New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#151 2024-06-30 10:03:41

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

Estimating the Total Cost of Compressed Air

At $0.25/1,000ft^3 or 28.3168m^3, filling up the 253L tank with 177.1m^3 of compressed air would cost $1.56.

If the car only has a range of 100 miles, then driving 15,000 miles per year costs $234.00.

At 250Wh/mile for the Tesla Model 3 and an electricity cost of $0.13/kWh, 15,000 miles, or 3,750kWh worth of electricity, costs $487.50.

If that same electricity to run the air compressor costs $0.13/kWh, then filling up the air tank costs $0.813, so 15,000 miles costs $121.96 per year.

I guess how much everyone else wants to spend to fill up their car is up to them, but I'm going to go with $121.96 per year, because money is still money.

When you make a car much cheaper to purchase, drive down the road, and maintain, you don't have to worry about selling them. They do that all on their own. You don't need to convince anyone of anything. Money talks. If the air tank lasts for 21,000 cycles, which is about where Type IV compressed H2 storage tank technology was 10 years ago, that represents enough driving to drive to the moon and back 4 times. At 25,000 pressure cycles, you can drive to the moon and back 5 times. The cost of driving to the moon and back 5 times on compressed air is $20,325, which happens to be about the same cost as the battery for a Tesla. Since the price of one of those Type IV tanks is about $5,000, I consider that a bargain.

COMPOSITE 700 BAR-VESSEL FOR ON-BOARD COMPRESSED GASEOUS HYDROGEN STORAGE

Based upon the Type IV 37L water capacity 700bar H2 storage tank figures from Page 8 of that report, the tank survived 15,000 pressure cycles from 20bar to 875bar, with the pressure cycling taking place at the incredible rate of 1 cycle per minute. If 100,000 tanks per year were produced, then the estimated cost of each tank would be $650. 7 of those tanks would be required to provide 253L of storage capacity, and would weigh 196kg. This is very close in total weight to the 182kg 253L Type IV tank that US DoE tested during the past 2 years, so the tanks are getting lighter as fiber technology improves, and you do get a reduction in total tank mass by using a singular larger storage tank, that's to the cube-square law. Total cost for all 7 of the 37L would be $4,550. Fabricating a single larger tank will save money because less material is used, less wear and tear on the tooling, fewer tank fittings such as regulator valves are required, etc.

Offline

Like button can go here

#152 2024-06-30 10:04:26

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

questioning why we have not developed such a vehicle

For kbd512 re Post #369

Thanks for continuing to develop a concept for a transportation option that uses compressed air.

The United States may not be an ideal market for a business venture to make, sell and to maintain a fleet of these vehicles, simply because of inertia of the established industries in this field. However, there are numerous other potential market opportunities.

There may be entrepreneurs who would be willing to make the massive investment your proposal requires, based upon the strength of your arguments in favor of this technology. Such entrepreneurs would (presumably) be looking for leadership qualities that would give them confidence the investment would be carried through to a successful outcome.

My understanding is that the compressed air vehicle is well understood, but that the technology has not yet succeeded in gaining significant market share. It seems to me that enlisting someone who specializes in marketing would make sense, to round out a vision of what seems like an attractive option. The potential market may exist in Africa, for example, where the population is younger than is true in other regions.

(th)

Offline

Like button can go here

#153 2024-06-30 10:05:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

Details

Let's use a real-world example. Since those tanks from the link in my prior post were being charged to 875bar and discharged to 20bar, let's assert that we can charge our 253L tank to 850bar using the latest fiber and resin matrix technology with a CNT additive to improve inter-laminar sheer strength. The goal here is not to make the storage tank any lighter, it's to make it seriously strong and thus better able to resist many thousands of pressure cycles, for ultimate durability / longevity in operation. I will assert that the tank and fittings will weigh about 200kg, and store 215m^3 of air, which would weigh about 277kg if it was completely dry. With 10% moisture, we're looking at 305kg. That leaves 495kg for the rest of the car (chassis, suspension, wheels, tires, brakes, cabin, air motors, flywheel energy storage system, electrical system, etc). Using fiber filled plastics or composites for the chassis, that should be doable.

Deprag makes an air tool equipped with a 4.5kW / 6hp air motor. It's a grinder, but the entire tool weighs 4.2kg. The air motor is only half of that, but 2kg vs 4.2kg makes little difference to the performance of the car.

At max output, or "fully loaded" as DePrag describes it, this turbine consumes 117cfm / of air and the tool speed is 6,400rpm. The free turbine speed likely falls somewhere between 60,000rpm and 120,00rpm. Idling, the air consumption rate is 42.4cfm.

In our example 1,000kg air powered car, we require 1.1627hp or 867W of power to maintain 75mph. That is "typical highway speed" here in Houston, whether the speed limit says 60mph or not. That's about 20% of the turbine's maximum output, so I will guess that's also 56% of max airflow rate based upon idle air consumption to keep the turbine spinning, or 1.855m^3 per minute. At that flow rate, our air supply will last about 95 minutes. That means our max range at 75mph is about 118.75 miles. If I'm 20% off of what the actual is, then range may only be 95 miles at 75mph. Either way, we should have enough power to maintain 75mph, if required. Most driving in Houston or Los Angeles happens at walking speed during rush hour, with 60mph being about as fast as you can drive at any point in time along any of the major freeways during rush hour. That said, "weekend speed" with light traffic will be 75mph, so that's how fast an air powered car must go to merely keep up with traffic.

Whilst cruising along a perfectly flat stretch of highway using minimal air motor power is all well and good, with only 12hp on tap from a pair of air motors, our acceleration rate would pose a danger to ourselves and others, if the vehicle's acceleration rate was limited by such pint-sized powerplants. We really need a flywheel to store the required power. The total energy consumed by an acceleration rate of 0-60 in 6 seconds is rather small, about 107Wh. However, the release rate would either require a much larger and more powerful air turbine (about 64kW) that also consumes far more air, and would thus be far more expensive to build, or we need an energy storage mechanism to convert turbine power into stored kinetic energy. Flywheels are capable of transferring enormous amounts of power over very brief periods of time.

A 10kg flywheel with a 10cm radius, spun up to 60,000rpm, about the same as what I would guess the free turbine speed is, it would store about 548Wh worth of rotational energy. That is more than enough power to accelerate to 75mph from a dead stop, and likely twice as large as it really needs to be, so significant weight and cost savings are available for trade studies. It could easily beat the Tesla Model S Plaid's 0-60 time if the flywheel was capable of transferring all that power in 2 seconds or less. I think the tires and vehicle weight will rapidly become limiting factors, though. Regardless, an air powered could still be a fun vehicle to drive, even with a "measly" 12hp.

The overriding point is that a pair of 6hp turbines for cruising and light acceleration, which are effectively tiny 2kg air tool motors, backed up by a flywheel, would provide the best overall vehicle performance under real world driving conditions, at the lowest total weight. I would estimate about 35kg for the entire powerplant (pair of power turbines, flywheel energy storage system, and transmission or direct drive to the powered axle.

Offline

Like button can go here

#154 2024-06-30 10:06:27

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

Design proposal

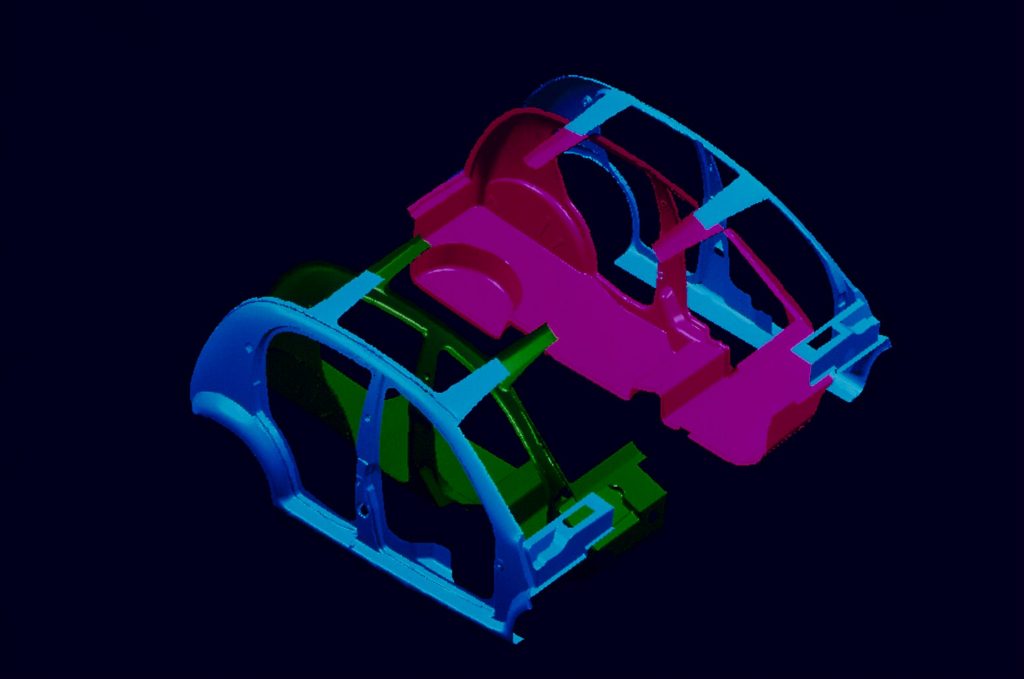

The Chrysler CCV is the correct general concept, but we're going to make changes to use air power, improve aerodynamics, and improve crash safety rating for driving on American roads.

Chrysler CCV Dimensions

Length: 144.1in

Width: 64.6in

Height: 63in

Curb Weight (w/o driver): 1,199lbs70 Gallon Air Tank Dimensions

Length: 44in

Diameter: 23inThe air powered car will be twice as heavy as the CCV, but about the same size, and approximately equal in weight to the Chevy Spark.

The critical design changes include where to mount that rather large and heavy 500kg air tank, attaching the suspension system to the chassis, rather than body-on-frame design of the CCV, and whether or not to use conventional doors or large front and rear opening hatches. I suspect we'll end up with a conventional design, although the usual assortment of equipment present under the hood of a Chevy Spark will be entirely absent from an air powered car, so the possibility of substantially reinforcing the sides with front and rear entry vs conventional car doors, remains an interesting possibility. That layout is similar to the front and rear hatches of the AirPod air powered car design.

The body requires fiber reinforcement at the 1,000kg weight class. We could use a renewable natural fiber like flax, so a FFRP composite. Our strength would improve to the level of a high grade glass fiber, with the ability to flex and absorb vibration to a much greater degree than GFRP or CFRP, without the nasty tendency to produce razor-sharp "chips" of composite materials in a crash- the crash residue is more like chips of fiberboard. Hemp or cotton flox would provide secondary reinforcement where parts are bonded together.

The air tank would be centrally mounted between the front and rear of the passenger compartment, acting as a substantive B-Pillar reinforcement (integrated into the chassis), while effectively distributing the weight of the heaviest vehicle component between both axles.

The vehicle's aero characteristics need to be improved over the Chrysler CCV (Cd unknown, but likely little better than the VW Bug) and Chevy Spark (Cd of 0.325 to 0.326).

Offline

Like button can go here

#155 2024-06-30 10:07:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

energy efficiency

These are the basic stats on US annual fuel consumption:

137,240,000,000 gallons of finished motor gasoline consumed in the US during 2023.

56,261,100,000 gallons of distillate fuels consumed in the US during 2023.

3,200,000,000,000 total miles driven by all US drivers per year.Now Let's consider the energy required to "charge" air powered cars that weigh about 1,000kg:

85,000kPa = 850bar

100kPa = 1bar (sea level atmospheric pressure)

3,600J / 3.6kJ = 1WhkJ = (P2 - P1) * V

kiloJoules = (Final Pressure in kPa - Initial Pressure in kPa) * Volume (in m^3)

kJ = (85000kPa - 100kPa) * 0.253 = 21,479.7kJ = 5,967WhWe'll assert that our compression process is about 80% efficient. Some compressors might be more or less efficient, but 80% is a good value to use for industrial scale air compressors. That implies actual compression energy is about 7,458Wh. That amount of energy provides about 100 miles of driving range for our air powered car.

32,000,000,000 * 7,458Wh = 238,656,000,000,000Wh = 238.656TWh

Constant power output of about 27,243,835,616Wh is required. This is equal to the output of 27 1GWe nuclear reactors. Spread across all 50 states, about 545MW, which is equal to the output from two large commercial electric power gas turbines.

However, we want to do this without consuming hydrocarbon or nuclear fuels or specialty metals, so we won't be converting any of that solar thermal power into hydrocarbon fuels or electricity. President Biden's administration blocked environmental permits for proposed new Copper and Lithium mines here in the US, so they clearly don't want EVs, either. Maybe someone in his administration finally figured out how much worse EVs are for the environment compared to burning oil. At the same time, Democrats block all new nuclear reactor permits, and see it as their duty to ensure that no new reactors are built. In conjunction with President Biden's continuation of the trade war tariffs with China, that's driven a stake through the heart of photovoltaics, wind turbines, and battery production expansion attempts. They're being taxed, tariffed, or otherwise regulated out of existence. We're essentially left with nothing, and unsurprisingly, we're not happy.

In an earnest attempt to both skirt around Democrats' apparent unwillingness to do anything constructive to reduce hydrocarbon fuel energy reliance, while actually addressing a minor aspect of climate change in a cost-effective way, I'm proposing using solar thermal power to compress air so we have workable and affordable energy to use to power our vehicles. I would think that this solution is the most environmentally benign of all options presented. It requires far less specialty metals input from Russia or China, unlike EVs. It's the option with the longest service life and lowest total cost of ownership. It's a poor man's solution to a rich man's silly game. The new "fuel" (compressed air) will be taxed to pay for the roads and bridges, since our haughty EV owners don't contribute anything to their upkeep.

Solar thermal requires quite a bit of steel and some Aluminum coating material to reflect and thermalize photons, as well as salt to store thermal power at night to continue production at a reduced rate. My materials of choice are steel, concrete, salt, air, and water in a closed loop subsystem for waste heat recovery from air compression, for purposes of additional mechanical power generation to improve overall air compression efficiency. Maybe we can improve overall energy utilization efficiency during compression to about 85%. Alternatively, we could supply flash-evaporated fresh water.

If our drivers had an affordable alternative to a gasoline powered vehicle for their daily commutes, then the US could potentially reduce our annual gasoline consumption by about 95%. We'll still need gasoline for light aircraft, power tools, and some off-road uses, but the quantity consumed will plummet. Providing a cheaper alternative to gasoline is the only viable way to end our reliance on it. Price sells cars and energy. EVs don't sell because they're too expensive for what they provide to most owners- a commuter type vehicle.

At 33,700Wh per gallon, we consume 4,624,988,000,000,000Wh worth of gasoline per year. That's about 19.38X more energy than compressing enough air to charge the tanks of air powered cars. This is not to suggest that the energy was used inefficiently, because the total weight being moved was not reflected in the top line energy consumption figures, merely that a light vehicle powered by air would consume a lot less energy.

At 250Wh/mile, if every vehicle on the road was a Tesla Model 3, then we need to supply 800,000,000,000,000Wh of electricity for our drivers to cover 3.2 trillion miles. That's about 3.35 times more energy than 1,000kg air powered cars would require. All their electrical and electronic gadgetry eats up a lot of power, and battery operated vehicles are almost twice as heavy, which is part of why they cost more and consume more energy. Heavy vehicles require more energy to operate, period. This also suggests that air powered vehicles could be made twice as heavy while still consuming no more energy than EVs. Air powered cars can't beat EVs on range or acceleration, but across every other metric EVs are toast, even before they self-immolate.

Offline

Like button can go here

#156 2024-06-30 10:08:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,173

Re: Running on Compressed Air?

tahanson43206,

If you're willing to "reserve" 3m^3 out of 215.05m^3 as unusable tank capacity, to allow you to operate the air turbines at 180psi vs 90psi, then your air consumption rate is cut in half.

58.5cfm / 4.5kW = 13cfm/kW

13cfm * 60 minutes = 780ft^3 per kWh

212m^3 / 22.0871m^3 per kWh = 9.598kWh

Edit:

505.15595kg / 9.598kWh = 52.631kg/kWh <- Substantially lower than the Lithium-ion battery pack on its own, in order to achieve 25,000 duty cycles before unacceptable degradation occurs for either the compressed air tank or the Lithium-ion battery packYour air turbine(s) might benefit from 1 or 2 additional expansion turbine blade-disks / "blisks" to extract more energy from air expansion, but you get 39% more energy to work with by regulating air pressure at 180psi (12.4bar) vs 90psi (6.2bar). There's obviously a practical limit as to how high you can go, and higher pressure equals more noise, but there are various commercial air tools which consume higher-psi air.

This would negate or offset any advantage Lithium-ion batteries provide, in terms of weight, if both technologies are expected to provide 25,000 duty cycles before they have to be taken out of service and replaced with new equipment.

Edit #2:

If you doubled the regulated / operating air pressure again, to 360psi, then you give up 6.28m^3 of tank capacity (the volume and weight of air in your storage tank which would be below your regulated air pressure), but your air consumption rate is cut in half again. Your tank's service life benefits from a less extreme pressure cycling as well.215.05m^3 (at 850bar) - 6.28m^3 ("lost" to operating at 360psi / 24.8211 = 208.77m^3

6.5cfm * 60 minutes = 390ft^3 per kWh

208.77m^3 / 11.0436m^3 per kWh = 18.834kWh

505.15595kg / 18.834kWh = 26.821kg/kWhOur compressed air's gravimetric energy density, relative to a Lithium-ion battery capable of surviving for 25,000 duty cycles, is now more than twice as good. At this point, we would definitely require a bespoke air expansion turbine design with more stages. Let's say our lighter air powered car requires 150Wh per mile, and we're no longer going to bother with the additional complication of a flywheel to conserve energy.

18,834Wh / 160Wh per mile = 117.7125 miles of driving range

If power was directly proportional to weight, then it should require 139Wh per mile, but I presume some inefficiency of air vs electricity.

Anyway... I hope this makes sense to you.

Offline

Like button can go here