New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2024-05-01 03:43:11

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,318

Planting Ships in the Ground

It occurs to me, looking at the designs of our most modern skyscrapers, that we're spending a lot of time, money, and energy planting what would otherwise be perfectly good ship hulls, in bedrock, where they can never go anywhere. Earth is quite literally covered with water, but to demonstrate our engineering prowess, we've fixated on building up instead of building out.

With the amount of time, money, and energy we've expended on glass and steel reinforced concrete, we could've flipped those boat hulls 90 degrees, built them from solid steel, and put them in the water where they belong. Ships at sea, the size of skyscrapers, don't have much to fear from the weather, or rising ocean levels, because they float. We're never going to run out of space to put them. We need slipways to launch them from and machines to build them quickly and with minimal labor, but welding them much closer to the ground in drydock has to be easier than this:

Concrete has low embodied energy compared to steel, but we're using enormous quantities of it, and recycling it is not so easy. Glass has more than double the embodied energy of steel and the sheets of this stuff on skyscrapers are as thick as the hull plating on many modern large ships. Globally, glass production is about 3X that of Aluminum production. Steel production is about 9X that of glass. Concrete production is about 16X that of steel production.

In the end, no energy is being saved. We're playing a silly shell game with silly results. None of this is intended to suggest that glass, concrete, and Aluminum aren't very useful, because they are, but we're only fooling ourselves if we think whatever we're presently doing is "saving" something. It's not.

People require sturdy structures to live in, they must have basic needs met, and they need jobs that provide a sense of accomplishment. A ship checks off most of those boxes. We still need farms, at least until we figure out how to synthesize food from scratch, but ships are great places to both transport and store people, food, fuel, and manufactured goods.

Why is it cheaper to build a luxurious cruise ship than a building? - Lu Ding - PhD Candidate

One of the newest cruise vessels, the MSC Bellissima cost £1 billion for its 450,000 sqm deck area spreading over 19 decks, which makes its construction cost £2200 (€2400) per square meter. This amount looks enormous, nevertheless, it includes its propulsion system, control and navigation systems, a grand atrium, 2 theatres, 12 restaurants, 4 swimming pools, a water park and all the interior decoration. To make the comparison, to my best knowledge, a new mixed-use project in Amsterdam may cost €2200-2800 per square meter to build, which becomes even more if high-rise construction is involved. This does not yet include the interior fit-out, costing another €500-1000 euros extra per square meter. This made me wonder, why are buildings we design nowadays so expensive to build? And why ship building, on the contrary, could have a lower price tag. In this article, I made a bold assumption of a few possible reasons to this:

Offline

Like button can go here

#2 2024-05-01 04:25:10

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,220

Re: Planting Ships in the Ground

I have sometimes wondered about the idea of building floating cities on rafts made from bouyant concrete cells. These could be anchored to the sea bed. A raft made from hexagonal concrete cells could be gradually expanded as a floating city expands. Individual cells would be held together using ropes or cables. The outer surfaces would be coated with polyethylene to keep sea water out of the concrete and prevent surface degradation.

There are many possible shallow sea bed locations where this could be done. The 'why' is a more complicated question. Cities tend to grow because they fill an economic niche in a larger economy. What niche would a floating city serve? Typically, small states have served as tax havens in the past. That is a parasitic function, but it serves some people well enough to keep these places going. A floating city state growing as a tax haven is certainly possible.

A small city could serve as a military base in certain strategic locations. A nation that has no territory in a region could create territory by making a floating base. It might be useful to the US to have a base like that in the South China Sea. I can see the Chinese building these in all sorts of places. Singapore grew as a city state, because it occupies a strategic choke point for trade going from east to west. A floating city could be sited in a strategically important location without the need to annex any other country's territory. It would function in ways not unlike an aircraft carrier, except it would be stationed in a particular location and would be much bigger. It could serve as a refuelling and victualling station for destroyers and other ships in the area.

Last edited by Calliban (2024-05-01 04:46:00)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#3 2024-05-01 05:26:36

- Terraformer

- Member

- From: The Fortunate Isles

- Registered: 2007-08-27

- Posts: 3,985

- Website

Re: Planting Ships in the Ground

Doggerland City could serve as a North Sea Free Port. A European Hong Kong with a liberal immigration policy, which won't alienate the existing population because there isn't one. Close to London, Paris, Rotterdam. The sea is only ~20m deep there, we should be able to build prefab breakwaters we can sink like the Maunsell Sea Forts?

The lack of existing population to complain makes them good for other purposes too. Like a prison. HMP Dogger Bank won't need much security so long as the boats are secured. We could also put asylum processing centres out there too...

Use what is abundant and build to last

Offline

Like button can go here

#4 2024-05-01 06:42:57

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,008

Re: Planting Ships in the Ground

For kbd512 re this interesting new topic !!!

Cruise ships are retired after service ...

I (vaguely) recall that at least one experiment was done in the US, to try to provide sturdy housing for low income folks using a docked ship.

That basic idea could be expanded, so that utility services are provided to an entire harbor full of such vessels.

The population would be protected from hurricanes, with suitable flexible mooring.

Update ... there may be something to be learned from US experience with retired shipping after World War II ...

https://baykeeper.org/blog/cleanup-ghos … w-complete

The web site at the link above describes a successful effort to persuade the US government to dismantle retired ships whose deterioration was causing harm to living creatures in and around the San Francisco bay.

If the concept of floating habitats is ever seriously pursued (setting aside existing wooden hulled ones that already exist) some thought might profitably be expended on design for a long service life that does not contaminate the water that supports the vessels.

Calliban's description of concrete floats coated in a plastic material sounds promising, if a plastic can be found that does not dissolve into the sea water.

Wood itself appears to have ability to serve as an interface between the ocean and a dry interior. Humans have some experience using various kinds of wood for this purpose.

(th)

Offline

Like button can go here

#5 2024-05-01 13:08:10

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,318

Re: Planting Ships in the Ground

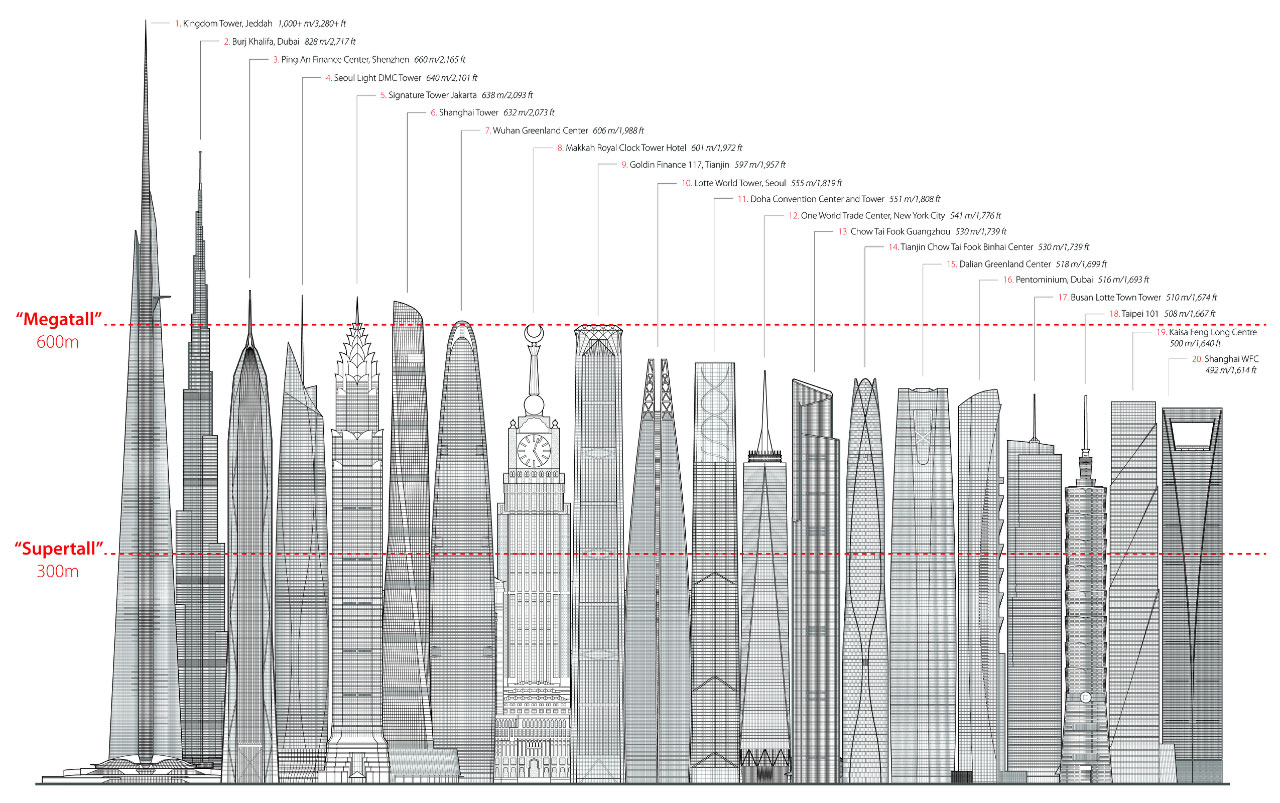

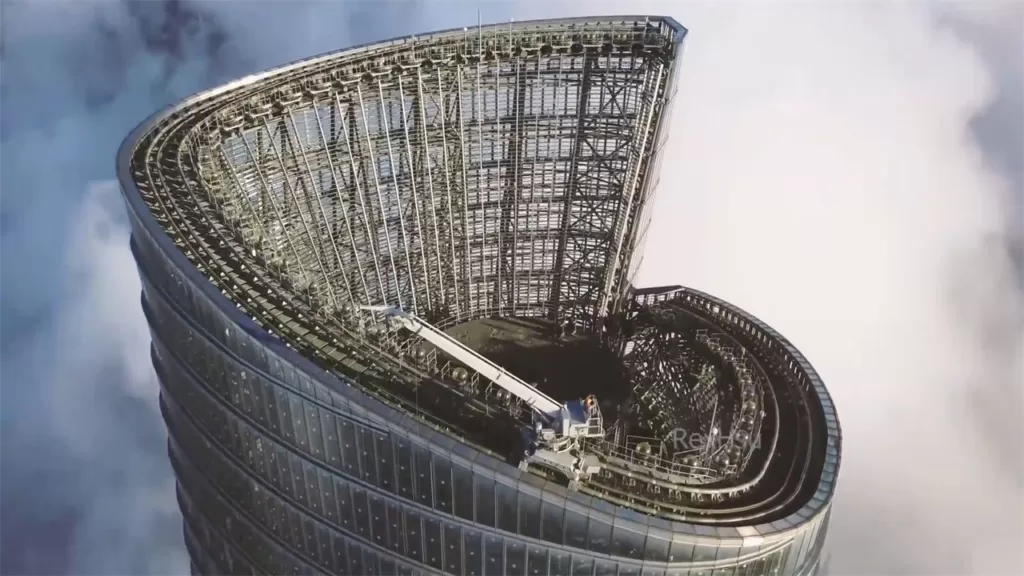

Ping An Finance Center, Seoul Light DMC Tower, Shanghai Tower, Wuhan Greenland Center, Lotte World Tower, Doha Convention Center, Tianjin Chow Tai Fook Binhai Center, Pentominium, and Shanghai WFC... All of those "buildings" are astonishingly good facsimiles of sleek ship hull designs that some architects thought would be a good idea to plant into the ground near the ocean, stern-first. They're all set into massive steel-reinforced concrete foundations. Why that seemed like a "good idea" when ships could be built instead, for far less money and material input, who knows? Those buildings all took multiple years to construct, as doctoral candidate Lu Ping pointed out, and they all cost a lot more than palatially well-appointed luxury cruise liners, which are now "home" to thousands of people. I would settle for a spartan but clean and well-equipped "seat at the table" for everyone, aboard ships so large and strong that they can only be sunk by deliberate human action.

Even the rather modest accommodations afforded to US Navy ships are far better able to sustain life than any palace of antiquity, they can and do travel millions of miles during their operational lives, and they're better protected than Fort Knox. The US Navy threw ordnance at one of their old super carriers for a couple of weeks before accepting that deliberate scuttling was the only way she'd go under. Megaton class nuclear weapons detonated within a few hundred yards didn't sink WWII escort carriers and battleships. Against a ship the size of a skyscraper, you'd have to detonate a nuclear weapon inside the ship to sink it. The larger the ship, the greater its internal compartmentalization, thus the more it takes to sink it. To sink a super carrier, you need to flood about 70% of the compartments below the water line. When all the hatches are battened down below the water line, that's not simple or easy to do. Against a skyscraper-sized ship with sufficient internal compartmentalization, that's functionally impossible without deliberate action. Titanic was a tinker toy compared to a "skyscraper ship", and she had no effective compartmentalization below her water line, in order to "save money". Design really does matter. Titanic was also built with rivets rather than welds. Tearing steel apart is not as easy as fracturing a rivet. There's no such thing as an "unsinkable ship", but there is such as thing as "cannot readily be sunk without deliberate acts carried out by those aboard to do so". Both super carriers and properly designed skyscraper ships both fall into this category.

As Lu Ping noted, steel is efficient, because steel is strong. Modern steels can be very strong- stronger than any alloy of Aluminum or Titanium by a lot, and Titanium suffers worse fatigue life than high strength steel when you make the Titanium alloy strong and hard. The leaps and bounds improvement of a bewildering variety of steel is the only real story. All the would-be "super alloys" are specialty products that don't see much use because there's not much they can do better than steel. There are no 350ksi Aluminum or Titanium alloys in existence, so far as I'm aware. In contrast, there are multiple different families of ultra high strength steels with different properties. Now that we have welding techniques and materials to use that are as strong and hard as the base metal, but no weaker or stronger or softer or harder, which is critically important to weld joint durability, we now possess the ability to make very strong and very light mega structures that resist both corrosion and deformation under load.

The right kind of steel doesn't appreciably corrode over 25 years. Nippon Steel NSGP-1 / NSGP-2:

Nippon Steel - NSGP-1 and NSGP-2 Corrosion Resistant Steels

Ultra-pure Iron from these new "green steel" projects, which always fail to consume less energy than traditional manufacturing methods, because energy input associated with reducing entropy is a "real concept" that is never going away, yet generally do succeed in producing measurably better end products, we have the materials we require to build with, and it happens to be the one structural metal we produce and consume more of, by a significant margin. Extreme purity Iron also implies slower corrosion, because oxidation of the microstructures (grain boundary reinforcements from alloying elements provide) that permit below-surface level corrosion to begin are dramatically reduced. Use of other metals like Lithium, Copper, Aluminum, and Titanium grab headlines, but steel continues to do the real work of building out a modern society.

Offline

Like button can go here