New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#376 2024-06-29 10:47:28

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

tahanson43206,

If you're willing to "reserve" 3m^3 out of 215.05m^3 as unusable tank capacity, to allow you to operate the air turbines at 180psi vs 90psi, then your air consumption rate is cut in half.

58.5cfm / 4.5kW = 13cfm/kW

13cfm * 60 minutes = 780ft^3 per kWh

212m^3 / 22.0871m^3 per kWh = 9.598kWh

Edit:

505.15595kg / 9.598kWh = 52.631kg/kWh <- Substantially lower than the Lithium-ion battery pack on its own, in order to achieve 25,000 duty cycles before unacceptable degradation occurs for either the compressed air tank or the Lithium-ion battery pack

Your air turbine(s) might benefit from 1 or 2 additional expansion turbine blade-disks / "blisks" to extract more energy from air expansion, but you get 39% more energy to work with by regulating air pressure at 180psi (12.4bar) vs 90psi (6.2bar). There's obviously a practical limit as to how high you can go, and higher pressure equals more noise, but there are various commercial air tools which consume higher-psi air.

This would negate or offset any advantage Lithium-ion batteries provide, in terms of weight, if both technologies are expected to provide 25,000 duty cycles before they have to be taken out of service and replaced with new equipment.

Edit #2:

If you doubled the regulated / operating air pressure again, to 360psi, then you give up 6.28m^3 of tank capacity (the volume and weight of air in your storage tank which would be below your regulated air pressure), but your air consumption rate is cut in half again. Your tank's service life benefits from a less extreme pressure cycling as well.

215.05m^3 (at 850bar) - 6.28m^3 ("lost" to operating at 360psi / 24.8211 = 208.77m^3

6.5cfm * 60 minutes = 390ft^3 per kWh

208.77m^3 / 11.0436m^3 per kWh = 18.834kWh

505.15595kg / 18.834kWh = 26.821kg/kWh

Our compressed air's gravimetric energy density, relative to a Lithium-ion battery capable of surviving for 25,000 duty cycles, is now more than twice as good. At this point, we would definitely require a bespoke air expansion turbine design with more stages. Let's say our lighter air powered car requires 150Wh per mile, and we're no longer going to bother with the additional complication of a flywheel to conserve energy.

18,834Wh / 160Wh per mile = 117.7125 miles of driving range

If power was directly proportional to weight, then it should require 139Wh per mile, but I presume some inefficiency of air vs electricity.

Anyway... I hope this makes sense to you.

Last edited by kbd512 (2024-06-29 11:24:04)

Offline

Like button can go here

#377 2024-07-01 21:53:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

In gas turbine engines, the overall pressure ratio is a major factor in fuel efficiency- just as in a piston engine, a higher compression ratio yields more efficient utilization of the energy contained within the fuel and air being combusted. For the air powered car's power turbine(s), rather than compressing and heating up incoming air by burning fuel, we're instead starting with highly compressed air which we're expanding through what would be the hot section and expansion turbine stages of a conventional gas turbine engine. If you start at a higher operating pressure, then you can add a greater number of expansion stages for substantially greater efficiency. Doubling the regulated air pressure fed into the turbine inlet halves the airflow rate for the same work done, so you gain quite a lot in terms of efficiency. The downside is that you start giving up capacity within your storage tank, and the noise produced starts to sound an awful lot like a conventional gas turbine engine.

If the regulated / working air pressure was set to 360psi, then the mass of air in the storage tank which remains below 360psi cannot be properly expanded through a turbine designed to operate with a 360psi inlet pressure. Similarly, conventional turbines violently surge or chug when smooth airflow through the core becomes turbulent, because that condition is associated with a pressure loss. The blades which extract energy from the air are shaped to work optimally with air at a given velocity and pressure.

To counteract this loss of air tank capacity, you could run multiple turbines optimized to operate at different regulated pressures to fully consume all of the air in the storage tank, especially since they're so light and compact. This still unavoidably adds some weight, complexity, and cost. However, even if this vehicle is primarily air-operated, all of its lights, heater, and any personal electronic devices, such as cell phones, all require electrical power.

I don't think I initially understood tahanson43206's point about electrical brakes. If he meant this new "brake-by-wire" system, then no, this vehicle will not have any of that ridiculous nonsense. If he actually meant an anti-lock braking system, then yes, this vehicle will use sensors and a computer to apply and release the brakes many times per second when the driver presses down on the brake pedal, in order to avoid wheel lock-up and skidding. ABS with ESC is required on all passenger vehicles made after 2012. Airbags were required since 1998. The cost of both systems is nominal, about $500 to $750, and the reduction in fatalities is very real, so these systems will be incorporated into the vehicle design because they don't materially affect the per-unit price the way using large quantities of Aluminum or Carbon Fiber do. All told, the safety equipment on a modern vehicle is a small portion of its total cost.

That said, the vehicles themselves and their restraint systems are what should protect their occupants in a crash. Air bags are a band-aid for poor restraint systems. Fatal accidents during racing are nearly unheard of these days, yet none of those race cars have air bags or ABS. ABS and ESC are driver aids for people who generally lack quick decision making and skill at driving. Motor vehicle fatality rates have stagnated since the end of the 1990s, following the introduction of air bags and ABS with ESC. More recently, motor vehicle fatality rates are rising again, because all vehicles have become so ridiculously large and heavy, relative to the 1990s. Pedestrian fatalities and fatalities from the monstrosities that cars and trucks have become is on the rise again. Large trucks and SUVs, falsely marketed as "being safe" (because they are large and heavy), all compare unfavorably to smaller and lighter sedans with a lower CG, meaning they score the lowest on NHTSA crash testing. All of that tells me that much of the supposed benefits of these "safety devices" or "safe heavy vehicles" are a poor substitute for the loss of common sense while doing something potentially dangerous, such as driving a large and heavy motor vehicle.

Anyway, the point is that these vehicles will still have the government mandated safety devices to prevent skidding and wheel lock-up. If I can figure out how to do the same thing without using electronics, then no electronics will be used where none are required. ABS, for example, doesn't specifically require electronics to do what it does, because the only thing the sensor does is translate a sine wave into decisions about hydraulic valve actuation. If you have permanent magnets that actuate air valves to apply and release the brakes, that can be done just as fast as any electro-hydro-mechanical system does it, but likely faster, because air brakes can be actuated and released faster than hydraulic brakes. The yaw rate sensor incorporated into ESP (Electronic Dynamic Stability Program) can also be entirely mechanical. ESP uses sensor input to determine if a vehicle is swerving or skidding relative to the steering input, and applies power or brakes to the other wheels to correct it. Every Cessna 172 I've flown came equipped with a highly accurate yaw rate sensor that wasn't electrically powered, and because it didn't require electricity, was completely unaffected by electronic glitches or loss of electrical power.

Using compressed air and magnets, we can achieve what the electronics do, but retain the ability to troubleshoot the system without more sily electronics. Boeing has already achieved "peak stupid" with electronics. We don't need more stupid. We need more recognition of the limitations of every system. We must then accept that adding more of what's already causing so many problems that the engineers who designed those systems cannot solve the problem, is not going to help, it's merely creating new problems which didn't previously exist. This is coming from someone who makes his living using computers. Given what I know about computers, I also know that further increasing the complexity of modern vehicle systems is not going to make them more affordable or more user-friendly for the average design engineer, mechanic, or driver.

All the endless tinkering with electronic control systems has not produced a more usable result, it's merely made the result unaffordable while ensuring that nobody actually knows what the software is doing, nor why, because no single person can keep track of all the moving parts involved. Regardless of how outwardly simple an electronic device or sensor system running a software program appears, there's so much going on inside that you wouldn't believe it. The simple fact that it works most of the time is the unbelievable part. It's great until it fails, and then it's not, because nobody can actually "fix it", they'll merely replace it, and hopefully that solves the problem. Firing the parts cannon at multi-thousand-dollar computers and battery packs is no longer a workable repair strategy. This is my answer to people who think we merely need to add some more sensors and software. Either figure out how to repair the system without replacing every bit of it, or you've reached the end of your rope with electronics.

Offline

Like button can go here

#378 2024-07-02 16:16:42

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

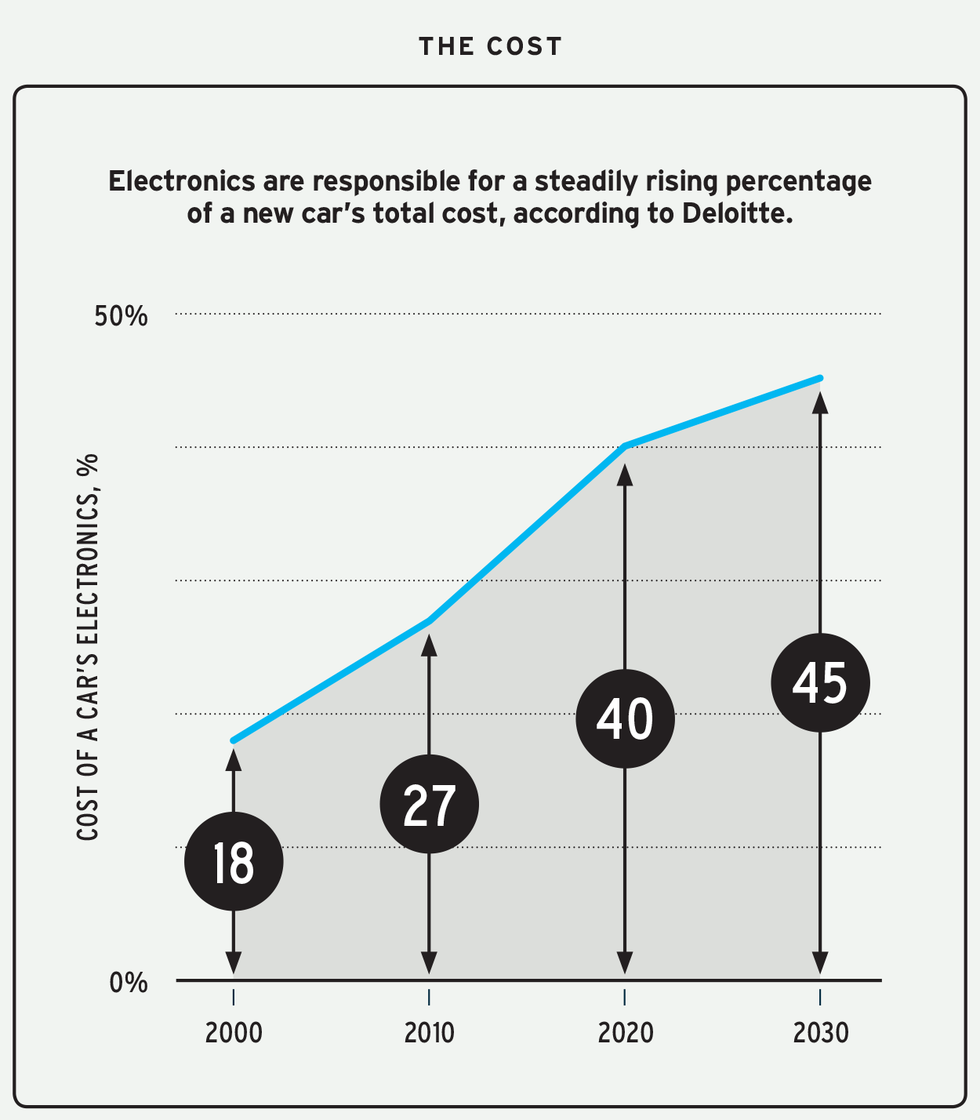

Electronics Account for 40 Percent of the Cost of a New Car

While individual chips may be cheap these days, the computer's significance is evident in just how many there are in a single car. Electronics are responsible for 40 percent of a new car's total cost.

All I can think to myself is how ridiculous it is that 40% of the cost of a machine the size and weight of a motor vehicle, which is primarily intended to roll around on paved roads rather than to take people into space, is solely devoted to computerization of the vehicle. Money is merely a proxy for energy and labor. That means the energy and labor that went into making the computers and sensors are greater than any other single component on the vehicle, regardless of weight, what it's made from, or mechanical complexity. For devices which represent such a small percentage of the total vehicle mass, and cannot be repaired at all, that's an unsustainable absurdity. That Car and Driver article was written 4 years ago. I'd be shocked if 50% to 60% of the cost of the latest vehicles isn't all the electronics they're equipped with.

A passenger car does not need more computers, sensors, and software than a Space Shuttle or a stealth vertical takeoff supersonic fighter jet with sensor fusion. All the vehicles made before computers, which have outlived nearly all computerized vehicles by a half century or more, is prima facie evidence that such is the case.

The vehicles made during the 1990s were the high water mark for reasonable usage of electronics to improve the function of specific vehicle components, such as the engine or transmission or braking system. Motor vehicle fatality rates have not improved since then, repair costs haven't improved since then, and vehicle longevity and total cost of ownership hasn't improved since then, either. Total cost of ownership is another proxy for energy and labor usage.

Apart from machining tolerances, the most impactful changes to vehicle efficiency since the 1990s are that most modern vehicles are now powered by turbocharged 4-cylinder engines with half the displacement of V-8 engines while producing the same power output, along with increased compression ratios.

As far as vehicle emissions are concerned, when Speed of Air introduced pistons designed to completely combust more of the fuel, for diesel engines that single change resulted in lower emissions than the combination of particulate matter filters and diesel exhaust fluid (urea). It reduced NOx, PM2.5, and CO to below the levels produced by all the emissions systems fitted to modern diesel powered vehicles. The greatest emissions reductions will not be achieved by improving or adding more electronics to the engine, but by increasing the efficiency of the fundamental processes which make the engine run.

High-Tech Cars Might Be More Trouble Than They’re Worth

Drivers may sacrifice safety and privacy in exchange for the advanced tech features in their "smart" cars

Modern cars are often described as "computers on wheels." They come with automated driver assistance systems, large display screens, Internet connections and a multitude of ways to sync with smartphones.

Yet in the rush to innovate and one-up competitors with ever newer technology, things may have gone too far. Some developments have made driving safer, but others veer toward tech excess that can actually harm drivers. Cars in the current generation can be pricier to repair, harder to understand and operate and, some experts in the field say, more likely to cause distraction and driver disengagement.

The Threat Behind Computerized Vehicles

The idea behind vehicular attacks is simple. Unlike conventional weapons, larger cars and trucks are more ubiquitous, and the potential cost to morale and the population as a whole is high. The main concession is that these transports need to be manned by a person with devious intent. However, the continued computerization of vehicles, as well as the push towards complete autonomous driving, may make this form of improvised ammunition much more effective and dangerous.

If we were serious about reducing motor vehicle fatalities, then we would accomplish that by mandating 7-point harnesses and racing helmets. Almost nobody dies in racing following 200mph impacts with walls that won't even budge when the race cars hit them. Most of the time, the drivers walk away from those horrific-looking accidents. The car is an absolute mangled mess, but other than being badly shaken up by the experience, the driver will frequently run away from their race car afterwards. If you won't accept those concessions to your "driving comfort", then accept that you don't actually care about your own safety as a motorist, you just want to spend money on electronic devices which make you "feel" as though you're in less danger than you truly are, which hopefully will reduce the severity of your injuries in a major accident, but will never provide a fraction of the protection of proper restraint systems and roll cages. A vehicle built like a "stock" racing car is the only kind of vehicle wherein you can have a head-on collision with a semi-truck and literally walk away from it most of the time. There are no absolute guarantees in life, but I would never want to be in any kind of "modern" or "classic" as-built passenger car in that situation.

The materials used to fabricate stock cars are lightweight steel tubing under fiberglass bodies, low-cost except for the labor used to weld the tubes together (which obviously can be and has been automated), and oddly enough, no computers are required to make them function as they do. All the bits and pieces that make them so performant are either purely mechanical or electrical for the ignition system only. Adding more electronic nonsense to a vehicle doesn't make it perform any better.

Every vehicle equipped with a catalytic fuel converter runs with a sub-optimal fuel-air ratio, almost 100% of the time, because they deliberately oscillate back-and-forth between too-rich and too-lean, in order to make the catalytic converter function. Speed of Air did with CFD-optimized pistons, what none of the major OEMs ever did with catalytic converters, diesel exhaust fluid, and particulate matter filters. This is indicative of the difference between a high quality mechanical design and the various electronically-controlled band-aid solutions added to existing products.

It would not matter in the slightest if we used computers or a new piston and valve train design to clean up the combustion process, except that the "golf ball" piston design would burn significantly less fuel, produce fewer emissions, and provide more power throughout the entire engine rpm range, which would increase the life of the engine so that a new one would not need to be built. That new piston design also greatly reduced soot in the oil, doubling the oil change interval up to what Caterpillar mandated as their maximum allowable oil change interval, without resorting to using solid rings, and worked equally well with Aluminum and "Monotherm" steel pistons. The tech was originally created to reduce emissions from gasoline engines, but worked even better with diesel engines.

If we have all this wild new computer tech at our disposal, then we should be using it to create improved designs that don't have the problems computers were added to rectify in the first place. The same applies to the air powered car. Whatever we can do with our computers to improve upon the fundamental turbine and brake design, we're going to make those improvements first, and then resort to computer controls for any systems for which there are no worthwhile mechanical design improvements to be had. That is the most appropriate way to go about automotive engineering. You start with the most impactful but lowest cost solutions first, and then add higher cost components to meet design requirements if lower cost solutions are not feasible.

Offline

Like button can go here

#379 2024-07-03 11:51:58

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

IT HAPPENED: One defective lithium-ion battery cell just killed 22 people | Auto Expert John Cadogan

People purchasing EVs should watch and listen to this engineer explain how to protect yourself from EV battery fires.

A Lithium-ion battery at a battery manufacturing plant in South Korea killed 22 people due to a manufacturing defect. Those at the scene apparently tried to put the fire out using portable fire extinguishers, and some subsequently died from toxic smoke inhalation after their efforts to put the fire out failed and thousands of other batteries nearby also caught fire and burned. The total quantity of batteries involved was approximately equal to 5 Tesla EV battery packs.

Offline

Like button can go here

#380 2024-07-03 13:21:40

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Fixing Americas car industry

If these guys can produce methanol (-> dimethyl ether) at the costs they say they can, I don't think purely battery electric vehicles have much of a future -- Terraform Industries. What's the point, when a DME powered car is significantly lighter, has a better range, and can be refuelled in a minute or two? Supposedly behaves similarly (I have no personal experience in this area) to LPG (Propane), which we already have plenty of experience with and can convert vehicles to run on.

Maybe we'll see lithium prices crashing... because the demand will evaporate.

Use what is abundant and build to last

Offline

Like button can go here

#381 2024-07-03 16:41:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

Terraformer,

As you pointed out, if we do need lightweight vehicles capable of exceptional range, then synthetic fuels are the way to achieve that in a way that still recycles the CO2. Nature already recycles CO2, and with the tech we already have, there's no reason we cannot do the same. If we power those processes using solar thermal and geothermal energy, then I think we have plenty of input power to scale-up to the degree required. If I read their website correctly, they're saying they can produce 90% of 1GGE in terms of CH4, for a dollar. If that's true, then even if it costs another dollar to convert CNG into gasoline or diesel fuel, then that is well worth the expense of direct air capture of CO2.

I'm hoping that people will begin to understand and accept that total efficiency is represented by the combination of input materials and labor, longevity in operation, and recyclability, which is representative of ultimate sustainability. There is nothing magical about combustion or electricity. Certain forms of energy are simply more suitable for powering certain kinds of devices. In the same way that powering a cell phone or other portable electronic device using a combustion engine is a ridiculous proposition, so is powering a car using the same technology that powers a laptop. It's a stunt, not a practical proposition, sort of like making an all-cast Iron plane fly. Given enough power, it can be done, but to what end?

Gases and liquids are much easier to work with for purposes of storing large amounts of energy, in comparison to solids. The work that company is doing with DAC more or less proves that. I've never asserted that this electric-everything future is a completely impossible objective, but achieving it will require strip mining large portions of the Earth to access the metals required, we must routinely achieve a level of specialty metals recycling we presently do not, and energy inputs from all sources that we are presently unwilling to devote to generating or storing more energy will only be used for that purpose, rather than all uses. I think leveling the entire Andes mountain range to get at the Copper is a waste of time, mostly because it will take too long and consume too much energy, but also because doing that puts us on an energy treadmill we cannot hop off of. Making absolutely everything electric is just not worth the trouble, even though it's theoretically possible to do, and will in fact lead to wild inefficiencies in terms of where all the energy is sunk, how much energy we can ultimately gain back with the tech we have, and what kind of future we will have as all of the toxic electronics and plastics waste really starts to pile up, long before we establish the recycling infrastructure required to reprocess it.

I use cell phones, tablets, and laptops as a proxy for what humanity will do with specialty metals waste. All the broken or obsolete devices will sit in a drawer or go to a landfill as demand for more of those metals surges. China now has many football fields of EVs that will never be sold to anyone. They "won" the manufacturing war to such a degree that they don't have enough customers to sell their products to. All the coal, oil, and gas energy used to make those EVs was squandered without result. It's probable that people wanted them, but could not afford them, so now that their batteries are "bricked" because they haven't been charged, they can no longer function as cars. They're not being crushed because they can't be recycled without removing the batteries to recycle those materials separately. Since it's energy and cost unfavorable to recycle the batteries, they'll sit there until the batteries short-circuit internally. What was the point of that? As I've said many times before, far too many people confuse activity with accomplishment.

If people want to power personal motor vehicles without burning something, then modern technology can facilitate that in a practical and sustainable way using compressed air or a heat source such as hot salt or rock. A vehicle so-powered will be quite heavy for the range it achieves, akin to early 20th century vehicles, but it's still not burning anything, the materials required are abundant / widely available / already mass manufactured, the vehicles will be reliable and durable, and refilling their tanks can be exceptionally cheap and almost as fast as gasoline or diesel. I don't see a particular problem with using them for short-range transportation within cities, where the general public will benefit from zero or near-zero engine exhaust. Knowing that they would be meaningfully better and could be made much cheaper than a combustion engine or battery powered vehicle, I would not object to purchasing and driving one. Since the energy source could be provided so cheaply, operating them would literally be pennies on the dollar.

Offline

Like button can go here

#382 2024-07-03 17:23:26

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,281

Re: Fixing Americas car industry

We have talked about producing synfuel from recycled CO2 and hydrogen before. The southern US would be a good place to do this, as it has ample sunlight for solar thermal power. Most of the components in solar thermal systems are fully recyclable low alloy steels. In our previous discussion, it was established that CO2 extraction from seawater was more efficient than air extraction, as the concentration in cold seawater can be up to 3g/kg, depending on temperature. Lightweight and efficient hybrid vehicles that get outstanding mpg would appear to be an important enabling technology, as synfuels will probably be relatively expensive. If we can produce 100mpg cars, then fuel costs will be less of a problem.

Compressed air cars that carry phase change materials to capture compression heat are very promissing. The University of Ontario built a prototype with a 60% energy recovery efficiency and an 80 mile range. That would be good enough for most people for day to day driving. If you need to drive further, just hire a diesel car.

https://www.inderscienceonline.com/doi/ … 021.117052

The problem may be consumer acceptance. I personally wouldn't mind an 80 mile range car for local trips, provided that I could recharge it outside my house. But a lot of people won't be happy with such limited range unless the car is very cheap and offers other benefits, like superior reliability. Longevity is a major advantage for an air car. Provided a steel pressure vessel is operated beneath its yield limit, it would have effectively infinite life. That makes it dramatically superior to lithium ion batteries, which seem to need replacement after as little as 1000 cycles. Given that people everywhere are getting poorer, a car that could feasibly last as long as human lifetime looks increasingly desirable.

Last edited by Calliban (2024-07-03 17:30:34)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#383 2024-07-04 13:40:35

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Fixing Americas car industry

More panels are being created for automobile use. GoSun, a company pioneering portable solar solutions, has unveiled its groundbreaking Solar EV Charger.

US: New portable solar charger enables EVs to recharge anywhere

GoSun’s Solar EV Charger addresses potential EV buyers’ concerns about running out of battery. The charger provides 1,200 watts of solar power and weighs 70 pounds. It can be installed on a vehicle’s roof rack. A company video shows how easily the panels can be unfolded and plugged into the car’s charge port. For security, the charger includes a lock to prevent theft.

According to the company, two people can install the charger in 20 minutes. While it can add up to 30 miles of range per day, on average, it provides 10-20 miles, depending on the vehicle and weather.

Online

Like button can go here

#384 2024-07-04 16:58:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

Calliban,

With modern Type IV 700bar CFRP tanks rated for 25,000 pressure cycles, or the exact same tank pressure tested over 15,000 cycles at 875bar, then for 15,000 miles of driving per year, a Type IV compressed air tank would last for 166 years, or 100 years of driving if the same tank was pressurized to 850bar. 15,000 miles per year equates to just over 41 miles of driving per day. The best "feature" of a compressed air car is that any mechanic with HVAC tools can tell you exactly what's wrong with the car (what's leaking). Nothing more sophisticated than a pressure gauge and volt meter is required for troubleshooting. If something isn't working as expected, then it's because a seal is leaking somewhere. Did I mention that it contains an air source suitable for reinflating your tires if you get a flat? If you run out of air on the side of the highway, then someone with another car can "refuel" your vehicle using an air hose.

Consumer acceptance will be based upon cost. People were perfectly willing to purchase EVs, but not at double the price of a gasoline car for similar or worse range, lower reliability, and various hazards not present with gasoline powered cars, such as the battery burning for a week after an accident. If a competitor vehicle is cheaper and its fuel source is cheaper than gasoline, yet just as easy / quick / simple to refill, then I think our green energy aspirants will have a winner. The people who test drove GM's EV1 said they would be perfectly happy with 100 miles of range, but GM thought nobody else would be, due to the projected cost of each vehicle. I want to know how many other people would be happy with a cheaper car and fuel source, assuming that they had the option between gasoline or diesel and compressed air. Maybe there won't be much of a market, but the one thing I know for sure about consumer behavior, is that price sells cars. The overwhelming majority of EVs on offer in the western world are priced like Cadillacs. Only so many people can afford to buy a Cadillac. That's not about desire or lack thereof, it's about cost. We all know why EVs cost so much, and that there's not much we can do about that aspect of the EV, because the cost is almost entirely the astonishing amount of energy to make the batteries and electronics.

Instead of throwing my hands up in the air and proclaiming that cleaner / greener (relative to competing alternatives) transportation is impossible, I took a circumspect approach to energy consumption and overall efficiency by zooming out far enough to evaluate as many aspects of the problem as I could (materials energy input, manufacturing energy input, operating energy input, and recycling energy input), before coming to the conclusion that a natural energy source like compressed air or thermal energy storage was the only valid engineering approach with the potential to reduce the cost to an acceptable value, and therefore entice rather than coerce more of the car buying public into buying cleaner / greener cars.

Leftists think they can use more force or coercion to solve every problem they encounter, to include energy problems. That approach may work with government, despite scant evidence that it's a valid long term solution, but it will never work with the ugly energy math of the physics involved. Within the realm of energy physics, what I want or would prefer to have is irrelevant. I'm being dictated to by physical and materials reality, not the other way around. This is a foreign concept to them, because they think solving any problem is only a matter of using enough force. Energy problems don't get solved by using more force, they get solved through shrewd analysis of the energy inputs, acceptance of practical technology limitations, and appropriate use of available energy sources. This is in fact an ideological problem which happens to relate to energy usage rather than governance. Making increasingly unrealistic demands of technology without appropriate concessions is not the way forward.

Offline

Like button can go here

#385 2024-07-22 18:13:30

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

FIRST MPG Test- Diesel OMEGA CAR - Video 2 of 3

104.27mpg using an old TDI engine, and 0-60 time is faster than a Dodge Viper.

39,750Wh per gallon of diesel fuel / 104mpg = 382.2Wh/mile

I'm guessing that Speed of Air pistons alone would push efficiency to the same level as a Tesla.

250Wh/mile / 0.7 (California's stated "well-to-wheels efficiency" on their grid) = 357.1Wh/mile

Speed of Air has demonstrated a consistent fuel economy improvement using their piston tech, of between 20% to 30%.

382.2 * 0.8 = 305.8Wh

That's less power consumption than a Tesla. If every passenger car achieved that sort of fuel economy, then less than half of the 73.5 billion gallons of diesel fuel the US consumed last year would be sufficient to cover all miles driven. Obviously, not all vehicles will be as fuel efficient as Casey Putsch's car, but the diesel fuel we presently consume is likely more than sufficient for all transportation uses, and the gasoline consumption would be limited to small power tools and light aircraft.

I'm quite certain we could make EVs more efficient by making them lighter, but that would further decrease their already limited range, and at that point, we may as well use compressed air for short trips.

Offline

Like button can go here

#386 2024-08-03 09:22:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Re: Fixing Americas car industry

GoSun's rooftop solar charger adds 30 miles to EV's range daily

A 70-lb (32-kg) box, measuring only 5 inches (12.7 cm) in height, sits atop the vehicle much like a rooftop cargo carrier. What sets it apart is the 200 watts of solar panels integrated into its roof, allowing for a continuous trickle charge while the vehicle is in motion.

This ingenious design amplifies the total solar output to an impressive 1,200 watts, significantly boosting the charging capacity.

A 120-V output cable plugs directly into the car’s charging port, providing Level 1 charging straight from the sun. GoSun has engineered the panels to withstand winds up to 30 mph (50 km/h), ensuring reliable performance even in challenging weather conditions. The closed box is also designed to handle highway speeds of up to 100 mph (160 km/h).

Under optimal sunlight conditions, it can provide up to 30 miles (50 km) of range per day. In more typical scenarios, EV owners can expect to gain between 10 to 20 miles (16 to 32 km) of range daily.

The GoSun EV Solar Charger is currently available for pre-order on the company’s website, with an estimated retail price of $2,999. GoSun has indicated that pre-assembled units will begin shipping to customers in 2025. The installation process is designed to be user-friendly, taking only about 20 minutes to complete.

Seems interesting but slightly more than I think it should cost.

Online

Like button can go here

#387 2024-08-03 13:24:15

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

What kind of aerodynamic drag does that device impart to the vehicle?

Why not just put an accordion-folding set of soft / flexible panels in the trunk and lash them to the top of the car?

It doesn't take very long to do that, maybe 2 minutes.

The cargo bin on the roof seems like an expensive solution in search of a problem to solve.

At 250Wh/mile, their device provides 2.5kWh per day. That seems achievable. They're claiming up to 7.5kWh under "optimal sunlight" conditions, seems dubious unless you both lived in a desert region and didn't drive the vehicle at all during the day... Maybe, but not likely, unless you drive to work while it's still dark outside, deploy the panels, and then leave work for home when it's dark outside.

$3,000 for 4m^2 worth of panel surface area?

That's a bit excessive for something that's mostly fabric and plastic- about 3X more than commercial panels. It's much lighter, obviously, but still.

The upside is that it charges the batteries very slowly, so far less damage over time than a fast charger.

Let's say you drive 15,000 miles per year like the average American does, and you get good but not great performance from this device, meaning it gives you 20 miles of range per day. You're driving an average of 41 miles per day, so you still have to charge the vehicle when you come home at night, and that charging has to be from the grid or a home solar installation.

Since this device cannot actually give you sufficient charge to make it through a day of normal commuting, what's the point?

The panel has to be good enough to give you about 41 miles of range.

Offline

Like button can go here

#388 2024-08-03 13:39:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

I had a "second thought" on this concept.

If the solar panel provided twice as much power as it actually does under "good" conditions, and you kept the battery's state-of-charge around 50% to more or less guarantee 5,000 charge/discharge cycles, and only drove 40 to 50 miles per day, then you have a viable solution that allows you to get your 50 miles per day of typical driving. Your car and panel combination then provides 250,000 miles over 13.7 years, which is about the same as what most people get from their compact gasoline powered daily commuter car costing half as much up-front, or about the same as the Tesla after gasoline and oil changes are included, but ignoring the fact that you're spending $1,500 per year on tires, so there is never a point where the Tesla actually achieves price parity with a gasoline powered car if both vehicles are required to pay road taxes.

That's about the only use case scenario for the vehicle and solar panel combination, if such solar panels actually existed, but then it truly does "power itself", so it doesn't draw any power from the overburdened electrical grid. IF it can do that, then it's a good investment if you have the money to pay for about 3 compact gasoline powered cars, but most people don't.

Offline

Like button can go here

#389 2024-08-28 06:32:56

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,281

Re: Fixing Americas car industry

1970s American cars were awful.

https://youtu.be/pjzpx_jUUA0?si=t9GpLKrnMYB7uvoq

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#390 2024-08-28 08:45:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

1970s American cars were the end result of the American government trying to dictate the functionality of various automotive components to the entire automotive industry. I drove and/or rode in various foreign cars from that era, both Japanese and European. None of them were anything to write home about.

Could the American automotive industry put more effort into better smaller vehicles?

They sure could have, but up until that point most Americans weren't actually buying smaller cars, so it largely would've been wasted effort. The land yachts of the 1970s came about specifically because that's what most car buyers were forking over their money to drive around in. Blaming the manufacturers for producing what their customers were actually buying is, frankly, a little baffling. Someone coming along decades later and saying to themselves, "Isn't this car garbage?", is somewhat humorous, but it shows how what people value either changes or differs from person-to-person.

The reason you can't find very many 1970s era Japanese cars to fix up and drive again, some of which were undeniably very cool, is that there simply weren't very many compared to what GM, Ford, and Chrysler sold. The greatest stand-out "feature" of foreign cars was their gas mileage. American cars typically weren't very good on that metric. Unfortunately, there really wasn't any "aftermarket" to source parts from for the Japanese and European cars. If they ever broke and you couldn't afford the dealers' parts prices, the cars had to be scrapped. IIRC, a lot of the smaller or cheaper cars from that era, regardless of national origin, had significant rust issues, especially up north.

Offline

Like button can go here

#391 2024-08-28 15:37:38

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,281

Re: Fixing Americas car industry

I don't disagree. Even by the standards of the 1970s, that is a truly awful car. American car companies did produce some good cars in the 70s, things like the Escort and the Capri. But those giant saloons were ugly then and still are. And they really didn't have any export value because most places did not have cheap gasoline.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#392 2024-08-28 20:38:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

Calliban,

I look at it in terms of what people were willing to purchase vs what was actually available to purchase. Regardless of what you or I think of those rolling lounges, with our 40+ years of hindsight, there were vanishingly few makes and models of cars which were definably "better" than whatever their contemporaries were. The relative worth of a vehicle, or any other tool, should be evaluated against whatever else was available at that time, in the same price range and market. Giant American sedans the size of pickup trucks never made sense in Europe, because Europe doesn't have tens of thousands of miles of multi-lane highways and individual parking lots larger than some European countries.

The Ford Escort and Mercury Capri were generally thought of as "rolling coffins" over here. My parents had a Ford Escort, until a driver in 70s pickup truck cut my mother off and forced her into the back of a Capital City Metro bus in Austin, Texas. I was in the car with her at the time. We were on our way to Church. We both survived, but not without injury. The car was totaled. The crash protection features kinda sorta worked, although she was braking all the way into the back of the bus. If we were going any faster, it would have been a very bad day. Anyway, overlay Texas on mainland Europe. Texas is merely one state, and not even the largest state at that. Europe technically has more land area, but it's only bigger by about the size of an extra "Virginia" added to the US. If you add Canada and Mexico, there's a vast land area to cover. Everything is much more spread out here.

I always thought of the tiny Japanese cars and VW Beetles as too small for American roads. They were good on gas (for the time) and had acceptable reliability when new, as far as that goes for 1970s anything, but they certainly weren't ideal for driving conditions over here. I would not want to drive one on the highway. I've always enjoyed the initially spirited performance of smaller cars, though. From about 0-40mph, they're the bee's knees.

Offline

Like button can go here

#393 2024-08-29 10:19:20

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Fixing Americas car industry

Something that rarely gets brought up in discussions of vehicles and transport options is that there isn't really anything that works for every or even most use cases. A large family car is oversized for a single person commute or picking up groceries, but a small kei car suited for those tasks is unsuited for families. And when the weather is nice, most people might be willing and able to leave either car at home and cycle for short trips. For long trips, and/or trips where they have to carry several passengers or large bulky objects, the minivan can come out of the driveway; otherwise, leave it at home.

I would like a small car designed by the same people who designed the Henry vacuum cleaner, the only vacuum cleaner still manufactured in Britain and undisputed king of hoovers. Very basic and simple design, bagged. Famous for being able to suck up anything -- I've used one to clear up small rubble before. And still be able to do it after a couple of decades of use. I wish Numatic made other appliances...

I want Britain to rebuild our manufacturing industry on the Henry Hoover design principles.

Use what is abundant and build to last

Offline

Like button can go here

#394 2024-08-29 16:17:19

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,439

Re: Fixing Americas car industry

Terraformer,

One thing I've never seen any automotive manufacturer do, which I thought would make cars modestly wider but much shorter, is mounting the engine to the firewall, transverse, front-wheel drive with all 4 wheels providing steering capability so that the limited steering travel from moving the wheels outboard onto the corners of the A-pillar and C-pillar is less of an issue, while eliminating most of the trunk and most of the hood. What this primarily does is make the car much shorter and stiffer. It uses the vehicle chassis similarly to how an aircraft or formula car uses it, such that the entire passenger compartment is a stiffened box to which all other major vehicle components are attached. There's not a lot of structure between the front and rear during a collision, but that's why the passenger compartment is stronger. Since the vehicle is also wider, there's less torsion when one corner goes over bumps in the road. It is mechanically somewhat more complex to build, but in terms of weight and space claim, much better than either a traditional front or rear engine vehicle layouts.

The British-built Aixro XR-50 naturally aspirated Wankel engine weighs 17kg and puts out 44hp. Combined with a Chrysler CCV-like chassis, you would have a very simplistic and much lighter car. The engine could be air-cooled, but liquid cooling is the current global standard because engine cooling is more assured. The "piston" is Iron rather than Aluminum so it does not expand / contract / crack, the eccentric shaft won't break at any normal power output level, even if it was tweaked to produce 88hp vs 44hp, and the ceramic metal seals to make the engine reliable are now well-developed tech. We could apply Speed-of-Air's emissions cleanup tech to the rotor surface, coat the rotor with an aerospace ceramic plasma spray, and Valvoline has a special detergent motor oil that prevents residue build-up on the seals. As long as it's kept lubricated properly, Wankels can last a long time. If it ever does fail, it's light enough to be removed from the vehicle without any special tools like a cherry picker or overhead crane.

Offline

Like button can go here

#395 2024-09-13 16:45:17

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,271

Online

Like button can go here