New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2024-05-03 12:13:31

Radian Aerospace spaceplane.

I enjoyed seeing the interview of Radian Aerospace co-founder Livingston Holder. He discusses why their sled-launched spaceplane is technically and financially feasible.

However, the horizontal launch method they propose has the disadvantage of needing heavy wings to support the fully-fueled weight of the spaceplane. In contrast a vertical launch method would use wings that only had to support the dry mass of the craft on return, resulting in much lighter wing weight. I advise Radian to do the trades to find which is the optimal method.

Additionally, I advise they base the core of their vehicle on existing upper stages to save on development costs and technical risk. I discuss using the Falcon 9 upper stage or Centaur upper stage for the purpose here:

Radian Aerospace spaceplane.

https://exoscientist.blogspot.com/2024/ … plane.html

Robert Clark

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#2 2024-05-08 13:57:36

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,174

- Website

Re: Radian Aerospace spaceplane.

All the proposed and all the actually-built orbital systems but one, over the decades, have been vertical launch. The only exception was the X-30 "National Aerospace Plane", or NASP. There is a very good reason for that.

If you do vertical launch, and fly a thrusted gravity turn at zero lift, you leave the sensible atmosphere at low supersonic Mach number, for rather mild ascent heating. If your vehicle is aerodynamically clean and slender, the energy you need to achieve is more-or-less represented by the surface low orbit speed, to which you need to add something like 10-15% to cover inevitable gravity and drag losses. To that you add budgets for rendezvous and for deorbit, and such like, for a "reasonable" dV requirement that results in "reasonable" mass ratios, especially if you do it 2-stage.

If you do it horizontal takeoff like an airplane, and you intend to fly a lifting ascent corridor to orbit, that corridor is a very narrow band of speeds vs altitude, below which heating is intolerable for all known materials, and above which the air is too thin for wings to hold you up. This corridor is NOT entry-in-reverse, despite the preconceived notions otherwise. During entry, your speed is orbital class until the final seconds, when the max deceleration gees pulse slows you suddenly. That keeps the high-heating exposure short, and thus survivable.

Flying to orbit up that lifting ascent corridor, most of your ascent is only supersonic to low hypersonic (at best), with the final pulse of acceleration coming only as you leave the sensible atmosphere. You are exposed to very significant heating for an order of magnitude-or-two longer time, rendering the heat protection problem pretty much insoluble with any of the technologies currently in hand.

Plus, there is the propulsion problem. No airbreathing propulsion concepts work well enough to produce significant climb rates, much above only 100-150-kft altitude. This is the "service ceiling problem" inherent to ALL airbreathing propulsion systems, of ANY type conceivable! Much of your ascent corridor is higher than that, where only rocket will work. Which is exactly why the scramjet X-30 project of the 1980's was nonsense from the word "go".

If instead you ascend to a "high" altitude near 40-60 kft, flying subsonic to low supersonic in airbreathing propulsion, you can pull up into the zero-lift thrusted gravity turn and leave the atmosphere at modest supersonic speed like a vertical launch rocket, but only in rocket propulsion! The airbreathers will be running short of thrust in the thin air. It is inherent. This option can actually be attractive if you stage the design: an airplane to reach "high" altitude at high subsonic to low supersonic speed, which then launches a rocket that makes the pull-up and ballistic trajectory from there.

Even if you do that last, it is the pull-up requirement that threatens feasibility. Your rocket is quite heavy, and will need big, strong (and heavy) wings to generate enough lift to successfully pull up to something like 45+ degrees above horizontal. You will use a LOT of rocket propellant during this pull-up, as did Pegasus. To avoid that, the launch airplane instead must perform the pull-up maneuver, which will require rocket propulsion added to its airbreathing propulsion. Either way, you are going to use more rocket propellant than most casual observers would anticipate, something like a dV nearer twice orbital speed than "only" several percent more than orbital speed. It is inevitable. Which is EXACTLY why Pegasus was staged.

All of this is quite independent of how your craft returns. If it returns at all.

Ugly little fact of life, but there it is. Which is also exactly why I am not a fan of horizontal takeoff concepts for reaching orbit.

GW

Last edited by GW Johnson (2024-05-08 14:05:29)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#3 2024-05-09 02:58:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Radian Aerospace spaceplane.

South Korea's KSLV-II launch vehicle is the closest performance analog I can find for this operating concept. All stages of that rocket burn Jet-A, rather than RP-1, and LOX, using gas generator cycle engines. That vehicle's wet mass is 200t, and its payload to a 200km orbit is 3,300kg.

For Radian One to function at all, while also remaining modestly mass-competitive with multi-stage launch vehicles, they need a lifting body design, not delta wings, and must keep the vehicle's dry mass fraction under control, despite requiring full reentry heating protection and dragging the entire vehicle's mass to orbit. I would think this implies CFRP construction, PICA-X heat shield materials, and very light landing gear, which is why the launch sled makes sense, so that integral structural hardpoints, rather than much stronger landing gear, supports the weight of the fully fueled vehicle. They also need to figure out how to tap into residual gaseous propellant for orbital maneuvering and the de-orbit burn, rather than separate RCS systems, which would add to the dry mass fraction.

It's going to be interesting to see if this ever goes anywhere.

Offline

Like button can go here

#4 2024-05-09 14:20:19

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,174

- Website

Re: Radian Aerospace spaceplane.

Myself, I favor vertical rocket launch of a two-stage winged vehicle, mounted belly-to-belly, with the larger of the two the first stage, that flies back to winged landing after releasing the second stage. That release would be at something like 2 km/s speeds and outside the sensible atmosphere, so its return is a re-entry heating and deceleration gees issue, although not as much an issue as an orbital return. Speeds at entry interface would be in the 2-3 km/s class, and the entry angles rather steep (30+ degrees?), so this is a serious area of concern. It only needs the wings to land the essentially-empty mass of the stage. Wings vs lifting body offer landing speeds in the 100-200 mph class, vs 200-300 mph.

The second stage provides most of the dV to orbit, but may use vacuum ascent engines to shoulder that requirement at a higher Isp. The two stages do not necessarily use the same propellant combinations, either. And the circularization, rendezvous, and de-orbit propulsion does NOT have to be the ascent propulsion! Could be a lifting body or it might be winged, but the mass to be landed is devoid of ascent propellant. Again, wings offer a lower landing speed. Entry heating is much higher at interface speed near 8 km/s, but the entry angle will be quite shallow: around 2-3 degrees.

Here's a thought: if the de-orbit and rendezvous propulsion is storables, there is no reason it could not also be used for go-around capability at landing when the mass is low (devoid of ascent propellant). Might just be another set of small engines usable at sea level.

Here's a safety item: this thing carries a payload deliverable to LEO. In an abort scenario, there might be no chance to off-load that payload! The design entry and landing conditions must still include that payload mass. The bigger that payload fraction, the bigger the effect upon the basic design.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#5 2024-05-09 19:12:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Radian Aerospace spaceplane.

Dr Clark,

If you're interested in evaluating realistic payload performance potentials from swapping-in different propellant combos in similarly-sized stages, then you may find the link below of interest to your trade studies:

The ideal rocket equation is manipulated to demonstrate the essential link between propellant density and specific impulse as the two primary stage performance drivers for a launch vehicle. This is illustrated by examining volume-limited stages such as first stages and boosters. This proves to be a good approximation for first-order or Phase A vehicle design studies for solid rocket motors and for liquid stages, except when comparing to hydrogen-fueled stages. A next-order mass model is developed that is able to model the mass differences between hydrogen-fueled and other stages. Propellants considered range in density from liquid methane to inhibited red fuming nitric acid. Calculated comparisons are shown for solid rocket boosters, liquid first stages, liquid upper stages, and a balloon-deployed single-stage-to-orbit concept. The derived relationships are ripe for inclusion in a multi-stage design space exploration and optimization algorithm, as well as for single-parameter comparisons such as those shown herein.

Dr Johnson, please let us know if what you see presented in the NTRS document link above looks generally correct.

Offline

Like button can go here

#6 2024-05-10 10:55:13

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,174

- Website

Re: Radian Aerospace spaceplane.

Kbd512:

Just glancing through it, it looks very much like some of the things that I do, rough-estimating vehicle sizings. It did not have a publication date, but I noticed the latest hardcopy reference was 2014, plus some things cited online that were viewed in 2015, so it's not that old a document. I'll have to look much closer, but they seemed to identify hydrogen oxygen as something they had to look at closer. Some of the ratios they looked at resemble rather closely some of the things I have used, regarding tankage. That's a good reference. I downloaded it. Thanks.

GW

Last edited by GW Johnson (2024-05-10 10:55:52)

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#7 2024-05-11 02:06:51

Re: Radian Aerospace spaceplane.

Dr Clark,

If you're interested in evaluating realistic payload performance potentials from swapping-in different propellant combos in similarly-sized stages, then you may find the link below of interest to your trade studies:

The ideal rocket equation is manipulated to demonstrate the essential link between propellant density and specific impulse as the two primary stage performance drivers for a launch vehicle. This is illustrated by examining volume-limited stages such as first stages and boosters. This proves to be a good approximation for first-order or Phase A vehicle design studies for solid rocket motors and for liquid stages, except when comparing to hydrogen-fueled stages. A next-order mass model is developed that is able to model the mass differences between hydrogen-fueled and other stages. Propellants considered range in density from liquid methane to inhibited red fuming nitric acid. Calculated comparisons are shown for solid rocket boosters, liquid first stages, liquid upper stages, and a balloon-deployed single-stage-to-orbit concept. The derived relationships are ripe for inclusion in a multi-stage design space exploration and optimization algorithm, as well as for single-parameter comparisons such as those shown herein.

Dr Johnson, please let us know if what you see presented in the NTRS document link above looks generally correct.

The article by Kibbey is hard to read. Two articles that argue clearly SSTO is possible and actually dense propellants are more efficient than hydrolox for SSTO are:

Alternate Propellants for SSTO Launchers.

Dr. Bruce Dunn

Adapted from a Presentation at:

Space Access 96

Phoenix Arizona

April 25 - 27, 1996

https://web.archive.org/web/20140215015 … llants.htm

And:

Single Stage To Orbit Mass Budgets Derived From Propellant Density and Specific Impulse.

John C. Whitehead

32nd AIAA/ASME/SAE/ASEE Joint Propulsion ConferenceLake Buena Vista, FLJuly 1-3, 1996

http://www.osti.gov/bridge/servlets/pur … 379977.pdf

Bob Clark

Last edited by RGClark (2024-05-11 02:07:38)

Old Space rule of acquisition (with a nod to Star Trek - the Next Generation):

“Anything worth doing is worth doing for a billion dollars.”

Offline

Like button can go here

#8 2024-05-12 04:55:07

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Radian Aerospace spaceplane.

Dr Clark,

I read your links / papers. I don't think SSTO is utterly impossible to achieve, but I do think SSTOs don't offer much over the most modern partially or fully reusable TSTO rocket designs. The cost and mass of the TPS, the expense of sophisticated specialty composites to stay within mass margins with adequate strength, low payload mass fraction (since so much of the orbited mass is wrapped up in the vehicle itself), and the relative low cost of upper stages make fully reusable SSTOs not mass or cost competitive with partially or fully reusable TSTOs. A fully reusable SSTO is more an object of affection than a practical vehicle design proposition.

The Space Shuttle was a 1.5 stage to orbit vehicle. Consider how much those orbiters cost to requalify after each flight. I'm sure we can do much better with modern materials and operating procedures, but everything that goes into making such a high performance vehicle reliable is also extraordinarily expensive to maintain. The most important cost saving measures would involve drastically reducing touch labor to refurbish the vehicles. As large as Starship is, I don't know if SpaceX will ever be able to fly it as cheaply as they need to, but time will tell.

Merely by looking at the gross mass to useful payload ratios of actual TSTOs and proposed SSTOs, I can see that the SSTOs generally require more propellant and structural mass than expendable rockets, with Skylon being the only exception, because it sources some of its O2 from the atmosphere. Skylon has never flown, nor has any proposed SSTO. That probably means there's more than a few nasty engineering challenges involved in making that work reliably, rather than any lack of trying.

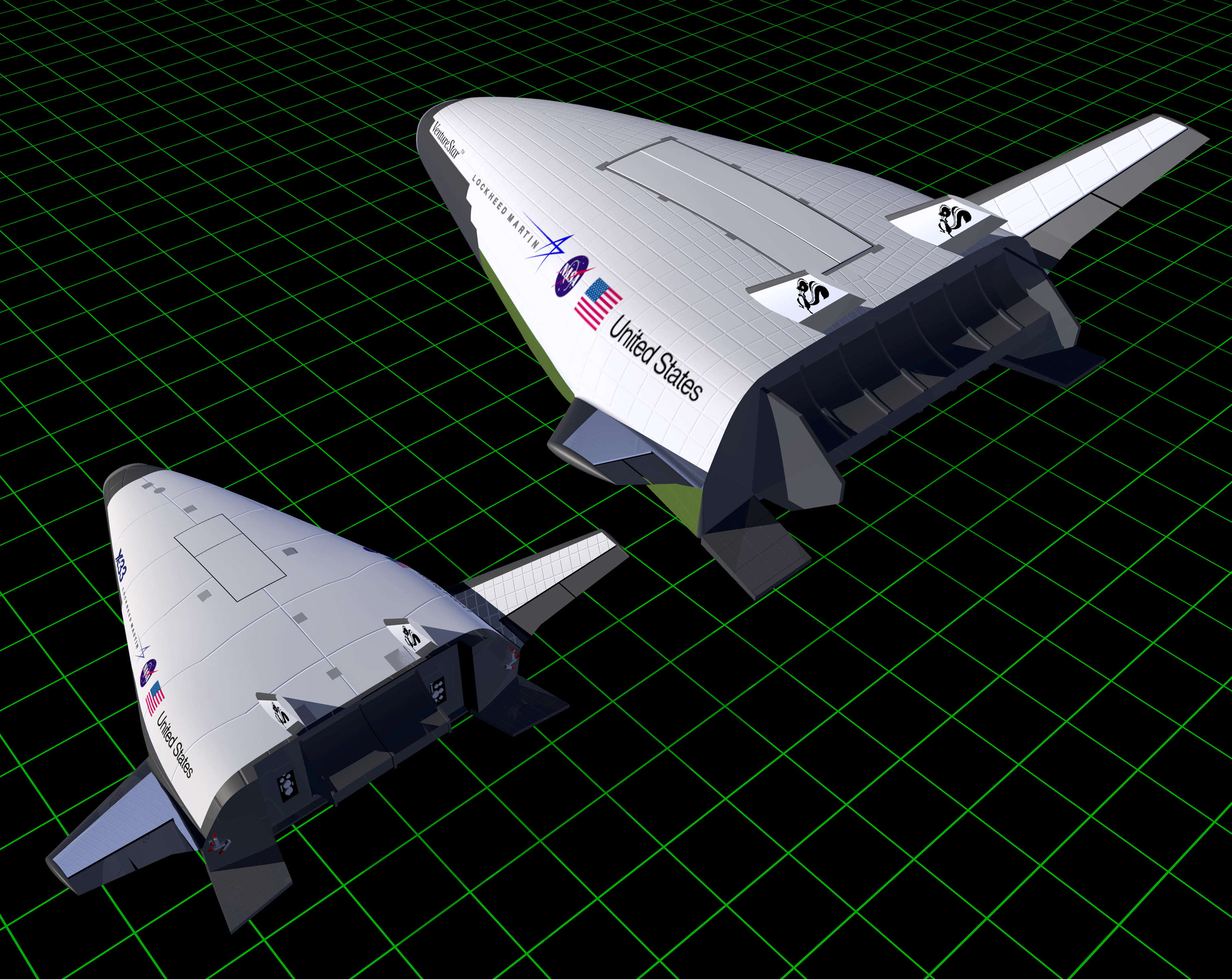

Gross Liftoff Mass to Useful Payload

Space Transportation System / Space Shuttle (partially reusable): 73.8:1

Lockheed-Martin VentureStar (fully reusable): 50:1

Rocket Labs Electron (expendable): 41.7:1

SpaceX Starship (fully reusable): 33.3:1

Atlas V 551 Configuration (expendable; 401 configuration shown below): 31.1:1

Rockwell "VTOHL 45t" Proposed Space Shuttle (fully reusable; pure LOX/LH2, never built): 25.7:1

Delta IV Heavy (expendable): 25.5:1

SpaceX Falcon 9: 24:1 (expendable); 31.4:1 (reusable)

Skylon: 21.7:1 (fully reusable, uses atmospheric O2 during ascent)

At best, a fully reusable SSTO that does not consume atmospheric O2 ends up being marginally worse than a fully reusable TSTO, or marginally better with air-breathing engines. At worst, a SSTO's payload is literally cut in half, relative to a comparable mass and size TSTO, such as Delta IV Heavy vs VentureStar. The required technology is far more mature today, but is it enough to make a SSTO a compelling option?

Offline

Like button can go here

#9 2024-05-12 10:59:34

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,174

- Website

Re: Radian Aerospace spaceplane.

Every time I look at the SSTO problem, I get the same results:

(1) you can only do this with LOX-LH2,

(2) you can only do this if the vehicle is all-expendable (but it is possible to properly dispose of it by deorbiting into the sea), and

(3) surprisingly-enough (especially to me!!) you can get into the same ~6-8% payload fraction class as most TSTO designs.

BUT, as #2 indicates this is all-expendable, and so can never be made to operate as cheaply as even a TSTO with only a reusable 1st stage.

Be aware that trying to do a lifting ascent to orbit runs into two fatal problems: (1) airbreathing is only attractive for a small fraction of the ascent very early, where altitudes and speeds are only supersonic and below about 35 km, and (2) the aeroheating problem is essentially insoluble because the exposure times are 1-to-2 orders of magnitude longer than those during entry.

Item 1 is because airbreathing thrust is crudely proportional to atmospheric ambient pressure, and above 35 km there isn't any significant pressure.

Also be aware that parallel-mounted nacelles (as in the Skylon tip-mounted engines) are entirely unsurvivable during entry, due to shock-impingement heating effects.

The lifting ascent problem has been known to be essentially insoluble since the X-15 days. So if you must do the gravity turn ascent instead, why take off horizontally, especially with a SSTO? Unless you build a staged design: carrier airplane with rocket second stage (which runs into the same problems Pegasus had).

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#10 2024-05-12 18:05:23

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Radian Aerospace spaceplane.

GW,

Super Lightweight (SLWT) External Tank (ET) Weight: 26,536kg (includes 2,188kg TPS)

SLWT ET Surface Area: 16,750ft^2

Orbiter Inert Weight: 74,844kg

Orbiter Surface Area: 11,895ft^2

Orbiter TPS Weight: 8,574.7kg

Orbiter RS-25 Engines: 9,531kg

6X SpaceX Raptor Engines: 9,600kg

Simple Surface Area Scale-Up of TPS Weight to Cover ET Volume: 23,236kg TPS

Silverbird Astronautics Payload Estimate for my notional SLWT ET-based SSTO: 71,595kg payload estimate, 47,835kg to 100,243kg is the 95% confidence interval for the estimate. This sounds exactly like the Rockwell SSTO "VTOHL 45t" Space Shuttle concept they wanted NASA to select. They probably didn't have the materials and engine tech to pull that off back then, but maybe we do today.

Suppose the entire primary structure is TorayCA T1100S filament / fiber. Tensile strength of the composite, not the fiber, is listed as 502ksi. Al-2195 is listed as 87ksi. If I throw in the 1.2X safety factor that one of the lead engineers stated was used in designing the orbiter's primary structure, then I should have plenty of additional material to play with for the wings and empennage, especially if I make the wings tankage, rather than dead weight. We know that CFRP works just fine at LOX/LCH4 temperatures, because we're building and launch CFRP tank rockets on the regular, and the composite is far less subject to Hydrogen embrittlement by LCH4 than LH2, even though there's still some of that going on due to free H2 in LNG. I don't have the dead weight of an interstage in this notional design, either, because I don't need to prevent the LOX from heating up LCH4 at the same temperature.

Let's consider total impulse for LOX/LH2 and LOX/LCH4, the two current propellant options we're most actively pursuing, because total impulse defines how much force can be exerted on the vehicle to push it downrange.

Space Shuttle's total burn duration was 520s and avg impulse was 2.0896MN per engine, or 6.2085MN for all 3 engines. The throttle-down to almost no thrust at Max-Q lasts for about 20s, so we'll use 500s. Total impulse is 3,104.25MNs.

Approximately 1,825,210kg of densified LOX/LCH4 would also fit inside the same volume as the LOX/LH2 in Space Shuttle External Tank, assuming a 1,147kg bulk density of both the LOX (1440kg/m^3) and LCH4 (423kg/m^3). I'm going to use 2.395MN per SpaceX Raptor 2. RS-25s weigh 3,177kg per engine, or 9,531kg in total. Raptor weighs 1,600kg per engine. That means 6X raptors weigh 9,600kg, so close enough, and total thrust is 14.37MN. Avg propellant mass flow rate per Raptor is ~720kg/s, or ~4,320kg/s for all 6 engines, so 422s of total thrusting time is possible with 1,825,210kg of propellant. That gives us 6,064MNs of total impulse, or almost 1.5X greater than the 3 RS-25s.

Space Shuttle ET LOX/LH2 propellant mass is 730,158kg, so 1,825,210kg is almost exactly 2.5X as much propellant stored in the same physical volume.

What do you make of that?

Offline

Like button can go here

#11 2024-05-13 10:39:08

- GW Johnson

- Member

- From: McGregor, Texas USA

- Registered: 2011-12-04

- Posts: 6,174

- Website

Re: Radian Aerospace spaceplane.

Kbd512;

The Shuttle 3xternal tank was big because the fuel was hydrogen. That cluster was NOT aerodynamically clean. I suspect the drag loss was probably somewhere in excess of 10% of surface orbital speed. Maybe quite far in excess.

Redesigned with LOX-LCH4, the tank would be quite a bit smaller designed to hold a mass equivalent in total impulse, that is true. That would reduce the drag loss some (and thereby the total impulse requirement), but no side-mounted cluster like that will ever be aerodynamically clean.

GW

GW Johnson

McGregor, Texas

"There is nothing as expensive as a dead crew, especially one dead from a bad management decision"

Offline

Like button can go here

#12 2024-05-13 13:29:36

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Radian Aerospace spaceplane.

GW,

Space Shuttle was designed for 650lb/ft^2 Max-Q, if that helps.

The link below, from NASA Space Flight Forums, shows a plot of the aero load vs time for ascent:

Shuttle Aerodynamics

Edit:

I never meant to suggest that we use a straight-up copy of the Space Shuttle External Tank. I'm only using that volume of propellant within the external tank, as a "reference propellant volume", in order to illustrate the total impulse provided by a given volume of propellant. At no point in time did I think / believe that the shaping of the External Tank was in any way "optimal" for any particular SSTO design.

With today's composites and various other structural materials, full flow staged combustion LOX/LCH4 engines, lightweight TPS such as PICA, and anticipated component masses, I wanted to know how much total impulse was provided for a given volume and mass of LOX/LH2 vs LOX/LCH4 or LOX/RP1. As the papers Dr Clark linked seemed to suggest, modeling LCH4 and RP1 provided more total impulse and lighter engines, therefore significantly reduced structural mass, when compared to LH2.

I would not have intuitively "guessed that", purely from my "common knowledge" understanding of what LH2 provides to upper stages, or the Space Shuttle for that matter. It's very counter-intuitive, because for the upper stage of a prototypical TSTO, LOX/LH2 is a great enabler. The demonstrated performance of LOX/RP1, even for very high performance Russian engines using exotic RP1 formulations, looks very "pedestrian" by way of comparison. It makes me think there might be something to this. We have to stop thinking about the vehicle design in terms of traditional metal construction or the composites of 30+ years ago, for which, as you already pointed out, there does not appear to be a viable solution. Composite technology move on from there.

There are flight qualified LOX, LNG, and even LH2 tanks, with either impermeable membranes or resins. Some of these test articles have survived 18,000 pressure cycles with O2, CNG, and H2, to stupidly high pressures far beyond what a rocket will ever see. H2 leakage rates are now on par with steel tanks. As you already pointed out, some leakage is inevitable, even through steel.

Modern composites can withstand higher temperatures than Aluminum before they're weakened to the same degree is Aluminum. They can resist permeation by cryogenic Oxygen, LNG, and to a lesser degree, LH2, without the use of a liner, even though there are spray-on liner materials now that also resist high pressure O2, CH4, and/or H2 permeation.

From TorayCA:

TC890 high temperature polyimide prepreg system utilizes PROOF Research Advanced Composites Division 900HT resin system. TC890 is a high temperature, polyimide-based thermoset prepreg with outstanding dry property retention at 343°C (650°F), wet service property retention at 288°C (550°F), and short-term and intermittent service temperature capability to 427°C (800°F). TC890 has been successfully demonstrated in short term, transient heating applications to temperatures as high as 1300°F. TC890 is an excellent non-MDA replacement for high temperature PMR-15 applications.

That seems like it should survive a transient heating event if the TPS can keep the temperature below 288C, and most certainly if it keeps it below 200C, because these composites are cured at higher temperatures than that.

Last edited by kbd512 (2024-05-13 14:28:06)

Offline

Like button can go here