear aerospike rocket engine).12 The aerospike engine is unique in its theoretical ability to maintain efficiency from sea level all the way into space. Unlike traditional bell-shaped nozzles, which are optimized for specific altitude ranges and suffer performance losses at others, the aerospike fires its exhausts down a central surface. The ambient airflow then acts as the remaining walls of the nozzle, allowing it to naturally tune its performance as speed and altitude change.12 This design directly addresses the critical challenge of requiring "one engine for all altitudes" 5, which is paramount for a single-stage vehicle that cannot shed optimized engine bells. The continued investment in aerospike technology, despite past failures such as the X-33 cancellation and the MIRA I crash, underscores its theoretical advantage for SSTO. If successful, it could significantly simplify the propulsion system by eliminating the need for multiple engines or complex staging, directly contributing to the "single-stage" ideal by optimizing thrust efficiency throughout the entire ascent profile. This highlights that propulsion system innovation remains a critical bottleneck for SSTO. The ability to efficiently convert propellant energy into thrust across the entire ascent profile is paramount to achieving the necessary delta-v within the stringent mass budget, and aerospikes represent one of the most promising, albeit challenging, pathways to this goal.Polaris Aerospace has future plans to test NOVA, a larger (26.2 ft / 8 m) supersonic prototype, starting in 2025, with the intention of developing it into a commercial product.12Stoke Space (USA): A Focus on 100% ReusabilityStoke Space, a US-based company, has articulated its ambition to build "100% reusable rockets" with a novel design, aiming to achieve "seamless mobility to, through, and from space".15 Their flagship product, the "Nova" rocket, is advertised as "100% reusable" and targets a "20x reduced cost to orbit".16 Stoke emphasizes rapid reusability and operational efficiency, with a particular focus on a "reusable upper-stage vehicle".16 The company is actively developing a full-flow staged combustion engine called Zenith and has already demonstrated a full-scale prototype of their reusable upper stage.16The explicit mention of a "reusable upper-stage vehicle" 16 indicates that Nova, by the strict definition of SSTO ("SSTO = Never drop parts"), is not a true single-stage-to-orbit vehicle, as it employs an upper stage, even if that stage is reusable.17 However, Stoke Space's core emphasis is on full reusability and drastically reduced costs, which aligns with the user's core interest in the "attractive" and "difficult" aspects of reusable space access. Discussions in the aerospace community often reveal that many individuals use "SSTO" when they are actually referring to a "fully reusable craft" or "SSTOL" (Single Stage To Orbit and Landing).17Stoke Space's approach exemplifies a broader industry trend, largely influenced by the success of companies like SpaceX, where the economic benefits of reusability are paramount, even if achieved through multi-staging. The strict "single-stage" definition becomes less critical than the "fully reusable" outcome, which is the ultimate driver for cost reduction and increased access. Stoke Space represents a pragmatic approach to achieving the benefits of SSTO—namely, low cost, high frequency, and rapid turnaround—without necessarily adhering to the strict "single-stage" technical definition, which remains exceptionally challenging. This suggests a potential future where the term "SSTO" might evolve or be supplemented by "Fully Reusable Launch Vehicle (FRLV)" to encompass systems that achieve the economic goals of SSTO through different architectural means. The industry appears to be prioritizing the outcome (low-cost, frequent access to space) over a specific design constraint (single stage), as long as the economic and operational benefits are realized.The following table provides an overview of these current global initiatives relevant to SSTO development:Table 2: Current Global SSTO-Relevant Initiatives OverviewProject NameCountry/CompanyPrimary Approach/Vehicle TypeKey Technologies/InnovationsReusability FocusCurrent Status/TimelineInvictusUK/ESA (Frazer-Nash, etc.)Air-breathing hypersonic demonstratorSABRE engine precooler 13Hypersonic flight with orbital potentialResearch program, Mach 5+ spaceplane by 2031 13Radian OneUSA/Radian AerospaceHorizontal launch spaceplaneRocket-powered sled for initial acceleration 11Full reusability (100 missions, 48hr turnaround) 11Scale model testing (current year), full flight tests 2028 11Polaris MIRAGermany/Polaris AerospaceAerospike spaceplaneAS-1 LOX/Kerosene linear aerospike engines 12SSTO ambition, reusable prototypesMIRA II/III prototypes flying soon (Nov 2024), NOVA prototype 2025 12Stoke NovaUSA/Stoke SpaceVertical launch reusable rocketReusable upper stage, full-flow staged combustion engine 16100% reusability, 20x cost reduction 16Prototype testing, engine hotfires (Zenith, Andromeda) 166. ConclusionsThe aspiration for Single-Stage-to-Orbit (SSTO) from Earth remains a compelling, yet unachieved, goal in spaceflight. The fundamental challenge lies in the "tyranny of the rocket equation," which imposes an exceptionally stringent mass budget, requiring nearly 90% of a vehicle's initial mass to be propellant for orbital insertion. This leaves minimal margin for structural components, engines, thermal protection, and payload, particularly for reusable designs that carry additional mass for re-entry and landing systems. Historical projects like the DC-X, X-33, and Roton, while demonstrating crucial technologies such as vertical landing and aerospike propulsion, ultimately faced cancellation due to the immense technical hurdles and economic viability concerns associated with these extreme mass fractions. The "stage-and-a-half" Atlas rocket serves as a historical testament to the pragmatic compromises engineers have made to achieve orbital flight, acknowledging the inherent difficulty of a true single-stage design.The current landscape of space launch reveals a nuanced evolution in the pursuit of cost reduction and increased access to space. While the dream of a true SSTO persists, the industry's focus is increasingly shifting towards fully reusable launch systems, even if they employ multiple stages. This shift is largely driven by the proven economic success of reusable multi-stage rockets, which have significantly lowered launch costs, making them highly competitive. Companies like Stoke Space, for instance, prioritize "100% reusability" and dramatic cost reduction, even if their designs incorporate a reusable upper stage, thereby not strictly adhering to the single-stage definition. This indicates that the ultimate goal is the outcome of low-cost, frequent, and reliable space access, rather than strict adherence to a single-stage architecture.Nevertheless, dedicated SSTO-relevant initiatives continue to push the boundaries of technology. The UK's Invictus program, leveraging the advanced SABRE engine precooler technology from the canceled Skylon project, exemplifies how foundational technological advancements can be salvaged and repurposed for future hypersonic and potentially orbital applications, even when the original grand vehicle concept is abandoned. Radian One's innovative use of a rocket-powered sled for horizontal launch demonstrates a strategic approach to mitigating the rocket equation by providing external launch assist, thereby reducing the onboard propellant requirement. Polaris Aerospace's persistent development of aerospike engines for its MIRA spaceplane platform highlights the ongoing pursuit of "one engine for all altitudes," a critical propulsion solution for single-stage vehicles.In conclusion, while the pure Earth-launched SSTO remains an elusive engineering feat due to fundamental physical constraints, the broader vision of low-cost, highly reusable space access is actively being pursued through diverse and innovative approaches. The industry is learning to balance theoretical ideals with practical engineering and economic realities, with the emphasis increasingly placed on achieving the benefits of reusability, whether through a strict single-stage design, external launch assists, or highly efficient multi-stage reusable architectures. The ongoing developments suggest a future where access to orbit will be significantly more affordable and routine, even if the final form of the "single-stage-to-orbit" vehicle deviates from its most rigid definition.

(th)

Offline

Like button can go here

#5 2025-07-26 08:44:05

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: SSTO History Atlas and other single stage launchers

This is a copy of Gemini's Research Report on SSTO status, formatted for display to readers...

The report includes reference to UK's Invictus...

Inventory of Single-Stage-to-Orbit Initiatives

1. Executive Summary

This report provides a comprehensive overview of Single-Stage-to-Orbit (SSTO) initiatives worldwide, distinguishing between historical concepts and current developments, particularly focusing on expendable versus fully reusable approaches. The pursuit of SSTO is fundamentally driven by the promise of drastically reduced space launch costs, primarily through the elimination of hardware jettisoning and the maximization of vehicle reusability.

Despite its compelling allure, no Earth-launched SSTO vehicle has yet achieved orbital velocity. This persistent challenge stems primarily from the "tyranny of the rocket equation," a fundamental physical constraint that necessitates an exceptionally high propellant mass fraction for any single-stage vehicle attempting to reach orbit from Earth's surface. This constraint imposes extreme engineering demands on every component, particularly regarding mass efficiency.

Historically, projects such as the McDonnell Douglas DC-X/DC-XA, Lockheed Martin X-33 VentureStar, and Roton demonstrated critical technologies and operational concepts, but ultimately encountered significant technical and economic hurdles that led to their cancellation. The Atlas rocket, while a groundbreaking design, employed a "stage-and-a-half" configuration, which involved discarding engines during ascent, thus not qualifying as a true SSTO. This design choice highlights early pragmatic compromises in rocket engineering to overcome the inherent difficulties of single-stage flight.

Current global efforts represent a renewed push to overcome these long-standing challenges through diverse technological pathways. Notable initiatives include the UK's Invictus program, which leverages the advanced SABRE engine technology originally developed for Skylon; Radian One's novel horizontal launch system incorporating a rocket-powered sled; and Polaris Aerospace's focus on aerospike spaceplanes. These projects are exploring various methods to improve mass efficiency and propulsion performance.

A critical distinction is evident in the contemporary landscape: while true SSTO remains a formidable technical goal, the broader industry focus is increasingly shifting towards fully reusable launch systems, even if these systems employ multiple stages. This pragmatic shift is largely influenced by the demonstrated success of reusable multi-stage systems, such as those developed by SpaceX, which have achieved significant cost reductions and operational efficiencies. These multi-stage reusable vehicles are proving to be economically competitive and often more readily achievable than strict SSTO designs, driving a re-evaluation of the most effective path to low-cost space access.

2. Introduction: The Enduring Quest for Single-Stage-to-Orbit

Defining Single-Stage-to-Orbit (SSTO) and its Aspirational Role in Space Access

Single-Stage-to-Orbit (SSTO) refers to a space vehicle engineered to reach Earth orbit from its surface without jettisoning any hardware components during its ascent. This implies that the entire vehicle, including its engines and propellant tanks, remains intact from liftoff through orbital insertion. The core vision driving SSTO development is the drastic reduction of space launch costs. By eliminating the need to discard expensive hardware, SSTO promises to enable complete vehicle reuse, fostering greater investment in the space sector, facilitating more frequent launch experiments, and ultimately paving the way for a future of low-cost private space access. The ultimate aspiration for many SSTO proponents is a vehicle that could operate much like a conventional winged aircraft, taking off and landing horizontally, thereby eliminating the need for complex and costly vertical launch infrastructure.

While the concept of SSTO has been successfully demonstrated from celestial bodies with significantly weaker gravitational fields and negligible atmospheric pressure, such as the Moon (achieved by the Apollo program's Lunar Module) and various robotic spacecraft of the Soviet Luna program, it has yet to be realized from Earth. Earth's formidable gravitational pull and dense atmosphere present unique and exceptionally challenging engineering obstacles that have historically proven difficult to overcome.

The Fundamental Challenge: "The Tyranny of the Rocket Equation"

The Tsiolkovsky rocket equation is a cornerstone mathematical principle in aerospace engineering that defines the fundamental performance limits of any rocket. It establishes a direct relationship between a rocket's maximum change in velocity (delta-v), the effective exhaust velocity of its engines, and the ratio of its initial total mass (including propellant, often referred to as wet mass) to its final mass (after propellant is expended, or dry mass). This equation illuminates the profound challenge inherent in achieving SSTO from Earth.

For a single-stage rocket to attain the necessary delta-v to reach Low Earth Orbit (LEO) from Earth's surface, which is approximately 9,700 meters per second (accounting for gravity and aerodynamic drag losses), an extraordinarily high proportion of its initial mass must be dedicated to propellant. For example, with a typical effective exhaust velocity of 4,500 m/s, approximately 88.4% of the vehicle's initial total mass must be propellant. This leaves a mere 11.6% of the initial mass for all other critical components, including the structural mass (such as the engine, control and guidance systems, tankage, and supporting structures) and the payload itself.

This severe mass budget is precisely what is often referred to as the "tyranny of the rocket equation" for SSTO. It mandates that every component of the vehicle, from its engines to its thermal protection system and internal structures, must be engineered to be incredibly lightweight while simultaneously possessing the strength and robustness to withstand the immense forces of launch, the extreme temperatures of hypersonic flight, and the stresses of re-entry. This challenge is further compounded by the additional mass requirements for reusability, such as landing gear, more durable structures, and thermal protection systems designed for multiple missions. This fundamental physical constraint explains why multi-stage rockets became the dominant paradigm in space launch. By shedding empty tanks and engines during ascent, multi-stage vehicles effectively improve the mass ratio for subsequent stages, making the achievement of orbital velocity significantly more feasible for a given initial mass and engine performance. Overcoming this inherent mass efficiency challenge is the primary driver behind many innovative SSTO design choices, including the development of air-breathing engines (which reduce the need for onboard oxidizer), highly efficient propulsion systems like aerospikes, or external launch assists like sleds. Each of these solutions aims to either reduce the required propellant mass fraction or provide initial energy without expending internal propellants, thereby making the stringent 11.6% dry mass budget for a practical payload more attainable.

3. Historical Context: Early Visions and Demonstrators

Pioneering Concepts and Theoretical Designs

The aspiration for Single-Stage-to-Orbit vehicles gained prominence in the early 1960s, giving rise to numerous visionary designs that pushed the boundaries of aerospace engineering. These early concepts, though largely theoretical, were instrumental in exploring the possibilities and identifying the immense challenges of SSTO.

Among the most prolific proponents was Philip Bono, an engineer at Douglas Aircraft Company, who championed various SSTO designs. He proposed the One Stage Orbital Space Truck (OOST) as an expendable SSTO concept, alongside a reusable counterpart named ROOST. Bono's later designs, such as the

Douglas SASSTO from 1967, continued to explore vertical takeoff and landing (VTOL) SSTO configurations.

Another ambitious early concept was NEXUS, proposed by Krafft Arnold Ehricke in the early 1960s. NEXUS was envisioned as a colossal reusable launch vehicle, with a projected diameter exceeding 50 meters and the capability to lift up to 2,000 short tons into Earth orbit, primarily intended for missions to the outer Solar System. In 1979, Rockwell International unveiled the

Star-Raker, a concept for a 100-ton payload heavy-lift spaceplane designed for horizontal takeoff and landing. This vehicle would have utilized a multi-cycle airbreather ramjet/cryogenic rocket engine system, combining LOX/LH2 rocket engines with turboramjets. Other notable early concepts included

ROMBUS (Reusable Orbital Module, Booster, and Utility Shuttle), Ithacus (a sub-orbital military transport derived from ROMBUS), Pegasus (a passenger and payload transport), and Hyperion (which proposed using a sled to build up speed before liftoff to conserve fuel). These pioneering designs, despite never being constructed, were crucial in establishing the theoretical framework and highlighting the formidable engineering hurdles associated with SSTO.

Key Demonstrator Programs and Their Lessons Learned

Over time, the theoretical concepts evolved into experimental programs aimed at demonstrating key SSTO technologies. These demonstrators provided invaluable practical experience, even when they did not achieve their ultimate goals.

McDonnell Douglas DC-X/DC-XA: Vertical Take-off and Landing (VTOL) Proof-of-Concept

The Delta Clipper Experimental (DC-X) was an uncrewed prototype of a reusable single-stage-to-orbit launch vehicle, developed by McDonnell Douglas in collaboration with the United States Department of Defense's Strategic Defense Initiative Organization (SDIO) from 1991 to 1993. Funding was subsequently continued by NASA until 1995. The DC-X was a one-third-scale prototype, standing 12 meters high with a 4.1-meter diameter, specifically designed to demonstrate vertical takeoff and landing (VTOL) capabilities, subsonic maneuverability, and airplane-like supportability and maintainability. Its design drew inspiration from Philip Bono's earlier SASSTO vehicle.

The DC-X completed a total of 12 flights—eight under McDonnell Douglas and four under NASA as the DC-X/A—between 1993 and 1996. The project was ultimately canceled after a test flight of the DC-XA in 1996 resulted in a fire, though it had successfully demonstrated the critical VTOL capabilities and rapid turnaround operations. The program's philosophy of "fly a little, break a little" emphasized rapid prototyping and gaining practical experience with fully reusable, quick-turnaround spacecraft. This approach proved instrumental in demonstrating the technical feasibility of precise vertical takeoff and landing for reusable rockets, a capability that has since become a cornerstone of many modern launch systems, most notably SpaceX's Falcon 9. The DC-X's legacy lies in validating a key operational mode essential for future reusable spaceflight.

Lockheed Martin X-33 VentureStar: Suborbital Demonstrator and its Technical Hurdles

In 1996, NASA selected Lockheed Martin to develop and fly the X-33 test vehicle, a half-scale, suborbital reusable spaceplane demonstrator, measuring 69 feet long and 77 feet wide with a gross liftoff weight of 285,000 pounds. The X-33's primary objective was to validate advanced technologies for a new full-scale reusable launch vehicle concept known as VentureStar, which was intended to be a true SSTO vehicle. The X-33 featured a distinctive lifting body shape, was powered by two XRS-2200 linear aerospike rocket engines (delivering 410,000 pounds of thrust at liftoff), and incorporated a durable metallic thermal protection system (TPS). The program aimed for an ambitious cost reduction, seeking to lower the cost of sending payloads to space from approximately US

10,000perpoundtojustUS1,000.

The X-33 program was canceled in 2001 before any test flights were conducted, primarily due to a failure during testing of its complex cryogenic liquid hydrogen tank. While the program did not achieve its flight objectives, it did accomplish significant successes in areas such as rapid flight hardware design, subsystem testing, and the development and testing of aerospike engines. The cancellation of the X-33, despite successful development of individual subsystems like the aerospike engines, illustrates the profound difficulty of scaling and integrating complex systems. The extreme mass fraction requirements of SSTO mean that every component, particularly large, lightweight cryogenic tanks, must perform flawlessly under immense structural and thermal stresses. The failure of even one critical, complex component can derail an entire ambitious program. This experience underscores that scaling up from a demonstrator to a full orbital vehicle introduces new, often unforeseen, engineering challenges that compound the inherent difficulty of SSTO. The X-33's fate serves as a significant lesson for SSTO development, emphasizing that the challenge extends beyond designing individual components to ensuring their reliable and robust integration within an extremely tight mass budget, especially for reusable systems.

Roton: A Unique Approach to Reusability with a Rotary Engine and Helicopter Landing

The Roton was a piloted commercial space vehicle design developed by Rotary Rocket Company in the late 1990s. It was conceived as a fully reusable, single-stage-to-orbit (SSTO) Vertical Take-off and Landing (VTOL) spacecraft, designed to transport up to 3,200 kg to LEO with a target price of $7 million per flight (in 1999 dollars).

The Roton featured several distinctive innovations. It was initially planned to use a novel rotary engine and, uniquely, a helicopter rotor system mounted on top for a controlled, pilot-directed landing. The rotor system would autorotate during descent and utilize tip rockets for a soft touchdown. The design called for an empty weight under 5% of its gross takeoff mass, a figure described as "very challenging" even for an expendable rocket, let alone one carrying a crew, rotor system, and thermal protection. This requirement directly illustrates the extreme demands imposed by the "tyranny of the rocket equation" on SSTO designs. The project was ultimately canceled in 2000 due to persistent technical challenges and insufficient investment.

The "Stage-and-a-Half" Atlas Rocket: Clarifying its Design and Why it Wasn't a True SSTO

The Atlas rocket family, which originated with the SM-65 Atlas Intercontinental Ballistic Missile (ICBM) in the late 1950s, is sometimes mentioned in discussions of SSTO due to its unique design. The Atlas employed an unusual "stage-and-a-half" or "parallel staging" configuration. During ascent, two outboard booster engines, along with their supporting structures, were jettisoned. The central sustainer engine and the vehicle's propellant tanks continued to fire throughout the remainder of the ascent.

This design, as explicitly stated, meant that the original versions of the Atlas did jettison hardware during ascent. Therefore, it was technically not a true SSTO vehicle, despite being referred to as "stage and a half". This design choice was a pragmatic engineering solution to the challenges posed by the rocket equation. By shedding the mass of two engines once they were no longer needed at higher altitudes, the Atlas effectively improved its mass ratio for the remainder of the ascent without incurring the full structural complexity and potential failure points of a traditional serial multi-stage separation. It achieved some of the performance benefits of staging, such as reducing the total vehicle weight for a given payload and delta-V, or allowing for a larger payload from the same initial vehicle , while simplifying the overall vehicle structure compared to a fully staged rocket. The Atlas's design highlights an early recognition of the immense difficulty of achieving SSTO from Earth. Engineers sought intermediate solutions to improve performance and mass efficiency under existing technological constraints, rather than pursuing a pure SSTO ideal at all costs. This historical example underscores that design choices in rocketry often involve finding optimal compromises between performance, complexity, reliability, and cost. The "stage-and-a-half" approach demonstrates that even partial staging can yield significant benefits, a lesson that continues to influence modern reusable multi-stage designs.

4. Expendable vs. Fully Reusable SSTO: Technical and Economic Distinctions

Detailed Technical Definitions of Each Category

To clarify the landscape of space launch, it is essential to define the categories of expendable and fully reusable systems, particularly within the context of Single-Stage-to-Orbit (SSTO).

An Expendable SSTO would, by the strict definition of SSTO, reach orbit without jettisoning any hardware during ascent. However, the term "expendable" would imply that the vehicle is discarded after a single use. Given the extreme technical difficulty and inherently high development costs associated with SSTO designs , building such a complex vehicle only to discard it after one mission would be economically unfeasible and environmentally unsustainable. Consequently, in practical aerospace discourse, the term "SSTO" is almost invariably associated with the concept of reusability.

A Fully Reusable SSTO represents the pinnacle of this aspiration. Such a vehicle would not only reach orbit without jettisoning any components but would also return its entire structure to Earth for refurbishment and subsequent missions. The primary projected advantage of this approach is the complete elimination of hardware replacement costs, which are inherent in expendable launch systems.

Advantages and Disadvantages of Expendable vs. Fully Reusable Systems (General Rocketry Context)

To fully appreciate the challenges and motivations behind SSTO, it is helpful to consider the broader advantages and disadvantages of expendable versus reusable systems in general rocketry, as these principles largely apply to the SSTO debate.

Multi-Stage Rockets (often expendable, or partially reusable):

Advantages: Multi-stage designs significantly reduce the total vehicle weight required to achieve a given payload capacity and delta-V, or conversely, enable a larger payload for the same initial vehicle size. By shedding empty tanks and engines, these systems dramatically improve the mass ratio for subsequent stages, making the attainment of orbital velocity more achievable. This approach also allows for higher maximum velocities for a given vehicle and can decrease the required specific impulse of engines.

Disadvantages: Multi-stage rockets are inherently more complex due to the multiple separation events, engine ignitions, and intricate control systems required during ascent. This increased complexity can lead to decreased reliability due to a greater number of potential failure points. From an economic perspective, the discarding of costly engines, avionics, and other hardware with each flight results in significantly increased recurring costs.

Fully Reusable Systems (including SSTO and reusable multi-stage):

Advantages: The primary projected advantage of fully reusable systems is the elimination of hardware replacement, which is a major cost driver in expendable launch systems. This promises drastically reduced recurring costs per launch. The prevailing belief among investors and developers is that reusing system elements will ultimately prove more economical than continually manufacturing and discarding expensive components.

Disadvantages (specific to Fully Reusable SSTO):

High Non-Recurring Costs: The design, development, research, and engineering (DDR&E) costs for reusable SSTO systems are substantially higher than for expendable systems. This is attributed to the extreme technical challenges that must be overcome, assuming these issues can be resolved at all.

Extreme Technical Complexity: A reusable SSTO demands an exceptionally robust vehicle capable of surviving numerous round trips into space. This requires breakthroughs in advanced materials, innovative construction techniques for sustained high-speed atmospheric flight, and sophisticated thermal protection systems for re-entry. Propulsion systems must also maintain high efficiency across an enormous range of altitudes and speeds.

Mass Penalties: The features necessary for reusability, such as landing gear, robust structures designed for multiple flights, and extensive thermal protection, add significant inert mass to the vehicle. This further exacerbates the "tyranny of the rocket equation," making it even more challenging to achieve the necessary mass fraction for orbit with a meaningful payload. For instance, while kerosene tanks can represent as little as 1% of their contents' weight, hydrogen tanks often must weigh 10% of their contents due to hydrogen's extremely low density and cryogenic nature, significantly impacting overall vehicle design and thrust-to-weight ratios.

High Maintenance: Reusable SSTO vehicles are likely to require a significantly higher degree of regular maintenance and refurbishment between flights to ensure safety and reliability, which adds to operational costs.

Low Payload Fraction: Rocket-powered SSTO vehicles are characterized by very high mass ratios and consequently very low payload fractions. For example, the payload might be around 1-2% for an Equatorial LEO, falling to as low as 0.25% for a Polar orbit. This limited payload capability has historically been a major disadvantage, hindering their development.

The Economic Viability Debate: SSTO vs. Multi-Stage Reusable Systems

A lively debate persists regarding the economic merits and drawbacks of reusable versus expendable systems. The central question is whether the substantial investment and technical hurdles of reusability, particularly for SSTO, are ultimately "worth it".

The current economic landscape of space launch is rapidly evolving. The emergence and success of highly reusable rockets, particularly from companies like SpaceX, have fundamentally altered the cost equation. These multi-stage reusable systems have driven down the cost of reaching low Earth orbit (LEO) to approximately US$3,000 per kilogram. This development presents a significant challenge for SSTO systems to compete economically, even if they achieve technical feasibility.