New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2023-04-04 09:27:23

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Horizontal Wind Turbine farms - management - Good Neighbor Policy

In a nearby topic, Louis introduced the concept of vertical turbines.

This topic is offered for discussion of horizontal wind turbines, which appear to be the most common form in 2023.

The first post in this topic is a report on a Good Neighbor policy in Kansas. The aircraft warning lights are a source of irritation to neighbors of wind farms in Kansas, and the article reports on a plan to turn on the warning lights when aircraft are nearby, and to keep them off otherwise. Since aircraft are very rare in the areas where wind farms are established, this seems (to me at least) like a sensible policy.

The cost of a radar installation is about 1/3 of the cost of a single wind turbine, and the radar can serve an entire farm. The farm owner should see a return on investment due to reduced burnout of red lights and other factors related to the warning system.

(th)

Offline

Like button can go here

#2 2023-04-04 09:28:52

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

https://www.yahoo.com/news/red-lights-b … 22595.html

Sen. Mike Thompson, R-Shawnee, said a radar system is about $1.5 million, and one should be enough for most developments. That's less than the approximate $5 million cost to build a single turbine, he said.

"This is really cutting-edge legislation that will probably go into other states," said Sen. Rob Olson, R-Olathe.

Lights atop wind turbines affect sleep and traffic, Kansas legislator says

(th)

Offline

Like button can go here

#3 2023-04-04 09:35:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

https://www.yahoo.com/finance/news/ship … 04638.html

19

KEVIN McGILL and JENNIFER McDERMOTT

Tue, April 4, 2023, 8:04 AM EDT

HOUMA, La. (AP) — In Louisiana bayou country, where oil rig supply ships are as much a part of the waterside scenery as shrimp boats, a new kind of seagoing behemoth is taking shape that marks offshore wind power's growing presence in the energy seascape.Louisiana shipbuilding giant Edison Chouest Offshore is assembling the 260-foot-long Eco Edison in coastal Terrebonne Parish, along the Houma Navigation Canal. It's being built for Ørsted, a Danish firm that builds and operates wind farms worldwide, and Eversource, a New England energy provider. When delivered next year, the ship will serve as floating housing for U.S. offshore wind technicians and a warehouse for their tools as they run and maintain wind farms in the Northeast.

I expect that offshore wind turbines will have red warning lights running 24*7, because aircraft can fly over the ocean without restriction.

However, wind farms that are visible from shore may irritate the folks on land, so the aircraft detection radar systems may be needed in those locations.

(th)

Offline

Like button can go here

#4 2023-04-04 15:43:18

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,300

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

This is an example of a really simple and easy to build, tilted horizontal axis turbine.

https://en.m.wikipedia.org/wiki/Tjasker

This design is native to the Netherlands and it is used exclusively as a low head drainage pump using a direct-drive archemedes screw. It is not particularly efficient, because the sails are so close to the ground. But it is easy to make from wood and uses simple friction bearings. In the Netherlands, the winds are predominantly westerly. So a turbine facing west will intercept the majority of wind energy without any need to turn into the wind.

Although slightly less efficient than horizontal axis, vertical axis turbines like the Savonis have the advantages of being easy to make from common materials like wood and old barrels, able to exploit wind from any direction, and they provide more torque at low wind speeds. These are machines that literally anyone can build out of junk. The high torque is advantageous if you want a machine that can provide direct mechanical power to a workshop driven by a line shaft.

https://en.m.wikipedia.org/wiki/Line_shaft

If large parts of the world end up deindustrialising, these are the sort of simple technologies that we could build locally on a shoe string budget.

Very simple machines like the Tjasker could provide goods transportation by pushing low head water into a pipe or canal. Trains of capsules or coupled barges could be carried by the flow at roughly human walking speed. If the world were to run out of diesel tomorrow, we could use a system like this to maintain goods transportation. At an average speed of 4mph, we could transport freight from coast to coast in the US in about a month, using simple wind machines to pump floating capsules along a tube or ditch. In the UK, which is much smaller and has more wind, such a system could work even better. If we needed to build a low cost goods transportation system on a shoe string with only the most basic resources, then this is something we could use. Large parts of the world are facing post-industrial collapse over the next several decades. The world is going to become disconnected and many resources will not be available to most people in most places. Having simple technologies that can work using local resources, will be an important way of sustaining civilisation.

Last edited by Calliban (2023-04-04 16:09:49)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#5 2023-04-04 19:38:45

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

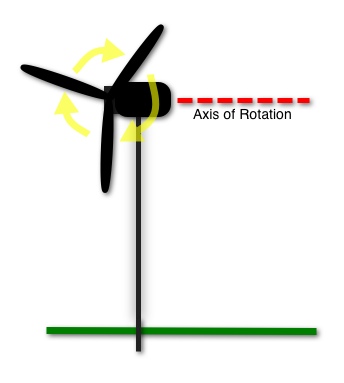

A horizontal wind turbine is classified as horizontal because the axis of the rotating turbine is horizontal, or parallel to the ground. They are the most efficient available wind turbine in today’s market. But, the biggest disadvantage of the HAWT is that it needs to be facing the wind in order to operate efficiently.

You see them in lots of places, and these are large and usually complained about when it comes to not being very esthetic in particular along mountain ridges.

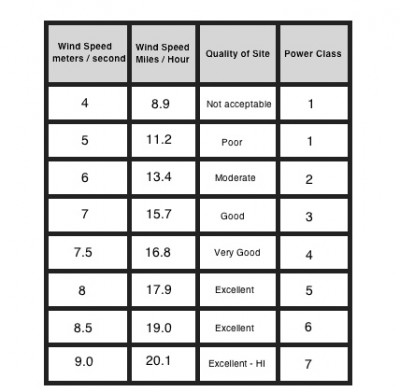

The main issue is the blade count, surface area and sweep of them all relate to the collecting energy that they can receive. Wind speed is also a crucial factor when deciding the power class wind turbine.

Offline

Like button can go here

#6 2024-01-26 09:55:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

NewMars appears to have landed on the Airloom mailing list. There are so many topics with "wind" in the title, I'm picking this one because the movement of the wings is horizontal.

Happy 2024 from Airloom Energy!

In reflecting on the past year, we found so much to celebrate. We welcomed amazing new members to our team; strengthened existing partnerships and formed valuable new ones; and were gratified by the tremendous outpouring of interest in our work.

We’ve shared links below to a few highlights from the year in review. Thank you for all your support, and we look forward to sharing new milestones and adventures with you throughout the coming year.

---------

? Airloom Welcomes Neal Rickner as CEO

? Fast Company: This Wind Turbine Looks Like Nothing You’ve Ever Seen Before

? TechCrunch: Airloom Has a Plan to Halve the Cost of Wind Power

? EEPower: Small Wind Turbine Functions like a Roller Coaster

?️ CleanTechnica: Craziest Ever Wind Turbine Is Not So Crazy After All

(th)

Offline

Like button can go here

#7 2024-01-26 17:42:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

Offline

Like button can go here

#8 2024-06-19 07:59:12

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

How Much Does a Home Wind Turbine Cost?

Highlights

The typical cost to install a home wind turbine ranges between $300 and $75,000.

Some of the factors that affect the total cost include the turbine’s type, size, and capacity; the wind speed requirements; the installation location; the cost of labor; ongoing maintenance costs; and available tax credits.

There are several benefits to installing a wind turbine at home, including decreased energy bills, increased home value, high efficiency, and clean energy.

Homeowners may be able to install a small wind turbine themselves; however, hiring a pro will result in a safe and compliant installation.Harnessing wind energy for residential use has become increasingly popular as people seek cleaner and more sustainable power sources. But just how much does it cost to install wind turbines on residential properties? The typical cost range for a home wind turbine installation can vary significantly, ranging from as little as $300 to as much as $75,000.

The wide range is due to cost factors such as the size and type of turbine, wind speed requirements, installation location, and site preparation. Each of these can vary significantly from one property (or part of the country) to another. Homeowners interested in using renewable energy on their property can learn more about what goes into estimating a home wind turbine cost, the benefits that come along with having a clean energy source at home, and ways to save money on installation.

Factors in Calculating Home Wind Turbine Cost

Determining an accurate budget to install a wind turbine for home use will require homeowners to review several factors in addition to speaking with a professional installation company. For example, turbine size, installation location, and ongoing maintenance fees can all influence installation and operating costs. While national average costs can serve as a useful benchmark, understanding local variations for labor and material costs can also help a homeowner properly budget for a wind turbine.Turbine Type, Size, and Capacity

Turbine type, size, and capacity play important roles in determining both the effectiveness and cost of wind energy systems. There are two main types of wind turbines for homes: roof-mounted and freestanding. Roof-mounted designs are the most cost-effective option, whereas freestanding options are the more expensive choice. However, the latter can generate greater amounts of electricity than a roof-mounted design.The size of a wind turbine refers to blade length and tower height. A larger turbine will likely have higher up-front material and installation costs than a small wind turbine. Similarly, the capacity of a turbine, or the maximum amount of electricity the unit can generate under ideal conditions, influences pricing. Homeowners can expect to pay more for higher-capacity turbines.

Wind Speed Requirements

The wind speed requirements for a home turbine correlates to the unit’s effectiveness, type of unit needed, and overall costs. Wind speed directly influences how much energy a turbine can generate and, in turn, how much potential return on investment a homeowner can expect. Homeowners can calculate their capacity factor (the measure of a turbine’s efficiency) with this basic formula:Capacity factor = (average wind speed) / (rated wind speed)

If the average wind speed is 6 meters per second (m/s), and the small wind turbine has a rated wind speed of 30 m/s, then the capacity factor would be 0.2 or 20 percent.

Capacity factor = (6 m/s) / (30 m/s) = 0.20

In this example, the turbine could generate electricity at 20 percent of its capacity, on average, which is more than the 17 percent average capacity as noted in the 2018 report by the U.S. Department of Energy.

Homeowners can then calculate the number of kilowatt (kW) hours that can be produced by a small wind turbine if the wind blows frequently.

Kilowatt hours per year = (number of hours in a year) x (unit’s power rating) x (capacity factor)

A typical home in a windy area needs a 10 or 15 kW turbine to provide sufficient power. This number can be multiplied by the number of hours in a year and the capacity factor.

8,760 x 15 x 0.20 = 26,280 kW hours per year

Understanding the rated wind speed and how it affects the capacity factor helps homeowners assess the suitability of a wind turbine for their location. If the average wind speed in an area is significantly lower than a turbine’s rated wind speed, then the turbine may not operate efficiently, resulting in lower energy production and potentially a poor return on investment. The American Wind Energy Association (AWEA) notes that homeowners usually pay an installation cost of $2,000 to $5,000 per kilowatt of the unit’s power capacity. This means it could cost between $30,000 and $75,000 to install a 15 kW wind turbine.

Generally speaking, turbines with higher-rated wind speeds may cost more to install due to their enhanced performance capabilities and advanced technology. However, they could also generate more energy and be more efficient in the long run.

Not only is the energy a benefit but there are also taxs credits as well... long article.

Offline

Like button can go here

#9 2024-12-19 08:27:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

This is an update from Airloom...

It shows the process by which a startup matures...

1 of 59

Monthly Update from Airloom Energy - December 2024Neal Rickner <info@airloom.energy> Unsubscribe

Dec 18, 2024, 7:24PM (13 hours ago)Friends of Airloom!

As we head into the holidays and close out 2024 we here at Airloom wish each of you a joyous and restful holiday season. It’s been quite a year for us, to say the least! Here are a few accomplishments we’re most proud of:

Closed Seed2 funding (thank you investors!)

Welcomed 7 new teammates

Built a strong team of (~30) contracted engineers

Won a direct Phase II SBIR ($1.25M)

Awarded EMF Funding ($5M)

Completed a loads analysis that enables system modeling & simulation

Developed design tools built from detailed trade analysis across aero, mechanical, electrical, and controls

Completed Phase I and Phase II Loomcamp where we welcomed input and critique from some of the world’s foremost experts in energy and systems engineering

Established strategic partnerships with key DoD allies, future commercial customers, and potential industry partners

Built relationships with potential Series A investors

Leased land in southeast Wyoming for our 2025 pilot

As we look ahead to 2025, here are a few things you should expect:Jan: Concept Design Review (CoDR)

Feb: Met towers installed to measure wind; belt and power take-off testing begins

March: Site construction begins

August: Critical Design Review (CDR)

October: Airloom turbine installed. Testing begins.

Nov/Dec: initial test resultsAirloom's CTO Andrew Streett presenting at Loomcamp Phase II

mark-1

Technical Progress

Product Technology:Concept Design Review (CoDR) is scheduled for January 22-23, 2025. This review will deep dive into subsystems concept designs to ensure that business needs are being met with “durable designs,” meaning they stand up to questions and other concepts proposed. This review will lock in the design baseline that will be further detailed, fabricated and ultimately built.

Dedicated Test Articles: The highest technical risks have been assessed and the Power Take Off (PTO), belt transfer of power, fatigue in these components, and the electrical performance are all tests that can be run before PDR to provide objective feedback to the team before final designs are completed. The team has scouted a location to house these tests and is in the process of completing the designs and ordering long lead items like generators, power electronics, controls electronics, and belts.

Verification of Simulation: Airloom’s simulation is home-grown and this phase shall validate that simulation. However that process doesn’t start after the Airloom System is on-site - it starts at the beginning. For the last 6 months the team has been working to verify wind models, turbulence modeling, force generation, and system efficiencies in an effort to steer the Airloom design to CoDR. We have been successful verifying the simulation against industry standard tools like NREL’s openFAST and Sandia’s OWENS. There are more verification steps but at this stage the verification work is progressing nicely to enter CoDR and will enter higher fidelity simulation in Simulink for presentation at PDR.

Project Delivery:

Leases Signed: Three separate leases signed in Albany, Carbon and Laramie counties. An additional four leases are in negotiation.

MET towers: Equipment has been purchased on a 4-6 week delivery timeline.

Permit Applications: With sites identified we are beginning the permit applications for the MET towers and then the site itself. We have already met with all three counties so have a good idea of what is required.Team

We welcomed a new teammate, Phillip Gregory who joins Airloom to lead site development. He’ll be based in Laramie. Phillip brings 20+ years of wind industry experience including time at Clearway Energy, NRG Energy, and Mitsubishi Power Systems America.

We’ve opened a role for a Senior Mechanical Engineer.

Commercial Update

We made it through the initial screening for the Earthshot Prize. Not sure how many more rounds there are, but are encouraged by making it this far.Invested additional time and focus to expand our collaboration with the National Renewable Energy Lab's (NREL's) National Wind Technology Center. We’ve been working on two projects with them: 1) a Techno-Economic Analysis and 2) modeling Airloom loads with their tool, OpenFAST. We visited their campus again in December and may open a few additional lines of effort.

We have pulled together the partners and resources to submit a TACFI package. We haven’t fully decided to pursue it and it’s worth noting that our USAF partners need to be fully bought in and supportive, and they are not yet (we think they’ll get there!).

We have decided to pursue a Defense Innovation Unit (DIU) funding opportunity called “Finance First.” We’ll submit this with one of our development partners (a big US developer).

Challenges

Aero Drag: We have updated the traveler and wing design such that the aero drag is substantially lower (nearly 50% lower). This took a redesign of the wheels, track, and support structure. We are in early concept design so we are going to find additional reductions as the design matures.Schedule: Priorities required that long lead and early designs of the dedicated test articles be prioritized over the concept designs for

subsystems like the wing pitch system. This is necessary to get data from the dedicated test articles before PDR so that lessons learned can be incorporated. With those designs firming up, we’re now shifting our focus to finishing wing pitch subsystem concept decisions around low cost, system robustness, and meeting the angle of attack (AoA) tolerances.Upcoming Priorities

Prepare for the Concept Design Review (CoDR)

Install MET towers at the top 3 pilot sites

Finalizing the site delivery scheduleAs we wrap up a remarkable year, we want to express our deepest gratitude for your interest in who we are and what we're building.

This year has been full of progress, milestones, and momentum—none of which would be possible without the hard work of our team, the enthusiasm of our partners, and the encouragement of our entire community.

From all of us at Airloom Energy, we wish you a joyful holiday season and a new year filled with health, happiness, and success. Here’s to even greater achievements in the year ahead!

Looking fwd,

The Airloom Team

The next era of wind power

airloom_energy_logo

Airloom.EnergyAirLoom Energy Inc., 5452 Aerospace Dr, Hwy 130, Laramie, Wyoming 82070

(th)

Last edited by tahanson43206 (2024-12-19 08:30:45)

Offline

Like button can go here

#10 2025-01-24 11:11:02

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

We have another update from Airloom.... Apparently they are receiving support from DOD, but having to compete vigorously for funding opportunities. The text below is from an email that included pictures which are not included here...

Monthly Update from Airloom Energy - January 2025

InboxNeal Rickner <neal@airloom.energy> Unsubscribe

Jan 23, 2025, 9:54AM (1 day ago)

to meheader_2

Friends of Airloom,We’re excited to share significant momentum across several fronts as we continue to drive Airloom Energy forward. Our technical progress remains strong, with key milestones achieved as we prepare for our next phase. We’ve signed leases in Wyoming for our pilot site, and we’ve ordered meteorological towers to validate site conditions.

We’ve also hired a dedicated site development manager. We have also increased our operations capacity, ensuring we’re well-positioned to execute fabrication and construction of our pilot system. Additionally, we’ve begun receiving Energy Matching Fund (EMF) reimbursements and submitted an application for the “Finance First” Defense Innovation Unit (DIU) funding opportunity.

Our relationships and visibility have grown, too. We received another letter of intent from a potential customer and engaged directly with Wyoming’s Congressional delegation, building critical political and industry support. We were also featured in multiple media outlets, including the Laramie Boomerang, Cowboy State Daily, and Recharge News, showcasing the growing interest in Airloom Energy’s potential.

Our biggest concern is that, as our progress has accelerated, our burn is higher than anticipated. We are actively pursuing a “Tactical Funding Increase” (TACFI) to our AFWERX SBIR Phase II that will match up to $2 of new funding. Accordingly, as of last week, we are embarking on a $2M Tacfi-match fundraise that will enable the TACFI $2M non-dilutive DoD funding match. This new funding will extend runway and enable testing after the Wyoming winter and substantially de-risk the pilot.

We’re energized by these advancements and grateful for your continued support as we work to deliver on our mission.

Screenshot 2025-01-20 150710

Figure: We find this graphic a useful benchmark. If Airloom can achieve 3-4x wind speed, the system will be producing efficiently!<< the graph shows a curve of wind speed vs vehicle velocity, with iceboat doing best in light wind >>

mark-1

Technical Progress

Following the success of Loomcamp Phase II, we’ve made significant strides in defining our product and identifying several viable pilot sites. Our team has finalized key dimensions and characteristics for the pilot systems, setting a clear foundation for development. We are now fully focused on preparing for the Concept Design Review (CoDR) Jan 22-23.Product Technology:

30 wings (10m wingspan), 29 towers (20m AGL), 4x100kW generators, belt PTO

Loads verification with NREL (openFAST) and Sandia (OWENS) turbulent outputs

L0 and L1 Requirements completeTechnical Updates

Aerodynamics - airfoil selectedAero System - 2nd analysis round for backrail, wakes, drag, and linear power density

Structure System - natural frequency, deflection, and stress initial results

Loads Simulation - Rev B output for ultimate and fatigue loads

Mechanical Systems - lower drag designs with less wheels

Electrical Systems - spec’ed and ordered generators, converter spec complete

Network and Controls - Block diagram and Simulink model complete

Testing & Instrumentation - Location secured for 4 tests with test plan

LCOE and BOM initial model complete

Product strategy - GTM: Data centers with expedited schedules

Production: Lowest LCOE possibleScreenshot 2025-01-20 152940

Figure: Test Stands A & B for belt and power take off testing design review

<< the image shows what appears to be a section of the full system to test belts and generator and related components.>>Screenshot 2025-01-20 153201

Figure: Initial structural analysis includes natural frequencies, stress and deflectionsProject Delivery:

MET tower equipment ordered

Leases for 4 sites w/ trade study objective decision

MET tower permits (1 of 4 submitted), Land permits (start submission Jan 25)

EPC RFP sent out to 5 contracting teams for feedback

mark-1

Commercial Update

Screenshot 2025-01-20 153605

Figure: Illustration of the logistical challenges with HAWT turbinesNew Letter of Intent signed

We commissioned, and have now reviewed a report from Boundary Stone Partners (BSP) that completed a whole-of-government review of potential funding opportunities for Airloom. The result of this review is that, while there are funding opportunities in many parts of the US Government, the US DoD has by far the highest concentration of opportunities for Airloom. There is also excellent alignment between the DoD’s need for resilient energy, and Airloom’s capabilities. As a result of these factors, Airloom will focus the limited resources we have to pursue funding from the US Government within the DoD.Note: that our target market is still the Utility-Scale Wind Market. We see DoD funding and partnerships as very much aligned with our path to this market.

We have been exploring the possibility of producing revenue with our pilot system. Rune Energy could be our very first customer. In addition to revenue, we’re putting together a deal that would include renewable energy credits (RECs) and qualification for the Investment or production tax credits (ITC or PTC). These credits, if we can get them, would then be sold/transferred to a 3rd party.

We will continue to pursue funding opportunities with DIU, AFWERX SBIR and other DoD funding opportunities. e.g., there are two additional Phase II awards, each worth $1.25M, that we will pursue.

mark-1Upcoming Priorities

As we look ahead, we remain deeply grateful for the support of our investors, advisors, and supporters, whose belief in our vision continues to propel us forward. Our immediate focus is on executing a successful Concept Design Review (CoDR), a critical milestone that will solidify our path to deployment.We are committed to staying on schedule, carefully managing our burn rate, and ensuring that every step we take aligns with our broader objectives.

We are also commencing a capital raise to extend our runway and position ourselves to fully leverage the $2M TACFI non-dilutive matching opportunity. This $2M raise will maximize the DoD $2M match and provide runway to allow testing after the Wyoming winter, and provide needed resources for the pilot.

Your partnership is invaluable as we navigate this exciting and pivotal phase for Airloom Energy. Thank you for your continued confidence in our mission.

Looking fwd,

The Airloom Team

The next era of wind power

airloom_energy_logo

Airloom.Energy

footer

AirLoom Energy Inc., 5452 Aerospace Dr, Hwy 130, Laramie, Wyoming 82070Unsubscribe Manage preferences

What these reports clearly show is the challenge of moving from an idea on paper to a working system that pays for itself.

Clearly the US Department of Defense sees a reasonable chance of success for this technology in general, and for this company in particular.

(th)

Offline

Like button can go here

#11 2025-01-25 07:13:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,388

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

I have been part of the competition contracts in the past for device creation. They start with statements of work and specifications to meet to achieve the funding.

Offline

Like button can go here

#12 2025-02-21 14:42:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,057

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

Here is the monthly update from AirLoom....

They appear to be making progress in design and funding. It appears that DOD funding would be helpful, and it still appears possible.

1 of 61

Monthly Update from Airloom Energy - February 2025

InboxNeal Rickner <info@airloom.energy> Unsubscribe

2:58PM (40 minutes ago)

to meheader_2

Friends of Airloom,

January was a milestone month for Airloom, marked by our successful Concept Design Review (CoDR). This in-depth review of our pilot system—across all subsystems—brought together >20 attendees to our California office. While the design isn’t fully closed, this was a critical step forward, bringing us closer to deployment. More details on this can be found in the technical section below.

We’ve also been focused on securing TACFI funding, a combined $4M funding opportunity that will accelerate our progress and help launch us into series A in strong form. Our recent visit to Washington, D.C., was a major step in that effort. Thanks to the support of our new Advisory Board members, Dave Belote and Ed Chupein, we met with key Pentagon officials. Their support for Airloom—recognizing our potential to solve a long-standing DoD energy challenge—should help pave the way for TACFI approval.

We have received a ton of interest in the $2M of new funding, but it’s not yet closed. Investors have been impressed by our progress over the past 10 months and like that their investment will be matched by non-dilutive gov't dollars.

Capital Hill 2025-02-18 114937

Figure: Airloom leadership at US Capitol Hill and Pentagon (DC Trip)Finally, we’re thrilled to announce that we’ve signed additional backup leases for the pilot site and installed our first MET tower—concrete steps toward the pilot. We’re planning a groundbreaking event in the coming months and hope you’ll consider attending.

mark-1

Technical Progress

The technical team hosted a two-day Concept Design Review (CoDR) on January 22-23, 2025. The review showcased several iterations of design work that the team has completed after LoomCamp on Oct 22-23rd, 2024 (3 months including holidays).Two key take-aways from the review were that great progress has been made, however mechanical design gaps and funding / budget strategy need to be closed quickly to stay on track.

The mechanical systems design hinges on simplicity, adaptability, and cost effectiveness. Concepts discussed at the review provide the basis of this assessment and next steps.

The funding and budget strategy required some realignment after LoomCamp based on project contingency, size of Airloom Pilot, tariff and material costs, and independent vs EPC execution.

CoDR 2025-02-18 115619

Figure: CoDR - Day 1 at Airloom Beach Office, (Dana Point, CA)Following CoDR the technical team has been focused on:

Mechanical systems design

New controls simulation autocoded for Airloom Pilot and

Costing for the Airloom Pilot system

Product Technology:

Mechanical system design has been progressing quickly over the last three weeks. The team has settled on a smaller track, smaller traveler, and a wing pitch control that mimics an elevator on an aircraft (on a boom behind the wing).

This control strategy reduces scope and simplifies the end of the track turn-around where the wind changes quickly as the airfoil transitions from the front rail to the back rail.

The smaller track and traveler is to reduce drag of the system and reduce costs of the amount of steel needed for the Airloom Pilot.

PTO 2025-02-18 120943

Figure: Traveler, Rail, Column, and Power Take-off (PTO) imagesOur team has transitioned our MATLAB simulation, that compared favorably to openFAST outputs, to a Simulink version to better align with controls development and autocoding to load on the plc for the Airloom Pilot.

This means that the simulation can handle (1) the loads output as well as (2) the controls development which will be directly loaded as controls software on the safety critical computers designed to control the Airloom Pilot. This is a major step forward for the Airloom team as the development is now moving towards Region 2 and 3 controls and testing plans consistent with PDR-level design.

Turbulent CFD 2025-02-18 121238

Figure: Time Step 45.66 sec turbulent CFD sim from upwind to downwind railsProject Delivery:

The project team has signed multiple leases, submitted our initial permits for our lead site, submitted FAA approval paperwork, and received parts for the MET towers on track for program execution.

One MET tower was installed and is reporting data at our lead site about 1 hour north of our Laramie, WY headquarters.

The MET tower is expected to help verify wind magnitude and direction allowing for confirmation of our simulation inputs as well as site layout.

The project team is also closely engaged with the product team to provide feedback on materials costs, fabrication estimates, and installation budgets. This is critical for preparing to fabricate parts and prepare the site for installation.MET 2025-02-18 121645

Figure: MET tower at Albany County primary siteWind Data 2025-02-18 121834

Figure: Wind rose for the initial few days of MET tower data capture

mark-1

Commercial Update

Pilot ProjectWe’re making solid progress on structuring the 2025 pilot project as a revenue-generating site. While not finalized, we are increasingly confident that we will have a paying customer—an outcome that unlocks additional value. A paying customer means eligibility for Renewable Energy Credits (RECs) and federal clean energy investment or production tax credits, which can then be sold in a transfer marketplace. These financial mechanisms are key to our long-term commercialization strategy and we’re seeing the pieces come together.

Beyond the Pilot

These same financial structures will also apply to our 2027 commercial demonstration project. In parallel, we have initiated discussions with project developers who focus on behind-the-meter, hybrid, data-center energy projects. These developers are focused on hyperscalers who are driving the AI and data-center boom and investing hundreds of billions in new infrastructure, and creating energy demand that the existing utility grid cannot meet.

For Airloom, these behind-the-meter projects offer an attractive pathway to commercialization, potentially addressing the financing challenges of First-of-a-Kind (FOAK) energy deployments. We see significant opportunity here and are actively exploring ways to align our technology with these emerging energy needs.

Other Key Commercial Updates

Working on a Cooperative Research and Development Agreement (CRADA) with NREL

Completing a techno-economic analysis in collaboration with NREL

Finalizing OpenFAST loads modeling with NREL

Three team members are currently enrolled in dCode’s government contracting course to strengthen our approach to securing government contracts.mark-1

Upcoming Priorities

As we push forward into 2025, our focus remains on execution—finalizing our pilot design, securing critical funding, and positioning Airloom for long-term success. The support from our investors, advisors, and partners continues to be invaluable, and we are deeply grateful for your commitment to our mission.

The momentum we’ve built over the past months sets the stage for an exciting year ahead. From preparing for our groundbreaking event to expanding commercial partnerships, the opportunities ahead are significant. We look forward to sharing more progress soon and, as always, welcome any introductions, insights, or support you can provide.

Looking fwd,

Neal

The next era of wind power

airloom_energy_logo

Airloom.Energy

footer

AirLoom Energy Inc., 5452 Aerospace Dr, Hwy 130, Laramie, Wyoming 82070Unsubscribe Manage preferences

(th)

Offline

Like button can go here

#13 2025-02-23 12:55:32

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,300

Re: Horizontal Wind Turbine farms - management - Good Neighbor Policy

The Airloom concept would be useful for offgrid power in countries and localities with strict planning laws. Here is the UK, you would struggle to get planning permission for a backyard wind turbine. Everyone needs a fence however. If that fence has moving parts that generate power, it is still a fence. The right choice of technology is about more than just technical practicality. It is a balance between that and a lot of other considerations.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here