New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2024-05-31 04:19:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

500 Passenger SSTO Design Concept

Design characteristics for a LOX/RP1 powered 500 passenger vertical takeoff / horizontal landing SSTO will be posted here.

Gross Liftoff Mass: 2,100,000kg

Propellant Mass: 2,000,000kg

Dry Vehicle Mass: 60,000kg

Payload Mass: 40,000kg

Total Delta-V Capability with 338s avg Isp: 10,091.52m/s

Propellant Volume: 1,634m^3

Expected Total Vehicle Internal Volume: 2,000m^3

Vehicle Volume (Cylinder Representation): 3.5mR x 51.97m H (2,000.04m^3)

Vehicle Surface Area (Cylinder Representation): 3.5mR x 51.97m H (1,219.85m^2)

Airframe (Propellant Tanks, Thrust Structure, Pressurized Cabin, Wings): 27,132kg

Engines: 16,185kg

Thermal Protection System: 6,551kg (1,219.85m^2 covered with 3 inch thick UltraMet tiles)

Landing Gear and Tires: 1,200kg

Remaining Mass Available (Avionics, Sensors, Flight Control Actuators, Life Support, Power, RCS, etc): 8,932kg

Engines

Type: LOX/RP1 Pump-Fed Oxidizer-Rich Full-Flow Staged Combustion

Total Sea Level Thrust: 3,150,000kgf / (30,890,947.5N / 31,891kN)

Nozzle: Non-Regeneratively Cooled Zirconium Carbide coated Reinforced Carbon-Carbon (NASA)

Sea Level Thrust-to-Weight: 200:1 (Raptor 3; ORFFSC)

Total Engine Mass: 17,485kg (Raptor 3 performance, translated to a 200:1 LOX/RP1 thrust-to-weight ratio)

Total Engine Mass with RCC Nozzles: 16,185kg

Isp(sl; vac; avg): 311s; 365s; 338s (RD-180; ORSC)

Turbopump Efficiency: 72%+ (Launcher Engine; ORSC)

C* Efficiency: 98%+ (Launcher Engine; ORSC)

Combustion Efficiency: 99%+ (Launcher Engine; ORSC)

Thrust Structure: LOX Tank Integrated Pusher Plate (ESA developed for Ariane 6 upper stages)

All engine specifications proven to be achievable by various currently operational LOX/LCH4 or LOX/RP1 engines tested at NASA facilities to verify performance and have been or are being used to power operational orbital class launch vehicles. NASA UHTC-coated RCC nozzle technology is less than half the weight of a regeneratively cooled Nickel-Copper alloy nozzle, which saves 100kg to 150kg of weight per Raptor class engine, and requires less maintenance. I have not included this weight savings in the engine mass estimate, so the engines will have slightly better than 200:1 thrust-to-weight. The Zirconium Carbide or Hafnium Diboride coating that NASA tested will have to be reapplied, via plasma spray, onto the nozzle surface, after every 10 flights or so. However, over that period of firing time no abnormal ablative degradation was noted. RCC is 1.6g/cm^3 to 1.98g/cm^3. Monel-type alloys commonly used by regeneratively cooled engines are around 8.8g/cm^3, so the weight savings per engine is very real. Raptor, Launcher, and the RD-180 all use heavy Copper-based alloys for their heat transfer properties. The RD-180, I think, uses a Copper-Chromium alloy vs Nickel-Copper (Monel) on the interior and a steel, possibly stainless, channel wall exterior jacket. Isp and thrust was good, but RD-180 is an excessively heavy engine compared to a Raptor.

Orbital Maneuvering and Reaction Control System

Type: LOX/RP1 residual propellant consumption

OMS Engines: Rocket Labs Rutherford Derivative electrically-driven pump-fed LOX/RP1

RCS Engines: electrically-driven pump-fed LOX/RP1

To avoid the cost, complexity, and mass penalties associated with usage of toxic N2O4/MMH propellants, this vehicle will use integrated orbital maneuvering and reaction control propulsion systems that consume residual propellants from either the main or header tanks.

Primary Airframe Fabrication Materials

Fiber:

TorayCA T1200 (1,160ksi, preferred)

or

TorayCA T1100G(1,015ksi, acceptable)

or

Hexcel HexTow IM10 (1,010ksi, acceptable)

Resin Matrix: PROOF Research 900HT (454C glass transition temperature)

Resin Matrix Additives: SWCNT or Graphene flakes (resin toughener, fiber ply bonding to reduce ILSS)

Notes:

SLS core stage has a 2,000m^3 LH2 tank, was constructed of Al-2219, and weighs 68,000kg. 2,000m^3 is about what I expect the total internal volume of the vehicle to be. Al-2195 saves about 5% on total mass, as compared to Al-2219, so 64,600kg if it was constructed from Al-2195. The IM7 fiber composite provided a 40% mass savings over Al-2195, so 38,760kg. HexTow IM7 (820ksi) has about 71% of the tensile strength of T1200 (1,160ksi), so the tank could be lighter by another 30%, meaning 27,132kg. The CNT resin matrix additive will then be used to impart additional inter-laminar shear strength, rather than to reduce weight.

Engine Thrust Structure

ESA has developed a propellant tank integrated composite engine thrust structures using IM7 or T1100G fiber or both. All parts that can be made stronger and lighter than 4130 tubular steel, or other high strength steel alloys such as 300M or AerMet 100, will use composite technology to constrain vehicle mass growth.

Thermal Protection System

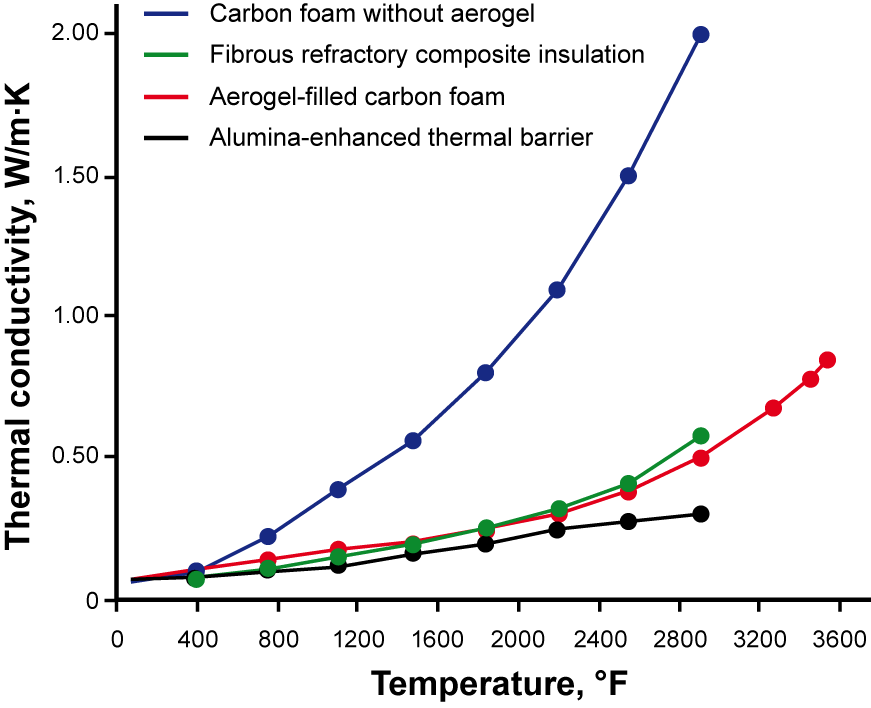

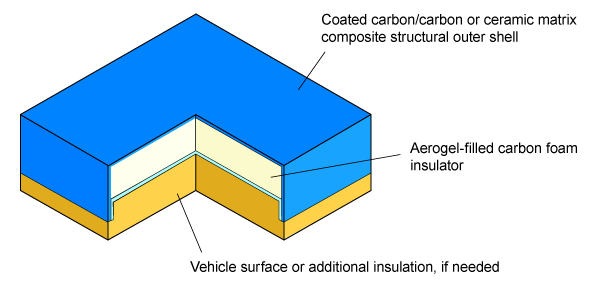

UltraMet Reinforced Carbon-Carbon Shells with Toughened / Reinforced AeroGel Foam Filled Insulating Tiles

4.4lbs/ft^3 density

AeroZero Aerogel Thermal Barrier Peel-and-Stick Films for Upper Vehicle Surfaces exposed to less intense heating

Notes:

1 inch thick RCC / Aerogel tiles exposed to 3,500F for 243 seconds resulted in a 350F backside temperature. This was repeatedly tested at the US Air Force Research Laboratory. Certain tiles will have Zirconium Carbide (underside, black), Hafnium Diboride (leading edges, gray), or Alumina (upper surfaces, white) coatings applied to them. These tiles are much lighter than Space Shuttle era tiles, provide enhanced thermal protection, as well as enhanced toughness and longevity, relative to predecessor tile technology.

AeroZero has a family of adhesive film products of varying thicknesses, toughness, and temperature ratings for a variety of applications and temperature ranges. They were designed to protect spacecraft and Lithium-ion battery boxes during thermal runaway events.

Double-sided AeroZero peel-and-stick film will serve as the first layer of airframe thermal protection over the entire integrated airframe and propellant tank structure, followed by UltraMet tiles where required.

Landing Gear System

Following military and airline industry movement in the same direction, this vehicle will incorporate composite landing gear components to minimize weight. For now, the main landing gear design will comprise a dual fore/aft oleo design, composite wheels with AeroZero film to thermally shield the inner wheel from hot RCC wheel brakes, and conventional Nitrogen-filled rubber tires.

Tubular 300M or AerMet 100 steel will utilize T1100G or HexTow IM10 overwraps to provide the required strength and a conventional steel inner bearing surface for the strut and piston arrangement.

Primary Electrical Power System

Given the short expected duration of these ferry flights to orbit, and to avoid the expense / weight / hazards of very large fuel cells or electro-chemical batteries, this vehicle will use miniature gas turbine powered variable frequency electric generators (VFGs) for ship's power, as presently used aboard all commercial aircraft.

Secondary Electric Power System

Since there will be 500 passengers aboard, all of them expelling CO2, life support and supplemental electrical power will be provided by Lithium-CO2 batteries that require CO2 input to produce electrical power output. Although these batteries are rechargeable using input electricity to expel the CO2, the most likely mode of operation is that they only intake CO2 for the short duration of the flight, with the CO2 discharged using ground power after the vehicle lands. After testing in space, this is viewed by NASA as a very high reliability system with an assured input.

Flight Control Avionics, Navigation, and Communications Systems

A central vehicle and mission computer will provide automated vehicle control during ascent and reentry. Navigation systems will include INS, GPS, and a Star Tracker as a backup. The cockpit will use all-glass multi-function touchscreen displays. After careful consideration of the use of cockpit windows for the pair of pilots, I decided that an array of redundant FLIR sensors, similar to the F-35s DAS subsystem, would provide a much better visual reference and situational awareness during all phases of flight. A miniature ultra-light Ku-band radar will provide all-weather navigation after reentry. Communications will use StarLink and software-defined high data rate radios.

Electro-Hydraulic Flight Control Surface Actuator System

Following airline industry practices towards greater electrification of existing commercial aircraft, all flight control surface actuators will be of the electro-hydraulic variety. In this type of actuator system, electrical power is supplied via a thinner / lighter / more damage tolerant electrical power cable to a small electric motor which pressurizes a comparatively tiny quantity of hydraulic fluid in a local rather than centralized reservoir and feed line system, making it self-contained with the exception of the electric power cable. This system will power ailerons, flaps, rudders, landing gear doors, and brakes. The Space Shuttle during the twilight years of its operation, Airbus and Boeing airliners, the F-35 and presumably B-21, all use this type of actuator system, which has proven more damage resistant in combat than centralized engine power pressurized hydraulic systems. The actuators are so light relative to pure hydraulic systems that backup actuators can be included for minimal weight.

Passenger Compartment Seating

Rather than using heavy airline style seats, all passengers will be strapped into removable fiber-based netting, laying flat on their backs for high-G tolerance, for the wild ride to orbit. Once in orbit, this netting will be removed to facilitate ease of movement about the cabin, for transfer to their awaiting interplanetary colonization ship.

Environmental Control and Life Support Systems

The primary load placed upon a vehicle carrying 500 passengers is their own body heat. This heat will be removed from the vehicle using an on-orbit deployable CNT ribbon radiator array, due to its exceptionally light weight and high thermal conductivity.

Cabin air will be revitalized using the dual-function Lithium-CO2 batteries, which will power the circulatory system that moves air through the cabin. COPVs containing Oxygen and Nitrogen will provide supplemental O2 and N2 to make up any losses.

Drinking water will be supplied via individual 2L plastic pouches.

The cabin lavatories will simply collect any waste products, and either dump them overboard after reentry, or return them to the ground for processing.

All passengers will be wearing lightweight pressure suits, socks, gloves, and a helmet. A centralized emergency O2 supply will provide the passengers with O2, if cabin pressurization is lost during ascent or reentry.

Offline

Like button can go here

#2 2024-05-31 06:18:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,134

Re: 500 Passenger SSTO Design Concept

Best wishes for success with this ambitious topic!

For comparison, here is a Google snippet about the Saturn V rocket at liftoff:

The Saturn V rocket was 363 feet tall, about the height of a 36-story building, and 60 feet taller than the Statue of Liberty. Fully fueled for liftoff, the Saturn V weighed 6.2 million pounds, the weight of about 400 elephants.

The Saturn V Rocket - Cradle of Aviation Museum

www.cradleofaviation.org › history › history › saturn-v-rocket

About Featured Snippets

That converts to 2,812,273 kilograms, so the 500 passenger vehicle would be about 3/4 the weight of Saturn V.

It would be impressive to watch this vehicle take off.

For comparison ...

Google snippet:

how much did starship flight 3 weigh at liftoff?

Elon Musk's launch company SpaceX launched Starship, the largest rocket ever made earlier this month for its third test flight. Starship, which is 120m (393ft) high and weighs 5,000 tonnes when fully fueled, successfully lifted off on March 14 from the company's base in Texas, USA.Mar 18, 2024

SpaceX launches third Starship test flight

Aerospace Testing International

https://www.aerospacetestinginternational.com › space

(th)

Last edited by tahanson43206 (2024-05-31 07:28:02)

Offline

Like button can go here

#3 2024-05-31 07:53:07

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,134

Re: 500 Passenger SSTO Design Concept

Gemini is Google's AI assistant...

I gave it the text from Post #1 through to but not including the graphs.

20240531 Gemini Evaluation 500 Passenger

I've reviewed the design characteristics you provided for the LOX/RP1 powered SSTO spacecraft and here are some observations and potential points for further consideration:

Overall:

The document provides a detailed overview of the spacecraft's design specifications, including mass breakdown, propulsion systems, materials, and thermal protection.

The calculations seem to be consistent and well-explained, using appropriate units and references.

The reasoning behind material and technology choices is clear and well-supported.

Specific Points:

Propellant Volume: The calculated propellant volume of 1,634 m^3 seems reasonable based on the given mass and density of LOX/RP1.

Vehicle Volume: The volume calculation based on the cylinder representation (2,000.04 m^3) matches the expected total vehicle internal volume (2,000 m^3).Engine Thrust-to-Weight Ratio: The 200:1 thrust-to-weight ratio for the engines is ambitious but potentially achievable based on existing Raptor 3 performance and NASA's UHTC-coated RCC nozzle technology.

Orbital Maneuvering and Reaction Control System: Utilizing residual propellant for orbital maneuvering and reaction control is a cost-effective and efficient approach.Primary Airframe Fabrication Materials: The choice of high-strength carbon fiber composites like TorayCA T1200 and HexTow IM10 is a good option for achieving significant weight savings compared to traditional aluminum alloys.

Engine Thrust Structure: Utilizing composite materials for the engine thrust structure aligns with the overall focus on weight reduction.

Thermal Protection System: The use of UltraMet RCC tiles and AeroZero aerogel films appears to provide a lightweight and effective thermal protection solution.Potential Areas for Further Review:

Engine Performance: While the chosen engine specifications seem plausible, it's crucial to verify their feasibility through detailed simulations and engineering analysis.

Aerodynamics: The document doesn't explicitly mention the aerodynamic design of the spacecraft. It's important to assess the aerodynamic performance and stability during various flight phases, especially during takeoff and landing.

Life Support Systems: The document doesn't detail the life support systems for 500 passengers. A detailed analysis of the required systems and their mass and volume is necessary.

Risk and Failure Modes: A comprehensive risk and failure mode analysis should be conducted to identify potential vulnerabilities and mitigation strategies.

Overall, the design specifications for the SSTO spacecraft appear well-considered and technically sound. However, further detailed analysis and engineering studies are recommended before finalizing the design and proceeding with development.

(th)

Last edited by tahanson43206 (2024-05-31 07:55:34)

Offline

Like button can go here

#4 2024-05-31 12:56:33

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: 500 Passenger SSTO Design Concept

tahanson43206,

This 500 passenger SSTO's liftoff thrust (6,944,553lbf) is modestly below that of the Space Shuttle (7,180,000lbf) and Saturn V (7,500,000lbf).

It's a powerful vehicle because it has to be, albeit vastly more propellant mass and volume efficient than:

1. Space Shuttle (SRBs: 1,003,492kg / 585.127m^3 of APCP and RS-25s: 735,601kg / 2,050.798m^3 of LOX/LH2)

2. Saturn V (S-IC First Stage: 2,280,000kg / 1,934m^3 of LOX/RP1)

In terms of mass and volume, the Space Shuttle External Tank volume alone matches the entire volume my SSTO requires. The first stage of the Saturn V has almost identical propellant mass and cylinder volume when compared to the total propellant mass and volume of my SSTO vehicle concept. My SSTOs payload mass fraction is only 2%, granted. While this may not seem like a good deal on paper, we're perfectly happy to load up just as much propellant into equally-sized propellant containers to send 3 to 7 people into orbit. The mass and volume efficiency of all existing space transport vehicles is horrendous compared to my SSTO proposal.

Propellant Burn Rate Per Passenger to Attain Orbital Velocity

Saturn V (3 passengers; 2,280,000kg LOX/RP1, 427,285kg LOX/LH2): 902,428kg

Saturn V (500 passengers; 2,280,000kg LOX/RP1, 427,285kg LOX/LH2): 5,415kg

Space Shuttle(7 passengers; 1,003,492kg APCP, 735,601kg LOX/LH2): 248,442kg

Space Shuttle(100 passengers; 1,003,492kg APCP, 735,601kg LOX/LH2): 17,391kg

SpaceX Starship (100 passengers; 4,600,000kg LOX/LCH4): 46,000kg

SpaceX Starship (500 passengers; 4,600,000kg LOX/LCH4): 9,200kg

kbd512 SSTO (500 passengers; 2,000,000kg LOX/RP1): 4,000kg

Which of these vehicles do we figure will get passengers to orbit cheaper and faster?

Stop using computer programs to tell you what I already know. Ask some pertinent questions.

A representative image of my SSTO concept (won't have the gaping hole in the nose since it's not an air-breather):

The image shown above is a true lifting body design, remarkably similar to any of the high speed airline transport design concepts coming from Boeing or Lockheed-Martin or any other aerospace company. They look very different than the historical Space Shuttle, which was more of a Delta-winged blunt body cargo transport. The Space Shuttle was very blunt around the leading edges because computer simulation's ability to optimize the aerodynamics of lifting bodies was still an emergent science back in the 1970s when it was designed. Later refined concepts or actual vehicles, such as all modern supersonic and especially hypersonic vehicles, have very different appearances because we have the ability to simulate how they behave across all phases of flight, and we have high strength / high heat resistant materials to allow for more efficient aerodynamic designs.

Rockwell VTOHL 45t SSTO

All of the conventional mid to late 1970s Space Shuttle designs, to include SSTO designs such as the one pictured above, featured very blunt bodies and delta wings.

Specifications for the Rockwell VTOHL 45t design study pictured above...

Gross Liftoff Mass: 1,158,192kg

Propellant Mass: 1,016,542kg

Empty Mass: 96,650kg (8.34% of gross liftoff mass; see Note #3)

Payload Mass: 45,000kg (3.89% of gross liftoff mass; see Note #3)

Length: 64m

Wingspan: 34.3m

Fuselage / Propellant Tank Diameter: not provided

Propellant Tank Volume: 2,574m^3 (see Note #1)

Engines: 5X LOX/LH2 (unspecified aerospike design if Rockwell's artwork is reflective of their intended design)

Isp(sl): 385s; Isp(vac): 467s (this level of performance has never been achieved by any LH2 powered vehicle)

Thrust(sl): 15,369.90kN; Thrust(vac): 18,643.471kN

Thrust per Engine: 3,073.98kN (see Note #2)

Note #1:

Minimally, this is 940m^3 larger than my propellant tanks using densified LOX/LH2, which nobody presently uses. It's 574m^3 larger than my total internal vehicle volume. The SLS core stage volume is 2,742m^3, so this vehicle's minimum propellant tank volume is very nearly the same size, but SLS only contains 987,472kg of propellant. That is how I know for a fact that this tank, which contains 17.3% more propellant mass than the SLS, would actually be nearer to 3,216m^3, about 61% larger than my entire RP1 powered vehicle's total internal volume.

Note #2:

Rockwell's proposed engine thrust level is almost identical to the now-retired RS-68A's 3,100kN sea level thrust. Each RS-68A engine weighs 6,740kg, so 5 engines would weigh 33,700kg. At the highest thrust-to-weight ever achieved by LOX/LH2, the engines would weigh 20,765kg. We could knock off another 750kg using RCC nozzles, based upon RS-25 component weights, so 20,015kg for all 5 engines. The vehicle has more propellant volume than total internal volume for the SSTO vehicle I'm proposing, and its engines represent a much greater fraction of its total weight. In my design, all that engine mass savings becomes propellant tank mass input. That means Rockwell's SSTO design has to have worse aerodynamics and a higher inert mass fraction, despite the propellant tank mass fraction being modestly lower. Any mass savings on the Rockwell SSTO's propellant tanks have been immediately consumed by the much heavier engines and making the larger propellant tanks stiffer and thus able to resist LH2 permeation from microcracking. Rockwell's overly-optimistic engine performance figures, especially for the 1970s, apply to LH2 engines with never-achieved thrust-to-weight ratios and Isp values. RS-25 uses about 204 bars of chamber pressure. Bump that up to 300 bars to come somewhere close to achieving Rockwell's quoted Isp figures, and your turbopumps get even larger and heavier, so your engines now weigh even more than RS-25s. Thrust-to-weight decreases as a result, but hey, those Isp numbers certainly look better. None of this actually helps, because most of the mass of a RP1 powered design is in the propellant tanks / airframe, where it needs to be, rather than sunk into low thrust-to-weight LH2 engines.

Note #3:

Knowing everything we know now about how the volume of a vehicle affects the total mass of material allocated to construct it, it should be abundantly clear why it is that LH2 SSTOs are such a bad idea. The less performant LH2 engines cannibalize the mass fraction which should be allocated to the propellant tanks / airframe mass fraction. Since the propellant tanks are 60% larger for the same Total Impulse (which represents Total Delta-V capability when applied to any given dry vehicle and payload mass), and the total vehicle volume increases by about 70% to carry the same payload, this combination of factors makes the entire concept unworkable or at the far edge of feasibility as you attempt to scale-up to a given total payload mass.

The notion that the LH2 powered vehicle is or could be lighter is almost entirely theoretical in nature, yet highly implausible in practice. Fixating on payload mass fraction is rather silly for a passenger transport service. The passenger mass fraction is far less relevant than the total fuel burn per passenger, because the passenger is paying for that fuel, as well as the cost of the materials used to construct the vehicle. Relative to materials costs, fuel costs absolutely dominate. You can see how this affects airline transport services and what fraction of their profits are consumed by paying for fuel vs paying off the bank loans taken out to purchase their jets. This becomes even more of an issue with orbital launch vehicles, because the propellant burn per passenger, even with my SSTO proposal, and even if most of it is LOX, is approximately equivalent to a non-stop flight around the world in a subsonic passenger jet. If you wish to contain costs, then propellant cost for a ride to orbit is the one to fixate on.

Cargo doesn't work quite the same way, because comparative propellant burn rate per kilogram of cargo delivered does make the TSTO a more attractive proposition for cargo delivery. You can't deliver a fraction of a passenger, so excess internal volume for cargo capacity only hurts fuel burn rate because it ties back to dry vehicle mass. Humans are mostly water and very small in total volume compared to a rocket stage or large satellite type vehicle. Unlike, say, a load of LOX/LCH4 propellant, you have to deliver all kilograms of all passengers for airline transport, yet any kilogram over the top of "all kilograms" directly translates into wasted propellant and heavier / more expensive rocket powered vehicles. Unfortunately, you can't easily resize a cargo vehicle so that it "only" weighs as much as it needs to, for transport of the exact tonnage of passengers going into orbit. My SSTO is intended for short flights taking passengers to much larger interplanetary transport vehicles where mass and volume are far less constrained because they're using electric propulsion of some variety for Earth-to-Moon/Mars/Venus/Mercury transport. The passengers aren't going to remain inside this SSTO for extended periods of time. Mission duration is about 1 day, at most.

As it concerns LOX/RP1 vs LOX/LH2...

For any given vehicle weight, it's nearly impossible to increase its internal volume by 60% to 70% while still arriving at a similar dry vehicle mass fraction when compared to one that is 60% smaller. That is why LH2 SSTOs only perform well on paper, where the limits of materials science and aero loads imposed by basic flight physics are meaningless. Anybody can scribble something on paper, but in real engineering a 50% increase in volume minimally implies either a 50% increase in strength and stiffness when the structure in question has been interally pressurized, or it gets significantly heavier.

If you've ever computed hoop stress before, for a 120 inch diameter vessel with a 0.08 inch wall thickness pressurized to 20psi, hoop stress is 15.02ksi. Increase the internal diameter by 50%, to 180 inches, same wall thickness, hoop stress is now 22.52ksi, a 50% increase. Now then, unless the material magically gets stronger, it still has to contain that stress without deforming, which leads to microcracking. For large vehicles, and my SSTO certainly qualifies, LOX and RP1 are pressurized to 22psi. LH2 is pressurized to 45psi. That means hoop stress on the tanks of my vehicle is at least 3.5X lower than for LH2, because it's a 68% smaller tank volume operating at half the pressure of LH2. Structurally speaking, since the load applied by internal pressurization is the greatest load applied, as compared to aero loads, I am stacking the deck heavily in favor of my selected design, which is why it can be so light.

Someone who understands basic structural design and material limitations should intuitively understand all of this. Yes, the propellant mass is about 50% heavier for a given payload to orbit. That really doesn't matter much when compared to total volume, total surface area, total loads applied by internal pressurization and indeed aero loads over total frontal area. The design goal here is to transport 500 passengers to orbit in a highly efficient manner, not to engage in a ridiculous payload mass fraction fascination. I'm designing this SSTO vehicle to be as light and small as it can feasibly be, relative to the volume of propellant required to attain orbit.

When I plug in 1,100t for the wet mass, 100t dry mass (because somehow a fully reusable LOX/LH2 powered SSTO that's 70% larger than my proposed LOX/RP1 SSTO design will have the exact same dry mass and payload mass fractions), and 427s for average Isp (using Rockwell's fictional never-achieved Isp figures for nonexistent, some 50 years later, LOX/LH2 engines), I get 10,041m/s of Delta-V capability. That is less Delta-V capability than my vehicle, not by a lot, but I think it adequately illustrates my point.

You cannot beat LOX/RP1 using a 50s to 75s higher Isp propellant combination with 3X worse propellant density. Basic geometry, physics, and unchanging materials properties are all firmly set against you accomplishing anything except driving up the dry mass fraction and cost of the SSTO vehicle while driving down its payload mass fraction, to the point of rendering the entire concept unworkable. That is the "tyranny of the basic materials mechanical properties, engine performance, and propellant density equation", as it applies to the structural engineering and payload performance limits imposed upon a technically feasible SSTO type vehicle.

It's little wonder that nobody has achieved this yet. They keep fixating on pointless errata related to rocket fuel economy. Zoom out far enough to visualize the entire design and all its implications. We have the materials tech and engine performance to do this if we spend more time scrutinizing the entire design, rather than one aspect of it. Thrust and propellant density bound the range of acceptable propellant bulk density selections and fuel burn rates (Isp). Anything that greatly resembles LOX/RP1 density and thrust is going to work well enough, so densified LOX/LC3H8 would work just as well as LOX/RP1. Materials and engine performance limitations further constrain the set of workable solutions. If LH2 engines matched RP1 engines' thrust-to-weight performance, then LH2 SSTO would instantly become far more feasible. Until that happens, a RP1 SSTO is still perfectly feasible to build using existing materials and engines.

Offline

Like button can go here

#5 2024-05-31 14:34:40

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: 500 Passenger SSTO Design Concept

Propellant Burn Rate per Passenger for Starship 2 and Starship 3 Variants

Starship 2 (5,150,000kg LOX/LCH4) fuel burn rate per passenger: 4,120kg

Starship 3 (6,350,000kg LOX/LCH4) fuel burn rate per passenger: 2,540kg

Booster Height increases by 12.95% between Starship 1 and 3, but they're going to load 22.73% more propellant into it. If the vehicle is still the same 9m core diameter, then I'm not sure how they're going to do that. That's a fairly large discrepancy unless they're doing serious densification that they weren't doing for Starship 1.

Starship 1 Booser contains 3,708m^3 of densified LOX/LCH4.

Starship 3 Booster contains 4,551m^3 of densified LOX/LCH4.

That is exactly 22.73% more propellant, but I have to increase cylinder height by 22%, NOT 12%, to go from 3,708^3 to 4,551m^3. Maybe there's something I haven't considered regarding internal tank geometry. I'm not quite sure what happened there with SpaceX's numbers. Their propellant load numbers don't add for Starship 3's booster height up without a substantial propellant densification or cylinder height increase, or a modest increase in cylinder diameter. Starship 1 tracks with what's been published about it. It's probably best to wait and see what Starship 3 is truly capable of before judging it. We'll know what Starship 2 is about to do soon enough.

If Starship 3 is actually able to achieve that level of propellant burn reduction, then a SSTO may no longer be warranted. Until then, I'm going to act as if magic won't happen on the basis of what appears to be faulty math or a major vehicle modification requiring complete recertification.

Offline

Like button can go here

#6 2024-06-17 15:34:51

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: 500 Passenger SSTO Design Concept

On request from tahanson43206, I've included this here.

Some of the background info on why this design will or at least should work as intended was derived from this article, or rather, the linked paper within the article:

The Space Review: Reassessing scramjets and spaceplanes

The article covers air-breathing SSTO concepts, which, while interesting and potentially useful, have a substantial thrust disadvantage compared to pure rocket power, more complex development tasks with attendant technical risks to the project, more development cost, and it's dubious that the required performance metrics can be fully met by ramjets or scramjets. Put another way, a highly concerted development effort to produce a ramjet or scramjet powered vehicle at a scale-up never before demonstrated would be required, and it still requires rocket thrust to both leave the ground and achieve orbit. Ramjet and scramjet engine operation is exceptionally simple, but the materials tech and computer modeling of combustion dynamics is not. Beyond that, the gaping hole in the vehicle to permit air breathing must be enclosed prior to reentry or highly refractory materials used. The air-breathing tech clearly has the potential to dramatically reduce the propellant load, but not without substantial additional development including flying prototypes to demonstrate the desired operational characteristics (combustion stability, airframe control throughout the flight regime, materials tech, etc), because computer models alone are insufficient.

Offline

Like button can go here

#7 2025-07-05 06:48:03

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,134

Re: 500 Passenger SSTO Design Concept

For all...

GW's work posted in the exrocketman.blogspot.com site is now available by a single click.

https://exrocketman.blogspot.com/search?q=ssto

The paper is detailed, with plenty of graphs to illustrate the text.

I am guessing here, but it is possible that anyone offering an opinion without reading the paper is indeed likely to be missing something important.

(th)

Offline

Like button can go here