New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2018-06-14 22:08:21

New high strength alloys for SSTO’s?

Space advocates will recall the X-33 was cancelled when its carbon composite

propellant tanks failed. But there may now be high strength aluminum alloys

that can fill that role. Then in fact the SSTO VentureStar may now be

possible:

DARPA's Spaceplane: an X-33 version, Page 2.

https://exoscientist.blogspot.com/2018/ … age-2.html

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2 2024-05-14 18:44:07

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,055

Re: New high strength alloys for SSTO’s?

This post is reserved for an index to posts that NewMars members may contribute over time.

The SSTO topic has been of interest to NewMars members since 2017-10-23 11:03:57.

The consensus in 2024 seems to be that SSTO is possible, if the vehicle is expendable.

A challenge for the SSTO enthusiast is to design a version that is reusable.

kbd512 delivered a post in May of 2024, explaining the advantages of an SSTO design for passenger transport to LEO from the surface of the Earth, if a practical design that is also reusable can be put into service.

I would like to see this collection of SSTO topics resolve into a practical solution that can be developed into a viable business.

99% of what I am seeing so far is reasons why the idea is impractical, or uneconomical, or both.

(th)

Offline

Like button can go here

#3 2024-05-14 19:07:07

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,382

Re: New high strength alloys for SSTO’s?

saving mass means not just trying to cheat the materials used but changing how its built as well.

Making shared walls much like the wing of a plane the tank shape as well.

Offline

Like button can go here

#4 2024-05-15 00:42:44

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,474

Re: New high strength alloys for SSTO’s?

Dr Clark,

Carbon composite saves about half-off the weight of standard aluminum tanks. But interestingly some new aluminum alloys have comparable high strength at lightweight as carbon composite and therefore could be used to give the lightweight tanks needed.

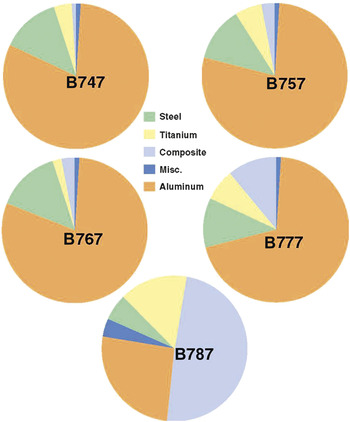

Aluminum alloys are not remotely as strong as aerospace composites, per unit weight. This is why all modern airliners use a substantial amount of composite material in their construction, but far less Aluminum than they did previously.

7068-T6 Aluminum - UTS: 103ksi; YS: 99.1ksi; Density: 2.85g/cm^3

MatWeb - 7068-T6; 7068-T6511 Rod & Bar

7075-T6 Aluminum - UTS 83ksi; YS: 73ksi; Density: 2.81g/cm^3

MatWeb - Aluminum 7075-T6; 7075-T651

TorayCA T1100G Fiber - UTS: 1,017ksi; Density: 1.79g/cm^3

Polyester Resin Density (max): 1.5g/cm^3

T1100G composite with 60% fiber-to-resin fill ratio - UTS: 502ksi; Density: 1.674g/cm^3

Resin Type: Epoxy, phenolic, polyester, vinyl ester

Toray T1100G Intermediate Modulus Fiber

None of those alloys shown on your graph have nearly as much tensile strength as a composite, per unit area or unit volume.

Almost the entire fuselage and wing are now composite structures, yet those little bits of metal still represent significant portions of the total vehicle weight. Metals are used where the engineers believe they're necessary and have the best mix of material properties, but sparingly if you want your aircraft to be reasonably strong and light in comparison to your competition.

The reason they're using more composites is shown here, in this graph of airline transport costs in the US, from 2019:

The airline services can control fuel consumption and therefore fuel costs by introducing lighter aircraft that burn less fuel. Try not paying your pilots or cabin crew, or not paying your aircraft loans / rents, and see how that goes. Nobody complains about lower fuel bills, not even the oil companies these days, because they're having a hard enough time finding more.

If airline services weren't concerned about fuel burn, then you wouldn't see more and more composites being used, along with more fuel efficient engines being introduced every year. It's not a giant engineering mistake. Even the Russian and Chinese made airliners are now mostly made from composite materials, because they still have to pay their fuel bills.

Offline

Like button can go here

#5 2024-05-19 23:07:22

Re: New high strength alloys for SSTO’s?

Thanks for that. The only thing I can think is perhaps the composites are not as strong in all directions so greater thickness is needed to get the required strength in all directions.

Here is an article that suggests the weight saving with composites over aluminum-lithium would be about 30%:

Published 1/28/2016

NASA/Boeing composite launch vehicle fuel tank scores firsts.

For more than 50 years, heavy metal cryogenic tanks have carried the liquid hydrogen (LH2) and oxygen necessary to launch vehicles into space. But in a joint effort, NASA and The Boeing Co. (Chicago, IL, US) have designed, fabricated and tested a composite cryotank that, if scaled up to current space launch system dimensions, would weigh 30% less and cost 25% less than the best aluminum-lithium cryotanks used today, and could warrant transport of as much as 1,400 kg of additional payload to low-Earth orbit and beyond.

https://www.compositesworld.com/article … res-firsts

Aluminum-lithium offers the lightest metal tanks commonly in use now, saving about 30% over standard aluminum. Then that means composites would save about 50% over standard aluminum since 0.7*0.7 = 0.49, about 50%.

In that blog post:

DARPA's Spaceplane: an X-33 version, Page 2.

https://exoscientist.blogspot.com/2018/ … age-2.html

I suggested new lightweight aluminum alloys would be about as lightweight as composites because they are twice as strong as standard aluminum for the weight:

This assumes for the metals this strength would be isotopic in all-directions so the greater strength would translate directly to weight savings in this case.

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#6 2024-05-20 09:05:35

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,474

Re: New high strength alloys for SSTO’s?

Dr Clark,

7xxx alloys are not used for cryogen tanks. They don't tolerate large and rapid temperature fluctuations particularly well, and 7xxx alloys are not fond of high heat, either. Despite their improved strength over other Aluminum alloys, they're also highly susceptible to stress-corrosion cracking. I think you should talk to a mechanical engineer who specializes in Aluminum alloys to understand why.

It looks like you've "shopped" this idea around on a rocketry forum and the other members there basically told you what I wrote a very lengthy response to last night, but then I decided you needed basic materials and engineering knowledge before the responses would make sense to you.

Fixating on one specific material property is not going to help your cause. I've already told you that CFRP grossly exceeds the yield strength of any metal alloy, and what I wrote about that was correct. If aero heating is a problem for modern CFRP resins, then it's a larger problem for Aluminum as well, because Aluminum didn't start with very much strength or stiffness at room temperature.

In many applications, stiffness or resistance to deformation is a much larger problem than pure yield strength. I think you need some engineering books to pick up the basics.

Do you have any idea how much faster / easier / cheaper it is to wind fiber around a mandrel / mold, in comparison to making a metal alloy tank as large yet impossibly thin and light as you want it to be?

Also, Elon Musk doesn't know what the hell he's talking about, with respect to material properties, and it's painfully obvious. You can't BS your way through mechanical engineering.

There are far better strong / light / high temperature resistant insulating materials than there are strong and light metal alloys.

The only thing SpaceX ultimately saved money on, presuming they intend to reuse the Starship vehicles, was the cost of the fabricating equipment, which is the sort of pennywise-pound foolish stuff that someone with no engineering experience would do.

In the end, the propellant tank structure is at least 10X heavier than it needs to be if it's made from stainless, which is 12.5X weaker than CFRP. Korean cold-rolled 304 cost $2,491/t. 300 series stainless prices are very close to the price of virgin Aluminum. US 304/304L slit coil is presently $2,050/t, so cost is nearly equal to T700 in terms of raw materials after strength differential is accounted for! T1100 fiber would cost about 5X as much, based on the T700 / T1100 cost differential, meaning 5X more than 304L at current 304L prices, for equal strength. 304L, at 39ksi YS, is 12.87X weaker than T1100 composite. There's simply no way that the rocket ends up being heavier, even after heat shielding material is applied. Someone looked at the strength of martensitic stainless steel vs austenitic (the material they're actually using), and simply "declared" that the rocket would be cheaper and lighter if it was made from steel. Ignorance has a real price tag attached to it.

The real issue at play here is fabrication time. SpaceX has a small standing army of welders to fabricate the steel tank structures. 2 to 4 people would stand around for about two weeks, feeding fiber spindles into a tape winding machine, watching the fiber being laid down on the mold / tool, and another 1 to 2 people would sit around to babysit the curing process. This is unskilled clean room labor. What they're doing is not physically demanding or dangerous, in contrast to welding of specialty steels. If you want to "scale up" CFRP manufacture, you need another tape winding machine, another mold, and another autoclave. 6 people and 3 machines can turn out around 52 rocket propellant tanks per year, or one per week. If he wants to build 1,000 rockets over 10 years, then 12 people and 6 machines. If he further invested in "Carbon Forging" machinery for mass production of autoclaved parts, then the curing process happens in mere minutes, rather than days. This is how Duc Helices produces CFRP propellers for light aircraft. Laying up the fiber takes much longer than curing or post-processing (all of which is accomplished in less than 5 minutes per blade), because they use pre-preg cloth rather than fiber roving / tow wound around a tool. Lamborghini, inventor of the "Carbon Forging" process, uses it to turn out body panels for vehicles made from chopped CFRP (exceptionally cheap material, yet almost as strong as cloth), and it's only modestly slower than metal stamping.

Do you think a 304L or 2195 vs T1100 rocket would be substantially cheaper, based upon labor costs for dozens of skilled welders?

When it comes to payload performance, even if every square inch of the composite requires some thermal protection, just as Aluminum does, you still come out ahead on labor time and capital expended per unit area of propellant tank, and time is typically money in business. That is why Rocket Labs uses CFRP. They figured out it would cost more money to fabricate propellant tanks from Aluminum-Lithium, as compared to CFRP, so they went with CFRP. It wasn't about the personal beliefs or ego of Peter Beck, just operating cost and thus cost to his investors. As more and more rocket startups use CFRP for the same reason- to save money, one has to wonder how much cheaper heavy metal can possibly be, for this particular application. The cost of Aluminum tank fabrication is presently eating ULA alive. They're using outdated processes that take too long and cost too much, so they're losing business to much cheaper SpaceX rockets with better Aluminum fabrication methods that don't involve a multi-stage mill / bend / heat treat process. When there's true competition, you either sink or swim. Capitalism is a ruthless and relentless process of weeding out inefficiency, unlike communism.

Offline

Like button can go here

#7 2024-05-20 11:45:14

Re: New high strength alloys for SSTO’s?

I agree with you the specifications for composites tensile strength suggests it should be 4 to 5 times lighter than aluminum. But for whatever reason when the tanks are produced they are only 50% lighter. By the way that is quite good since it means it would be lighter than any metal tanks in common use.

This is what I found after a Google search:

Bob Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#8 2024-05-20 12:20:56

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,382

Re: New high strength alloys for SSTO’s?

Space x was able to make such tanks but chose not to make use of them after the burst testing it did quite some time ago.

Offline

Like button can go here

#9 2024-05-20 19:55:38

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,474

Re: New high strength alloys for SSTO’s?

Dr Clark,

Along with yield strength, stiffness is another very real problem for large structures, and often more of a problem than pure tensile strength. Just because you can make something physically strong enough to resist being torn apart doesn't mean it's stiff enough to retain its shape when subjected to significant loads. If a structure continues to deform under load, then at some point it's also likely to fail.

A sky-high yield strength per unit weight is a great place to start. From there, you use geometry to impart the required stiffness. You have internal or external ribs / stringers / "stiffeners", honeycomb or "sandwich" core construction, and plain old material thickness. Doubling thickness provides 8X more stiffness. In the case of honeycomb / sandwich core, that does not equate to doubling weight. Since CFRP's density is about half that of Aluminum, it's a lot easier to add thickness and therefore stiffness for a given mass of material. Imbuing your structure or part with adequate stiffness is how / why you can still end up with a heavier part than what tensile strength alone would seem to dictate.

My overriding point, stated elsewhere, is that if the Space Shuttle External Tank was originally made from Al-2195 and weighed 26,536kg, then I have plenty of CFRP material volume to work with to supply enough strength and stiffness, if my material of choice is 5X stronger and 2X stiffer than Al-2195, for a given weight. I can enclose more propellant volume without running out of strength or stiffness. It's not my intent to greatly reduce the structural mass, because that is not possible for a 500 passenger SSTO. I want to use all of that allocated mass to provide sufficient strength and stiffness for reusability.

Modulus of Elasticity for Selected Materials:

7075-T6 Aluminum: 10,400ksi

Ti-6Al-4V: 16,500ksi

T1100G composite: 23,000ksi

Aermet 100 steel: 28,200ksi

Tungsten: 58,000ksi

Offline

Like button can go here

#10 2025-07-05 06:55:05

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,055

Re: New high strength alloys for SSTO’s?

For all...

GW's work posted in the exrocketman.blogspot.com site is now available by a single click.

https://exrocketman.blogspot.com/search?q=ssto

The paper is detailed, with plenty of graphs to illustrate the text.

I am guessing here, but it is possible that anyone offering an opinion without reading the paper is indeed likely to be missing something important.

(th)

Offline

Like button can go here