New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2021-10-20 12:17:18

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For SpaceNut ... we did not appear to have a topic dedicated to this topic.

Since GW Johnson has been working on this specific technology, I am hoping this topic will be helpful for collecting knowledge and insights.

GW Johnson has published at least one article in ExRocketman, and I expect there will be more articles or posts in future.

(th)

Offline

Like button can go here

#2 2021-10-20 12:18:52

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson re Article in Review

Thanks for providing the draft of your work-in-progress!

I am taking a break after reaching page 3.

This post is reserved for an index to posts that may be contributed by NewMars members over time:

Update 2024/10/30 kbd512 re magnetic pumping: https://newmars.com/forums/viewtopic.ph … 86#p227586

Update 2025/05/16 GW Johnson collected multiple papers on refueling with cryogenic fluids on orbit

https://newmars.com/forums/viewtopic.ph … 24#p231724

(th)

Offline

Like button can go here

#3 2021-10-20 16:59:34

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,316

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

https://exrocketman.blogspot.com/2021/0 … tions.html

Propellant Ullage Problem and Solutions

Offline

Like button can go here

#4 2021-10-20 17:12:51

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,457

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

GW,

Why no mention of capillary action to control the movement of propellant within the tanks?

Offline

Like button can go here

#5 2022-04-20 17:34:47

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,316

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

repost if we are making a tank on orbit system

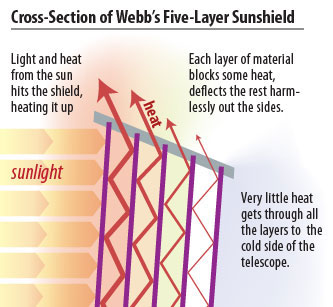

We know that the James watt shield aids in the keeping of liquid Helium cold to control the boil-off with 50 Kelvin shield The Sunshield Webb/NASA

The sunshield will allow the telescope to cool down to a temperature below 50 Kelvin (-370°F, or -223°C) by passively radiating its heat into space. The near-infrared instruments (NIRCam, NIRSpec, FGS/NIRISS) will work at about 39 K (-389°F, -234°C) through a passive cooling system. The mid-infrared instrument (MIRI) will work at a temperature of 7 K (-447°F, -266°C), using a helium refrigerator, or cryocooler system.

Of course the Starship is refueled in Earth orbit, the fuel can be sub-cooled, but not below -182 °C since that's the freezing point of Methane. So not as much shielding will be required....I did do a boiloff run and found if we fill it to slowly that we would loss a starship or 2 fillings to get it full due to the boil off.

https://www.reddit.com/r/SpaceXLounge/c … ions_uses/of course liquid hydrogen can be liquefied by cooling to approximately 20 K (−253 °C) at atmospheric pressure [5,6,7].

https://iopscience.iop.org/article/10.1 … 012012/pdf

Zero boil-off methods for large-scale liquid hydrogen tanks using integrated refrigeration and storageRemember that the tanks for the large ship are even larger than that of several starships....

5 layers to the shield

Kapton. Each layer is coated with aluminum, and the sun-facing side of the two hottest layers (designated Layer 1 and Layer 2) also have a "doped-silicon" (or treated silicon) coating to reflect the sun's heat back into space.

Each layer of the sunshield is incredibly thin. Layer 1 will face the sun and is only 0.05 millimeters (0.002 inches) thick, while the other four layers are 0.025 mm (0.001 inches). The thickness of the aluminum and silicon coatings are even smaller. The silicon coating is ~50 nanometers (nm) (1.9 microinches) thick, while the aluminum coating is ~100 nm (3.93 microinches) thick.

Offline

Like button can go here

#6 2022-04-20 17:41:34

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For SpaceNut re #5

Thanks for this helpful addition to the topic!

On a related note ... Dr. Johnson just sent a copy of his Lunar Propellant study to several members of the North Houston chapter of the NSS.

In the correspondence was a reminder of our plan to send the link to his presentation to Executive Director James Burk.

I have received no confirmation that the link arrived safely.

It may well have !!! I am simply unable to confirm safe arrival.

The intention here is to try to build a higher level connection between the Mars Society and the NSS.

(th)_

Offline

Like button can go here

#7 2024-05-10 20:06:27

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson (in particular and all welcome)...

https://www.youtube.com/watch?v=Uju2g-yUDFE

At about 10 minutes into this video about SpaceX plans, a NASA representative is interviewed. The subject is on-orbit refueling and the key concept is that ullage is assumed. Details about how the ullage will be achieved are not provided, or at least, ** I ** did not hear any.

I didn't watch most of the video... there is some nice animation.

There ** was ** a report that the on orbit refueling test in flight #3 was successful.

(th)

Offline

Like button can go here

#8 2024-05-11 12:57:06

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,128

- Website

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

Tom:

I heard no ullage solutions either.

All I know is that when you first go into free fall, the propellant in a tank breaks up into free-floating globules, but eventually these form a film all over all of the inside surface. If the volume is large, that film is significantly thick.

If the surface tension is also high, then you could suck quite slowly from that thick film, as long as you don't suck hard enough to cause a cavitation, meaning the surface tension cannot hold sway. The same would hold true for a pressure difference-driven transfer.

I prefer the ullage-thrust solution to settle the fluid into one pool somewhere in the tank. That is usually conceived as axial thrust settling fluid into the bottom ends of tanks, but that affects trajectory, too. I prefer spin gravity settling in one or another geometry. That requires more plumbing, but does not affect trajectory.

Almost nobody but me ever mentions spin gravity settling, though. I wonder why?

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Online

Like button can go here

#9 2024-05-11 13:34:47

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson re #8

There is a window of opportunity for the spin-refuel solution you've described in your papers.

The ullage solution might make sense if the change in orbit is useful.

Clearly, both NASA and SpaceX are devoting their energies (and funds) to making the ullage solution viable.

In my opinion (based mostly on your work) the spin solution is ideal for a fuel depot.

***

For all ... this topic is available for analysis of the ullage generation orbital mechanics that NASA and SpaceX are obviously planning to manage. It would be interesting (to me for sure) to seen what an on-orbit ullage solution for a Starship sized vehicle would look like.

(th)

Offline

Like button can go here

#10 2024-05-11 14:30:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,316

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

The real issue for a fuel depot is the selection of the fuel types to be made use of once one build it.

Each fuel type has many requirements to keep the fuel from boiling.

This means temperature control whether by shade or by heating.

It's one of the reasons that the ISS has such a large power source and it's the same for the Artemis capsules solar design which gathers and uses more energy than a human needs on the planet's surface.

Offline

Like button can go here

#11 2024-05-14 03:04:29

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

I am a layman on the topic of rocketry. But for missions to the moon and Mars, orbital refuelling makes only limited sense to me. Most of the Starship upper stages sent from Earth to Mars or to the moon, will be canibalised on the surface of the respective bodies. Only a minority will be returning to Earth. Those that do return to Earth will benefit from orbital refuelling, as this then obviates the need to launch a fresh Starship from Earth surface for future trips to Mars. But for the majority of missions, a direct throw from Earth surface would appear to offer a superior mass ratio in terms of kg delivered to Mars per kg launched from Earth. For this task we would want a three stage, partially reusable rocket vehicle. The lower two stages would be reusable and would return to Earth. The upper stage would be designed to fly one way to its destination and would be parts upon reaching the surface.

On orbit refuelling only makes sense for the relatively brief period in which Starships are used to carry human beings between the two planets in both directions. It will very quickly become economically desirable to build an interplanetary ship equipped with high-ISP propulsion. At this point, orbital refuelling of Starships becomes obsolete, as these vehicles will only be used to ferry people and supplies between planetary surfaces and low orbits. But until the development of such a ship, orbital refuelling would appear to offer few advantages over a direct throw, three-stage rocket. Any thoughts?

Last edited by Calliban (2024-05-14 03:07:18)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#12 2024-05-14 19:03:22

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,316

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

When refueling is an issue is when the payload is so low as compared to an empty ship waiting to be refilled. That makes little sense to use that ship as a lander at a destination since the amount of fuel is so huge.

Offline

Like button can go here

#13 2024-10-27 07:56:37

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

This post is inspired by a YouTube video that appeared in late October 2024.

The title is: SpaceX New Crazy Plan for Starship Flight 6...

The opening sequence includes a hint from "Alex"....

SpaceX demo of Starship's ship-to-ship propellant transfer next year will likely entail twin Starship launches and booster recoveries at Starbase.

(th)

Offline

Like button can go here

#14 2024-10-27 10:27:50

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,128

- Website

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

It makes more sense to go to Mars (or the moon, or anywhere else out there) from Earth orbit than directly from the surface, because you can wait in orbit until the trajectory geometry is "just right". Apollo did that going to the moon. They relit the S-IVB stage in LEO to escape onto the lunar trajectory.

Had they not gone with the separate LM, and lunar orbit rendezvous, it would have taken 2 Saturn-5 launches for one Apollo mission to go to the moon: one a tanker to refuel the other for orbital departure. That's because landing the Apollo capsule with a huge "service module" directly onto the moon made the Apollo cluster way larger and heavier, far beyond the capability of a single Saturn-5.

Now, if you try to make your lunar or planetary vehicle reusable, you have to recover it. You can avoid the extra weight and enormous design complications of entry if you recover in Earth orbit, rather than directly on the surface. Once you do it that way, you are looking at refilling and re-flying your vehicle again and again, from Earth orbit.

Propellant for refills has to be shipped up to that orbit. The easiest one to reach from the surface is low circular Earth orbit, at relatively low inclination. The others have delta-vee requirements that are 30-40% higher, very near direct escape. And THAT is why elliptic capture and departure make sense, but only with a recoverable and reusable "tug" to get you from low circular into the elliptic capture departure orbit. Now you have two reusable vehicles flying only in space: the lunar or planetary transport, and the departure/arrival tug. You will need some sort of tanker to keep them refilled in low Earth orbit.

You're going to need a facility in low Earth orbit where you accumulate and store the propellants (a propellant depot), and a facility where you can assemble your large lunar and planetary transports. There is simply no reason at all why these two functions cannot be just one big facility. You'll pay a lot to build it, but going elsewhere will always be horribly expensive, unless you build it. You get what you pay for!

There's one other critical aspect of going this route: your lunar and planetary transports are designed only for flying in space, not landing. Otherwise they are too heavy and too badly design-compromised to function adequately as transports. That means when they get to their destinations (moon, Mars, elsewhere), they go into orbit. You will need some sort of dedicated-design lander when you get there. THAT is the lesson to be learned from our experience with Apollo lunar orbit rendezvous.

Basically, you cannot afford the weights unless you do it this way. Chemical propulsion, even nuclear thermal, is inadequate to do it any other way. THAT is the lesson to be learned from the experiences accumulated since the dawn of the Space Age with Sputnik 1 in 1957. Why fight that?

"Starship/Superheavy" is first and foremost the big transport from Earth's surface to low orbit. Its upper stage "Starship" just happens to be big enough to mis-use and refill on-orbit to go elsewhere, something that is justifiable only if you have no other vehicle designs ready. But those other vehicle designs would be far more efficient at going elsewhere, once they exist.

Chicken-and-egg. You use what you have ready at hand. But you switch when you get better stuff available. And you WILL have to have that better stuff to attempt any large permanent settlements anywhere else outside Earth orbit. It's simply too expensive any other way.

GW

Last edited by GW Johnson (2024-10-27 10:36:22)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Online

Like button can go here

#15 2024-10-27 19:20:02

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson....

There are NO/Nada/Zero orbital refueling facilities in orbit around Earth right now....

You have the same chance as anyone else who might be thinking along these lines...

In your previous work on orbital refueling, you described the various methods that might be considered, and ended up with a concept for rotation around the long axis of the delivery tank (as I recall).

SpaceX appears to be thinking about using ullage, and if that is the case, two Starships side by side, with ullage from either or both might work, if the transfer can be completed before the ullage propellant runs out.

it seems to me that the destination tank does not need to be concerned about rotation. If your delivery tank is rotated, and the receiving tank is stationary, then the delivery pipe needs to be able to rotate as well. Is a valve capable of rotation like that possible?

Update: We're talking about (at a minimum):

1) LOX

2) Kerosene

3) Liquid Methane

4) LH2 (as a stretch capability)

Perhaps a bit of leakage at the joint is not too much of a concern, if moving the product rapidly prevents loss due to boil off.

Update a bit later:

OK... If we accept as practical the idea of a slip joint able to deal with cryogenic materials, then we are left with the need to rotate the sending tank, while the receiving tank is stationary.

If a Starship arrives with a shipment of propellant, then it would (presumably) have to rotate to deliver it's contents to the refueling facility, and specifically to a tank sized for the purpose.

On the ** other ** hand, if you are asked to refuel a Starship from your store, then the Starship can be stationary and the storage tank needs to rotate.

Some further thought is clearly needed ...

(th)

Offline

Like button can go here

#16 2024-10-28 08:34:00

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,128

- Website

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

I think you are also looking at NTO and at least a couple of the hydrazines: MMH and UDMH (which the Russians have been using).

I would not complicate valve designs by trying to accommodate spin differentials. It's going to be tough enough doing this reliably in zero-gee and vacuum as it is. The tanker or receiving ship can dock to the facility supply tank, which undocks from the facility, and the docked pair pull away to a safe distance from the facility. There they spin up locked together as a single unit for the transfer, rifle bullet spin mode. Once done, de-spin the docked pair, redock the tank to the facility, and undock from that tank.

That technology path is the smallest departure from technologies we already have in-hand. All you need to add is alternate peripheral sump drains for a spinning tank, and some larger-thrust roll attitude thrusters for the spin-up and spin-down.

You just need a little bit of radial gee from the spin to settle the propellant in the spinning tank, and you just take your time to allow that low gee to do its work. The time to fall through a radius at that low gee level is a "time constant". About 3 or maybe 4 time constants, and everything should be settled enough to get a pump suction.

Doing it with spin ullage instead of translation ullage decouples the entire process from affecting the orbit at all.

Why not just keep it that simple?

As for "Starship" tankers or receiving craft that use translation ullage, you can do that, too, but you have to undo the resulting changes to the orbit to return the tank to the facility. It's just a bit more attitude thruster propellant. My plan can accommodate both ullage approaches. You just get exactly what you pay for!

GW

Last edited by GW Johnson (2024-10-28 08:43:08)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Online

Like button can go here

#17 2024-10-28 08:54:06

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson....

Management of a facility like the one you describe will be challenging.

I'm not offering an opinion here... just observing...

In the scenario you've proposed, a free flying vehicle will approach the station, so you have the challenge of keeping that vessel moving in the right direction at the right velocity and attitude, while activities of all kinds are going on elsewhere in the station. Your computer controller will be directing the arriving vessel to a docking port for a tank of propellant that is filled and waiting for the dock.

Upon docking, the filled tank will be released from it's nest and the combined systems will move a short distance away from the station. Now the combined system will be directed to spin up while maintaining exact position with respect to the the station, while other vessels are arriving, rotating and departing.

This scenario has been considered in great detail by at least one science fiction writer. Management of such a facility is way out of the capability of a human so you'll have hired a first rate software team, and they will probably have recommended enlisting artificial intelligence for the task.

After the spin up and propellant transfer, I presume the refilled vessel will be responsible for despinning the pair, returning the now empty tank to the port, disengaging from the tank, and then carefully maneuvering away from the station. Since most vessels will need both propellants, and since only one can be delivered at a time, the process will have to be repeated for each arriving customer vessel.

The situation will be complicated further if the arriving vessel has personnel on board. The rotation procedure will be mildly irritating to humans, but it may just be the cost of doing business. My guess is you'll provide a passenger lounge so that refueling can take place without irritating or endangering the passengers.

The whole refueling process is going to take an Earth day, because the celestial mechanics of this complex operation cannot be hurried.

It seems to me four completely separate dockings will be required for a passenger vessel... One will be to drop off passengers, two will be for propellant, and the fourth will be to load supplies for the passengers, the passengers themselves, and whatever additional touchups that are routine in an airline operation on Earth. I presume inspections would be a part of the routine, although inspectors might board during the first docking to be sure the vessel is in condition to refuel. A lot of systems have to be working perfectly to perform the operation you've described.

After thinking this through, I've concluded a rotating coupler for a refueling tank might seem trivial in complexity.

(th)

Offline

Like button can go here

#18 2024-10-28 09:07:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson...

A gigantic piston pump might be able to deliver propellant to a customer vessel without rotation.

Please tell me (probably again) why a gigantic piston pump would not be suitable for this application?

If you filled the pump with whatever material is needed before the customer vessel docks, then the piston can shove the propellant toward the front of the tank and out through the connecting hose. If some propellant leaks past the outer rim of the piston, so what? It will remain in the piston tank, so none is lost.

If you were to decide to implement this idea, then an arriving vessel could refuel from both sides simultaneously, because there would be no rotation required.

The passengers could exit to the lounge and inspectors could visit the vessel during the refueling. Only one docking would be required.

Update:

The delivery of propellant from Earth or the Moon would ** still ** require rotation, but no passengers would be involved. The reason is that such vessels would need to use the rotation method to evacuate the tank(s). Thus, as I am seeing the station growing, it would provide the rotation facilities for arriving shipments, and the piston refueling method for departing vessels.

You might even provide ullage refueling for customers who insist upon this method. Customers would pay extra for the ullage service, since additional propellant is required to provide the thrust.

You could also insist that the ullage customers accept refueling some distance from the station, since they would be under thrust during the operation. In that scenario, you would top off the ullage delivery vehicle from supplies at the station, and the ullage delivery vehicle would travel out to the arriving ullage customer.

Reminder: inexpensive (or least expensive) restocking of the station is most likely to be provided by either spinlaunch or gas gun deliveries with solid rocket assistance for the orbit matching operation. We have suspended work on the solid fuel rocket engines for SpinLaunch, but I'd like to get back to that study. We left off with a fairly solid idea of the altitude the SpinLaunch system could deliver, and you had started work on solving the problem of designing a solid fuel rocket able to withstand horizontal G's in the thousands. My recollection is that the solution shaping up was to put a temporary filler in the cavity of the rocket. That filler would ignite and propel itself out the nozzle, while igniting the propellant of the engine during it's departure.

The gas gun solid rocket would be much less difficult to design, since you have already dealt with linear acceleration of solid rocket motors.

(th)

Offline

Like button can go here

#19 2024-10-28 16:11:25

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,128

- Website

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

(1) it would be heavy

(2) what kind of piston ring seals would you use for cryogenics?

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Online

Like button can go here

#20 2024-10-28 17:29:16

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson re #19

Thank you for taking up the flow of this topic!

For item #1, I offer the suggestion that this facility is going to be massive. In another topic, you've already accepted the idea of combining a vehicle assembly area with the refueling service. This facility is going to need to house passengers and crew, so it should (and ultimately ** will ** ) include habitats, and they may look a lot like the sketch you did recently in another topic.

For item #1, .... The refueling station is going to need to accept incoming shipments of propellant and other supplies such as water, oxygen for breathing and all manner of other items needed to sustain passengers and crew, as well as a work force.

The permanently mounted delivery tank is able to serve an arriving vehicle with one kind of propellant, while another similar/identical system pumps the other half of the propellant pair into the other side of the arriving vessel. The tank will need to be large enough to hold the propellant that the arriving vessel needs.

2) I have tried to make the point that the seal for the piston is not a concern, or shouldn't be a concern. The piston needs to be designed so it can move in the tank, and with as close a fit as practical. There is NO need to worry about any leakage around the edge of the piston, because whatever leaks is NOT lost, but is simply collected when the piston returns to home position.

What ** is ** a concern is delivering the Quantity of propellant to the customer vessel that the customer paid for. For that reason, the tank needs to be large enough to accommodate the largest vessel likely to stop by.

I have already accepted that the arriving shipments of propellant can be spun to insure every drop that was sent up from Earth is delivered into the refueling station stores.

***

I have also offered the observation that this facility is going to be too large to move when LEO junk is a threat. There need to be systems designed to deal with the problem, and legal systems set up to impose penalties on any Earth-based entity that crossed the path of the station.

(th)

Offline

Like button can go here

#21 2024-10-29 10:50:11

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,128

- Website

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

I repeat: what are you going to use for a piston ring or seal, with cryogens? There are NO polymers that remain flexible enough at usable sizes and thicknesses, to do any good at such temperatures!

Anything that gets past your piston may still be inside the housing or cylinder, but at low pressure. How will you increase its pressure to get in back into the tank?

Such a piston pump/syringe will have a pushrod that moves the piston. There will have the be a seal around that rod, or any leakage will go right to space. Same question applies: what are you going to use for that sliding rod seal, when cryogenics rules out all polymers?

You can get away with a static O-ring seal on valves and plumbing fittings, as long as you obtain the seal before you expose the fitting to cryogenic cold, AND you ensure there is absolutely NO chance of motion at all, at the seal in that fitting! Moving seals are an entirely different sealing problem, and currently an impossible, non-existent, technology at cryogenic temperatures.

The spinning-tank approach simply avoids every single one of those fatal difficulties.

I went "spinning tank" for the cryogens, because there are no usable polymers at cryogenic temperature to support bladdered expulsion, which I would have greatly preferred. I recommend bladdered expulsion heartily for the (room-temperature) storables (which includes kerosene!), as a solution proven for decades. But you simply cannot do that with LOX, LCH4, or LH2. If we could, it would have already been done! It has not been done, so QED, it still cannot be done with any known technology.

GW

Last edited by GW Johnson (2024-10-29 10:56:22)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Online

Like button can go here

#22 2024-10-29 12:57:45

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For GW Johnson and all NewMars members....

This topic is available for developing solutions to the complex challenge of designing and deploying a station able to refuel rockets, perform assembly, and provide high quality care for human passengers and crew.

There will be thousands of problems to be solved along the way, and GW Johnson has identified just one of them.

We need some Real Universe data on the effectiveness of a piston working against a cylinder full of LOX or LH2 or any of the other cryogenic materials that customers may need.

I have noted the value of the rotating tank procedure for arriving shipments of propellant and other liquids.

I have pointed out that it is NOT a good idea to spin up a ship full of people, and I have given some of the reasons for this operational nightmare.

As an alternative, I have proposed a fixed delivery system that provides LOX and liquid propellant simultaneously to the same customer vessel, without spinning.

We need some Real Universe data to validate or falsify my proposal.

A test satellite would contain the apparatus to be tested, observing equipment, and supplies of liquids of various kinds to be tested.

My hypothesis is that a piston that has a gap between it's outer surface and the inner surface of the delivery tank will succeed in pushing the cryogen into the customer vessel while allowing a small fraction of the cryogen past the edge into the back side of the tank. My expectation is that the material that flows past the edge of the piston will warm to gas and become part of the gas in that part of the tank. Meanwhile, the vast majority of the material to be delivered will have made it's way through the delivery port into the customer vessel.

Quite possibly my hypothesis could be tested in a laboratory on Earth, with the caveat that gravity will be acting on the test article, and I don't know what effect that might have.

Update: the piston might be pushed by gas, so that the piston rod would be eliminated. The need is to apply pressure to the liquid cryogen to encourage it to flow into the customer vessel. After the delivery is finished, and the customer vessel has closed off it's intake port, the delivery tank can be pressurized in the front end with gas so that the piston is moved to the back, ready for another load of cryogen.

(th)

Offline

Like button can go here

#23 2024-10-30 04:47:01

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,457

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

I've never seen anyone use a magnetic pumping method. A strong permanent magnet inside the tank, or electromagnet sandwiched between an inner and outer tank wall, could easily move oxidizers and fuels around. You wouldn't be able to get every last drop out of the tank, but you'd get most of it. LOX is strongly paramagnetic. LH2, LCH4, and RP-1 are all weakly diamagnetic.

Levitating Liquid Oxygen Droplets Dancing In a Magnetic Trap

Gravity works, obviously, but providing artificial gravity in orbit for a propellant tank farm requires special geometry and balancing, possibly special strengthening of certain parts as well. Using ullage thrusting motors requires messing with the tank farm's orbit and burning propellant (not much, granted, but every drop costs quite a bit). Pistons and bladders require some type of sealing to take place at cryogenic temperatures. Moving a magnet around inside the tank or flipping the switch on an electromagnet should not require much in the way of power or complexity. An electromagnet could be external to the propellant tank and possibly provide high field strengths or rotating fields to make the fluid behave in desirable ways (such as forming a vortex as the fluid is pushed through the spigot), via superconducting. I don't know what "the best" method is, but I think magnets and electromagnets are worth pursuing as options.

Offline

Like button can go here

#24 2024-10-30 06:37:53

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

For kbd512 re #23

Your post was added to Post #2 index with the reference to magnetic pumping

***

For GW Johnson.... your proposal for axial rotation of both the delivery vehicle and the receiving vehicle are noted. Your concept requires several capabilities of the station, to insure success:

1) The two vehicles must be symmetrical and able to rotate without wobble

2) If separation of the system from the station is required, then the station must be able to manage operation of co-orbiting equipment.

***

In this post, I will attempt to add detail to my proposal for a movable partition for pumping of cryogenic liquids.

It has been observed that a seal between a movable partition and the wall of a cryogenic tank is not possible.

My response is that no seal is necessary.

If I had the drawing skills of a Void or GW Johnson, I would show the cryogenic tank with a movable partition in the middle.

I would show cryogenic liquid on one side of the partition, and I would show that same material in the gaseous state on the other side of the partition.

If I were able to show forces in play, I would show the gas applying pressure to the movable partition, and I would show the liquid gushing through the delivery port into a cryogenic tank in a customer vessel, securely clamped to the station.

In a more elaborate drawing, I would show the customer vessel clamped between cryogenic delivery systems so that one is able to deliver LOX while the other delivers the liquid propellant.

(th)

Offline

Like button can go here

#25 2025-05-04 15:25:33

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,019

Re: On Orbit Propellant Refueling Techniques Depot Rotation Ullage

Here is the latest concept developed and published by GW Johnson!

Search terms: cryogenic propellant counter rotate

This one has the distinct advantage that it does NOT require the delivery vehicle to spin up to deliver fuel to the customer.

All the action happens inside the tank.

(th)

Offline

Like button can go here