New Mars Forums

You are not logged in.

- Topics: Active | Unanswered

Announcement

#351 2024-04-01 10:07:04

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

Spaniard,

I'm not assuming anything. I can use my eyeballs to simply look at the prices for absolutely any commodity over time. You're the one refusing to acknowledge that prices have gone up in the past 4 years, by a lot, because it doesn't support your belief about renewables getting cheaper over time. The thing is, prices for absolutely eveything have gone up, and to protect your beliefs about renewable energy, you're refusing to address ugly objective reality.

The issue with Lithium is not that it was double the price a year ago, but prices have fallen since then so it's no longer an issue of any substance. The issue is that the price of Lithium / gasoline / bread / furniture / etc, is never going back down to where it was before COVID. That is purely a product of inflation from governments spending money they don't have. It's stuctural. There's no amount of money that can be printed to solve that problem.

The variables at play was the market charged more money for Lithium because demand shot up and the world collectively lost its mind over COVID. The same applied to all other commodities and goods or services, be it gasoline or eggs and bacon, until it created destruction for demand of that product, at which point the prices went down to levels consumers could afford, because fewer and fewer people were buying the goods or services or commodities at the prices being demanded. That's an example of market dysfunction that is not unique to anything related to green energy. Green energy was neither the cause of nor the result of the market panic, but like everything else, green energy machines were affected.

The present price increases are not a temporary "blip" or "spike". They're permanent. Gasoline could be purchased for less than a dollar per gallon when I was a child. Gasoline prices are never going back down to $1 per gallon for any significant period of time, unless something cataclysmic happens. So, this belief about prices being capable of going down forever is clearly and objectively false, especially over greater periods of time measured in decades. You know what else you can't get for $1 anymore? A gallon of milk, or a loaf of bread, or a dozen eggs. That stuff is now permanently more expensive as well, and not because there's a shortage of milk, bread, or eggs.

I'm laying out reality as it presently is, you don't like it because it doesn't support your beliefs about what reality should be, so you're presenting a bunch of "what-ifs" and generalizations instead of making a simple acknowledgment that what is presently going on is the opposte of what you're claiming about the future. To be clear "what is going on", has been going on since before I was born. Cheap energy depletion has caused a stagnation of growth over decades.

If I predicted that the average purchase price of a car would be greater in 10 to 20 years time, as compared to car prices today, then I'd be correct almost 100% of the time unless we were to cherry pick the starting and ending point to try and manipulate the result to show something is cheaper or more expensive.

Incidentally, this is how upsets or "disappointments" as you called them, tend to happen. Someone is telling you something that is self-evident, you don't want to hear it because you don't like what it means, and insist that everything is fine, despite the evidence to the contrary. How is this any different than false beliefs about climate change not existing or going away?

Offline

Like button can go here

#352 2024-04-01 10:42:18

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

Spaniard,

Renewables remain competitive when the cost of energy storage or production when there is no sunlight or wind is completely ignored. Everybody who has renewable energy knows that the cost of any kind of renewable plus storage is completely uncompetitive with coal.

Transportation costs are largely one-time costs for devices that will be installed any used over 15 to 25 years, so this argument doesn't withstand cursory scrutiny. If the cost of shipping a solar panel was $50 or $100, that makes almost no difference at all to the cost of energy over 25 years.

Yes, I've heard this common refrain that we only need more renewables, and then we'll quit burning coal. Germany has more installed renewables than just about any other country on the planet. They're still burning coal.

The energy storage market is part of the same energy generating market as the one involving renewable energy, because it's feeding power into the same electric grid. This claim is absurd. If renewables didn't need energy storage, and storage was just an optional extra, like adding Bluetooth audio to a car stereo, then you would have a point, but since renewables are intermittent, it's not optional without daily electric grid crashes, the power is going to the same place as the renewable energy generating plants, and is therefore part of the same market, whether you think so or not.

Yes, we are "way below the level of required storage" in all parts of the world. That means lots and lots of additional money, materials, and energy must be spent to create that green energy storage, which goes well beyond what renewable energy requires when natural gas and coal backstop their variability. One thing certainly is true, and that is electricity bills and water bills are going way up from where they were previously. People who are not ideological would notice "what's changed", which is the cost of energy, which is largely driven by all the inputs, which are all substantially higher for green energy, and somebody is going to pay for that, and that "somebody" is always going to be the consumer of the energy, never the producer of it, because the producer is a business, and no business can remain in business if their operating costs exceed revenue for a great enough period of time to wipe out any reserve money or profits that they have invested into their business.

What we will see in the coming years is burning of coal and gas at increasing rates, until there is no more left to burn, and then we won't have the surplus energy presently being used to create green energy machines at the rate demanded. This is "coffin corner", as I call it, because when the energy runs out, shortly thereafter you start filling coffins with all of your "mistakes". This planet doesn't natively support a population of 8 billion people without energy sources as dense and abundant and always-available as hydrocarbon or nuclear energy. I have all of human history up to the point of industrialization to point to as evidence for that assertion. We've had windmills to grind grain for centuries and we used solar power to grow our food. At no point in time in our pre-industrial history was the average life expectancy much beyond 30 to 40, even though a comparative handful of people lived into old age. Anyway, depopulation is an active / ongoing phenomenon, so maybe we have one remaining "get out of energy jail free" card to play here, or at least I hope we do.

Offline

Like button can go here

#353 2024-04-01 11:53:53

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

All I want is an actual win to point to, not something that is performative or "feel good" in nature, but an actual unmistakable achievement showing, in no uncertain terms, that "we installed XYZ renewable energy here, and then our total global CO2 emissions were reduced, full stop". I consider that a victory. I don't consider happy talk about the future or playing semantics games with definitions of terms or ignoring what we see that we don't like to be an achievement. Thus far, at best, we might achieve a pyrrhic victory at some undefined point in the future, but that would first require total global CO2 emissions to remain unchanged from where we started from decades ago. In another 10 years, if per-capita CO2 emissions haven't improved, then perhaps it's time to consider alternative approaches to energy generation which might have an absolute positive effect on emissions. We've been working on photovoltaics and wind turbines since the 1970s. If this all-electric future takes another century to implement, then it's a future solution we can revisit after we actually reduce our emissions.

Offline

Like button can go here

#354 2024-04-01 18:24:11

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Why the Green Energy Transition Won’t Happen

According to natural resource investors Goehring & Rosencwajg, about 2/3rds of the price drop in solar projects from 2008 to 2020, was a result of falling energy costs and very low interest rates. When you consider that inflation adjusted interest rates were less than zero, it is no wonder that capital intensive, front end loaded projects were historically cheap. That is precisely the problem with low interest rates. They can stimulate growth, but they also encourage inefficient use of capital.

https://blog.gorozen.com/blog/the-price … -subsidies

Goehring & Rosencwajg don't specifically mention the use of slave labour and cheap coal in China. But we know this is part of the reason for declining costs as well. The investment driven growth model in China, also led to really dramatic declines in the cost of industrial materials like steel, after about 2011. All of these things have played in favour of solar PV, which is the most energy and material resource intensive means of generating electricity (See Table 10.4, in link below).

https://www.energy.gov/sites/prod/files … pter10.pdf

Unfortunately, cost declines cannot continue forever, especially for an energy source that needs so much steel, concrete, copper, etc, to produce each TWh of energy. When the cost of materials increases, so to does everything that is being made from those materials. That includes solar powerplants.

https://colitetech.com/blog/why-is-the- … ncreasing/

A couple of other things are clear from the references above. (1) The poor EROEI of solar PV is a direct result of its low power density and the heavy material needs that result; (2) Wind power is much superior to solar PV in terms of overall EROI and materials needed per TWh. (3) Dealing with intermittency through storage, cuts EROEI by roughly half. This suggests that the best way to use renewable energy is to avoid storage and simply accept the fact that demand must adapt to supply. There is no way around that without terminally crushing the whole system EROEI.

There are plenty of people who find these facts of life to be unacceptable. But they aren't negotiable. These are physics driven problems that stem from low power density.

Last edited by Calliban (2024-04-01 18:28:22)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#355 2024-04-02 00:33:44

- Spaniard

- Member

- From: Spain

- Registered: 2008-04-18

- Posts: 144

Re: Why the Green Energy Transition Won’t Happen

https://medium.com/@erofeev.yury/solar- … 711debf309

Solar photovoltaic energy is growing at a monstrous rate. For example, BloombergNEF expects that about 400 GW of solar energy capacity will be commissioned around the world this year.

One of the factors for rapid growth is the reduction in prices for equipment and solar panels.

Aside from a two-year bump between 2020 and 2022, when solar module prices rose more than 50%, the cost of photovoltaic systems has fallen steadily since the mid-2000s, averaging about 10 to 15 percent per year.

In 2023, module price declines resumed, reaching an all-time low of around $150/kW (15 cents/W) — a staggering 42% drop from the January 2020 price.

Rethink Energy predicts that wholesale solar module prices will halve again by 2040 in a new report.

The decline in silicon prices through 2030 will be driven by “a wide range of incremental technology upgrades that will continue at a slower pace through 2040.”

“By 2040, silicon-perovskite tandems — perhaps some will even be silicon-perovskite-perovskite — will account for 61% of the market share,” the authors say.

A report from Rethink Technology Research predicts that the price of PV systems, based on the current “off-the-line silicon solar module cost in China” of US$154/kW, will fall again to US$92.2/kW by 2030 year and 71.1 US dollars/kW by 2040 — a decrease of 53%.

Offline

Like button can go here

#356 2024-04-02 04:50:22

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Why the Green Energy Transition Won’t Happen

Solar photovoltaic energy is growing at a monstrous rate. For example, BloombergNEF expects that about 400 GW of solar energy capacity will be commissioned around the world this year.

Much depends on how long the Chinese system holds together. They are using forced labour to convert stranded coal into a product (PV modules) that they can ship out by rail. It is an innovative, though inhumane, approach. But it does offer some insight into how stranded fossil fuel reserves can be exploited in other places. Most other places on Earth have no equivelant of Uiyger forced labour. Nor would it be acceptable in most countries. We couldn't replicate the Chinese model using stranded coal in Australia or Russia, for example. Even the Russians aren't low enough to do what the Chinese are doing to the Uiygers and Siberia doesn't have a high enough population density to try it. But if stranded coal or gas can be turned into something energy dense that can be shipped, i.e. aluminium, then we have a way of putting an otherwise trapped energy resource to use.

EROEI is only weakly relevant to the case of Chinese solar PV. They are using extremely cheap coal to build modules. That coal would otherwise be useless to them and labour costs are minimal thanks to slavery. PV modules are therefore a very effective way of storing coal based energy accessed by slave labour. It is unethical on just about every level imaginable - climate, human rights, trade ethics, sustainability - the list is long. But for the time being it works for them and for anyone else that wants to build solar capacity and doesn't care to look too closely at what it takes to do it.

The question is, are we willing to hold our noses and buy up this energy source whilst it is available? It isn't a bad deal financially, but it is effectively a trade in human bones and flesh. Not really that different to the lampshades the Nazis manufactured from the skin of slaughtered Jews, Slavs and Gypsies. Very practical I'm sure, but would you really want one in your house? The Chinese are selling a product of slave labour that the western Left doesn't want to sanction too strongly because it aligns with their Green transition goals. So they mostly turn the other cheek and turn their attention to boycotting Isreali pistachios instead. So the Chinese equivelant of skin lampshades will continue to get made, until they either run out of Uiygers or their demographic collapse ends their export dominated economic model. Whichever comes first.

The Chinese model isn't really compatible with reducing CO2 emissions or any human rights consideration. But maybe there are other ways of making it work that don't flood the atmosphere with CO2? We could find a country where nuclear safety regulation is more sensible and build out lots of nuclear reactors far more cheaply than could ever be done in the west. That cheap electricity coukd then be used to make solar modules that are installed in idiot run countries like Germany and Britain. That way, the PV panels are storing nuclear energy instead of coal based energy. We would still need cheap labour to build the panels. Bangladesh perhaps?

Last edited by Calliban (2024-04-02 05:15:38)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#357 2024-04-02 19:09:47

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Why the Green Energy Transition Won’t Happen

Some 20% of the world's refining capacity is at risk of closure.

https://oilprice.com/Energy/Energy-Gene … osure.html

Mostly in OECD countries. The official stated reason is declining demand due to EVs. Saying that makes people feel happy about it. But so far this is having a minor effect on petroleum product demand. Product demand has been dropping in OECD countries since 2008. At this time, EVs were little more than prototype curiosities. One real factor behind declining demand is declining prosperity for the majority of people. As people get poorer, oil products become less affordable. Couple that with demographic ageing in the western world and you have a perfect recipe for falling demand. Falling EROIE of petroleum is making it less affordable to a poorer population. At the same time, workforce is shrinking. Declining oil demand is therefore a harbinger of economic ruin.

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#358 2024-04-03 00:41:56

- Spaniard

- Member

- From: Spain

- Registered: 2008-04-18

- Posts: 144

Re: Why the Green Energy Transition Won’t Happen

Much depends on how long the Chinese system holds together. They are using forced labour to convert stranded coal into a product (PV modules) that they can ship out by rail. It is an innovative, though inhumane, approach. But it does offer some insight into how stranded fossil fuel reserves can be exploited in other places. Most other places on Earth have no equivelant of Uiyger forced labour. Nor would it be acceptable in most countries.

https://tradingeconomics.com/china/wages

Wages in China has being on the rising all of these years, and coal in the mix has slightly lost weight (relative. Of course, in total consumption they have grown because total energy has grown more than the change of the mix).

You can check the mix here.

https://ourworldindata.org/energy-mix

Although you need to select manually China instead of worldwide and relative instead of absolute. Then the trend is clear.

So both arguments, worsening labor conditions and more coal usage doesn't match the data on China.

Offline

Like button can go here

#359 2024-04-03 01:46:35

- Spaniard

- Member

- From: Spain

- Registered: 2008-04-18

- Posts: 144

Re: Why the Green Energy Transition Won’t Happen

Some 20% of the world's refining capacity is at risk of closure.

https://oilprice.com/Energy/Energy-Gene … osure.htmlMostly in OECD countries. The official stated reason is declining demand due to EVs. Saying that makes people feel happy about it. But so far this is having a minor effect on petroleum product demand. Product demand has been dropping in OECD countries since 2008. At this time, EVs were little more than prototype curiosities. One real factor behind declining demand is declining prosperity for the majority of people. As people get poorer, oil products become less affordable. Couple that with demographic ageing in the western world and you have a perfect recipe for falling demand. Falling EROIE of petroleum is making it less affordable to a poorer population. At the same time, workforce is shrinking. Declining oil demand is therefore a harbinger of economic ruin.

I seems I lost my last response.

Anyway, as I said before, investors doesn't look EROEI. Investors only care about return of investment. They will only see if the investment will be good or bad. As the number of voices against the usage of fossil fuels grows, and it exists a growing risk of fossil fuel bans or massive investment on replacement, the risk of investment on oil also raises.

Besides, BEV are not the only technology that reduce oil. Hybrids, while only reduce a fraction, that reduction is also noticeable. But the greatest reason is not CURRENT data, but bad FUTURE perspectives. This kind of infrastructure can have amortization periods of three decades, so the risks are high.

Investors will wait in countries where the growing demand is not clear, waiting if the prices raises. With higher prices, the amortization period shrink and also the risk of investment.

OR... the demand will really shrink, and the new capacity won't be needed. The old capacity will probably be extended beyond their optimal lifetime because there is no enough time to the new capacity to amortize, at least at the same levels than the previous years.

I personally expect a mix of both. If the BEV replacement come sooner, oil prices should maintain or even reduce a little, but I expect to maintain and even increase a little because the infrastructure becomes old and cost more to maintain. Also the reduction of oil investment will generate a cascade of reduction of scale that will hit against it.

But it's also true than if we replace fast enough, the first oil wheels to close will be the least profitable (so, most expensive) so there are a mix of variables in both directions.

I expect slightly raising price in oil, while contained, as too high will push the BEV replacement sooner. Still, there is a limit to the speed of the replacement because multiple bottlenecks, so there will be multiple spikes in prices as the change is very fast and not enough and too much offer and demand can change very quickly.

The same can occur in the renewables/EV side. In fact, there is currently growing voices warning about a lack of lithium PRODUCTION. Nothing about reserves, but a possible surge in BEV interest beyond some predictions that will require to use more lithium than current investment in the lithium industry.

That can surely occur, and the reason is basically the same. Contradictory projections about the future. Most investors prefer to wait than risk in a investment that it's not clear.

If the EV expand more than the conservative projections, they will soon lack lithium production, raising the prices, generating a new wave of investments that will drop the price sometime later.

These phenomenons are not energy related, but pure economic.

Offline

Like button can go here

#360 2024-04-03 08:22:13

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Why the Green Energy Transition Won’t Happen

Anyway, as I said before, investors doesn't look EROEI. Investors only care about return of investment. They will only see if the investment will be good or bad. As the number of voices against the usage of fossil fuels grows, and it exists a growing risk of fossil fuel bans or massive investment on replacement, the risk of investment on oil also raises.

Spaniard, EROEI tells us how viable an energy source is as an energy source. There are all sorts of issues that can distort short term investment decisions. The Chinese use of stranded coal and slave labour have made Chinese panels extremely cheap. But if an energy source has EROEI of 2.45, it is clearly impossible for it to produce enough energy to replace itself before end of life. If we were ever to try and do that, the result would be so expensive as to be unaffordable, because there just isn't enough surplus energy to do anything useful.

This is key for photovoltaics to be a large part of the solution that gets us off of fossil fuels. If it cannot be built without huge investments of fossil fuels, then it isn't useful as part of a net zero programme. There is no work around that can change that unless it can increase the EROEI and allow solar panels to be built using energy from solar panels. That is the key for sustainability for any energy source. The best it can ever be under present technology sets is a fossil fuel extender - a way of using otherwise stranded fossil fuel to make something that stores the energy. It can do that, but under that scenario it won't do anything to reduce CO2 emissions. And this is all that photovoltaics are as things stand - a way of storing fossil fuel energy.

There is no way of arguing or wordsmithing this problem in a way that changes anything. If the EROEI calculated by Charles Hall is close to reality, then it isn't possible to make PV without subsidising it with another high EROEI energy source. It isn't negotiable - nothing we say here will actually change it. It isn't a function of politics that will change depending on how well we debate. It is a physics problem.

That isn't to say that PV has no place at all in our future solution sets. Even if it is an energy sink, it can still have local uses, in much the same way as other tools can be useful even if they don't produce energy at all. I have a PV powered watch. Even though it likely took more energy to make the solar cell than it will ever return, it is still a better option overall than batteries. Likewise for powering traffic lights in the middle of nowhere. Even with EROEI <1, PV could still be the cost optimum solution if the other options are a DG that needs to be refuelled daily or a power cable that is miles long connecting to the grid. This remains true for many small power uses where the cost of grid connection is the greatest cost. But an energy source with EROEI 2.45 cannot do the heavy lifting that society needs. It cannot power steel production or transportation or the local district heating network.

This is a result of the first and second laws of thermodynamics. The energy produced by an energy source, must ultimately cover its own maintenance needs and the maintenance and operation of the system it powers. If EROEI is too low, then there just isn't enough surplus energy to do those things. We can talk about that more if you find it useful, but unless you or I can invent something new here it isn't going to change. It doesn't matter how much you want it to work if the physics is against it.

The rollout of BEVs is a seperate but related issue. Kbd512 and I have already explained on the 'Lithium for Batteries' thread why this probably isn't a sustainable solution either. So I won't repeat that discussion here. That doesn't mean it won't continue in some form for a while longer. It just isn't contributing to sustainability goals. It is digging us into a deeper hole, quite literally.

Last edited by Calliban (2024-04-03 08:42:17)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#361 2024-04-03 08:52:50

- Spaniard

- Member

- From: Spain

- Registered: 2008-04-18

- Posts: 144

Re: Why the Green Energy Transition Won’t Happen

Spaniard, EROEI tells us how viable an energy source is as an energy source.

The EROEI you are insisting is more and more difficult to conciliate with the data of the constant advancements and renewable forecasts of Terawatts of new power.

I already told about it. The industry focus on LCOE, because that's the important number for investors to calculate their return of investment.

But continuous improvement of LCOE are incompatible with fixed EROEI. More and more excuses are needed to "explain" why this happen.

While the answer is simple although some people dislike. EROEI data is obsolete or wrong. Sometimes even intentionally manipulated. After all, one of the most focused community around this value is the peakoiler community and their discourse depends on that value to be bad.

Otherwise the renewables would be perfectly fine to replace our current energy model and their proposition for "degrowth" is unnecessary.

For the same reasons, other groups how dislike the competition of the renewable in their markets also uses this to justify attacks and stops to the renewable initiative.

But... whatever. If you want to believe that EROEI calculus are in the right, and LCOE are just temporary, suit yourself waiting for the renewable to fail.

Offline

Like button can go here

#362 2024-04-03 13:37:41

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

Spaniard,

But continuous improvement of LCOE are incompatible with fixed EROEI.

I don't think anyone here has ever claimed that the EROEI of wind and solar is engraved in stone, so this is a strawman argument against a claim that was never made by Calliban, myself, or others. You made that up in your head because your belief system felt threatened, so you attempted to assign your belief about what we said to what we actually told you.

We are claiming that even after short-term to mid-term improvements are taken into consideration, the gross EROEI of the entire solution is not very likely to become dramatically more favorable to an electronics-based energy generation and storage solution, which is what the bulk of money is being spent on at the present time. Electricity is already powering many industrial processes and the majority of residential / commercial energy needs. To believe there will be some fantastic reduction in energy consumption if absolutely everything was powered by electricity, is to ignore the present electrical energy consumption.

When 70% of the energy consumption comes from photovoltaics and wind turbines, there will be a requirement for either a storage of some kind or dramatic over-production of energy to account for diurnal and seasonal variability. All forms of energy storage result in a significant net reduction in EROEI, and that includes coal. Maintaining a coal pile costs money. Maintaining an electrochemical battery also costs money. The major difference is in the total cost of the energy storage system over time. For coal, you store it by dumping it on the ground. Any reasonably flat patch of dirt will work. A battery doesn't do so well when it's exposed to the elements, so we devise elaborate means to protect it. In addition to the battery itself and all equipment required to use it, all of that "stuff we do to protect the battery" requires energy input. In total, the battery requires dramatically more energy input, even if it's dramatically more electrically efficient than coal.

The poorest grades of coal store about 5,000Wh/kg. The best batteries money can buy store about 500Wh/kg. Short of some miraculous new discovery related to battery energy density, it's highly improbable that electrochemical batteries ever achieve 5,000Wh/kg in our lifetimes. I don't have a crystal ball, and neither do you, but I wouldn't bet any money on that happening. If we're going to use other energy storage methods and devices, then those methods are likely to have even poorer energy densities than Lithium-ion batteries, as well as total efficiencies, so they will require even more materials. They might be much cheaper or more abundant materials, but we will require more of them if their energy densities are lower than Lithium-ion.

All of this strongly implies that the cost of energy won't go down as ever-greater consumption of more energy-intensive materials is required to inch closer to wind and solar becoming 70% of all power generation. The IEA has noted that the cost of green energy machines has only increased over the past 4 years, but expects cost reductions to occur this year, because that forecast is compatible with their desires for photovoltaics and wind turbines. It's entirely belief-based, rather than recent history-based. If that doesn't happen, they'll say it'll happen in 2025. Eventually, a thinking person would have to notice that there were non-repeatable reasons behind the dramatic apparent initial cost reductions that weren't related to dramatic improvements in battery efficiency, and that those trends cannot continue forever. Aluminum was once more expensive than Gold, but process improvement made it dramatically cheaper than Gold, but a century later there are no fundamentally new ways in which Aluminum production has improved to make it dramatically cheaper than it already is. There are clearly limits to the improvements possible with any given process or technology, whether it produces a base metal like Aluminum, a solar panel, a car, or a house.

LCOE can be manipulated in ways that EROEI cannot. I can vote for legislators who write laws that make it functionally impossible to build or even operate an existing nuclear reactor, but that's an artificial manipulation of the market. The physics of how much material is required didn't change, I just voted for someone who would ensure that my favored sources of energy would be made artificially more competitive by legislating their competition out of existence. That's objective reality here in America. The NRC exists for the express purpose of making nuclear energy cost-prohibitive. We've even had NRC members, to include the chairman of the NRC, make public statements, an article in The Washington Post, to that effect. The article's title is a misnomer, because he said that his beliefs about nuclear power were that it was a greater threat to humanity than climate change, and that anything but nuclear power was "more acceptable", even if that meant burning coal.

He arrived at his view that it should be banned while he was chairman, as he stated in the article, not afterwards as the title implies to those who don't read more than the headline. He went about implementing his ideology by preventing the approval of new build nuclear reactors. There have been no new nuclear reactors built after the NRC was formed. All the reactors built now were on the books before the NRC existed.

After I left the NRC in 2012, I argued that we needed new ways to prevent accidents altogether. When a reactor incident occurs, the plant should not release any harmful radiation outside the plant itself. I was not yet antinuclear, just pro-public-safety. But nuclear proponents still see this as “antinuclear.” They knew, as I did, that most plants operating today do not meet the “no off-site release” test. I think a reasonable standard for any source of electricity should be that it doesn’t contaminate your community for decades.

The plastics used to create insulation for wires for batteries and photovoltaics and wind turbines use chemicals that contaminate the ground, essentially forever. Mercury and Arsenic never become non-toxic over time. They're toxic to humans and most other forms of life, from now until the end of time.

Coal and natural gas do not create this kind of acute accident hazard, though they do present a different kind of danger. Large dams for hydroelectric power could require evacuation of nearby communities if they failed — but without the lasting contamination effect of radiation. And solar, wind and geothermal energy pose no safety threat at all.

Wait, so there's no Mercury and Arsenic or Radon in coal dust anymore?

This guy must be a clown, yet he was the NRC Chairman, appointed by our beloved Democrats.

I must have missed the part where Gallium Arsenide solar panels were made without Gallium or Arsenic.

I must have missed the part where you can go bathing in the water used by Lithium mines without dying.

This is what happens when you hold dogmatic religious beliefs about energy without much apparent understanding of math and science.

Gregory Jaczko served on the Nuclear Regulatory Commission from 2005 to 2009, and as its chairman from 2009 to 2012. The author of "Confessions of a Rogue Nuclear Regulator," he is the founder of Wind Future LLC and teaches at Georgetown University and Princeton University.

He wasn't any kind of a "rogue", though, he did what every single Democrat appointed to the NRC has done since it was created. The only people who we appoint to the NRC are leftist wind and solar zealots who think their sole job is to prevent nuclear power from doing what it did for France before their own green religious zealots gained power and used it to promote their backwards ideology.

When they talk about the cost of electricity going down, they're not talking about what consumers actually pay, which is always higher with wind and solar than it is with any other forms of energy, until the market is so heavily manipulated as to make that statement true by virtue of not allowing any other forms of energy to exist.

EROEI data is obsolete or wrong.

Two different people can believe different things about the same data, but to assert that any data which disagrees with your beliefs about the data is "obsolete or wrong" strains credulity.

Offline

Like button can go here

#363 2024-04-16 19:42:42

- SpaceNut

- Administrator

- From: New Hampshire

- Registered: 2004-07-22

- Posts: 30,616

Re: Why the Green Energy Transition Won’t Happen

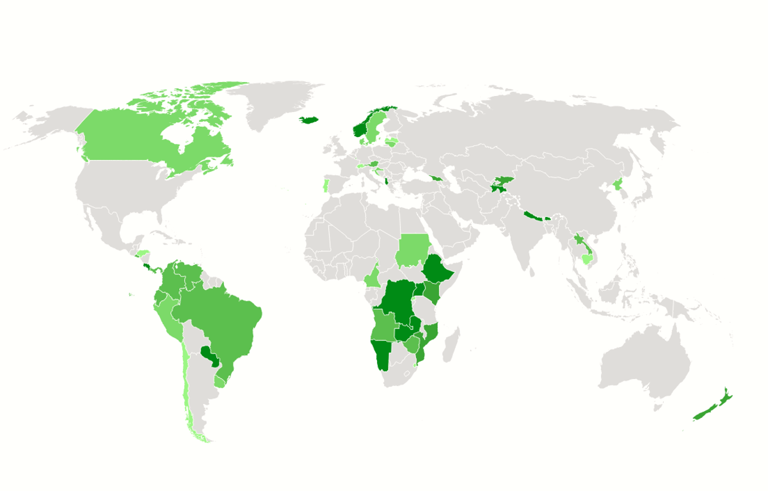

Seems some have figured this out... Seven countries now generate 100% of their electricity from renewable energy

Offline

Like button can go here

#364 2024-04-19 04:22:42

- Calliban

- Member

- From: Northern England, UK

- Registered: 2019-08-18

- Posts: 4,305

Re: Why the Green Energy Transition Won’t Happen

The S-CO2 power generation cycle appears to be something that shows a lot of promiss, but no one is willing to provide the cash to develop it. This proposed biomass powerplant will generate steam at 565°C.

https://www.zmescience.com/science/uk-l … n-6738831/

At those temperatures, an S-CO2 power cycle would be more efficient and the turbomachinery should be more compact. That suggests to me that S-CO2 power cycles should benefit from lower capital costs when equipment is fully commercialised. But no one appears to be building it. It is still considered to be a speculative technology with applications limited to advanced nuclear reactors that never seem to get built. Yet it would appear to me to be a key enabling technology for integrating renewable energy into the grid, as it is readily compatible with molten salt heat storage.

Last edited by Calliban (2024-04-19 04:25:00)

"Plan and prepare for every possibility, and you will never act. It is nobler to have courage as we stumble into half the things we fear than to analyse every possible obstacle and begin nothing. Great things are achieved by embracing great dangers."

Offline

Like button can go here

#365 2024-04-19 06:22:42

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Why the Green Energy Transition Won’t Happen

For Calliban re #364

Please think about how this technology (S-CO2) might be made feasible in the context of the thermal energy project you've been discussing with Terraformer.

The technology may not be competitive today, but a large public project funded for results, without regard to cost, might lead to discovery of ways to make components that ** are ** competitive.

The Apollo Moon Landings were a publicly funded project done without the usual capitalist limits on expense, due to the enormous value of the investment for national prestige and technical achievement.

While you often write about cost factors, and under "normal" circumstances that is a "good thing" in a national high priority demonstration project, the usual caps on investment are removed, and the project is given the resources needed to achieve the objective.

If you allow yourself to imagine being funded at whatever level is needed, you may be able to create a design that would ** work ** and Terraformer has the daunting challenge of selling your proposal to a skeptical public.

Along the way, you will discover the exact reasons why particular components are expensive (materials? labor? energy required?), and then you will be able to spot opportunities to improve manufacturing efficiency.

The Universe provides materials and energy for free. It is ** only ** human participation that has any cost whatsoever.

If humans are involved, there will be expense.

Knowing that, you will be able to carefully examine the flow from free to expensive, and discover the hot spots where ingenuity will improve performance.

For SpaceNut .... this is an example of something that might go into a new category for Projects.

In the new phpBB3 demo forum, I have created a Category for Projects, and added Large Ship as a topic,

As a homework exercise, please see if you can figure out how to add a Forum for Terraformer and Calliban's Thermal Energy Storage project.

Don't worry about details like name or description. These can be edited later when more information is available.

(th)

Offline

Like button can go here

#366 2024-04-19 10:30:43

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

tahanson43206,

sCO2 technology was developed, specifically because it was more competitive than steam or existing gas turbine engine technology. There is no such thing as a 50% efficient 10MWe conventional gas turbine, let alone a 50% efficient 250kWe conventional gas turbine. There is most definitely no such thing as a 300MWe steam turbine the size of an office desk.

sCO2 has the backing of NREL (National Renewable Energy Laboratory), NETL (National Energy Technology Laboratory), US DoE, SWRI (SouthWest Research Institute), General Electric, Toshiba, Barber-Nichols (the people who gave us the RS-25 turbopumps, amongst other things), Ingersoll-Rand (the people who gave us supersonic inlet velocity CO2 compressors that reduce the size of coal power plant CO2 scrubbers from a house to a 20ft transport container), Allison (the people who make the transmission gearboxes for large trucks, as well as gas turbine engines), and a number of universities around the country, and in Europe. The renewable energy people are mostly oblivious to this because they think absolutely everything is about electricity and its magical efficiency.

There is an operational commercial electric power pilot plant here in Texas, not too far from Houston. Results from the pilot plant have been so good that they're already building a full-scale 300MWe power plant. The technology is real, it's actively being used and developed in the real world, and it has major financial and efficiency implications for natural gas power plants, because it does scale so well, because it is so compact compared to competing options, and because it really does work.

20 years ago, we lacked the simulation technology to understand enough about how CO2 flow through the turbine differs from steam or hot effluent gases from combustion to accurately model how such an engine might produce better results than conventional gas turbine technology that existed at that time. Today, we have that understanding from conducting the basic research required with computing tech that came along about 15 years ago. We have worked out how to get 100,000 operating hours out of the hot components, to include the power turbine, turbine casing, piping, and the heat exchangers.

The end result is a scalable technology that produces a high level of efficiency across multiple turbine sizes. In conventional gas turbines, they become considerably more efficient as they're scaled up in size. This limits the number and types of applications where they make economic sense. This is why you don't see very many aircraft gas turbine engines below about 550hp. Smaller turbines have existed for many decades now, but even the most modern ones have fuel efficiency figures that are horrific, even at altitude. That was the entire reason that so many decades were spent trying to develop small / light / reliable diesel engines for light aircraft. Diesels were fairly efficient over a very wide range of throttle settings and operating altitudes.

I don't expect sCO2 engines to replace conventional gas turbines in aircraft, but they have real potential for powering ships and heavy motorized vehicles such as the M1 Abrams main battle tanks. The fuel efficiency improvement over the 1MW output AGT-1500 that presently powers the M1 Abrams would be truly remarkable.

Ships the size of aircraft carriers could have removable engine components that would fit through standard hatches used by personnel. You'd still need a hand crane or "cherry picker" to move it, because steel is very heavy, but the engine itself would be so tiny that a complete power turbine and its casing would fit through the same hatches that personnel go through to reach the main spaces (engine room, fire room) of a ship. No other engine technology allows you to do that. Conventional LM2500 marine gas turbine engines are the size of 40ft transport containers. Steam turbines become massive non-removable integral parts of a ship's structure at the output level demanded by an aircraft carrier. If you wreck one, then you have to cut it out of the ship while the ship is laid up in a dry dock. Whenever reactors are involved, there's even more complexity added to the steam turbine repair or replacement job. sCO2 makes that a parts swap job that can take place while the ship is underway. It's hard to express what kind of technological windfall this will be for military and commercial shipping.

The same radical increase in power density applies to Wright Electric's aircraft electric motors. 2MWe / 200kg electric motors to provide ship's power, that can also be installed or carted off the ship using a cherry picker. Wright Electric says their motors scaled between 500kWe and 4MWe. Even if it never powers an aircraft, it has obvious applications aboard a ship, to radically reduce space claims. This is another technological windfall. Generators can be placed where you need them aboard ship, because all the parts involved might weigh less than a computer server rack, for example. That means a gun mount no longer needs a bunch of electrical cables or hydraulics routed to it. Every major combat system can have its own self-contained power supply to provide primary or backup power. When the system is in operation, it can rapidly spin up its own power turbine to provide electricity, but ship's power doesn't need to constantly supply power through Copper cables thicker than your thumb, most of which is entirely wasted because it's not used most of the time, to ensure that power is always available when required.

As small as these things are, where you put the engines, electric generators, heat exchangers, and all other parts of the power and propulsion plant now becomes an option for ship designers. They don't occupy huge amounts of space, don't significantly affect the weight and balance of a ship, and multiples of these units can be installed for redundancy. For commercial shipping, that means you don't have stupid accidents from failures of ship's power causing container ships to crash into bridges, such as what happened in Baltimore, Maryland. That means you don't need a diesel engine the size of a house. The metal in the sCO2 turbine may be expensive relative to cast Iron, but it's not nearly as expensive as 100X more metal in a marine diesel engine, the machining requirements are reduced, and making engine components is now being done with 3D printing. Both the total number of components and the overall complexity of them is radically reduced. Mechanically, a sCO2 gas turbine is no more complex than an electric motor.

These sorts of changes are ones that actually matter at a macro level, because they save the most fuel. Will we muck that up by simply building more, thus consuming more energy? Almost certainly, but at least energy will be available as a result. That said, sCO2 doesn't "only" help combustion engines, it helps solar thermal, nuclear thermal, and geothermal, all at the same time.

Supersonic Inlet Velocity CO2 compressors - economically capturing CO2 from coal and natural gas power plants by drastically reducing the input power to drive the turbomachinery, the waste heat generated by compression, and radically reducing the number of stages of compression from 10 to 12, down to 1 or 2. This has applications for small gas turbine engines, because the rampressor can cram air, as well as CO2, into a very small space and use the shockwave to work with rather than against the turbine wheel. High quality waste heat is generated that could be pumped right back into a molten salt using a heat exchanger.

Supercritical CO2 gas turbines - Provides a power output level independent (250kW to 300MW+), broad-spectrum increase in thermal efficiency with a simultaneous reduction in size and weight of the turbine components. This replaces most gas turbine engines.

We need to figure out how to create supersonic supercritical CO2 compressors, or S3CO2 engines. All conventional gas turbine engines use subsonic inlets, which is why you'll see 10+ compressor stages to suck air into the engine. Imagine if we could do that with 2 stages, dump the waste heat into an auxiliary CO2 compressor that drives the main shaft, much like the turbocompounding engines that made 400mph piston engine airliners a reality after WWII, and we send a cooler / denser intake charge through to the hot section of the engine. Dramatic power increases per unit size and weight are possible.

Oxy-Fuel combustion - reducing Carbon Monoxide, makes CO2 easier to capture because the combustion byproducts are nearly pure CO2, reduces thermal losses to heating up inert Nitrogen gas (outside of piston engine applications where that is helpful to increasing cylinder pressures), and increasing temperatures, thus providing greater thermal efficiency

10kW/kg to 20kW/kg electric motors with air cooling - making electric motor-generators compact and lightweight components of engines, rather than heavy and cumbersome devices that have to be cut out of the hull of a ship to get serviced, only moveable with large cranes and special semi-truck trailers with dozens of tires.

There is no singular technology that will enable an actual sustainable green energy transition. Electronics and electrical devices play an important but overall minor role. They are not central to any realistically sustainable path forward. They've been over-hyped by people with techno fetishes which have resulted in one-dimensional thinking. Every energy problem is a combustion engine, therefore every energy solution must be a purely electrical device of some kind. Few of the people promoting them have any real understanding of how energy systems are presently used by society, nor why they were designed the way they were. That is why there hasn't been any large scale transition. That is why the wild increase in the production of photovoltaics, wind turbines, and batteries has failed to simply keep pace with the rate of increase of energy consumption. Germany is a prime example of a large scale failure of photovoltaics, wind turbines, and electrochemical batteries to live up to their hype. Their CO2 emissions level are exactly where they were when they started that project, and this excludes all the CO2 emissions to create all the electrical systems they've installed. Anyone with basic math skills could predict what would and did happen, because Germany was and is a truly absurd place to put photovoltaics and wind turbines, but apparently even PhDs cannot do math when ideologically-held beliefs about technology are threatened by objective reality.

If the electrical grid we have today largely works, even though it's primarily powered by combustion of hydrocarbon fuels, then the only proper task to pursue was to replace the burning of hydrocarbon fuels while leaving the grid relatively unchanged. Knowing that electronics or electrical devices were unable to do that without massive increases in electrical energy storage, that strategy was doomed to failure and should've been discarded as unworkable. Instead, they doubled-down on what clearly couldn't work, and in point of fact, didn't. Hundreds of billions of dollars did not need to be spent to keep CO2 emissions exactly where they were when the Energiewende project began. The requisite technologies already existed to do that, most notably nuclear thermal and solar thermal power. Both technically feasible solutions were rejected for entirely ideological rather than technical reasons. If the same amount of money was spent on nuclear reactors as was spent on photovoltaics, wind turbines, and batteries, 100% of Germany's electrical energy could have been provided without burning any coal or gas.

This is the unavoidable problem associated with mixing ideology and technical subject matter. The ideology only reinforces itself, even when the fundamentals of the technical solution are firmly set against the ideology. You cannot run an industrial economy using electronic energy generating and storage devices, which is why Germany is now well into the process of rapidly de-industrializing.

Offline

Like button can go here

#367 2024-04-19 10:55:13

- tahanson43206

- Moderator

- Registered: 2018-04-27

- Posts: 24,125

Re: Why the Green Energy Transition Won’t Happen

For kbd512 re #366

Calliban is the member of this forum who might be interested in your enthusiasm for CO2 machinery...

The S-CO2 power generation cycle appears to be something that shows a lot of promiss, but no one is willing to provide the cash to develop it. This proposed biomass powerplant will generate steam at 565°C.

https://www.zmescience.com/science/uk-l … n-6738831/

In contrast to your wild enthusiasm, Calliban appears (from the post quoted above) to be unconvinced.

If you think the CO2 technology has any value for Terraformer's project, please convince Calliban to specify that technology in a practical business plan.

All the hand waving we might do in this tiny forum will have no effect unless it is translated into actual plans that will pass muster at a City Council meeting.

I'd like to see something happen. You appear to be in a position to provide helpful advice.

Alienating half the population of Earth with unwise comments is something I would ** think ** we would want to avoid?

(th)

Offline

Like button can go here

#368 2024-04-19 12:05:20

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

Two frequently overlooked aspects of a successful vs failed energy transition are the national security implications and societal cohesion.

Firstly, the very idea that you can talk your way out of any fight, or somehow avoid all conflict, if only you acted in some specific way, is flat out wrong and false at every conceivable level and in every possible way, period. By no means should you actively seek out any conflict, but neither should you be so naive as to believe that conflict won't actively seek you out, even though you were never interested in fighting with anyone.

The defense industrial base of every allied nation has certain defense spending obligations it's required to meet.

1. Every nation which wishes to remain sovereign and independent must maintain a professional standing army led by a core of educated officers (bachelor of science for lower ranks, master of science of doctorate for higher ranks) who will manage and direct military operations, when the need arises.

2. Every nation must have a supply of arms and munitions to supply to their troops. This takes the form of small arms to equip individual soldiers, mortars and artillery for fire support, armored personnel carriers to transport soldiers and their equipment around the battlefield, and main battle tanks that provide direct fire support. More recently, in lieu of a professional air force, drones are a new requirement for battlefield recon, scouting, and light attack roles traditionally filled by much more expensive aviation assets. Helicopters and fixed wing cargo transports are nice to have, but they may not be usable on a modern battlefield without well-established air supremacy.

3. A professional air force and navy are very expensive to maintain to the degree required to make them survivable in combat, but the roles such assets fill are still important, so patrol and transport vessels and surveillance aircraft, manned or unmanned, are minimally required when the nation in question has ocean front property.

Anything beyond that is highly desirable to have available if your nation can afford it and your leadership decides it's important to have available to keep the peace, but those listed capabilities are integral to any competent fighting force seeking to present a credible threat of resistance to any would-be aggressor state.

Every aspect of those listed capabilities are incredibly energy and resource intensive. They require steel, Titanium and other light alloys to reduce the weight of certain parts, Copper, Lead, plastics and rubber, diesel fuel, production of complex motorized vehicles and the machinery used to create them, weapon systems such as small and large caliber cannons, explosives, computers, radar and infrared sensors, as well as various other electronics such as radios and night vision devices. Some defense items your nation may be able to easily procure from allied nations for a fair price, but others really must be made at home. Unfortunately, those home-built items typically represent the lion's share of input energy and maerials, because they involve manufacture of crew served weapons, vehicles, munitions, small arms, armor, uniforms, and software development to operate nationally customized drones and sensor systems to create a "big picture" of the battlefield conditions your military is facing. You will receive aid from your allies, but that aid may not be timely, or it may be insufficient.

Ukraine desperately needs artillery shells and howitzers, for example. 155mm artillery is NATO standard, even though other calibers such as 105mm light howitzers are still used. A factory that makes artillery shells in volumes relevant to a shooting war is not a small facility, and it continuously consumes energy like it's going out of style. As we see in the case of Ukraine, there's no pragmatic way to outsource this capability, either. Artillery shells and propellant charges are very heavy and expensive to produce and transport. Modern explosives are not sensitive at all to rough handling, thankfully, yet they are also the most energy intensive part of the entire process of making an artillery shell. You need a chemical factory and you need highly skilled operators who know enough to not get themselves killed, which implies a high level of education and training. That requires teachers, relationships, communication skills, knowledge transfer materials from ABCs to "don't mix Chemical A with Chemical B unless you want to get blown into the middle of next week", computers, abundant food, clean water, sanitation, and the list goes on. Law and order are quite important as well. All of this stuff is interconnected, and you cannot reasonably obtain one item from the list that you really want, without also obtaining all the others.

You, personally, may not want to spend any of your national treasure or energy on these costly defense items and services, but they will always be an important aspect of assuring that you and your children will have a worthwhile future to look forward to, even as they threaten to take it away. The fundamental point behind this, is that national defense requires a lot of energy, which undergirds all other aspects of a thriving human society. As such, your foundational energy supply needs to be highly reliable, durable, long-lived, not subject to the capricious nature of the local weather, and secure against attack. Thermal power systems check off all of those boxes.

Secondly, the very idea that you can expect to receive all the "goodies" of a high-functioning civil society, without an equal willingness to pay the price required to maintain such a state of affairs, is another blatant falsehood. The price to be paid is cheap / abundant / secure energy, abundant food and fresh water supplies, a local industrial base capable of supplying most of your civil and military needs, and a national culture that values your own people above all others. Societal cohesion demands that almost everyone buys into the national logos and mythos.

When people are not worried about where their next gallon of gas or kilowatt-hour of electricity is coming from to get to work and feed their children, society will thrive. Conflict never goes away entirely, because jealousy is an incurable human emotion that is part of the human condition, but you will rarely see people in affluent neighborhoods busting down the doors of their neighbors to take what they have. When you have an education, a job that can pay your bills, a car to take you where you need to go, a roof over your head, food and drink for your family, a little entertainment here or there, and a future retirement to look forward to, most reasonable people would not risk all of that to go take something from someone else. That is why we have civilized societies. A well-functioning society basically squashes the perceived need to do any of that, and instead rewards greater cooperation. When you don't have those things, and cannot see a path forward to obtain them, that is when real conflict begins, and that can get very ugly, very fast.

That is the "how and why" energy matters so much to the security of a nation and its citizenry.

Offline

Like button can go here

#369 2024-04-19 12:37:25

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

tahanson43206,

I don't have "wild enthusiasm" for much of anything. I do look for things that work well, or at least to the degree required, which are critical aspects of providing the things society wants or expects. On-demand energy is one of the things society wants and expects, so then I go looking for technologies that provide that in better ways than what we currently have or use. I'm not sure how or why you or others think real money hasn't already been devoted to developing sCO2 turbines, but your beliefs about this are also entirely irrelevant to plainly observable objective reality.

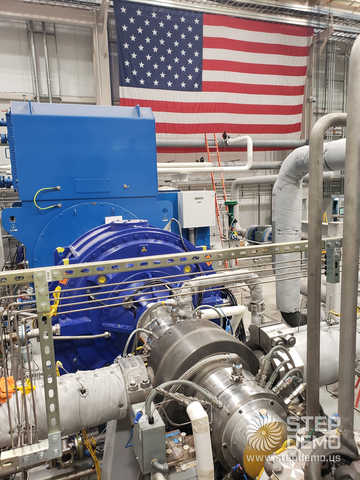

STEP Demo pilot plant makes new breakthrough for sCO2 power generation

The Supercritical Transformational Electric Power (STEP) Demo pilot plant, a $169 million, 10-megawatt supercritical carbon dioxide (sCO2) test facility at Southwest Research Institute (SwRI) in San Antonio, has achieved an industry first during commissioning by firing its natural gas heater and operating its turbine up to an intermediate speed of 18,000 rpm.

“Operating the integrated system is a noteworthy accomplishment. It follows the team’s successful component-based commissioning activities and demonstrates combined operation of all equipment, including plant controls, compressor, heat exchangers, heater, turbine and CO2 inventory in addition to the facility’s electrical and gas supply and cooling water systems,” said Dr. Tim Allison, director of SwRI’s Department of Machinery.

The STEP Demo project developed in collaboration with SwRI, GTI Energy, GE Vernova, the U.S. Department of Energy/National Energy Technology Laboratory (U.S. DOE/NETL), and several industry participants. The project’s central goal is to dramatically improve the efficiency, economics, operational flexibility, space requirements and environmental performance of this new technology. The STEP Demo pilot plant is one of the largest demonstration facilities in the world for sCO2 technology, and achieved mechanical completion in October 2023, when major subsystems were installed and began commissioning.

System commissioning tests will continue over the next several months to achieve maximum power in its current configuration by increasing operating temperatures to 500 °C and ramping up the full turbine speed of 27,000 rpm. The turbine was developed jointly by SwRI and GE Vernova Research Center and is being tested in a simple recuperated configuration of the plant. The plant will eventually operate at 715 °C to achieve full 10 MWe output.

“This is an important step for our sCO2 demonstration plant,” said SwRI Project Manager Dr. Jeff Moore. “The STEP Demo team is thrilled to have achieved this significant milestone of integrated plant operation.”

STEP Demo is a unique facility designed to demonstrate high-temperature sCO2 power generation, which increases efficiency by as much as 10% due to its favorable thermodynamic properties. Carbon dioxide is nontoxic and nonflammable and, when it is held above a critical temperature and pressure, it can act like a gas while having the density near that of a liquid. The sCO2 turbomachinery is approximately one-tenth the size of conventional power plant components, which shrinks the physical footprint and construction cost of any new facilities. Additionally, the sCO2 power cycles are compatible with many heat sources including concentrating solar power, industrial waste heat, geothermal power and advanced nuclear power plants.

“I am excited that our team is now starting to demonstrate supercritical CO2 technology that can have a positive impact on the planet by making clean energy more affordable and efficient, and decarbonizing more challenging industrial applications through waste heat recovery,” said Bill Follett, STEP Demo program director at GTI Energy.

SwRI is an industry leader in the development of sCO2 power cycles. Staff members have conducted numerous U.S. Department of Energy projects advancing the efficiency, reliability and commercial readiness of sCO2 power cycle turbomachinery, heat exchangers, cycles and systems. The team’s extensive experience with sCO2 technology is key to making the STEP Demo project a successful landmark demonstration.

For more information, visit https://www.swri.org/industry/advanced- … ilot-plant .

SwRI, GTI Energy, GE celebrate mechanical completion of $155 million supercritical CO2 pilot plant

Novel Gas Power Plant With No Air Emissions Set in Texas

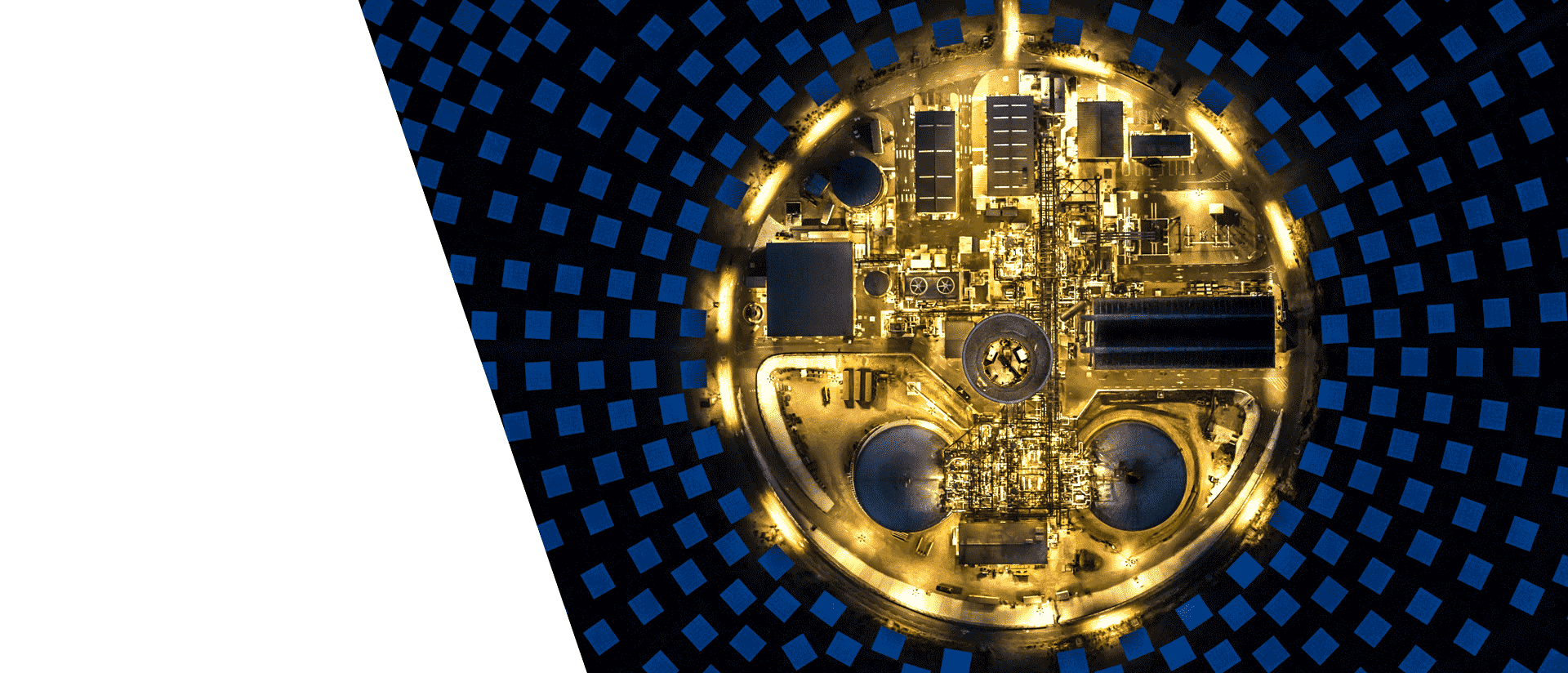

Natural gas power plant developer NET Power LLC, with partners Baker Hughes, Occidental Petroleum and Constellation Energy, will narrow selection of an EPC contractor by year end to build an estimated $750-million to $950-milloin million utility scale power plant that it claims will be the world's first to burn natural gas with oxygen to generate power and produce pure carbon dioxide as a sellable byproduct with no harmful air emissions.

The project will be built in the Texas Permian Basin at an Occidental hosted site near Odessa.

A 50-MW pilot plant created to test the closed-loop supercritical technology—which was completed in La Porte, Texas near Houston by EPC contractor McDermott in 2021—successfully synchronized the power it produced to the Texas electric grid after operating for more than 1,500 hours.

When completed, the larger Odessa project will combust natural gas and capture an estimated 860,000 tonnes of CO2 per year, NET Power said “The technology can get energy out of natural gas with no emissions, no tailpipe, no stack,” firm CEO Ron DeGregorio told ENR. Pure oxygen reduces fuel consumption and increases flame temperatures, with no nitrogen oxides, sulfur oxides or carbon dioxide emitted to the air, he said.

The resulting CO2 is expanded in the turbine and moves into the heat exchanger where water is removed and remaining CO2 is either recaptured or compressed, pumped back into high pressure and reheated in the heat exchanger. The process produces “pipeline quality industrial CO2,” he said, which can be sequestered.

The plant does not have units to capture air emissions of CO2 and other harmful substances. Its only air emission is water, DeGregorio added.

The technology is clean, reliable, dispatchable and economical, according to the CEO. “It will be able to compete without subsidies on a levelized cost of electricity and will beat highly efficient combined-cycle plants with carbon capture at the end of the pipe,” he said.

NET Power’s technology was ranked by the Massachusetts Institute of Technology in 2018 as one of its 10 breakthrough technologies.

“The plant puts the carbon dioxide released from burning natural gas under high pressure and heat, using the resulting supercritical CO2 as the ‘working fluid’ that drives a specially built turbine. “Much of the CO2 can be continuously recycled; the rest can be captured cheaply,” said MIT Technology Review. “Of all the clean-energy technologies in development, NET Power’s is one of the furthest along to promise more than a marginal advance in cutting carbon emissions.”

Multiple Revenue Streams

The utility-scale project to be built will generate 370 MW of power, with 300 MW going to the grid and 70 MW used to run the plant’s air separator unit. The technology burns pure oxygen, which requires the separation of air. “The cost is figured into the economics,” DeGregorio said.

The plant will have multiple revenue streams related to its power generated as well as to the CO2, nitrogen and argon byproducts produced.

Pre-front end engineering and design is complete, with final engineering expected to begin in early 2023, after the EPC contractor is selected, DeGregorio said.

There are five shortlisted construction contenders for the project that he declined to name. They will be narrowed to two before a final selection is made.

The contractor will update the cost estimate and design the project in a way to make it more modular, DeGregorio said. Construction is set to begin in 2024 and finish in 2026.

NET Power has five other projects in the works, including two 280-MW plants in the U.S. that are being co-developed with Cayote Energy in Colorado and with Broadwing Energy in Illinois, as well as a 300-MW project in the U.K. with Whitetail Energy. Others are planned with Frog Lake Energy in Canada and with Wilhelmshaven Green Energy in Germany.

The developer also is working with other large utilities that have shown interest in building plants, DeGregorio said, as well as with multiple energy investment funds. “We have a lot going on,” said the executive, who added that NET Power also licenses its technology.

Energy technology company Baker Hughes joined the Permian Basin group in January and is developing the facility’s supercritical CO2 turboexpanders and other pumping and compression technology and will provide equipment for other projects.

The pilot plant was built with Toshiba equipment but Baker Hughes will supply it for the scaled-up project.

DeGregorio said NET Power has been quietly developing the technology for 12 years until completion of the demonstration plant. The original idea for the technology came from scientists at low-carbon energy developer 8 Rivers, which worked with air separators and is an early investor in NET Power.

Early investors also include Constellation. Occidental joined in 2014 and now is its largest investor. McDermott was previously an investor.

Occidental said Nov. 9 that its third-quarter profit rose to $2.5 billion in the three-month period ended Sept. 30, compared to $628 million during the same time last year—with the firm citing higher gas and oil prices due to the Ukraine war. Revenue increased nearly 40% to $19.5 billion, the firm said, compared to $6.8 billion in the same 2021 period.

The energy firm also noted a continued focus on carbon capture, eyeing development of up to 30 direct air capture plants in Kleberg County, 'texas, in an area it said has access to underground geologic reservoirs that could store captured carbon.

NETPower said it intends to pursue government support, including loans and incentives under the 2021 federal infrastructure law and carbon capture tax credits in the new Inflation Reduction Act.

All the people who need to be convinced, and those would be the people who have invested their money, have already been convinced.

The Odessa Supercritical CO2 Power Plant is coming online in 2026.

Continue your disbelief, or don't. I really don't care. It has no bearing on reality. This is happening right now. All those pictures you see of the facilities from the links I provided were built here in Texas (San Antonio, La Porte, Odessa is still under construction). They're not internet hoaxes. You can see overhead Google imagery of them. No belief in what I write is required.

Offline

Like button can go here

#370 2024-04-19 12:50:31

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

Oh look, it's not just here in Texas, this project is in Spain:

The wonderful thing about reality is that it's real.

Edit:

The EU funded H2020 SOLARSCO2OL project aims to demonstrate a 2 MW supercritical CO2 (sCO2) cycle with heat provided by molten salts in a relevant industrial operational environment at the premises of an existing solar complex in Spain, composed of a 50 MW Concentrating Solar Power (CSP) plant and a 6.1 MW dual-axis tracking PV plant. The new pilot plant will consist of a purposely designed molten-salt storage system including a molten salt electric heater, a storage tank, and the salt-to-sCO2 primary heater connected to the sCO2 cycle. In specific relation to the turbomachinery, the project aims to demonstrate the reliability and the technical performance of all key components present in a simple Brayton sCO2 cycle, including the balance of plant and control systems. Ultimately, the overarching goal of the project is to serve as a stepping-stone towards hybrid sCO2 based CSP and PV plants able to provide cost-efficient, flexible, modular, scalable, and dispatchable solar power. Besides the specific demonstration objectives, and related component development and verification, the project aims to investigate the techno-economic performance of advanced hybrid CSP-PV layouts combining electric heaters and sCO2 cycles at higher temperatures, as well as the social and environmental acceptability of the proposed solutions. The project started in October 2020 and will span for a period of 4 years, with three clear phases: design optimization (up to months 18-24); manufacturing, prototype tests, detailed engineering, procurement, and installation (up to month 36); and operational experience, analysis and conclusive recommendations during the last year. The anticipated budget for the project is 15.5 M€, and it has received a grant of 10M€ from the European Commission. The SOLARSCO2OL consortium is formed by 15 partners from industry and academia with complementary expertise in the fields of CSP and turbomachinery. In this paper, an overview of the project objectives, deliverables, and time plan is presented together with a condensed first-year summary including preliminary results from the conceptualization and design phases for the demonstration plant and its components.

Last edited by kbd512 (2024-04-19 12:58:34)

Offline

Like button can go here

#371 2024-04-19 13:35:01

- kbd512

- Administrator

- Registered: 2015-01-02

- Posts: 8,518

Re: Why the Green Energy Transition Won’t Happen

It looks like the Chinese are in the process of testing sCO2 gas turbines as well:

Shouhang and EDF to Test s-CO2 Cycle in Concentrated Solar Power

China could be the first to deploy s-CO2 in CSP

The world’s initial Concentrated SolarPower (CSP) plants continue to use the legacy steam cycles of conventional thermal plants. But steam cycle is a mature technology with temperature-based efficiency limits, hampering the potential to raise efficiency and lower costs. Consequently, international researchers have investigated a new power cycle, a closed loop supercritical carbon dioxide cycle (s-CO2).

Marking the first time s-CO2 cycle will be tested in an operating CSP plant, starting this month, the French utility company EDF will partner with Chinese CSP technology manufacturer Shouhang to convert a demonstration CSP plant built three years ago at the Gobi Desert solar park at Dunhuang from steam cycle to an s-CO2 power block.

“The way that people approach risk in China is different; I think they are more open for such innovation. They don’t trust so much the modeling work; so they build it. It’s quite sad that today it’s easier to do such projects in China than in a western country, but it makes working in China very exciting,” commented Yann Le-Moullec, EDF Chief Engineer in China R&D.

Le-Moullec, who announced the study-Retrofit of Dunhuang 10MW molten salt plant with a high temperature supercritical CO2 cycle at the Annual SolarPACES Conference 2018 in Morocco, is now working in China to implement the EDF collaboration with Shouhang, which built the 10MW plant to be used in the demonstration and was among the first to complete a 100MW tower CSP project in China’s first batch of demonstration projects.