New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2025-02-06 16:22:22

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Fiber Optic Topological Mirrors

A "fiber optic topological mirror" refers to a specialized optical fiber designed using principles from topology, where the light propagation is manipulated in a way that makes the light highly resistant to disruptions caused by structural imperfections, effectively acting like a mirror that reflects light back with minimal signal loss, even when the fiber is bent or twisted; this is achieved by utilizing specific patterns in the fiber's core structure that create "topological edge states" which confine light along the fiber's edges, protecting it from disturbances within the fiber's core.

Key points about fiber optic topological mirrors:

Unlike regular optical fibers that rely solely on total internal reflection, topological fibers leverage topological concepts to guide light along specific pathways, making them more robust against perturbations.Edge states:

In a topological fiber, light is confined to travel along the edges of the fiber core, which are considered "topological edge states," offering increased immunity to defects or variations in the fiber structure.Applications:

These mirrors could be used in applications where signal integrity is critical, like high-speed data transmission, optical sensing, and quantum photonics, as they can maintain signal quality even in challenging environments.How it works:

The fiber is engineered with a specific pattern of refractive index variations in its core, creating a "topological lattice" that allows light to propagate along the edges of the fiber.Light confinement:

Due to the topological design, light is confined to travel along these edge states, even if the fiber is bent or twisted, minimizing signal degradation.

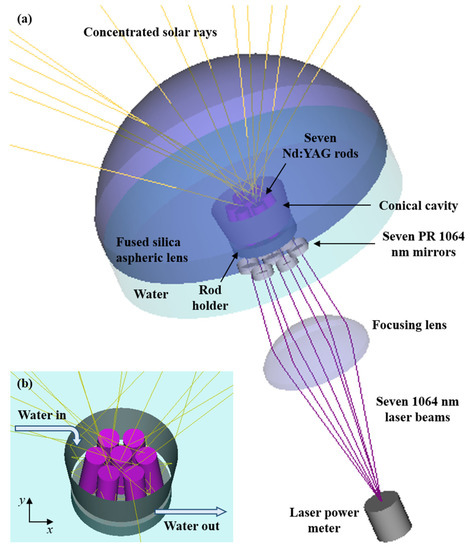

In my case, I'm more interested in using this phenomenon to direct photonic power from the Sun, into the core of a solar thermal rocket, using thin sheets of lightweight fiber, to direct photonic power from the Sun back to a single volume, a "reactor core" if you will, in order create temperatures similar to what solid core nuclear thermal rockets operate at, but without the expense and political headaches that stem from using fission reactors in space.

Between Mercury and Mars, I think this tech could serve as a propulsion scheme for a large interplanetary transport ship, not focused on raw thrust or power density, as with the core of a nuclear thermal rocket's reactor core, but more of an engine that sits between LOX/LH2 and ion engines, in terms of Isp and thrust.

Why would this be useful to have?

We can use abundant pure Hydrogen propellant, at an Isp of 1,000s or so. For a very large ship, I don't want a large amount of thrust that requires special strengthening. I don't want to generate tens to even hundreds of megawatts of electrical power for brief periods of ion engine firing, either. I want a thermally-generated thrust measured in low single-digit kilonewtons, acting on my properly shielded transport ship for a matter of hours to days, to gradually but efficiently break orbit and inject the ship onto an interplanetary trajectory towards Venus or Mars, as examples. This tech is intended to use pure photonic power, rather than explosive chemical bi-propellants or gobs of electrical power and expensive specialty inert gases like Xenon.

Offline

Like button can go here

#2 2025-02-06 16:31:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,413

Re: Fiber Optic Topological Mirrors

This post is reserved for an index to posts that may be contributed by NewMars members over time.

The topic itself flows from work kbd512 has been doing in other topics.

Best wishes for success of both the topic and the research.

(th)

Offline

Like button can go here

#3 2025-02-15 15:56:57

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Fiber Optic Topological Mirrors

The only significant problem I'm learning about with this tech is transporting the photonic power back to the engine without large and heavy optical cables. At first I could not figure out if the materials and tech existed to create a topological mirror so that a paper-thin sheet of optical fiber could be engineered to either direct through total internal reflection or the use of a topological mirror, effectively "turn" the stream of incoming photons 90 degrees, perpendicular to the optical sheet / fiber, to get them flowing through a fiber optic cable acting as a "pipe" to transmit the photons back to the engine. Now that I know this is less of a problem than I originally thought, and there's a large and growing body of work using paper thin strands and sheets of fibers to do this, the next major problem is the achievable optical power density before that photonic power start damaging the fiber (degrading its internal structure such that it no longer functions as a TIR lens or topological mirror).

The power density limit for the most common kind of Silica fiber optic cabling is 2W/mm^2. To deliver 1kW, while providing long-term durability, you need a fiber optic cable of approximately 25.4mm in diameter.

The design I had in mind is 40MW of optical power. A 100m long fiber optic cable capable of delivering 1kW of power would need to be about 25.4mm in diameter, so assuming a fully-dense 2.2g/cm^3 Silica-based fiber, that would weigh ~111.476kg. The total weight of fiber for the collector surface area to absorb 40MW of photonic power, is around 64,662kg, but to that we must add additional mass to deliver that much power back to the engine.

If the total mass is near 100,000kg, which seems achievable, then our power delivery system's power achievable density is 400W/kg, similar to the gravimetric energy density of a high performance Lithium-ion battery. In comparison to Copper wiring, the practically achievable W/kg ranges between 500W and 1,000W, but the higher the wattage per kilogram, the greater the heat generated, the greater the internal electrical resistance, and the higher the total power loss. On top of that, Silicon-based photovoltaics typically only convert 25% to 35% of the photonic power into electrical power, so the achievable kW/kg value is much lower than electrical conductivity alone would suggest.

Aluminum wiring would not be a suitable conductor material in Space, either, due to the substantial temperature fluctuations causing rapid work-hardening and subsequent cracking as the Aluminum alloy wiring flexes from temperature fluctuations driven by vehicle attitude (whether or not the wiring is in full Sun or darkness or some combination of illumination and thus heating) and power generated, thus internal heating rate from electrical resistance. Maybe there's an Aluminum alloy that can withstand that for some period of time, such as 2024 (a Copper-based Aluminum alloy), but longer-term, repeated flexing will take its toll and cause electrical shorts as connections are broken. Here on Earth where we use Aluminum for long distance power transmission lines, we use very soft alloys that are mostly "permanently flexed" by the force of gravity, and remain anchored to the towers they're connected to, so they really don't move around a lot and the temperature swings are far lower than they are in space. This is not to say there's not some sort of technical solution, merely that at the present time, when we use photovoltaics in space, we use Copper wiring. The photovoltaics themselves use Silver wiring on the wafers, a highly malleable metal with the absolute best electrical conductivity of all the metals. Maybe there's a way to use geometry to limit the work hardening of the Aluminum alloy, but it's a known "fact-of-life" that all Aluminum alloys work harden and then crack from repeated flexing.

The overall point is that optical power and electrical power provided by photovoltaics are likely to result in similar total power delivery system weights.

Thin film photovoltaics, at 15% BOL efficiency, will end up weighing 19,594kg for the panel area alone. The Copper wiring and electrical power inverters will rapidly add back a lot of weight, because the wiring runs will be much longer. Photonic power is near 100% efficient in transmission through fiber optics, so long as you remain under the power density limit for the type of fiber you're using. Thin film photovoltaic surface area to generate 40MWe is around 195,935m^2. Fiber optic panel / topological mirror surface area to generate 40MWp is 29,391m^2. That is a massive difference, about 6.67X smaller for the pure photonic power delivery solution. Needless to say, you will need a lot more Copper wiring or suffer from electrical resistance heating and further power losses, so even if Copper carries double the absolute gravimetric power density of Silica-based fiber optics, the dramatic increase in total collector surface area required, due to the very low conversion efficiency of thin film photovoltaics, greatly diminishes the mass advantages provided by electrical resistance heating of the Hydrogen propellant vs direct photonic heating.

Offline

Like button can go here

#4 2025-02-15 18:25:02

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Fiber Optic Topological Mirrors

How tricky would it be for a stationary platform to focus sunlight into a beam with such optics? If it can be directly used, rather than requiring conversion to electricity then to e.g. a maser to transmit power, the system should be less complex (efficiency is a far less pressing issue in this case, given how much sunlight is available). Stationary platforms will not be so mass constrained, so they can be scaled up to ensure the same beam intensity whether around Terra or out at the Trojans or by Saturn. Illuminating a ship with 10kW/m^2 of sunlight should give pretty good power to mass ratio for its collection system...

Use what is abundant and build to last

Offline

Like button can go here

#5 2025-02-16 04:30:48

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,349

Re: Fiber Optic Topological Mirrors

Terraformer,

There are in fact solar-pumped lasers that don't use any electricity, and therefore last much longer in operation than electrical and electronic components. They use thin layers of special chemical dopants to facilitate lasing when struck by focused sunlight. My opinion is that if you were to use this as an offboard power source, for whatever purpose, then the real efficiency problem ultimately becomes how effectively you can transmit that laser beam power to whatever it's powering. We're talking about beam collimation over vast distances, which is difficult to do without very large apertures.

Solar pumping converts broadband sunlight into efficient laser light

I will readily admit that 4.64% efficiency doesn't seem very appealing, but let's consider the total conversion efficiency for our competing methods:

1. Photovoltaics provide input power, and then a laser diode uses the electricity to produce laser power

1,361Wp/m^2 * 35% BOL photovoltaic cell efficiency = 476.35We

476.35We * 40% BOL efficient laser diode = 190.54Wp (coherent)

2. 4.64% efficient direct solar pumped laser power

1,361Wp/m^2 * 4.64% direct conversion efficiency = 63.1504Wp (coherent)

That means we only need to achieve 14% direct conversion efficiency for the overall efficiency to be the same as using electrical power from 35% efficient triple-junction photovoltaics, which NASA pays $1M/kWe to use in their satellites.

As a first application, I think orbital direct solar-pumped lasers have applications in communications and computing.

Pure photonic computers can use 1,000,000X to 10,000,000X less input power for compute power equivalent to our latest generation of electronics, thus the conversion efficiency from sunlight to coherent light is far less of an issue than the fact that it does not consume vast amounts of electrical power, most of which will be generated by burning something.

Although phosphors can temporarily directly store direct photonic power for later use, much like a super capacitor, for bulk photonic power I think heating Silicon until it's glowing white hot has great potential to store the photonic power necessary to feed our massive and ever-growing compute infrastructure.

If we're not going to start using nuclear reactors, which I also support, to reliably power all this new AI computing infrastructure and their photonic analogs, which are rapidly taking over where electronics fall short, then perhaps we can use a photonic power solution that does not get "fried" every time there's a power surge from a storm "blowing up" the electrical systems.

The end goal should be to use the Sun to deliver most of the power, but to do so in a reliable and durable way that electronics have thus far failed to provide. If we ever get fusion working or we fall back on fission, then we still have a viable option if the nuclear option fails.

We've discussed at length some promising alternatives for bulk power delivery for heating purposes, which solar thermal (direct use of photons to generate heat) is ideal for.

The issue with district heating networks is the amount of materials they require, plus the fact that burying heat pipes requires a trenching machine to dig trenches. Fiber optic cable laying is already something that we do so often that we've developed special methods for doing it that don't disturb much of the surface activity over the top of the cable being buried. When a hole was dug for the fiber cable in our neighborhood, they had this machine that punched the hole and pulled the cable through which was basically towed behind a pickup truck. When we bury pipes, there's a big hole in the ground, they dig up entire streets, and generally mess up whatever is above the pipe. If it was possible to bury a power-over-fiber cable network that could heat your home's hot water tank or cook your food, then it would have the benefit of exceptional efficiency over great distances combined with the ability to use far less material and not have to eventually deal with corrosion damage or burst pipes, as would be the case with steam or hot CO2.

This tech is very interesting for both terrestrial and in-space applications. It removes a lot of the cost and annoyances associated with burying electrical power cables and water pipes. We have this alternative with great potential, which maybe means we only need heating networks when we actually need steam, such as making paper. Perhaps direct photonic power will become an electrical power replacement. I still like the district heating idea for places where we have geothermal power readily available, but America, Russia, and China are huge, so I think we want to pursue a more efficient transmission medium to deliver power over the vast distances involved. As far as which type of power distribution system will be more long-term reliable with less maintenance, that's harder to know. Fiber optic cables can also last for decades, but we have many historical examples of heating networks where that infrastructure was operated successfully for the better part of a century.

Do you have any thoughts or comments on this?

Offline

Like button can go here