New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#27 2008-02-09 06:07:54

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Shipyard?

Use them to build a Shipyard?

Use what is abundant and build to last

Offline

Like button can go here

#28 2008-02-09 18:52:15

Re: Shipyard?

So...if they could be used to build a shipyard...then couldn't they also be used to build ships? Making them, by definition, a shipyard?

So, in essence, you want to build the shipyard out of Bigelow modules. Okay, I suppose there's nothing in principle preventing that.

Offline

Like button can go here

#29 2008-02-10 04:56:59

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,988

- Website

Re: Shipyard?

Would a Falcon 9 be able to take a Bigelow module up? And would one be able to take a DreamChaser up?

Use what is abundant and build to last

Offline

Like button can go here

#30 2008-02-10 10:17:06

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,299

- Website

Re: Shipyard?

Let's see. A real habitat will be bigger than the demonstraton module that Bigelow flew. TransHAB was designed to be the length and diameter of the Shuttle cargo bay, but would inflate to 3 times diameter making it 9 times the cross-section area. Since the length would remain the same, that means 9 times the volume. To be this big, a Bigelow habitat would have to be about 5 times the diameter and 4 times the length of the Geneisis I or II demonstration modules. At 5 times diameter it would be 5*5=25 times the area, and at 4 times the length that means 100 times the mass. Genesis massed about 1360 kilograms, so a full-size habitat module would mass about 136,000 kilograms or 136 metric tonnes. Falcon 9 can lift 10,400kg to a 185km circular orbit if launched from Kwajalein. That launch site has 9° longitude, so the inclination would also be 9°. That's not good enough.

If you scale-down a full-size module to twice the diameter and same length of the Destiny laboratory module, it would still have 4 times the volume. That would be 8.4m diameter and 8.4m length, or 3.36 times the diameter of Genesis and 1.9 times the length. That would be 3.36*3.36*1.9=21.45 times the mass. So 29,172kg launch mass. Still too big for Falcon 9.

If you make the Bigelow module the same size as Destiny, it would be 1.68*1.68*1.9=5.36256 times the mass, so 7,293kg launch mass. That Falcon 9 could lift.

Of course if you launch Falcon 9 from Cape Canaveral AFS instead of Kwajalein, and launch it to ~390km altitude instead of 185km, you could reach ISS. The higher your orbit, the less atmospheric drag. To get completely out of the atmosphere so the orbit just won't decay, you have to get at least 800km which is medium orbit. The Van Allen radiation belts are around there. Higher launch latitude results in higher orbital inclination, which results in lower launch mass. Falcon 9 can lift 9,900kg to 185km circular orbit at 28.5° inclination if launched from the Cape. ISS is at 41.6° inclination, so reduce launch mass. Higher altitude also means lower launch mass. So the question is just how big do you want the hab, and where will it go?

Offline

Like button can go here

#31 2008-02-10 12:57:06

- cIclops

- Member

- Registered: 2005-06-16

- Posts: 3,230

Re: Shipyard?

The mass of an inflatable module scales much closer to its area than the volume, that is to the square of the size not the cube.

[color=darkred]Let's go to Mars and far beyond - triple NASA's budget ![/color] [url=irc://freenode#space] #space channel !! [/url] [url=http://www.youtube.com/user/c1cl0ps] - videos !!![/url]

Offline

Like button can go here

#32 2020-10-09 16:57:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Shipyard?

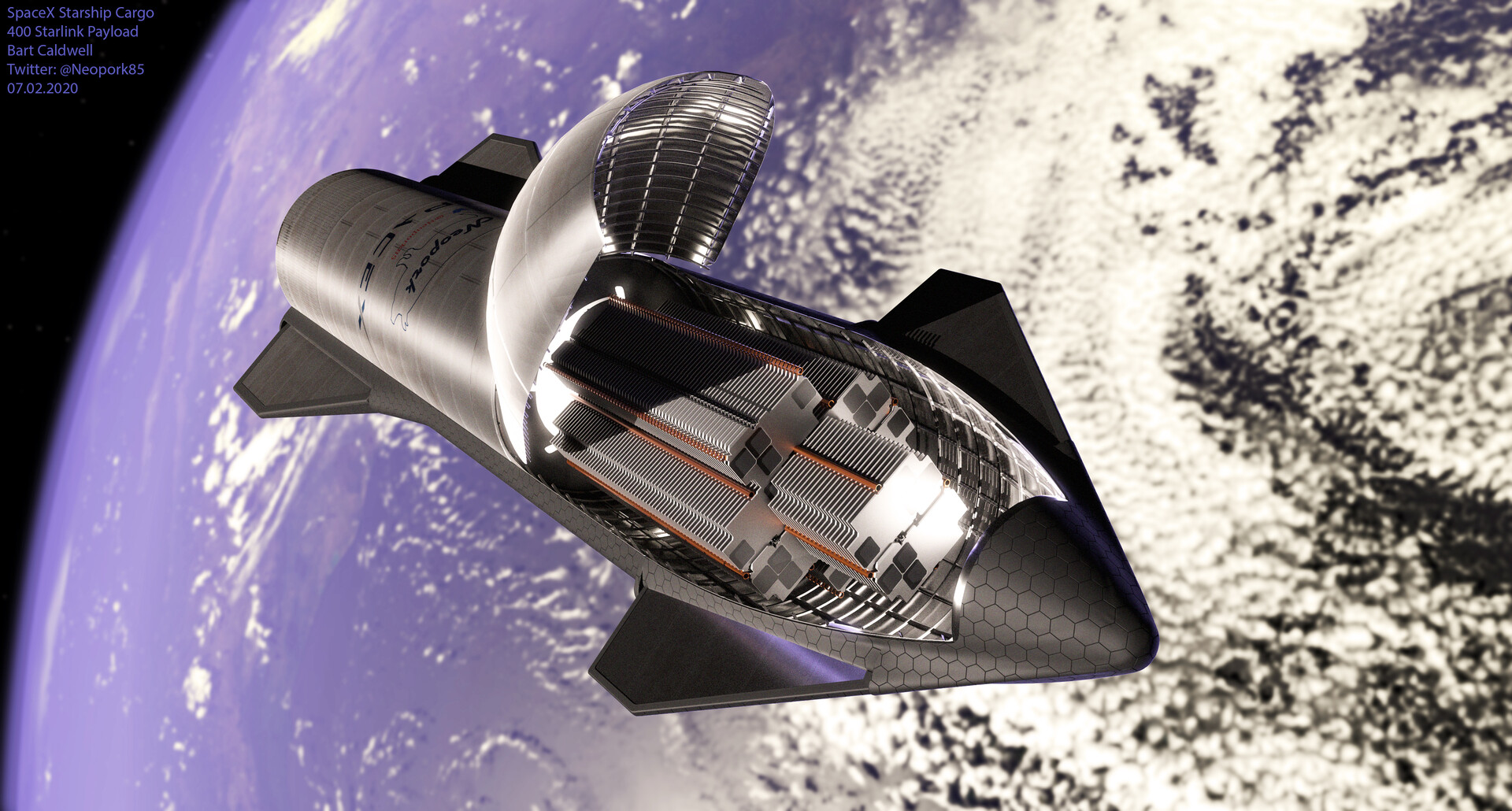

Using what we have to leverage the big build of a ship for mars...

Offline

Like button can go here

#33 2020-10-11 07:27:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Shipyard?

GW has posted before about a dry dock using aluminium framing and mylar sheeting. It wouldn't be pressurised, but it would be well lit and free of temperature extremes, allowing the workers to use simple mechanical counter-pressure suits rather than the bulky suits they have today.

Offline

Like button can go here

#34 2024-06-29 14:45:53

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Shipyard?

Without a spacewalk it's going to be hard to open the craft to see what the real issues are.

Just one more reason to add a space shipyard port so as to be able to make repairs by allowing it into a shuttle sized bay or larger as required so that a crew can go into it once the bay doors are closed. Inside the bay would be a shuttle arm to catch and secure anything brought in for repairs. This could also include satellites.

Offline

Like button can go here

#35 2024-06-29 21:17:48

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,299

- Website

Re: Shipyard?

Repair of a spacecraft is an interesting issue. What about an inflatable the size of TransHAB? But without the central core? TransHAB was supposed to be the same length as Shuttle's cargo bay, but inflates to 3 times diameter. So 60 feet long by 45 feet diameter. With a large fabric round door at one end, with hard ring for the door edge /seal. Could the ring wrap into 3 hoops, then spring out in space? One ring for the inflatable "doorjam", another for the door edge. With rubber O-ring for air- tight seal. The other end would have a CBM hatch. LED lights inside. Equipment to inflate, with pumps to decompress while scavenging as much air as possible. Inner liner of Nomex so it can withstand heat such as welding. Not direct contact with welded metal but walls won't melt when repairing a Starliner inside. Launch this to ISS by Falcon Heavy with all 3 core stages recovered. Rendezvous with ISS using a Cygnus service module. ISS arm would grab it and bearth to a CBM hatch the same way Cygnus normally does.

Video of folding a ring in 3, with fabric tube attached to ring.

YouTube: How to fold a ring in three

Offline

Like button can go here

#36 2024-06-29 22:05:54

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,299

- Website

Re: Shipyard?

Extendible scissor arm with soft docking ring for APAS/NDS to attach Starliner outside then pull it in?

Offline

Like button can go here

#37 2024-06-30 00:16:59

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Shipyard?

All the candidate spacecraft to repair use bipropellant hypergolic-ignition pressure-fed thrusters. The propellants are quite lethally toxic. What if you have a leak while you are trying to get into one of these craft to make repairs?

Even if you do an unpressurized (but enclosed and thermally stabilized) work bay, the leak risk is still a huge problem to solve. Residues get on your suit, and come inside the airlock with you. And if both species leak and touch, you have an explosion and fire.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#38 2024-06-30 15:41:58

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,299

- Website

Re: Shipyard?

Damn! You're right. There is no way around that. I have talked of using liquid methane / LOX for RCS thrusters, but no one is using it. My mission plan to send humans to the Moon using Dragon and two Falcon Heavy launches would use LCH4/LOX for the Dragon trunk for TEI, for the lunar module, and the crasher stage. But it hasn't happened. Orion was originally supposed to use LCH4/LOX for all engines of its service module, but they ran out of money so convinced Europe to give them service modules designed for their ATV cargo ship. So now they all use MMH/N2O4 aka MMH/NTO: Dragon, Starliner, and Orion. Even Cygnus and Japan's unmanned HTV. I don't have which propellants Dream Chaser uses, but I suspect it's also MMH/N2O4. Russia uses UDMH/N2O4 for their Soyuz and Progress.

Offline

Like button can go here

#39 2024-06-30 16:41:46

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Shipyard?

I would think that man is capable of neutralizing these chemicals and covering the areas where it might be possible and once its contaminations is contained then it's possible to work on the ship.

All fuels will have precaution and handling to make it safe to be around.

https://ntrs.nasa.gov/api/citations/201 … 033304.pdf

https://onlinelibrary.wiley.com/doi/ful … 014/729313

Offline

Like button can go here

#40 2024-07-01 09:34:39

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Shipyard?

They'll have to find some way around the leak hazards of toxicity and fire/explosion. Probably off-loading those propellants, and venting the tanks and plumbing to vacuum for a day or so, before bringing it inside for work.

Those hypergolic storable propellants for extremely-simple and utterly-reliable (except Starliner) thrusters are just too attractive. If you do LOX-LCH4, you can do them pressure fed, down at under-100 psia chamber pressures, but you must ignite the burn with "something". In vacuum. Cold.

About the only thing that I know works as that "something" is TEB injection just as the LOX flow begins, during which you start the methane. TEB is every bit as serious a toxicity risk and fire/explosion hazard as NTO and any of the hydrazines. And there is the enormous difficulty of utterly-precise timing. And the resulting more ragged-looking pressure & thrust traces with time.

There is a reason they use NTO/any of the hydrazines, despite the risks of toxicity and fire/explosion: it really works quite well, very simply and easily, and with good performance, including a nice clean ignition and a clean cut-off. And with small thruster propellant tanks, you can afford the weight of higher tank pressures, resulting in higher chamber pressures (100 psia and up) and the resulting better performance out of the thrusters (not CFvac, but c* is a function of Pc, with Isp proportional to c*).

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#41 2024-07-01 11:57:23

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,299

- Website

Re: Shipyard?

Two companies were hired to develop thrusters for the service module for Orion, using LOX/LCH4. Sized for RCS thrusters. Here is a document directly from NASA about testing of one of them. This page has the abstract, the full document is just a single page, a PDF that can be downloaded from a link at the bottom.

NASA: Development and Test of a Rocket Engine Using Environmentally Friendly Propellants

• Injectors: designed so the fuel and the oxidizer impinge in the combustion chamber while the igniter lights the main combustion chamber.

• Source of Ignition: chosen because laser provides a more centered and precise spark. An alternative igniter, a spark plug, can be substituted in the same mounting feature.

My point is LOX/LCH4 could be done, but hasn't been. As GW pointed out, any potential vehicles for such a repair bay use hypergolics. And if repairs are required at all, that means something went wrong. That raises the risk of leaks, and all the problems GW said.

Offline

Like button can go here

#42 2024-07-04 08:54:16

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,110

- Website

Re: Shipyard?

I would love to see a "shipyard" started in the form of a repair and maintenance bay of some kind. Building a pressurizable one is a real problem still, but building an unpressurized one is not! That's a space frame of light pipe or tubing, covered with space blankets, and with banks of electrically-powered lights inside, hanging on that space frame.

This space frame bay needs to attach to "something", which "something" also has the fittings to hang onto the vehicle being serviced, and also other fittings to provide a "footing" for the crew doing the servicing. Visibility is not an issue with the lighting. Temperatures are also not an issue, with the space frame covered, so that neither the sun nor deep space can be seen. Workpiece temperatures are controlled by the power of the lighting. It is a radiational balance thing.

If the servicing crew were using MCP suits, they could be far more effective, especially if these suits were of the vacuum-protective underwear type that were shown feasible back in the 1960's by Dr. Webb. Inside the temperature-controlled bay, there is little need for heavy insulating garments. It is even possible to doff the gloves and do very delicate fine work barehanded, for up to about half an hour at a time.

My first notion of this concept, without the protected bay, was posted on my "exrocketman" blog site 2 August 2011, as "End of an Era Need Not Be End of a Capability". I updated this with the enclosed, lighted bay (unpressurized) in an "exrocketman" article 11 February 2014, as "On Orbit Repair and Assembly Facility".

GW

Last edited by GW Johnson (2024-07-04 09:04:50)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#43 2024-07-04 08:58:03

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 29,932

Re: Shipyard?

Cut the wings nose and tail off and dock it to the station

Make the diameter larger as we need to....

One could adapt the starship since its quite large and would once docked not return.

This would also create a fuel depot as well.

Offline

Like button can go here