New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#1 2021-12-13 20:52:12

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Cast Iron / Cast Steel Architecture

I found this wiki article that describes an architectural form that is all but lost to the western world.

https://en.m.wikipedia.org/wiki/Cast-iron_architecture

These are the magnificent structures that I want to build on Mars. Cast iron has weak tensile strength, but is enormously strong in compression. I think it will be important on Mars for two reasons. Firstly, it will be the first metal we can produce in abundance. Secondly, most of our cities and habitable structures will be built underground. Shielding out cosmic rays and protecting structures from temperature swings, makes this a necessity on Mars. This means that most Martian structures will be built as compressive structures. But people living underground won't necessarily tolerate a cramped and dark existence. They will want wide open spaces. Cast iron and cast steel fulfil this need, because their huge compressive strength allows for enormous spans to be bridged with slender structural members. Cast iron structures are beautiful in a way that modern I-beam structures fail to be. Those Victorian cast iron buildings were works of art. Oscar Wilde famously said that all objects should either be functional or beautiful and preferably both. Cast iron fulfils both.

We can produce quite adequate cast irons on Mars by reducing iron rich Martian sands using hot hydrogen gas and then removing the reduced iron with a magnet. This reduced iron is then melted in an electric furnace and oxygen is bubbled through it to remove sulphur and phosphorus impurities. Carbon is added to increase hardness and reduce melting point. Next, the molten iron is poured into sand molds and allowed to cool. All we need is a big nuclear reactor to produce the electricity needed for the electric furnace and hydrogen production. And we need a lot of equipment to pile regolith over the structure and mine the iron rich soil. Kbd512 has suggested giant nuclear powered vehicles for that job. We could use mostly carbon steels to make those vehicles, provided that we keep them warm. Not a problem given the presence of heat generating nuclear reactors on-board.

Cast iron could provide an early basis for transportation on Mars. Cast irons are generally far more corrosion resistant than carbon steels. Regolith covered, cast iron pipes can carry water from polar regions into our city. They could also carry floating capsule trains carrying ores mined from other parts of the planet. A cast iron pipe, some 1000km long, 0.5m in diameter, with wall thickness 1cm, would weigh 123,000 tonnes. An iron works, powered by a 1000MWe AHR nuclear reactor, could produce this much iron in about six weeks. The capsule pipeline, moving at 3m/s, could carry up to 18.5 million tonnes of materials each year - about 150x its own weight. Within a few decades of founding a Martian iron works, Mars could be gridded with pipeline networks, carrying resources to the city state from every part of the planet.

But long before pipelines reach that extent, railways constructed from carbon manganese steel on cast iron plinths, will allow rapid transportation of people and goods across the planet. Trains powered by compact nuclear reactors will ultimately allow any Martian to circumnavigate the planet in 1 week.

Iron and steel, produced by foundries powered by low cost nuclear fission reactors, will be the products that enable Mars colonisation to proceed rapidly. They will be key to everything else.

Last edited by Calliban (2021-12-13 21:26:21)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#2 2021-12-14 03:51:06

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,362

- Website

Re: Cast Iron / Cast Steel Architecture

We don't need to transport water over long distances. Instead build your city next to a major deposit of ice.

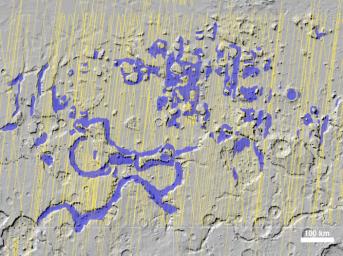

Glaciers discovered by the shallow radar instrument called SHARAD on Mars Reconnaissance Orbiter.

This map of a region known as Deuteronilus Mensae, in the northern hemisphere, shows locations of the detected ice deposits in blue. The yellow lines indicate ground tracks of the radar observations from multiple orbits of the spacecraft.

The ice, up to 1 kilometer (0.6 mile) thick, is found adjacent to steep cliffs and hillsides, where rocky debris from slopes covers and protects the ice from sublimation into the atmosphere.

The base map of this image is shaded relief topography obtained by the Mars Orbiter Laser Altimeter on NASA's Mars Global Surveyor. The image is centered at 42.2 degrees north latitude and 24.7 degrees east longitude. It covers an area 1050 kilometers by 775 kilometers (650 miles by 481 miles).

A global map of Mars showing the distributions of features thought to be debris-covered glaciers (shown in yellow) in Mars’ mid-latitude regions. The basemap is made of colour images from the Viking 1 and Viking 2 orbiters. The glacier distributions are from maps by Levy et al. 2014 3 and Souness et al. 2012

A glacier-like form in Mars’ northern mid-latitudes (42° north, a similar latitude to northern Spain on Earth). It is approximately 8 km long. This perspective view was generated from 25 cm resolution images taken by the High Resolution Imaging Science Experiment (HiRISE) camera on the NASA Mars Reconnaissance Orbiter spacecraft. The HiRISE image is draped over a 3D surface which was generated from two ‘stereo pair’ images taken from different angles by the spacecraft.

A lineated valley fill in Mars’ northern mid-latitudes. The inferred direction of past ice flow is from the bottom to the top of the image. The main trunk is fed by two large tributary glaciers. Image mosaic from the Context Camera on Mars Reconnaissance Orbiter.

A ‘concentric crater fill’ type glacier occupying an impact crater in Mars’ northern mid-latitudes. The distinctive concentric surface flowlines give these features their name. In this example, the glacier has almost completely infilled the crater; only the rim of the crater is visible. Image mosaic from the Context Camera on Mars Reconnaissance Orbiter.

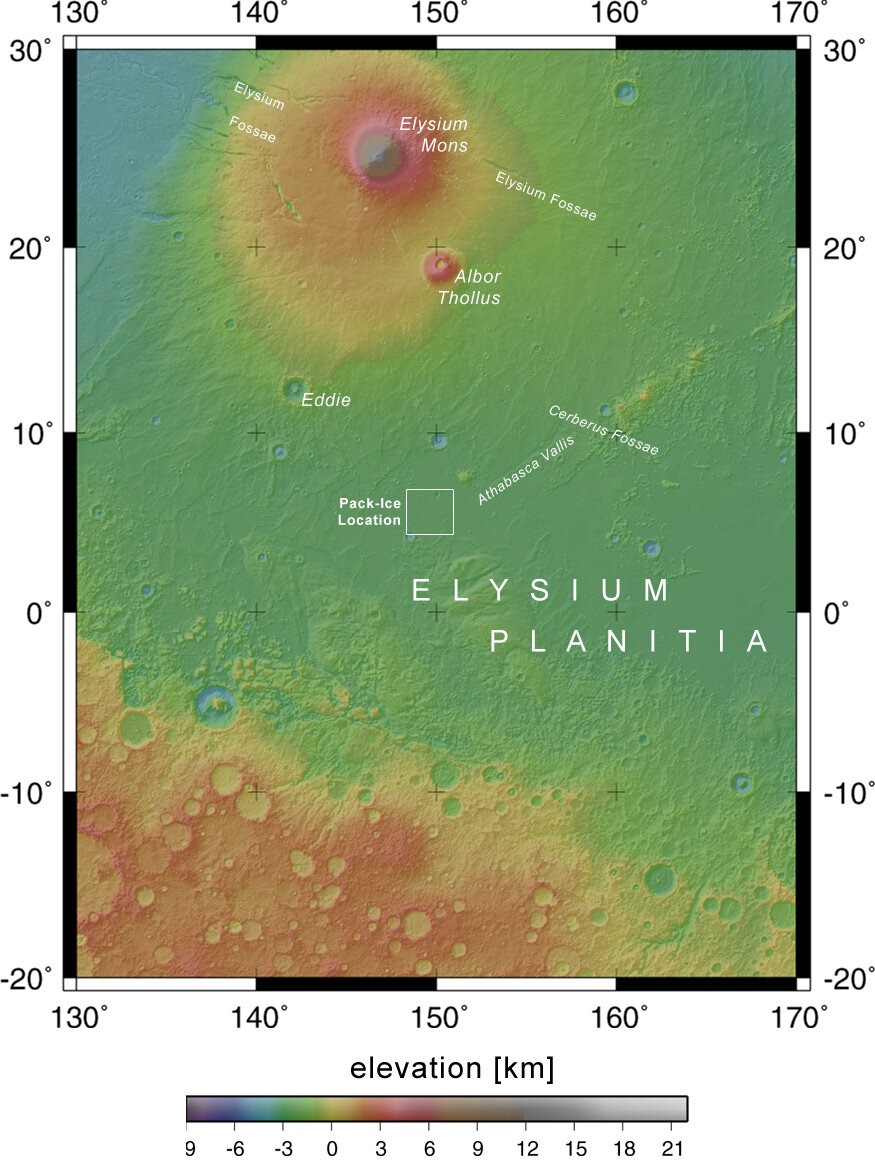

Most people want a location close to the equator. Mars is cold so you want the warmest possible location. There's also the "frozen pack ice" of Elysium Planetia.

From the European Space Agency: ESA’s Mars Express sees signs of a ‘frozen sea’

This image, taken by the High Resolution Stereo Camera (HRSC) on board ESA’s Mars Express spacecraft, shows what appears to be a dust-covered frozen sea near the Martian equator.

It shows a flat plain, part of the Elysium Planitia, that is covered with irregular blocky shapes. They look just like the rafts of fragmented sea ice that lie off the coast of Antarctica on Earth. This scene, taken during orbit 32, is a few tens of kilometres across, and is centred on latitude 5º North and longitude 150º East.

The water that formed the sea appears to have originated beneath the surface of Mars, and to have come out through a series of fractures known as the Cerberus Fossae, from where it flowed in a catastrophic flood.It collected in a vast area about 800 kilometres long and 900 kilometres wide with a depth of about 45 metres. As the water started to freeze, floating pack ice broke up into rafts. These became later covered in ash and dust from volcanic eruptions in the region.

Above image is from New Scientist, taken by High Resolution Stereo Camera on Mars Express. It shows "sploosh" craters. They can only form by meteorite impacts on ice. The perfectly smooth bowl of the crater is ice melted by the impact. The floor of the crater in the centre is flat and rough, that's the ground beneath the ice. And a small pit in that flat floor is where the meteorite impacted. The ridge around the rim is where slush splashed up and froze. These craters show scientists depth of the ice, and is how ESA scientists confirm the ice is still there.

Note: the volume of ice in the "frozen pack ice" is greater than all the water in the Great Lakes combined, and depth is the same as Lake Erie. Or equal to the water of the North Sea.

Offline

Like button can go here

#3 2021-12-14 05:51:54

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Re: Cast Iron / Cast Steel Architecture

Robert, that is impressive. The first base should probably be no more than 30° North. Ideally, we want a low lying site with a relatively high atmospheric pressure.

We have talked in the past about how best to get water out of the ground. Kbd512 raised a topic on nuclear powered vehicles using an AHR as a heat source. A mobile reactor on a large trailer, could be used to inject heat directly into bore holes. A reactor of this type could produce power for the base, whilst dumping waste heat into the bore hole. Satellite wells can be dug after a defined thermal soaking time. This takes care of the waste heat problem and the water supply problem, as the reactor no longer needs a radiator. Water can be withdrawn from satellite wells using submersible pumps.

It occurs to me that the low atmospheric pressure of Mars would allow well water to be desalination by boiling using low grade waste heat at temperatures as low as 30°C. Well water would flow through a condenser and would reenter the well at a temperature of 20°C. The use of a well as a heat sink allows a relatively low temperature nuclear reactor to generate power efficiently without need for an enormous radiator.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#4 2021-12-14 15:29:10

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,362

- Website

Re: Cast Iron / Cast Steel Architecture

Water - Boiling Points at Vacuum Pressure

8.25 mbar absolute is a pressure recorded by Curiosity at Gale Crater before ascending Mount Sharp. At that pressure clean water boils at 4.4°C. Salt can increase boiling point, but 58 grams in 1 litre increases boiling by 0.5°C. Mars dirt has salt and the frozepack ice was formed when a volcano melted permafrost that was the bottom of the ocean before it dried out, so we expect salt in Mars ice, but how much will that actually increase boiling point?

Increasing pressure in the ice cavity to 18.25 mbar absolute will increase boiling point to 16.4°C. That's 10 mbar relative to Mars ambient. Mars pressure varies with weather and time of day, but let's use this for simplicity. Brine is defined as >35 g/l, so shall we assume extreme salt at 58 g/l? That will increase boiling by 0.5°C. So we're up to 16.9°C. You could keep temperature below that and pump up the water.

Or as you said, let it boil and collect steam. Condense clean desalinated water.

Offline

Like button can go here

#5 2021-12-14 16:33:32

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,291

Re: Cast Iron / Cast Steel Architecture

Back on the original topic, the use of cast iron allows strong structural members to be mass produced using sand casting techniques. Martian regolith, sieved to exclude anything larger than 0.5mm, would be the idea material. It contains so much alkali metal oxides that it will form a gypsum like cement when mixed with water. We would put damp regolith into a mold and press it onto the forming shape we want to cast. Warm it to 30°C and allow it to set and dry for several hours. Then remove the forming shape and strap the two halves back together to form a casting mold.

Extremely ornate objects can be formed in this way. Things like furniture, staircases, doors and ornaments. More importantly, it is possible to build huge compressive dome structures from just a few repeating elements that are keyed together. Foundations can be provided by sintered stone plinths set in regolith based concrete on rubble.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#6 2021-12-14 16:44:40

- RobertDyck

- Moderator

- From: Winnipeg, Canada

- Registered: 2002-08-20

- Posts: 8,362

- Website

Re: Cast Iron / Cast Steel Architecture

Mars soil and water set at ~30°C gives you consistency of brick. Should work for your application. One researcher tried it without water, just pressure.

https://www.smithsonianmag.com/smart-ne … -180963077

Offline

Like button can go here

#7 2021-12-14 18:40:20

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,297

Re: Cast Iron / Cast Steel Architecture

Cast metals are of a lower energy to create and have many uses.

You can additive process to shape with crude initial molds.

Offline

Like button can go here

#8 2024-04-14 15:39:32

- Mars_B4_Moon

- Member

- Registered: 2006-03-23

- Posts: 9,776

Re: Cast Iron / Cast Steel Architecture

NASA’s First Moon Buggy Since Apollo: Here’s What We Know So Far

https://gizmodo.com/nasa-artemis-first- … 1851387152

Thanks to a layer of molten rock, Mars' core appears bigger than it is

https://www.space.com/mars-core-molten-silicon-rock

Offline

Like button can go here

#9 2024-04-14 19:42:15

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 23,993

Re: Cast Iron / Cast Steel Architecture

For SpaceNut re #7

What you said about using additive processes (3D printing) rings a bell! I'm hoping you might be willing to do some searches for articles about that.

It ** seems * to me that Shapeways is offering something along those lines.

Calliban created this topic with castings as the theme, but 3D printed "castings" may in fact be a realistic option.

I assume the object that is 3D printed needs to be heated to allow all the iron to bond together.

But that's just a guess. ('m hoping you can find articles that clarify that point.

(th)

Offline

Like button can go here