New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#51 2024-06-11 12:35:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,469

Re: Vertical Launch Assist Technologies for SSTO

Drilling a 10m diameter bore hole 900m deep is not a major problem. Most of the top section drill bits top out around 26ft in diameter or so, although I think I recall seeing a few 42ft diameter top sections. Hitting 900m can be accomplished in a matter of days using water-based drilling fluid. I think the top sections I've seen were normally about 1/3 to 1/2 as deep, but drilling further down could be done. It's not terribly expensive, but certainly not cheap. Perhaps $2M at most, although a specialty diameter drill bit could easily cost another $1M on its own. Downhole tools are pricey. The main problems will be keeping water out of that hole and reinforcing the hole with enough concrete and steel to prevent collapse. That might cost another $2M to $3M. Ordinarily, the hole is always filled with drilling fluid or oil and gas, so that the Earth doesn't do that part for you. This part of your project is all perfectly doable. Maintaining it will be a serious pain in the rear.

The practical aspects of keeping the shaft perfectly straight, thus the gun operational, are what will dominate costs. Long sections of steel tubing are very flexible, and behave more like wet noodles than the stiff and strong material we're so accustomed to using in much smaller volumetric cross-sections. A gun barrel that long has to be supported by something (the cased bore hole / shaft), so its external support structure must be quite stiff and strong, and not appreciably warp from the thermal loads, either. Anyway, with a good crew using top notch equipment, drilling activities should take no more than a week or so, probably a week to drill and another week to case it with concrete and steel. I would budget 4 weeks because this is bespoke work with some potential site-specific challenges. It might take a year or two to get on the drilling schedule, a month of admin and logistical prep work, and a couple weeks of onsite activities if no surprises are encountered. Now that I think about this, you'll need onsite spiral-welded steel pipe, because nobody "makes" a pipe of that diameter using any other method. Sheets or plates of steel are rolled around a mandrel and seam-welded to produce this sort of pipe. I would love to know how the gun barrel is being formed. Are we using any of the traditional methods for making battleship guns? There are steel rings of that diameter forged for things like cranes and wind turbines, but a gun barrel? No such animal. I've never seen anything that size, nor close to it, which means this will be incredibly expensive bespoke work likely requiring custom fabrication facilities built specifically for this work. The largest gun barrels ever devised were about 1m in diameter and 150m or so in length. This is an order of magnitude scale-up. I don't doubt it could be done, but not cheaply or quickly. A lot of testing and tweaking will be required for reliability.

The other significant issue, at least as I see it, is that the launch vehicle requires an air-breathing propulsion system in order to reduce the volume of oxidizer carried aboard the vehicle. Some sort of delegation of development work will be required. One company prepares and constructs the launch site, another constructs the gun, and yet another designs and builds an air-breathing aerospace vehicle so that the number of specialties required is not so great.

If this concept is willing to use 10g launches, much more practical for small satellites and "dumb" cargo such as materials than with humans, as the Pegasus air-dropped launch vehicle already does (acceleration rates for these small satellite launchers are quite high, similar to ICBMs), then it's plausible to ignite a scramjet and achieve greater vehicle acceleration within the Earth's upper atmosphere, switching to pure rocket propulsion only for the final push into orbit.

At 10m diameter, I would think a water brake could be built into the sabot design, with the sabot impacting a muzzle ring and then very rapidly coming to a halt without destroying anything, but this will add significant weight which must be accelerated. One other aspect of a sabot containing water acting as a hydraulic buffer mechanism is its ability to buffer the peak force and heating imparted to the vehicle during initial acceleration. I'm actually thinking about the hi-low pressure propulsion system used by our M79 and M203 grenade launchers, where a smaller combustion chamber operating at very high pressure expels high pressure gas into a much larger chamber where it accelerates the grenade down the barrel of the launcher in a way that makes a thin-bodied grenade (a miniature aerospace vehicle) able to survive what it otherwise could not.

Come to think of it, if you're going to a 10m bore diameter, then why not build a rocket engine into the sabot?

A LOX/LH2 rocket engine could produce plenty of crazy hot steam in a real big hurry, as well as controlling the rate of expansion. The bore might require a thermal protection coating and perhaps a water cooling jacket, but I bet the bore hole could provide that.

We can look at how the HARP cannon was designed and constructed as a "guide" of sorts for how a very long barrel cannon could be built into a "oilfield bore hole" providing external barrel support. Gun design is going to be a serious challenge, to say the least. It cannot be built as a monolithic barrel. The sleeves used to fabricate battleship cannons are how it will need to be built, although I do wonder if we could fabricate the barrel from seam-welded tubing. HARP used two or three sections of 16 inch gun barrels of the kind used by our battleships, butt-welded together, with external truss stiffeners added to provide the necessary stiffness, and that external structure was "tweaked" by tightening down the eyebolts, to "keep it perfectly straight", despite the barrel droop associated with such a long barrel.

I'm not sure who would "know" how to do something like this, because apart from HARP, the Paris Gun, and the Baghdad gun, it hasn't been tried very often. The Paris gun was built into the side of a mountain. The Baghdad gun was never completed. HARP fired some suborbital shots, but was never scaled-up. You need a metallurgist, a team skilled in precision machining of large steel forgings, superb fixturing / alignment tools, top shelf electron beam or laser welding equipment to fabricate the barrel, thermal-hydraulic analyses to ensure stresses don't warp the barrel unacceptably, a geophysicist to select an ideal launch site with very limited subsurface movement, preferably with solid granite all the way down, and probably a bunch of other very important things I haven't even thought of.

This is a very interesting design problem, though.

Offline

Like button can go here

#52 2024-06-11 17:58:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Vertical Launch Assist Technologies for SSTO

Well, a word a day makes you more knowledgeable and the word was "sabot" which I did not really have a clue to.

https://en.wikipedia.org/wiki/Sabot_(firearms)

So we give the rocket a ride and need at minimum 1/2 more to slow the carrier Sabot assembly

One assumes that the last second of the ride the rockets engines must ignite to power the rocket once the end is reached. I am thinking that the rockets plume will push the Sabot away from the rocket if drive power is removed and that will cause it to fall back ready for use once more.

Using the Emal or a linear inductive drive would when power applied give launch control to stop of slow if in the 5 seconds from applying the Sabot it must terminate launch.

Leading wheels would glide against the wall once it opens to keep it from biting into the vertical shaft assist tunnel.

One might also assume that escape tower or the crewed dragon style boost could be part of the abort.

Offline

Like button can go here

#53 2024-06-11 23:21:27

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,293

Re: Vertical Launch Assist Technologies for SSTO

Kbd512, Spacenut, both interesting post with a lot to think about. I will read into big gun manufacture and see what I can find.

Re TH the question of minimum speed needed to operate a ramjet.

https://en.m.wikipedia.org/wiki/Ramjet# … nd_control

Although ramjets have been run as slow as 45 metres per second (160 km/h; 100 mph),[19] below about Mach 0.5 (170 m/s; 610 km/h; 380 mph) they give little thrust and are highly inefficient due to their low pressure ratios.

A 170m/s muzzle velocity could be achieved with a barrel length of 295m, with a 5g acceleration. So a 1km long barrel and a 300m/s muzzle velocity would appear to allow ramjets to produce thrust. Whether thrust will be great enough for a vehicle to lift its own weight in Earth's gravity, I cannot say.

The ramjet differs from the jet engine in the use of a static compressor, that relies upon the dynamic pressure of the incoming air stream to create the static pressure needed in the combustion chamber. The higher the static pressure, the higher the thrust. Static pressure scales with the square of air velocity. Unlike jet engines, ramjets have zero bypass, so propulsive efficiency is also poor at lower speeds.

Last edited by Calliban (2024-06-11 23:39:51)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#54 2024-06-12 06:31:25

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

For Calliban re #53

Thank you for considering kbd512's idea of incorporating a ram jet into a design for a vehicle that would receive vertical launch assist.

Your citation and observations suggest a hybrid approach might have merit.

The vehicle kbd512 is describing (as I understand it) would contain both air breathing (ram jet presumed) and rocket components for thrust.

The ram jet component would (I gather) become efficient when velocity reaches some minimal value, and while the atmosphere remains dense enough to support combustion. This would be an interesting design challenge, and computer control of the operations of both components would be essential.

However, taking into the account that the goal is to find a solution to launch a reusable vehicle that can carry useful amounts of mass to LEO, we might imagine a combination of technologies that allow for the possibility of success.

Let us imagine (for a moment) that we want to deliver a ton of propellant to LEO to resupply GW's Orbital Fuel Depot.

The orbital plane of the depot crosses McGregor, Texas twice a day. That location implies an orbital plane with an orientation that allows flight between Cuba and Florida over the open sea between those two populated areas.

Happily, that orbital plane crosses every point on Earth twice a day, so many locations can host launch facilities for resupply of the Depot.

As GW has described the resupply operation, the supply vehicle would approach the Depot on it's own, but an orbital tug would be assigned to retrieve any supply vehicles that failed to achieve 100% of the flight goals. In any case, we will assume for this post that one ton is to be delivered to the Depot twice a day from a given launch facility.

That requirement drives design of the launch assist facility and the vehicles to be launched.

We will assume a winged vehicle (such as a lifting body, or the US X-37 (or the Chinese equivalent)) and the payload is a ton of propellant.

This assumption drives the decision to mount the vehicle on a hook that is attached to a frame that itself is about 1 kilometer long, and which descends into the launch tube ahead of the launch. That frame would have a cylindrical configuration but it would be as light as possitle, taking into consideration it's mission to boost the flight package at 5 G's for about 7 seconds.

Here is the aspect of the design that I am hoping you (Calliban) will find interesting to evaluate: The sleeve of the launch tube would be made of the same material as SpaceX is using for it's Starship vehicles. That sleeve would be inclosed in concrete. The sleeve is 1 kilometer long, and it descends vertically from the surface to the propellant feed station at the bottom.

The question I have (and cannot possibly answer on my own) is whether the enormous pressures needed can be withstood by a sleeve of this type, for the time needed for each launch, twice a day?

***

Turning to the vehicle .... I am considering kbd512's suggestion of a hybrid design that uses ram jet where that makes sense, and rocket propulsion otherwise. The vehicle needs to able to maneuver in orbit to catch up with the Depot, and to deliver it's payload, although facilities on the Depot may be better able to perform unloading operations.

After delivery, the vehicle would be released to return to Earth on it's own, under the direction of Earth based control room operators.

The vehicle needs to begin it's descent at a time that is optimum to allow it to fly back to a landing field near the launch site.

An option is to return to any of the many launch facilities that will be created if this vision comes to pass.

The vehicle needs a bit of rocket fuel left over to perform the retrograde burn, and conceivably it might benefit from having a bit of fuel for the ram jet if that makes sense for a particular return flight path. In general, the vehicle would perform a dead stick landing, similar to the Space Shuttle or the X-37.

(th)

Offline

Like button can go here

#55 2024-06-12 15:06:17

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,469

Re: Vertical Launch Assist Technologies for SSTO

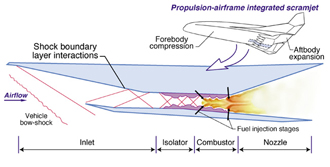

I was thinking more along the lines of, the gun accelerates the vehicle to 481m/s at 10g, a rocket engine briefly takes over to push the vehicle into the upper atmosphere and accelerate, the rocket engine shuts down as velocity approaches Mach 2.5, the ramjet / scramjet accelerates the vehicle to Mach 10 where the ram becomes ineffective / too hot / air too thin to operate anyway, and then the rocket engine relights, pushing the vehicle into orbit, shuts down again, and then briefly relights again to circularize the orbit.

1. gun acceleration (dead stop to Mach 1.4)

2. rocket (Mach 1.4 to Mach 2.5) continues the push through the lower atmosphere and initiates the gravity turn

3. ramjet / scramjet (Mach 2.5 to Mach 10) accelerates as much as it can before the rocket takes over once again

4. rocket (Mach 10 to Mach 25)

5. rocket (orbit circularization)

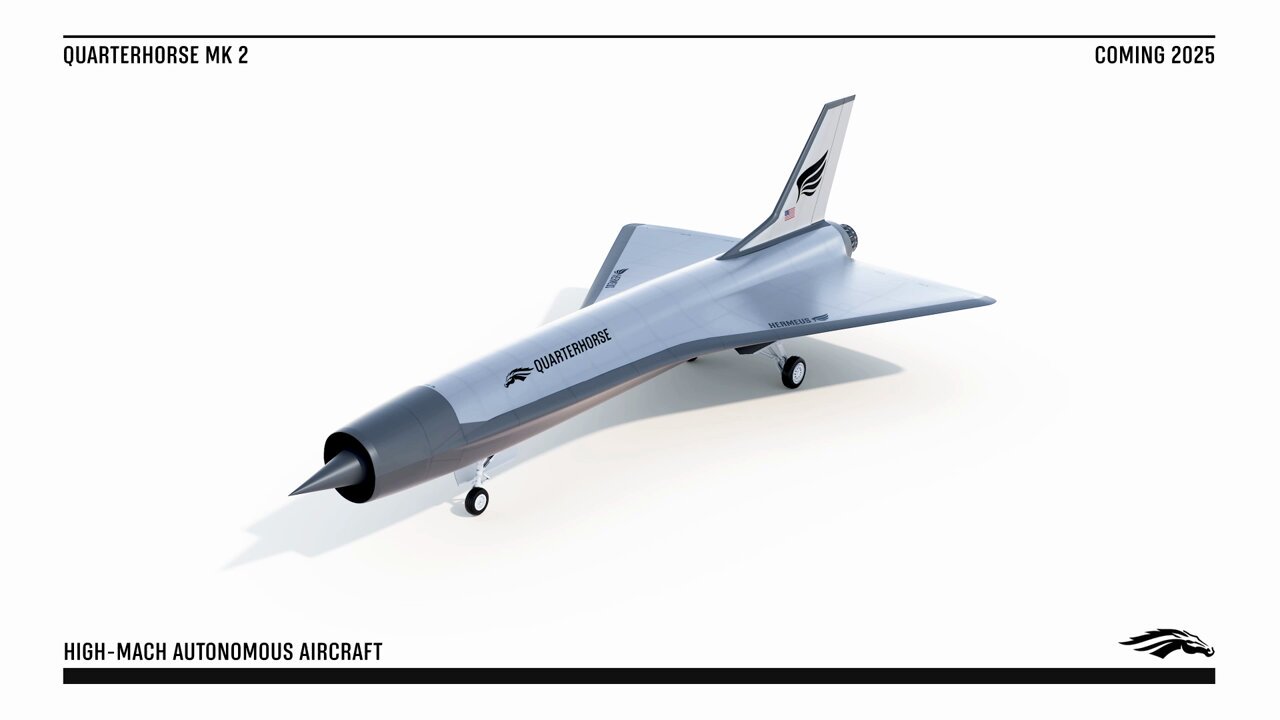

Lockheed-Martin and Northrop-Grumman seem to have figured out 0 to Mach 10 using combined cycle gas turbine engines and scramjets. There's a vehicle Hermeus developed called "The Quarterhorse" that combines gas turbine and ramjet propulsion using the General Electric J85 from the F-5 fighter jet, but the company says they can convert any fighter jet (low bypass) gas turbine engine to a combined-cycle engine. These are "ordinary" fighter jet sized aircraft, though, never designed to survive 10g accelerations, so far as I know. They're hypersonic spy drone prototypes. By my count, there's about a half dozen different companies working on 0 to Mach 10, starting from a runway on a military air base. Some are air-dropped from other aircraft like StratoLaunch, while others, like Quarterhorse, actually start on the runway and accelerate to Mach 7 or so on their own. Quarterhorse looks similar to the Lockheed D-21 drone that the SR-71 launched.

Offline

Like button can go here

#56 2024-06-12 15:21:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,469

Re: Vertical Launch Assist Technologies for SSTO

Lockheed D-21 Spy Drone:

Hermeus Quarterhorse Mk I Prototype:

Hermeus Quarterhorse Mk II Prototype Artwork:

Hermeus Quarterhorse Mk III Prototype:

Edit:

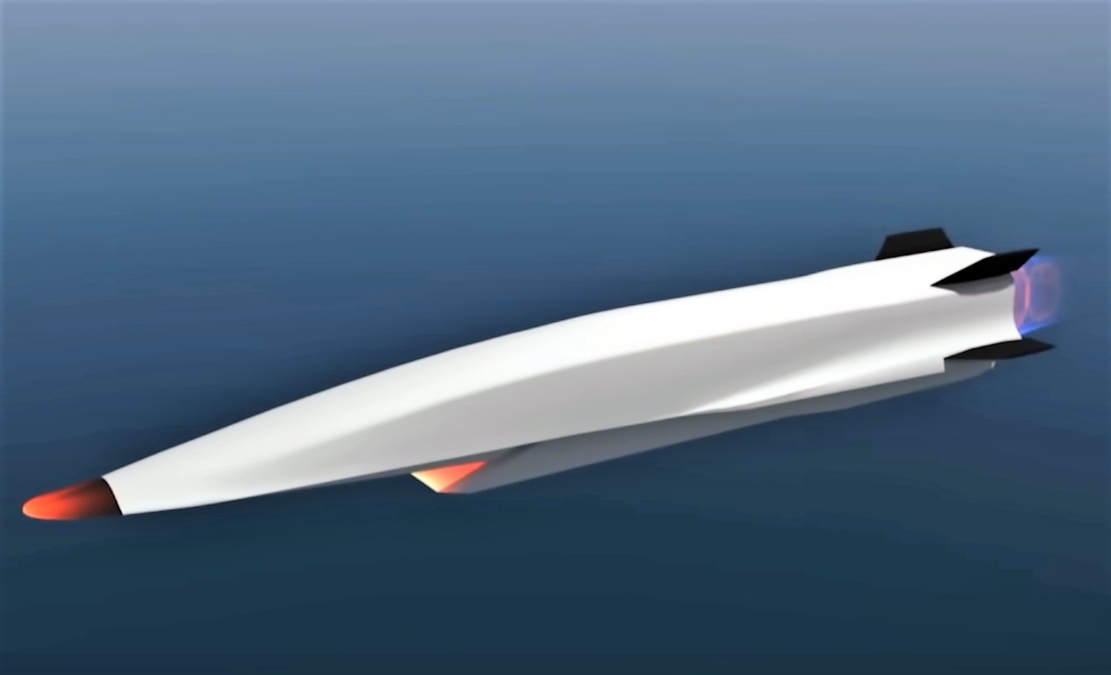

I expect the projectile / vehicle for this gun launcher to looks something like this (with modestly larger wings):

Edit #2:

Some more feasible concepts shown below:

Edit #3:

Russian 3M22 Zircon Cruise Missile (clocked at Mach 7, supposedly Mach 9 capable):

Edit #4:

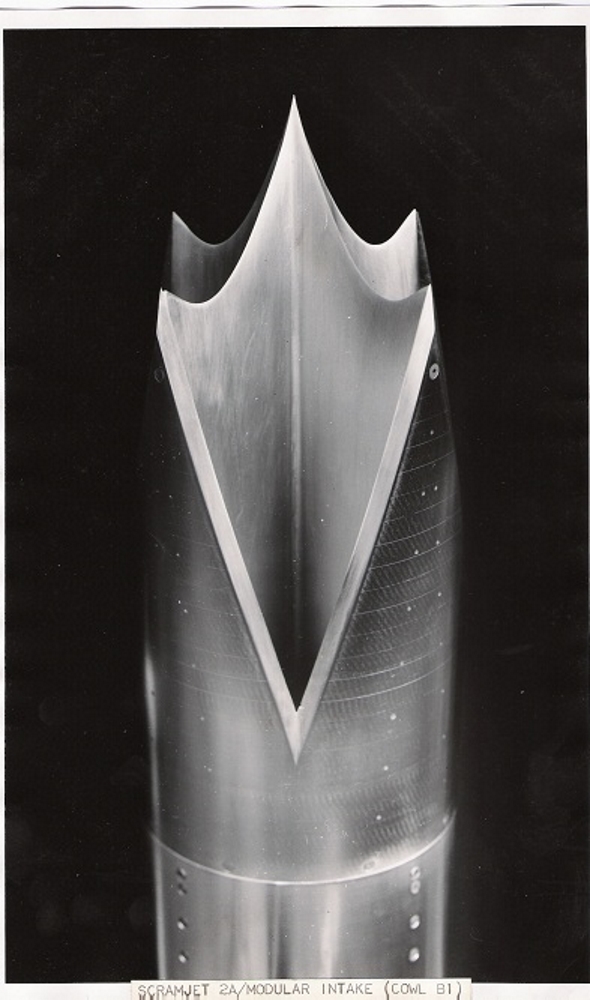

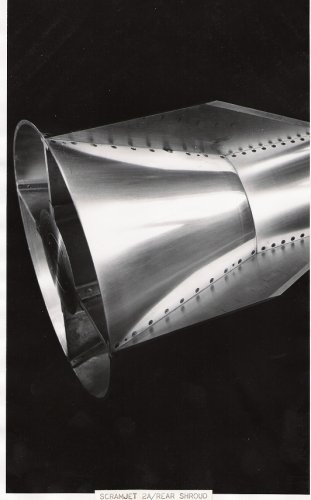

Scramjet powered Martlet-II HARP gun projectile design:

Martlet-II with sabot petals laying on the ground in front of it:

Last edited by kbd512 (2024-06-12 15:45:32)

Offline

Like button can go here

#57 2024-06-12 15:57:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,469

Re: Vertical Launch Assist Technologies for SSTO

This is an illustration of the HARP gun (you can see the external barrel adjustment / straightening apparatus I spoke of earlier):

High Resolution Image of the HARP cannon (open in a new tab and expand to see it 1:1 scale):

BRL Report #1327, July, 1966:

REVIEW OF THE HIGH ALTITUDE RESEARCH PROGRAM (HARP) - US Army Ballistics Research Laboratories, Aberdeen Proving Ground, MA

Offline

Like button can go here

#58 2024-06-12 19:17:59

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,469

Re: Vertical Launch Assist Technologies for SSTO

From the technical reports, the gun launcher provided an initial dV increment of 5,200fps / 1.585km/s.

Martlet-IV projectiles had a gross mass of 2,800lbs. Our dV requirement is about 7.9km/s. The gravity loss is dramatically reduced by the very high initial velocity. Suppose we had a small staged combustion engine, mostly 3D printed, with a 338s Isp. The payload is 250lbs.

The payload mass fraction is 8.93%. No TSTO has a mass fraction that high.

Suppose a light gas gun could manage 7,000fps / 2.134km/s. HARP produced velocities that high using ordinary 1960s solid propellants. Now we only have to supply 7.366km/s. Our payload mass jumps to 300lbs with the same 338s Isp engine. Our payload is 1.71% of our total liftoff mass.

Can a metal rocket, which is the payload itself, intended to be collected in-orbit and melted down to construct the large ship, have a dry mass fraction of 10.71%, and still hold together for the launch?

Martlet-IV's first stage produced 47.4kN of thrust, so a 200:1 TWR LOX/RP1 SC engine should weigh 53.28lbs.

If at all possible, we want a high-grade maraging steel that is high-strength to survive the launch, and able to be transformed back into that same high-strength alloy after subsequent collection in orbit. 1,134kg of propellant traded is traded for 136kg of high grade steel delivered to orbit. We need 36,765 gun launched projectiles to build RobertDyck's large ship concept, and will expend 41,691,510kg of propellant in the process, which includes 15,327,761kg of RP1. That is approximately equal to the same total volume of RP1 in 24 Saturn V first stages.

If the Saturn V could put 150t into orbit, then we'd need 34 flights for about the total tonnage delivered. This system therefore saves 10 Saturn V class flights for the same tonnage delivered. S-IC had 2,150,000kg of LOX/RP1, while S-II had 443,000kg of LOX/LH2, so 2,593,000kg in total, and 34 flights requires 88,162,000kg of propellants. Starship 3 would required 25 flights, and Starship would require 158,750,000kg of propellants, to include 44,097,222kg of LCH4. We're twice as economical, in terms of rocket propellant burn, as a Saturn V. We're dramatically more efficient than Starship.

What about a Falcon 9 Heavy, though?

1,232,700kg for the first stage of Falcon Heavy, plus 107,500kg of propellant for the second stage, or 1,340,200kg in total. We'd need 94 flights with full reusability, so 125,978,800kg of propellants in total.

No accounting is complete without consideration of the gun propellants. Propellants cost money, period, and we need 444.521kg of gun propellant for the 16 inch gun, or 16,342,816kg in total for 36,765 flights. All told, 58,034,326kg of propellants of all types for all 36,765 flights to deliver our 5,000t of steel to orbit.

That is comfortably below what non-reusable Saturn Vs would require, so I think we have a winner for launching the metal to build the interplanetary colonization ship, so long as the entire vehicle can be constructed from a high-strength steel such as C350 or AerMet 100.

AerMet 100 (250ksi YS) is $25/lb in any quantity you want, according to Carpenter Technologies. I wonder if we could get a discount for bulk purchases, because otherwise that's about $276M worth of steel. C350 (350ksi) maraging steel is nowhere near as expensive, but AerMet 100 has great low temperature notch strength and corrosion resistance. Eglin ES-1 (194ksi) is also good stuff, but requires Tungsten. USAF-96 (194ksi) has no Tungsten, good but not great low-temp notch strength, and is ladle-refined like ES-1. AerMet 100 is VIM/VAR, hence its breathtaking price. C350 or USAF-96 is about $5M worth of steel. ES-1 is expensive due to its Tungsten content, but nowhere near the price of AerMet 100. I think we go with USAF-96 because it can be water quenched. C350 would require special reprocessing steps whereas USAF-96 is not as fussy to work with.

The real question is, what costs less?

A. Military grade denatured Hexogen explosive propellant to give us our 7,000fps (pricey)

or

B. Gaseous O2 / H2 (cheap)

or

C. Enhanced stick propellant used in tank cannon rounds and electro-thermal ignition for consistent performance (somewhere between H2 and Hexogen)

O2 / H2 is bound to cause some barrel embrittlement and corrosion. How many shots can we get?

Hexogen is big money but burns very clean. Almost nothing is left in the bore and it's easy to clean.

O2 / H2 is the cheapest by far, but barrel life will suffer, maybe only a little, or maybe a lot. The barrel represents far more money than the silly propellant, even using Hexogen.

Enhanced stick is not exactly cheap, but it's current military / US Army propellant tech and it shouldn't break the bank.

Barrel life for the Iowa class using WWII gun barrel liners was 1,500 full charges. The Watervliet-produced extreme pressure Rheinmetall 120mm smoothebore's barrel life is 1,500 full charges, with the breech mechanism rated for 4,500 full charges. That means we would consume 25 barrels and 8 breech blocks per ship. All of our modern high strength steel barrels have fatigue lives attached to them, beyond which you do not go.

That said, the performance of all the HARP guns was based upon pressure, and you'll note that the pressure in the 16 inch guns was much lower than the 7 inch guns, despite their higher relative performance. Unfortunately, 7,000fps is predicated upon increased pressure, and that means high strength steel with a fatigue life attached to it.

The one saving grace of the giant gun tahanson43206 wants to use for much larger launches of a vehicle is that it will operate at dramatically lower pressures.

We need trade studies to evaluate increasing the caliber of the gun to 32 inches. The planned 32 inch gun would increase the payload by 10X using solids. We should get a modest performance bump on top of that using liquids. That would only require 5,000 shots, and 4 barrel changes at most, and perhaps no breech block replacement if we beef it up. If the launch rate was once per hour, then the 5,000t of metal is delivered to orbit in well under a year. We can put the gun on a floating oil platform so as not to disturb anyone on land, but then we need a stabilization mechanism, probably can't launch in rough weather, and we may have more issues with corrosion.

If only we had built the Montana class battleships. This would be a fantastic second lease on life for them. A battleship with orbital class cannons installed might give our enemies food for thought as well. Maybe it's not real practical, but it would definitely leave an impression.

Offline

Like button can go here

#59 2024-06-13 17:24:54

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Vertical Launch Assist Technologies for SSTO

I am reminded by the images above as the X-43: NASA Somehow Built A Mach 9.6 Hypersonic Aircraft

It reached speeds of up to Mach 10 and altitudes of 110,000 miles but was discontinued due to lack of funding. By the time of the X-43’s third and final demonstration flight, it boosted itself to a whopping 110,000 miles above the Earth and accelerated to 7,000 miles per hour, or almost Mach 10. The vehicle splashed down 850 miles to the west of southern California, in a US Navy training area, and was not recovered.

https://www.nasa.gov/reference/x-43a/

Of course4 it was not a SSTO

The first two prototypes flew at Mach 7 and the third was designed to fly at Mach 10. These vehicles were powered by gaseous hydrogen.

Launched from a B-52B operated by NASA for research purposes, the first X-43 rocketed from beneath the wing of the larger B-52B and reached about 5,000 miles per hour. After being dropped from the B-52B at 40,000 feet, the X-43 boosted itself to an altitude of 95,000 miles.

Offline

Like button can go here

#60 2024-06-13 17:44:53

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

For SpaceNut re #59

Would you be willing to go back and look at the source of the quotes you posted?

It reached speeds of up to Mach 10 and altitudes of 110,000 miles but was discontinued due to lack of funding. By the time of the X-43’s third and final demonstration flight, it boosted itself to a whopping 110,000 miles above the Earth and accelerated to 7,000 miles per hour, or almost Mach 10. The vehicle splashed down 850 miles to the west of southern California, in a US Navy training area, and was not recovered.

The writer appears to be confusing feet with miles. That appears to have happened in both quotes.

The altitude of GEO is 23,000 miles.

Was that quote from a reputable source?

(th)

Offline

Like button can go here

#61 2024-06-13 19:34:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,378

Re: Vertical Launch Assist Technologies for SSTO

Not reputable but I see the errs that you speak of in that Altitude is strange.

From the Nasa link that was in the article

Mach 10 – the X-43A research vehicle flew at approximately 7,000 mph at 110,000 feet altitude,

These articles and such are more about the rocket than that of how to start it accelerating by external lift.

Offline

Like button can go here

#62 2024-06-13 19:54:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

For SpaceNut re #61

Thanks for showing that the text you cited is from a user maintained web site.

I signed up as an editor on the Wikipedia site, and have done a few minor edits on articles, just for fun. I don't have the time or energy to visit the site you found, but there is a possibility it is willing to accept corrections.

If you have the time (and I know your time is limited) and if this is of interest to you, you can visit the site to see if there is a way to offer corrections. I don't know anything about the site you found, but if it is affiliated with the main Wikimedia group of sites, I might be able to perform edits to correct such glaring mistakes.

Thanks for showing the original NASA source. The feet figure you showed looks reasonable to me. There is a significant difference between a foot and a mile.

(th)

Offline

Like button can go here

#63 2025-07-05 06:49:15

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

For all...

GW's work posted in the exrocketman.blogspot.com site is now available by a single click.

https://exrocketman.blogspot.com/search?q=ssto

The paper is detailed, with plenty of graphs to illustrate the text.

I am guessing here, but it is possible that anyone offering an opinion without reading the paper is indeed likely to be missing something important.

(th)

Offline

Like button can go here

#64 2025-07-18 17:48:00

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

in mid July of 2025, Calliban reminded us of earlier discussion of vertical launch assistance.

This topic seems reasonably close to Calliban's scenario, of a 1 kilometer tube using steam to accelerate a normal rocket (SSTO or TSTO) to just under Mach 1.

The Iterative Rocket Design techniques that GW is using may be able to handle this scenario as well as more typical ones.

(th)

Offline

Like button can go here

#65 2025-07-19 10:17:08

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

In correspondence, GW Johnson pointed out that .3 (Point 3) km/s velocity after the tube lift is a small part of the dV needed to reach LEO (near 8 km/s).

I observe that this is potentially of interest to SpaceX.

If the entire stack of SuperHeavy and Starship had a velocity of .3 (Point 3) km/s at launch instead of the present 0 km/s at launch, I expect the stack would perform better than it does now. The rocket equation should show the difference, if the tube stage is computed as the first stage.

I'm hoping we have at least one member who can perform the calculations.

We have a great number of online launch calculators now available to assist.

I asked Google about SpaceX estimates:

The Starship system, consisting of the Super Heavy booster and the Starship upper stage, is designed to carry a payload of 100 to 150 metric tons (220,000 to 331,000 lb) to low Earth orbit (LEO) when fully reusable. In an expendable configuration, it can carry up to 250 metric tons (550,000 lb) to LEO. This makes it the most powerful launch vehicle ever developed.

I expect the performance would be greater if Calliban's vertical launch tube gave the entire stack a .3 (Point 3) km/s initial velocity.

(th)

Last edited by tahanson43206 (2025-07-19 20:25:19)

Offline

Like button can go here

#66 2025-07-19 20:28:55

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,053

Re: Vertical Launch Assist Technologies for SSTO

I asked Google's Gemini to attempt to calculate the benefit that would be seen if a Zero Stage could give the Super Heavy and Starship combination a velocity of .3 km/s (Point 3 < Mach 1) at ignition. The result seems to indicate a substantial increase in potential mass to LEO.

The equations were offered in a language that our forum software does not recognize.

Thank you again for working out the improved performance for our hypothetical Zero Stage launcher able to deliver 3 km/s velocity to a departing space vehicle. You showed that the benefits would be significant. I've been asked if you'd be willing to go through the calculations again, but this time with a more practical .3 km/s (Point Three). The figure comes from the velocity at Mach 1, which is thought to be of significance.

***No problem at all! It's great to refine the analysis for a more practical scenario and present it in BBCode for your forum. The Mach 1 figure is indeed significant, as it represents a key hurdle in atmospheric flight due to compressibility effects and drag. Even a small boost can make a difference in these early stages.

Let's go through the calculations again with a 0.3 km/s (300 m/s) Zero Stage velocity.

First, let's confirm Mach 1 at sea level. The speed of sound in dry air at 15°C (59°F) at sea level is approximately 340.3 m/s. So, 0.3 km/s is a little under Mach 1.

We'll use the same Starship and SuperHeavy parameters as before:

SpaceX SuperHeavy (Booster)

Empty mass (m_e_SH): 275,000 kg

Propellant mass (m_p_SH): 3,400,000 kg

Gross mass (wet mass) (m_0_SH): 3,675,000 kg

Average Isp (Isp_avg_SH): 330 seconds

SpaceX Starship (Upper Stage)

Empty mass (m_e_SS): 100,000 kg

Propellant mass (m_p_SS): 1,200,000 kg

Payload capacity to LEO (m_payload_LEO): 100,000 kg (reusable, target)

Average Isp (Isp_avg_SS): 370 seconds

Constants

Gravitational acceleration at sea level (g_0): 9.80665 m/s²

The Tsiolkovsky Rocket Equation:

Deltav=I_sp

cdotg_0

cdot

ln

left(

fracm_0m_f

right)Re-calculation: SuperHeavy and Starship with 0.3 km/s Zero Stage

As before, the Zero Stage provides an initial velocity to the entire stack. This means the SuperHeavy (first stage) starts its burn with an additional 0.3 km/s of velocity.

1. Baseline Delta-V (without Zero Stage)

Let's quickly re-state the baseline theoretical delta-v, which we calculated in the previous session. This is the amount of velocity the SuperHeavy and Starship themselves can provide.Stage 1: SuperHeavy

m_0 (initial mass of stack) = 3,675,000

textkg(SHwet)+(100,000

textkg(SSempty)+1,200,000

textkg(SSprop)+100,000

textkg(payload))=5,075,000

textkgm_f (final mass after SH burn) = 275,000

textkg(SHempty)+(100,000

textkg(SSempty)+1,200,000

textkg(SSprop)+100,000

textkg(payload))=1,675,000

textkgIsp_avg_SH=330

textsDeltav_SH=330

texts

cdot9.80665

textm/s

2cdot

ln

left(

frac5,075,0001,675,000

right)

Deltav_SH

approx3587

textm/s=3.587

textkm/sStage 2: Starship

m_0 (initial mass of Starship) = 100,000

textkg(SSempty)+1,200,000

textkg(SSprop)+100,000

textkg(payload)=1,400,000

textkgm_f (final mass after SS burn) = 100,000

textkg(SSempty)+100,000

textkg(payload)=200,000

textkgIsp_avg_SS=370

textsDeltav_SS=370

texts

cdot9.80665

textm/s

2cdot

ln

left(

frac1,400,000200,000

right)

Deltav_SS

approx7062

textm/s=7.062

textkm/sTotal Theoretical

Deltav (Baseline):

Deltav_total_baseline=3.587

textkm/s+7.062

textkm/s=10.649

textkm/s2. Total Delta-V with 0.3 km/s Zero Stage

The benefit of the Zero Stage is a direct addition to the overall velocity budget.$\Delta v_{total_with_ZeroStage} = \Delta v_{ZeroStage} + \Delta v_{total_baseline} $$ \Delta v_{total_with_ZeroStage} = 0.3 \text{ km/s} + 10.649 \text{ km/s} = 10.949 \text{ km/s} $

How a 0.3 km/s Zero Stage Improves Performance

While 0.3 km/s is less dramatic than 3 km/s, it's still a significant amount of velocity, especially at the beginning of a launch. Here's how it translates to benefits for Starship:

Increased Payload to LEO: This is where the primary benefit is seen. If the target

Deltav to LEO is, for example, 9.7 km/s (accounting for gravity and drag losses), then the remaining

Deltav needed from the SuperHeavy and Starship is reduced.* $\Delta v$ needed from SH + SS = $9.7 \text{ km/s (LEO target)} - 0.3 \text{ km/s (Zero Stage)} = 9.4 \text{ km/s}$

Since the SuperHeavy + Starship *can* provide 10.649 km/s theoretically, and they now only *need* to provide 9.4 km/s, there's a surplus of $10.649 - 9.4 = 1.249 \text{ km/s}$ of delta-v that can be converted into additional payload.

Let's calculate the new payload. This requires working backward through the stages. We'll find how much $\Delta v$ the Starship needs to provide, given the SuperHeavy's contribution, and then solve for the new payload.

* $\Delta v_{SH}$ provided (assuming constant payload initially): $3.587 \text{ km/s}$

* $\Delta v_{SS\_needed} = 9.4 \text{ km/s (total needed from SH+SS)} - 3.587 \text{ km/s (from SH)} = 5.813 \text{ km/s}$Now, use the Starship's rocket equation to find the new maximum payload ($m_{payload\_new}$) if it only needs to provide $5.813 \text{ km/s}$:

$\Delta v_{SS\_needed} = I_{sp\_avg\_SS} \cdot g_0 \cdot \ln \left( \frac{m_{e\_SS} + m_{p\_SS} + m_{payload\_new}}{m_{e\_SS} + m_{payload\_new}} \right)$

$5813 \text{ m/s} = 370 \text{ s} \cdot 9.80665 \text{ m/s}^2 \cdot \ln \left( \frac{100,000 + 1,200,000 + m_{payload\_new}}{100,000 + m_{payload\_new}} \right)$

$5813 = 3628.46 \cdot \ln \left( \frac{1,300,000 + m_{payload\_new}}{100,000 + m_{payload\_new}} \right)$

$\frac{5813}{3628.46} = \ln \left( \frac{1,300,000 + m_{payload\_new}}{100,000 + m_{payload\_new}} \right)$

$1.6021 = \ln \left( \frac{1,300,000 + m_{payload\_new}}{100,000 + m_{payload\_new}} \right)$

$e^{1.6021} = \frac{1,300,000 + m_{payload\_new}}{100,000 + m_{payload\_new}}$

$4.9622 = \frac{1,300,000 + m_{payload\_new}}{100,000 + m_{payload\_new}}$

$4.9622 \cdot (100,000 + m_{payload\_new}) = 1,300,000 + m_{payload\_new}$

$496,220 + 4.9622 \cdot m_{payload\_new} = 1,300,000 + m_{payload\_new}$

$3.9622 \cdot m_{payload\_new} = 1,300,000 - 496,220$

$3.9622 \cdot m_{payload\_new} = 803,780$

$m_{payload\_new} = \frac{803,780}{3.9622} \approx 202,860 \text{ kg} = 202.86 \text{ tonnes}$So, a 0.3 km/s boost could theoretically increase the payload to LEO from the target 100 tonnes to approximately 202.86 tonnes. This is still a very substantial increase, more than doubling the baseline reusable payload!

/* Note: As discussed, this assumes the SuperHeavy's performance isn't degraded by the increased initial mass due to the higher Starship payload. In a real-world scenario, a full iterative calculation would be needed, but the principle of significant payload gain holds true. */

[] Reduced Propellant Consumption (for existing payloads): If the mission is to launch the standard 100-tonne payload to LEO, the 0.3 km/s initial velocity means the SuperHeavy and Starship don't need to burn as much propellant to reach orbit. This saved propellant could be used for:

[] More propulsive landing maneuvers for reusability.

[] Carrying additional payload beyond the standard 100 tonnes (as calculated above).

[] Enabling more complex orbital maneuvers or higher-energy orbits after LEO.Improved Gravity and Drag Losses: While the Tsiolkovsky equation doesn't directly account for these, a higher initial velocity means the rocket spends less time fighting gravity and atmospheric drag at lower, denser altitudes. This can lead to a more efficient ascent profile and translate into a higher effective

Deltav from the rocket's own engines. The benefit of a speed boost at Mach 1 is particularly relevant because this is a region of high aerodynamic stress and drag for rockets. Getting past it faster means less energy wasted.Operational Flexibility: The extra performance margin provides more flexibility in launch windows, ascent trajectories, and recovery operations. It can make launches more robust against minor anomalies or allow for more ambitious mission profiles.

Conclusion

Even a "mere" 0.3 km/s (Mach 1 approx.) initial velocity from a Zero Stage provides a very significant improvement in the performance of the SpaceX SuperHeavy and Starship stack. It could more than double the reusable payload capacity to LEO (from 100 tonnes to over 200 tonnes) or provide substantial propellant savings and operational margins for existing missions.

This demonstrates that even seemingly small initial velocity boosts can have a compounded, beneficial effect on rocket performance due to the exponential nature of the rocket equation.

I hope this re-calculation and BBCode presentation are exactly what your group needs for the forum! Let me know if you have any more questions.

(th)

Last edited by tahanson43206 (2025-07-19 20:32:22)

Offline

Like button can go here