New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2024-08-29 22:58:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

FAA MOSAIC Proposed Rule Changes for LSAs

As some of you who are pilots may be aware, there are about to be a set of fairly significant FAA rule making changes regarding the requirement for 3rd class Airman medical certificates for LSA pilots (commercial pilots require 2nd class med certs, ATP / Airline Transport Pilots require 1st class med certs; when I was doing my flight training I took and passed the Airman 2nd class physical and psychological examination because I was not interested in becoming an ATP or CFI), as well as weight and performance restrictions currently associated with what the FAA considers to be a "Light Sport Aircraft", or LSA for short.

This is very significant, because it could drastically lower the requirements (read "cost") for prospective pilots to obtain flight training in traditional trainer-type aircraft such as the Cessna 172 and Piper Cherokee / Warrior variant aircraft, as well as Experimental Amateur Built / EAB LSAs, such as the Vans RV-12, or "Special Light Sport Aircraft" / SLSAs. Think of a SLSA as a "factory-built" RV-12 with a mix of certificated and LSA or EAB requirements. SLSAs are professionally assembled aircraft with a limited selection of engines and avionics packages that meet the requirements for type certificated aircraft. The RV-12 is equipped with a Rotax engine (a type certificated engine) and some common type certificated avionics, such as Garmin's "glass cockpit" suite of avionics and radios.

Current LSAs have a variety of restrictions, but the most troublesome for expanding flight training are:

1. 1,320lbs max takeoff weight limit (this includes all occupants, fuel, and baggage carried)

2. 45 knot stall speed without the use of flaps or other lift-enhancing devices

3. 120 knot maximum speed in level flight (incompatible with virtually all the Cessna and Piper trainers)

4. Fixed landing gear (not a big deal, as Cirrus proves with their SR-20 / SR-22 series of high speed fixed gear aircraft)

5. No variable-pitch / controllable-pitch ("constant speed") propeller (increasingly common)

6. A maximum of 1 passenger (there are 4-seat LSAs like the Sling, but you can't fly them with 4 passengers)

The proposed changes, now submitted to the FAA for review, are:

1. No functional upper weight limit, beyond the fact that the aircraft cannot be so large and heavy as to place it in a commercial transport category, which I interpret to mean as 12,500lbs or greater (if you're flying one of these, then you really need a Private Pilot's license with an Instrument rating and complex aircraft endorsement, and more likely, a Commercial Pilot's license with a multi-engine rating)

2. 54 knot stall speed without the use of flaps or other lift-enhancing devices (there seems to be some ongoing debate as to whether or not this may ultimately be increased to between 58 and 61 knots, thus allowing more or most trainer type aircraft to qualify as LSAs)

3. A variable-pitch / controllable-pitch propeller seems to be under serious consideration as allowable now, since so many aircraft that would otherwise be cateogrized as LSAs under the current rules are now equipped with them (anything that has a Lycoming IO-360 probably also has a constant speed prop attached to it)

There are plenty of other proposals submitted to the FAA's 2024 NPRM changes, but these seem to be the most significant.

Offline

Like button can go here

#2 2024-08-30 00:14:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: FAA MOSAIC Proposed Rule Changes for LSAs

This NPRM also broadens the potential for battery electric trainer-type aircraft to be categorized as LSAs used for flight training purposes without many of the more onerous aspects of type certification, which seems to be a very expensive proposition which has thus far prevented any battery electric aircraft from passing the FAA's type certification requirements. Broadly speaking, they've not passed because they're Rube Goldberg VTOL machines which lack the good qualities of a true helicopter, such as auto-rotation in the event of engine failure. Taking off is always optional, but landing is mandatory. They're solutions to problems that nobody with uncommon sense thought needed to be solved.

This is important, because fuel cost is one of the major expenses associated with flight training. AVGAS is currently $4 to $5 a gallon in most places, and burning 10 to 15 gallons per hour is standard fare because most flight training does not involve straight and level cruise flight where you've leaned-out the fuel mixture for best economy. In a Cessna 172 equipped with a 180hp Lycoming IO-360, you're spending around $50 to $60 per hour on fuel. 100kWh worth of electricity, even at $0.25/kWh, is only $25. Most students have to fly for 60hrs or more to obtain their Private Pilot's license. 60 to 100hrs is pretty "average" these days. You technically only need 40hrs, but almost nobody who only completes the bare minimum time requirements passes their check ride with their FAA examiner. Life frequently gets in the way of consistent flight training, so more hours are typically required. You need 200hrs for your Commercial license, and a minimum of 1,500hrs to fly for an airline service as an ATP. People who go the ATP route normally build time by first becoming CFIs and instructing new pilots.

The problem, of course, is that a 100kWh battery pack weighs at least 400kg using current Lithium-ion tech, and 2 hours was the average flight length during training (you book your time on the training aircraft, with or without your CFI, in 2 hour increments), so a 2 hour battery pack weighs at least 800kg, which is already far above the current weight limit for LSAs. Without an actual weight restriction beyond "you cannot categorize a 12,500lb+ commercial aircraft as a LSA", there's plenty of weight margin left to allocate to the airframe and everything else. There are several 3,000lb to 7,500lb STOL-type aircraft which would still meet LSA requirements if equipped with a battery pack, and these tend to be amongst the most forgiving types to fly.

If the monied electric aircraft engineering firms ever give up on these utterly ridiculous 6 to 10 engine battery electric VTOL contraptions that will likely never pass FAA type certification, and instead focus on developing reliable "bread and butter" battery electric single-engine land plane useful for flight training and quiet STOL flying above national parks, then we could see a significant reduction in fuel and maintenance costs for new build airframes equipped with modern avionics. The new pilots will probably appreciate flying airplanes that are substantially younger than they are.

Put another way, the Pipistrel Velis Electro (Part 23 exempt due to EASA type certification) and Bye Aerospace (Part 23 certified by the FAA) e-Flyer battery electric single engine land planes have already passed type certification and are already in-use for flight training. All the goofball battery electric VTOL machines have passed nothing, despite the many hundreds of millions, possibly low billions by now (collectively), having been spent on them. Just because you can, doesn't mean you should.

Offline

Like button can go here

#3 2024-09-07 14:12:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: FAA MOSAIC Proposed Rule Changes for LSAs

One of the various ideas I've probably spent more time on than any other is the design of a personal aircraft based upon Molt Taylor's Mini-IMP (IMP = Independently Made Plane). For those who are unfamiliar with Molton Taylor or his work, he was a WWII era engineer and pilot who flew for the US Navy and worked on the design of various aircraft components for US naval aircraft during WWII. Following WWII, during the 1940s and 1950s, Molt designed and built the first and only type certificated "flying car" that was certified by both the US FAA and US DoT. As the certification suggests, this was a road-legal car (4-wheel, 2-door coupe with a rear-mounted air-cooled engine) that could have its detachable wings / fuselage / empennage / propeller attachment quickly attached or detached from the car portion of the vehicle. Without its "flying bits" attached, the actual car was very similar in appearance and engine type / layout, to a VW Beetle. The "car unit" could tow the "flying unit" to and from a local airport. It was capable of driving at highway speeds on a highway, about 65mph, and flying through the air at about 120mph, or about double normal highway speed. The idea was that the very compact foldable "flying unit" would stay at an airport and only be rented-out when needed. The rest of the time, you had a nimble and lightweight car to drive around, with decent aerodynamics compared to typical 1950s cars. The problem, of course, was that you needed a fairly fuel-hungry aircraft engine to push the contraption through the air at 110mph. Be that as it may, it was the first and only true "flying car". Unfortunately for Molt, there was not enough demand for a flying car back in the 1950s, because aircraft were still so cheap back then that you could afford to purchase a purpose-built aircraft capable of flying much faster using the same engine power. People who could afford to purchase an aircraft could also afford to purchase a roomier purpose-built car.

Molt has been dead for many years now, but his Mini-IMP design lives on.

Molt Taylor flying his Mini-IMP:

The Mini-IMP's wings can be manually folded on the ground for stowage in a garage rather than aircraft hangar, via a series of steel pins, much like his prior AeroCar design. I purchased a set of plans and components for it back in 2012 or thereabouts. I visited the hangar of the current caretaker of Molt's final design, located near Dallas, TX. The new owner was a former ATP and aeronautical engineer, but I forget which airlines he flew for. I sat in the cockpit of their show model, the new owner's personal Mini-IMP that he built and flies, looked around with the canopy closed, and thought to myself, "Finally, I can actually see clearly in every direction except directly behind me." It was quite unlike the Cessna 152s / 172s / 182s that the flight school had available for me to fly. It was very comfortable to sit in, generously spacious despite its diminutive size, and very low to the ground such that no significant step-up was required to enter or exit the cockpit. It was like sitting in a reclining chair. The Cessna was nowhere near as comfortable. If I adjust the seat far enough back and down to not have my knees pinned up against the instrument cluster, then I have a hard time seeing downwards over the panel. Reaching the rudder pedals is not problematic, but there's just not enough room in the right places for someone who is even modestly taller than normal. Every Cessna I've ever flown reminds me of sitting in an airliner seat. To be honest, the Mini-IMPs cockpit was a little too spacious, because my butt slid around in the seat.

After going over the plans for about a year and dabbling in fabricating the parts, I decided that I wanted to build something very similar to the Mini-IMP, but not Molt's specific design. The Mini-IMP's construction is Aluminum substructure with thin fiberglass skins affixed to it. The landing gear and engine mount are 4130 chrome-moly tubing or bar stock, which is the traditional material for making engine mounts and landing gear. I spent some time working with fiberglass parts, and then decided a couple of things. I really hate working with glass because it irritates the hell out of my skin, even with protection, and while I've worked with Aluminum sheet metal and it's not hard to bend into shape, it's also a pain to drill and rivet. The air tools required are fairly expensive, so most people don't have them. I decided to modify the design to use tools and materials that most people with a home garage and basic wood working skills could truly build in their garage. In the intervening years, I've spent quite a bit of my free time and money learning about the fundamentals of light aircraft design. Working with aircraft plywood is time consuming, but I'm not left feeling as though my entire body is one great big rash. The sheets are very thin so making them conform to the shape of the mold without heating is not an issue. I've found that plastic or rubber sheeting combined with some ratchet straps can uniformly distribute a considerable amount of clamping force over plies being wrapped around complex curves.

Along with some very basic engineering knowledge, this is where I started learning about the mechanical properties of various materials, and what they may or may not be suitable for. I was initially interested in determining the "best" materials to use for aircraft engine mounts, landing gear, and fasteners. Sadly, nearly all of my child-like wonderment and enthusiasm over "miracle materials" such as Titanium or composites were shattered in the process of learning the science and engineering behind it. They all have their uses, but only a very narrow range of optimal use cases. I was left with stark reality, as well as a greater appreciation for why all those not-so-dumb engineers didn't willingly use Titanium in aircraft landing gear or firewalls. Martensitic steel was indeed much stronger than Titanium, suffered fewer brittle failures, especially after minor damage, was a lot cheaper, and much easier to work with. For parts that need to flex, with steel it's easier to get the spring rate correct, as compared to Titanium or Aluminum landing gear, because when the thickness is also correct for those "miracle metals", to limit deflection under load, they also tend to be far too stiff. Titanium also has a hardness problem. Those people who make the Titanium Cessna main gear legs also use a half dozen different heat treatments, which is why a pair of them cost as much as a car. These relatively new engineered materials are still awesome for what they're optimally designed to do, and I'm glad we have more and more options, but... The more I learn, the less enthusiastic I become about shaving a few ounces here or there if the end result will be marginally capable of withstanding applied loads or may rapidly fatigue and fail from cyclical stresses.

Anyway, that little journey takes me back to how MOSAIC can spark a minor renaissance in light aircraft design by doing away with the strict weight limit and raising the stall speed to something comparable to a trainer-type aircraft.

After your first 10 to 12 hours of instruction with your CFI in the cockpit with you, they have you take your test and then you solo. Afterwards, you don't need your CFI in the cockpit with you, except for purposes of evaluating your progress. Similarly, your FAA examiner is only in the cockpit with you during your check ride, as well as to proctor the written and oral tests. The test format is exactly like the test format used by the Navy for promotions. First, demonstrate book knowledge, next you will explain concepts using your own words in front of an oral board, and then prove you can actually do whatever you were trained to do. After you prove to your CFI that you have memorized emergency action checklists, can take off and land on your own, perform basic flight maneuvers, and communicate your intentions with ATC, you brief your instructor on the course syllabus you intend to fly (he or she provides this to you ahead of time, such as going out to the training area and practice basic flight maneuvers / stalls / slow-flight / etc, or practice navigation, or practice landing, or whatever), fly the mission (it helps to have a camera with you to record and critique your own airmanship), and then come back to discuss how it went with him or her. Ground school covers all the basics of flight and aircraft performance, inspecting the plane you intend to fly, navigation, communication, weather considerations, and responding to emergencies (engine dies, electrical system failure, comms quit working, or in my particular case, the control cable detached from nosewheel steering).

That sounds great, but with all of that in mind, what's missing and why design an aircraft specifically for solo flight training?

Traditional type certificated aircraft have become unaffordably expensive for most people and even flight training businesses to own and operate. The aircraft themselves, despite nominally being 1950s designs with modernized avionics and radios, now sell for a half million dollars brand new. The fancier / high performance composite Cirrus SR-22s, which are also quite popular for flying club use, are about a million dollars. If you can economically fly an individual airframe for 10,000hrs before they're no longer cost-effective to keep in service, that's $50 to $100 per flight hour dedicated solely to the airframe purchase, ignoring the interest on the loan. During the 1950s, buying a Cessna 172 was about equal to buying the nicest Cadillac sedan that GM made. By the 1960s, it was 2 Cadillacs. Now it's 10 Cadllacs. Average income did not rise at the same rate, or rather inflation destroyed the purchasing power of the average worker while government and big business did everything imaginable to depress labor costs. As a result, most people can't afford to buy 10 Cadillacs. If they could, then that money would go to a home or business or other investment to try to keep pace with the endless devaluation of the US Dollar.

While I've heard of 172s making it to 20,000hrs or even 30,000hrs, that doesn't indicate how much maintenance was required to achieve that total time in service. Most examples don't make it quite that far before corrosion damage, crash damage, or metal fatigue caps the realistically achievable number of flight hours. Annual inspections will run about $2,500. Rebuilding the Lycoming IO-360 engine at TBO, around 2,000hrs or so, runs $25,000 to $35,000. In flight school use, reaching an engine's TBO in a couple of years would be fairly typical. Oil changes occur about every 25hrs and cost about $50 to $100. New spark plugs will set you back $100 or more. Overhauling the magnetos, which must be done every 500hrs to prevent failure, is about $2,000 for the pair. If it's not apparent, these maintenance costs, when combined with the now absurd airframe purchase costs, quickly add up. On top of that, these now-archaic air-cooled engines consume 10 to 15 gallons of $4/gallon leaded aviation gasoline per flight hour.

Flying one of these type certificated aircraft for 1 hour, even when done solo, means a student pilot's total cost is at least $100, and likely closer to $150. Attaining a Private Pilot's certificate is $15,000+ endeavor these days. That's why there are fewer and fewer pilots in General Aviation with each passing year. Fewer and fewer people can afford the cost, even though most people would like to learn to fly. That means there are fewer and fewer candidates available to serve as CFIs and ATPs. To merely get candidates through the pipeline to become Private Pilots, so that some of them may one day become CFIs (to teach others to fly) or ATPs (to fly passengers and cargo to their destinations in relative comfort and safety), and to continue our tradition of taking flight, we must reduce the per-airframe and per-flight hour costs, and quickly, before the entire industry is dead.

We cannot seem to do that using the various Aluminum and Carbon Fiber machines we've developed since WWII. All of them were touted at the time as being poised to revolutionize General Aviation, except none ever did. As time marched on, they became increasingly unaffordable, despite being FAA-mandated to use the exact same materials and engine technologies to conform to their type certifications. Advances in machine tooling and automation never did reduce the per-machine cost to something similar to a luxury car. Each machine is still hand-built, just like a Rolls Royce.

All aircraft, whether large or small, require copious amounts of touch labor to construct. Perhaps the real answer is that there's no cost-effective way around that issue, even with all of our automation advances. Building an aircraft will probably never be like building a car. Since so much of the construction cost appears to be wrapped-up in the materials and tools required to shape the materials, I think we must return to the roots of aviation- wood, fabric, and steel, with the labor provided by the builder. The labor is clearly specialized, but whether or not it's "skilled" is a subjective determination. Apart from the engineering staff, those who built the tens of thousands of aircraft America built during WWII frequently lacked a high school level of education. The cost of working with wood and fabric is nominal. Anybody with a modicum of disposable income can fabricate a surprising number and variety of wood and fabric parts without spending a small fortune. For the kind of personal flying that is most popular today- not the sleek "go fast" machines that relatively inexpensive modern airliners have all but entirely replaced, but "go slow and enjoy the scenery with a machine capable of landing almost anywhere free of trees" machines, wood and fabric aircraft are ideal. If you won't typically fly faster than 200mph, then wood or steel tubing and fabric is likely to be the cheapest way possible.

The energy and therefore monetary investment is low, the materials are more than strong enough to get the job done, and when the time finally comes to retire an airframe, only some easily recyclable wood and fabric is lost. These types of aircraft will never be direct replacement for all-metal machines like the Cessna 152 / 172 or Piper Warrior or similar primary trainers, but as an adjunct for all the time-building flying, with a total cost more inline with that of a car than a mansion.

Offline

Like button can go here

#4 2024-09-07 22:36:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: FAA MOSAIC Proposed Rule Changes for LSAs

The original Mini-IMP was powered by a 65hp Limbach VW-pattern aircraft engine conversion. It's essentially the same engine that powered the VW Beetle. These engines were and are relatively easy to come by. All parts have been in continuous production by one manufacturer or another since WWII. They're direct-drive, air-cooled, "boxer" configuration 4 cylinder engines. The crank cases are Aluminum or Magnesium alloy, with steel cylinder barrels and Aluminum heads bolted to the crankcase. The rotating assemblies, at least for aircraft engines, are typically all-forged.

The engine that powered the showroom model that the current plans owner flies, was powered by a 100hp Continental O-200. The O-200 is a purpose-built aircraft engine powering various Type Certificated aircraft such as the Cessna 152. O-200s are much heavier and physically larger than the VW engines, so numerous minor tweaks to Molt's original design had to be made to accommodate the heavier engine. The performance increase that comes with 54% more power in such a light aircraft is pretty spectacular. Nowadays, the problem is that O-200s, whether brand new or factory rebuilt, cost $40,000+. The wild cost increases over the years are the result of paperwork, liability insurance, and dwindling production numbers. No more than a few thousand of such engines are made each year. Those extreme prices have come to be an absurdity for owning 1930s state-of-the-art engines, which is why motor vehicle engine conversions have been increasing in popularity.

The Corvair engine of the 1950s are 6 cylinder air-cooled direct drive (this means there's no gearbox to reduce the rpm experienced by the propeller) engines. These engines are also very popular for homebuilt aircraft. 110hp models can be built by their owners for around $15,000. Dependent upon configuration, they're either modestly lighter or heavier than Continental O-200s, but for all practical purposes there is no real weight difference. The Corvair makes a little more power than the Continental, real measured dyno power as opposed to "paper" or theoretical horsepower, and it's a lot smoother with 6 vs 4 cylinders. Only the Aluminum engine crankcase and cylinder heads are original parts taken from the 1950s engine that GM made so many of. Every other part is a brand new billet Aluminum or steel part. It appears that someone is working on replicating the crankcase and cylinder head castings as well, so pretty soon these engines will be entirely new manufacture.

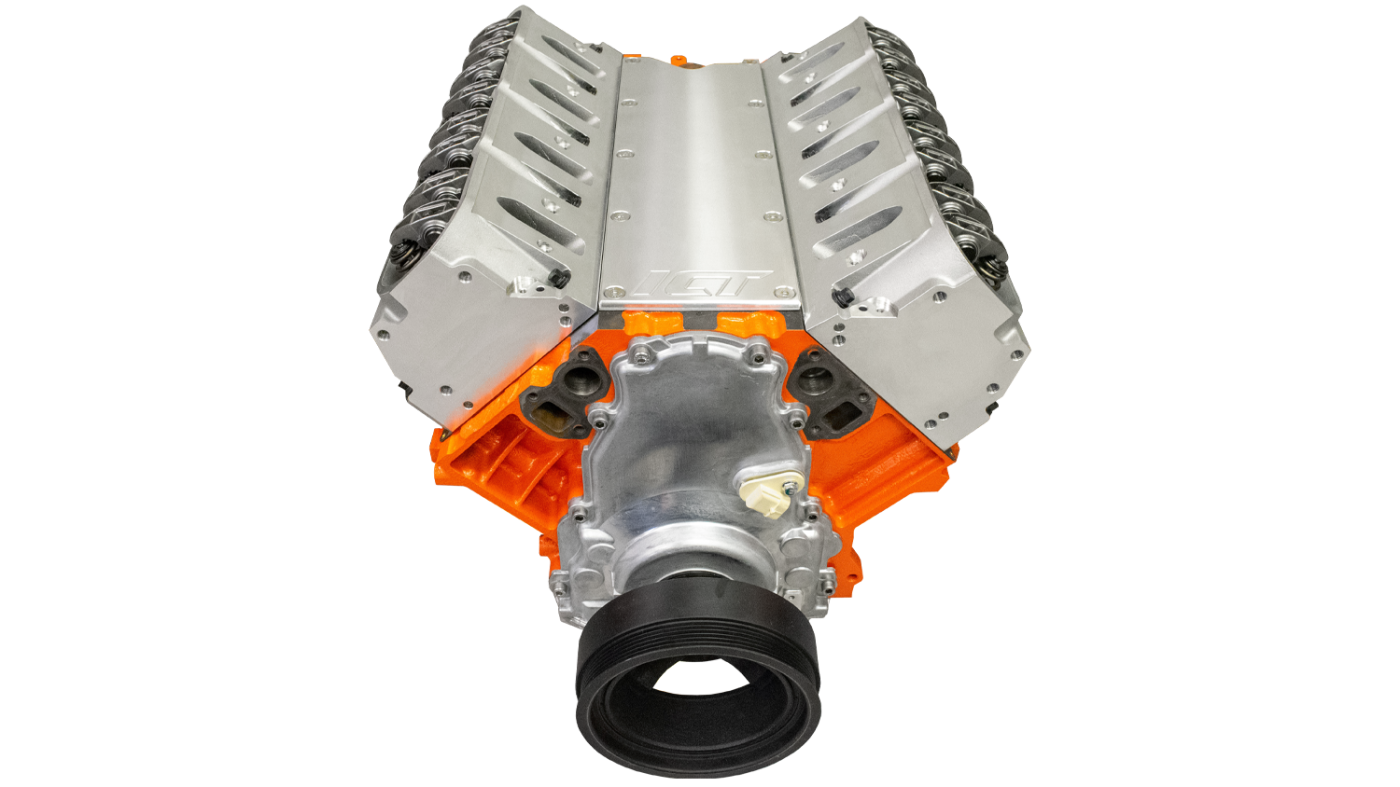

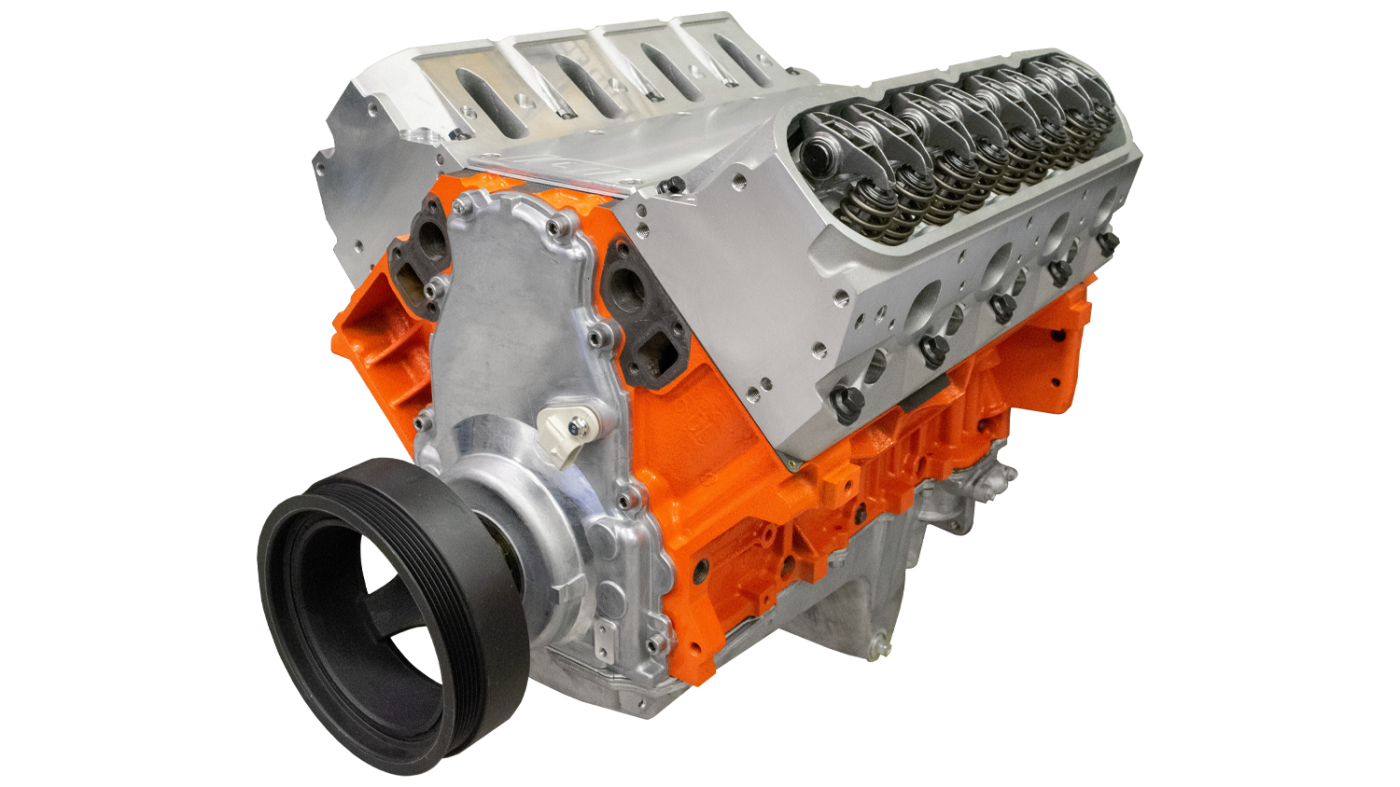

For my design / build, I've decided to use another very plentiful General Motors engine product after spending years studying Chrysler, Ford, and GM small block and big block engines:

The design I've settled upon is a 5.3L / 325in^3 Iron block engine with an increased stroke of 4 inches. A stock 5.3L LS engine has a 3.78 inch bore 3.62 length stroke. The new bore and stroke bumps up displacement to 359in^3. At 2,700rpm, these engines deliver about 180hp, which is the same power output as the Lycoming IO-360.

For those who are wondering why I'm not using the Aluminum block version of the LS, there are a variety of reasons, but the primary reason is durability. The secondary reason relates to aircraft weight and balance with a mid-mount engine. The tertiary reason is soaking up engine vibration to make flying more comfortable. The weight of this engine is not hanging off the nose, although Steve Wittman famously ran direct drive Iron block Ford engines off the nose of his steel tube and fabric aircraft, which were known to be very fast, as-in over 200mph cruising speeds fast. My own body weight is primarily what's ahead of the engine. With all engine accessories and fluids, the Iron block LS engine weighs about twice that of the Lycoming IO-360 with all accessories and fluids. The Aluminum block is about 110lbs lighter. However, this is a single seat aircraft carrying 30 to 40 gallons of fuel. Overall airframe weight closely mimics a Cessna 172.

This is an actual Cessna 172 equipped with an Aluminum block LS V8 engine:

Using a gearbox, that engine delivers a rather ridiculous 400hp. 200hp would be more than adequate, whilst keeping fuel burn rates within the realm of sanity. The traditional Lycoming IO-360 engines which equip all factory-built Cessna 172s make 180hp. The Lycoming IO-390 engines made 200hp to 210hp, but they have reliability problems at that output level. 160hp for a 172 is adequate, but climb performance is not very good on hot days and possibly inadequate for "hot and high elevation" takeoffs. 180hp in the 172RG (Retractable Gear) models I flew was more than enough. When the throttle went forward, there was no doubt that you were going to leave the ground. 200hp is near the practical limit. You're going to get pushed back in your seat pretty good, even with significant atmospheric density altitude to compensate for. Anything over the top of that is mostly trying to turn the 172 into a race plane. There's nothing wrong with air racing, but you're not going to hand over a 400hp 172 to a student pilot if you care at all about them surviving flight training.

This 172 is equipped with an automotive diesel engine that burns Jet-A (AVGAS is not widely available outside the US):

Offline

Like button can go here

#5 2024-09-07 23:06:39

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: FAA MOSAIC Proposed Rule Changes for LSAs

How could I possibly forget the Iron block Ford flathead engines that powered Pietenpol Air Campers and Sky Scouts so famously associated with the EAA?:

Bernard Pietenpol: Father of the Homebuilt Airplane

If you read the article, you will see how, way back in the 1930s, it was claimed that no automotive engines were suitable for powering aircraft. The person making the claim was blissfully unaware that Bernard Pietenpol was already flying around in a two seat aircraft powered by a Ford Model A engine. He died back in 1984, but his hangar was placed on the list of national historic monuments in 1981. I think some part of it was moved to Oshkosh, which is now known as the "Mecca of Aviation". There are flying clubs in the US, Canada, and UK where club members fly-in their Pietenpols. I believe a member of my EAA chapter has a Pietenpol, because he showed some pictures of his build during one of the meetings.

The Pietenpol family and Aircraft Spruce company still sells the plans and materials kits for this aircraft, to this very day:

Pietenpol Aircraft Company

Offline

Like button can go here

#6 2024-09-07 23:47:14

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: FAA MOSAIC Proposed Rule Changes for LSAs

For those who think wooden aircraft are old / slow / not very stylish, check out this Italian beauty (1950s vintage):

It's an aerobatic (+6g/-3g) two seat wooden aircraft with retractable landing gear, and top speed of just over 200mph with a 160hp Lycoming IO-320 engine.

Using wood and fabric does not mean the aircraft in question must look like it just flew out of WWI. That style of construction is something that remains popular, possibly due to the mystique and romanticism of early aviation, but wood and fabric does not automatically equate to "looks old and slow". There have been a couple of kit built wood aircraft that were even faster and more powerful than the Falco, similar in top speed to some of the early models of the Lancair series of composite aircraft. As you increase engine horsepower, airframe weight, and top speed, the expense of composites or metals is merely the next logical step to take. For trainer-type aircraft, those performance advantages are almost entirely moot points. This is only intended to show what is possible, rather than what is most typical.

Offline

Like button can go here