New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#126 2024-04-29 04:10:02

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Doing some simple math on what seasonal battery energy storage will cost the state of California, not the entire US, they think they need 36,300,000 MWh worth of battery energy storage to deal with seasonal demand fluctuations. Over-building photovoltaics just means more land use and environmental destruction, more embodied energy, lower EROEI, and even higher prices paid by consumers, plus more burning of hydrocarbon fuels.

The 3,000MWh Tesla Lithium-ion battery cost built at Vistra Moss Landing cost $560M.

The State of California thinks needs 36.3 million MWh worth of Tesla's battery storage to deal with photovoltaic power fluctuation by both seasonal and diurnal cycles:

$0.18666/Wh * 36,300,000,000,000Wh of energy storage = $6,776,000,000,000

Think about where the price has to go, to best $0.18666 per Watt-hour of electrical energy storage. Can it drop to zero? It pretty much has to, or photovoltaics are not going to provide 70% of the energy, now or ever.

$6,776,000,000,000 / $850,000,000,000 (FY2024 US military budget) = 7.97 years of America's FY2024 military budget

In 10 years when the Tesla battery croaks, we'll need another $6.776 trillion dollars to replace it

If you can't see why we're never going to do this "electronic-everything" insanity, it's because you're a magical thinker, so no amount of explaining will help you understand.

Crescent Dunes sold power at $0.135/kWh, and included 10 hours of storage, which means it stored enough power to actually produce it's nameplate capacity 91.4% of the time, which was also built for the State of California.

If Crescent Dunes was "too expensive" or "not profitable", then nothing involving sufficient electrochemical battery energy storage will fit that description for many decades to come.

What happened with Crescent Dunes?

The failures at the plant had zero to do with the plant not working, and almost everything to do with the people building the plant not following the instructions of Aerojet-Rocketdyne, the people who designed the plant, who did actually know what they were doing.

What was the moral of the story?

Never accept a pennywise pound foolish design or operating concept.

What are photovoltaics and electrochemical batteries?

A pennywise pound foolish design concept that is never going to scale-up to the degree required, unless electrochemical batteries become 6X cheaper than they already are. Since 70% to 80% of the cost of all photovoltaics and electrochemical batteries is now the raw materials used, that's a really good indicator that such a thing is highly unlikely to ever happen- unless the prices of photovoltaics and battery making materials alone continues to fall while all other prices increase. Over the past 5 years, we've seen the opposite happen. All prices have increased, to include the price of Lithium, Copper, and Silicon, because that's how market economics works when demand grossly exceeds supply.

The batteries will be replaced 2.5X during the life of the photovoltaics and the photovoltaics will be replaced 3X as often as a solar thermal power plant. All of that costs money. The costs won't be "miracled away" by ridiculous beliefs about things only continuing to get cheaper into perpetuity. That clearly isn't happening right now, and the assertions that they will happen in the future require that costs only run in one direction over time. Scarcity and depletion ensure that won't happen.

A solar sulphur cycle to make unlimited thermal energy storage

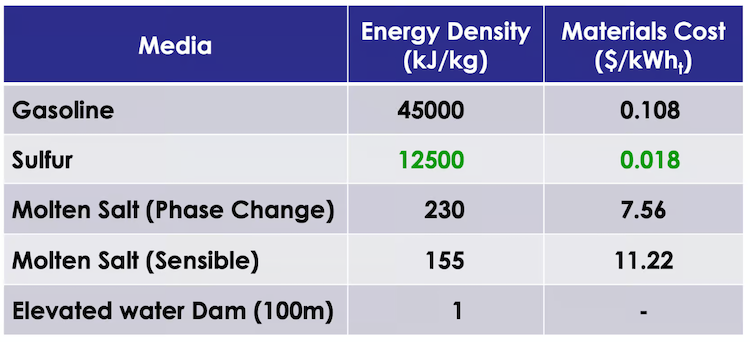

Are Lithium-ion batteries ever going to cost $0.018/kg, while storing 12.5MJ/kg?

Current Lithium-ion batteries store perhaps 1MJ/kg when they're brand new. Either a miracle is going to happen to increase battery energy density by 10X, as well as cycle life and durability, or far more likely, no such thing will happen during our lifetimes, so we're stuck with a pennywise pound foolish "solution" that solves nothing at the scale of the problem of attempting to replace hydrocarbon fuels.

tahanson43206 asked for more info about the costs of solar thermal power during our last weekly meeting, so here's some of that:

Profitability and break-even points, ROI with CSP alone and TES, spinning reserve capacity credits, etc (from 2010):

The Value of Concentrating Solar Power and Thermal Energy Storage

The part I like is that a backcasting statistical model for CSP can predict profitability with 87% accuracy / fidelity to actual. They said that TES cannot be justified on economics alone, but neither can photovoltaics with batteries. That said, if you want a 70% wind and solar powered electric grid, then that can only be done profitably using a dirt-cheap energy storage medium. No kind of electrochemical battery is anywhere close to the price of dirt, unlike Sulfur, which is $18 per 1,000kg, and it stores 12.5X more energy than any kind of battery, and it can be recycled endlessly, and it can be stored outside on the ground like dirt or coal, and it never "loses capacity" as it ages (because Sulfur is Sulfur forever), and it requires no additional mining activities to provide a supply sufficient to meet global energy storage requirements. The "pit of crushed rock" idea from MIT is even cheaper, at $2 to $4 per kWh.

Much like fusion, cheap / reliable / long-lasting electrochemical batteries are only 5 to 10 years away. Just like fusion, they always will be.

Offline

Like button can go here

#127 2024-04-29 04:37:50

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,292

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

They might do better storing anhydrous sulphur dioxide as a chilled liquefied gas. Its boiling point is -10°C. Concentrated sulphuric acid will dissolve almost any container on a timeframe that is short compared to the life of the plant. Decomposition of sulphur dioxide requires temperatures up to 950°C. That is difficult to achieve even with concentrated solar and corrosion will be a severe problem. I can't see this solution having much milage. The iodine sulphur cycle was once touted as a promissing method of converting concentrated solar heat into hydrogen. It has never advanced very much, because the temperatures needed are challenging and sulphuric acid is too corrosive. Same problem here.

One thing that molten salt has in its favour is that it is non-toxic and does not produce dangerous gases. Nitrate salts are also non-corrosive to stainless steels.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#128 2024-04-29 04:59:09

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,292

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

We could use sulphur dioxide in either brayton or rankine power cycles on Mars. The atmosphere and surface are dry, so there is very little moisture to contaminate the working fluid. The temperatures are low enough to allow SO2 to condense at pressures <1bar. Under standard conditions, it is 67% denser than CO2, allowing even more compact turbines and compressors. That has economic benefits. We won't be breathing the air on Mars, so an SO2 leak won't be a toxicity concern.

The critical temperature of SO2 is 431K or 158°C. So we won't need to dry the vapour if heating to 200°C.

https://www.engineeringtoolbox.com/crit … d_997.html

A solar trough concentrator can use water as its working fluid at 15.35atm. Using a rankine cycle, fluid is reinjected into the boiler as liquid. So pumping losses can be minimal. We could incorpirate a recuperator between the LP turbine and condenser to recover heat from the exhausted SO2. A 30% efficiency should be achievable, even at a working temperature as low as 200°C. A low cycle pressure is desirable if we are making components using ISRU. It allows the use of ductile cast irons rather than high performance steels. The SO2 is non-corrosive so long as water is kept out of it.

Last edited by Calliban (2024-04-29 05:21:39)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#129 2024-04-29 12:56:31

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

4 Materials to Consider for Heat Transfer Applications Involving Sulfuric Acid

Umax Advanced Ceramic - Silicon Carbide Cermaic Heat Exchangers

Sulfuric Acid Concentration Plant

A Laboratory-Scale Sulfuric Acid Decomposition Apparatus for Use in Hydrogen Production Cycles

As part of the US DOE Nuclear Hydrogen Initiative, Sandia National Laboratories is developing the high temperature process for conversion of sulfuric acid to produce sulfur dioxide as part of the thermochemical Sulfur-Iodine (S-I) cycle that produces hydrogen from water. The Sandia process will be integrated with other sections of the S-I cycle in the near future to complete a demonstration-scale S-I process. In the Sandia process, sulfuric acid is concentrated by vacuum distillation and then catalytically decomposed at high temperature (850°C) to produce sulfur dioxide, oxygen and water. Major problems in the process, corrosion and failure of high-temperature connections of process equipment, have been virtually eliminated through the development of an integrated acid decomposer constructed of silicon carbide and quartz. The unit integrates acid boiling, superheating and decomposition into a single unit operation and provides for exceptional heat recuperation. The design of acid decomposition process, the new acid decomposer, other process units and materials of construction for the process are described and discussed.

2006 DOE Hydrogen Program Review - Sulfur-Iodine Thermochemical Cycle

Did anybody else catch the power density of the chemical reactor core?

It's 75MW/m^3.

The AP-1000 nuclear reactor design is 109.7MW/m^3.

That means the power density of the Sulfuric acid chemical reactor pressure vessel approaches that of an advanced nuclear reactor design.

If we can't make that work, then 700Wh/L / 0.7MWh/m^3 Lithium-ion battery energy density is far too poor to even bother with.

Sulfuric acid is 1,840kg/m^3 at room temperature, so our chemical reactant stores 23,000MJ/m^3 (12.5MJ/kg * 1,840kg/m^3) or 6.389MWh of thermal power per cubic meter of reactant volume. Even if we're only 50% efficient at turning that thermal power into electricity, that's still 4.5X better than the latest and greatest Lithium-ion batteries. Battery manufacturers would give up almost any amount of money for a 4.5X volumetric energy density improvement. The batteries could get even heavier but EV manufacturers wouldn't care if you could simply get rid of the ridiculously high volume occupied by all types of electrochemical batteries, in comparison to gasoline. The volume consumed by a battery is its own form of inefficiency, due to all the packaging materials required to enclose the battery, as most of the battery pack is not active material, it's packaging materials.

36,300,000,000,000Wh / 3,194,500Wh/m^3 (50% thermal efficiency) = 11,363,281m^3

36,300,000,000,000Wh / 700,000Wh/m^3 (Lithium-ion batteries) = 51,857,143m^3

Sulfuric acid is the most widely produced bulk chemical across the globe with a yearly output of around 201.6 million tons.Mar 24, 2023.

201,600,000,000kg per year / 1,840kg = 109,565,217m^3

California only represents about 7.18% of the total annual US electric energy consumption, but they need about 9.64% of the total annual Sulfuric acid supply to achieve 100% "green energy" consumption, according to them.

Total global Lithium production was 180,000t in 2023, as opposed to 201,600,000t of Sulfuric acid.

Are we going to scale that up multiple orders of magnitude to meet demand?

Obviously not.

Why, then, is everybody acting as if we are, when anyone who can count knows that is not going to happen in the next 20 years?

The process of opening a new mine is about as fast as the process of approving and building a new nuclear reactor.

Alternatively, we're going to create a miracle battery with 5X greater energy density, so that Lithium production doesn't falter and the battery can store as much energy as a reversible oxidation reaction. We're going to invent some brand new electrochemical battery tech to supply the energy required, because otherwise there's not enough metal production to implement the solution. We also make 100,000t of Sodium metal, annually. I'm not so sure that's gonna scale up quickly, either, and because energy density is lower than Lithium, of course we'll need evern more metal to work with.

Offline

Like button can go here

#130 2024-04-29 14:15:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Most elemental Sulfur production in America / China / Russia / Saudi Arabia / elsewhere comes from refining oil and natural gas. That is another way in which hydrocarbon fuels serve multiple purposes.

Domestic elemental Sulfur production was 8,706,000,000kg in 2019, according to USGS 2021 data.

8,706,000,000kg / 1,840kg per cubic meter = 4,731,522m^3

That means we need more than 2 years of domestic Sulfur production to power California, a state that only consumes 7% of the total energy of the US. I wish someone else besides myself or Calliban could begin to appreciate the enormous scale of the task of replacing hydrocarbon fuels, and stop pretending that some new photovoltaic or battery invention will come along to solve a problem that is entirely about production of the materials and machines required to do the work.

"Knowing" how much of what materials are required is only basic math and accounting skills. If you don't like the numbers, then you need to come up with a new invention. We've been working on electrochemical battery technology for more than 100 years. We have Lead-acid, Nickel-Cadmium, Nickel Metal Hydride, Lithium-ion, and Sodium-ion. Every rechargeable battery cell chemistry is some minor variation thereof, but none of them remotely approach the energy density of chemical oxidation reactions involving Carbon, Hydrogen, and Sulfur.

Are electrochemical batteries great bits of tech?

Sure they are. For powering your cell phone, wristwatch, or laptop, they absolutely are. In spite of how great they are for small portable electronic devices or cordless power tools, all of them are exceptionally poor at powering anything significantly larger and more powerful than that. Despite all the ridiculous stunts which have attempted to make "Lead airplanes" fly, nobody with more uncommon sense than money is buying airplanes made from Lead. The reason is not a big oil company conspiracy to prevent us from ushering in the new era of Lead airplanes. Devices which need to be reasonably light and compact, such as all motorized transport vehicles that move at highway speeds or faster, in order to make them most useful for the widest possible range of uses, are no longer light and compact when batteries are used. That is the real ideology-free reason that engineers pursued combustion engines over batteries for powering vehicles. Engineers don't really care if you want them to engineer something ridiculous, either. They'll happily take your money. Fools and their money are easily separated from each other, and if you can do it legally, the fool will be none the wiser, but much poorer, so even within a litigious society such as America, being foolish with money still has real consequences.

US EPA - Sulfur Supply Chain - Executive Summary

Applications: waste water treatment, Sulfuric acid production, fertilizers and pesticides production, chemicals production.

Offline

Like button can go here

#131 2024-04-29 18:28:36

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Seems that after reading all of the posts on scroll compressors used in the expanding means changing the turbine units blade shape as there are no or not many of them in the 10kw range and lower for use of the shelf. Will need to continue reading about expander design for making a solar thermal power creation unit.

Seems that sulfur is abundant on mars so we could make lots of these after the first is brought to mars from insitu materials.

Offline

Like button can go here

#132 2024-05-03 12:57:05

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

The sun helps too but you need to be clear of trees.

“Very Sunny” means something very different in Denver (245 days with sun) than it does in Portland, Oregon (142 days with sun), even if there are no shade trees around the house. Therefore, consider the map below.

My climate is more like Portland being in NH.

Offline

Like button can go here

#133 2024-05-03 13:39:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

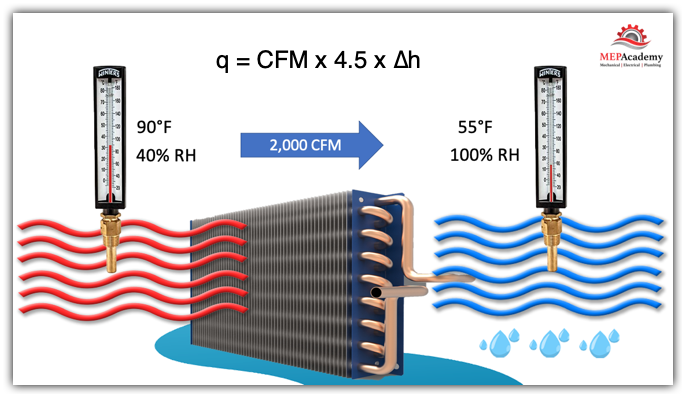

Some of the issues I have been working through is that the equivalents for energy are not all the same even when the BTU's are as the working media is not the same.

Understanding the Formula to Calculate BTUH

You may be familiar with the formula BTUH = CFM x ΔT x 1.08. This same formula is often rearranged to use for determining airflow by measuring the heat input and temperature rise.

CFM=BTUH/( ΔT x 1.08)To get the BTU per hour (BTUH) with electric strips you use the formula: BTUH = volts x amps x 3.41 BTUH/watt

Together the formula looks like:

CFM = (volt x amps x 3.41)/ ( ΔT x 1.08)The factor 3.41 comes from physics. It is the number of BTUs produced by one watt-hour of electricity. But where does the 1.08 factor come from? The "magic number" 1.08 is convenience factor. It is basically a bunch of math combined into one factor as a shortcut. You may recall that the specific heat formula is used for changing the temperature of something. The specific heat formula is:

BTU = weight x ΔT x Specific HeatThis has one big problem: we don’t measure airflow by weight, but by volume. AHRI Standard air weighs 0.075 pounds per cubic foot. We can convert a volume to a weight by multiplying the volume by 0.075 lbs/ft3. Another issue is that we tend to measure airflow by the minute and BTUs by the hour. You can fix that by multiplying times 60. Finally, we need the specific heat of air, which is 0.24. When you multiply the air volume by 0.075 to turn CFM into pounds per minute, multiply pounds per minute by 60 to get pounds per hour, and multiply by the specific heat of air 0.24, you end up with 1.08 (60 x .075 x 0.24 = 1.08). The number is not really a constant because the volume of the air varies a lot with temperature, which changes the "magic number."

This formula is accurate for dry air at around 70°F, but it is not accurate when the air temperature gets very much colder or warmer than 70°F. For example, 1.08 really does not work with flue gas or airflow in freezers because the air volume has changed, which changes the convenience factor. At 400°F the air only weighs 0.043 lbs/ft3. So the convenience factor changes to 0.62(60 x 0.043 x 0.24 = 0.62). At 0°F, a cubic foot of air weighs 0.086 lbs/ft3. This changes the convenience factor to 1.24 (60 x 0.086 x 0.24 = 1.24). The weight per volume also changes with elevation and humidity, although the change due to humidity is small. Even the specific heat changes as the air temperature changes, but again, the changes are small.

This is all to say that if you are dealing with air around room temperature, feel free to use the 1.08 convenience factor. However, if you are dealing with air at a much different temperature, you should look up the weight of air at the temperature you are working with. The table below lists the weight of a cubic foot of air at different temperatures so that you can perform correct air calculations at temperatures other than 70°F.

Temperature Weight lb/ft3 Convenience Factor Temperature Weight lb/ft3 Convenience Factor

0°F 0.08625 1.24 175°F 0.06255 0.90

10°F 0.08441 1.22 200°F 0.06018 0.87

20°F 0.08265 1.19 225°F 0.05797 0.84

30°F 0.08096 1.17 250°F 0.05591 0.81

40°F 0.07935 1.14 275°F 0.05399 0.79

50°F 0.07780 1.12 300°F 0.05219 0.76

60°F 0.07631 1.10 325°F 0.05051 0.74

70°F 0.07487 1.08 350°F 0.04894 0.72

80°F 0.07349 1.06 375°F 0.04746 0.70

90°F 0.07217 1.04 400°F 0.04608 0.68

100°F 0.07089 1.02 425°F 0.04478 0.66

110°F 0.06965 1.00 450°F 0.04357 0.64

120°F 0.06846 0.99 475°F 0.04242 0.63

130°F 0.06730 0.97 500°F 0.04134 0.61

140°F 0.06619 0.95 525°F 0.04031 0.60

150°F 0.06511 0.94 550°F 0.03933 0.59

Sensible and Latent Heat Transfer Equation for Air

q = m ∆h

q = CFM x 0.075 lb/ft2 x 60 min/hour x ∆h

q = CFM x 4.5 x ∆h

CFM is ft3/minute

M is the overall mass flow rate of air

h is the Enthalpy (Btu/lb.)

BTU calculation formula for air conditioner

now matter how you spell it I need 36,000 btu's for capabilitry for teh home size by foot print.

Offline

Like button can go here

#134 2024-05-03 15:59:03

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

Do the implications of what's printed on that map more or less indicate that photovoltaics aren't going to be feasible everywhere, and that the first task of any energy intermittent collection system, is to then store that energy for on-demand release to the electric grid?

When I think about the implications of intermittent energy, that's what I'm thinking about. How can we store enough hours of energy, at the scale required, for the concept to be workable at the human civilization scale? I don't fixate on what may or may not become available "in the future". None of these electronic energy generating concepts have a prayer at being human civilization scale solutions without multiple invention miracles prior to implementation.

That was why I came to the conclusion that a solar thermal system, most of which come with 10 hours of energy storage, would deliver power cheaper than a photovoltaic / wind turbine / natural gas / electrochemical battery solution, all of which are required to ensure that electronic devices supply stable power, and that such a solution was long-term and large-scale infeasible. That was not what I wanted to discover along the way, but that is ugly reality. That is why, after 40+ years of continuous technology development, photovoltaics or wind turbines with electrochemical batteries remains grossly uneconomic. It was never a solution using any known or projected future technology.

Solar thermal energy prices include 10 hours of storage, and solar thermal power plants operate over 90% of the hours in a year, which means they're every bit as reliable as nuclear reactors at actually delivering their rated power output, and recorded power production figures for the existing experimental solar thermal facilities bear this out. My thoughts on this were not random. There was nothing intrinsic to photovoltaics and wind turbines that I took issue with. If it works, it works. Aesthetics are irrelevant to an actual engineer. All the combination of factors limiting feasibility are heavily stacked against photovoltaics / wind turbines / electrochemical batteries, making them utterly impractical large scale solutions to deliver power at affordable prices.

A solar thermal power plant is no different in actual operation than a gas turbine, coal burner, nuclear reactor, or geothermal well, with the exception of what supplies the input heat energy to spin the electric generator. You turn it on, it gradually comes up to full output, and then as long as the Sun keeps shining, it continues to produce consistent output over time. That is what we require. That is real world usable power that doesn't mandate "reimagining" the way in which all extant electric power grids work, or radical changes to how we consume energy. Solar thermal is presently the cheapest of all possible long-term sustainable options for generating reliable on-demand power for whatever purposes humanity requires. Whether or not photovoltaics are cheaper when the Sun is high in the sky is irrelevant without equally cheap fast storage from electrochemical batteries or super capacitors or flywheels or similar high density storage systems. No battery lasts long enough, no super capacitor or flywheel achieves electrochemical battery energy density, and none of those systems can be built at the scale required. Energy demand doesn't stop the moment day turns into night. All forms of fast storage are dramatically more expensive than heated salt / rock / sand / water / air.

Until someone invents a new kind of battery that lasts 75 years and stores as much energy per unit weight and volume as a gallon of gasoline or kilo of coal, in order to change that paradigm, then we should move forward with energy generation and storage systems that can and do supply the energy in the form we require, at prices we can tolerate, which implies solar thermal or geothermal or nuclear thermal solutions, dependent upon local solar insolation.

The new energy system needs to be built from the ground up, which means extraction and refinement of the required materials without burning something, transforming those materials into machines without burning something, and then providing reliable 24/7/365 electrical or thermal power output without burning something. Partial measures won't help, nor will declarative statements about energy sources that don't match reality or vague references to future technologies or states of affairs in technology that don't presently exist. Then and only then should we worry about what comes out of the tailpipe of some transportation machine. As Norway already proves, with their 80%+ market penetration of EVs, has only resulted in a 10% decline in oil demand. That means the other 90% of the hydrocarbon fuel energy consumption was where the real climate change problem was. This is similar to California mandating that trains don't use diesel engines, when they contribute a grand total of 1% of our CO2 emissions, while moving 40% to 50% of all the freight. I don't know about you, but I like 90% solutions much more than I like 10% or 1% solutions. Ideologues shouldn't be in charge of energy decisions, because they're symbol-minded people with no understanding of cause and effect, let alone energy.

Offline

Like button can go here

#135 2024-05-03 16:24:10

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

It does have its place to use but not as a primary as the efficiency is not high enough. The solar concentrated thermal with the double of the PV panels makes that more attractive for sure.

For me its still requires tracking to get more of that energy from the sun as not doing so gets just 3 hours in winter and 5 during summer at best. But with it I would get 5 hrs in winter due to low angle but 9 hours in summer due to trees in the west that would block the light.

Even knowing my energy use for each season, the issue is that is an average and does nothing for knowing how large the peaks are.

Of course, we must choose a temperature range for the working fluid of choice and then we must select parts that can tolerate these values of heat and pressure.

Currently I am researching to scale for home use expander or turbo expander design.

https://www.simmsusa.com/wp-content/upl … anders.pdf

Fundamentals of turboexpander design and operation

Experimental Testing of an Organic Rankine Cycle with Scroll-type Expander

Offline

Like button can go here

#136 2024-05-04 17:40:45

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

Assert for a moment that photovoltaics are more efficient because you theoretically could get more Watt-hours of power out of them, over the course of a day or a year, in comparison to thermal systems, if only you had a way to store some of the power being generated. You can overbuild photovoltaics until the cows come home, but the moment the Sun slips over the horizon, no power is being generated.

Why is nobody building any energy storage subsystem to complement these large photovoltaic power plants?

Do you have any idea how much power we're losing whenever we cannot immediately consume it?

Rather than burn natural gas or coal continuously to maintain a spinning reserve, regardless of whether or not the sun is shining, why are we not complementing photovoltaics with energy storage, be it electrical (flywheels, super capacitors, gravity) or electrochemical batteries or thermal in nature?

If you're going to continue to burn natural gas in the background, even when you're going to dump the generated power straight into the ground just to claim you're generating "CO2 free power", how does that actually "help" reduce hydrocarbon fuel energy consumption?

Adding energy storage either makes the plant much more expensive, it makes it impractical, or the end goal is not to actually reduce CO2 emissions, despite all the claims to the contrary. Unless and until we stop consuming any energy when the Sun quits shining or the wind stops blowing, then a storage system is mandatory, and must be included in the cost of any energy generating plant claiming to be CO2-free, because in actual practice we revert back to burning something whenever there is no attached energy storage subsystem.

BU-802b: What does Elevated Self-discharge Do?

Battery System: Estimated Self-Discharge Rates

Primary lithium-metal: 10% in 5 years

Alkaline: 2–3% per year (7-10 years shelf life)

Lead-acid: 10–15% in 24h, then 10-15% per month

Nickel-based: Li-ion, NiCd, NiMH

Lithium-ion: 5% in 24h, then 1–2% per month (plus 3% for safety circuit)

The molten-salt based solar thermal energy storage subsystem at Crescent Dunes was designed to only "lose" about 2% of its stored thermal energy.

Concentrating Solar Power and Thermal Energy Storage

The US generated 4,178TWh of electricity in 2023. If we have an intermittent energy storage system, then we need to store about half of all the power we produce in a day. 5,723,287,671,233Wh / 5.7TWh of energy storage is equivalent to 12 hours of electrical energy storage.

NaCl / Sodium Chloride has a mass of 2,170kg per cubic meter and a specific heat capacity of 880J/kg°C. It melts at 801°C. With a hot side temperature of 600°C and a cold side temperature of 200°C, salt stores 352,000J/kg, or 763,840,000J/m^3. Let's say we could recover 35% of that heat energy, or 267,344,000J / 74,262Wh, as electricity.

5,723,287,671,233Wh / 74,262Wh per cubic meter = 77,068,860m^3 or 167,239,426t of Salt

Cast Iron has a mass of 7,873kg per cubic meter and a specific heat capacity of 449J/kg°C. It melts at 1,204°C. With a hot side temperature of 600°C and a cold side temperature of 200°C, Iron stores 179,600J/kg, 1,413,990,800J/m^3. Let's say we could recover 35% of that heat energy, or 494,896,780J / 137,471Wh, as electricity.

5,723,287,671,233Wh / 137,471Wh per cubic meter = 41,632,691m^3 or 327,774,176t of Iron

Iron-based thermal energy storage is 54% the volume of Salt-based storage, but 196% as heavy as Salt. The salt will undoubtedly be much cheaper to purchase, but salt will corrode steel when hot. The US produces about 40 to 45 million metric tons of NaCl per year, going back to 1975. It's one of the most remarkably stable commodity product outputs over time that I've seen. US steel production fluctuates between about 80 and 90 million metric tons per year, since about 2008. Current salt prices are $60 to $120 per metric ton, so split the difference and say $90 per metric ton, so $15,051,548,340 worth of salt. Scrap Iron price is presently $92 per metric ton, so $30,155,224,192 USD.

The so-called "climate change" bill set aside $392B for "dealing with climate change". There was clearly more than enough money to build out thermal energy storage to store 12 hours of power, even after the cost of labor and any energy-intensive material transformations took place. Captured waste CO2 from power plants would provide the working fluid for sCO2 gas turbines. There's clearly no shortage whatsoever of this material. That begs the question:

If thermal energy storage costs so little to purchase, then why was no storage added to the US electric grid if the "the plan" is to make everything electric?

Inquiring minds want to know why such dirt cheap thermal energy storage systems were not built with any of that funding. It would enable all photovoltaic and wind turbine power systems to store energy very cheaply, with very little loss over time.

For the low price of 1 to 2 Ford class super carriers, which is apparently chump change to Uncle Sam, the US could've purchased the raw materials for 12 hours of electrical energy storage. All photovoltaic and electric energy generating systems could either buffer their power through the onsite thermal energy buffer, or deliver it directly to the grid whenever the getting is good. Even if we decided to go all-in on photovoltaics, energy storage guarantees that power is available at all times. That is how we actually use power in the real world. When we plug something in, we expect power to be available. Beyond that, a suitably large energy storage subsystem eliminates the requirement to overhaul or replace every piece of the existing electrical grid, decrepit as it may be.

If we decided that doing something meaningful to reduce CO2 production was on the agenda, rather than just spending money, it would have to involve ceasing to burn fuel to generate electricity whenever the Sun stops shining or the wind quits blowing, because that is the exact reason why no natural gas or coal fired power plant can ever shut down, here in America. The amount of money involved in thermal energy storage is so trivial that I fail to grasp why it wasn't first in line to receive funding from the climate change bill. Even waste heat from existing gas turbine or coal fired or nuclear power plants could be used to store thermal power to generate more electricity, so it's applicable to any kind of power plant. 12 hours of energy storage also gives you 12 hours to figure out your problem and fix it if your power plant quits working, or at least to gracefully shut down the grid if repairs take longer than 12 hours. Hospitals, pharmacies, and other critical infrastructure could receive priority power, for example.

Offline

Like button can go here

#137 2024-05-04 18:36:44

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,045

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

For all ... it is easy to be distracted as we post in this forum ...

Some very interesting posts have appeared in this topic recently, but they have very little to do with the purpose of ** this ** topic.

SpaceNut.... if you are going to build a solar trough energy collection system, please use this topic to report your design and progress.

If you (or anyone) are going to debate topics not related to solar trough design, construction, operation or maintenance, please find a more suitable topic.

(th)

Offline

Like button can go here

#138 2024-05-05 10:22:32

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Just a trough ends with storage volume at a max temperature of stagnation where no amount of heat coming in changes the temperature of the working fluid. At that point no work is being performed to do anything with the heat that has been stored and to separate what is to be done once you have the volume of heat is meaningless.

A disconnected topic does not start with where the heat comes from, nor will it answer any other questions for that heat usage as it's a store of value for entropy which has multiple variables to make use of. That all changes with the working fluid or materials that retain the heat. as to make use of a solid as a liquid means what phase change. Same holds true for a gas to liquid.

It's the same as trying to build a rocket when the tank is all that you desire as a topic as it ends with nothing.

The comparison of the PV to the trough was only in efficiency. Saying that a trough of the same foot print is better.

Topic contains

Trough Solar Collector-

1. Design- circle, parabolic flat ect

2. Construction- material type for each for desired temperature range

3. Operation- meaning fixed, 1 axis, or 2 axis to desired output from a store

4. Maintenance meaning longevity doing nothing, greasing bearings, cleaning reflective surface to applying protectants.

Offline

Like button can go here

#139 2024-05-05 13:30:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

was making a post and closed it

postr 13 is about parabolic shape to the trough so is post 25 at the end of the first page.

post 57 as well as 59 contain more for the troughs shape.

post 64 - 69 has more on the shape

post 95 is more on the parabolic

Temperature rise for size of the reflector.

How to calculate the temperature of a receiving point from concentrated solar power?

https://www.builditsolar.com/Projects/C … rating.htm

here are a batch of links that I had open

https://www.sciencedirect.com/science/a … 9701000098

https://www.nrel.gov/docs/fy21osti/77829.pdf

https://www.researchgate.net/publicatio … _Model_SAM

https://www.sbp.solar/parabolic-troughs/?lang=en

https://solartechadvisor.com/parabolic- … ollectors/

https://www.sciencedirect.com/science/a … 1118310743

https://www.sciencedirect.com/science/a … 2X20310252

https://www.sciencedirect.com/science/a … 2110000675

“Very Sunny” means something very different in Denver (245 days with sun) than it does in Portland, Oregon (142 days with sun), even if there are no shade trees around the house. Therefore, consider the map below.

My climate is more like Portland being in NH.

Offline

Like button can go here

#140 2024-05-05 16:20:21

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

One frequently overlooked aspect of overall plant efficiency is the shaping of the heliostats. One of the primary reasons that solar power towers have low overall efficiency than they theoretically should have is making the design of all mirrors the same. They're flat "billboard" mirrors. The mirrors near the tower have 80% to 90% optical efficiency, because most of the reflected photonic energy strikes the tower receiver assembly at much shorter distances, whereas the mirrors further away from the tower have efficiencies below 50%, sometimes well below, simply because all mirrors are flat. Without any shaping applied to the more distant mirrors from the receiver assembly, a great deal of the photonic energy is flung every which way but at the molten salt cavity being heated.

Bespoke mirror designs obviously increase cost over a piece of flat glass or sheet metal, but not to the degree people would think, due to manufacturing methods. In the case of Aluminized sheet steel, the flat stock can be "bent" or "shaped" to focus the reflected radiation, using the exact same hydroforming method used to create the complex compound curves of the ribs in an Aluminum aircraft wing. Some of the more advanced forming machines and methods don't even require a purpose built forming die. This also complicates assembly, as each mirror then has a specific place it belongs in the heliostat field, but this can be solved by adding laser-etched QR codes to each mirror base and mirror assembly. If it works for aircraft manufacture, it'll work for onsite heliostat assembly as well. Perhaps flat stock and the metal forming machine should be delivered to the assembly site, and then each mirror is "bent" onsite.

Crescent Dunes was built using onsite glass making, so why not onsite polished metal bending?

The flat stock manufacturing method I suggested using was the exact same method used to mass manufacture all modern vehicle exhaust systems behind the catalytic converter. Thin low cost sheet steel is coated with Aluminum, not typically polished in the case of a motor vehicle exhaust system because polishing adds cost, then stamped or formed into shape using hydroforming equipment, with or without specific dies.

A coil of Aluminized sheet steel:

A polished Aluminized sheet steel exhaust tip for a car:

An Aluminized steel roofing / decking sheet:

Aluminized steel piping:

It comes in different colors:

Hydroforming can create very complex shapes to optimize stiffness and strength:

Alternative hydroforming method dispenses with bladder, and achieves 60,000psi:

This is how we'll form our bespoke / bar-coded mirrors:

Ford Motor Company hydroformed welded sheet steel automotive chassis:

We even have expansion joint hoses to connect hot / high-pressure fluid lines:

We can even do furniture for when the construction crew requires rest breaks:

Simply because they could, that's "why":

Hydroformed GM LS-7 engine exhaust header / manifold:

The metal thickness I originally proposed is well in excess of what is actually required. 2mm thick is overkill for this application, especially after I looked at the support structures backing the glass mirrors.

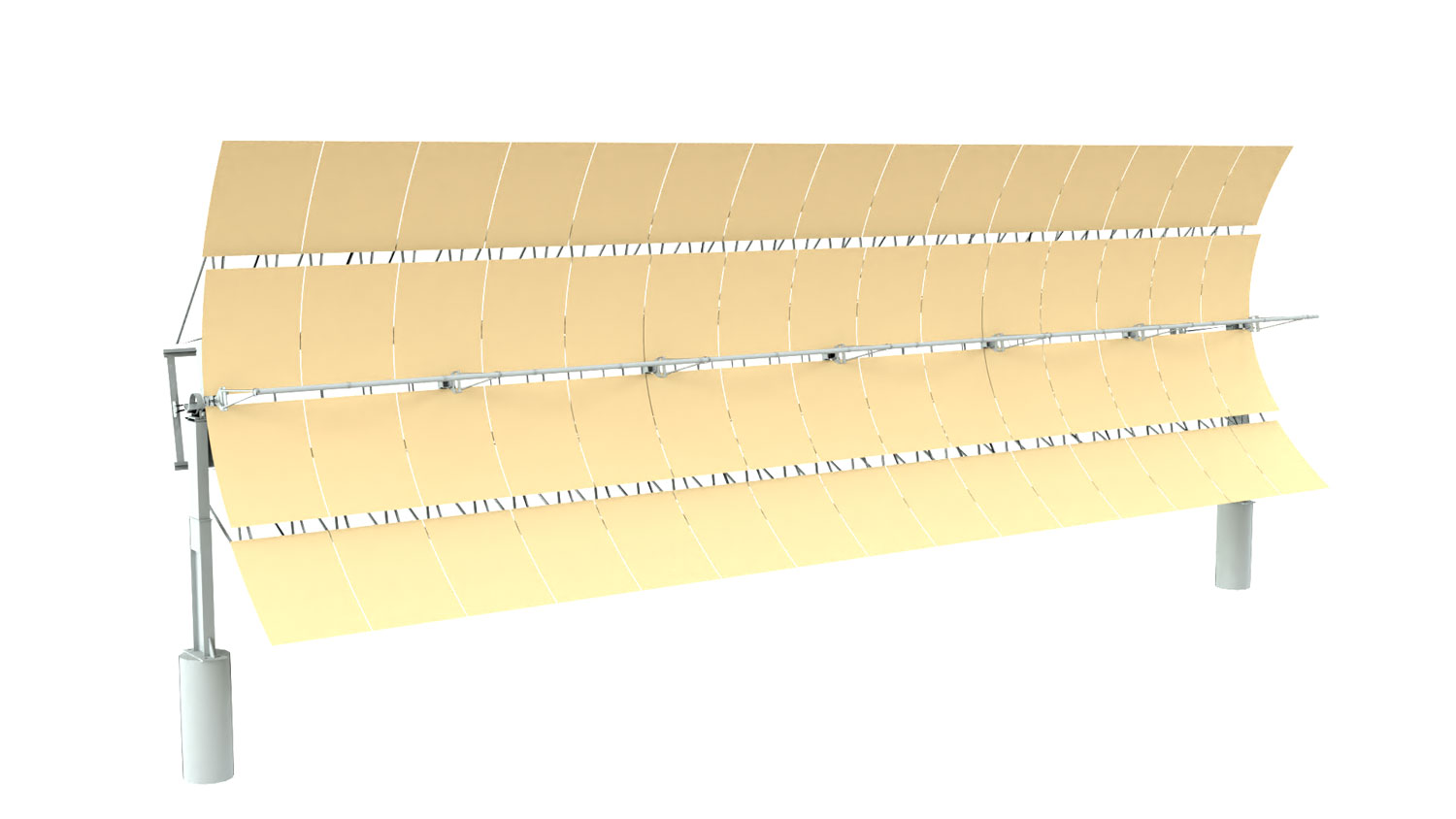

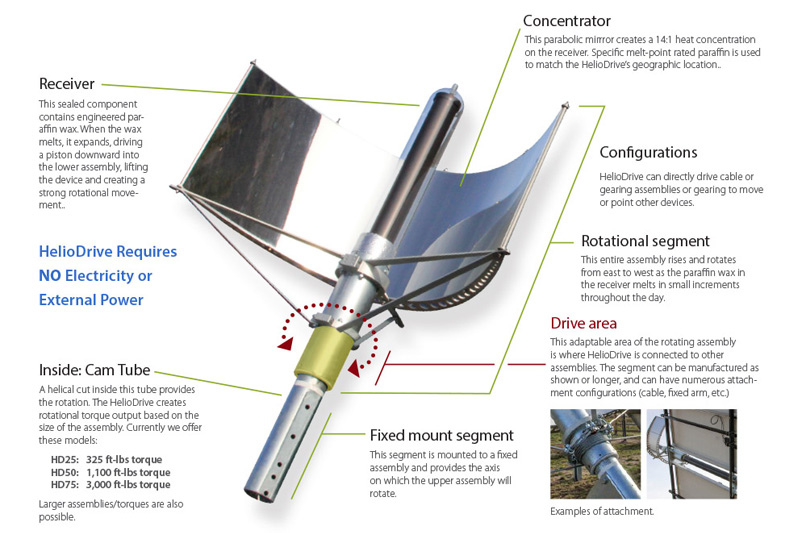

Heliostats used with solar power towers are dual-axis tracking machines. Solar troughs are single-axis unless they're parabolic dishes. Either way, there are dual axis Sun trackers, which I've provided a link to, which do not use electricity at all. They're mechanical metal and glass machines that can be mass manufactured very cheaply and provide tremendous torque to drive the tracking gear attached to the main mirror assembly. They do need to be individually adjusted, but once set, they're mostly "set-it-and-forget-it".

The suggestion of using hot-rolled steel was a cost optimization that went a bit too far. America mostly, almost exclusively, makes cold rolled steel product, which is more expensive than hot-rolled steel, but has an excellent surface finish that will make the Aluminum coating and polishing job a lot easier.

As far as maintenance is concerned, all mechanical or electrical or electro-mechanical systems require maintenance, but the maintenance of an entirely mechanical system requires hand tools and perhaps hand-operated cranes to adjust and repair. We're talking about steel and concrete here. Every industrialized nation on this planet knows how to maintain steel and concrete, and so do most developing nations. Simplicity and repeatability is key to global adoption. In developing nations like Pakistan, the reason you see far more all-mechanical diesel engines, is that their people, with bare minimum tooling, can maintain and operate those machines. You can't simply "drop off" a bunch of whiz-bang electronic equipment and expect their average mechanic to maintain it.

Sulas Industries all-mechanical dual-axis sun tracker (this was initially posted in 2013):

When I think about how this system is supposed to deliver power, it does so by minimizing rather than maximizing complexity the way photovoltaics, wind turbines, and electrochemical batteries do. At the end of the day, if the equipment keeping your people alive requires a college degree in engineering to maintain, then there's something wrong with your design, not the average worker. All the more sophisticated electrical and electronic devices we have over here are intended for a people who literally grew up with all the advanced technology. This does not describe the average person alive today, who has little to no understanding about how a computer works. Even the people who claim to have some better-than-baseline understand are largely ignorant. That is why adoption of newer and potentially better technology has been rather slow, and will continue to be slow.

After we decided to go back to harnessing ambient energy flows over more concentrated forms like hydrocarbon fuels and nuclear fuels, we needed to be very shrewd about how we approached design, to make the end product affordable and practical for widespread adoption. All-mechanical systems make this green energy technology accessible to people from first-world to third-world.

Simple things tend to be the most profound. A wheel is not terribly complex from a technical or mechanical standpoint, but wheels had a profound impact on transport and every other aspect of modern life. A rubber tire is multiple steps beyond the first wooden wheels, but we didn't go from wooden wagon wheels to airless composite and rubber "tweels", which is what our green energy enthusiasts want to do. I feel like the people who want this green energy technology really want to live within some sort of Jetsons cartoon fantasy, with no regard to the practicality of their "lifestyle choices" for the average person. When uptake of their favored technologies slowed, such as with EVs, they blamed everyone and everything but their own inability to accept that profound change is very hard to do, and that the average person cannot afford to roll around in a car that costs as much as a Cadillac and comes with a lot of ifs / ands / buts regarding how and when it can be operated, relative to the combustion engine vehicles they purport to replace.

I used to work with this lady from Thailand with a PhD in, IIRC, Geology or some specialization within Geology. We'll call her "Jane", even though that is not her name. After she'd been with the oil company we both worked for, for about 12 years in her case, only 2 in my case, she decided to leave to work at her family's restaurant, selling, of all things, Thai food. I asked her why she would leave such a well-paying job as hers, to essentially fill orders for food and cook in a restaurant. I said, "so Jane, what's up with you leaving the company?" She replied with, "Well, I understand some parts of what you and I work on, but it's all horridly complex, I don't understand all of it anymore, plus it's a giant hassle that keeps me up at night and working on the weekends, and I'd rather spend time with my family and children." At the time she had, I think, two small children, younger than mine, although I think she was only a few years younger than I was. That was perfectly understandable to me, even if I thought she was making a mistake, but in her mind that made perfect sense, and I cannot fault her logic, in recognizing and accepting that we're spending ridiculous amounts of time and effort trying to maintain a level of sophistication in our computerized systems that goes beyond what the average educated person can understand and make use of. Anything far beyond what is minimally necessary to accomplish a given task, and then move on to the next problem, is almost certainly a waste of effort. That is what all these modern electronic systems have become- something to keep people busy "maintaining efficiency", but not actually accomplishing very much.

Therein lies our problem. In our zeal to put all these green energy plans together, we've neglected that all-important human element. The average EV owner has no clue how their vehicle works, there's literally nothing they can do to maintain it, except to put air in the tires or plug it into the wall socket. Perhaps this is how they wish to interact with their transportation technology. I'm not them, so I can't say what they expect, other than that it generally works. Almost none of them could begin to actually determine if something significant was wrong with their car. Their electronic vehicle works perfectly until it doesn't, and then their only realistic option is to throw the entire car away and buy a new one. For many people, myself included, that is an insane idea. It's insane to me that the entire battery pack, or perhaps the entire vehicle, simply has to be replaced because one lousy cell went bad or had a manufacturing defect. We don' throw the entire engine away in a combustion powered vehicle because one spark plug quit working.

That said, energy generating and storage systems are incredibly expensive. Even the simplest ones are non-trivial in their complexity. Most of us simply cannot afford to throw them away every 10 to 25 years because some two cent electronic component burned out on a random circuit board somewhere, or one battery out of a couple thousand quit working.

So then, what is the "great object" of a thermal mechanical green energy generating and storage system?

To be simple enough that just about anyone can be trained to build and operate it, to be physically robust and user maintainable, to not require materials or technologies beyond our grasp, to not require sweeping changes to all aspects of how we presently generate or consume energy, and to become a pervasive permanent fixture of modernity that most people can get onboard with.

Those are all qualities which electronic devices lack. There are no gears to grease, no screws to tweak just so, and no possibility of significant alterations absent a complete redesign. The electronics will function perfectly until they don't, and then there is only complete replacement, which is no option at all.

Nobody involved with electronics gave any thought to how or even if they could be maintained. They did not concern themselves with where the materials would come from. Recycling was an afterthought, since it requires more energy and effort than making a new one from scratch. They tried to implement far too many sweeping changes at the same time. In short, they were throwing stuff at the wall to see what would stick, and that "wall of physics" they're throwing stuff at, happens to be made from Teflon. The only things that stick to it are those things which are in agreement with physics. Attempt to assert that energy density or economics doesn't matter, and both of those idea slide right off that wall.

Broad strokes, this is what we're going to do with solar thermal power:

1. We're going to entirely replace combustion, as well as electronics, for electrical power generation. We simply do not need or want our energy generating and storage devices to require precise computer control, unless absolutely necessary. When the power supply is continuous and can load-follow, that added bit of complexity is not necessary. Whatever minor efficiency improvement has been made in one functional area has been lost in many others, such as ultimate sustainability and maintainability.

2. We're going to work on repowering our industrial processes, which include mining, refining, chemicals production, as well as foodstuffs and fuels synthesis. We're doing vertical integration here, except for all of these interconnected processes. To wit, as tahanson43206 has pointed out himself, we seem to have an increasingly desperate fresh water situation, our transportation infrastructure and electric grids are in shambles across virtually all industrialized nations, we're running out of specialty metals to economically extract, and our hydrocarbon energy supplies are now badly depleted, so we need to focus on fixing those aspects of energy and material supply. This is a time for rebuilding, but not simply "building something" the way the Chinese built entire cities where nobody could actually live.

3. After that foundational work has been completed, then, with an energy supply as clean and free of long-term problems as we can reasonably make it, we will focus our efforts on devising more practical ways to electrify transportation using emergent technologies. To do that, we first have to create a long-term sustainable electric energy supply suitable for doing that. Families in California with EVs consume 2X to 4X as much electricity as they previously did, but the supply situation there is rather dire. Band-aid fixes aren't going to cut it.

Instead of simply espousing an ideology not grounded in technological reality, we're going to follow a logical progression of technology development and implementation, similar to that applied throughout the 19th and 20th centuries, as well as how our military goes about implementing new engine and fuel technologies. They start with stationary power plants, and then gradually develop or adapt the technology to more demanding applications, such as aviation. Had we followed this course of action about 20 to 40 years ago, we would have CO2-free power today, whether nuclear thermal or solar thermal, and this asinine Chinese fire drill situation we find ourselves in now wouldn't be impeding all forward progress.

Offline

Like button can go here

#141 2024-05-05 16:27:51

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

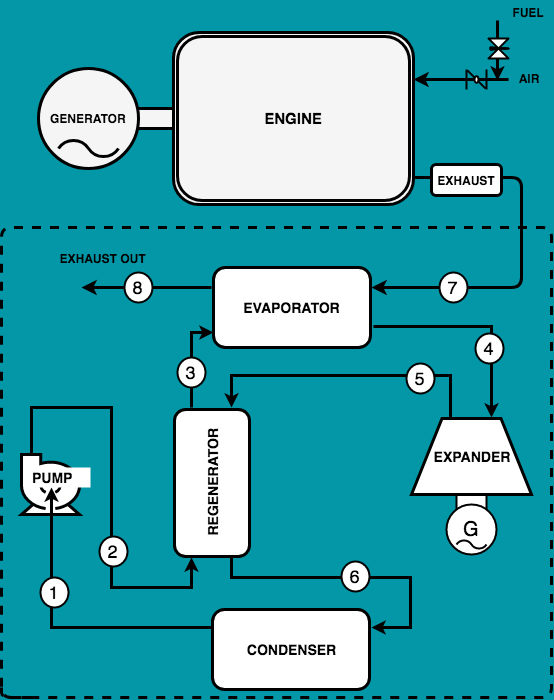

Waste heat as a source

of course, day to day we can get it from

Of course, heat sources can go into the evaporator which is a how we are going to produce power after picking the pressures, fluids and even more. The location of the evaporator is also where a store of heat could remain so that we can produce power over a larger period of time.

Offline

Like button can go here

#142 2024-05-12 11:08:19

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Offline

Like button can go here

#143 2024-05-15 17:35:38

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Sunlight-trapping device can generate temperatures over 1000°C

Solar furnaces, which use an array of moveable mirrors to focus sunlight onto a receiver that reaches high temperatures, could be used at manufacturing sites as an alternative to burning fossil fuels. However, they are currently quite inefficient at converting solar energy to temperatures higher than 1000°C, says Casati.

To improve the efficiency of such devices, Casati and his colleagues have designed a heat-trapping solar receiver with a 300 millimetre layer of quartz around it.

Quartz is a semi-transparent material that allows light energy to pass through it but blocks thermal energy. This means that as the silicon heats up from the concentrated sunlight, the quartz prevents thermal energy leaking back out, trapping the heat and reducing energy loss in the system.

According to heat transfer models, the silicon shield could enable receivers to get to temperatures of up to 1200°C while keeping 70 per cent of the energy input in the system. Without the silicon shield, the energy efficiency drops to just 40 per cent for the same temperature.

Offline

Like button can go here

#144 2025-10-14 15:21:33

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

If we're going to add that much metal to an already energy-intensive device like a photovoltaic cell, why not build a simpler and more robust solar thermal concentrator?

AI Overview

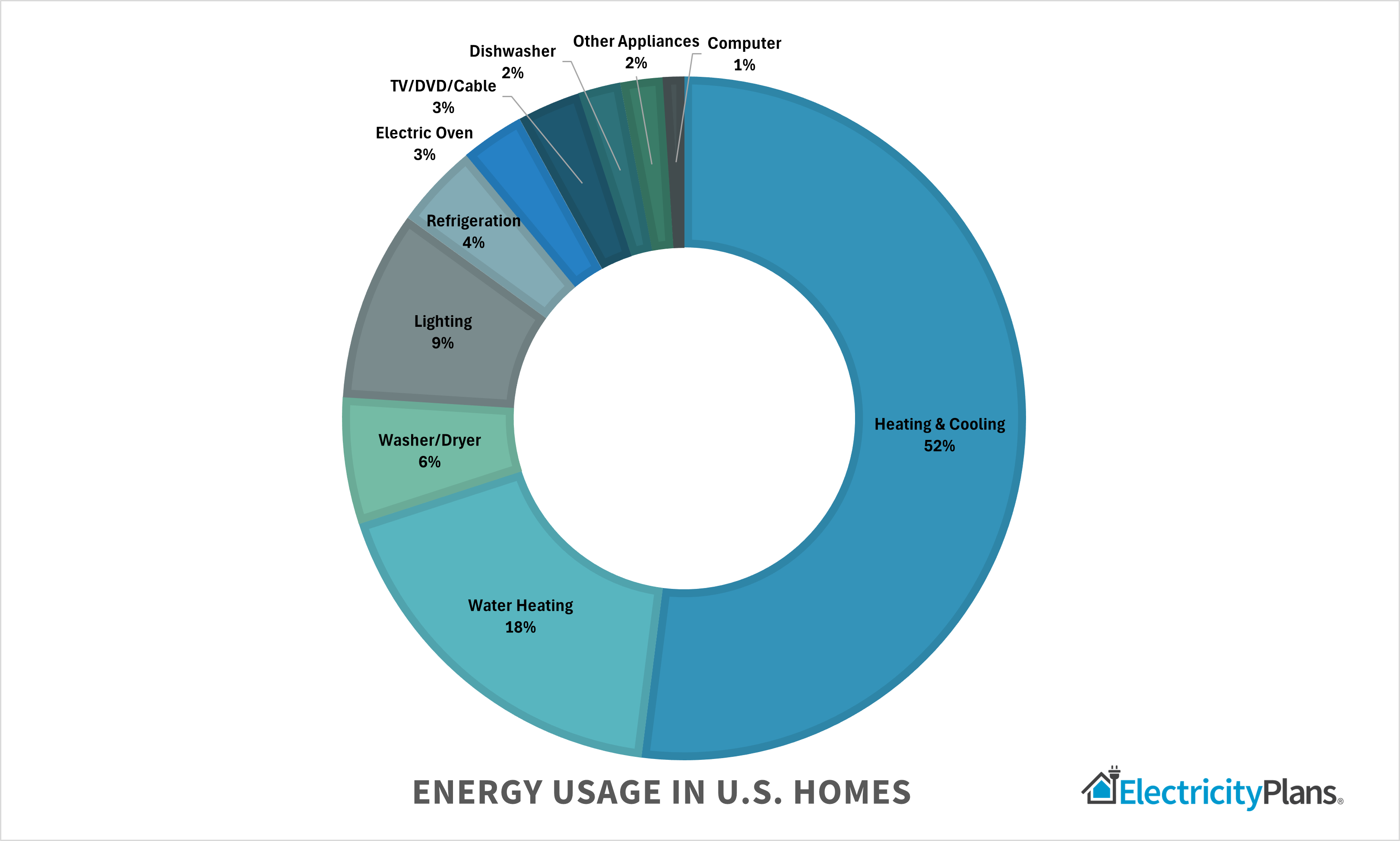

On average, a U.S. home consumes approximately 1.2 to 1.25 kilowatt-hours (kWh) per hour. This figure is an average calculated from yearly data and represents the overall rate of energy usage, but actual consumption varies throughout the day and seasonally.

For instance, the average 2022 annual consumption of electricity was 10,791 kWh per household.

10,791 kWh per year / 365 days = ~29.56 kWh per day

29.56 kWh per day / 24 hours = ~1.23 kWh per hour

Factors affecting average hourly electrical use

Hourly electrical usage fluctuates significantly depending on several factors:

Time of day: Demand for electricity is typically highest during the afternoon and evening hours when occupants are home, cooking, and using appliances like air conditioning.

Season and climate: A home's biggest energy drain is typically from heating or cooling systems. Homes in hot climates use more energy for air conditioning in the summer, while those in cold climates use more for heating in the winter.

Appliance usage: The average hourly consumption changes depending on which appliances are being used. High-wattage devices like air conditioners, electric ovens, and clothes dryers consume significant power when running.

Household size: A larger household typically has more occupants and appliances, leading to higher overall energy use.

For a more accurate comparison, the U.S. Energy Information Administration (EIA) notes that a single-family detached home in the South consumes much more electricity than an apartment in the Northeas

That said we need to store and regulate power output at the sizing for the concentrator based on inconsistent daily input of solar energy collection hours.

AI Overview

Concentrated solar thermal (CST) energy is not feasible for residential electricity generation due to its high cost and complexity. It is almost exclusively used for large-scale, utility-level power plants. For a U.S. home, the standard solution for converting sunlight into usable electricity is a photovoltaic (PV) panel system, typically including battery storage.

Here is a BBCode guide on how to size a residential solar PV system based on average hourly electrical consumption.

Sizing Residential Solar Photovoltaic (PV) for a U.S. Home

For the average U.S. home, which uses roughly 30 kWh per day, a solar PV system will need a capacity of around 6 kW. This can vary significantly depending on your location, lifestyle, and home size.

Step 1: Determine Your Hourly and Daily Energy Needs

Locate your total energy usage: Review your last 12 months of utility bills to find your annual kilowatt-hour (kWh) usage. Using a year's worth of data accounts for seasonal spikes, such as higher air conditioner use in summer.

Calculate your daily average: Divide your total annual kWh by 365 to get your average daily consumption.

Estimate your hourly usage: Divide your daily average by 24 hours to find your average hourly consumption. However, note that a battery storage system is necessary to provide power during the night, as solar panels only generate electricity during daylight hours.

Step 2: Find Your Peak Sun Hours

Look up your location's peak sun hours: Use a map or a tool from the National Renewable Energy Laboratory (NREL) to find the average number of "peak sun hours" per day in your area. These are the hours where the solar intensity is high enough to generate the maximum power from your panels.

Step 3: Calculate the Required System Size (in kW)

Calculate the ideal daily output: Divide your average daily kWh usage by your area's peak sun hours.

Add a buffer for inefficiency: Multiply the result by 1.2 (or 120%) to account for energy losses from the wiring, inverter, and system degradation over time. This gives you the size of the system in kilowatts (kW).

Consider future use: If you plan to add a new electric vehicle or appliance, increase your system size to account for the additional load.

Step 4: Estimate the Number of Panels

Find your panel wattage: Look up the rated wattage (W) of the specific solar panels you are considering. A common residential panel has a wattage between 300W and 450W.

Determine the number of panels: Divide your required system size (in watts) by the panel's wattage.Required System Size (in watts) / Panel Wattage (in watts) = Number of PanelsNote: A 1 kW system is 1,000 watts.

Step 5: Account for Energy Storage

Determine battery needs: For full backup power, your battery storage capacity (in kWh) should roughly match your average daily energy consumption. For example, a home using 25 kWh daily might start with a 10–15 kWh battery and expand later.

Consider discharge rate: Batteries have a discharge rate that affects how many appliances can be run simultaneously. This is especially important for running heavy-duty items like an air conditioner.

Example Calculation for an Average U.S. Home

Assumptions:

Daily Consumption: 30 kWh

Peak Sun Hours: 5 (varies by location)

Panel Wattage: 400 W

Calculation:

Required Power Output: 30 kWh / 5 h = 6 kW

Adjusted for Inefficiency: 6 kW x 1.20 = 7.2 kW

Required Number of Panels: (7.2 x 1,000 W) / 400 W = 18 panels

Approximate Battery Storage: ~25 kWh for a full day of backupAI Overview To size a solar thermal concentrator for a daily thermal energy demand of 40 kWh, you need to consider several key variables, most importantly the average daily peak sun hours for your specific location. The aperture area, or the size of the collector, is directly dependent on the amount of available sunshine and the system's efficiency. Calculation overview The general formula to find the required aperture area of the concentrator is:\(Area=\frac{Total~Daily~Energy~Required}{(Solar~Irradiance)\times (System~Efficiency)}\)Here is a breakdown of the steps involved in the calculation.

Step 1: Determine average daily solar irradiance Find the average daily peak sun hours for your location. This is a measure of the amount of solar radiation available per day, often expressed in \(kWh/m^{2}/day\). You can find this data from solar radiation maps or resources like the National Renewable Energy Laboratory (NREL). Example: For a location with 5 peak sun hours, the daily solar irradiance is approximately \(5~kWh/m^{2}/day\).

Step 2: Estimate system efficiency The overall efficiency of a concentrating solar thermal system can vary based on several factors, including: The type of concentrator (e.g., parabolic dish, trough).Optical losses from reflections and the receiver.Thermal losses from the receiver to the environment. For a preliminary estimate, a thermal efficiency (Eta) of about 80% is a reasonable starting assumption. It is important to note that this is a conservative value; a real-world system will have many loss factors. You may also need to budget for additional losses, such as a 20% overhead, to account for real-world inefficiencies.

Step 3: Calculate the required collector area Using the daily energy demand of 40 kWh, the location's average daily solar irradiance, and the estimated system efficiency, you can calculate the required aperture area. Formula:\(Area~(m^{2})=\frac{40~kWh}{(Peak~Sun~Hours~in~kWh/m^{2})\times (Efficiency)}\)Example calculation:Let's assume your location has an average of 5 peak sun hours (\(5~kWh/m^{2}/day\)) and you estimate a system efficiency of 80% (0.80). \(Area~(m^{2})=\frac{40~kWh/day}{(5~kWh/m^{2}/day)\times (0.80)}\)\(Area~(m^{2})=\frac{40~kWh/day}{4~kWh/m^{2}/day}\)\(Area~(m^{2})=10~m^{2}\)In this example, you would need a concentrator with an aperture area of approximately 10 square meters. Additional factors for refined sizing For a more precise sizing, consider these additional factors:

Seasonal variation:

Your calculation is based on an average day. Energy production will be higher in summer and lower in winter. For consistent year-round performance, you must size the system based on the minimum sun hours for your location.Tracking systems:

A concentrator's performance is highly dependent on how well it tracks the sun. One-axis or two-axis tracking systems will yield more energy than a stationary collector, but also increase complexity and cost.Thermal storage:

Storing excess thermal energy in a tank allows you to use the energy when the sun is not shining. The storage size should be matched to your usage patterns and the solar field to optimize daily operation.Collector type:

Different concentrator designs have different efficiencies and space requirements. Common types include parabolic troughs, dishes, and linear Fresnel collectors.Safety factors:

It is often wise to oversize the system slightly to account for cloudy days, system degradation over time, and other inefficiencies

Offline

Like button can go here

#145 2025-10-15 15:20:06

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,460

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

SpaceNut,

The overwhelming majority of energy consumption in all western homes, US or otherwise, is for direct heating and cooling applications. Thermal energy accounts for almost 75% of all the energy consumed in the average home, possibly more now that large TVs / desktop computers / incandescent bulbs have largely been replaced by laptops or cell phones and LED bulbs. That means a home's HVAC system is responsible for most of that 1.2-1.25kW figure. Home solar systems that fit on the roof of the home cannot provide that energy directly, because they're insufficiently powerful.

We had 67 photovoltaic panels on the roof and 2 Tesla Power Walls next to the breakers of the last home we owned. At no point in time did those devices directly provide the input electrical energy for our home's HVAC system, because they weren't capable of doing so. I asked the licensed electrical engineer who sold us our home solar system, what would be required to directly power the 3 AC units associated with our HVAC system, and he told me that most of our property's back yard would also need photovoltaic panels covering it. He said somewhere between double and triple the number of panels we actually had installed would be required to directly power our home's HVAC system, as well as another 2 to 4 Tesla Power Walls, in addition to the 2 Tesla Power Walls that were installed, to store more electrical power for use at night. Such a large photovoltaic / battery bank system would also be 50% to 60% of our home's purchase price. Texas does not allow ground-mount photovoltaic panels to be installed on residential property.

Our photovoltaics were, IIRC, 26.5% efficient, at BOL. Converting photonic / thermal power to electrical power is not terribly efficient, but using rooftop and ground hot / cold sinks to power HVAC systems is more practical because so much power from the Sun is NOT lost up-front by using photovoltaics to convert the incoming photonic energy into electrical energy. Until radically more efficient and less costly photovoltaics become available, the total quantity of thermalized photonic energy available from the Sun, per unit of collector surface area, is at least 3X greater, using less costly equipment. In simpler terms, our home's rooftop provided sufficient surface area to host thermal power collection equipment capable of generating high temperatures for the "hot side" of the thermal power transfer loop.

90% (visible spectrum photons to thermal spectrum photons) vs 26.5% (photons to electron movement) is a much greater total percentage of input power to work with, per unit of collector surface area, especially since the energy consumption system it's primarily being fed into is a thermal power transfer system (an over-glorified refrigerant loop- a device that works on the principle of a hot and cold sink). An HVAC system, a refrigerator, and cooking appliances all produce thermal output.

If most homes in America had 75% of their energy consumption provided by an onsite system that doesn't need to be connected to any grid, doesn't require a large amount of space in the yard, and doesn't require anything more complex and costly than some additional indoor plumbing to transfer thermal power from "rooftop water heat tech", that single change would deliver a major reduction in emissions at a cost that most people could actually afford to roll into their home's purchase price. Although there certainly are more exotic materials and refrigerants such a system could use, we're mostly talking about steel and water.

Offline

Like button can go here

#146 2025-10-23 15:02:58

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

Solar collector Using

To boil liquid Freon at atmospheric pressure, the required temperature depends on the specific type of refrigerant, as "Freon" refers to a family of different chemicals.

Common Freon refrigerants and their boiling points at atmospheric pressure:

[] Freon-12 (R-12): Boils at approximately -29.8°C (-21.6°F). This refrigerant is an ozone-depleting substance and has been largely phased out.

[] Freon-22 (R-22): Has a boiling point of around -40.8°C (-41.4°F). Like R-12, this refrigerant is a hydrochlorofluorocarbon (HCFC) and is being phased out.Freon 410A (R-410A): A blend that boils at approximately -51.6°C (-60.8°F). It is an HFC refrigerant and a common replacement for R-22.

Key considerations

Boiling temperature is dependent on pressure. The boiling points listed above are specifically for atmospheric pressure. In a refrigeration system, the refrigerant's pressure is varied to control the boiling and condensing temperatures. For example, to raise Freon's boiling point, its pressure must be increasedThe temperature required to boil liquid "freon" varies significantly based on the specific type of refrigerant and, most importantly, the system's pressure. For example, at atmospheric pressure, R-22 boils at approximately \(-40^{\circ }F\) (\(-40^{\circ }C\)). However, in a typical HVAC system, pressure is much higher in the condenser, which raises the boiling point to a much higher temperature, allowing it to release heat. Pressure is the key factor: The temperature at which a refrigerant boils is called its saturation temperature, and it changes drastically with pressure. Higher pressure leads to a higher boiling point.Examples of boiling points:R-22: Boils at about \(-40^{\circ }F\) (\(-40^{\circ }C\)) at atmospheric pressure, but can boil at a higher temperature of \(+20^{\circ }C\) at a pressure of 6 atmospheres.R-410A: Boils at \(-51^{\circ }C\) at atmospheric pressure.R-134a: Boils at \(-26^{\circ }C\) at atmospheric pressure.Evaporator vs. condenser: A refrigerant enters the evaporator as a cold, low-pressure liquid and boils at a very low temperature to absorb heat. In the condenser, pressure is increased, which raises the boiling point to a higher temperature so the refrigerant can release heat to the surroundings.

Offline

Like button can go here

#147 2025-10-24 17:39:44

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

I figure that if it can be done over in Africa then I should be able to build something too that works. Sun-powered system developed by MIT students could provide electricity, heat and cooling to rural schools and clinics.

Bringing power to the people — and heat as well

Affordable solar power using auto parts could make this electricity source far more available.

This system uses 4 troughs that are 3 m x 5m to collect the suns energy into oil that is heat exhanged for a Freon boiler to turbine and then heat exchanged to heat hot water and and then air cooled before recompressing the freon for the next cycle. The turbine produces 1 kw for the 24hr a day use from a 6 solar hrs of collection. The hot water side is 10 kw into 200 to 300 gallons of water as well.

From the facts that one more collector area gives more electrical and thermal energy greater than 3kw is enough for my use when it can be stored in batteries and a sine wave invertor to provide power when I need it.

Make inprovements to construction where possible.

SMALL SCALE SOLAR ORC SYSTEM FOR DISTRIBUTED POWER

Offline

Like button can go here

#148 2025-10-26 16:47:06

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,338

Re: Trough Solar Collector- Design- Construction- Operation- Maintenance

In concentrated solar power (CSP) systems, thermal oil is used as a heat transfer fluid (HTF) and can also function as a thermal energy storage (TES) medium. There are no standardized, universally applicable charts for the volume of thermal oil, as the required volume is specific to the design of each individual plant and its storage capacity.

The volume of thermal oil in a CSP plant depends on the system's design and operating parameters, including:

Total system capacity:

The overall power output of the plant.Collection area:

The size of the solar field (e.g., parabolic troughs) that collects the solar energy.

Storage capacity:

The number of hours the plant can operate on stored thermal energy after the sun sets.

Type of CSP technology:

Parabolic trough systems are most commonly associated with thermal oil, while solar tower systems often use molten salt, which allows for higher operating temperatures.

Thermal oil properties:

The specific heat, density, and operating temperature range of the chosen thermal oil (e.g., Therminol 66). How thermal oil volume is calculated for a CSP plant While no generic chart exists, the total thermal oil volume is derived from several key calculations:1. Thermal energy storage (TES) volume: This is the most significant part of the thermal oil volume. It is calculated based on the required storage capacity and the oil's thermal properties. Formula:\(V_{\text{storage}}=\frac{E_{\text{storage}}}{\rho \cdot c_{p}\cdot \Delta T}\) \(V_{\text{storage}}\) = Volume of thermal oil in the storage tanks (m\({}^{3}\))\(E_{\text{storage}}\) = Total thermal energy required for storage (in Joules or kWh)\(\rho \) = Density of the thermal oil (kg/m\({}^{3}\))\(c_{p}\) = Specific heat capacity of the thermal oil (J/kg·K)\(\Delta T\) = The temperature difference between the hot and cold oil in the two-tank storage system (K)

2. Heat transfer fluid (HTF) volume: This is the volume of oil circulating through the solar collector field, piping, and heat exchangers. Formula:\(V_{\text{HTF}}=V_{\text{collectors}}+V_{\text{piping}}+V_{\text{exchangers}}\) \(V_{\text{collectors}}\) = Volume of oil inside the receiver tubes of the parabolic troughs.\(V_{\text{piping}}\) = Volume of oil in the network of pipes connecting the solar field to the storage and power block.\(V_{\text{exchangers}}\) = Volume of oil within the heat exchangers that transfer heat to the power cycle (e.g., steam generator).

3. Expansion volume: Thermal oil, like any fluid, expands and contracts with temperature changes. An expansion vessel is required to accommodate this volume change and maintain system pressure.

Example:

Thermal storage volume calculation The following example illustrates the calculation for a 100 MW CSP plant with 6 hours of thermal oil storage.Assumptions:

Storage capacity: 6 hoursHeat transfer fluid:Thermal power rating:

100 MWth (assuming a 100 MW electric power output, the thermal power is higher due to turbine efficiency)Temperature difference (\(\Delta T\)): 390°C (hot oil) - 290°C (cold oil) = 100 KOil density (\(\rho \)): ~780 kg/m³ at the average temperatureSpecific heat (\(c_{p}\)): ~2.3 kJ/kg·K Calculation: Total thermal energy (\(E_{\text{storage}}\)):\(E_{\text{storage}}=\text{Power}\times \text{Time}=100\text{\ MWth}\times 6\text{\ h}=600\text{\ MWh}\)Convert to Joules:\(600\text{\ MWh}\times 3.6\times 10^{9}\text{\ J/MWh}=2.16\times 10^{12}\text{\ J}\)Required storage volume (\(V_{\text{storage}}\)):\(V_{\text{storage}}=\frac{E_{\text{storage}}}{\rho \cdot c_{p}\cdot \Delta T}=\frac{2.16\times 10^{12}\text{\ J}}{(780\text{\ kg/m}^{3})(2300\text{\ J/kg\cdotp K})(100\text{\ K})}\approx 12,000\text{\ m}^{3}\) This is the volume for the thermal energy storage tanks alone.The total volume would also include the fluid in the collector field and piping, which could add another 10% to 20% to the total.

Factors that determine the quantity of solar oil include:

System scale:

The quantity of thermal oil is a function of the solar collector area and the thermal energy storage tank volume. Larger systems require significantly more oil.Thermal energy storage (TES):