New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

Pages: 1

#1 2024-05-24 11:16:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

SSTO Operating Costs

This topic is related to the cost of operating a SSTO.

There is a propellant cost differential above / beyond TSTO, since all of the propellant and structural mass must be carried to and returned from orbit in a single stage reusable launch vehicle.

How Much Does Rocket Fuel Really Cost?

According to moving average US defense prices, LH2 costs around $6.1 a kilogram (though standard prices by the Defense Working Capital Fund indicate a much higher price of $30.5/kg). RP-1 presents a cheaper option at $2.3/kg. The document lists CH4 at $8.8/kg, while LOX comes in at $0.27/kg. Meanwhile, solids cost around $5/kg as of 2008, while hybrid propellants are significantly more expensive. HTPB (which is not listed in the document but discussed in this 2008 study by Purdue School of Aeronautics and Astronautics) comes in at $8/kg and hydrogen peroxide at $10.36/kg. Hydrazine tops the chart at up to around $75.8/kg.

Prices Per Kilogram

LOX: $0.10 (onsite production; typical) to $0.27 (offsite supplier)

RP1: $2.30 (offsite supplier only)

LH2: $6.10 to $30.50 (offsite supplier only; nobody electrolyzes water onsite, nor do they crack natural gas onsite)

LCH4: $8.80 (offsite supplier only; this is largely due to pipeline costs, liquefaction, and removal of Mercaptans)

Propellant Cost Estimates for 2,000t SSTO Propellant Combinations for 40,000kg Payload

Estimates relate to delivery of a 40,000kg payload to a 185km by 185km Orbit, from Cape Canaveral / Kennedy Space Center, except 2,000t of LOX/LH2 is not required to deliver a 40,000kg payload to that target orbit, nor would that much LH2 fit inside a SSTO launch vehicle of approximately the same size as either LOX/LCH4 or LOX/RP1 SSTO vehicle. Thus, these propellant costs estimates are merely reflective of sourcing 2,000t worth of propellant combination, while the LCH4 and RP1 estimates are also actually capable of delivering that payload tonnage to that orbit, so their costs are reflective of what you would expect to pay for the propellants.

LOX: $166,667 to $450,000 for 1,666,667kg

LH2: $2,033,333 to $10,166,667 for 333,333kg

LOX/LH2 Propellant Total: $2,200,000 to $10,616,667

LOX: $144,444 to $390,000

LCH4: $4,888,889 for 555,556kg

LOX/LCH4 Propellant Total: $5,033,333 to $5,278,889

LOX: $125,926K to $340,000 for 1,259,259kg

RP1: $1,703,704 for 740,741kg

LOX/RP1 Propellant Total: $1,829,630 to $2,043,704

If LH2 can be cheaply electrolyzed onsite, then you absolutely will get more bang for your buck. Unfortunately, using the Space Shuttle External Tank as a representative propellant tank volume model is insufficient. There's not enough volume for the LH2 required, in order to achieve orbit with the same 40,000kg payload that LCH4 or RP1 can deliver. 70% CH4 (by weight) "gelled" LH2 propellant (according to NASA testing) retains 89% of the Specific Impulse of neat LH2 while propellant density increases by about 60% (71kg/m^3 to 177kg/m^3), so the propellant volume required to achieve equivalent payload delivery using LCH4-sized propellant tank volumes becomes workable. Isp is up by about 8% over LCH4 (Raptor engine technology), so you will get modestly more payload using gelled LH2, but it's almost a wash.

Neat LH2 simply requires too much volume. The density is so low that the propellant tank volume becomes unworkable if sufficient strength and stiffness are required. Short of substantially stronger structural materials, such as CNT, for LH2 fuel tank fabrication, you end up with a structure that could survive a single trip, but won't be soft landing anywhere, because it's too flimsy. This is why the comparison with LCH4 and RP1 doesn't work, unless the LH2 has a high mass fraction of CH4 gellant added to it, to bring its density up to about half that of densified LCH4. On top of that, engines with a sufficient thrust-to-weight ratio simply don't exist. Maybe gelled LH2 would change that, but I'm guessing that the thrust-to-weight ratio upper limit for neat LH2 is 100:1, so gelled LH2 is probably 125:1, LCH4 is 150:1, and RP1 is 200:1 (using extant engine and materials tech, achievable combustion chamber pressures, workable nozzle designs, etc).

All of these mass and volume estimates / generalizations assume densified propellants, similar to what SpaceX / ULA / NASA presently use i operational launch vehicles. If you spent the money / energy to chill the propellants to cryogenic temperatures, then you may as well spend a little bit more to pack in significantly more propellant. Your vehicle can be meaningfully smaller as a result, since vehicle cost is dry mass driven. Propellant densification is literal peanuts, cost-wise, by way of comparison.

Follow-on posts will contain some pad and facilities infrastructure cost estimates, because any reusable vehicle requires routine maintenance, there are real cost benefits to onsite LOX production, as noted above, and any other required elements of the program, such as runways, have real price tags attached to them. Some cost sharing with the Air Force, civil airline operators, or cities which pay for their airports, may be possible, but there will be cost incurred, regardless of working arrangements. All of this factors into evaluating SSTO operational costs, which are non-trivial, just as they are for conventional expendable TSTO partially or fully reusable TSTO. In the end, someone has to be willing to pay for all of this.

Offline

Like button can go here

#2 2024-05-24 12:22:01

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,046

Re: SSTO Operating Costs

This post is reserved for an index to posts that may be contributed by NewMars members over time.

Costs of related items will vary so NewMars members who follow prices are invited to report current values.

(th)

Offline

Like button can go here

#3 2024-05-24 13:19:48

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: SSTO Operating Costs

A quick note about exotic and toxic propellants:

The trade space of acceptable solutions for this area of SSTO research now appears to be rather constrained by what we now know from past experimentation.

There are a handful of other fuels and oxidizers that look more favorable, at least on paper, as compared to H2, CH4, or RP1. None of them offered compelling enough performance advantages to replace those propellants. Cryogenic / densified C3H8 (Propane) can offer a payload increase over RP1, but almost nobody uses Propane rocket engines.

There are a number of historical or seldom used engines that consume various NTO Nitrogen Tetroxide and Hydrazine derivatives, mostly limited to Russian and Chinese launch vehicles these days. The Titan, Proton, and Long March rockets are the stand-out examples of rockets that use or did use such propellants. We largely stopped using significant quantities of storable Hydrazine-based propellants, specifically because they are so toxic, but most of all, very expensive and time consuming to properly handle. Periodic launches could use such storable chemicals, but LOX, RP1, LCH4, LH2, or APCP and HTPB solids are our go-to propellants we're most familiar with in modern times, in America. The "little bit extra" of performance you can get from those storable liquids was not deemed worth the "lot bit extra" of the problems you must deal with.

Toxic oxidizers choices such as Chlorine or Fluorine might offer improved Specific Impulse over Oxygen, but they're highly reactive with composite resins as well as metals (Fluorine destroys most materials), require special handling skills and equipment to avoid killing yourself during propellant loading, and they're not mass-manufactured in nearly the same volume that LOX is.

H2O2 doesn't offer any payload performance improvement over LOX, to the point that it's essentially usable in a SSTO, much less worth the hassle and hazard of using it at high concentration levels where it can spontaneous decompose and destroy the vehicle and pad infrastructure.

NTO / MMH offers about a 16% density impulse improvement over RP1, with a modestly poorer Specific Impulse.

LOX / MMH offer a modest Specific Impulse improvement over RP1, with a 9% Density Impulse improvement.

There definitely appears to be a "sweet spot" for SSTO propellants where both the Specific Impulse and Density Impulse are sufficient to allow for reasonably compact propellant tanks and reasonably high rocket engine performance. 310s (RP1) to 410s (LH2 gelled with CH4) seems to be the lower and upper bounds for acceptable Specific Impulse from the propellant combination selected. If you try to go lower to get more compact propellant storage, all your payload mass fraction gets consumed by low Specific Impulse. If you try to go higher, all your payload mass fraction gets consumed by propellant tank mass.

The only realistic way to use LH2 fuel to improve payload mass fraction is to implement CNT-based composites. The only realistic way to use solids is to implement both CNT-based composites and to reduce the cost of the input materials used to make solids. Either way, that's a tall order and you still have poorer relative performance to extant liquid engines burning RP1, LCH4, LC3H8, or LH2 gelled with CH4. As with so many other problems in life, there are definite materials limits involved with well-developed and reliable technology, and propellants are not an exception to that rule. Storable oxidizers that are not cryogenic are either toxic or dangerous or have poor Specific Impulse or all of the above. Maybe some bright young chemist can concoct a reasonably non-toxic storable oxidizer with acceptable performance in a rocket engine, but thus far nobody has.

Offline

Like button can go here

#4 2024-05-25 11:22:04

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,346

Offline

Like button can go here

#5 2024-05-25 14:33:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: SSTO Operating Costs

SpaceNut,

Is that supposed to be an image or a link?

I don't think it came through on the forums.

Offline

Like button can go here

#6 2024-05-26 02:42:35

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: SSTO Operating Costs

SSTO TSTO tif File converted to jpeg

Offline

Like button can go here

#7 2024-05-26 07:42:13

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,346

Re: SSTO Operating Costs

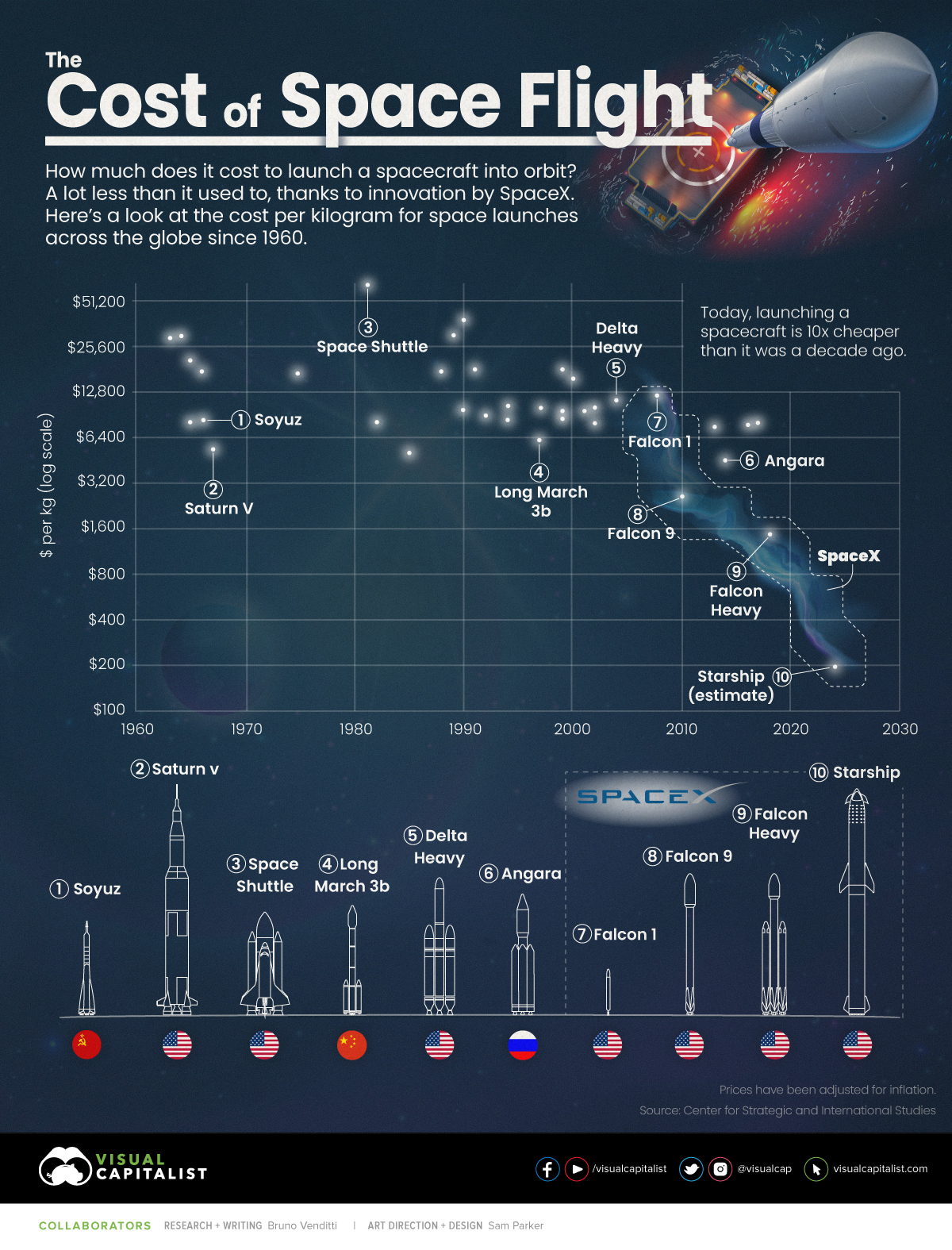

Space x Falcon 9 is listing for 62 million and was targeted for 50 plus flights.

Of course, Space x is making money even at that level and if we are launching 50 or 100 people to Leo then man is getting to orbit for less that tourist trips to the ISS.

Offline

Like button can go here

#8 2024-05-30 11:04:26

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,046

Re: SSTO Operating Costs

I asked ChatGPT4o to estimate the cost of hydrogen and oxygen for kbd512's notional SSTO vehicle ...

Summary of Costs:

Cost of Liquid Hydrogen (LH2): $296,540.28

Cost of Liquid Oxygen (LOX): $54,365.72

Total Cost of Propellant: $350,906.00

This is the estimated cost of the propellant needed for a single launch. To determine the ticket price for a single human to travel to space in this hypothetical vehicle, other factors such as vehicle construction, maintenance, operations, crew costs, and additional mission expenses would need to be considered. However, this gives a foundational estimate based solely on the propellant costs.

It seems possible that a ticket might cost $1,000,000 in this scenario.

Cost Analysis for a Ticket to Space

Introduction

To estimate the typical price for a ride to the International Space Station (ISS) or a similar orbital mission, we will consider historical examples of space tourists and recent commercial spaceflights.Examples of Space Tourists and Their Costs:

Dennis Tito (2001): Paid approximately $20 million to fly to the ISS with Russia's Soyuz program.

Guy Laliberté (2009): Paid around $40 million for a trip to the ISS.

Anousheh Ansari (2006): Paid around $20 million for her spaceflight to the ISS.

Yusaku Maezawa (2021): Paid an undisclosed amount for a trip to the ISS, estimated to be around $50 million.

Jeff Bezos, Richard Branson, and Wally Funk (2021): Participated in suborbital flights with Blue Origin and Virgin Galactic. While exact costs for Bezos and Branson are not publicly detailed, Virgin Galactic's ticket prices are around $450,000 per seat for future suborbital flights.

Recent Commercial Flights:

SpaceX Crew Dragon (Axiom Space missions): Prices for private astronauts to the ISS have been quoted around $55 million per seat.

Average Price Range

Based on these examples, we can observe that the price for a trip to the ISS or a similar orbital mission has generally ranged from $20 million to $55 million in recent years.Estimation

Given these figures, it's reasonable to estimate that the cost for a seat on a modern commercial flight to low Earth orbit (LEO) or the ISS would typically be in the range of $50 million.Summary:

Dennis Tito (2001): $20 million

Guy Laliberté (2009): $40 million

Anousheh Ansari (2006): $20 million

Yusaku Maezawa (2021): Estimated $50 million

Axiom Space (SpaceX Crew Dragon): $55 million

Conclusion

- Typical Price Range for a Ride to the ISS: $20 million to $55 million

- Estimated Average Price: Around $50 millionConsidering these figures, a ticket price of $1,000,000 for a trip to LEO would indeed be considered a significant bargain compared to current market prices.

The purpose of this post is to attempt to incentivize NewMars members to employ creative thinking and a variety of skills to design a vehicle that can provide taxi service to LEO at this rate.

The vehicle and it's cargo/payload must mass no more than 16,348 kilograms delivered to LEO.

The return-to-Earth flight will weigh less, assuming the passenger and cargo are delivered.

This would be a gossamer spacecraft, comparable to the famous gossamer aircraft that was flown across the English Channel.

On June 12, 1979, the Gossamer Albatross, with Bryan Allen as pilot, became the first human-powered aircraft to fly across the English Channel. The flight lasted 2 hours and 49 minutes and covered 36.2 kilometers (22.5 miles) between Folkestone, England, and Cap Gris Nez, France.

MacCready "Gossamer Albatross"

(th)

Last edited by tahanson43206 (2024-05-30 11:12:22)

Offline

Like button can go here

#9 2024-05-30 14:25:44

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: SSTO Operating Costs

tahanson43206,

Have either you or ChatGPT figured out yet why my proposed design carries 500 passengers and uses RP1 as the fuel?

Hydrogen is always more expensive than RP1, in actual practice, rather than what it should theoretically cost. We pay about $30/kg of Hydrogen. The fact that it uses less fuel doesn't make it any cheaper, because the quantity of fuel is not substantially less and it's much more expensive to make, transport, and handle.

No RP1 will ever be lost to boil-off. We won't have to worry about Hydrogen permeation and embrittlement. We won't have heavy engines with low TWR. Whatever minor weight differential we give up in terms of airframe strengthening, we make up for in terms of engine weight.

My propellant cost estimate is about $5,000 per passenger, which is the same as a business class ticket from LAX to Tokyo, except you're flying into orbit, rather than another city on the other side of the Pacific Ocean.

Since a 500 passenger TSTO does in fact require more thrust to reach orbit, that means more engines and more airframes. Starship's booster requires more than double the thrust of my proposed 500 passenger TSTO. I don't care how cheap SpaceX engines are (about $250K at this time), they require more engines burning a lot more fuel, the performance being demanded is every bit as extreme, and therefore maintenance costs will be higher, period. They have 33 engines on the first stage alone, plus 9 engines on the second stage.

Engines, fueling systems, flight control surface actuators, landing gear, and other moving parts of the airframe are what airline services spend serious money on. The airframe itself does require periodic maintenance, but things that move at high speed or get really hot are what costs the most money. The fewer moving parts, the lower the total cost, end of story. Starship is virtually the same size as this vehicle, but is fabricated from very heavy and low-strength austenitic stainless steel. It has tile-based surface insulation, same as this vehicle.

I don't see how a more complex vehicle with a lot more moving parts will ultimately become cheaper, except possibly by the kilogram of cargo delivered. We don't bother to pressurize the cargo compartment of an airliner, because that costs more money. That may be fine for cargo, but we're clearly willing to spend more money on the passengers, rather than forcing them to wear oxygen masks the entire flight duration. So, even if you can make cargo delivery cheaper than passenger delivery, there's clearly an acceptable premium attached to people movers vs cargo movers.

SSTO people movers will never compete with TSTO cargo movers on cost per kilo, but I think the airline industry already proves that they don't have to. Whether or not we could pinch pennies on fuel and materials, whenever humans are involved, only so much of that is allowed to happen before the government starts asking what your company is doing and why you're subjecting people to unnecessary risks to save a little bit of money.

Let's say we charged $10,000 per ticket and that the vehicle in question costs $250M to build- a fairly reasonable estimate, I think, for a high performance airliner, and about what Boeing 787s or Airbus A350s cost, despite the fact that they're constructed with a far greater tonnage of CFRP per airframe. As commercial aircraft go, cost is nearly always in proportion to weight. This vehicle is far lighter than any airliner of equivalent capacity, but it's made from semi-exotic materials, mostly composites and aerogels, with some high strength steel of the engines. After 100 flights with butts in all seats, we've paid off the cost of the airframe. If we can feasibly operate the plane for another 900 flights, that's $225B in profit. That seems far too high for a legit business, which means we need to reduce per-ticket cost to about the same as a business flight from LAX to Tokyo, which is about $6,000. It'll probably be a bit more than that, but you can see where this is going. It has to be operated like a commercial airline service, and priced accordingly, with the caveat that we require automated airframe and thermal protection system maintenance, engine health monitoring, and the passengers need to sign waivers to contain insurance costs.

Offline

Like button can go here

#10 2024-05-30 15:14:26

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: SSTO Operating Costs

AEROSPACE ENERGY STANDARD PRICES FOR DOD CUSTOMERS EFFECTIVE 1 OCT 2017

CY: CYLINDER

CZ: CUBIC METER

GL: GALLON

LB: POUND

LI: LITER

MC: THOUSAND CUBIC FEET (OF GAS)

TN: TON / 2,000 POUNDS

NSN 9135-00-965-2527 (PROPELLANT,OXYGEN): $129.97/TN

NSN 9130-01-522-9767 (PROPELLANT,ROCKET GRADE KEROSENE): $93.87/GL

NSN 9135-00-823-8133 (PROPELLANT,HYDROGEN): $152.45/MC

NSN 9135-00-890-2011 (PROPELLANT PRESSURIZING AGENT,HELIUM): $278.72

NSN 9135-00-823-8115 (PROPELLANT PRESSURIZING AGENT,NITROGEN): $7.50/MC

Note: Some NSNs from the list are either not current or haven't been procured by the government in over a year.

Offline

Like button can go here

#11 2025-07-05 06:52:50

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,046

Re: SSTO Operating Costs

For all...

GW's work posted in the exrocketman.blogspot.com site is now available by a single click.

https://exrocketman.blogspot.com/search?q=ssto

The paper is detailed, with plenty of graphs to illustrate the text.

I am guessing here, but it is possible that anyone offering an opinion without reading the paper is indeed likely to be missing something important.

(th)

Offline

Like button can go here

Pages: 1